Featured Application

This research is important for industries relying on repetitive tasks, as it provides insights into ergonomic risk factors and promotes interventions to enhance worker health and productivity.

Abstract

(1) Background: This study examines the association between asymmetrical movements of an assembly line and machining workers and their overall well-being. The primary aim is to quantify the extent to which asymmetrical movements serve as predictors of work-related musculoskeletal disorders (WMSDs) among these workers and their overall well-being. The study emphasises the predictive relationships between asymmetry metrics and health outcomes. (2) Methods: The study included 86 employees from an automotive manufacturing plant, categorised into machining workers (MWEs) and assembly workers (AWEs). The employment duration spanned from 6 months to 40 years. Inertial motion capture technology was employed alongside the Goldberg 28-item General Health Questionnaire for a retrospective observational analysis and assessment of worker well-being. Movement dynamics were evaluated using a Motion Activity Index (MAI) to measure movement intensity, asymmetry, and quality. (3) Results: The machining group demonstrated nearly double the range of motion (median ROM: 36.6° vs. 25.5°, p = 0.019) and peak angular velocities up to eight times higher (median: 40°/s vs. 5°/s) in lumbar and thoracic rotations compared to the assembly group. Significant differences in ROM and movement speeds were observed (p < 0.001). The MAI showed higher dynamic and symmetrical movements in the machining group (36.6% vs. 25.5%, p = 0.019). No significant mental health issues were identified, aside from complaints related to somatic symptoms. (4) Conclusions: This study highlights significant occupational risks due to movement asymmetry in industrial settings, revealing substantial differences in joint angular displacements, velocities, and accelerations between machining and assembly workers. The findings emphasise the importance of targeted ergonomic interventions to enhance worker well-being and advocate for preventive health measures in occupational environments.

1. Introduction

In the realm of workplace health prevention, the integration of ergonomic principles has emerged as a pivotal area of focus, marked by an increasing reliance on advanced technical tools, such as inertial motion analysis systems. The evolution of ergonomics research, driven by the imperative to enhance workers’ safety and well-being, has introduced sophisticated methodologies for capturing kinematic, kinetic, and electromyographic data [1]. These advancements facilitate a comprehensive understanding of workers’ performance, with a particular emphasis on motion and posture analysis as foundational tools for the diagnosis, treatment, and prevention of musculoskeletal disorders (MSDs) [2,3,4,5,6]. Notably, assessing human motion during functional activities stands at the forefront of efforts to promote health and prevent workplace injuries, underscoring the critical importance of accurate ergonomic evaluations. Recent advancements underscore the importance of assessing movement ergonomics, propelled by technological innovations, such as inertial systems for human motion analysis. This research trajectory highlights a gap in traditional workplace ergonomic assessments, often neglecting the implications of movement asymmetry [7]. Despite the expectation for symmetrical limb movements to minimise energy expenditure during routine activities, the reality of workplace tasks, particularly in settings characterised by repetitive motions, such as assembly lines or machining operations, frequently deviates from this ideal [8]. This discrepancy not only elevates the risk of energy inefficiency but also predisposes workers to a spectrum of orthopaedic and neurological complications arising from prolonged asymmetric limb movements.

In light of the European standards presenting guidance to the designer of machinery or its component parts [9], the concept of repetitiveness in occupational tasks is often characterised by the continuous replication of identical cycles, technical actions, and movements throughout a substantial portion of a conventional workday. Particularly perilous are those repetitive movements that incessantly engage the same joints and muscle groups, compounded by the frequency, velocity, and duration of such activities [10,11]. The analysis of task repetitiveness necessitates an examination of the steps or cycles involved. The inherent danger of work characterised by repetitive movements is augmented by the limited opportunity for workers to fully recuperate in the brief intervals between these actions, leading to a heightened risk of injury should the activity persist in the face of mounting fatigue [11]. Repetitive motions, intrinsic to uniform work activities, pose significant risks, particularly when combined with awkward postures and forceful exertions. These risks are further amplified in tasks involving asymmetrical movements—a hallmark of production or assembly line work where one hand stabilises an object. At the same time, the other performs rapid actions, such as connecting or integrating components. The frequent repetition of such motions, occurring every few seconds over extended periods, like an eight-hour shift, leads to cumulative fatigue and muscle strain, ultimately resulting in injuries or musculoskeletal disorders (MSDs) [12,13,14].

Globally, MSDs constitute a significant health predicament with profound socio-economic repercussions. They afflict approximately a third of the global populace, emerging as a predominant cause of chronic disability, absence due to illness, diminished work productivity, and quality of life [15,16]. It is significant to underscore that the incidence of these disorders within certain working demographics and/or occupational sectors markedly surpasses that in the general populace [17]. In this discourse, they are delineated as work-related musculoskeletal disorders (WMSDs), the most prevalent work-associated health complication within the European Union, affecting workers across all sectors and vocations [18]. Moreover, they amplify work fatigue and exhaustion while diminishing overall well-being. They also precipitate substantial organisational and societal costs (estimated at approximately 17.2 billion EUR, 45–55 billion USD), through prolonged sick leaves, reduced productivity, and increased staff turnover rates [19,20]. Consequently, countless organisations and institutions strive to alleviate WMSDs by implementing ergonomic solutions or occupational hazard prevention across diverse industries and professions.

In the realm of workplace ergonomics, the elucidation and mitigation of movement asymmetry are paramount. Movement asymmetry entails the unequal utilisation or positioning of disparate body parts during work activities [21]. Evidence substantiates that asymmetrical positioning and awkward movements during work precipitate numerous injuries and MSDs [22,23,24], alongside general fatigue [25], bodily pain, and a sensation of overexertion [26]. Furthermore, there is indicative evidence that appropriate posture, the absence of awkward positions, and ergonomic movements may enhance well-being, mental health [27], and positive work attitudes, such as motivation [28] and satisfaction [29,30].

Observational methodologies frequently serve as the preferred approach to evaluate the physical workload, identify occupational hazards, monitor the impacts of ergonomic adjustments, and investigate these phenomena. Although numerous methods exist, such as the Occupational Repetitive Actions (OCRA) [10], Job Strain Index (JSI) [31], and Assessment of Repetitive Tasks of the Upper Limbs (the ART tool) [32], no singular method suffices for all purposes or objectives [33].

The interplay between workplace ergonomics and employee well-being has recently attracted heightened attention [27,34], especially within the context of assembly line work environments. Movement asymmetry—unequal or imbalanced physical activity during work—is emerging as a pivotal factor in deciphering this relationship. While ergonomic principles traditionally advocate for symmetry in the movement to minimise energy expenditure and optimise efficiency, real-world scenarios, notably in manufacturing settings, frequently deviate from this ideal due to task nature and workplace design. Despite their prevalence and influence, the specific mechanisms through which asymmetrical movements contribute to WMSDs and the overall well-being of workers remain insufficiently explored.

To address this knowledge gap, this study aims to answer the following research questions:

- What is the extent and nature of movement asymmetry among assembly line and machining workers, and does it pose an occupational risk for developing work-related musculoskeletal disorders (WMSDs)?

- How do these asymmetrical, repetitive movements impact various aspects of workers’ overall well-being, including both physical and mental health?

To address these questions, this research rigorously examines the risk factors linked to movement asymmetry in the workplace and develops a comprehensive observational technique for evaluating movement ergonomics. Additionally, this study explores the connection between asymmetrical movements in assembly line and machining workers and their overall well-being. This inquiry is especially relevant in settings where repetitive and unbalanced physical activities are the norm, such as in manufacturing or assembly line work, underscoring its pertinence to health promotion and preventive strategies in occupational health.

