Optimizing Reinforcement Bar Fabrication in Construction Projects via Multi-Dimensional Applications in Building Information Modeling

Abstract

1. Introduction

2. Literature Review

3. Methodology and Module Development

3.1. Module 1: Defining Requirement Parameters

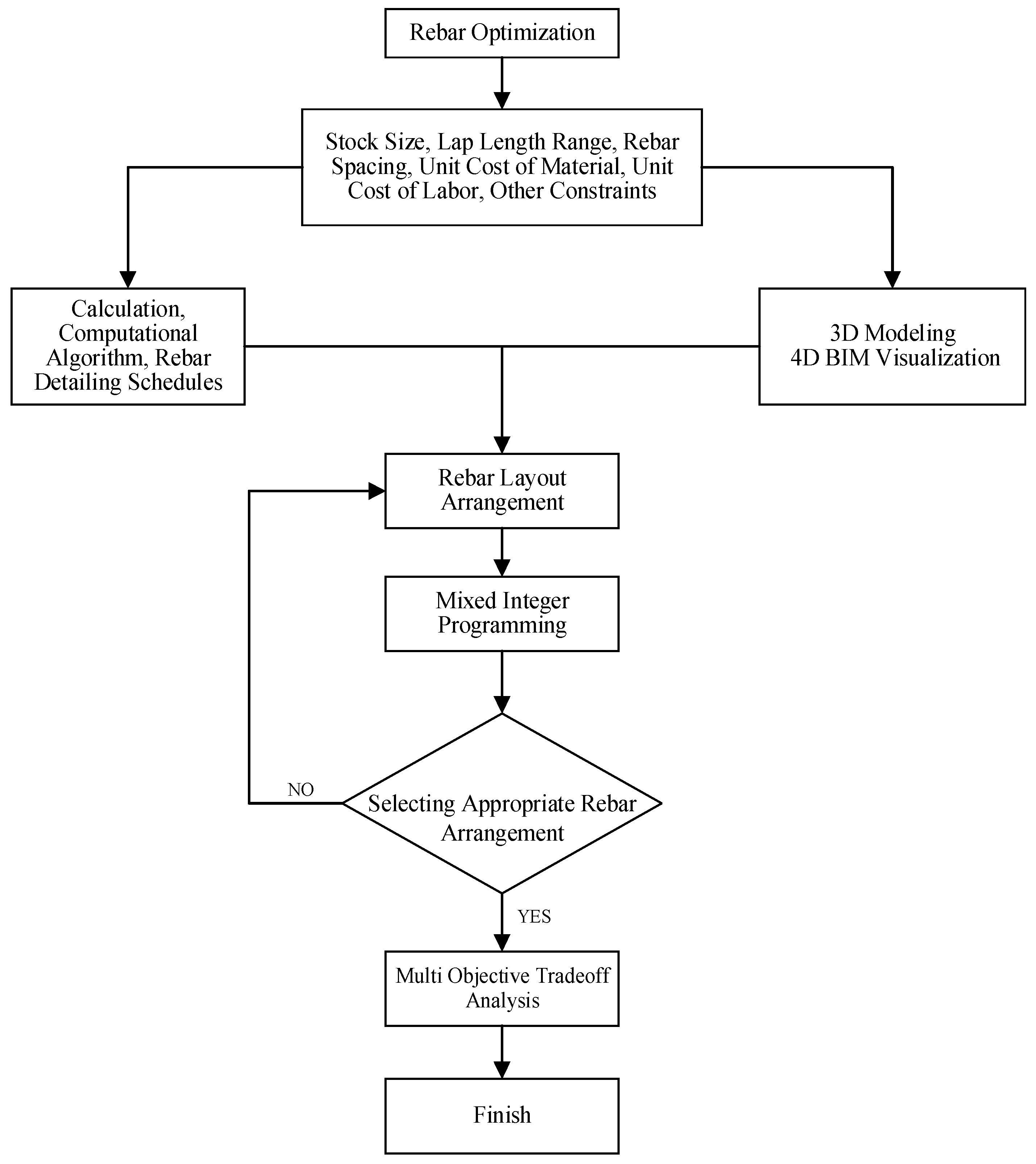

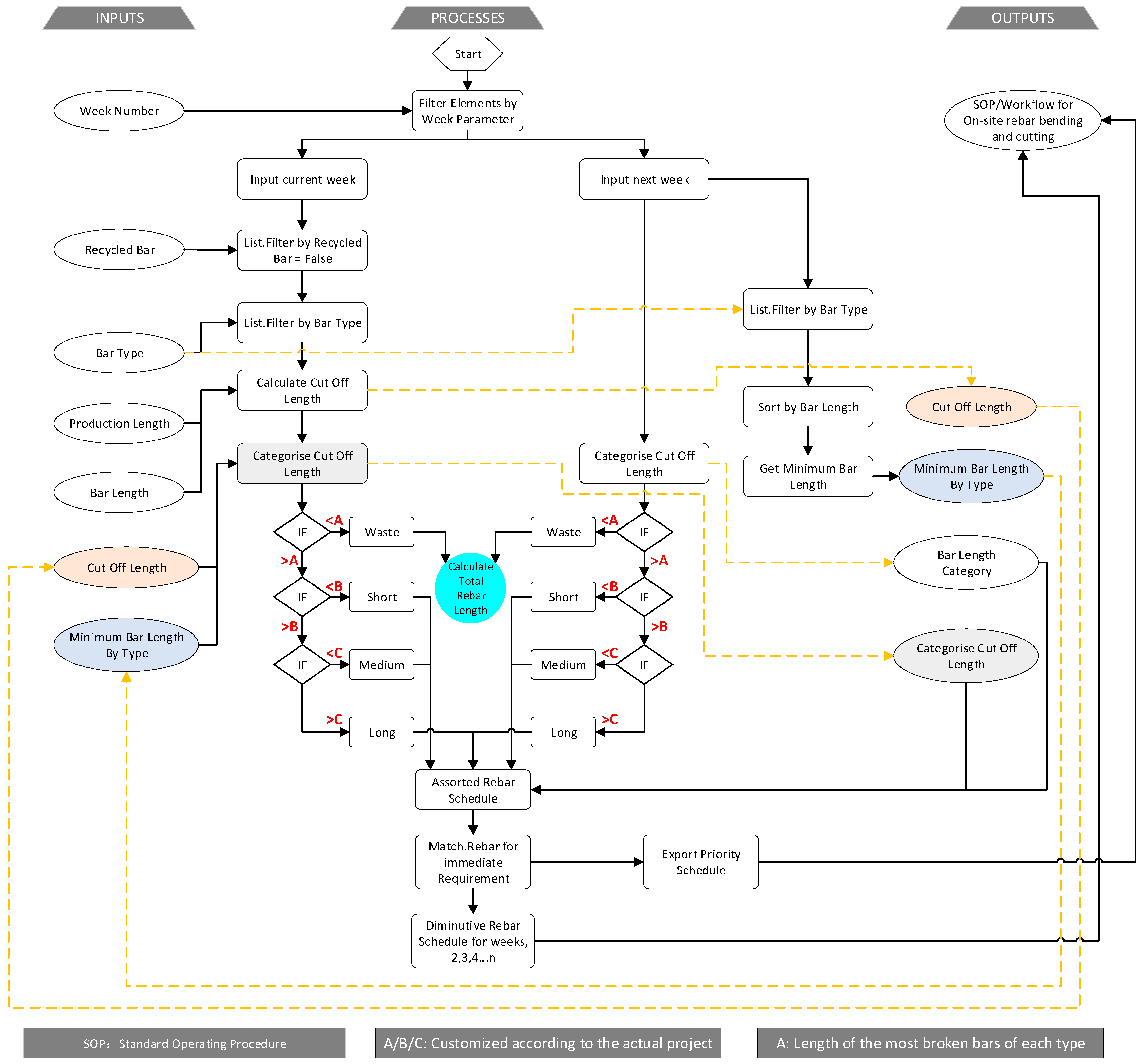

3.2. Module 2: Developing a Process-Flow Framework for the Optimization Script

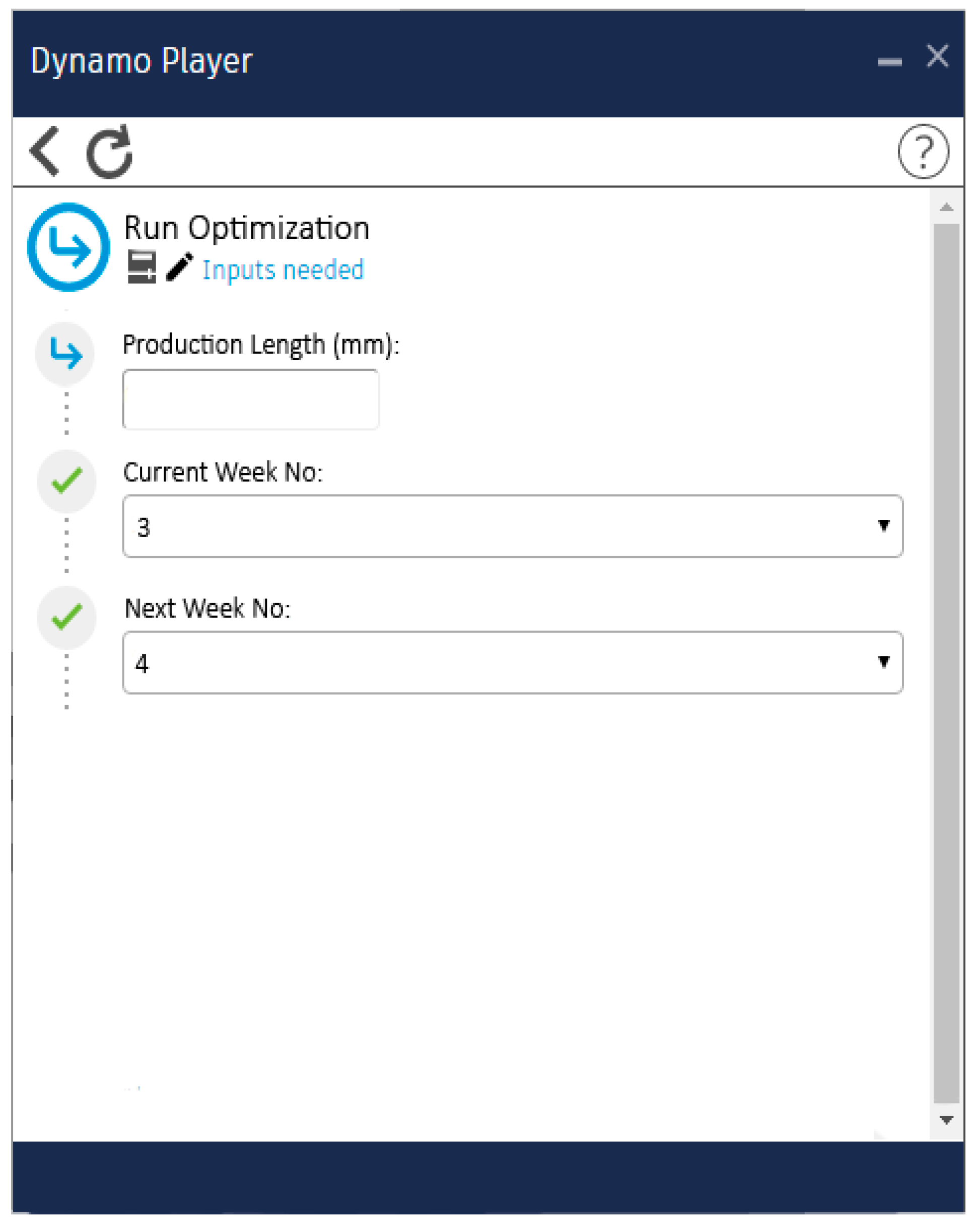

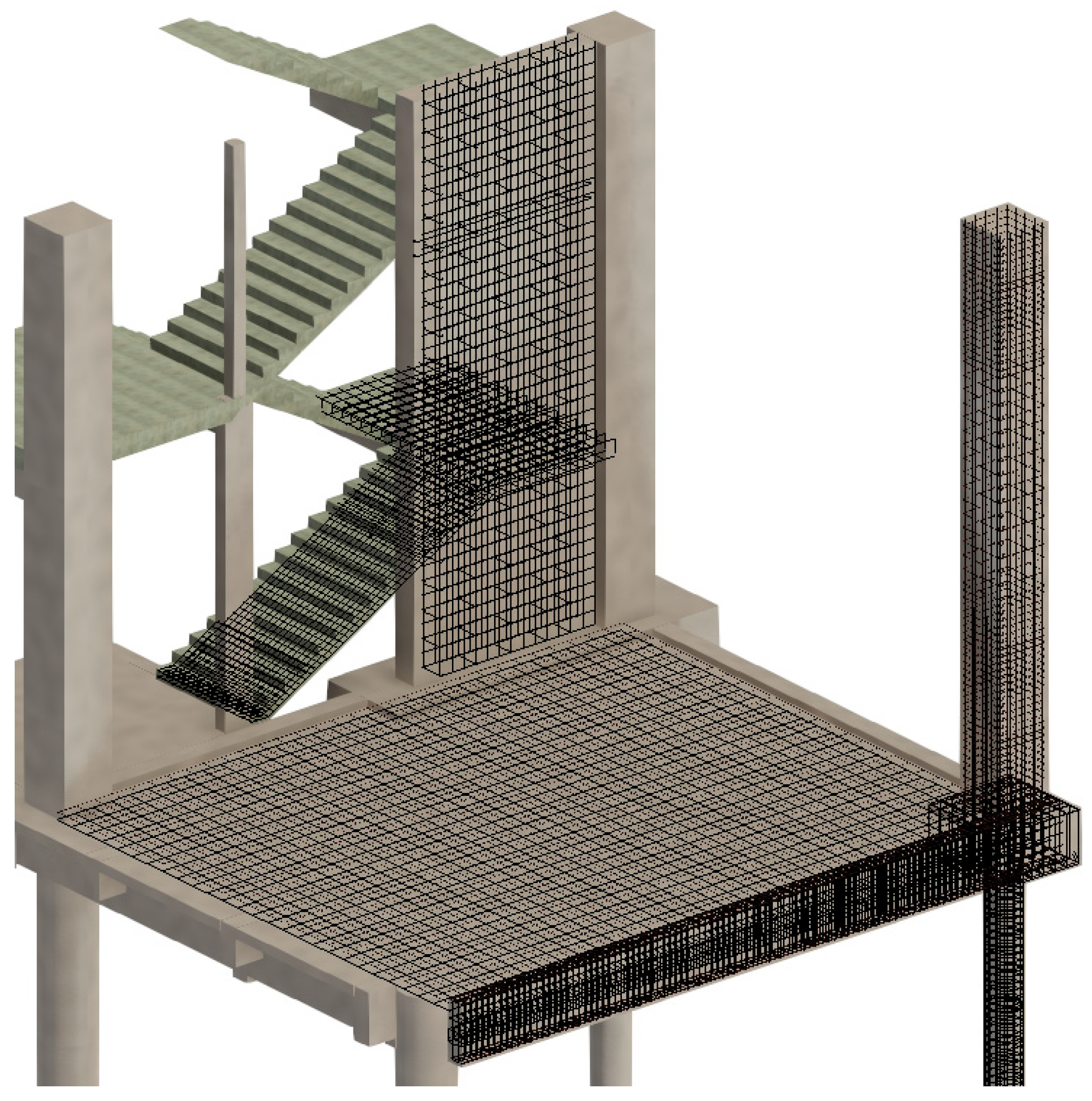

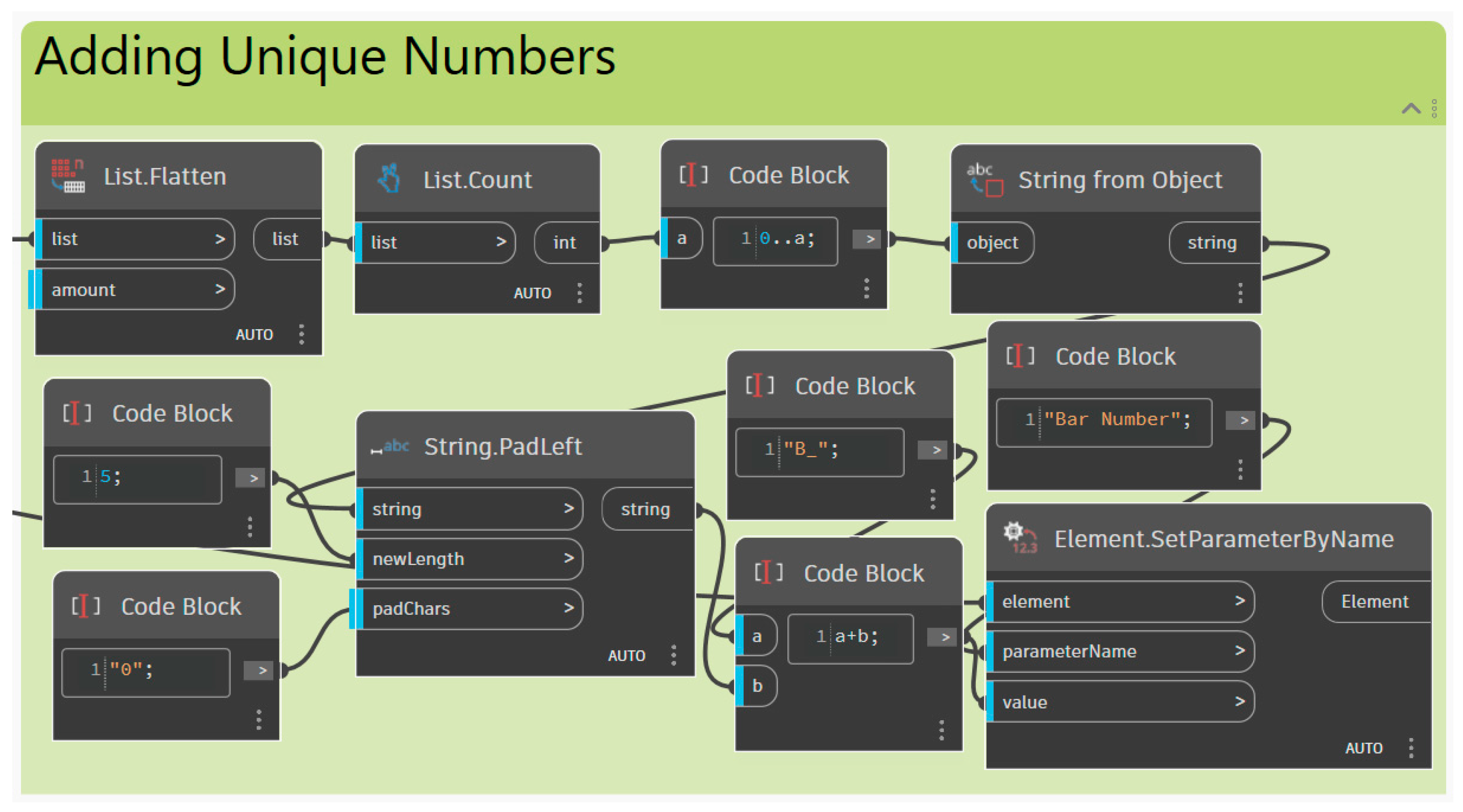

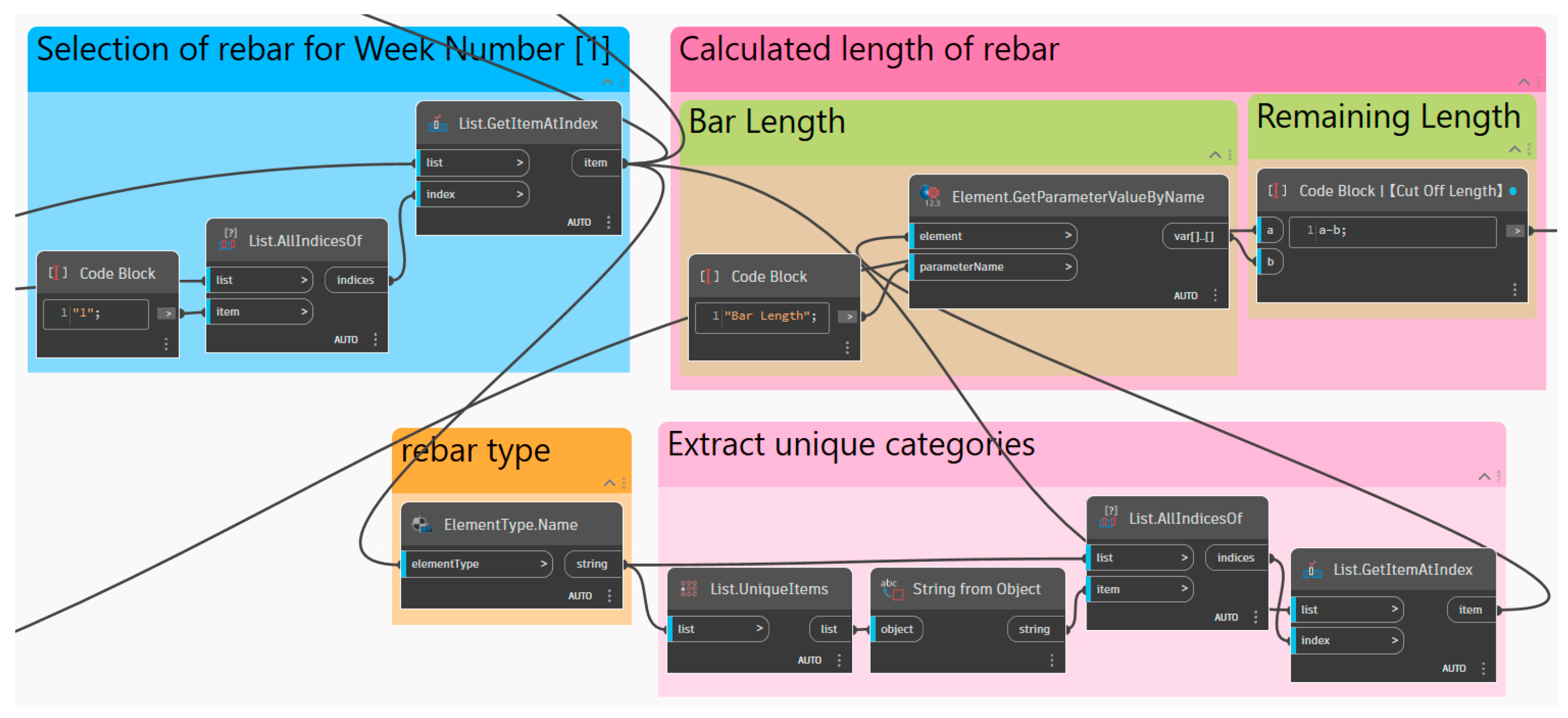

3.3. Module 3: Creating the Script in Dynamo

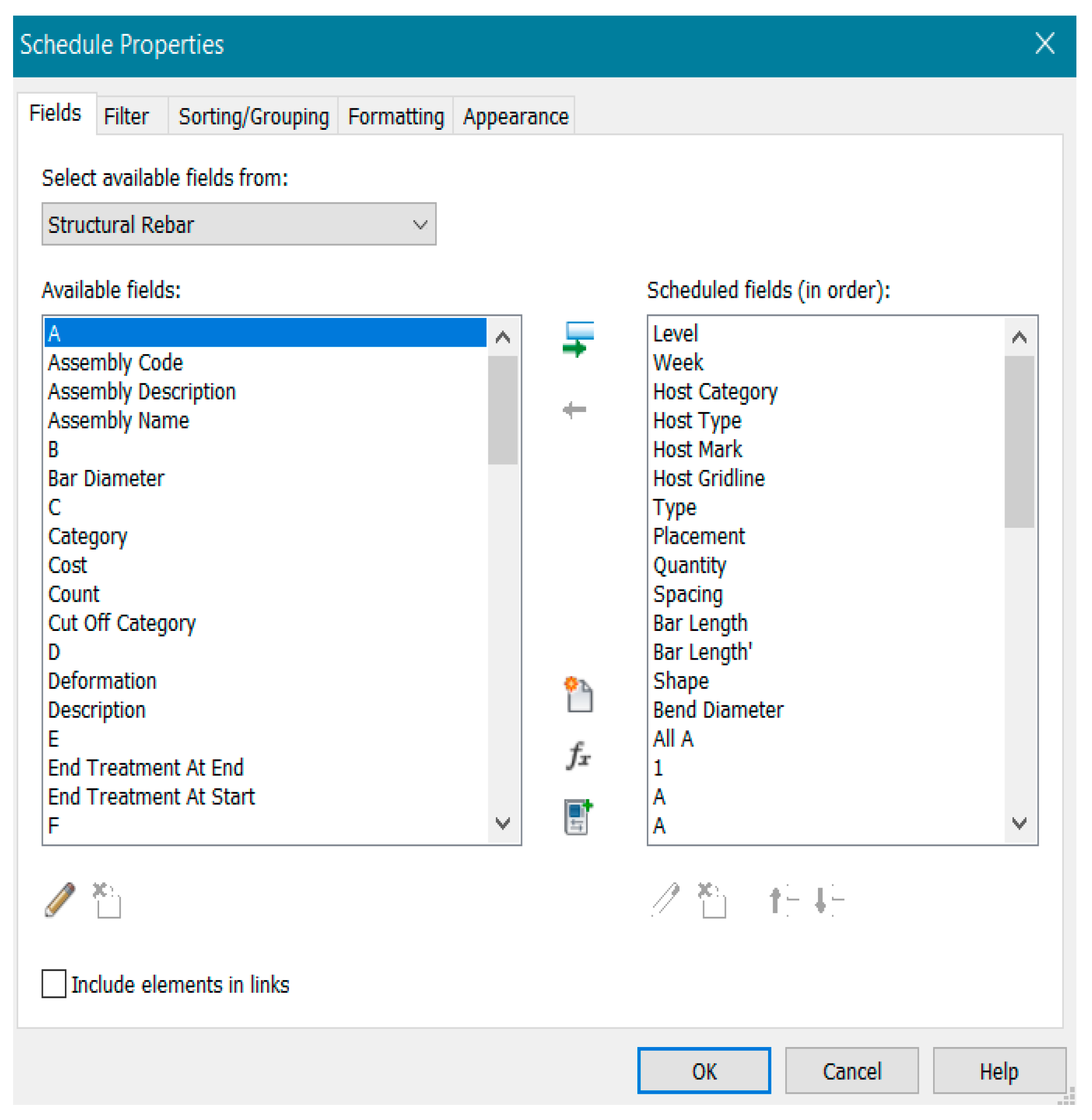

3.4. Module 4: Exporting to Revit Schedule

4. Validation of the Optimization Script

4.1. Case Study 1

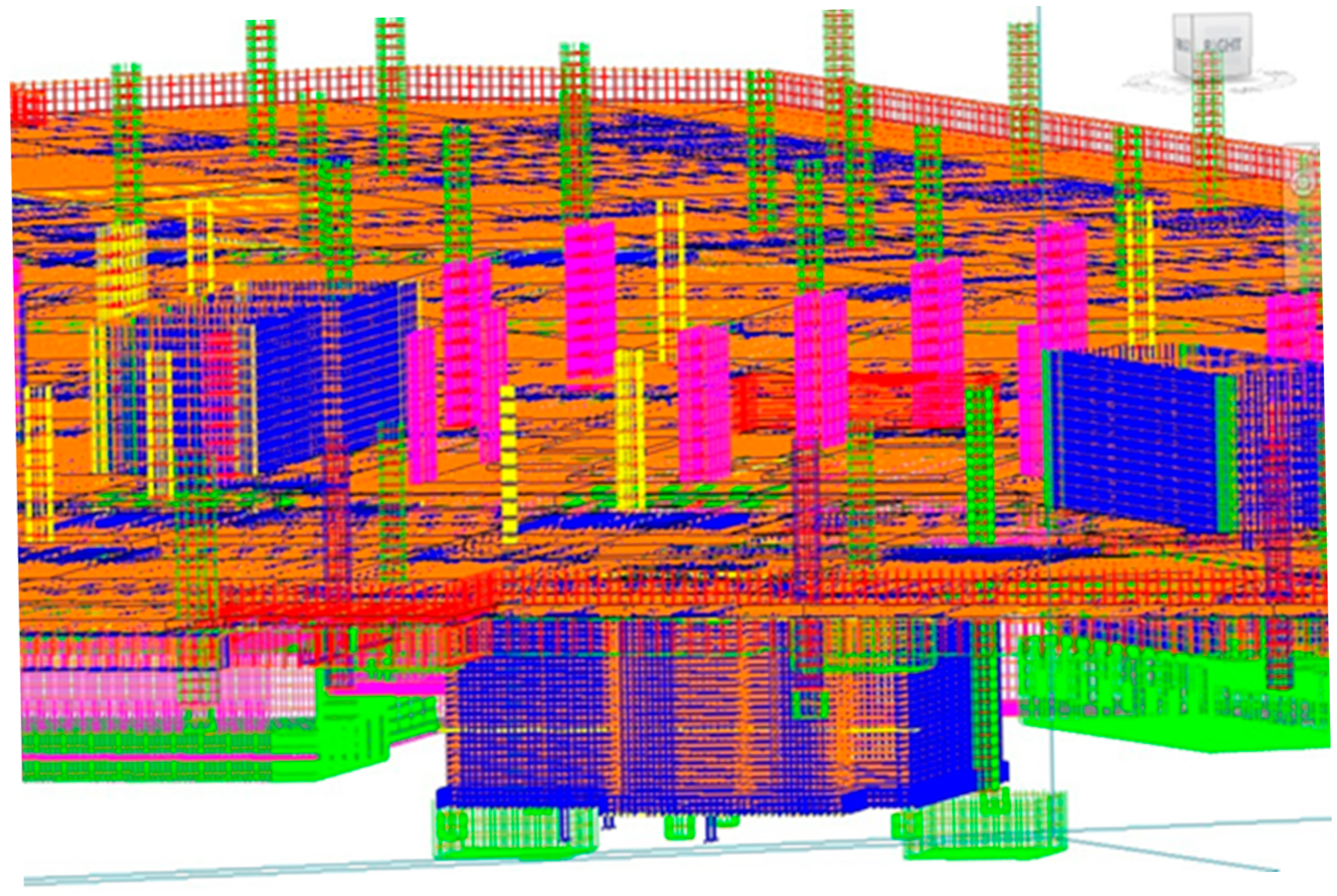

4.2. Case Study 2

4.2.1. Analysis of the First Component—Pile Caps

4.2.2. Analysis of the Second Component—Ground Beams

4.2.3. Analysis of the Third Component—Slabs

4.2.4. Analysis of the Fourth Component—Sewage Treatment Plant (STP)

5. Discussions and Conclusions

5.1. Summary and Interpretation of Results

5.2. Research Contributions

