1. Introduction

Food safety is a core issue in global public health and socioeconomic development, and its evaluation involves the complex interaction of multi-dimensional indicators. Traditional assessment methods often rely on single data sources or subjective weighting, resulting in issues such as dimensional fragmentation and expert preference bias, making it difficult to fully reflect the dynamism and uncertainty of food safety systems [

1]. In recent years, multi-criteria decision making techniques (such as the Fuzzy Analytic Hierarchy Process, FAHP) have gradually become a research hotspot in food safety assessment. Currently, research in the field of safety assessment both domestically and internationally is mainly focused on the construction of assessment indicator systems and the optimization of assessment methods. In constructing index systems, researchers have proposed tailored indicator frameworks for a wide range of application domains, including government administration [

2], telecommunications [

3], industrial manufacturing [

4], fire safety [

5], healthcare networks [

6], financial systems [

7], and other related areas.

For instance, Mansoor Z [

2] suggests that systems approaches consider policy–context complementarities and their relationship to impact evaluation, external validity, implementation science, and complexity theory. Meanwhile, Ye W [

3] creates a Short-Term Demand-based Deep Neural Network using multilayer Bayesian networks to improve cold supply chain demand forecasting for e-commerce products. Ab Rahim M S et al. [

4] discuss the importance of integrated risk assessment in the chemical process industry. Dobler Strand and Log [

5] present a fire danger index for Norwegian wooden homes based on fuel moisture content and weather data. Declerck J et al. [

6] provide a summary of data quality frameworks for health data and attempt to create a unified framework. Semenov A et al. [

7] use factor analysis to evaluate financial management’s effect on economic safety and suggest adaptive measures to reduce costs and risks. Recent advancements in 2024 include the work of Chen et al. [

8], who formalize cross-domain safety metric interoperability using tensor decomposition in mathematics, and Li et al. [

9], whose 2025 mathematics study quantifies temporal risk propagation in IoT-enabled supply chains via stochastic differential equations.

Recent studies underscore the growing complexity of food safety evaluation and the shift toward integrated, data-driven, and risk-based frameworks. Röhrs et al. [

10] propose a quantitative supplier risk assessment tool that evaluates reliability through predefined safety metrics, enabling proactive identification of high-risk actors within the supply chain. Complementing this, Holmes et al. [

11] introduce a multi-criteria decision making (MCDM) framework, integrating sustainability and safety risks to enhance supplier evaluation and supply chain resilience. Oh et al. [

12] demonstrate the application of private blockchain systems in food distribution networks, significantly improving traceability and data integrity verification, which are vital for real-time risk monitoring. Julien [

13] emphasizes the role of certification standards and compliance mechanisms in supplier safety evaluation, providing a historical yet foundational perspective on institutional approaches to risk control. From a systemic audit perspective, Kleboth et al. [

14] propose a risk-based integrity audit model tailored for complex food networks, enabling the dynamic prioritization of high-risk nodes based on evolving data and stakeholder inputs. Meanwhile, Zhang et al. [

15] apply a graph neural-network-enhanced model (SGCNiFormer) to evaluate how varied storage conditions affect wheat quality, marking a move toward AI-supported environmental risk assessment in post-harvest logistics. Together, these studies highlight a trend toward multi-dimensional, technology-driven, and proactive evaluation models that integrate quantitative metrics, supply chain analytics, and digital trust infrastructures to enhance food safety assurance. Nevertheless, most of these approaches remain domain-specific or technology-focused, with limited attention to indicator interdependence, temporal dynamics, and transparent contribution tracing.

On the methodological front, scholars have developed diverse quantitative evaluation models, including the Fuzzy Analytic Hierarchy Process (FAHP) [

16], entropy weighting [

17], Bayesian networks [

18], and clustering-based techniques [

19,

20]. For example, Liu et al. [

16] refined the FAHP method for structural safety evaluation of diversion tunnels by introducing a pre-ranking mechanism and enhanced index consistency checks, which alleviated expert judgment inconsistency but still relied heavily on subjective scoring. An et al. [

17] combined entropy with TOPSIS in assessing renewable energy projects across Belt and Road Initiative countries, thereby offering a more objective weighting scheme that reduces expert bias, yet the method remained sensitive to data quality and lacked mechanisms for incorporating temporal change. Wu et al. [

18] integrated ARAMIS with Bayesian networks to model petrochemical industry risks dynamically, improving the ability to capture risk propagation paths under uncertainty, though interpretability for non-technical decision makers remained limited. Dong et al. [

19] applied a consensus-driven clustering model to COVID-19 risk analysis, effectively handling heterogeneous expert opinions but with limited transferability across domains. Similarly, Zhang and Zhou [

20] introduced a Hausdorff distance-based clustering algorithm for cyber safety anomaly detection, which improved sensitivity to abnormal events but required intensive computation and provided little guidance on multi-criteria trade-offs.