2. Materials and Methods

The study adopted a dual-method approach, encompassing both an observational retrospective analysis and a survey-based evaluation. The observational aspect of the study was retrospective in nature, focusing on past data and behaviours within the workplace. Complementing this, a survey was conducted to gauge the well-being of employees in their work environment. These methodologies were implemented in the setting of a manufacturing plant, part of a global automotive multinational corporation. All observations were conducted during the work shift.

2.1. Participants

Participants were assigned to identical shift schedules. The range of their employment duration exhibited a moderate diversity, spanning from as short as half a year to as long as forty years, with an average tenure of 12.3 years. Our participant group consisted of two distinct categories: 42 individuals—machining workstation employees (MWEs) and 44 assembly workstation employees (AWEs). The MWE group had an average age of 41.9 years, with their body mass averaging at 79.9 kg and an average height of 1.76 m (Table 1). These employees were distributed across 12 different devices. In contrast, the AWE group, working on nine devices, were relatively younger, with an average age of 35.5 years, a body mass of 69.2 kg, and an average height of 1.69 m. Eligibility for participation in this research was determined based on specific inclusion criteria. Participants were required to have a minimum of six months of experience at their respective workstations. Additionally, the age cap was set at 60 years. An important health-related exclusion criterion was the absence of clinically diagnosed chronic or recurring musculoskeletal pain that might influence the participant’s range or speed of movement, such as chronic lower back pain, joint pain associated with osteoarthritis, or ongoing pain resulting from prior musculoskeletal injuries. Mild or temporary musculoskeletal discomfort was not grounds for exclusion.

Table 1.

Comparison of demographic characteristics between machining workers (MWEs) and assembly workers (AWEs). Values are presented as the mean ± standard deviation, with ranges indicated in brackets for work experience. A statistical analysis using the t-test for independent samples revealed no significant differences between the groups (p > 0.05).

Prior to the initial study, we conducted a comprehensive evaluation of manufacturing (MWE) and assembly (AWE) workstations in relation to work-related risk factors. These evaluations, carried out triennially, involve a series of “ergo-checks”—initial assessments for potential risk factors in the workplace environment. The methodology for these ergonomic assessments entails employing a bespoke risk evaluation checklist, designed in-house to identify high-risk factors. Repetitive movements are analysed in alignment with the European standard for handling of low loads at high frequency [35] and the OCRA method, while tasks involving the carrying, pushing, and pulling of objects are evaluated according to additional standards [36,37]. One-handed lifting tasks are assessed following the standard for manual handling of machinery and component parts of machinery [38] whereas two-handed lifting tasks are examined using the NIOSH norm. Throughout the data-collection process, adherence to established ergonomic standards is maintained to ensure consistency and reliability.

This research project received approval from the company’s Health and Safety division and garnered support from the human resources department. The biomechanical procedures were ethically conducted in compliance with the Declaration of Helsinki on human experimentation. The study received approval from the Rector’s Committee for Research Ethics at Wroclaw University of Economics and Business (case no. 33/2020). All participants were fully informed about the study’s objectives and procedures and provided their informed consent, including permission to publish the data in an anonymised format.

2.2. Measurement Set-Up

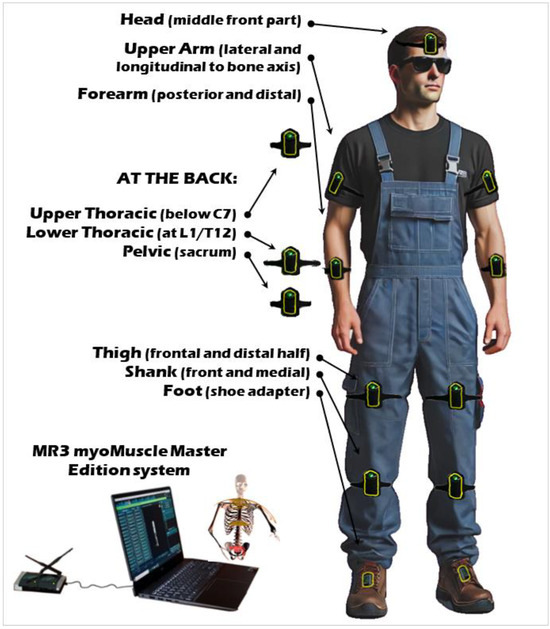

We employed the myoMuscle Master Edition system (myoMOTION™, Noraxon, Scottsdale, AZ, USA) equipped with Master Research 3.0 (MR3) software to record pertinent parameters. This system has 16 inertial motion units (IMUs), utilising inertial sensor technology. The IMUs, incorporating a triad of sensors—a 3D accelerometer, gyroscope, and magnetometer—utilise fusion algorithms to transform sensor data into three-dimensional rotation angles (yaw–pitch–roll or navigation angles) in absolute space. The inertial motion capture system comprising sensors was affixed to the body of the participant (Figure 1), as per the established myoMOTION protocol delineated in the instruction manual. This setup was tasked with recording body accelerations. The scientific validity and high precision of the Inertial Measurement Unit (IMU) system in determining angles have been previously affirmed, exhibiting a maximum error margin of ±0.4 degrees for static assessments and ±1.2 degrees for dynamic evaluations [34,39].

Figure 1.

An experimental setup involving a computer workstation and the positioning of IMU sensors on an employee’s body. The image shows the locations of IMU sensors on the body, providing a visual example of the model used in the study. The computer workstation was equipped with MR3 software for data collection and analysis, and the body is positioned frontally to facilitate accurate motion tracking during calibration.

The current study systematically examined a series of standardised machining tasks. These tasks comprised the following steps: (1) lifting four components simultaneously—three with one hand and one with the other—from a metal container; (2) clearing metal chips from the clamping base; (3) securing components onto the clamping device; (4) performing the deburring process; (5) transferring the components to an engraving machine to initiate the marking cycle; (6) conducting a visual inspection to ensure task accuracy; and (7) placing the components onto a hanger. The manipulation processes were primarily unilateral, with the left limb performing active manipulative actions, while the right limb played a stabilising and supportive role. Each component weighed approximately 520 g before the operation and 380 g after processing. These standardised tasks facilitated accurate motion capture using inertial sensors, allowing for a detailed analysis of angular displacements, velocities, and asymmetries in the thoracic and lumbar regions. The experimental setup also included a series of standardised assembly tasks, specifically focusing on constructing the spring-piston unit. The task sequence consisted of the following steps: (1) retrieving the spring with the left hand from its designated container; (2) picking up the piston with the right hand from the corresponding piston box; (3) positioning the spring pack vertically within the centring sleeve; (4) placing the piston on top of the spring pack; (5) performing a visual inspection to verify the accuracy of the operation; and (6) transferring the completed spring-piston unit to the next assembly point. The weights of the components used in this process ranged between 100 and 400 g.

The measurements were subjected to a pre-processing procedure. This involved a thorough review of the collected data, leading to the elimination of any records that were incorrectly logged. Initially, there was one such case. Following this, each remaining record underwent a meticulous verification process against the workstation manual to ensure its accuracy and reliability.