- Development of a Novel Computational Framework for Proactive Waste Minimization. This research introduces an intelligent Dynamo script embedded in BIM that moves beyond reactive cutting stock solutions. By automatically determining optimal rebar cut-off lengths based on construction schedules and integrating manufacturing constraints upfront, the method proactively minimizes material waste at the source. This provides a practical digital tool for implementing circular economy strategies in steel construction, generating structurally efficient designs that are inherently material-efficient.

- Empirical Validation through Real-World Implementation and Performance Benchmarking. The proposed framework was implemented and evaluated in a commercial construction project, demonstrating measurable savings in both time and materials. This practical performance evaluation in an authentic setting underscores the method’s immediate applicability and commercial viability, providing robust evidence to support its potential for industry-wide adoption.

- A Paradigm Shift in Optimization through Seamless Digital Integration. The work bridges the gap between structural design, fabrication, and supply chain logistics. By producing a digital inventory of components directly from the design model, the framework enables seamless integration with prefabrication and supply chain logistics. This facilitates accurate material ordering, off-site production, and streamlined project management, establishing a cohesive workflow that paves the way for enhanced resource efficiency and digitalization in construction.

5.3. Limitations and Future Research Directions

- Optimization Algorithm Constraints: The current method employs a “one-pass” optimization with a list-based sorting mechanism, which does not guarantee a globally optimal solution and may potentially underestimate the maximum achievable savings. Future work should explore more advanced techniques, such as heuristic algorithms or multi-criteria decision analysis, to narrow the gap between the achieved results and a theoretical optimum.

- Applicability and Model Dependency: The method’s effectiveness is primarily demonstrated on standard rebar types and regular geometries. Its applicability to structures with highly irregular shapes or projects with a wide variety of non-standard bar types