Influence of Heat Treatment on Properties and Microstructure of EN AW-6082 Aluminium Alloy Drawpieces After Single-Point Incremental Sheet Forming

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

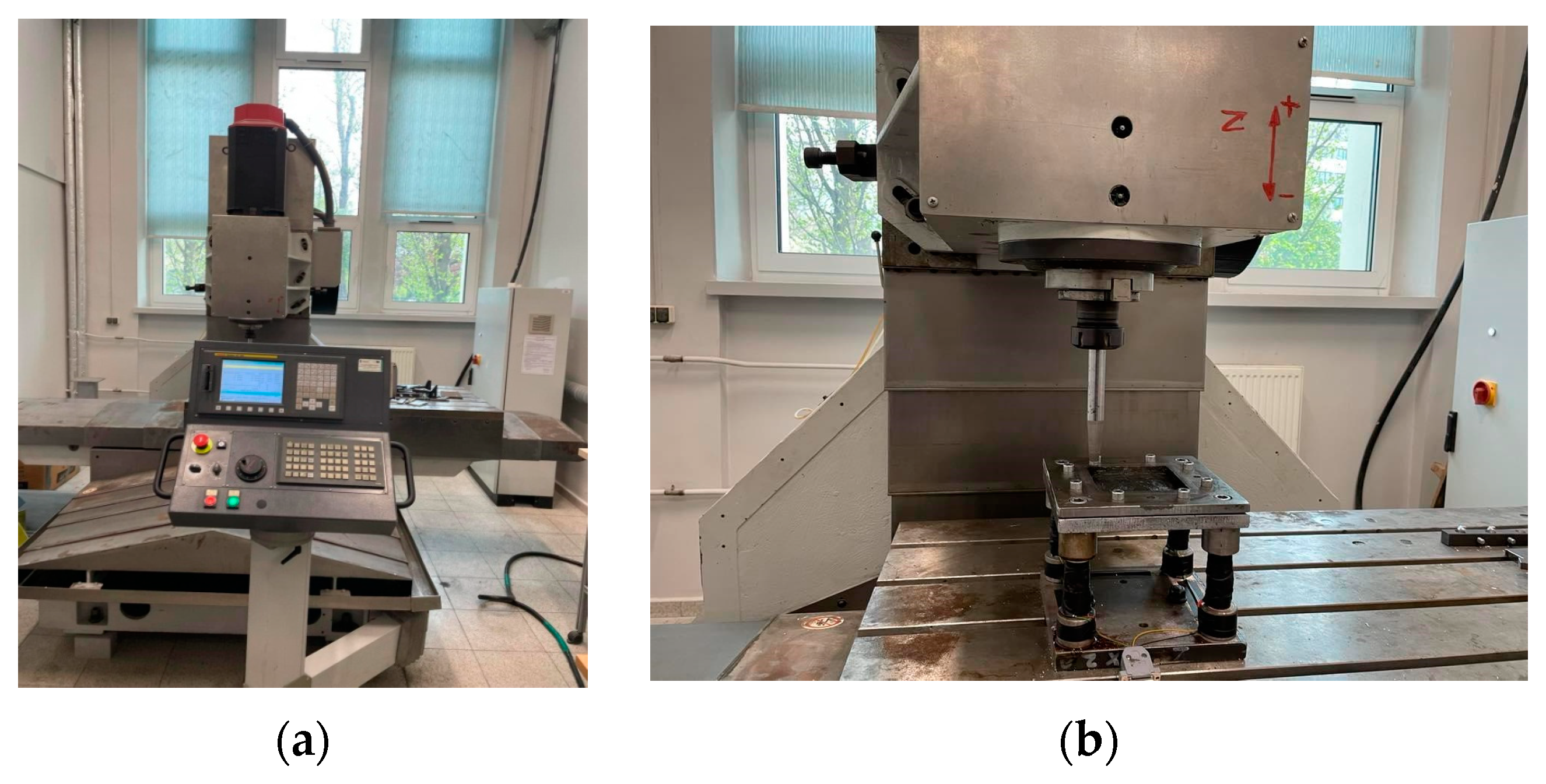

2.2. Incremental Sheet-Forming Methodology

3. Results and Discussion

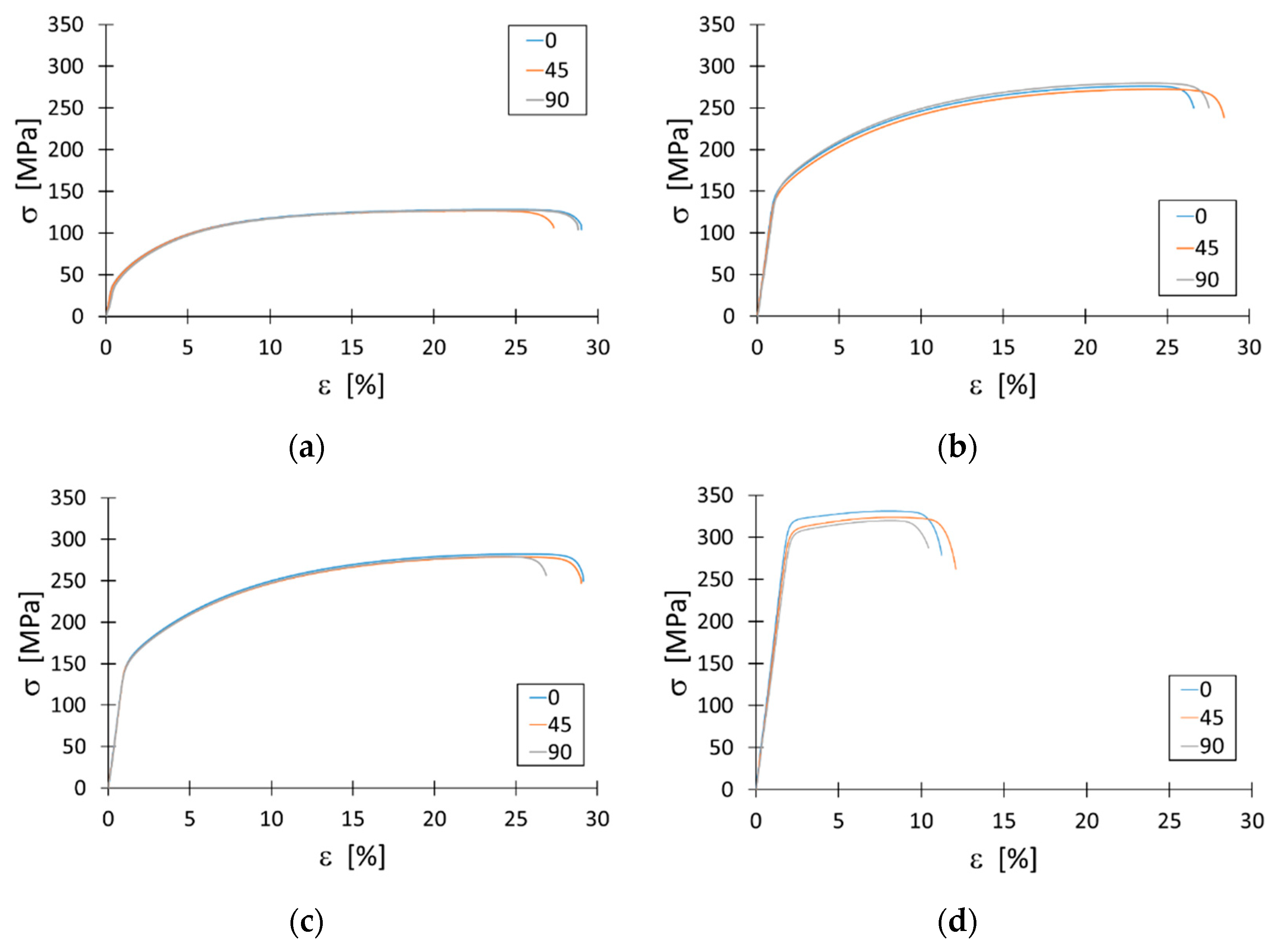

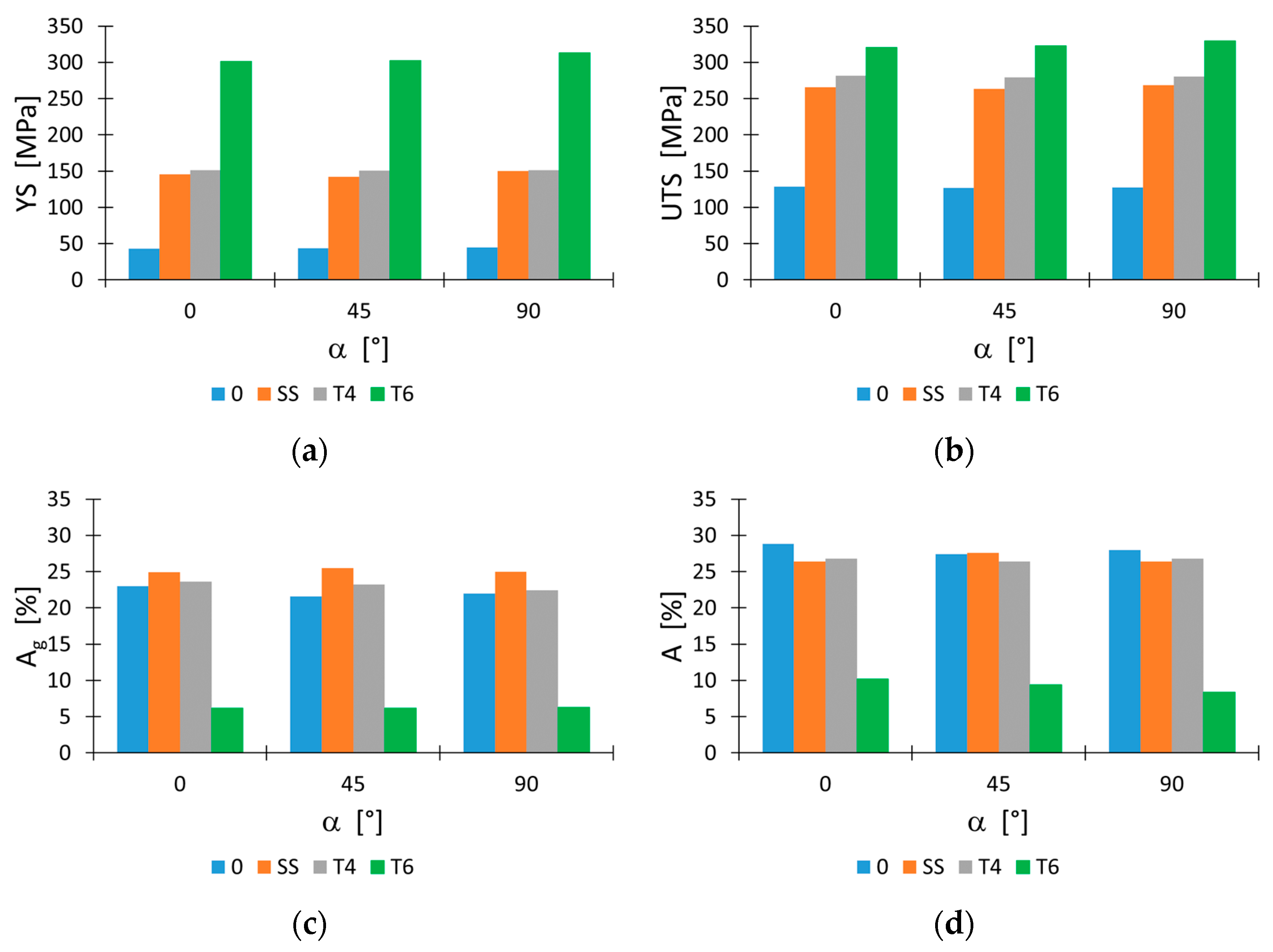

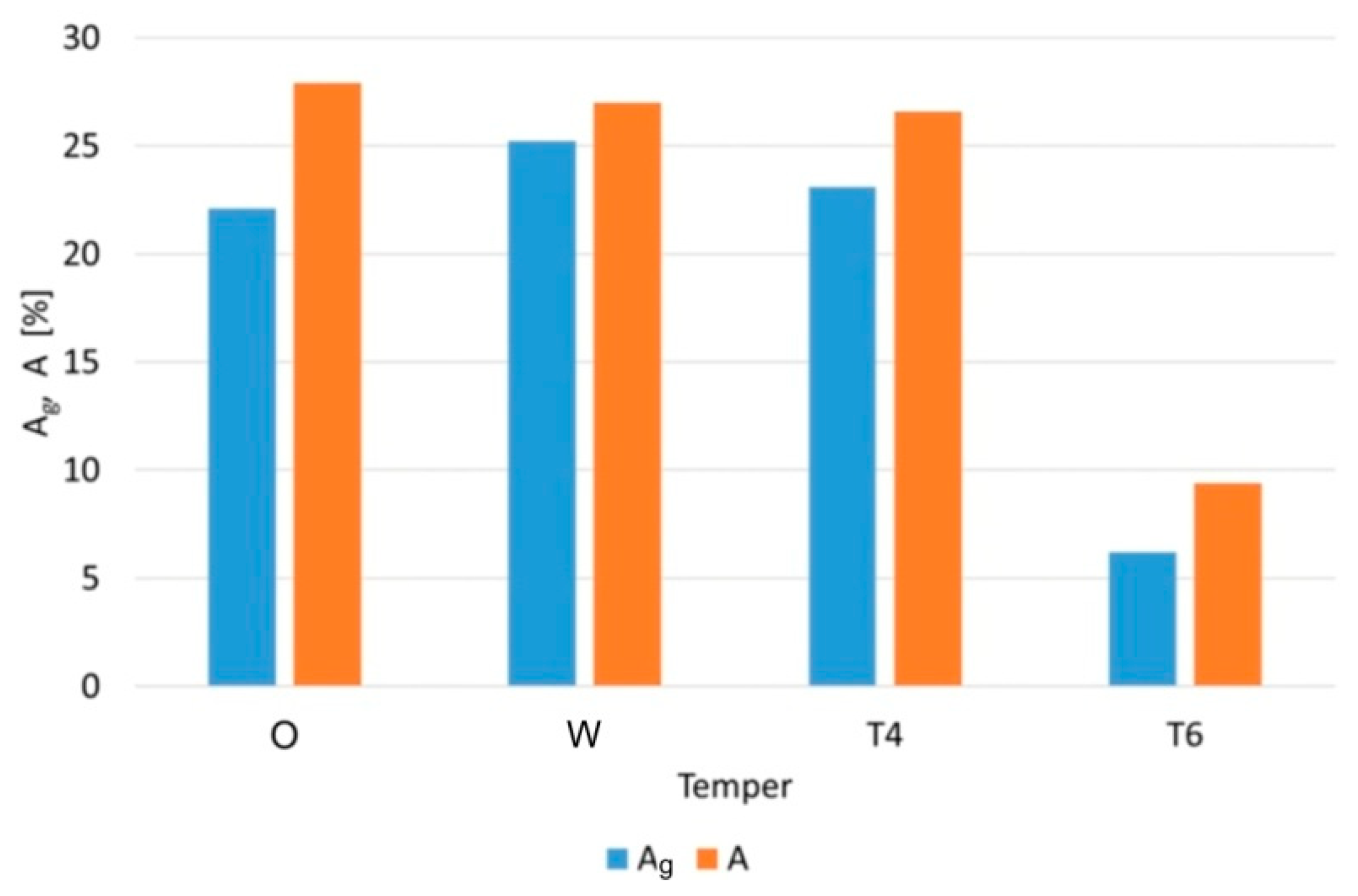

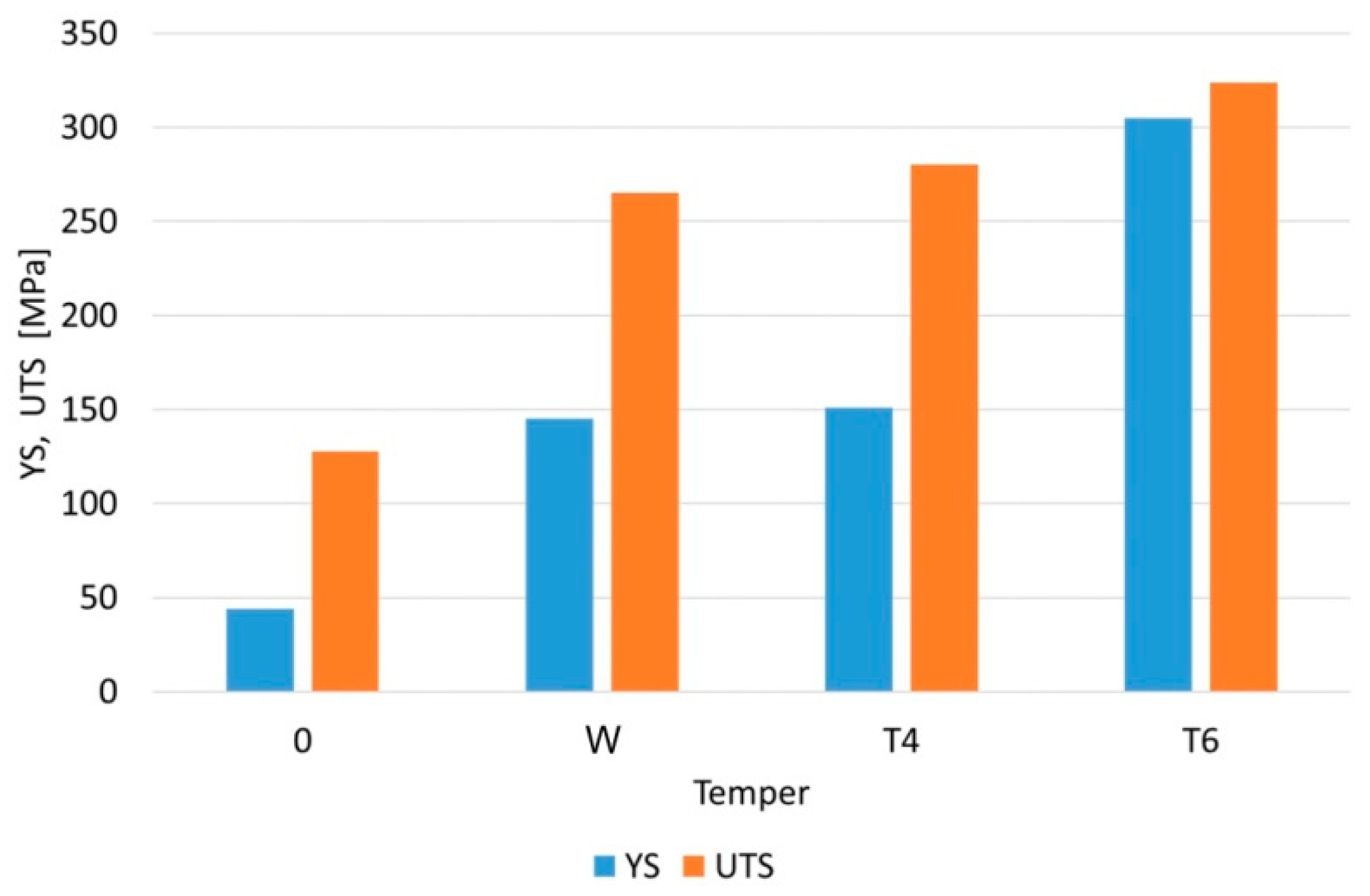

3.1. Mechanical Properties of Sheet Metals

3.2. Sheet Hardness

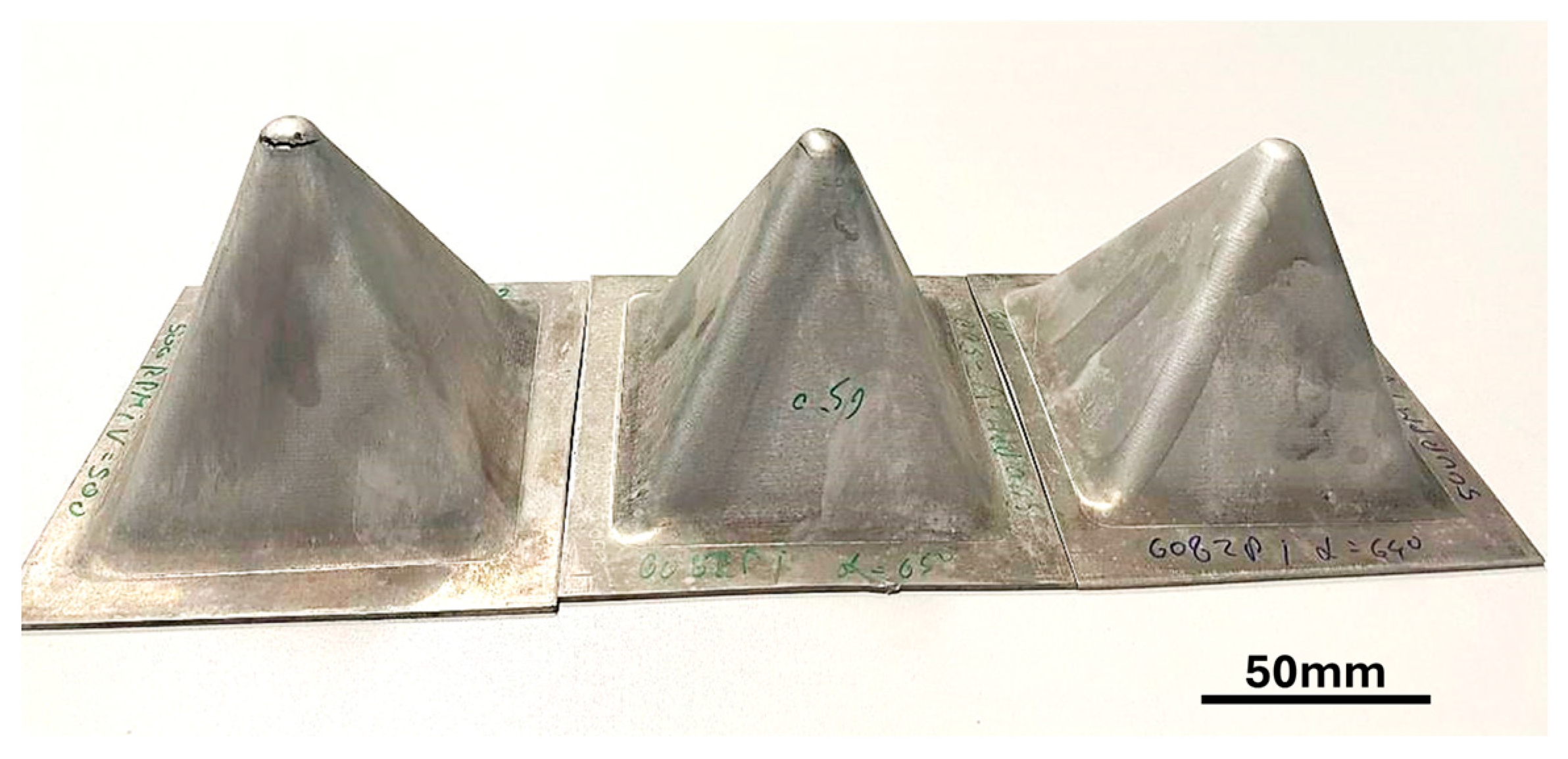

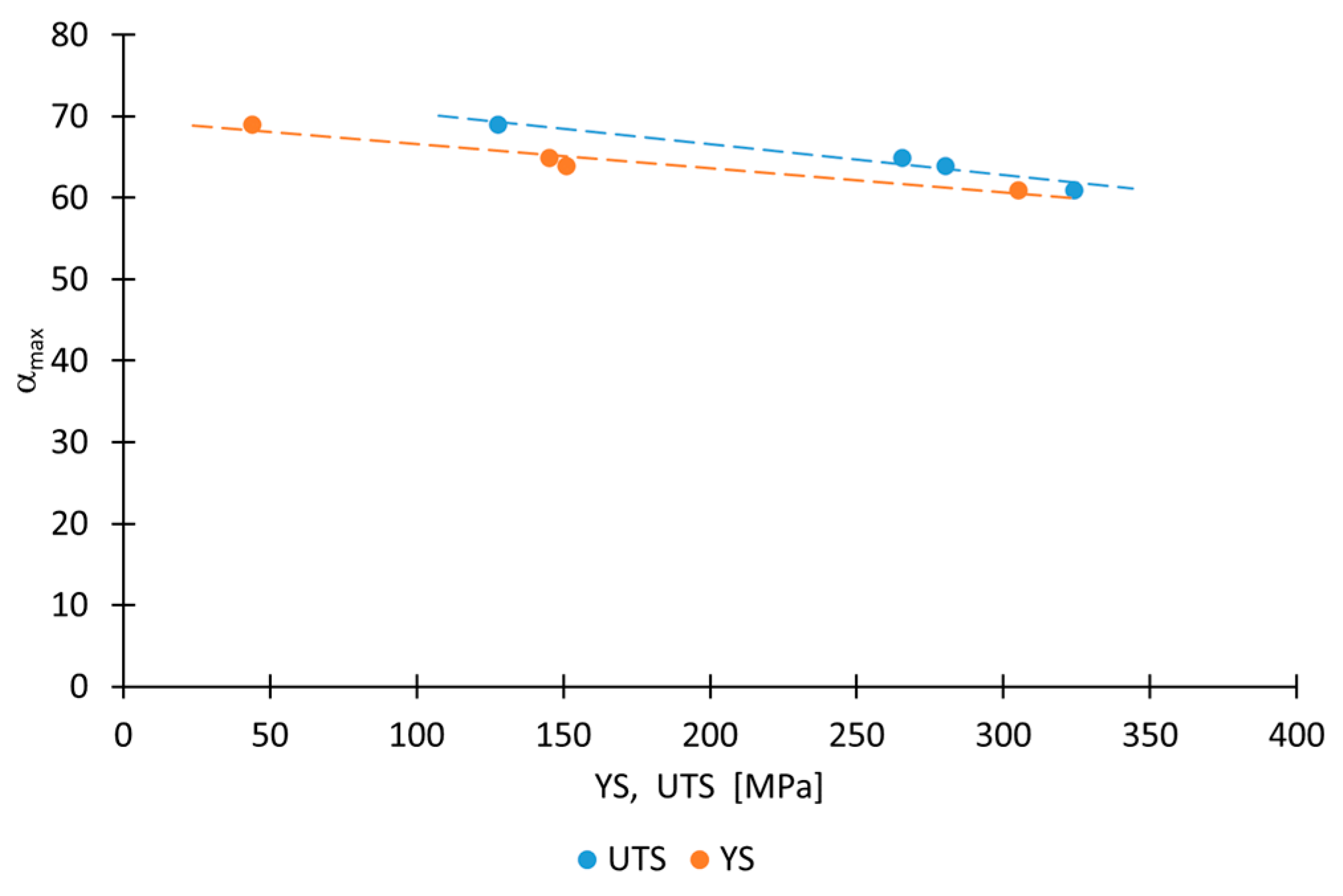

3.3. The Limit-Forming Angle

3.4. Temperature During Forming