2.3. Assessment of Well-Being

In order to check the well-being of participants, we looked for a tool that focused on their physical aspects. We decided to use Goldberg’s 28-item General Health Questionnaire (GHQ 28) [40]. The GHQ-28 assesses four dimensions of distress: somatic complaints, anxiety and insomnia, social dysfunction, and depression. Each subscale comprises seven items, rated on a 4-point scale: 0 (“less than usual”), 1 (“no more than usual”), 2 (“rather more than usual”), and 3 (“much more than usual”). Higher scores on each subscale indicate lower levels of well-being. The mean scores reflecting average well-being levels are 26.1 for the total scale, with subscale averages of 7.8 for somatic complaints, 7.3 for anxiety and insomnia, 7.9 for social dysfunction, and 3.1 for depression. [40]. The population experiencing ill health, derived from individuals receiving care through mental health services and psychiatric clinics, records an average score of 41.2 on the total GHQ-28 scale. Subscale averages are 10.2 for somatic complaints, 10.8 for anxiety and insomnia, 10.9 for social dysfunction, and 9.3 for depression [40].

2.4. Procedures

A 30 min observation period was conducted by an experienced technician to monitor the repetitive tasks of the workers. The procedures adhered to the recommendations of the International Society of Biomechanics regarding the definitions of joint coordinate systems, ensuring the standardised reporting of human joint motion, as well as intersegmental forces and moments during human movement analysis [41]. An inertial motion capture system was primarily utilised to monitor a 16-segment biomechanical model of the human body within a three-dimensional measurement space. The system employed Euler angles and medial angles to determine the position and orientation of the segments. Furthermore, it characterised three-dimensional movements by decomposing them into three orthogonal planes for a detailed analysis. Data collection occurred in the manufacturing or assembly section of the enterprise, with a focused effort to exclude potential sources of bias or confounding elements, such as jammed components or unscheduled intermissions. No evidence of magnetic field interference or cross-talk artefacts was detected from active machinery influencing the recording results.

IMU sensors were affixed to the relevant body segments utilising elastic straps and self-adhesive tape, aligning the y-axis with the frontal horizontal plane and the z-axis with the sagittal horizontal plane, as per the myoMOTION protocol manual. The placement of each sensor was meticulously verified for each participant, followed by system calibration in accordance with the manufacturer’s guidelines. This ensured the precision of data collection. The sensors, numbering sixteen in total, operated at a maximal sampling rate of 100 Hertz for each sensor. These procedures were consistently applied across the entirety of the study.

2.5. Data Processing

The performance of workers during professional activities at the workstation was evaluated comprehensively using a range of criteria, including the measurement of mobility (angular displacements, linear velocities, and accelerations) of relevant body parts. Biomechanical and statistical analyses were conducted to identify the most pertinent variables that were both interpretable and aligned with the research objectives. The derived formulas adhered to the principles of classical mechanics and biomechanical standards for reporting human movement. Additionally, the selected variables conformed to established standards for assessing risks associated with repetitive tasks, working postures, and force limits during machinery operations. A thorough review of signal processing techniques for biomedical data was conducted, and advanced system-build fusion algorithms were utilised. Signals were processed using Kalman filtering, incorporating a digital bandpass Finite Impulse Response filter with a recommended default value of 79 points. This method facilitated direct access to processed IMU sensor data for a subsequent analysis, ensuring accuracy and reliability in the evaluation.

The production cycles of each participant were analysed according to the number of cycles and the cycle time in seconds. The start of the cycle was defined as the time when the worker reached for the part.

The mobility of employees at machining or assembly workstations was assessed by separately characterising angular displacements (angles) and angular velocities (the rate of change of angular displacement over time) of the primary body parts engaged during work. Specific focus was placed on the movements of the pelvis, lower back (lumbar region), upper trunk (thorax), shoulder complex (connecting the upper arm to the axial skeleton at the thorax), upper arms, and forearms linked by the elbow joints. Following the International Society of Biomechanics recommendations for the reporting of human joint motion [42,43], the following angles (measured in degrees) were chosen for left and right sides and sampled every 0.01 per cent of cycle time, in particular, the following:

- For the pelvis—Pelvic tilt: Forward (positive) or backward (negative) movement of the pelvis in the sagittal plane relative to the global coordinate system. Pelvic obliquity: Upward (positive) or downward (negative) movement of the pelvis in the frontal plane. Pelvic rotation: Internal (positive) or external (negative) rotation of the pelvis in the transversal plane.

- For the lower trunk (lumbar region)— Lumbar flexion-extension: Anterior (positive) or posterior (negative) movement of the lumbar region in the sagittal plane. Lumbar lateral flexion: Movement of the lumbar region to the left (positive) or right (negative) in the frontal plane. Lumbar internal–external rotation: Internal (positive) or external (negative) rotation of the lumbar region in the transversal plane.

- For the upper trunk (thorax)—Thoracic flexion–extension: Anterior (positive) or posterior (negative) movement of the thorax in the sagittal plane. Thoracic lateral flexion: Movement of the thorax to the left (positive) or right (negative) in the frontal plane. Thoracic internal–external rotation: Internal (positive) or external (negative) rotation of the thorax relative to the global coordinate system in the transversal plane.

- For the shoulders—Shoulder flexion–extension: Anterior (positive) or posterior (negative) movement of the humerus relative to the thorax in the sagittal plane. Shoulder abduction–adduction: Abduction (positive) or adduction (negative) movement of the humerus relative to the thorax in the frontal plane. Shoulder internal–external rotation: Internal (positive) or external (negative) rotation of the humerus in the transversal plane.

- For the elbows—Elbow flexion–extension: Positive (flexion) or negative (hyperextension) movement of the forearm relative to the humerus along the transversal axis.

The study excluded hand movements relative to forearms due to the interference of protective gloves with IMU sensor installation and the potential impact on the production cycle. Additionally, the standing posture of employees necessitated the omission of a lower extremity movement analysis.

In addition, sensor-based linear acceleration (in one-thousandths of the Earth’s gravitational acceleration (mili g), where g = 9.81 m/s2 is the gravitational constant) was measured in 3 translational degrees of freedom (X,Y,Z). The cartesian components were then used to calculate the resultant linear acceleration and expressed in m/sec2. A basic formula was used to calculate the magnitude of the resulting acceleration as equal to the square root of the sum of the squares of its components along the axis.

The linear velocity was calculated by integrating the appropriate acceleration signal between neighbouring samples using the Integration function in MR3 software, assuming a known initial velocity. Integration is a process that sums up the acceleration over each small time interval to find the change in velocity for that interval. The resulting velocity underwent further processing (smoothing), to ensure that it accurately represents the movement being measured.

The following parameters were selected to characterise workers’ mobility: the median (central tendency) and ± interquartile range (IQR, a measure of dispersion for skewed distributions) for the maximum value (Max), minimum value (Min), and range of motion (ROM, calculated as Max–Min). Movements exhibiting extreme median values (Min or Max), asymmetry (e.g., excessive tilts from the neutral position or significant side differences), or exceptionally low or high variability (indicated by the IQR) were identified as potential indicators of risk for work-related musculoskeletal disorders (WRMDs).