requires further validation. Furthermore, the optimization is highly sensitive to the accuracy and detail of the underlying BIM model. Inaccurate rebar geometry or incomplete information can compromise performance, underscoring the critical need for high Levels of Information Need (LOIN) and Development (LOD).

- Scalability and Robustness in Practical Scenarios: The case study validation, while positive, highlights the need to investigate the method’s scalability to very large-scale projects or its integration into high-volume prefabrication facilities. Additionally, the current framework does not account for dynamic external factors such as weather, labor skill variability, and on-site logistical changes, which can influence material usage and schedule on active construction sites. Integrating these variables would significantly improve the method’s robustness and real-world adaptability.

5.4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| API | Application Programming Interface |

| BIM | Building Information Modeling |

| AECO | Architecture, Engineering, Construction, and Operations |

| VE | Value Engineering |

| 3D | Third Dimension |

| 4D | Fourth Dimension |

| HGA | Hybrid Genetic Algorithm |

| CSP | Cutting Stock Problem |

| IFC | Industry Foundation Class |

References

- Umar, U.A.; Shafiq, N.; Ahmad, F.A. A case study on the effective implementation of the reuse and recycling of construction & demolition waste management practices in Malaysia. Ain Shams Eng. J. 2021, 12, 283–291. [Google Scholar] [CrossRef]

- Morsi, D.M.A.; Ismaeel, W.S.E.; Ehab, A.; Othman, A.A.E. BIM-based life cycle assessment for different structural system scenarios of a residential building. Ain Shams Eng. J. 2022, 13, 101802. [Google Scholar] [CrossRef]

- Nicał, A. Optimization of reinforcement steel supply to precast concrete plants. Arab. J. Geosci. 2019, 12, 207. [Google Scholar] [CrossRef]

- Nigussie, T.; Chandrasekar, M.K. Influence of rebar practice in the total cost of building construction projects: The case of hawassa city, ethiopia. Int. J. Eng. Sci. Tech. 2020, 12, 54–65. [Google Scholar] [CrossRef]

- Cho, S.; Na, S. The Reduction of CO2 Emissions by Application of High-Strength Reinforcing Bars to Three Different Structural Systems in South Korea. Sustainability 2017, 9, 1652. [Google Scholar] [CrossRef]

