Enhancing Machinery-Aided Composting Through Multiobjective Optimization

Abstract

1. Introduction

- Three innovative multiobjective optimization models for the composting process are introduced.

- The first model focuses on minimizing the overall cost of the composting process while ensuring an efficient allocation of available machinery. The most notable feature of this model is that it directly reduces machine maintenance costs by ensuring a balanced use of all available machines.

- The second model builds upon the first, aiming to not only reduce costs but also maintain CO2 emissions at minimal levels. This model stands out by aligning itself with global sustainability goals by seeking a reduction in CO2 emissions.

- The third model prioritizes minimizing CO2 emissions while simultaneously maximizing the capacity for processing organic waste. The impact of this proposal is the robustness of the model, which allows its adaptation to large-scale composting facilities.

Related Work

2. Materials and Methods

2.1. Multiobjective Optimization Problem

2.2. Generalized Assignment Problem

2.3. Proposed Models

- Each compost pile must undergo exactly three processing operations per cycle, with each cycle lasting six days.

- Following each processing operation, the compost pile is required to remain at rest for one day.

- The working schedule consists of 8 h shifts, of which H hours are considered fully productive.

- A compost pile cannot be processed simultaneously by more than one machine.

- The uniformity of compost piles is not considered.

2.3.1. Model 1: Multiobjective Generalized Assignment Problem Approach (MOGAP)

Remark

2.3.2. Model 2: Constrained Multiobjective Generalized Assignment Approach (CMOGAP)

2.3.3. Model 3: Multiobjective Optimization Problem Approach (MOP)

3. Results

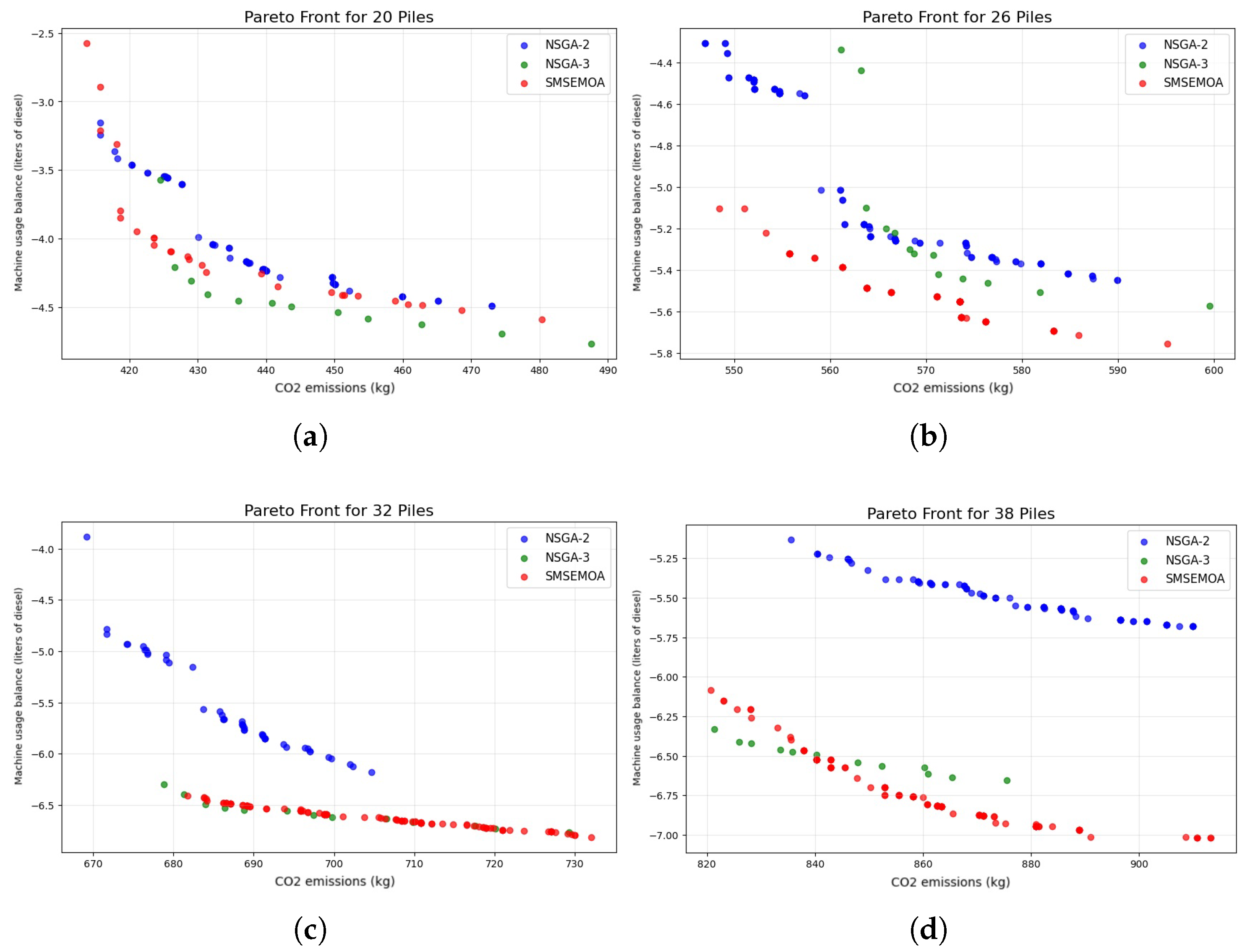

3.1. Solving Model 1

3.2. Solving Model 2

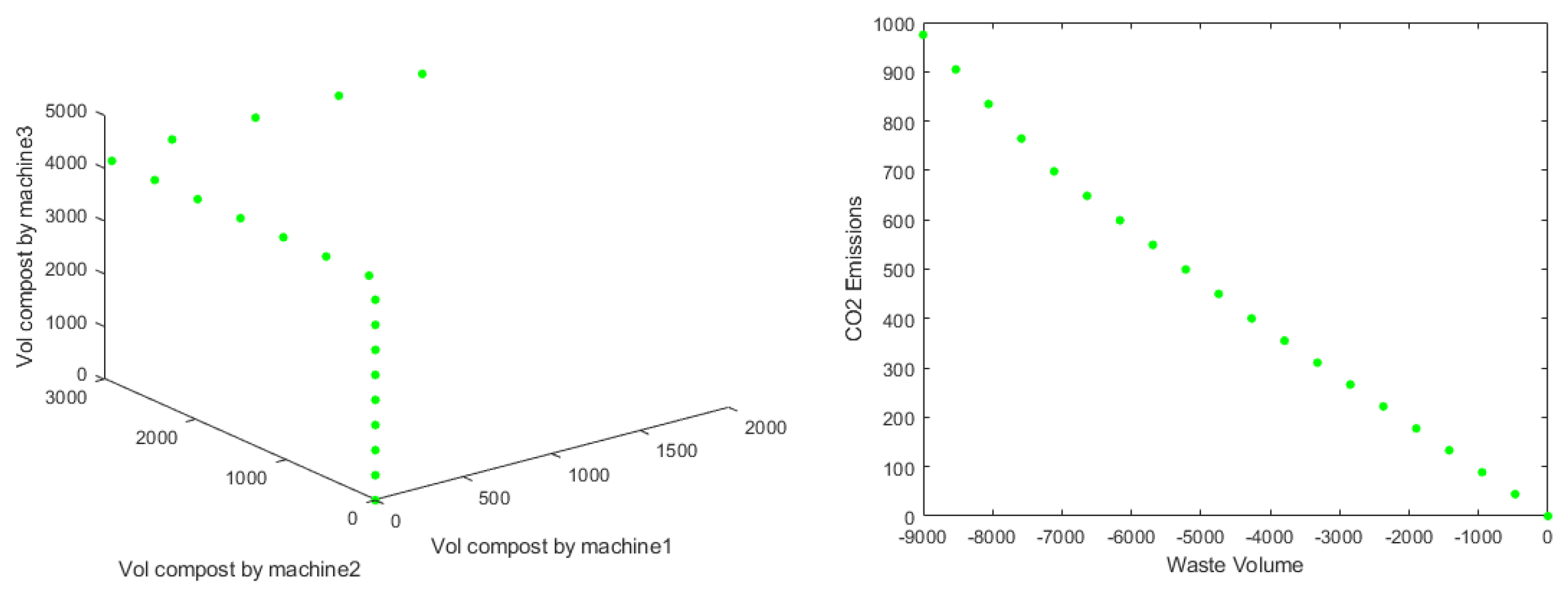

3.3. Solving Model 3

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MOP | Multiobjective Optimization Problem |