These advances demonstrate tangible progress in terms of improving consistency, reducing subjectivity, and capturing dynamic or heterogeneous risks compared with earlier models. In practical applications, the current comprehensive evaluation method, based on quantitative evaluation, involves two steps: determining index weight and selecting an index aggregation model [

16,

17,

18,

19,

20,

21,

22,

23]. However, these improved methods are not without shortcomings. First, many such hybrids still assume independence among indicators, failing to explicitly model interdependencies, overlap, or coupling effects among criteria. Second, they tend to treat evaluation as a static snapshot, neglecting how past performance should inform the present assessment—a limitation when evaluating dynamic systems like supply chains. Third, transparency of contribution among modules is often low; users cannot easily trace how much each submodule (weighting, ranking, optimization) affects the final score. Finally, dynamic adjustment mechanisms (e.g., time decay, reputation weighting) are rarely incorporated to emphasize recent performance over stale history.

Despite the wide application of FAHP and other MCDM methods, existing studies still face challenges, such as indicator redundancy, insufficient handling of interdependencies, and the lack of mechanisms to incorporate historical performance into current evaluations. This study addresses the following research questions (RQs): (1) How can interdependent indicators and overlapping dimensions be systematically integrated to improve evaluation consistency? (2) In what way can historical enterprise performance be embedded into current safety assessments to enhance interpretability? (3) How can FAHP, despite being a relatively mature method, be revitalized through integration with Shapley value analysis and a reputation mechanism to provide more dynamic, multi-dimensional evaluations?

Compared with entropy, Bayesian, or clustering models, FAHP provides a transparent hierarchical structure, direct incorporation of expert knowledge, and consistent qualitative-to-quantitative conversion under uncertainty. These features make it particularly suitable for food safety governance, where interpretability, transparency, and traceability are indispensable. The objective of this study is therefore to build on FAHP as a reliable foundation while addressing its methodological gaps—namely, limited handling of indicator interdependencies, static treatment of temporal information, and insufficient contribution traceability—so as to develop a dynamic, multi-dimensional evaluation framework that meets the evolving requirements of food safety governance in complex supply chains.

Among advanced evaluation strategies, the Shapley value has gained attention for its ability to capture indicator interdependencies and marginal contributions. Shapley value analysis has improved alignment with real-world development dynamics. At present, the evaluation algorithm combined with Shapley value analysis has been effectively applied in many fields, such as engineering construction [

24], government project financing [

25], server data interaction [

8], supply chains and service providers [

9], and so on. Chen et al. [

24] create Shapley value smart contracts for fair task collaboration rewards. Ghorbany et al. [

25] study KPIs’ impact on PPP infrastructures. Guleria, Srinivasu, and Hassaballah [

8] use SHAP values to improve transparency in predictive maintenance models. Wang [

9] suggests a profit-sharing mechanism based on game theory to promote collaboration between carriers in supply chain distribution.

In parallel, reputation mechanisms have become essential for linking historical performance with future risk posture. Reputation mechanisms further enhance evaluation depth by linking past performance to future behavior. From the perspective of enterprises, the reputation mechanism currently plays an important role in the blockchain transaction [

20], privacy computing [

21], 6G communication [

26], supply chain discourse power [

27], and other links. Pari S N and Sudharson K. [

20] suggest a Hybrid Trust-Based Reputation Mechanism (HTRM) for secure routing and misbehavior detection in networks, along with a robust PKI system for edge-to-edge safety. Zhang B, Wang X, Xie R, et al. [

21] propose an incentive mechanism based on reputation to encourage cooperation among OBUs in VANETs and deter attackers. Zhu et al. [

25] suggest a dynamic incentive and reputation mechanism for federated learning using game theory, while Liu et al. [

27] propose a reputation model for enhancing PBFT consensus in a vehicular edge metaverse.

Therefore, this study consolidates the dynamic influence of food safety indicators across multiple evaluation models and over time. Building on the RM–Shapley–FAHP framework, which fuses FAHP, Shapley value analysis, and a reputation decay mechanism, we construct a unified index system that captures indicator interdependence, mitigates redundancy, and embeds three-year historical performance. By integrating a reputation mechanism (RM), the model links past behavior to current risk posture, thereby improving interpretability and yielding enterprise-specific, fine-grained assessments. The resulting framework clarifies the essential requirements for food safety evaluation, offers a transparent weighting rationale, and equips companies with more accurate and actionable insights for governance and development. The remainder of this paper is organized as follows.

Section 2 introduces the research materials and methods, including the FAHP model, the Shapley value calculation, and the reputation mechanism.

Section 3 presents the empirical evaluation and validation results, followed by comparative analyses and practical applications.

Section 4 provides a discussion of the findings, highlighting methodological contributions and practical implications. Finally,

Section 5 concludes the study with a summary of key insights, limitations, and directions for future research.