- Hu, Y.; Castro-Lacouture, D. Clash relevance prediction based on machine learning. J. Comput. Civ. Eng. 2019, 33, 04018060. [Google Scholar] [CrossRef]

- Liu, J.; Liu, P.; Feng, L.; Wu, W.; Li, D.; Chen, Y.F. Automated clash resolution for reinforcement steel design in concrete frames via Q-learning and building information modeling. Autom. Constr. 2020, 112, 103062. [Google Scholar] [CrossRef]

- Zhang, J.P.; Hu, Z.Z. BIM- and 4D-based integrated solution of analysis and management for conflicts and structural safety problems during construction: 1. Principles and methodologies. Autom. Constr. 2011, 20, 155–166. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Wong, B.C.L.; Chan, C.M.; Cheng, J.C.P.; Gan, V.J.L. BIM-BVBS integration with openBIM standards for automatic prefabrication of steel reinforcement. Autom. Constr. 2021, 125, 103654. [Google Scholar] [CrossRef]

- Lien, L.-C.; Dolgorsuren, U. BIM-based steel reinforcing bar detail construction design and picking optimization. Structures 2023, 49, 520–536. [Google Scholar] [CrossRef]

- Liu, P.; Qi, H.; Liu, J.; Feng, L.; Li, D.; Guo, J. Automated clash resolution for reinforcement steel design in precast concrete wall panels via generative adversarial network and reinforcement learning. Adv. Eng. Inform. 2023, 58, 102131. [Google Scholar] [CrossRef]

- Tan, Y.; Xu, W.; Chen, K.; Deng, C.; Wang, P. An interactive and collaborative augmented reality environment for civil engineering education: Steel reinforcement bars teaching as an example. ECAM 2024, 31, 1100–1122. [Google Scholar] [CrossRef]

- Khant, L.P.; Widjaja, D.D.; Kwon, K.; Kim, S. A BIM-based bar bending schedule generation algorithm with enhanced accuracy. Buildings 2024, 14, 1207. [Google Scholar] [CrossRef]

- Khan, A.M.; Alaloul, W.S.; Musarat, M.A.; Fayyaz, A.M. Optimizing sustainable alternatives in value engineering Decision-Making through BIM-Integrated plugin automation for buildings. Ain Shams Eng. J. 2025, 16, 103373. [Google Scholar] [CrossRef]

- Shi, A.; Shirowzhan, S.; Sepasgozar, S.M.; Kaboli, A. 5D BIM applications in quantity surveying: Dynamo and 3D printing technologies. In Smart Cities and Construction Technologies; InTech Open: London, UK, 2020; Volume 139. [Google Scholar]

- Salamak, M.; Jasinski, M.; Plaszczyk, T.; Zarski, M. Analytical modelling in Dynamo. Sect. Build. Struct. Struct. Mech. 2018, 18, 36–43. [Google Scholar] [CrossRef]

- Alzara, M.; Yosri, A.M.; Alruwaili, A.; Cuce, E.; Eldin, S.M.; Ehab, A. Dynamo script and a BIM-based process for measuring embodied carbon in buildings during the design phase. Int. J. Low-Carbon Technol. 2023, 18, 943–955. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Zhou, J. Enhancing environmental sustainability over building life cycles through green BIM: A review. Autom. Constr. 2015, 57, 156–165. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.M.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers, and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Zheng, C.; Lu, M. Optimized reinforcement detailing design for sustainable construction: Slab case study. Procedia Eng. 2016, 145, 1478–1485. [Google Scholar] [CrossRef]

- Monteiro, A.; Martins, J.P. A survey on modeling guidelines for quantity takeoff-oriented BIM-based design. Autom. Constr. 2013, 35, 238–253. [Google Scholar] [CrossRef]

- Marzouk, M.; Hisham, M. Implementing multi-objective genetic algorithms for scheduling optimization of construction projects. Autom. Constr. 2012, 22, 434–445. [Google Scholar] [CrossRef]

- Kim, H.; Anderson, K.; Lee, S.; Hildreth, J. Generating construction schedules through automatic data extraction using open BIM (building information modeling) technology. Autom. Constr. 2013, 35, 285–295. [Google Scholar] [CrossRef]

- Mangal, M.; Wang, Q.; Cheng, J.C.P. Automated clash resolution of steel rebar in RC beam- column joints using BIM and GA. In Proceedings of the 2017 34rd ISARC, Taipei, Taiwan, 28 June–1 July 2017. [Google Scholar] [CrossRef]

- Ma, Z.; Wei, Z.; Zhang, X. Semi-automatic and specification-compliant cost estimation for prefabricated buildings based on BIM and ontologies. Autom. Constr. 2013, 35, 405–413. [Google Scholar] [CrossRef]

- Ding, L.; Zhou, Y.; Akinci, B. Building Information Modeling (BIM) application framework: The process of expanding from 3D to computable nD. Autom. Constr. 2014, 46, 82–93. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Li, K.C.T. Developing a BIM-Assisted 3D Access Point Placement Optimization Algorithm for Enhancing Wi-Fi Fingerprint-Based Indoor Positioning. In Computing in Civil Engineering 2019, Atlanta, Georgia; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 232–240. [Google Scholar] [CrossRef]

- Eastman, C.; Sacks, R.; Lee, G. Development and implementation of advanced manufacturing technologies in construction: Computer-integrated construction beyond BIM. Automation in Construction 2020, 113, 103120. [Google Scholar] [CrossRef]

- Liu, J.; Xu, C.; Wu, Z.; Chen, Y.F. Intelligent rebar layout in RC building frames using artificial potential field. Autom. Constr. 2020, 114, 103172. [Google Scholar] [CrossRef]

- Li, H.; Chan, G.; Huang, T.; Skitmore, M. A review of studies on prefabrication in construction project management. Autom. Constr. 2014, 39, 113–125. [Google Scholar] [CrossRef]

- Tran, T.B.; Dinh, T.P.; Nguyen, T.D.H.N.; Ly, D.H.; Kim, B.; Ahn, Y. An Integrated BIM-Based Application for Automating the Conceptual Design for Vietnamese Vernacular Architecture: Using Revit and Dynamo. Appl. Sci. 2025, 15, 6776. [Google Scholar] [CrossRef]

- Nguyen, T.D.H.N.; Ahn, Y.; Kim, B. Integrated Digital-Twin-Based Decision Support System for Relocatable Module Allocation Plan: Case Study of Relocatable Modular School System. Appl. Sci. 2025, 15, 2211. [Google Scholar] [CrossRef]

- Elghaish, F.; Abrishami, S. Developing a framework to revolutionise the 4D BIM process: IPD-based solution. CI 2020, 20, 401–420. [Google Scholar] [CrossRef]

