Product Design Analysis with Regard to Recycling and Selected Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

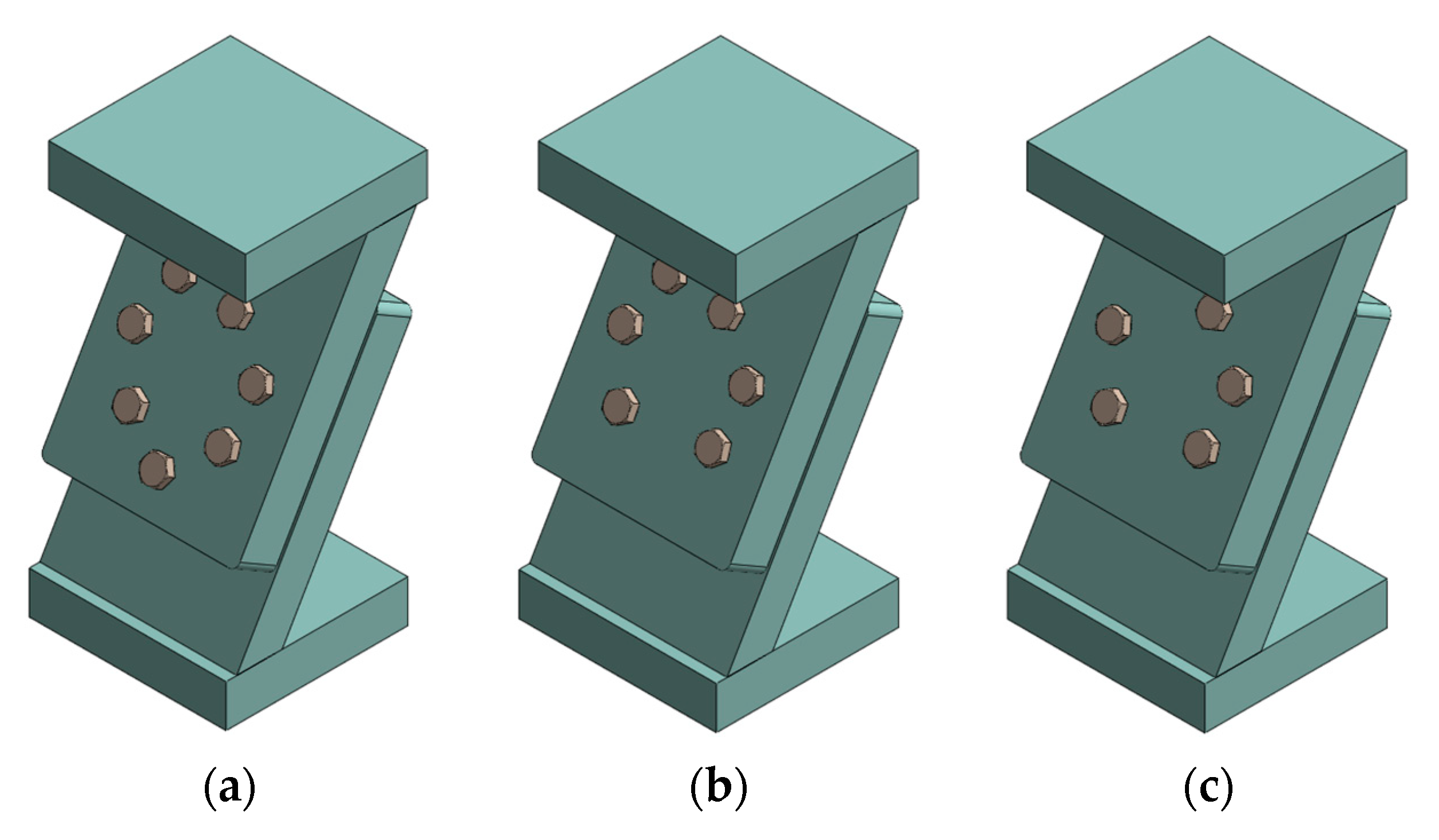

2.1. Characteristics of the Tested Connections

2.2. Recycling Product Model

- Enhanced connection attributes with dismantling attributes (connection constraints);

- Material recycling attributes;

- Product categorisation.