2.6. Preselection of Variables

The method for reducing the number of variables followed the methodology of Araveeporn [44] and consisted of reducing the number of highly correlated variables and selecting the most important (most significant) differentiating variables, including a non-parametric correlation analysis (rho-Spearman correlation) across groups of variables, multivariate discriminant analysis using linear classification functions (DFA) with a selected combination of independent variables (factors), and descriptor variables, in terms of the grouping variable (study group, gender, and study period). Discriminant analysis was performed to determine precisely which of the correlated variables had the least effect on the study group’s gait variability (least variance). Discriminant function analysis assumptions were made. It was ascertained whether these assumptions were met, specifically whether the variables in the groups had a mutually low correlation and whether they belong to mutually exclusive groups (based on the result of the correlation analysis in the groups of variables); whether each group consists of at least two observations; whether the input variables are measured on interval or icosahedral scales; whether the number of observations is greater than the number of discriminating variables by more than two; whether the discriminating variables are not highly correlated and whether highly correlated variables do not appear in the equation of the discriminant function; whether the covariance matrices calculated for all groups are equal to each other; and whether the population has a multivariate normal distribution. Discriminant analysis was carried out in a stepwise progressive manner [44], which made it possible to trace the stages of testing the discriminant power of the variables characterising the study groups (including them in the discriminant functions) and to provide various detailed options containing measures. In order to qualify a variable for the model, it was necessary to include it in the set of 47 variables characterised by the highest variance and low correlation with other variables (high discriminatory power—low value of alpha-Wilks’ statistic and high F statistic of introduction). To conclude, a total of 20 variables (7 variables for the right side, 7 variables for the left side, and 6 variables for the central (trunk) segment) characterised the range of movement; 20 variables (7 variables for the right side, 7 variables for the left side, and 6 variables for the central (trunk) segment) characterised linear speed of movements and 7 variables (2 variables for the right side, 1 variables for the left side, and 3 variables for the central (trunk) segment) characterised linear acceleration of these movements.

The procedure for reducing the number of variables aimed to preselect the N-element space of uncorrelated variables (N = 16 for the left side, N = 16 for the right side) from the whole set (globally for the whole body N = 47). If more variables are identified, the first 16 singular variables with the highest variance and impact value will be selected for the construction of the Motion Activity Index.

2.7. Motion Activity Index

The Motion Activity Index (MAI), based on the concept of the Gait Profile Score [45], was proposed to reflect the intensity and activity of workers’ movements. The MAI is a one-dimensional and standardised index based on preselected variables (characterising range of motion, velocities, and accelerations) and describes the “quality” and dynamics of movements. In general, the MAI is defined as the square root of the average of the squares of an Xi variable across N variables:

where Xi is a variable, and i changes from 1 to N, where N is the total number of preselected variables (N = 16 for the left side, N = 16 for the right side, and N = 47 globally for the whole body). The higher the value of the MAI index, the more dynamic the movements. This dual application of the MAI—focusing separately on the right and left sides, as well as on a global scale—ensures a comprehensive representation of workers’ movement activity in various dimensions of motion. While the MAI does not directly measure health outcomes, it may offer valuable insights into movement dynamics. These dynamics are crucial for identifying potential health risks linked to asymmetrical, repetitive movements, which are known precursors to musculoskeletal disorders. The MAI can help guide targeted ergonomic interventions to address these identified risks before health complications arise.

2.8. Statistical Calculations

The interquartile range (IQR), also known as the midspread, represents the statistical spread around the median and is calculated as the difference between the upper (Q3) and lower (Q1) quartiles (IQR = Q3 − Q1). Based on the research question and objectives, the Mann–Whitney U-test was utilised to compare differences between the unpaired machining workstation employees (MWEs) and assembly workstation employees (AWEs), with a significance level of α = 0.05, reflecting the non-normal distribution of the data as indicated by the Shapiro–Wilk test. For dependent samples, the Wilcoxon signed-rank test was applied to compare the right and left sides within each group, aligning with the non-parametric requirements of the data. While the MWE and AWE workstations share similarities in standing posture and work characteristics, notably in job rotation, they may differ significantly in terms of activity. The statistical power was deemed adequate for identifying the outlined differences. Particularly, the partial η2 effect size for the data extracted ranged from 0.72 to 0.89. All statistical analyses were conducted using Statistica 13.1 (TIBCO Software Inc., Santa Clara, CA, USA).

3. Results

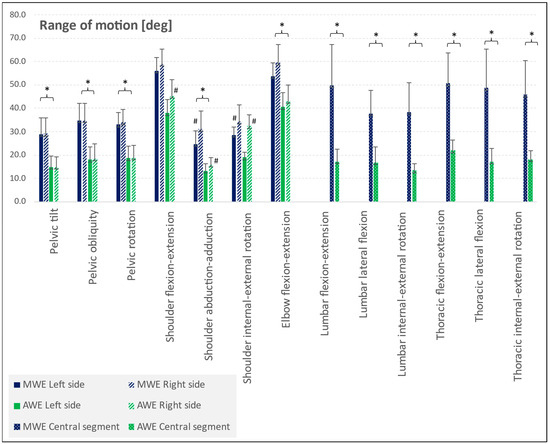

Figure 2 presents a detailed analysis of joint angular displacements for both machining workstation employees (MWEs) and assembly workstation employees (AWEs). The data reveal that the MWE group (blue bars) generally operated within a notably wider range of motion (ROM)—roughly double—compared to the AWE group (green bars) across all evaluated measures (encompassing both left and right sides, as well as central segments). Statistically significant differences in ROM were observed between the MWE and AWE groups in almost all measured aspects, except for movements involving shoulder and elbow flexion–extension. Notably, the MWE group exhibited symmetrical movement patterns with a minor inclination towards the right side. In contrast, the AWE group displayed more pronounced asymmetry, especially in the movements of the shoulder and elbow joints.

Figure 2.

The results of angular displacements (in degrees) for the machining workstation employees (MWEs) and assembly workstation employees (AWEs). The median ± IQR of the range of motion (ROM) in specific joints for the left or right side, as well as the central segment, are presented. The MWE group is represented by blue bars and the AWE group by green bars. Significant differences between MWE and AWE groups are marked with an asterisk (*), based on p-values calculated using the unpaired Mann–Whitney U-test. Differences between the left and right sides within groups are indicated with a hash (#), based on p-values calculated using the dependent samples Wilcoxon signed-rank test.

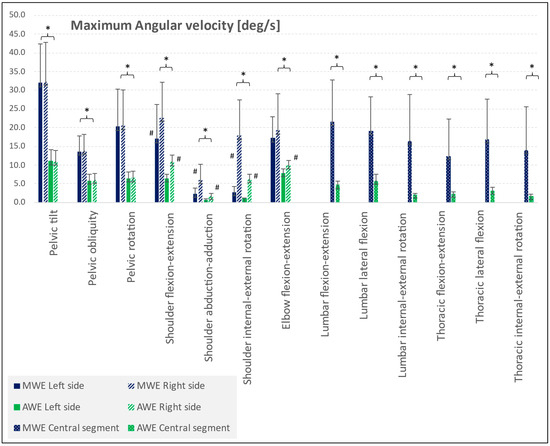

Figure 3 presents the findings of the highest angular velocities achieved, measured in degrees per second, by employees at the machining (MWE) and assembly workstations (AWE). There was a notable variance in movement speeds between the two groups across all measured parameters. Specifically, the machining group (blue bars) exhibited significantly higher activity, with peak velocities reaching up to eight-fold greater, particularly in lumbar and thoracic rotations, compared to the assembly group (green bars). In terms of the range of motion (ROM), the MWE group demonstrated comparable velocities for both left and right sides, with the exception of shoulder abduction and rotation, where the differences were statistically significant (p < 0.05). In contrast, the AWE group displayed greater maximum speeds predominantly on the right side for all upper extremity movements, with these differences also being statistically significant (p < 0.05).

Figure 3.

The results of maximum angular velocity (in degrees per second) for the machining workstation employees (MWEs) and assembly workstation employees (AWEs). The median ± IQR of the maximum angular velocity in specific joints for the left or right side, as well as the central segment, are presented. The MWE group is represented by blue bars and the AWE group by green bars. Significant differences between MWE and AWE groups are marked with an asterisk (*), based on p-values calculated using the unpaired Mann–Whitney U-test. Differences between the left and right sides within groups are indicated with a hash (#), based on p-values calculated using the dependent samples Wilcoxon signed-rank test.