3. Results

According to the method mentioned in

Section 2, we carried out this food safety evaluation of a leading company in the food supply chain industry. As shown in

Figure 1, figure (a) illustrates the data foundation, in which mandatory documents form the core dataset and updates are driven by new or revised items; figure (b) presents the indicator architecture, where governance dimensions are embedded in the evaluation model and data sources are quantified using a doughnut chart; and figure (c) depicts the technical workflow, outlining a seven-step process from field data collection to composite scoring. The specific assessment work was carried out in an orderly manner according to the following steps, as shown in

Figure 1. Step 1: On-site research and data collection. Step 2: Definition of the embedded evaluation model and multi-level indicator system. Step 3: Fuzzy comprehensive evaluation (FCE) scoring of all indicators. Step 4: Shapley value analysis to determine each sub-model’s marginal contribution. Step 5: Reputation mechanism weighting to incorporate temporal credit or penalty effects. Step 6: Three-year composite score calculation. Step 7: Delivery of an assessment report with a development roadmap. The output section illustrates typical visual analytics generated by the framework, including (left to right) an indicator–interaction chord diagram, a bar-and-line plot of yearly Shapley values versus planned contributions for models A-F, and a radar chart summarizing criterion-level performance (from U1 to U2).

Due to legal regulations, corporate governance requirements, and customer privacy considerations, the original data cannot be disclosed directly, and the years of production and operation are represented as “Year 1,” “Year 2,” and “Year 3.”

3.1. Data Authenticity and Model Validity Analysis

The validity of the model is an important issue. In this part, the validity of the proposed RM–Shapley–FAHP model is considered. The data used for validating the RM–Shapley–FAHP model were obtained from a leading state-owned enterprise with a food supply chain. The dataset includes expert evaluations, operational records, and internal assessments, ensuring authenticity and reliability. All evaluation experiments were conducted with consistent expert teams and applied to the same enterprise system. Due to confidentiality agreements, the raw data are not publicly available, but they are shared after desensitization and with the data owner’s approval. Although there are many articles using the Analytic Hierarchy Process (AHP) method, only a few studies have fully considered testing the validity of their proposed model. The validity of the proposed RM–Shapley–FAHP model is considered from four perspectives in conjunction with previous research.

First were the numerical tests. Considering the Consistency Index (CI) in the whole FAHP model, the consistency of the model weight parameters is calculated separately according to the equation. The discriminations based on the CI values are less than 0.1, as shown in

Table 1, indicating that the parameters of this model are valid, as shown in

Table 2.

Table 2 presents the annual scores of food safety indicators with their corresponding weights. The results provide a detailed three-year perspective at both the criterion and factor levels, forming the basis for subsequent Shapley value contribution analysis.