2.3. Finite Element Models

- Normal stiffness factor equal to 10;

- Tangential stiffness factor equal to 1;

- Coefficient of static friction equal to 0.14.

3. Results

3.1. Product Recycling Properties

3.2. FEM Calculation Results

- Average deflection in the z-axis of the top plate under pressure p—dtp;

- Stiffness of the connection—k;

- Maximum reduced stresses according to the von Mises formula—sr.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarancic, D.; Pigosso, D.C.A.; McAloone, T.C. Evaluation and instantiation of a generic process model for early-stage sustainable product-service system design within three manufacturing companies. J. Clean. Prod. 2024, 458, 142543. [Google Scholar] [CrossRef]

- Grzejda, R. Modelling Nonlinear Multi-Bolted Connections: A Case of Operational Condition. In Proceedings of the 15th International Scientific Conference ‘Engineering for Rural Development 2016’, Jelgava, Latvia, 25–27 May 2016; pp. 336–341. [Google Scholar]

- Chybowski, L.; Nozdrzykowski, K.; Grządziel, Z.; Dorobczyński, L. Evaluation of model-based control of reaction forces at the supports of large-size crankshafts. Sensors 2020, 20, 2654. [Google Scholar] [CrossRef] [PubMed]

- Śnieżek, L.; Grzelak, K.; Torzewski, J.; Kluczyński, J. Study of the Mechanical Properties Components Made by SLM Additive Technology. In Proceedings of the 11th International Conference on Intelligent Technologies in Logistics and Mechatronics Systems, Panevezys, Lithuania, 28–29 April 2016; pp. 145–153. [Google Scholar]

- Zmarzły, P. Technological heredity of the turning process. Teh. Vjesn. 2020, 27, 1194–1203. [Google Scholar]

- Mucha, W. Comparison of machine learning algorithms for structure state prediction in operational load monitoring. Sensors 2020, 20, 7087. [Google Scholar] [CrossRef] [PubMed]

- Wysmulski, P. Load eccentricity of compressed composite Z-columns in non-linear state. Materials 2022, 15, 7631. [Google Scholar] [CrossRef] [PubMed]

- Abratanski, A.; Grzejda, R.; Perz, R. Feasibility study of topology optimization of the control system frame for the missile with canard configuration. Aircr. Eng. Aerosp. Technol. 2023, 95, 814–819. [Google Scholar] [CrossRef]

- Zhou, H.; Li, W.; Hao, X.; Zong, G.; Yi, X.; Xu, J.; Ou, R.; Wang, Q. Recycling end-of-life WPC products into ultra-high-filled, high-performance wood fiber/polyethylene composites: A sustainable strategy for clean and cyclic processing in the WPC industry. J. Mater. Res. Technol. 2022, 18, 1–14. [Google Scholar] [CrossRef]

- Xia, H.; Han, J.; Milisavljevic-Syed, J. Predictive modeling for the quantity of recycled end-of-life products using optimized ensemble learners. Resour. Conserv. Recycl. 2023, 197, 107073. [Google Scholar] [CrossRef]

- Kitayama, S.; Iuorio, O. Disassembly and reuse of structural members in steel-framed buildings: State-of-the-art review of connection systems and future research trends. J. Archit. Eng. 2023, 29, 03123006. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: Berkeley, CA, USA, 2002. [Google Scholar]

- MacArthur, E. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Isle of Wight, UK, 2015. [Google Scholar]

- Stahel, W.R. The circular economy. Nat. News 2016, 531, 435. [Google Scholar] [CrossRef] [PubMed]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Diakun, J.; Dostatni, E.; Rojek, I.; Rybacki, P. Recycling-oriented analysis of domestic vacuum cleaner. J. Phys. Conf. Ser. 2022, 2198, 012061. [Google Scholar] [CrossRef]