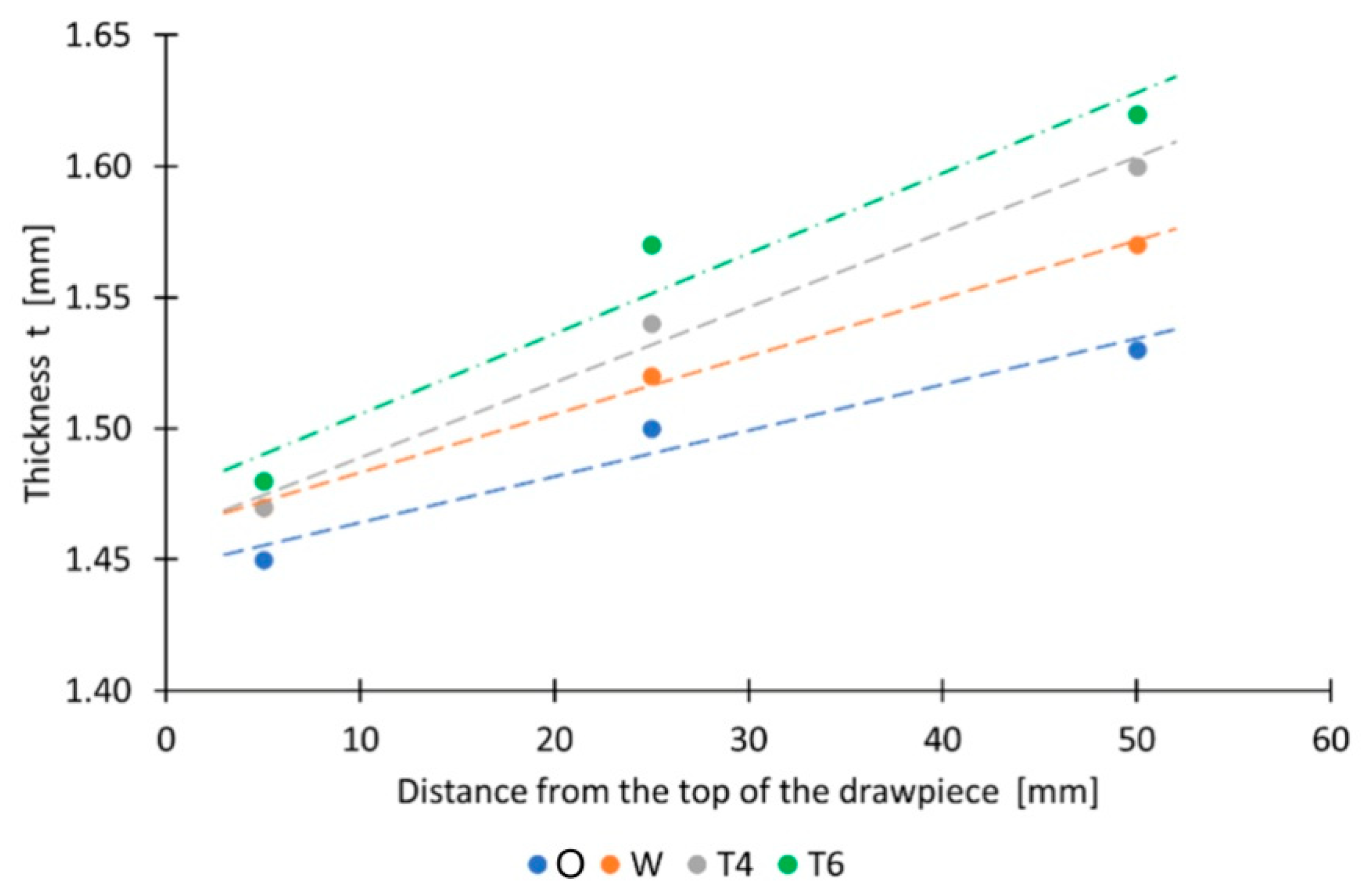

3.5. Drawpiece Wall Thickness

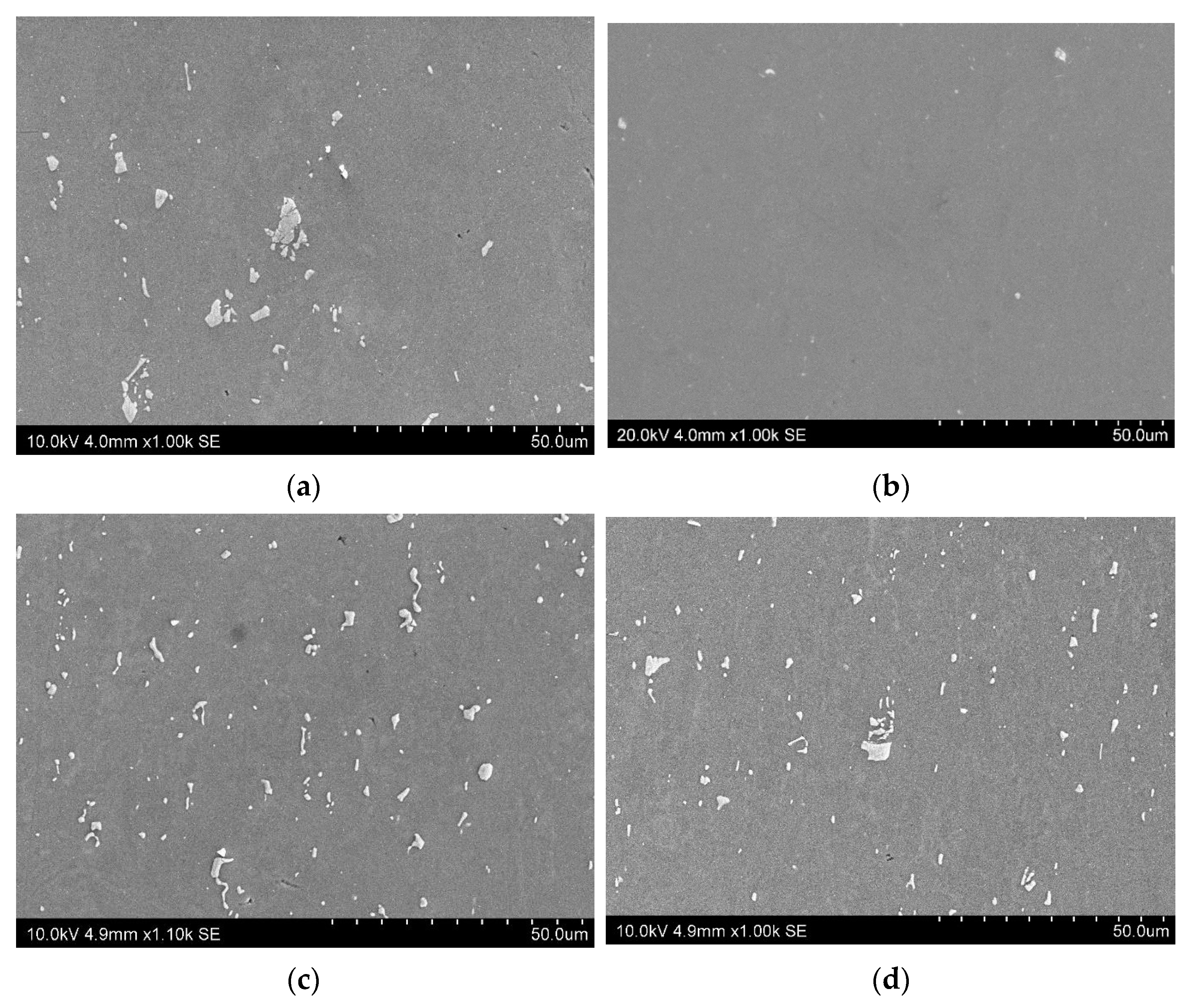

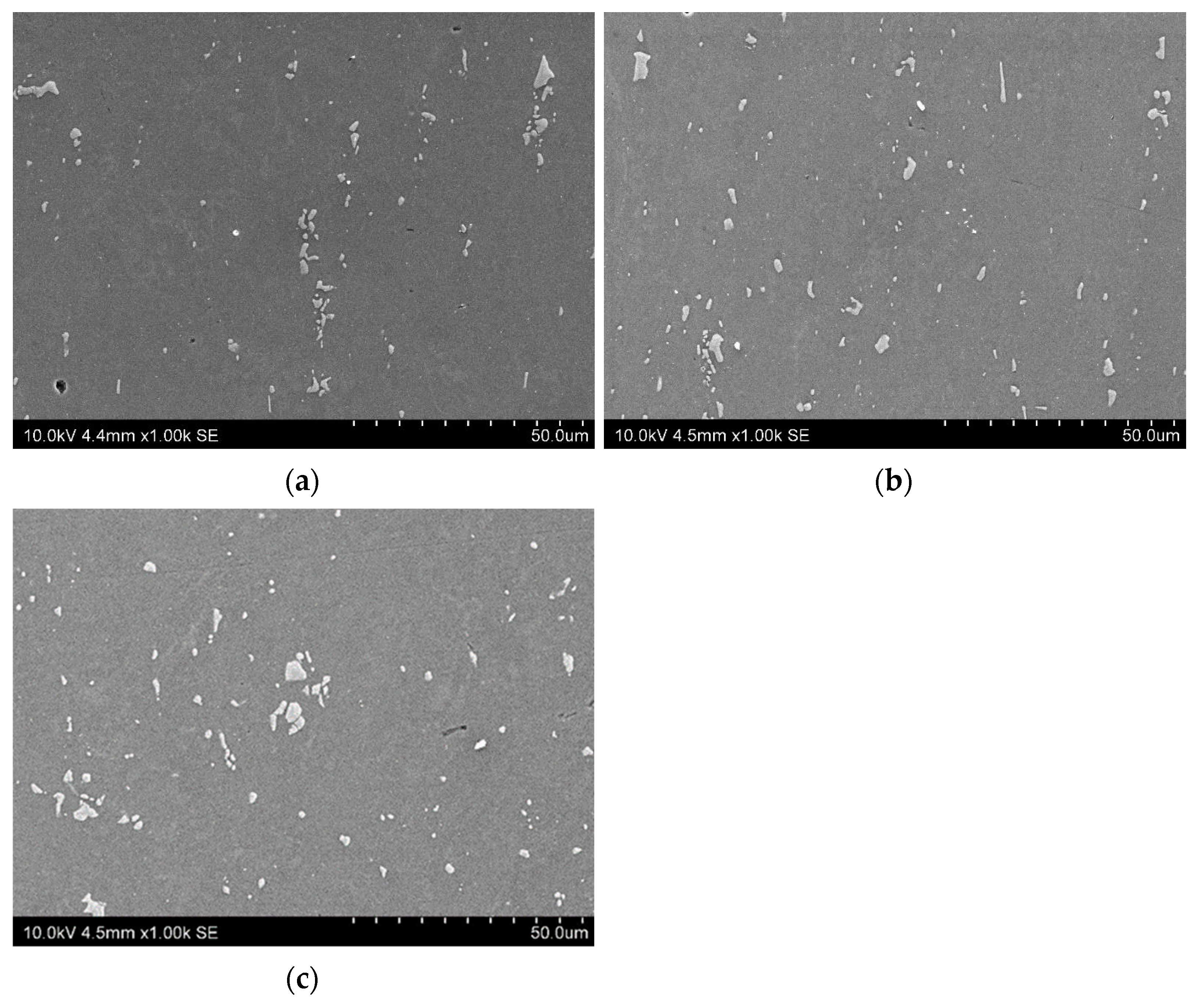

3.6. Microstructure

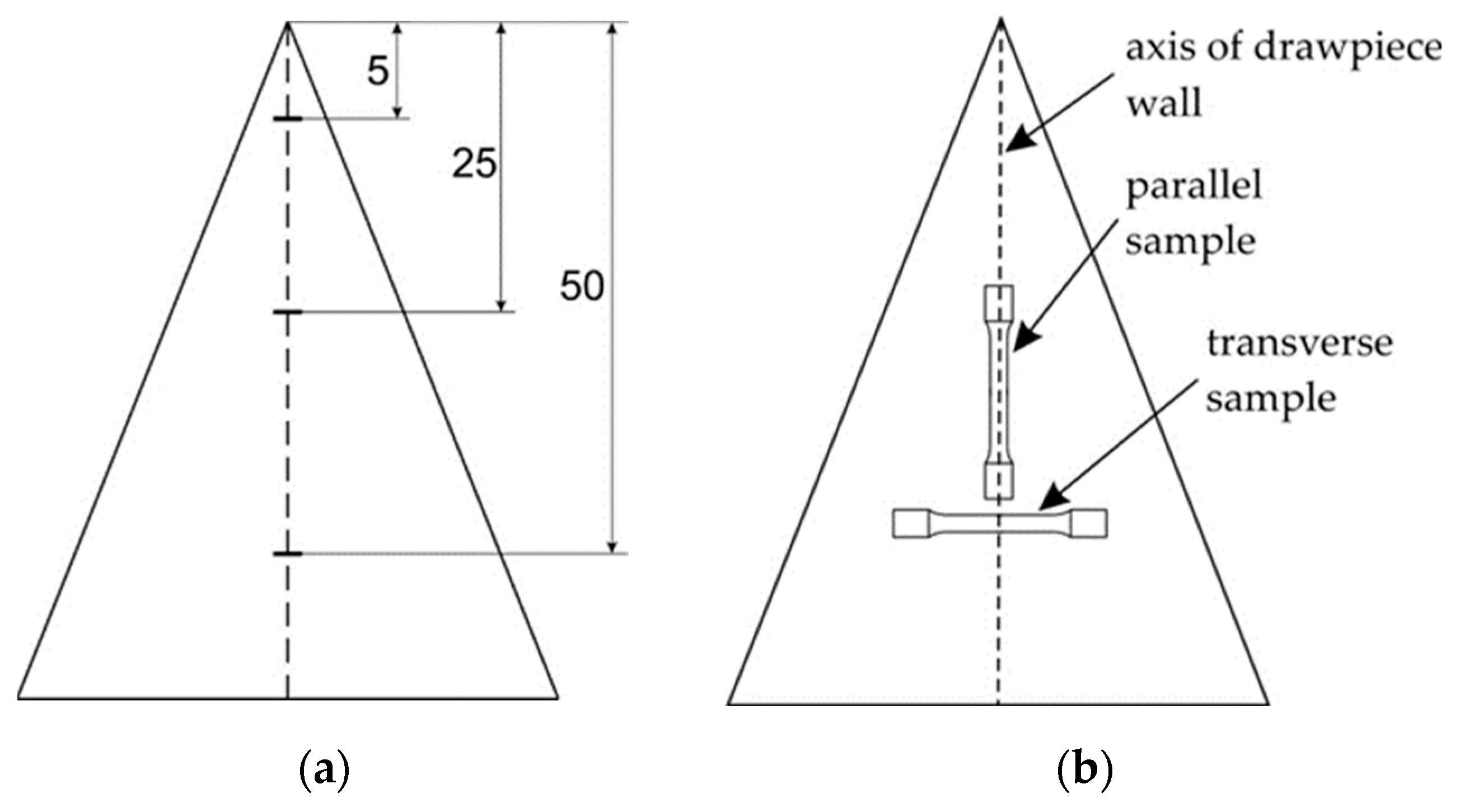

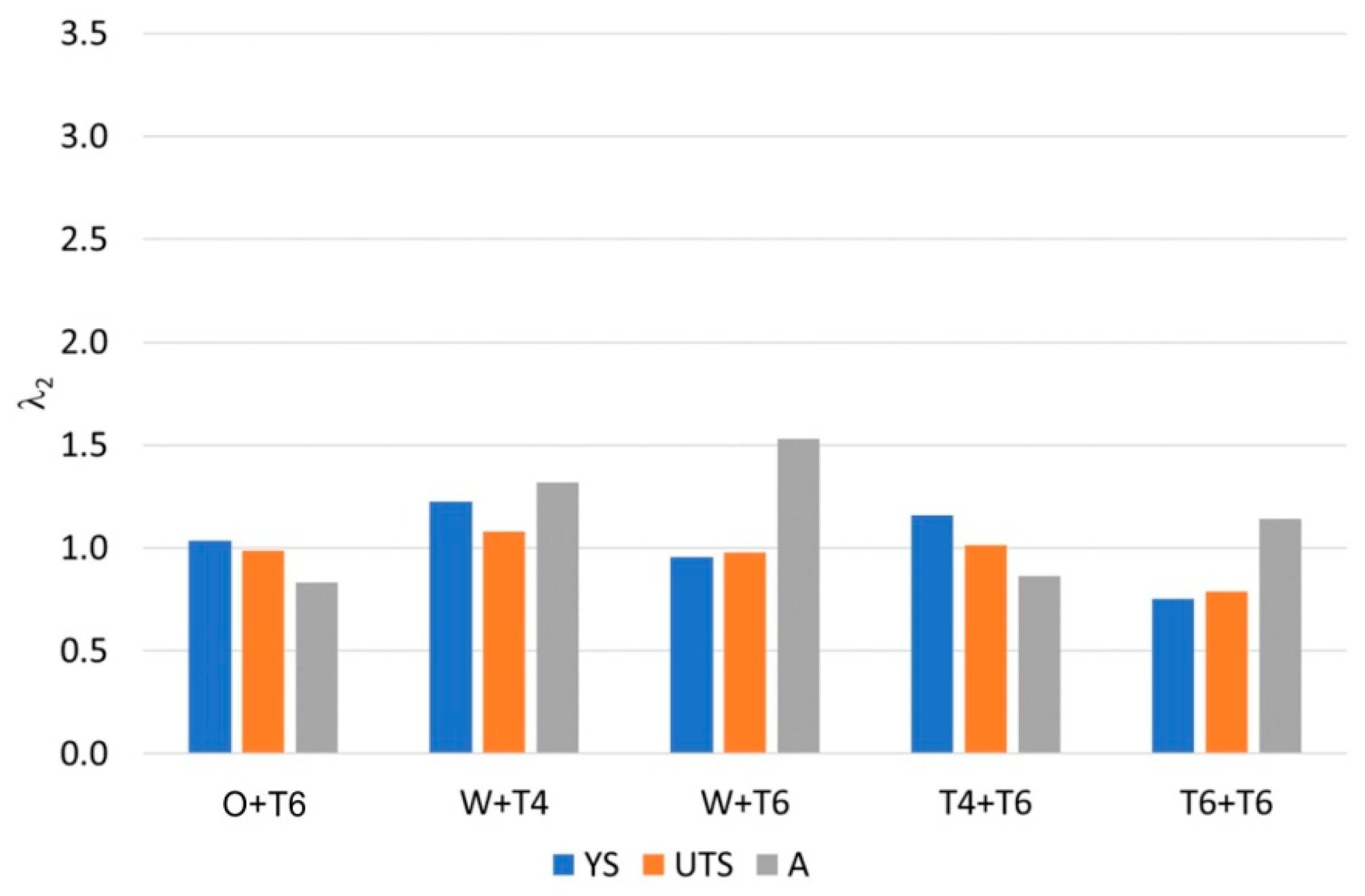

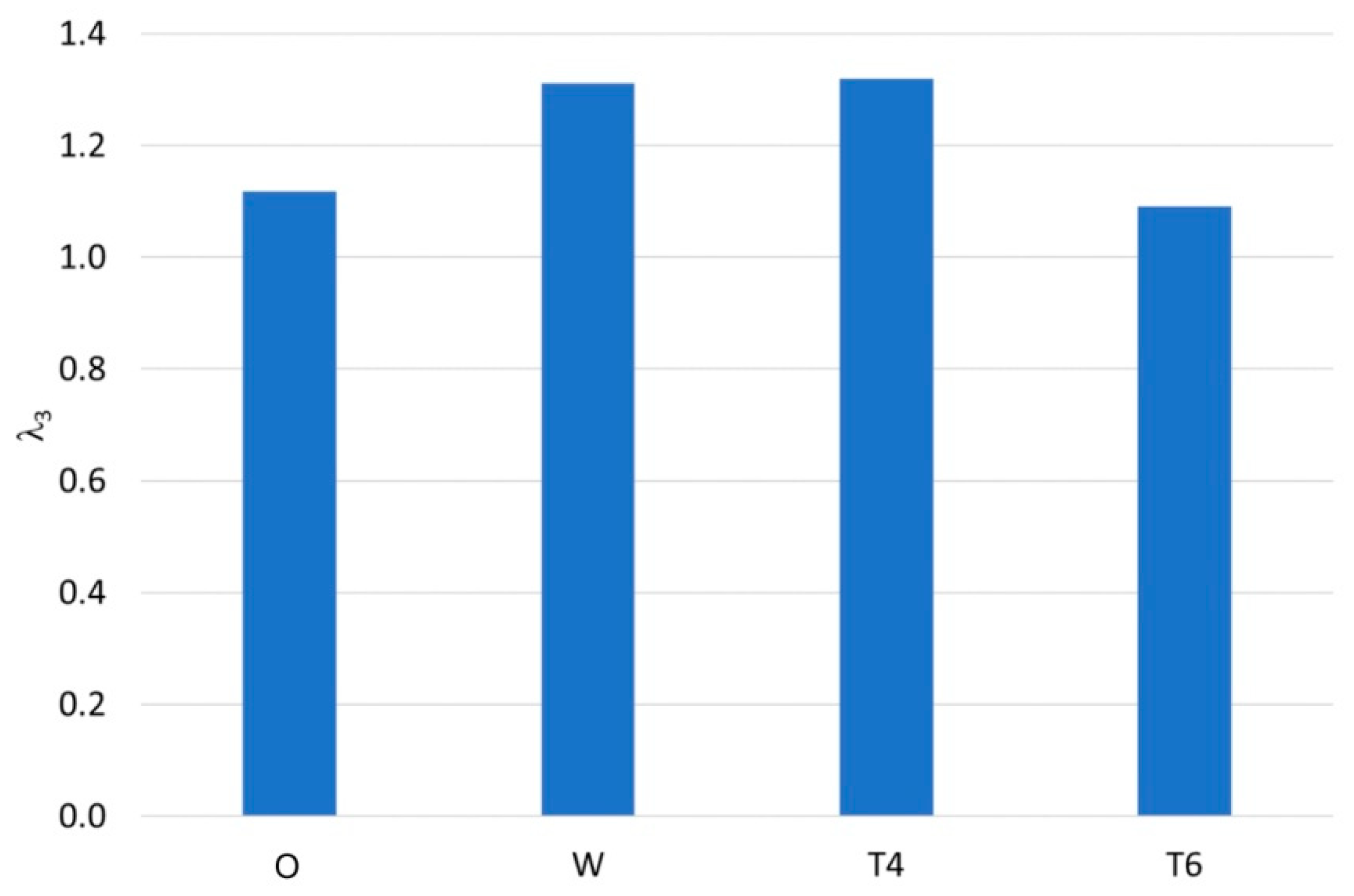

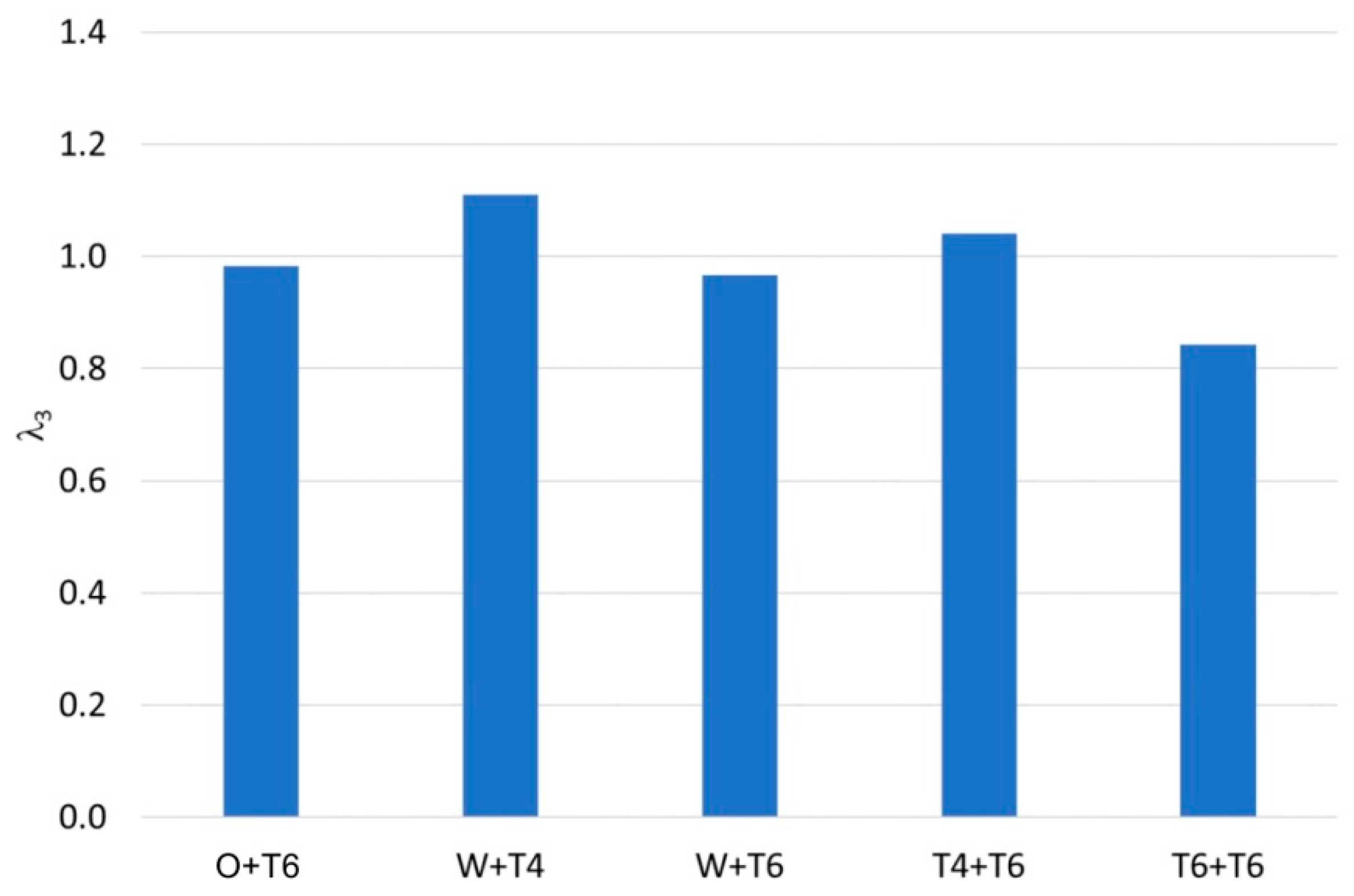

3.7. Mechanical Properties of Drawpieces

3.8. Hardness of Drawpieces

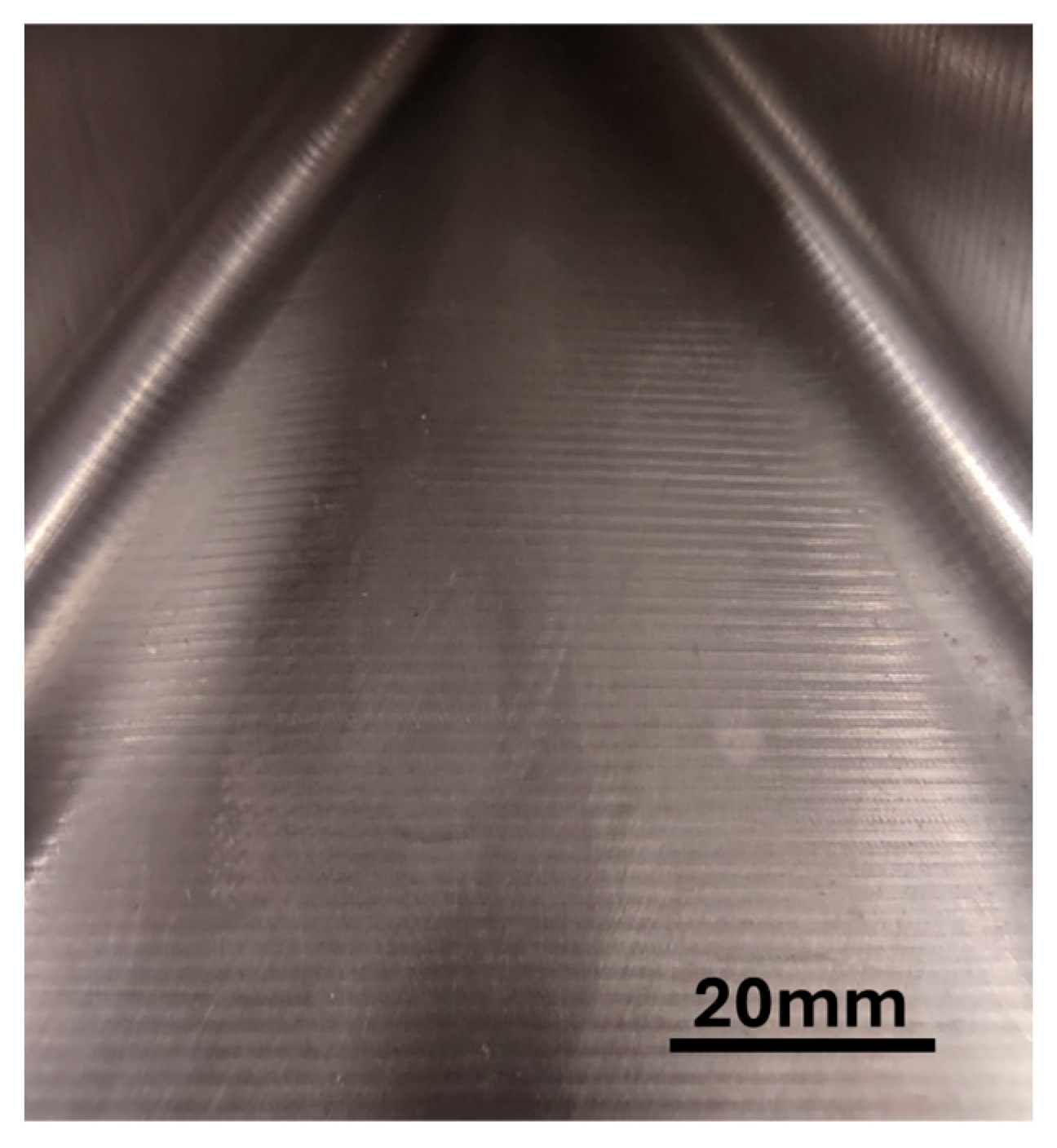

3.9. Surface Roughness

4. Conclusions

- Incremental forming had no effect on the size and number of the observed precipitates in the material. However, additional heat treatment after forming contributed to the observation of