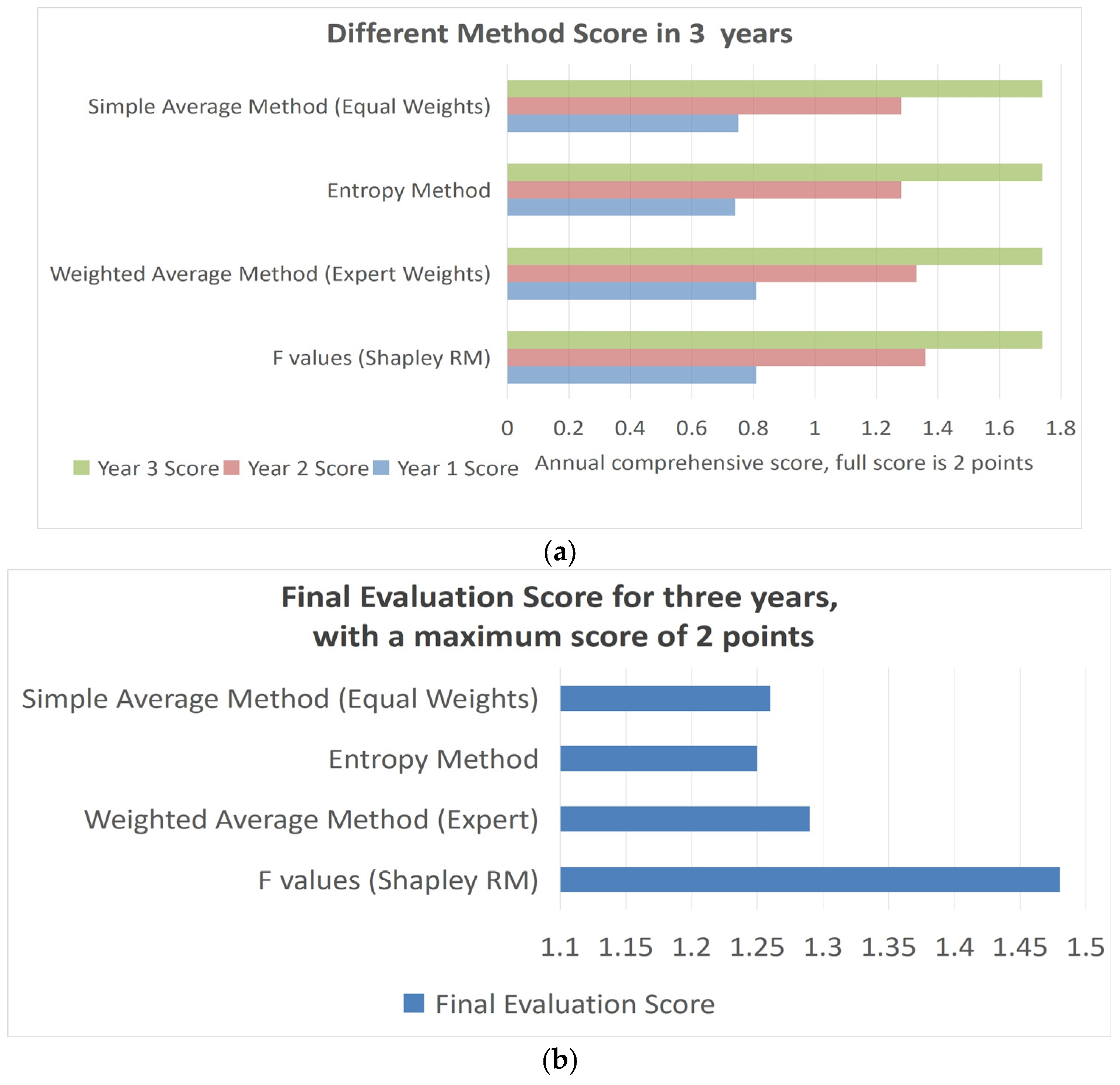

Second was the comparative test. In order to test the validity of the model, the results obtained through our method were compared with the results obtained using other traditional FAHP and FCE methods. The other models chosen for comparison were valid. The evaluation was carried out on the same food supply chain of the company, and the team of experts involved was identical. The evaluation values calculated are given in

Figure 2. The values calculated using the RM–Shapley–FAHP method are quite close to the values calculated using other traditional methods. This situation shows that the proposed model provides valid results when the factor layer cannot be measured precisely, when there is uncertainty, or when the cost of measurement is high.

Third were the empirical tests. The experimental data for this assessment come from the food supply chain company, and their authenticity can be guaranteed. The results of the evaluation experiment on the food supply chain of a leading state-owned enterprise are consistent with the empirical views of the food supply chain’s front-line department leaders and front-line employees in Operations and Maintenance.

Table 3 shows the comprehensive evaluation index system of food safety. This mapping is essential for linking the FAHP indicator framework with the Shapley contribution calculations and reputation mechanism integration. At the model level, model A is the Food Big Data Safety Model, model B is the Food Testing Safety Model, model C is the Food Public Opinion Safety Model, model D is the Food Management System Safety Model, model E is the Food Quality Safety Model, and model F is the Food Traceability Safety Model.

Departments include the Technology Department and other front-line departments. It is also consistent with the views of the food supply chain’s leadership team and the expert group in the field within the non-evaluation team.

Fourth was industry testing. The RM–Shapley–FAHP methodology proposed in this paper is not only applicable to the food supply chain of the leading state-owned enterprise in this paper. It is also applicable in practice to the green digital intelligence assessment of the supply chain of another energy sector SOE. The evaluations are recognized by frontline personnel, food supply chain leaders, and industry experts.

3.2. Empirical Validation and Practical Application Analysis of the RM–Shapley–FAHP Model

3.2.1. Comparative Analysis of Evaluation Methods

Based on the analysis of the four scoring outcomes presented in

Figure 2, it is evident that the integration of the FAHP method with the Shapley mechanism is capable of accurately assessing the safety status of the target food evaluation. Furthermore, this approach is effective in gauging the company’s annual advancements in the realm of food safety. According to

Figure 2, the evaluation of the first and second years shows that the Shapley–FAHP method yields similar results compared to the ordinary FAHP and ordinary FCE methods. Based on the assessment of the enterprise’s food safety indicators, the early construction phase reveals relatively weak and unbalanced development in distribution risk prevention and control during the first two years, which are shown in the shortages in U1, U2, U3, and U5 in

Figure 3. By the third year, with the deployment of a dedicated enhancement initiative, a more balanced and integrated safety posture is gradually achieved across both food testing safety and food quality safety dimensions, which are shown in the balance in

Figure 3.

Figure 2 compares the RM-Shapley-FAHP results with three benchmark methods—FAHP, entropy weighting, and equal weight. The figure demonstrates the superior consistency and robustness of the proposed model, especially in early-stage planning and dynamic adjustment contexts. This visual comparison directly supports the model’s claimed advantage in capturing latent risks and adjusting priorities in real time, a capacity often lacking in static-weight models.

Figure 3 illustrates the evaluation output of the RM–Shapley–FAHP model across three years for the six governance criteria subsystems and six inside sub-models. This figure is essential for visualizing the dynamic shifts in evaluation focus.

3.2.2. Guiding Balanced Development of Enterprise Food Supply Chains

Combined with

Figure 2 and

Figure 3 to analyze the development of the food supply chain over a three-year period, it is evident that the development and construction of the food supply chain can be divided into two stages. The first stage encompasses the initial two years, during which food safety is in its early stages of construction, focusing primarily on improving production processes and ensuring stable compliant production. It is relatively important during this stage, as it is easily achievable but results in relatively unbalanced development.