- Diakun, J. Recycling Product Model and its application for quantitative assessment of product recycling properties. Sustainability 2024, 16, 2880. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Henriques, R.; Figueiredo, F.; Nunes, J. Product-services for a resource-efficient and circular economy: An updated review. Sustainability 2023, 15, 12077. [Google Scholar] [CrossRef]

- Mang, P.; Haggard, B. Regenerative Development: A Framework for Evolving Sustainability; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Morseletto, P. Restorative and regenerative: Exploring the concepts in the circular economy. J. Ind. Ecol. 2020, 24, 763–773. [Google Scholar] [CrossRef]

- Jeandin, T.; Mascle, C. A new model to select fasteners in design for disassembly. Procedia CIRP 2016, 40, 425–430. [Google Scholar] [CrossRef][Green Version]

- Blachowski, B.; Gutkowski, W. Effect of damaged circular flange-bolted connections on behaviour of tall towers, modelled by multilevel substructuring. Eng. Struct. 2016, 111, 93–103. [Google Scholar] [CrossRef]

- Jaszak, P. Prediction of the durability of a gasket operating in a bolted-flange-joint subjected to cyclic bending. Eng. Fail. Anal. 2021, 120, 105027. [Google Scholar] [CrossRef]

- Grzejda, R.; Parus, A. Health assessment of a multi-bolted connection due to removing selected bolts. FME Trans. 2021, 49, 634–642. [Google Scholar] [CrossRef]

- van Schaik, A.; Reuter, M.A. The use of fuzzy rule models to link automotive design to recycling rate calculation. Miner. Eng. 2007, 20, 875–890. [Google Scholar] [CrossRef]

- Gaustad, G.; Olivetti, E.; Kirchain, R. Improving aluminum recycling: A survey of sorting and impurity removal technologies. Resour. Conserv. Recycl. 2012, 58, 79–87. [Google Scholar] [CrossRef]

- Paraskevas, D.; Kellens, K.; Dewulf, W.; Duflou, J.R. Environmental modelling of aluminium recycling: A Life Cycle Assessment tool for sustainable metal management. J. Clean. Prod. 2015, 105, 357–370. [Google Scholar] [CrossRef]

- Soo, V.K.; Peeters, J.; Paraskevas, D.; Compston, P.; Doolan, M.; Duflou, J.R. Sustainable aluminium recycling of end-of-life products: A joining techniques perspective. J. Clean. Prod. 2018, 178, 119–132. [Google Scholar] [CrossRef]

- Kreilis, J.; Zeltins, E. Reuse of Steel Structural Elements with Bolted Connections. In Proceedings of the 6th International Scientific Conference ‘Research for Environment and Civil Engineering Development 17’, Jelgava, Latvia, 2–3 November 2017; pp. 48–53. [Google Scholar]

- Kitayama, S.; Iuorio, O. Using bolted connections for the construction, de-construction and reuse of lightweight exterior infill walls: Experimental study. Archit. Struct. Constr. 2024, 4, 123–133. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, W.; Chen, H.; Chen, Z. Damage analysis and mechanical performance evaluation of frame structures in recycling. Structures 2024, 66, 106906. [Google Scholar] [CrossRef]

- Dai, X.; Yang, J.; Lam, D.; Sheehan, T.; Zhou, K. Experiment and numerical modelling of a demountable steel connection system for reuse. J. Constr. Steel Res. 2022, 198, 107534. [Google Scholar] [CrossRef]

- Soo, V.K.; Compston, P.; Doolan, M. The influence of joint technologies on ELV recyclability. Waste Manag. 2017, 68, 421–433. [Google Scholar] [CrossRef] [PubMed]

- Abe, Y.; Kato, T.; Mori, K. Aluminium alloy self-pierce riveting for joining of aluminium alloy sheets. Key Eng. Mater. 2009, 410–411, 79–86. [Google Scholar] [CrossRef]

- Hoang, N.-H.; Porcaro, R.; Langseth, M.; Hanssen, A.-G. Self-piercing riveting connections using aluminium rivets. Int. J. Solids Struct. 2010, 47, 427–439. [Google Scholar] [CrossRef]