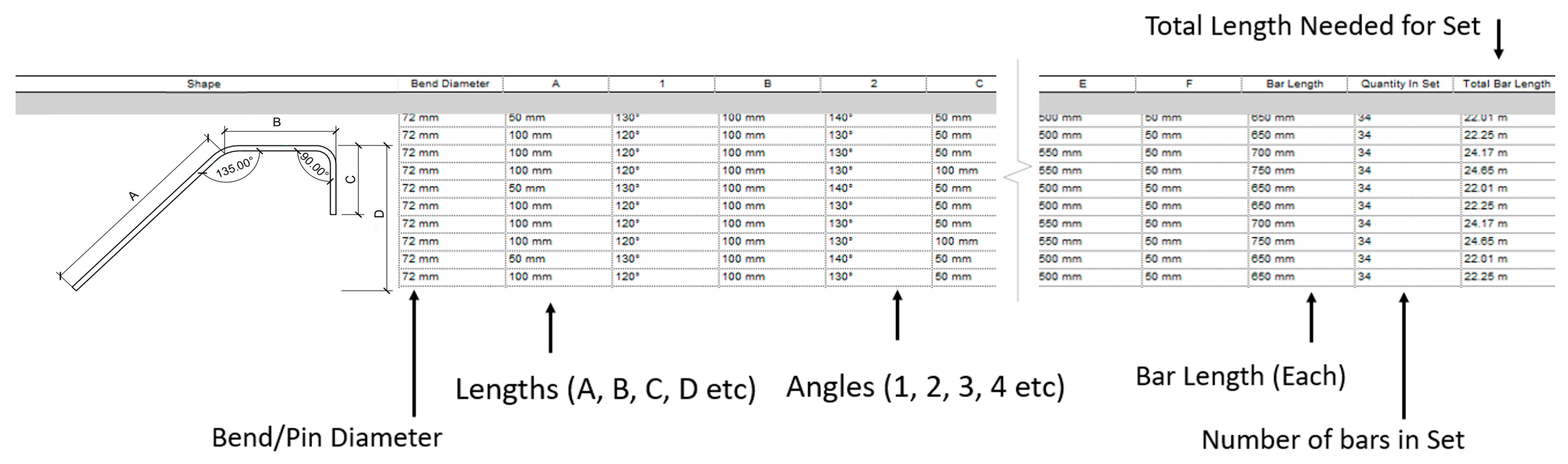

| Parameter Name | Parameter Type | Format/Units | Examples | Description |

|---|---|---|---|---|

| Standard Length | User Input | Integer/mm | 12,000 | The length of the bars supplied by the factory. |

| Week Number | User Input | Integer/Number | 2, 3, 4, etc. | Select the current week number (when cut-offs are created) and the next week’s number (when cut-offs are used). |

| Bar Type | Model Input | String (Category) | T12, T16, T20 | The type and diameter of the rebar. |

| Bar Length * | Model Input | Integer/mm | 6400 | Length of cut bar needed. |

| Host Type * | Model Input | String | 1P4 | The type of component that the rebar belongs to, i.e., CS1 Type Slab or 500 × 500 Column. |

| Host Mark * | Model Input | String | J8 | A unique code is assigned to each component in the model for identification purposes. |

| Bar Number | Model Input | Integer | 12 | A unique number assigned to each set of rebar within a component for identification purposes. |

| Cut-Off Length | Calculated Parameter | Integer/mm | 5600 | The length that is cut off each bar during fabrication, i.e., production length—bar length. |

| Min Length by Type | Calculated Parameter | Integer/mm | 400 | Defines the minimum length needed for each type of bar. Any length lower than this value will be categorized as waste. |

| Waste Length | Calculated Parameter | Integer/mm | 5600 | The length that is wasted after rebar sorting under their respective categories. |

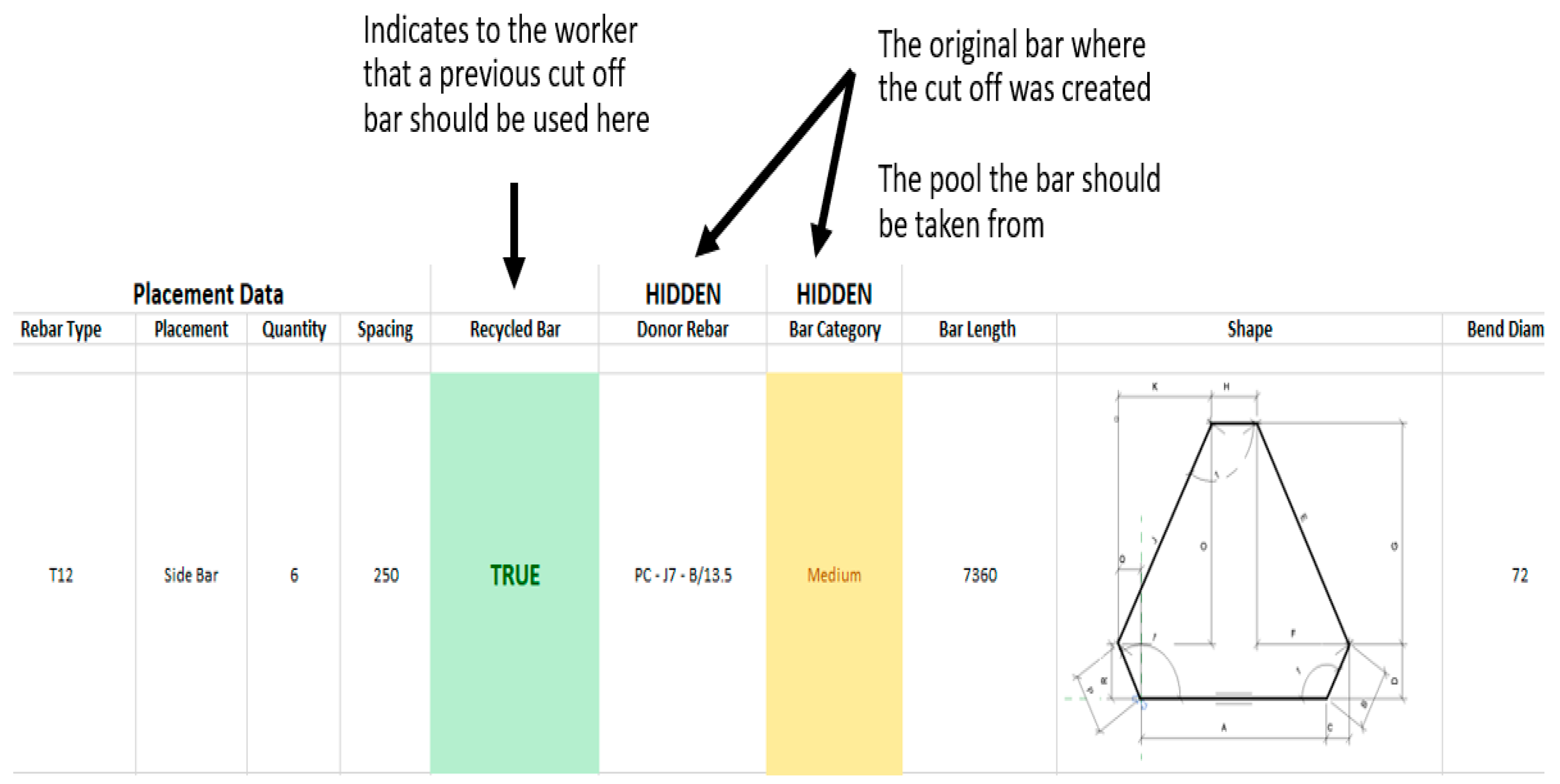

| Cut-Off Category | Calculated Parameter | String (Category) | Waste, Short, Medium, Long | Rebar categories for categorization and matching purposes. |