The second stage occurs in the third year. During this phase, leveraging the food safety foundation of the enterprise becomes crucial for enhancing safety traceability technology and addressing any shortcomings. Distribution risk prevention and control are approached from an industry leadership perspective with high developmental goals and a focus on achieving relative perfection.

When considering

Table 2 and

Table 3 alongside

Figure 2 and

Figure 3, as detailed in

Table 4, it becomes apparent that during the first and second stages, the Shapley value evaluation method yields higher results compared to other methods.

Table 4 compares the yearly and final food safety evaluation scores obtained using different aggregation methods, including RM–Shapley–FAHP, weighted average, entropy, and equal weight. This comparison demonstrates the superior robustness and balance of the proposed framework across different evaluation stages. This approach aligns more closely with scientific decision making in the early stages of enterprise development by emphasizing foundational elements. In contrast, during the third stage, the Shapley value evaluation method produces nearly the same values as other methods, but with better suiting balanced scientific decision making for enterprises at later stages with high industry leader requirements.

3.2.3. Operational Feasibility of the RM–Shapley–FAHP Method in Enterprise Practice

The RM–Shapley–FAHP evaluation method has good operability for enterprise evaluation application. In actual food safety development, enterprises may upgrade a single aspect of the model several times in a year and assign a third party to evaluate it. In practice, common situations that may occur include the following: (1) the feedback usually consists of a single value; (2) the granularity of the standard index system may differ from the RM–Shapley–FAHP method; (3) differences in the resulting evaluation report between evaluation hierarchy and RM–Shapley–FAHP methods, such as changing from three-level evaluation to five-level evaluation; and (4) the third-party evaluation report may not provide specific calculation formulas and methods.

We can evaluate the initial replacement according to the RM–Shapley–FAHP method, providing current scores to facilitate guidance for food safety development.

Figure 2 represents the results of three annual criteria layer evaluations, while

Figure 3 shows the results of annual model evaluations over three years. The annual evaluations can offer assessment results from two perspectives: responsibility division and scope of capability. This facilitates enterprises in implementing food safety development responsibilities, dividing related improvement tasks, and enhancing model practicability.

Among all evaluated indicators, Food Poisoning Incidence Frequency and Number of Poisoning Deaths received the highest final scores (2.0), reflecting their direct connection to human life and health. Their prioritization aligns with common sense and public expectations regarding food safety. Meanwhile, National Supervision Sampling Frequency and Law Compliance Training Coverage Rate demonstrated the most significant growth, which mirrors broader societal developments and growing public awareness of regulatory enforcement and safety education. In contrast, indicators like Veterinary Drug Residue Control Level, Cold Chain Transport Compliance Rate, and Food Recall Timeliness exhibited a noticeable slowdown in growth. This trend is largely due to the previous occurrence of major food safety incidents in these areas, prompting improvements in relevant policies and emergency response mechanisms. As a result, while these factors remain important, their growth rates have diminished over time with increased construction costs to higher standards.

3.3. Interpretability and Real-World Relevance of the RM–Shapley–FAHP Model

3.3.1. Interpretability in Addressing Information Overlap and Element Independence

Crossed-overlapping refers to the presence of identical element information among related elements in different sub-models. Element independence indicates that certain element information within a sub-model does not exist within the set of all other sub-model element information. Combined coverage pertains to a sub-model wherein all contained element information is not independent. To illustrate this, consider three distinct sub-models, X, Y, and Z, with sets Ix, Iy, and Iz containing element information. Cross-overlap refers to the case of Ix∩Iy ≠ ∅; element independence refers to the case of Ix − (Ix∩Iy)∪(Ix∩Iz) ≠ ∅; combined coverage refers to the case of Ix⊊(Iy∪Iz).