- Mori, K.; Abe, Y. A review on mechanical joining of aluminium and high strength steel sheets by plastic deformation. Int. J. Lightweight Mater. Manuf. 2018, 1, 1–11. [Google Scholar] [CrossRef]

- Chien, J.M.; McKinstry, K.C.; Baek, C.; Horvath, A.; Dornfeld, D. Multi-objective analysis on joining technologies. In Leveraging Technology for a Sustainable World; Dornfeld, D.A., Linke, B.S., Eds.; Springer: Heidelberg, Germany, 2012; pp. 287–292. [Google Scholar]

- Rathmann, C.; Fleczok, B.; Lygin, K.; Meier, H. Optimizing the Recycling Process of a Roof Edge Profile by Using Shape Memory Alloy Connecting Elements. In Proceedings of the ASME 2014 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Newport, RI, USA, 8–10 September 2014. [Google Scholar]

- Sodhi, R.; Sonnenberg, M.; Das, S. Evaluating the unfastening effort in design for disassembly and serviceability. J. Eng. Des. 2004, 15, 69–90. [Google Scholar] [CrossRef]

- Vanegas, P.; Peeters, J.R.; Cattrysse, D.; Tecchio, P.; Ardente, F.; Mathieux, F.; Dewulf, W.; Duflou, J.R. Ease of disassembly of products to support circular economy strategies. Resour. Conserv. Recycl. 2018, 135, 323–334. [Google Scholar] [CrossRef] [PubMed]

- de Aguiar, J.; de Oliveira, L.; da Silva, J.O.; Bond, D.; Scalice, R.K.; Becker, D. A design tool to diagnose product recyclability during product design phase. J. Clean. Prod. 2017, 141, 219–229. [Google Scholar] [CrossRef]

- Dostatni, E. Recycling assessment measures implemented in the system. In Ecodesign of Products in CAD 3D Environment with the Use of Agent Technology; Dostatni, E., Ed.; Publishing House of Poznan University of Technology: Poznan, Poland, 2014; pp. 89–93. (In Polish) [Google Scholar]

- Dostatni, E.; Diakun, J.; Grajewski, D.; Wichniarek, R.; Karwasz, A. Multi-agent system to support decision-making process in design for recycling. Soft Comput. 2016, 20, 4347–4361. [Google Scholar] [CrossRef]

- Leal, J.M.; Pompidou, S.; Charbuillet, C.; Perry, N. Design for and from recycling: A circular ecodesign approach to improve the circular economy. Sustainability 2020, 12, 9861. [Google Scholar] [CrossRef]

- Miatliuk, K.; Lukaszewicz, A.; Siemieniako, F. Coordination method in design of forming operations of hierarchical solid objects. In Proceedings of the International Conference on Control, Automation and Systems, Seoul, Republic of Korea, 14–17 October 2008; pp. 2724–2727. [Google Scholar]

- Łukaszewicz, A.; Miatliuk, K. Reverse engineering approach for object with free-form surfaces using standard surface-solid parametric CAD system. Solid. State Phenom. 2009, 147–149, 706–711. [Google Scholar] [CrossRef]

- Palenica, P.; Powałka, B.; Grzejda, R. Assessment of modal parameters of a building structure model. Springer Proc. Math. Stat. 2016, 181, 319–325. [Google Scholar]

- Grzejda, R. Modelling Nonlinear Multi-Bolted Connections: A Case of the Assembly Condition. In Proceedings of the 15th International Scientific Conference ‘Engineering for Rural Development 2016’, Jelgava, Latvia, 25–27 May 2016; pp. 329–335. [Google Scholar]

- PN-EN ISO 4014; Fasteners, Hexagon Head Bolts, Product Grades A and B. Polish Committee for Standardization: Warsaw, Poland, 2022.

- PN-EN ISO 4032; Fasteners, Hexagon Regular Nuts (Style 1). Polish Committee for Standardization: Warsaw, Poland, 2024.

- Round Head Rivets. Available online: https://eurobolt.com.pl/produkt/din-660-pn-82952-iso-1051-nity-z-lbem-kulistym/ (accessed on 27 December 2024).