| GAP | Generalized Assignment Problem |

| ILP | Integer Linear Programming |

| GA | Genetic Algorithm |

| MOGAP | Multiobjective Generalized Assignment Problem Approach |

| CMOGAP | Constrained Multiobjective Generalized Assignment Approach |

| CO2 | Carbon Dioxide |

| NOx | Nitrogen Oxides |

| HV | Hypervolume Indicator |

References

- Dehghani, M.H.; Omrani, G.A.; Karri, R.R. Solid waste—Sources, toxicity, and their consequences to human health. In Soft Computing Techniques in Solid Waste and Wastewater Management; Elsevier: Amsterdam, The Netherlands, 2021; pp. 205–213. [Google Scholar]

- Lim, S.L.; Lee, L.H.; Wu, T.Y. Sustainability of using composting and vermicomposting technologies for organic solid waste biotransformation: Recent overview, greenhouse gases emissions and economic analysis. J. Clean. Prod. 2016, 111, 262–278. [Google Scholar] [CrossRef]

- Román, P.; Martínez, M.M.; Pantoja, A. Manual de Compostaje del Agricultor. Experiencias en América Latina. FAO: Rome, Italy, 2015. [Google Scholar]

- De Jesús, N.; Lara, A.; Uribe, L. Aplicación de un modelo Flow Shop con máquinas paralelas para optimización de ciclos de compostaje. Mem. De La RNAFM 2023, 28, 445–453. [Google Scholar]

- Andrade-Ibarra, Y.; Trejo-Ramirez, U.; Cuate, O.; Lara, A.; Uribe, L. Optimization of Generalized Assignment Problem for a Machinery-Aided Composting Process. In Proceedings of the Ibero-American Conference on Artificial Intelligence, Montevideo, Uruguay, 13–15 November 2024; pp. 453–457. [Google Scholar]

- Sokac, T.; Valinger, D.; Benkovic, M.; Jurina, T.; Kljusuric, J.; Redovnikovic, I.; Tušek, A. Application of Optimization and Modeling for the Composting Process Enhancement. Processes 2022, 10, 229. [Google Scholar] [CrossRef]

- Pang, J.; Ansari, M.; Zaroog, O.S.; Ali, M.H.; Sapuan, S. Taguchi design optimization of machining parameters on the CNC end milling process of halloysite nanotube with aluminium reinforced epoxy matrix (HNT/Al/Ep) hybrid composite. HBRC J. 2014, 10, 138–144. [Google Scholar] [CrossRef]

- Sharma, D.; Yadav, K.D.; Kumar, S. Biotransformation of flower waste composting: Optimization of waste combinations using response surface methodology. Bioresour. Technol. 2018, 270, 198–207. [Google Scholar] [CrossRef]

- Calabi-Floody, M.; Medina, J.; Suazo, J.; Ordiqueo, M.; Aponte, H.; Mora, M.d.L.L.; Rumpel, C. Optimization of wheat straw co-composting for carrier material development. Waste Manag. 2019, 98, 37–49. [Google Scholar] [CrossRef]

- Alavi, N.; Dehvari, M.; Alekhamis, G.; Goudarzi, G.; Neisi, A.; Babaei, A.A. Application of electro-Fenton process for treatment of composting plant leachate: Kinetics, operational parameters and modeling. J. Environ. Health Sci. Eng. 2019, 17, 417–431. [Google Scholar] [CrossRef]

- Salvia, M.; Cosmi, C.; Macchiato, M.; Mangiamele, L. Waste management system optimisation for Southern Italy with MARKAL model. Resour. Conserv. Recycl. 2002, 34, 91–106. [Google Scholar] [CrossRef]