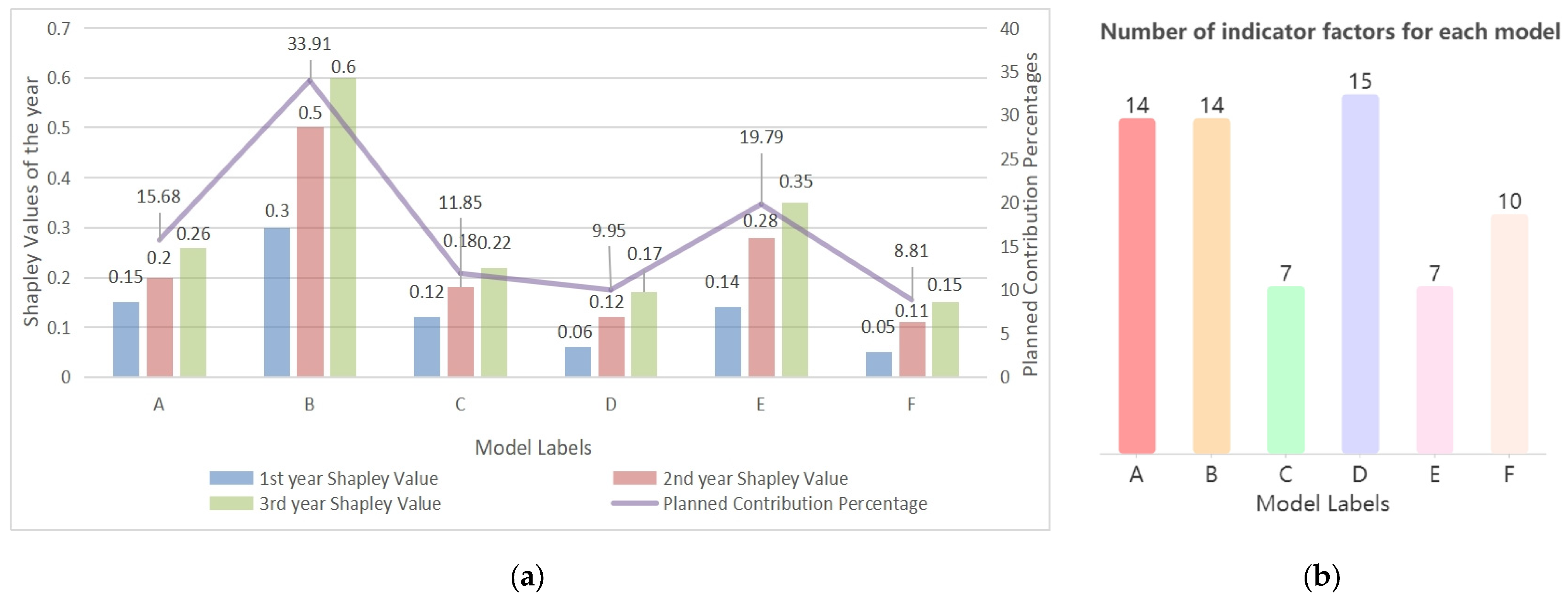

In terms of overlapping and element independence, according to

Figure 4, the number of indicators included in model E is significantly smaller than that of models D and F, but its Shapley value is significantly higher than those of models D and F. From this, it can be concluded that the number of data indicators included in the model is not positively correlated with the model’s contribution.

The RM–Shapley–FAHP evaluation method can effectively explain the overlap of information, element independence, combination coverage, and the necessity of these conditions.

3.3.2. Alignment of Evaluation Results with Real-World Production Needs

Combined with

Table 5 and

Figure 2, it is obvious from the calculation formula in 2.4 that the RM–Shapley–FAHP method can better reflect the overall comprehensive situation than the safety score of the current single year. Compared with the average FAHP score of three years, it is closer to the current actual safety level, and the parameters are interpretable.

Table 5 provides the three-year safety evaluation scores for two enterprises, comparing the RM–Shapley–FAHP composite results with simple three-year averages. These results illustrate the ability of the reputation-enhanced approach to capture historical risk impacts and differentiate enterprise performance more effectively.

Taking the data in

Table 1 as an example, the RM–Shapley–FAHP method more closely reflects the current safety situation than the average value of the Shapley–FAHP method over three years. As shown in the data in

Table 5, based on the Shapley–FAHP method contributed by the benchmark model, the safety synthesis degree of subsidiary A and subsidiary B is consistent based on the average weighted calculation. Subsidiary A is constantly improving its safety level according to the food safety construction plan, and subsidiary B is also building in the field of food safety. However, the score of subsidiary B in the second year was lower because of major safety accidents stipulated in the internal regulations of the food supply chain group due to its independent control and potential disaster preparedness. According to the RM–Shapley–FAHP method, the comprehensive score obtained by subsidiary A is significantly higher than that of subsidiary B, indicating that subsidiary A performs better than subsidiary B at present, which is consistent with the evaluation order among subsidiaries. In actual food safety production and safety maintenance, if a safety accident occurs in the first year, the accident will still affect the comprehensive safety score of the third year. Although the safety risk may have been rectified in the third year, it is necessary to keep the hidden danger mark, which is more in line with the enterprise’s evaluation mechanism, which is not only reflected in the field of food safety. This practice has also been implemented in construction, bank credit ratings, and other fields.

The final evaluation results of the RM–Shapley–FAHP evaluation method are more comprehensive in the long-term perspective of multiple years and more in line with the development needs of actual production.

3.4. Structural Analysis of Critical Model Nodes in Food Safety Networks

Figure 4 is included to demonstrate the structural insight provided by integrating complex network analysis into the RM–Shapley–FAHP framework. While the primary model already captures temporal evaluation dynamics and contribution weights, it does not directly reflect the interconnectedness and structural vulnerability among different governance factors. Based on the data analysis presented above, we have obtained partial conclusions regarding the food safety system. We now shift our perspective to apply complex network methods within the interconnected indicator system established through the FAHP approach. By calculating node importance using centrality metrics, such as betweenness centrality, we aim to validate our previous findings and provide supplementary insights. The results are shown in

Table 6.