| New Bar Category | Calculated Parameter | String (Category) | Short, Medium, Long | Rebar categories for categorization and matching purposes. |

| Recycled Bar | Calculated Parameter | Boolean | True/False | Defines whether or not this bar is made from a fresh production length or a previous cut-off length. |

| Donor Rebar | Calculated Parameter | Combined String (Host Type + Host Mark + Rebar Mark) | PC–J7–B/13.5 | When Recycled Bar = True, this parameter shows which cut-off length can be used here. |

| Next Rebar | Calculated Parameter | Combined String (Host Type + Host Mark + Rebar Mark) | PC–J7–B/13.5 | If a match is found, this parameter shows where the cut-off length can be used next. |

| Element Type | Rebar Type (φ) | Total Length (m) | Waste Rebar Length (m) | Cost Savings (Converted to USD) |

|---|---|---|---|---|

| structural foundation | 8 | 79.52 | 2.24 | 34.21 |

| 12 | 71.69 | 0.32 | ||

| 14 | 109.76 | 34.24 | ||

| 18 | 44.8 | 3.2 | ||

| structural framework | 8 | 457.67 | 6.16 | 42.74 |

| 12 | 59.4 | 12.6 | ||

| 20 | 35.08 | 0.92 | ||

| 25 | 37.76 | 10.24 | ||

| structural column | 10 | 253.59 | 63.99 | 72.57 |

| 20 | 126.84 | 17.16 | ||

| 25 | 42.28 | 5.72 | ||

| structural wall | 8 | 50.6 | 0.18 | 24.09 |

| 10 | 454.22 | 55.78 | ||

| slab | 8 | 478.36 | 112.64 | 31.07 |

| 10 | 478.36 | 112.64 | ||

| stairs | 8 | 308.51 | 11.93 | 15.53 |

| 10 | 91.6 | 28.4 | ||

| Total cost savings | 220.21 | |||

| Element Type | Rebar Type (φ) | Total Tonnage (T) | Tons of Waste Generated (T) | Cost Savings (Converted to USD) |

|---|---|---|---|---|

| structural foundation | 8 | 1.09 | 0.04 | 877.51 |

| 12 | 2.22 | 0.01 | ||

| 14 | 4.65 | 1.66 | ||

| 18 | 3.14 | 0.26 | ||

| structural framework | 8 | 37.96 | 0.51 | 5231.24 |

| 12 | 11.08 | 2.34 | ||

| 20 | 18.20 | 0.47 | ||

| 25 | 30.53 | 8.28 | ||

| structural column | 10 | 38.33 | 9.67 | 11,495.22 |

| 20 | 76.76 | 10.38 | ||

| 25 | 39.88 | 5.40 | ||

| structural wall | 8 | 0.60 | 0.002 | 470.02 |

| 10 | 8.41 | 1.03 | ||

| slab | 8 | 39.68 | 9.34 | 10,901.50 |

| 10 | 61.98 | 14.59 | ||

| stairs | 8 | 1.71 | 0.07 | 141.60 |

| 10 | 0.79 | 0.25 | ||

| Total cost savings | 29,117.09 | |||

| Element Type | No of Production Bars Used | Tons of Waste Generated (T) | Weight Difference | % Change | Cost Savings (Converted to USD) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Best | Actual | Worst | Best | Actual | Worst | (Worst—Actual) | |||

| Pile Cap | 195 | 937 | 1123 | 0.03 | 27.14 | 33.35 | 6.20 | 23% | 3611 |

| Ground Beams | 40 | 161 | 183 | 0.04 | 0.99 | 1.47 | 0.47 | 48% | 261 |

| Slabs | 189 | 2089 | 9032 | 0.00 | 21.49 | 30.29 | 8.80 | 41% | 9302 |

| STP (Mixed) | 2878 | 5495 | 6439 | 0.01 | 52.81 | 64.88 | 12.066 | 23% | 7270 |

| Total | 3302 | 8682 | 16,777 | 0.082 | 95.70 | 129.98 | 34.28 | 36% | 20,653 |

| Case Study | Element Type | Tons of Waste Generated (T) | % Change | Cost Savings (Converted to USD) | ||

|---|---|---|---|---|---|---|

| Best | Actual | Worst | ||||

| 1 | structural foundation | 0.01 | 1.65 | 1.96 | 18% | 877.51 |

| structural framework | 0.07 | 8.27 | 11.62 | 40% | 5231.24 | |

| structural column | 0.04 | 19.38 | 25.45 | 31% | 11,495.22 | |

| structural wall | 0.002 | 0.78 | 1.03 | 32% | 470.02 | |

| slab | 0.02 | 14.59 | 23.94 | 64% | 10,901.50 | |

| stairs | 0.03 | 0.24 | 0.31 | 29% | 141.60 | |

| Total cost savings | 29,117.09 | |||||

| 2 | Pile Cap | 0.03 | 27.14 | 33.35 | 23% | 3611 |

| Ground Beams | 0.04 | 0.99 | 1.47 | 48% | 261 | |

| Slabs | 0.00 | 21.49 | 30.29 | 41% | 9302 | |

| STP (Mixed) | 0.01 | 52.81 | 64.88 | 23% | 7270 | |

| Total cost savings | 20,653 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Liu, Y.; Liao, X.; Chai, C.; Chong, H.-Y.; Huang, Y.; Zhou, Z. Optimizing Reinforcement Bar Fabrication in Construction Projects via Multi-Dimensional Applications in Building Information Modeling. Appl. Sci. 2025, 15, 10807. https://doi.org/10.3390/app151910807

Luo Y, Liu Y, Liao X, Chai C, Chong H-Y, Huang Y, Zhou Z. Optimizing Reinforcement Bar Fabrication in Construction Projects via Multi-Dimensional Applications in Building Information Modeling. Applied Sciences. 2025; 15(19):10807. https://doi.org/10.3390/app151910807

Chicago/Turabian StyleLuo, Yu, Yiminxuan Liu, Xiaofeng Liao, Changsaar Chai, Heap-Yih Chong, Yongtong Huang, and Zhaoyin Zhou. 2025. "Optimizing Reinforcement Bar Fabrication in Construction Projects via Multi-Dimensional Applications in Building Information Modeling" Applied Sciences 15, no. 19: 10807. https://doi.org/10.3390/app151910807

APA StyleLuo, Y., Liu, Y., Liao, X., Chai, C., Chong, H.-Y., Huang, Y., & Zhou, Z. (2025). Optimizing Reinforcement Bar Fabrication in Construction Projects via Multi-Dimensional Applications in Building Information Modeling. Applied Sciences, 15(19), 10807. https://doi.org/10.3390/app151910807