The highest linear accelerations, as displayed in Table 2, recorded on average for all upper extremity and central body segments, did not surpass 0.33 m/s2 (approximately 2.5% of gravitational acceleration). In line with earlier findings, the MWE group exhibited more dynamic movements, showing notably higher accelerations than the AWE group across all acceleration measurements. Contradicting prior reports, the right side was less dynamic for both groups. All observed lateral differences between the groups were statistically significant, with p-values less than 0.05.

Table 2.

The results of linear accelerations (in degrees per second squared) for the machining workstation employees (MWEs) and assembly workstation employees (AWEs). The median +/− IQR of the maximum values of acceleration in the particular joints for the left (LT) or right (RT) side or a central segment is accompanied by the significant p-values of test statistics between groups (p1) or between sides within groups (p2, p3).

Taking into account all of the previously mentioned components, a Motion Activity Index (MAI) was calculated for both the left and right sides and collectively for the left, right, and central segments, as shown in Table 3. Generally, it was observed that the MWE group exhibited a higher level of activity compared to the AWE group (36.6% vs. 25.5%, p = 0.019). The movements of the MWE employees were predominantly symmetrical (p > 0.05), with a minor tendency towards more activity on the right side. In contrast, the AWE group demonstrated asymmetrical movements, with a notably higher activity level on the right side (p = 0.043).

Table 3.

The results of normalised motion activity indexes (denoted by the per cent sign) for the machining workstation employees (MWEs) and assembly workstation employees (AWEs). The median +/− IQR of the maximum values of acceleration in the particular joints for the left (LT) or right (RT) side or a central segment is accompanied by the significant p-values of test statistics between groups (p1) or between sides within groups (p2, p3).

The study’s comparison between the well-being of its participants and benchmark scores for average well-being and ill-health populations (referenced in Table 4) revealed no significant mental health issues, except for complaints related to somatic symptoms. These issues were predominantly associated with persistent fatigue, characterised by sensations of poor health, weariness, weakness, sickness, recurring headaches, and feeling overwhelmed.

Table 4.

Comparison of well-being results with scoring for average well-being and ill-health population according to norms for GHQ 28.

The findings indicate that repetitive motions required in manufacturing tasks, often involving asymmetrical body positions, detrimentally affect physical health, leading to fatigue and exhaustion. Furthermore, approximately 74% of the participants in the study scored higher than the average value of the “healthy sample,” indicating substantial concerns regarding somatic well-being. This includes frequent experiences of exhaustion, weakness, tiredness, and various bodily pains.

4. Discussion

The present research has thoroughly investigated the risk factors associated with movement asymmetry in the workplace and developed an observational technique to assess movement ergonomics. This exploration holds particular significance in environments dominated by repetitive and unbalanced physical activities, such as manufacturing or assembly-line work, thereby accentuating its relevance to health promotion and preventative strategies in occupational health.

The analysis of joint angular displacements between machining workstation employees (MWEs) and assembly workstation employees (AWEs) yields profound insights into the ergonomic dynamics of these two occupational groups. The data underscored a significant divergence in the range of motion (ROM) employed by the two groups, with MWE demonstrating approximately double the ROM of their AWE counterparts. This disparity, transcending nearly all evaluated measures, underscores a fundamental ergonomic variance potentially attributable to the distinct nature of tasks performed within each workstation type. The observation that statistically significant differences in ROM were present in almost all measures, barring shoulder and elbow flexion–extension movements, invites a nuanced interpretation. This suggests that while certain joint movements are universally constrained or facilitated by workplace ergonomics, others are distinctly influenced by the specific demands of the workstation. The symmetry in movement patterns observed in the MWE group, albeit with a slight right-side inclination, contrasts sharply with the pronounced asymmetry evident in the AWE group’s shoulder and elbow movements. This distinction could reflect the repetitive, unidimensional tasks typical of assembly lines, often predisposing workers to asymmetrical posture adoption due to repetitive task performance. From a broader perspective, our findings resonate with existing literature that identifies movement asymmetry as a significant ergonomic risk factor, predisposing workers to musculoskeletal disorders (MSDs). Similarly to our research, Porta et al. [46] provided a quantitative analysis of the intensity and symmetry of upper limb use in healthcare workers, utilising wrist-worn accelerometers to assess the ergonomic risks associated with MSDs. The research highlights the importance of understanding repetitiveness and movement asymmetries in the workplace, emphasising the need for accurate, ergonomic risk assessments for healthcare workers. The findings from Porta et al. align with the observed differences in joint angular displacements observed in MWEs and AWEs, which were studied in our study. While our research focuses on the industrial sector, Porta et al. extend the discussion to healthcare settings, reinforcing that movement asymmetry is pervasive across different professional domains. The pronounced asymmetry observed in AWE could, therefore, signify a higher ergonomic risk compared to the more symmetrical movement patterns of MWEs. This aligns with the meta-analysis study [47] on sedentary work tasks, which suggests that symmetrical movement patterns are associated with reduced physical strain and a lower incidence of work-related musculoskeletal disorders. Moreover, the minor right-side inclination observed in the MWE group aligns with the natural tendency for right-side dominance in the general population. This suggests that workstation design and task allocation should consider natural physiological and biomechanical predispositions to optimise ergonomic outcomes.

Also, regarding the speed of movement, the highest angular velocities attained by employees at machining (MWE) and assembly workstations (AWE) offer a profound insight into the kinematic disparities inherent to these occupational roles. The marked variance observed in movement speeds between the two groups, especially the significantly higher activity levels in the machining group with peak velocities up to 8 times greater in lumbar and thoracic rotations, underscores the distinct ergonomic challenges faced by workers in different operational contexts. This divergence in kinematic behaviour, particularly the notable differences in the range of motion (ROM) and the predominance of higher maximum speeds on the right side for all upper extremity movements in the AWE group, aligns with the working hypotheses that posited significant disparities in movement patterns across different workstation types due to the varying nature of tasks performed. The findings resonate with previous studies [48,49,50,51], highlighting the impact of occupational activities on workers’ biomechanical and physiological profiles, suggesting that the specific demands of machining and assembly tasks contribute to distinct ergonomic risk profiles. For instance, the elevated activity levels in the lumbar and thoracic regions among MWE participants mirror the intensive physical demands and dynamic movements characteristic of machining operations, which may predispose workers to a higher risk of musculoskeletal disorders in these areas. Conversely, the AWE group’s significant right-side bias in upper extremity movements reflects the repetitive, unidirectional nature of assembly tasks, potentially exacerbating the risk of overuse injuries on the dominant side.

Our results also present an intriguing narrative on the dynamics of workplace movements in the context of the acceleration of movements. The observed linear accelerations across upper extremity and central body segments do not exceed 0.33 m/s2 in workplace activities, even in more dynamic roles, and produce accelerations significantly lower than gravitational acceleration. This finding suggests that most workplace movements are of low intensity but may vary considerably across studied job roles. The more dynamic movements, as evidenced by notably higher accelerations (i.e., observed in the machining group), support the notion that manual work entails more vigorous physical activity than assembly employees. This distinction is crucial for ergonomic interventions, highlighting the need for tailored solutions that address the specific physical demands of different types of work. The unexpected finding of the right side being less dynamic contradicts previous reports, suggesting a possible shift in work practices or a reflection of the specific demographics of our study groups.