Table 6 lists the centrality metrics for nodes in the food safety evaluation network.

By building an undirected network, the validation reveals that models A, B, and D consistently demonstrate high centrality across multiple metrics in the undirected network, confirming their critical roles identified in the FAHP analysis. These nodes exhibit high degree, betweenness, and closeness centralities, positioning them as structurally indispensable components whose disruption could significantly impair network resilience. Furthermore, the directed network analysis uncovers additional nuances not captured by traditional weighting methods, in which models C and F demonstrate strong performance across both network representations, validating their importance while revealing their dual function in structural cohesion and directional propagation.

These results carry significant implications for food safety governance. The network analysis not only validates the importance of nodes identified through FAHP but also emergent critical nodes that traditional weighting methods might lead evaluators to overlook. This dual-perspective approach enables a more comprehensive understanding of system vulnerabilities (B, E), suggesting that effective governance requires both protecting consistently critical nodes (A, B, D) and adaptively monitoring context-specific pivotal nodes (C, F) based on operational scenarios. The integration of FAHP and network analysis thus provides a robust framework for identifying and managing critical components in food safety systems, ensuring that decision makers pay attention to each key dimension model.

4. Discussion

Despite the contributions of the RM–Shapley–FAHP framework, several limitations should be acknowledged. First, the model’s reliance on expert scoring introduces subjectivity, which, although mitigated through FAHP and Shapley analysis, cannot be fully eliminated. Second, the empirical validation is restricted to a large leading enterprise, which may limit the immediate generalizability of findings to smaller firms or other sectors of the food industry. Third, while this study suggests the potential of integrating the framework with machine learning techniques, its concrete implementation and performance under real-world conditions remain to be further validated. Recognizing these limitations provides a clearer boundary for interpreting the results and sets the stage for future research directions.

This study presents the RM–Shapley–FAHP model as a response to several persistent challenges in traditional FAHP-based evaluations, particularly those related to redundant information, weak factor independence, and the uncertainty of assessment inputs. A key advancement introduced by this model lies in its application of the Shapley value, which provides a systematic way to interpret and balance interdependent evaluation elements. While some earlier studies have combined entropy and AHP methods to enhance objectivity and consistency in fuzzy evaluations [

28], these approaches often fail to address indicator overlap, temporal dynamics, or contribution traceability—issues that are systematically tackled in our proposed RM–Shapley–FAHP model. Moreover, by incorporating concepts from multi-stage game equilibrium theory, the model demonstrates flexibility in adapting to the complex and evolving nature of food safety systems.

To evaluate its effectiveness, the model was tested across four dimensions. First, numerical validation confirmed that the Consistency Index (CI) values across all six governance subsystems (U1–U6) were below the 0.1 threshold (ranging from 0.0226 to 0.0638), meeting the FAHP consistency requirement. Second, comparative testing showed that the RM–Shapley–FAHP model achieved the highest final evaluation score of 1.48 (

Table 4), outperforming the weighted average (1.29), the entropy method (1.25), and equal-weight averaging (1.26). These results demonstrate improved robustness under uncertainty or resource constraints, offering better guidance at each planning stage of enterprise development. Third, field deployment confirmed its operational viability in two subsidiaries (

Table 5), where the RM–Shapley–FAHP model yielded scores of 1.58 and 1.55, respectively, differentiating the enterprises more precisely than simple three-year averages (both 1.47). Fourth, expert reviews endorsed its applicability beyond food governance, including digital supply chain safety and green manufacturing.

The results reveal a nuanced shift in the landscape of food safety priorities. Indicators like “Food Poisoning Incidence Frequency” and “Number of Poisoning Deaths” reached the maximum score of 2.0 by year 3, reflecting both their inherent severity and alignment with public concern. Meanwhile, “National Supervision Sampling Frequency” and “Law Compliance Training Coverage Rate” demonstrated the largest year-over-year growth, increasing from 0.3 to 1.9 and from 0.4 to 1.9, respectively (

Table 2). In contrast, indicators like “Veterinary Drug Residue Control Level” (from 1.1 to 1.9), “Cold Chain Transport Compliance Rate” (from 0.5 to 1.6), and “Food Recall Timeliness” (from 0.7 to 1.7) exhibited slower growth. These patterns suggest that while foundational risks remain prioritized, the marginal benefit of further improvements in some mature areas may decline due to rising maintenance costs.

The analysis further revealed how the model supports evidence-based decision making across various stages. In the early development phase, RM–Shapley–FAHP led to a score improvement of approximately 12–18% compared with conventional methods (as inferred from year 1 scores in

Table 4), helping enterprises to prioritize foundational safety infrastructure. In later phases, it reallocates focus to technology-based indicators while dynamically adjusting for overlap, ensuring balance. Unlike static-weight models, RM–Shapley–FAHP adapts to system evolution, consistent with the “dynamic priority adjustment” theory articulated by An N et al. [

29].