additional precipitates in the test materials, especially in the case of drawpieces made from solutionised sheet metal and sheet metal that was aged after the ISF process.

- The hardening state of the workpiece material had a significant effect on the formability of the material in the ISF process. It was found that with the increase in the strength of the material (from the O condition to the T6 tempering state), the value of the limit-forming angle of the drawpiece wall decreased from 69° (for annealed sheet) to 61° (for artificially aged material), which was also associated with a decrease in the plasticity of the material.

- As a result of incremental forming, the strength properties and hardness of the ISFed pyramids increased, despite the temperature increase at the contact area between the forming tool and the sheet metal to 130 °C. This was due to the dominant influence of work hardening on the material properties after forming. The greatest increase was observed for the drawpiece made of annealed sheet metal. In the case of material in the T6 condition, the lowest values of the limit-forming angle were obtained and, consequently, the lowest increase in material strength.

- Additional heat treatment after forming contributed to the increase in strength and hardness properties only in the case of drawpieces made of solutionised workpiece metal (and naturally aged after forming) and naturally aged workpiece material (and artificially aged after forming). In these materials, further precipitation hardening of the EN AW-6082 aluminium alloy occurred. In the remaining cases, especially for the T6 + T6 material, there was a decrease in strength, which may be related to the ageing of the material as a result of excesively long heating at 170 °C (for 6 h).

- The surface roughness of the walls of the drawpieces was higher than that of the sheet metal in the as-received state, especially when measured in the direction parallel to the drawpiece wall axis. This was related to the ISF process conditions, especially the vertical step size. The use of a lower vertical stem size value could contribute to lower values of the Ra and Rz parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Trzepieciński, T.; Najm, S.M. Current Trends in Metallic Materials for Body Panels and Structural Members Used in the Automotive Industry. Materials 2024, 17, 590. [Google Scholar] [CrossRef]

- EN 1706:2020; Aluminum and Aluminum Alloys—Castings—Chemical Composition and Mechanical Properties. European Committee of Standardization: Brussels, Belgium, 2020.

- PN-EN 573-3:2020+A1:2022-11; Aluminium and Aluminium Alloys—Chemical Composition and Form of Wrought Products—Part 3: Chemical Composition and Form of Products. PKN: Warsaw, Poland, 2022.