- Correia, J.A.F.O.; da Silva, A.L.L.; Xin, H.; Lesiuk, G.; Zhu, S.-P.; de Jesus, A.M.P.; Fernandes, A.A. Fatigue performance prediction of S235 base steel plates in the riveted connections. Structures 2021, 30, 745–755. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, Q.; Xiong, L.; Li, J.; Bu, Y.; Bao, Y. A unified evaluation method for fatigue resistance of riveted joints based on structural stress approach. Int. J. Fatigue 2022, 160, 106871. [Google Scholar] [CrossRef]

- Grzejda, R.; Warzecha, M.; Urbanowicz, K. Determination of pretension in bolts for structural health monitoring of multi-bolted connection: FEM approach. Lubricants 2022, 10, 75. [Google Scholar] [CrossRef]

- Aluminum Alloy A356. Available online: https://www.sunrise-metal.com/aluminum-alloy-a356 (accessed on 29 November 2024).

- ASTM A992; Standard Specification for Structural Steel Shapes. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM A276; Standard Specification for Free-Machining Stainless Steel Bars. ASTM International: West Conshohocken, PA, USA, 2022.

- Karwasz, A. Recycling costs analysis. In Ecodesign of Products in CAD 3D Environment with the Use of Agent Technology; Dostatni, E., Ed.; Publishing House of Poznan University of Technology: Poznan, Poland, 2014; pp. 94–98. (In Polish) [Google Scholar]

- Scrap Metal Purchase. Available online: https://www.ekosylwia.pl/cennik (accessed on 4 November 2024).

- Ordinance of the Council of Ministers on the Amount of the Minimum Remuneration and the Minimum Hourly Rate in 2024. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20230001893/O/D20231893.pdf (accessed on 29 November 2024).

- de Jesus, A.M.P.; da Silva, A.L.L.; Correia, J.A.F.O. Fatigue of riveted and bolted joints made of puddle iron—A numerical approach. J. Constr. Steel Res. 2014, 102, 164–177. [Google Scholar] [CrossRef]

- Leonetti, D.; Maljaars, J.; Pasquarelli, G.; Brando, G. Rivet clamping force of as-built hot-riveted connections in steel bridges. J. Constr. Steel Res. 2020, 167, 105955. [Google Scholar] [CrossRef]

- Midas NFX Manuals and Tutorials. Available online: https://midassupport.jitbit.com/helpdesk/KB/View/32637163-midas-nfx-manuals-and-tutorials (accessed on 2 December 2024).

- Grzesik, W. Effect of the machine parts surface topography features on the machine service. Mechanik 2015, 88, 587–593. (In Polish) [Google Scholar] [CrossRef]

- Grzejda, R.; Perz, R. Compressive strength analysis of a steel bolted connection under bolt loss conditions. Commun. Sci. Lett. Univ. Žilina 2022, 24, B319–B327. [Google Scholar] [CrossRef]

- Satheesh Kumar, K.V.; Selvakumar, P.; Jagadeeswari, R.; Dharmaraj, M.; Uvanshankar, K.R.; Yogeswaran, B. Stress analysis of riveted and bolted joints using analytical and experimental approach. Mater. Today Proc. 2021, 42 Pt 2, 1091–1099. [Google Scholar] [CrossRef]

- Pawłowski, K. The Bearing Capacity of Hybrid Bolted and Riveted Joints in Steel Bridge Structures. In Proceedings of the XIV International Conference on Metal Structures, Poznan, Poland, 16–18 June 2021; pp. 342–348. [Google Scholar]

- Feng, S.; Gong, Y.; Neugebauer, J.; Raabe, D.; Liotti, E.; Grant, P.S. Multi-Technique Investigation of Fe-Rich Intermetallic Compounds for More Impurity-Tolerant Al Alloys. In Proceedings of the Presented at Annual Meeting of DPG and DPG Spring Meeting of the Condensed Matter Section, Berlin, Germany, 17–22 March 2024. [Google Scholar]