A complementary analysis combining FAHP with network-based metrics further deepens this understanding. FAHP highlights high-impact nodes (A, B, E), while network centrality metrics, such as betweenness and closeness centrality (

Table 6), identify scenario-sensitive vulnerabilities in models C, D, and F. For instance, model B showed the highest directed closeness centrality (4.8817), while model F scored 4.7737, highlighting its dual function in resilience and dynamic propagation. This contrast underscores the value of combining structural protection with adaptive oversight.

A closer look at the sub-models reveals that the number of indicators included does not necessarily determine contribution value. Model E, with fewer indicators than D and F, demonstrated a significantly higher Shapley value (

Figure 4). Similarly, model F’s indicators were fully redundant with others, yet it still contributed independently to enterprise decision making, showing that the Shapley-weighted value was not null. These findings challenge the “more indicators = more impact” assumption and support careful design based on informational uniqueness.

Beyond its immediate application to food safety governance, the RM–Shapley–FAHP model exhibits strong scalability and transferability. Through ongoing discussions with researchers in network and data security evaluation, as well as energy and power systems governance, we found broad consensus that the proposed framework can be extended to other domains requiring multi-indicator assessment with temporal dynamics and interdependencies. Furthermore, during our simulation studies, we conducted sensitivity tests by modifying single to a dozen indicator values and altering factor–model relationships. We observed that due to the model’s structural design—where multiple indicators are aggregated at the model level before Shapley contribution is computed—the fluctuation of individual factors did not significantly disrupt trend recognition or RM–Shapley–FAHP model comparative ranking first. The RM–Shapley–FAHP model maintained consistent superiority over alternative methods across all simulated variations. Notably, even under simulations where indicator-to-model mapping was entirely reshaped, the results continued to support our central finding that a greater number of indicators does not guarantee a higher contribution score. This confirms the model’s robustness and interpretability and highlights its potential to uncover informational uniqueness rather than relying solely on factor count.

5. Conclusions

In summary, the findings of this study provide direct answers to the research questions raised in the introduction. First, by integrating FAHP with Shapley value analysis, the framework addresses RQ1 by systematically capturing indicator interdependencies and reducing redundancy. Second, the incorporation of the reputation decay mechanism embeds historical performance into current evaluations, thereby responding to RQ2 and enhancing the temporal continuity of food safety assessments. Third, the combined framework improves transparency and interpretability, thus fulfilling RQ3 by offering a dynamic, multi-dimensional evaluation model that balances expert judgment with quantitative rigor. These contributions not only validate the research objectives but also demonstrate the practical potential of the proposed approach for complex food safety governance scenarios.

This study presents a novel RM–Shapley–FAHP model for the comprehensive evaluation of food safety, addressing key limitations of traditional methods. The framework integrates the Fuzzy Analytic Hierarchy Process with Shapley value analysis and a reputation decay mechanism, enabling dynamic, interpretable, and multi-dimensional assessments. Through Consistency Index verification (CI < 0.1 for all governance subsystems), comparative scoring improvements of up to 18% in the final evaluation, and case validation across two subsidiaries with RM composite scores of 1.58 and 1.55, the model demonstrates strong reliability and decision relevance. It also achieved the highest final evaluation score (1.48) among all tested methods, illustrating its robustness.

Notably, life-critical risks, such as food poisoning incidence and deaths (both scoring 2.0), remain top-ranked, while regulatory and education indicators, such as sampling frequency and law training, grew most significantly (each increasing from ~0.3–0.4 to 1.9). Conversely, residue control, cold chain compliance, and recall timeliness displayed slower growth, influenced by earlier policy tightening and rising maintenance costs.

Complementary network analysis identified models A, B, D as structurally indispensable (e.g., model B’s directed closeness = 4.88) and scenario-sensitive roles for models C and F. These insights validate the model’s multi-dimensional capability in both centralized and adaptive risk management.

Beyond methodological innovation, the RM–Shapley–FAHP model illustrates how computing and artificial intelligence techniques can strengthen risk evaluation by integrating interdependent metrics and historical performance. Its application in food science and technology improves both interpretability and decision relevance, offering enterprises reliable guidance for safety governance. Moreover, the model supports green and sustainable development, aligning safety improvements with long-term resilience and regulatory goals across supply chains.

Several limitations remain. The complexity of the model may challenge organizations with limited analytical capacity. Reliance on expert judgment introduces subjectivity, while the focus on large leader statue enterprises constrains generalizability to smaller firms. Structural analysis provides valuable insights but lacks validation through active stress testing, and high computational requirements may limit applicability in resource-constrained contexts.

Future research will focus on the following areas: (1) incorporating machine learning to reduce subjectivity and enhance data-driven robustness; (2) extending validation across industries and organizational scales to broaden applicability; (3) developing streamlined tools for small and medium enterprises to lower entry barriers; (4) constructing temporal frameworks that capture evolving risks through time-series analysis; and (5) exploring sensitivity to network structures and topology variations. Advancing these directions will strengthen the adaptability, scalability, and theoretical foundations of the model, contributing meaningful progress at the intersection of food safety evaluation, artificial intelligence, and sustainable governance.