- Langille, M.R.; Diak, B.J.; De Geuser, F.; Deschamps, A.; Guiglionda, G. Asymmetry of strain rate sensitivity between up- and down-changes in 6000 series aluminium alloys of varying Si content. Mater. Sci. Eng. A 2020, 788, 139517. [Google Scholar] [CrossRef]

- Xu, X.; Liu, Z.; Zhang, B.; Chen, H.; Zhang, J.; Wang, T.; Zhang, K.; Zhang, J.; Huang, P. Effect of Mn content on microstructure and properties of 6000 series aluminum alloy. Appl. Phys. A 2019, 125, 490. [Google Scholar] [CrossRef]

- Ismail, A.; Mohamed, M.S. Review on sheet metal forming process of aluminium alloys. In Proceedings of the 17th International AMME Conference, Cairo, Egypt, 19–21 April 2016; pp. 129–141. [Google Scholar]

- Kleiner, M.; Geiger, M.; Klaus, A. Manufacturing of lightweight components by metal forming. CIRP Ann. 2003, 52, 521–542. [Google Scholar] [CrossRef]

- Guzmán-Flores, I.; Granda-Gutiérrez, E.E.; Cruz-González, C.E.; Hernández-García, H.M.; Díaz-Guillén, J.C.; Flores-González, L.; Praga-Alejo, R.J.; Martínez-Delgado, D.I. Enhancing the mechanical properties of a 6061 aluminum alloy by heat treatment from the perspective of Taguchi design-of-experiments. Appl. Sci. 2024, 14, 5407. [Google Scholar] [CrossRef]

- Van Huis, M.A.; Chen, J.H.; Sluiter, M.H.F.; Zandbergen, H.W. Phase stability and structural features of matrix-embedded hardening precipitates in Al–Mg–Si alloys in the early stages of evolution. Acta Mater. 2007, 55, 2183–2199. [Google Scholar] [CrossRef]

- Ding, L.; Jia, Z.; Nie, J.-F.; Weng, Y.; Cao, L.; Chen, H.; Wu, X.; Liu, Q. The structural and compositional evolution of precipitates in Al-Mg-Si-Cu alloy. Acta Mater. 2018, 145, 437–450. [Google Scholar] [CrossRef]

- Naronikar, A.H.; Jamadagni, H.N.A.; Simha, A.; Saikiran, B. Optimizing the heat treatment parameters of Al-6061 required for better formability. Mater. Today Proc. 2018, 5, 24240–24247. [Google Scholar] [CrossRef]

- Nicolaides, L.; Mandelis, A.; Beingessner, C.J. Physical mechanisms of thermal-diffusivity depth-profile generation in a hardened lowalloy Mn, Si, Cr, Mo steel reconstructed by photothermal radiometry. J. Appl. Phys. 2001, 89, 7879–7884. [Google Scholar] [CrossRef]

- Fournier, D.; Roger, J.P.; Bellouati, A.; Boué, C.; Stamm, H.; Lakestani, F. Correlation between hardness and thermal diffusivity. Anal. Sci. 2001, 17, 158–160. [Google Scholar]

- Dell’Avvocato, G.; Palumbo, D.; Galietti, U. A non-destructive thermographic procedure for the evaluation of heat treatment in Usibor®1500 through the thermal diffusivity measurement. NDT E Int. 2023, 133, 102748. [Google Scholar] [CrossRef]

- Dell’Avvocato, G.; Bison, P.; Palmieri, M.E.; Ferrarini, G.; Palumbo, D.; Tricarico, L.; Galietti, U. Non-destructive estimation of mechanical properties in Usibor® 1500 via thermal diffusivity measurements: A thermographic procedure. NDT E Int. 2024, 143, 103034. [Google Scholar] [CrossRef]

- Formisano, A.; Boccarusso, L.; Durante, M. Optimization of single-point incremental forming of polymer sheets through FEM. Materials 2023, 16, 451. [Google Scholar] [CrossRef] [PubMed]

- Najm, S.M.; Paniti, I. Investigation and machine learning-based prediction of parametric effects of single point incremental forming on pillow effect and wall profile of AlMn1Mg1 aluminum alloy sheets. J. Intell. Manuf. 2023, 34, 331–367. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Najm, S.M.; Oleksik, V.; Vasilca, D.; Paniti, I.; Szpunar, M. Recent developments and future challenges in incremental sheet forming of aluminium and aluminium alloy sheets. Metals 2022, 12, 124. [Google Scholar] [CrossRef]

- Żaba, K.; Puchlerska, S.; Kuczek, Ł.; Trzepieciński, T.; Maj, P. Effect of step size on the formability of Al/Cu bimetallic sheets in single point incremental sheet forming. Materials 2023, 16, 367. [Google Scholar] [CrossRef] [PubMed]

- Davarpanah, M.A.; Malhotra, R. Formability and failure modes in single point incremental forming of metal-polymer laminates. Procedia Manuf. 2018, 26, 343–348. [Google Scholar] [CrossRef]

- Davarpanah, M.A.; Mirkouei, A.; Yu, X.; Malhotra, R.; Pilla, S. Effects of incremental depth and tool rotation on failure modes and microstructural properties in Single Point Incremental Forming of polymers. J. Mater. Process. Technol. 2015, 222, 287–300. [Google Scholar] [CrossRef]

- Özgen, B.; Lazoğlu, İ.; Durgun, İ. Experimental investigation of the process parameters on the forming force for single point incremental forming. In Proceedings of the 16th International Conference on Machine Design and Production, İzmir, Turkiye, 30 June–3 July 2014; pp. 1–15. [Google Scholar]

- Popp, M.O.; Rusu, G.P.; Oleksik, V.; Biris, C. Influence of vertical step on forces and dimensional accuracy of SPIF parts—A numerical investigation. IOP Conf. Ser. Mater. Sci. Eng. 2020, 968, 012020. [Google Scholar] [CrossRef]

- Kumar, P.; Priyadarshi, S.; Roy, J.J.; Samal, M.L.; Jain, P.K.; Tandon, P. Effect of tool shape on surface finish of components formed through incremental sheet forming process. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015. Paper No: IMECE2015-53282. [Google Scholar] [CrossRef]

- Ragai, I.; Goldstein, J.; Meyer, C.; Upcraft, C. Effect of tool material and process parameters on surface conditions in single point incremental forming (SPIF) of polymeric materials. In Proceedings of the ASME 2022 International Mechanical Engineering Congress and Exposition, Columbus, OH, USA, 30 October–3 November 2022. Paper No: IMECE2022-95951. [Google Scholar] [CrossRef]

- Şen, N.; Şirin, S.; Kıvak, T.; Civek, T.; Seçgin, Ö. A new lubrication approach in the SPIF process: Evaluation of the applicability and tribological performance of MQL. Tribol. Int. 2022, 171, 107546. [Google Scholar] [CrossRef]

- Said, L.B.; Mars, J.; Wali, M.; Dammak, F. Effects of the tool path strategies on incremental sheet metal forming process. Mech. Ind. 2016, 17, 411. [Google Scholar] [CrossRef]

- Kumar, N.; Bharti, S.; Krishnaswamy, H.; Agrawal, A. Exploring deformation mechanics of temperature assisted incremental forming with hybrid heating. J. Manuf. Process. 2023, 104, 472–484. [Google Scholar] [CrossRef]

- Cusanno, A.; Negrini, N.C.; Villa, T.; Farè, S.; Garcia-Romeu, M.L.; Palumbo, G. Post Forming Analysis and In Vitro Biological Characterization of AZ31B Processed by Incremental Forming and Coated with Electrospun Polycaprolactone. J. Manuf. Sci. Eng. 2021, 143, 011012. [Google Scholar] [CrossRef]

- Fratini, L.; Ambrogio, G.; Di Lorenzo, R.; Filice, L.; Micari, F. Influence of mechanical properties of the sheet material on formability in single point incremental forming. CIRP Ann.–Manuf. Technol. 2004, 53, 207–210. [Google Scholar] [CrossRef]

- Ham, M.; Jeswiet, J. Forming limit curves in single point incremental forming. CIRP Ann.–Manuf. Technol. 2007, 56, 277–280. [Google Scholar] [CrossRef]

- Lu, B.; Fang, Y.; Xu, D.K.; Chen, J.; Ou, H.; Moser, N.H.; Cao, J. Mechanism investigation of friction-related effects in single point incremental forming using a developed oblique roller-ball tool. Int. J. Mach. Tools Manuf. 2014, 85, 14–29. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Li, Y.; Hu, L.; Pang, Q.; Hu, Z. Investigation of Pre-Aged Hardening Single-Point Incremental Forming Process and Mechanical Properties of AA6061 Aluminum Alloy. Materials 2023, 16, 4154. [Google Scholar] [CrossRef]

- Gulati, V.; Aryal, A.; Katyal, P.; Goswami, A. Process parameters optimization in single point incremental forming. J. Inst. Eng. Ser. C 2016, 97, 185–193. [Google Scholar] [CrossRef]

- Alinaghian, I.; Ranjbar, H.; Beheshtizad, M.A. Forming limit investigation of AA6061 friction stir welded blank in a single point incremental forming process: RSM approach. Trans. Indian Inst. Met. 2017, 70, 2303–2318. [Google Scholar] [CrossRef]

- Ghaferi, M.; Mirnia, M.J.; Elyasi, M.; Jamshidi Aval, H. Evaluation of different heat treatment cycles on improving single point incremental forming of AA6061 aluminum alloy. Int. J. Adv. Manuf. Technol. 2019, 105, 83–100. [Google Scholar] [CrossRef]

- Rubino, F.; Esperto, V.; Paulo, R.M.F.; Tucci, F.; Carlone, P. Integrated manufacturing of AA6082 by friction stir welding and incremental forming: Strain analysis of deformed samples. Procedia Manuf. 2020, 47, 440–444. [Google Scholar] [CrossRef]

- Reddy, A.C. Evaluation of single point incremental forming process for parabolic AA6082 cups. Int. J. Sci. Eng. Res. 2017, 8, 964–970. [Google Scholar]

- ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- EN 573-3; Aluminium and Aluminium Alloys—Chemical Composition and Form of Wrought Products—Part 3: Chemical Composition and Form Products. CEN: Brussels, Belgium, 2019.

- EN 755-2; Aluminium and Aluminium Alloys—Extruded Rod/Bar, Tube and Profiles—Part 2: Mechanical Properties. CEN: Brussels, Belgium, 2016.