- Zacal, J.; Pavlik, J.; Kunzova, I. Influence of shape of pressure vessel shell on bolt working load and tightness. MM Sci. J. 2021, 6, 5448–5451. [Google Scholar] [CrossRef]

- Zacal, J.; Folta, Z.; Struz, J.; Trochta, M. Influence of symmetry of tightened parts on the force in a bolted joint. Symmetry 2023, 15, 276. [Google Scholar] [CrossRef]

- Zampieri, P.; Curtarello, A.; Maiorana, E.; Pellegrino, C. A review of the fatigue strength of shear bolted connections. Int. J. Steel Struct. 2019, 19, 1084–1098. [Google Scholar] [CrossRef]

| ID | Connected Parts | Connecting Parts | Connection Nature | Connection Type | Dismantled | Dismantling Time [s] |

|---|---|---|---|---|---|---|

| cc01 | plate_vertical_01/ | ISO 4014 M10 × 80:1 | Temporary | Threaded | Yes | 5 |

| plate_vertical_02 | ISO 4032 M10:1 | |||||

| cc02 | plate_vertical_01/ | ISO 4014 M10 × 80:2 | Temporary | Threaded | Yes | 5 |

| plate_vertical_02 | ISO 4032 M10:2 | |||||

| cc03 | plate_vertical_01/ | ISO 4014 M10 × 80:3 | Temporary | Threaded | Yes | 5 |

| plate_vertical_02 | ISO 4032 M10:3 | |||||

| cc04 | plate_vertical_01/ | ISO 4014 M10 × 80:4 | Temporary | Threaded | Yes | 5 |

| plate_vertical_02 | ISO 4032 M10:4 | |||||

| cc05 | plate_vertical_01/ | ISO 4014 M10 × 80:5 | Temporary | Threaded | Yes | 5 |

| plate_vertical_02 | ISO 4032 M10:5 | |||||

| cc06 | plate_vertical_01/ | ISO 4014 M10 × 80:6 | Temporary | Threaded | Yes | 5 |

| plate_vertical_02 | ISO 4032 M10:6 | |||||

| cc07 | plate_vertical_01/ | ISO 4014 M10 × 80:7 | Temporary | Threaded | Yes | 5 |

| plate_vertical_02 | ISO 4032 M10:7 | |||||

| cc08 1 | plate_vertical_01/plate_up | – | Permanent | Welded | No | – |

| cc09 1 | plate_vertical_01/plate_up | – | Permanent | Welded | No | – |

| cc10 2 | plate_vertical_02/plate_down | – | Permanent | Welded | No | – |

| cc11 2 | plate_vertical_02/plate_down | – | Permanent | Welded | No | – |

| Total: | 35 |

| ID | Connected Parts | Connecting Part | Connection Nature | Connection Type | Dismantled | Dismantling Time [s] |

|---|---|---|---|---|---|---|

| cc01 | plate_vertical_01/ plate_vertical_02 | PN-M-82952-10 × 65 × 56:1 | Permanent | Riveted | Yes | 11 |

| cc02 | plate_vertical_01/ plate_vertical_02 | PN-M-82952-10 × 65 × 56:2 | Permanent | Riveted | Yes | 11 |

| cc03 | plate_vertical_01/ plate_vertical_02 | PN-M-82952-10 × 65 × 56:3 | Permanent | Riveted | Yes | 11 |

| cc04 | plate_vertical_01/ plate_vertical_02 | PN-M-82952-10 × 65 × 56:4 | Permanent | Riveted | Yes | 11 |

| cc05 | plate_vertical_01/ plate_vertical_02 | PN-M-82952-10 × 65 × 56:5 | Permanent | Riveted | Yes | 11 |

| cc06 | plate_vertical_01/ plate_vertical_02 | PN-M-82952-10 × 65 × 56:6 | Permanent | Riveted | Yes | 11 |

| cc07 | plate_vertical_01/ plate_vertical_02 | PN-M-82952-10 × 65 × 56:7 | Permanent | Riveted | Yes | 11 |