The implications of these results extend beyond the immediate context of workplace ergonomics, offering a broader perspective on the relationship among work conditions, physical health, and well-being. They underscore the importance of comprehensive ergonomic assessments and interventions that consider work-related health’s physical and mental aspects. This study’s findings also highlight the potential benefits of promoting symmetrical movements and reducing the reliance on repetitive, asymmetrical tasks. The introduction of the Motion Activity Index (MAI) offers a novel quantitative measure of workplace activity levels, revealing that the MWE group exhibited a higher overall level of activity (median ROM: 36.6° vs. 25.5°, p = 0.019). The predominantly symmetrical movements among MWE employees, with a minor tendency towards more activity on the right side, contrast the AWE group’s asymmetrical movements and higher activity levels on the right side (p = 0.043). These findings challenge and extend our understanding of workplace ergonomics, suggesting that the nature of work significantly influences movement symmetry and activity levels.

In the broader context, these results highlight the complexity of assessing and addressing ergonomic risks in the workplace. They confirm the necessity of considering both the intensity and symmetry of movements in ergonomic evaluations. The comparison of well-being between the study participants and established benchmarks for average well-being versus the ill-health population further emphasises the nuanced impact of work environment ergonomics on mental and somatic health. The prevalence of somatic symptoms among participants, especially those related to persistent fatigue and bodily pains, echoes the findings of earlier studies that have linked repetitive and asymmetrical tasks to physical strain and discomfort. This is particularly relevant because many participants reported health concerns exceeding those of a “standard” well-being level. Such outcomes suggest that even in the absence of overt mental health issues, the physical demands of specific work tasks can significantly affect workers’ somatic well-being. Future research should explore the longitudinal impact of these factors on worker health and productivity, focusing on developing targeted ergonomic interventions that can adapt to the evolving nature of work. Additionally, further studies could investigate the underlying causes of the observed asymmetry in the production employees group, potentially leading to more personalised ergonomic solutions. The findings also suggest the utility of the demonstrated Motion Activity Index (MAI) as a tool for assessing the effectiveness of ergonomic interventions over time, offering a path towards more dynamic and responsive ergonomic practices. To address the identified movement asymmetries, practical solutions, such as ergonomic workstation redesign, task rotation, physical conditioning programs, and assistive technologies could be implemented [52]. These methods are well-documented in the ergonomic literature as effective strategies for reducing movement asymmetry and preventing musculoskeletal disorders in occupational settings.

4.1. Study Limitations and Areas for Improvement

The study also presents several limitations regarding sample diversity, methodology, and scope, which should be acknowledged. First, the division of participants into machining and assembly work groups, while informative, may have limited the analysis of individual variability in movement asymmetry and well-being within each group, potentially overlooking subtle intra-group differences. Second, using cross-sectional data restricts the ability to make causal inferences regarding the impact of asymmetrical movements on long-term health outcomes, particularly musculoskeletal disorders. The reliance on inertial motion capture technology, though effective for movement tracking, may also not fully capture the complex postural shifts or micro-adjustments made by workers during tasks, thereby potentially underestimating certain ergonomic risks. Lastly, while the Motion Activity Index (MAI) offers a useful quantitative assessment of movement dynamics, it may not fully encompass other influential ergonomic factors, such as psychosocial stress or task variation, which could also contribute to well-being outcomes. Future studies would benefit from a longitudinal design, a broader range of ergonomic variables, and a more granular analysis of individual worker profiles to improve the generalisability and comprehensiveness of these findings.

4.2. Future Directions and Research Implications

Looking forward, these results illuminate several avenues for future research. Firstly, longitudinal studies could elucidate the long-term effects of these kinematic differences on workers’ health, particularly in relation to the development of musculoskeletal disorders. Additionally, experimental studies investigating the efficacy of specific ergonomic interventions in mitigating the identified risks could provide actionable insights for occupational health practitioners. Lastly, exploring the psychological and social dimensions of workplace ergonomics, such as workers’ perceptions of physical strain and the impact of ergonomic improvements on job satisfaction and productivity, could offer a holistic understanding of the interplay among the work environment, health, and well-being. For future research, it is imperative to explore intervention strategies that can mitigate the ergonomic risks associated with pronounced asymmetry, particularly in assembly line settings. Investigating the impact of tailored ergonomic interventions, such as adjustable workstation designs or the integration of more varied tasks, could offer valuable insights into reducing the incidence of MSDs among AWEs. Additionally, longitudinal studies assessing the long-term effects of these interventions on worker health and productivity would significantly contribute to the field of workplace ergonomics.

5. Conclusions

In conclusion, our study contributes to the growing body of evidence underscoring the importance of ergonomic considerations in workplace design and task allocation. Especially, our research demonstrates the following:

- profound ergonomic disparities were observed between machining workstation employees (MWEs) and assembly workstation employees (AWEs), with MWE demonstrating a wider range of motion (ROM) and higher angular velocities. A quantitative analysis revealed a median ROM difference of 11.1° and angular velocity differences of up to 35°/s in specific movements, underscoring the impact of task-specific demands on movement patterns and ergonomic risk;

- thee pronounced asymmetry observed in assembly line workers, particularly in shoulder and elbow movements, highlights asymmetrical movement as a significant ergonomic risk factor—this predisposition towards asymmetry in repetitive tasks may contribute to the increased prevalence of musculoskeletal disorders (MSDs);

- the differences in joint angular displacements, angular velocities, and accelerations between MWE and AWE groups provide crucial insights into the kinematic behaviours inherent to these occupational roles, indicating distinct ergonomic challenges and the need for tailored ergonomic interventions;

- the alignment with existing literature, suggesting that movement symmetry is associated with reduced physical strain and a lower incidence of work-related MSDs, emphasises the importance of promoting symmetrical movement patterns in workplace design and necessitating ergonomic solutions that are sensitive to the specific demands of different workstations;

- a relation between movement asymmetry and somatic symptoms among workers suggests that ergonomic risk factors extend beyond physical health, impacting overall well-being and necessitating comprehensive health promotion and preventive strategies;

- the introduction of the Motion Activity Index (MAI) as a quantitative measure offers valuable insights into activity levels and movement symmetry, presenting a tool for assessing and optimising ergonomic interventions;

- the findings advocate for ergonomic interventions that address both the intensity and symmetry of movements, highlighting the necessity of a holistic approach to workplace ergonomics.

Author Contributions

Conceptualisation, S.W., D.M.-W. and B.C.; methodology, S.W. and D.M.-W.; statistical analysis, S.W.; data collection, S.W. and D.M.-W.; writing—original draft preparation, S.W. and D.M.-W.; funding acquisition, S.W., D.M.-W. and B.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Higher Education in Poland under the “Regional Initiative of Excellence” programme 2019–2022, project number 015/RID/2018/19. The APC was funded by an internal grant from Wroclaw University of Health and Sport Sciences.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and was approved by the Institutional Review Board (or Ethics Committee) of the Wroclaw University of Economics and Business (protocol code 33/2020). This research project also received approval from the company’s Health and Safety division and support from the human resources department. Biomechanical procedures were conducted ethically, and participants provided informed consent, including permission to publish data in an anonymised format.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study. Written informed consent for publication was obtained from participants who can be identified. Written informed consent has been obtained from the employee(s) to publish this paper.

Data Availability Statement

Data supporting the findings of this study are included within the article; further inquiries can be directed to the corresponding author.