- Mrówka, G.; Sieniawski, J.; Nowotnik, A. Effect of heat treatment on tensile and fracture toughness properties of 6082 alloy. J. Achiev. Mater. Manuf. Eng. 2009, 32, 162–170. [Google Scholar]

- Fujda, M.; Matvija, M.; Zubko, P. Comparison of the Natural Ageing Behaviour of EN AW 6082 and Lead Free EN AW 6023 Aluminium Alloys. KEM 2013, 586, 125–128. [Google Scholar] [CrossRef]

- Sakuda, T.; Matsabura, S.; Sakamoto, M.; Fukuhara, G. Deformation analysis for stretching forming of sheet metal with CNC machine tools. In Proceedings of the 6th ICTP Conference, Nuremberg, Germany, 19–24 September 1999; pp. 1501–1504. [Google Scholar]

- Ambrogio, G.; Filice, L.; Gagliardi, F.; Micari, F. Sheet thinning prediction in single point incre-mental forming. Adv. Mater. Res. 2005, 6–8, 479–486. [Google Scholar] [CrossRef]

- Kapłon, P.; Pezda, J. Obróbka cieplna elementu przelotowego uchwytu wahliwego. In Projektowanie, Badania I Eksploatacja—2023; Rysiński, J., Ed.; Wydawnictwo Naukowe Uniwersytetu Biel-sko-Bialskiego: Bielsko Biała, Poland, 2023. [Google Scholar]

- Mirnia, M.J.; Vahdani, M.; Shamsari, M. Ductile damage and deformation mechanics in multistage single point incremental forming. Int. J. Mech. Sci. 2018, 136, 396–412. [Google Scholar] [CrossRef]

- Al-Ghamdi, K.A.; Hussain, G. On the Free-Surface Roughness in Incremental Forming of a Sheet Metal: A Study from the Perspective of ISF Strain, Surface Morphology, Post-Forming Properties, and Process Conditions. Metals 2019, 9, 553. [Google Scholar] [CrossRef]

- Echrif, S.B.M.; Hrairi, M. Significant parameters for the surface roughness in incremental forming process. Mater. Manuf. Process. 2014, 29, 697–703. [Google Scholar] [CrossRef]

- Abd Ali, R.; Chen, W.; Al-Furjan, M.S.H.; Jin, X.; Wang, Z. Experimental Investigation and Op-timal Prediction of Maximum Forming Angle and Surface Roughness of an Al/SUS Bimetal Sheet in an Incremental Forming Process Using Machine Learning. Materials 2019, 12, 4150. [Google Scholar] [CrossRef]

- Maqbool, F.; Bambach, M. Dominant deformation mechanisms in single point incremental forming (SPIF) and their effect on geometrical accuracy. Int. J. Mech. Sci. 2018, 136, 279–292. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.7–1.3 | max 0.50 | max 0.10 | 0.4–1.0 | 0.6–1.2 | max 0.25 | max 0.20 | max 0.10 | remainder |

| Temper | Wall Thickness, mm | YS, MPa | UTS, MPa | A, % |

|---|---|---|---|---|

| O | t ≤ 25 | 60 | 130 | 14 |

| T4 | t ≤ 25 | 110 | 205 | 8 |

| T6 | t ≤ 5 | 250 | 290 | 8 |

| 5 < t ≤ 25 | 260 | 310 | 10 |

| Temper Designation | Description |

|---|---|

| O | Annealed sample (sample placed in a furnace at 575 °C for 2 h, cooled with the furnace) |

| W | Solution-heat-treated sample (sample placed in a furnace at 575 °C for 2 h, cooled in water at 25 °C) |

| T4 | Solution heat treated and naturally aged sample (sample placed in a furnace at 575 °C for 2 h and naturally aged at 20 °C for 500 h) |

| T6 | Solution-heat-treated and artificially aged sample (sample placed in a furnace at 575 °C for 2 h and artificially aged at 190 °C for 6 h) |

| Temper Designation | Description |

|---|---|

| O + T6 | Annealed sample after forming, solutionizing and artificial ageing (sample placed in a furnace at 575 °C for 2 h and artificially aged at 170 °C for 6 h) |

| W + T4 | Solution-heat-treated sample after forming, solution heat treated and naturally aged (sample placed in a furnace at 575 °C for 2 h and naturally aged at room temperature for 30 days) |

| W + T6 | Solution-heat-treated sample after forming, solution heat treated and artificially aged (sample placed in a furnace at 575 °C for 2 h and artificially aged at 170 °C for 6 h) |

| T4 + T6 | Solution-heat-treated and naturally aged sample after forming, solution-heat-treated and artificially aged sample |

| T6 + T6 | Solution-heat-treated and artificially aged sample after forming, solution-heat-treated and artificially aged sample |

| Temper Designation | Sample Orientation, ° | YS, MPa | UTS, MPa | Ag, % | A, % |

|---|---|---|---|---|---|

| O | 0 | 43.2 | 128.4 | 23.0 | 28.8 |

| 45 | 43.5 | 127.1 | 21.6 | 27.4 | |

| 90 | 45.0 | 127.3 | 22.0 | 28.0 | |

| Average | 43.8 | 127.5 | 22.1 | 27.9 | |

| W | 0 | 145.7 | 265.7 | 24.9 | 26.4 |

| 45 | 142.2 | 263.3 | 25.5 | 27.6 | |

| 90 | 150.1 | 268.6 | 25.0 | 26.4 | |

| Average | 145.1 | 265.2 | 25.2 | 27.0 | |

| T4 | 0 | 151.0 | 281.6 | 23.6 | 26.8 |

| 45 | 150.7 | 279.2 | 23.2 | 26.4 | |

| 90 | 151.0 | 280.4 | 22.4 | 26.8 | |

| Average | 150.9 | 280.1 | 23.1 | 26.6 | |

| T6 | 0 | 301.5 | 320.6 | 6.2 | 10.2 |

| 45 | 302.5 | 322.8 | 6.2 | 9.4 | |

| 90 | 313.3 | 329.9 | 6.3 | 8.4 | |

| Average | 305.0 | 324.0 | 6.2 | 9.4 |

| Temper Designation | Vickers Hardness HV1 |

|---|---|

| O | 51 |

| W | 90 |

| T4 | 94 |

| T6 | 111 |

| Temper Designation | Limit-Forming Angle αmax, ° |

|---|---|

| O | 69 |

| W | 65 |

| T4 | 64 |

| T6 | 61 |

| Temper Designation | Measured Wall Thickness at Selected Points, mm | Wall Thickness According to Sine Law, mm | ||

|---|---|---|---|---|

| 1 (5 mm) | 2 (25 mm) | 3 (50 mm) | ||

| O | 1.45 | 1.50 | 1.53 | 0.72 |

| W | 1.47 | 1.52 | 1.57 | 0.85 |

| T4 | 1.47 | 1.54 | 1.60 | 0.88 |

| T6 | 1.48 | 1.57 | 1.62 | 0.97 |

| Temper Designation | Sample Orientation | YS, MPa | UTS, MPa | A, % |

|---|---|---|---|---|

| O | transverse | 109 | 158 | 8.2 |

| parallel | 146 | 169 | 10.4 | |

| W | transverse | 269 | 324 | 4.4 |

| parallel | 275 | 338 | 5.4 | |

| T4 | transverse | 282 | 339 | 7.2 |

| parallel | 289 | 351 | 6.6 | |

| T6 | transverse | 321 | 368 | 6.6 |

| parallel | 333 | 390 | 6.8 | |

| O + T6 | transverse | 131 | 161 | 7.7 |

| parallel | 133 | 162 | 7.8 | |

| W + T4 | transverse | 325 | 349 | 6.8 |

| parallel | 342 | 365 | 6.1 | |

| W + T6 | transverse | 248 | 313 | 7.2 |

| parallel | 273 | 335 | 7.8 | |

| T4 + T6 | transverse | 323 | 340 | 5.8 |

| parallel | 339 | 358 | 6.1 | |

| T6 + T6 | transverse | 241 | 290 | 7.6 |

| parallel | 252 | 308 | 7.7 |

| Temper Designation | Vickers Hardness HV1 |

|---|---|

| O | 57 |

| W | 118 |

| T4 | 124 |

| T6 | 121 |

| O + T6 | 56 |

| W + T4 | 131 |

| W + T6 | 114 |

| T4 + T6 | 129 |

| T6 + T6 | 102 |

| Temper Designation | Surface of Drawpiece | Orientation of Measurement Relative to the Axis of the Drawpiece Wall, ° | Ra, μm | Rz, μm |

|---|---|---|---|---|

| O | inner | 0 | 2.95 | 16.37 |

| O | inner | 90 | 2.59 | 15.06 |

| O | outer | 0 | 2.06 | 10.89 |

| O | outer | 90 | 1.69 | 8.96 |

| W | inner | 0 | 3.08 | 16.69 |

| W | inner | 90 | 2.76 | 13.84 |

| W | outer | 0 | 2.47 | 13.27 |

| W | outer | 90 | 2.19 | 11.87 |

| T4 | inner | 0 | 3.21 | 17.51 |

| T4 | inner | 90 | 2.81 | 14.46 |

| T4 | outer | 0 | 2.52 | 13.42 |

| T4 | outer | 90 | 2.26 | 12.05 |

| T6 | inner | 0 | 3.35 | 18.86 |

| T6 | inner | 90 | 2.92 | 15.98 |

| T6 | outer | 0 | 2.58 | 13.57 |

| T6 | outer | 90 | 2.23 | 12.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuczek, Ł.; Żaba, K.; Trzepieciński, T.; Wąsikowski, M.; Balcerzak, M.; Sitek, R. Influence of Heat Treatment on Properties and Microstructure of EN AW-6082 Aluminium Alloy Drawpieces After Single-Point Incremental Sheet Forming. Appl. Sci. 2025, 15, 783. https://doi.org/10.3390/app15020783

Kuczek Ł, Żaba K, Trzepieciński T, Wąsikowski M, Balcerzak M, Sitek R. Influence of Heat Treatment on Properties and Microstructure of EN AW-6082 Aluminium Alloy Drawpieces After Single-Point Incremental Sheet Forming. Applied Sciences. 2025; 15(2):783. https://doi.org/10.3390/app15020783

Chicago/Turabian StyleKuczek, Łukasz, Krzysztof Żaba, Tomasz Trzepieciński, Mateusz Wąsikowski, Maciej Balcerzak, and Ryszard Sitek. 2025. "Influence of Heat Treatment on Properties and Microstructure of EN AW-6082 Aluminium Alloy Drawpieces After Single-Point Incremental Sheet Forming" Applied Sciences 15, no. 2: 783. https://doi.org/10.3390/app15020783

APA StyleKuczek, Ł., Żaba, K., Trzepieciński, T., Wąsikowski, M., Balcerzak, M., & Sitek, R. (2025). Influence of Heat Treatment on Properties and Microstructure of EN AW-6082 Aluminium Alloy Drawpieces After Single-Point Incremental Sheet Forming. Applied Sciences, 15(2), 783. https://doi.org/10.3390/app15020783