| cc08 1 | plate_vertical_01/plate_up | – | Permanent | Welded | No | – |

| cc09 1 | plate_vertical_01/plate_up | – | Permanent | Welded | No | – |

| cc10 2 | plate_vertical_02/plate_down | – | Permanent | Welded | No | – |

| cc11 2 | plate_vertical_02/plate_down | – | Permanent | Welded | No | – |

| Total: | 77 |

| Part Name | Material | Elastic Modulus [GPa] | Poisson’s Ratio [–] | Tensile Strength [MPa] |

|---|---|---|---|---|

| Top plate | A356.0-T6 | 72 | 0.33 | 200 |

| Bottom plate | A992 | 200 | 0.3 | 450 |

| Top base | A356.0-T6 | 72 | 0.33 | 200 |

| Bottom base | A992 | 200 | 0.3 | 450 |

| Bolt | 440C | 200 | 0.28 | 758 |

| Nut | 440C | 200 | 0.28 | 758 |

| Rivet | 440C | 200 | 0.28 | 758 |

| Variant | Number of Nodes | Number of Finite Elements |

|---|---|---|

| 1a | 32,837 | 47,225 |

| 1b | 29,762 | 42,201 |

| 1c | 26,312 | 36,494 |

| 2a | 23,504 | 30,780 |

| 2b | 21,590 | 27,776 |

| 2c | 19,762 | 25,150 |

| Part Name | Variant 1a | Variant 1b | Variant 1c | Variant 2a | Variant 2b | Variant 2c |

|---|---|---|---|---|---|---|

| plate_vertical_01 | 2 | 2 | 2 | 2 | 2 | 2 |

| plate_vertical_02 | 2 | 2 | 2 | 2 | 2 | 2 |

| plate_up | 1 | 1 | 1 | 1 | 1 | 1 |

| plate_down | 1 | 1 | 1 | 1 | 1 | 1 |

| Variant 1a | Variant 1b | Variant 1c | Variant 2a | Variant 2b | Variant 2c | |

|---|---|---|---|---|---|---|

| Total TFI | 27.2 | 25.6 | 24.0 | 44.0 | 40.0 | 36.0 |

| Variant | Total Disassembly Time [s] | Total Disassembly Cost [c.u.] | Material Recycling Profit [c.u.] | Total Recycling Profit [c.u.] |

|---|---|---|---|---|

| 1a | 35 | 0.27 | 21.60 | 21.33 |

| 1b | 30 | 0.23 | 21.60 | 21.36 |

| 1c | 25 | 0.20 | 21.59 | 21.40 |

| 2a | 77 | 0.60 | 21.53 | 20.93 |

| 2b | 66 | 0.52 | 21.54 | 21.02 |

| 2c | 55 | 0.43 | 21.55 | 21.12 |

| Variant | dtp [mm] | k [kN/mm] | sr [MPa] |

|---|---|---|---|

| 1a | 0.1429 | 21.83 | 404.6 |

| 1b | 0.1596 | 19.55 | 476.4 |

| 1c | 0.1922 | 16.23 | 621.4 |

| 2a | 0.0226 | 137.9 | 23.45 |

| 2b | 0.0233 | 133.7 | 30.93 |

| 2c | 0.0236 | 132.0 | 36.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diakun, J.; Grzejda, R. Product Design Analysis with Regard to Recycling and Selected Mechanical Properties. Appl. Sci. 2025, 15, 512. https://doi.org/10.3390/app15020512

Diakun J, Grzejda R. Product Design Analysis with Regard to Recycling and Selected Mechanical Properties. Applied Sciences. 2025; 15(2):512. https://doi.org/10.3390/app15020512

Chicago/Turabian StyleDiakun, Jacek, and Rafał Grzejda. 2025. "Product Design Analysis with Regard to Recycling and Selected Mechanical Properties" Applied Sciences 15, no. 2: 512. https://doi.org/10.3390/app15020512

APA StyleDiakun, J., & Grzejda, R. (2025). Product Design Analysis with Regard to Recycling and Selected Mechanical Properties. Applied Sciences, 15(2), 512. https://doi.org/10.3390/app15020512