Acknowledgments

The authors thank the technical staff of the Wroclaw University of Health and Sport Sciences for their assistance with data collection and the company’s Health and Safety division for their support in facilitating this study. Additionally, we appreciate the administrative support provided by the administrative staff of both universities.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rhodes, J.; Tagawa, A.; McCoy, A.; Bazett-Jones, D.; Skinner, A.; Leveille, L.; Franklin, C.; Chafetz, R.; Tulchin-Francis, K. Using Motion Analysis in the Evaluation, Treatment & Rehabilitation of Pediatric & Adolescent Knee Injuries: A Review of the Literature. Clin. Sports Med. 2022, 41, 671–685. [Google Scholar] [CrossRef]

- Yoon, T.-L.; Min, J.-H.; Kim, H.-N. Effect of Using an 8-Figure Shoulder Brace on Posture and Muscle Activities during the Performance of Dental Hygiene Procedures. Int. J. Environ. Res. Public Health 2020, 17, 8494. [Google Scholar] [CrossRef]

- Netto, K.; Francis-Pester, G.; Lewis, C.; Dunnill, P.; Darling, R. Posture and Muscle Activity during Waste Collection Work. Ann. Work. Expo. Health 2022, 66, 119–123. [Google Scholar] [CrossRef]

- Matsumoto, H.; Ueki, M.; Uehara, K.; Noma, H.; Nozawa, N.; Osaki, M.; Hagino, H. Comparison of Healthcare Workers Transferring Patients Using Either Conventional or Robotic Wheelchairs: Kinematic, Electromyographic, and Electrocardiographic Analyses. J. Healthc. Eng. 2016, 2016, 5963432. [Google Scholar] [CrossRef]

- Hölzel, C.; Bengler, K.; Dressel, T. Ergonomic Evaluation of Upper Limb Movements in the Automobile Production Measured by Means of Motion Capturing. In Proceedings of the 3rd International Digital Human Modelling Symposium DHM 2014, Odaiba, Japan, 20–22 May 2014. [Google Scholar]

- Umer, W.; Li, H.; Szeto, G.P.Y.; Wong, A.Y.L. Identification of Biomechanical Risk Factors for the Development of Lower-Back Disorders during Manual Rebar Tying. J. Constr. Eng. Manag. 2016, 143, 04016080. [Google Scholar] [CrossRef]

- Paulus, D.C.; Settlage, D.M.; Schilling, B.K. Comparison of Isoinertial to Simulated Inertial Force from a Controlled Resistance Exercise Device for Spaceflight—Biomed 2011. Biomed. Sci. Instrum. 2011, 47, 41–45. [Google Scholar]

- Hurkmans, H.L.P.; Bussmann, J.B.J.; Benda, E.; Verhaar, J.A.N.; Stam, H.J. Techniques for Measuring Weight Bearing during Standing and Walking. Clin. Biomech. 2003, 18, 576–589. [Google Scholar] [CrossRef]

- EN 1005-5:2007; Safety of Machinery—Human Physical Performance—Part 5: Risk Assessment for Repetitive Handling at High Frequency. European Committee for Standardization (CEN): Brussels, Belgium, 2007.

- Roman-Liu, D. Repetitive Task Indicator as a Tool for Assessment of Upper Limb Musculoskeletal Load Induced by Repetitive Task. Ergonomics 2007, 50, 1740–1760. [Google Scholar] [CrossRef]

- Petreanu, V.; Seracin, A.-M. Risk Factors for Musculoskeletal Disorders Development: Hand-Arm Tasks, Repetitive Work. Available online: https://oshwiki.eu/wiki/Risk_factors_for_musculoskeletal_disorders_development:_hand-arm_tasks,_repetitive_work (accessed on 30 January 2023).

- Liu, G.; Dobbins, C.; D’Souza, M.; Phuong, N. A Machine Learning Approach for Detecting Fatigue during Repetitive Physical Tasks. Pers. Ubiquitous Comput. 2023, 27, 2103–2120. [Google Scholar] [CrossRef]

- Sultan, S.; Abdel-Malek, K.; Arora, J.; Bhatt, R. Human Simulation System for Injury Assessment Due to Repetitive Loading. Adv. Intell. Syst. Comput. 2018, 591, 131–140. [Google Scholar] [CrossRef]

- Halwani, Y.; Salcudean, T.S.E.; Fels, S.S. Multimodal Interface Design for Ultrasound Machines. In Qatar Foundation Annual Research Conference Proceedings; HBKU Press: Doha, Qatar, 2016; Volume 2016, p. ICTSP2476. [Google Scholar] [CrossRef]

- Briggs, A.M.; Woolf, A.D.; Dreinhöfer, K.; Homb, N.; Hoy, D.G.; Kopansky-Giles, D.; Åkesson, K.; March, L. Reducing the Global Burden of Musculoskeletal Conditions. Bull. World Health Organ. 2018, 96, 366–368. [Google Scholar] [CrossRef] [PubMed]

- Marques, A.; Cerdeira, M.; Veiga, D.; Gouveia, É.R.; Ferrari, G.; Peralta, M. Physical Activity Trajectories and Quality of Life in Older Adults. Human. Mov. 2023, 24, 18–24. [Google Scholar] [CrossRef]

- Hagberg, M.; Violante, F.S.; Bonfiglioli, R.; Descatha, A.; Gold, J.; Evanoff, B.; Sluiter, J.K. Prevention of Musculoskeletal Disorders in Workers: Classification and Health Surveillance—Statements of the Scientific Committee on Musculoskeletal Disorders of the International Commission on Occupational Health. BMC Musculoskelet. Disord. 2012, 13, 109. [Google Scholar] [CrossRef]

- European Agency for Safety and Health at Work. Third European Survey of Enterprises on New and Emerging Risks (ESENER 2019): How European Workplaces Manage Safety and Health. Publications Office of the European Union, 2022. Available online: https://data.europa.eu/doi/10.2802/881291 (accessed on 2 February 2024).

- NIOSH. Musculoskeletal Disorders and Workplace Factors: A Critical Review of Epidemiologic Evidence for Work-Related Musculoskeletal Disorders of the Neck, Upper Extremity, and Low Back; Publication No. 97BB1411997; DHHS (NIOSH): Cincinnati, OH, USA, 1997. [Google Scholar]

- Work-Related Musculoskeletal Disorders: Prevalence, Costs and Demographics in the EU. Available online: https://op.europa.eu/en/publication-detail/-/publication/5819be4f-0393-11eb-a511-01aa75ed71a1/language-en (accessed on 2 February 2024).

- Makhoul, P.J.; Sinden, K.E.; MacPhee, R.S.; Fischer, S.L. Relative Contribution of Lower Body Work as a Biomechanical Determinant of Spine Sparing Technique During Common Paramedic Lifting Tasks. J. Appl. Biomech. 2017, 33, 137–143. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Edwards, D.J.; Pärn, E.A.; Seo, J.; Wong, A.Y.L. Biomechanical Analysis of Risk Factors for Work-Related Musculoskeletal Disorders during Repetitive Lifting Task in Construction Workers. Autom. Constr. 2017, 83, 41–47. [Google Scholar] [CrossRef]

- Bhattacharya, A.; McGlothlin, J.D. (Eds.) Occupational Ergonomics—Theory and Applications, 2nd ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2011; ISBN 978-1-4398-1935-7. [Google Scholar]

- Buckle, P.W.; Jason Devereux, J. The Nature of Work-Related Neck and Upper Limb Musculoskeletal Disorders. Appl. Ergon. 2002, 33, 207–217. [Google Scholar] [CrossRef]

- Bosch, T.; de Looze, M.P.; van Dieën, J.H. Development of Fatigue and Discomfort in the Upper Trapezius Muscle during Light Manual Work. Ergonomics 2007, 50, 161–177. [Google Scholar] [CrossRef]

- Traumann, A.; Tint, P.; Merisalu, E.; Hiir, K. Evaluating the Changes in the Functional Status of the Musculoskeletal System before and after an Intervention among Sewing Machine Operators with Partial Work Ability. J. Biomim. Biomater. Biomed. Eng. 2020, 47, 127–135. [Google Scholar] [CrossRef]

- Nagano, H.; Sarashina, E.; Sparrow, W.; Mizukami, K.; Begg, R. General Mental Health Is Associated with Gait Asymmetry. Sensors 2019, 19, 4908. [Google Scholar] [CrossRef] [PubMed]

- Helali, F.; Lönnroth, E.-C.; Shahnavaz, H. Participatory Ergonomics Intervention in an Industrially Developing Country—A Case Study. Int. J. Occup. Saf. Ergon. 2008, 14, 159–176. [Google Scholar] [CrossRef][Green Version]

- Shin, W.; Park, M. Ergonomic Interventions for Prevention of Work-Related Musculoskeletal Disorders in a Small Manufacturing Assembly Line. Int. J. Occup. Saf. Ergon. 2019, 25, 110–122. [Google Scholar] [CrossRef]

- Saw Bin, W.; Richardson, S.; Yeow, P.H.P. An Ergonomics Study of a Semiconductors Factory in an IDC for Improvement in Occupational Health and Safety. Int. J. Occup. Saf. Ergon. 2010, 16, 345–356. [Google Scholar] [CrossRef]

- Moore, J.S.; Garg, A. The Strain Index: A Proposed Method to Analyze Jobs For Risk of Distal Upper Extremity Disorders. Am. Ind. Hyg. Assoc. J. 1995, 56, 443–458. [Google Scholar] [CrossRef]

- Health and Safety Executive (HSE). Assessment of Repetitive Tasks of the Upper Limbs (the ART Tool). In Guidance for Employers; HSE Publications: London, UK, 2010; ISBN 978 0 7176 6393 4. [Google Scholar]

- Takala, E.P.; Pehkonen, I.; Forsman, M.; Hansson, G.Å.; Mathiassen, S.E.; Neumann, W.P.; Sjøgaard, G.; Veiersted, K.B.; Westgaard, R.H.; Winkel, J. Systematic Evaluation of Observational Methods Assessing Biomechanical Exposures at Work. Scand. J. Work Environ. Health 2010, 36, 3–24. [Google Scholar] [CrossRef]

- Winiarski, S.; Molek-Winiarska, D.; Chomątowska, B.; Sipko, T.; Dyvak, M. Added Value of Motion Capture Technology for Occupational Health and Safety Innovations. Hum. Technol. 2021, 17, 235–260. [Google Scholar] [CrossRef]

- ISO 11228-3:2007; Ergonomics—Manual Handling—Part 3: Handling of Low Loads at High Frequency. International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO 11228-1:2021; Ergonomics—Manual Handling—Part 1: Lifting, Lowering and Carrying. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 11228-2:2007; Ergonomics—Manual Handling—Part 2: Pushing and Pulling. International Organization for Standardization: Geneva, Switzerland, 2007.

- EN 1005-2:2003+A1:2008; Safety of Machinery—Human Physical Performance—Part 2: Manual Handling of Machinery and Component Parts of Machinery. European Committee for Standardization (CEN): Brussels, Belgium, 2008.

- Teufl, W.; Miezal, M.; Taetz, B.; Fröhlich, M.; Bleser, G. Validity of Inertial Sensor Based 3D Joint Kinematics of Static and Dynamic Sport and Physiotherapy Specific Movements. PLoS ONE 2019, 14, e0213064. [Google Scholar] [CrossRef]

- Goldberg, D.P.; Williams, P. A User’s Guide to the General Health Questionnaire; NFER-Nelson Publishing Company: London, UK, 1991. [Google Scholar]

- Derrick, T.R.; van den Bogert, A.J.; Cereatti, A.; Dumas, R.; Fantozzi, S.; Leardini, A. ISB Recommendations on the Reporting of Intersegmental Forces and Moments during Human Motion Analysis. J. Biomech. 2020, 99, 109533. [Google Scholar] [CrossRef]

- Bańkosz, Z.; Winiarski, S. Using Wearable Inertial Sensors to Estimate Kinematic Parameters and Variability in the Table Tennis Topspin Forehand Stroke. Appl. Bionics Biomech. 2020, 2020, 8413948. [Google Scholar] [CrossRef]

- Bańkosz, Z.; Winiarski, S. The Application of Statistical Parametric Mapping to Evaluate Differences in Topspin Backhand between Chinese and Polish Female Table Tennis Players. Appl. Bionics Biomech. 2021, 2021, 5555874. [Google Scholar] [CrossRef]

- Araveeporn, A. Comparing the Linear and Quadratic Discriminant Analysis of Diabetes Disease Classification Based on Data Multicollinearity. Int. J. Math. Math. Sci. 2022, 2022, 7829795. [Google Scholar] [CrossRef]

- Baker, R. Gait Analysis Methods in Rehabilitation. J. Neuroeng. Rehabil. 2006, 3, 4. [Google Scholar] [CrossRef]

- Porta, M.; Casu, G.; Leban, B.; Pau, M. Quantitative Characterization of Upper Limb Intensity and Symmetry of Use in Healthcare Workers Using Wrist-Worn Accelerometers. In International Conference on Human-Computer Interaction; Lecture Notes in Computer Science (Including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer Nature: Cham, Switzerland, 2023; pp. 194–204. [Google Scholar] [CrossRef]

- Dzakpasu, F.Q.S.; Carver, A.; Brakenridge, C.J.; Cicuttini, F.; Urquhart, D.M.; Owen, N.; Dunstan, D.W. Musculoskeletal Pain and Sedentary Behaviour in Occupational and Non-Occupational Settings: A Systematic Review with Meta-Analysis. Int. J. Behav. Nutr. Phys. Act. 2021, 18, 159. [Google Scholar] [CrossRef]

- Hulshof, C.T.J.; Pega, F.; Neupane, S.; van der Molen, H.F.; Colosio, C.; Daams, J.G.; Descatha, A.; Kc, P.; Kuijer, P.P.F.M.; Mandic-Rajcevic, S.; et al. The Prevalence of Occupational Exposure to Ergonomic Risk Factors: A Systematic Review and Meta-Analysis from the WHO/ILO Joint Estimates of the Work-Related Burden of Disease and Injury. Environ. Int. 2021, 146, 106157. [Google Scholar] [CrossRef] [PubMed]

- Masci, F.; Rosecrance, J.; Mixco, A.; Cortinovis, I.; Calcante, A.; Mandic-Rajcevic, S.; Colosio, C. Personal and Occupational Factors Contributing to Biomechanical Risk of the Distal Upper Limb among Dairy Workers in the Lombardy Region of Italy. Appl. Ergon. 2020, 83, 102796. [Google Scholar] [CrossRef]

- Nygaard, N.P.B.; Thomsen, G.F.; Rasmussen, J.; Skadhauge, L.R.; Gram, B. Ergonomic and Individual Risk Factors for Musculoskeletal Pain in the Ageing Workforce. BMC Public Health 2022, 22, 1975. [Google Scholar] [CrossRef]

- Hoe, V.C.W.; Urquhart, D.M.; Kelsall, H.L.; Zamri, E.N.; Sim, M.R. Ergonomic Interventions for Preventing Work-related Musculoskeletal Disorders of the Upper Limb and Neck among Office Workers. Cochrane Database Syst. Rev. 2018, 2018, CD008570. [Google Scholar] [CrossRef]

- Odebiyi, D.O.; Okafor, U.A.C. Musculoskeletal Disorders, Workplace Ergonomics and Injury Prevention. In Ergonomics—New Insights; IntechOpen: London, UK, 2023; ISBN 978-1-80356-471-5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).