- Ng, W.; Varbanov, P.; Klemeš, J.; Hegyhati, M.; Bertok, B.; Heckl, I.; Lam, H. Waste to energy for small cities: Economics versus carbon footprint. Chem. Eng. Trans. 2013, 35, 889–894. [Google Scholar]

- Malaysia, I. Optimal process network for municipal solid waste management in. J. Clean. Prod. 2013, 30, 1e11. [Google Scholar]

- Ross, G.T.; Soland, R.M. A multicriteria approach to the location of public facilities. Eur. J. Oper. Res. 1980, 4, 307–321. [Google Scholar] [CrossRef]

- Chrobak, M.; Feige, U.; Hajiaghayi, M.T.; Khanna, S.; Li, F.; Naor, S. A greedy approximation algorithm for minimum-gap scheduling. J. Sched. 2017, 20, 279–292. [Google Scholar] [CrossRef]

- Sahu, A.; Tapadar, R. Solving the Assignment Problem using Genetic Algorithm and Simulated Annealing. In Proceedings of the IMECS 2006, Hong Kong, China, 20–22 June 2006; pp. 762–765. [Google Scholar]

- Sethanan, K.; Pitakaso, R. Improved differential evolution algorithms for solving generalized assignment problem. Expert Syst. Appl. 2016, 45, 450–459. [Google Scholar] [CrossRef]

- Xia, C.; He, Q.; Jiang, Z.Z.; Chen, X.; Meng, X. A Discrete Differential Evolution Algorithm for the Multi-Objective Generalized Assignment Problem. J. Comput. Theor. Nanosci. 2013, 10, 2819–2825. [Google Scholar] [CrossRef]

- Kar, S.; Basu, K.; Mukherjee, S. Solution of a class of generalized assignment problem. J. Intell. Fuzzy Syst. 2017, 33, 1687–1697. [Google Scholar] [CrossRef]

- Kleeman, M.P.; Lamont, G.B. The multi-objective constrained assignment problem. In Proceedings of the 8th Annual Conference on Genetic and Evolutionary Computation, Seattle, WA, USA, 8–12 July 2006. [Google Scholar]

- Prakash, S.; Sharma, M.; Singh, A. Pareto optimal solutions for multi-objective generalized assignment problem. S. Afr. J. Ind. Eng. 2011, 21, 91–100. [Google Scholar] [CrossRef]

- Alsabt, R.; Alkhaldi, W.; Adenle, Y.A.; Alshuwaikhat, H.M. Optimizing waste management strategies through artificial intelligence and machine learning—An economic and environmental impact study. Clean. Waste Syst. 2024, 8, 100158. [Google Scholar] [CrossRef]

- Shravani, N.; Vigneshwari, S. Optimizing Waste Management through Intelligent Machine Learning Systems: A Comparative Study. In Proceedings of the 2023 14th International Conference on Computing Communication and Networking Technologies (ICCCNT), Delhi, India, 6–8 July 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Gruler, A.; Fikar, C.; Juan, A.A.; Hirsch, P.; Contreras-Bolton, C. Supporting multi-depot and stochastic waste collection management in clustered urban areas via simulation–optimization. J. Simul. 2017, 11, 11–19. [Google Scholar] [CrossRef]

- Liang, J.; Lin, H.; Yue, C.; Suganthan, P.N.; Wang, Y. Multiobjective Differential Evolution for Higher-Dimensional Multimodal Multiobjective Optimization. IEEE/CAA J. Autom. Sin. 2024, 11, 1458–1475. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, M.; Guo, X.; Qi, L.; Gao, K.; Albeshri, A. Multiobjective Scheduling of Energy-Efficient Stochastic Hybrid Open Shop With Brain Storm Optimization and Simulation Evaluation. IEEE Trans. Syst. Man, Cybern. Syst. 2024, 54, 4260–4272. [Google Scholar] [CrossRef]

- Lian, Z.; Gu, X.; Jiao, B. A Dual Similar Particle Swarm Optimization Algorithm for Job-Shop Scheduling with Penalty. In Proceedings of the 2006 6th World Congress on Intelligent Control and Automation, Dalian, China, 21–23 June 2006; Volume 2, pp. 7312–7316. [Google Scholar] [CrossRef]

- Ye, T.; Zhang, Z.; Zhang, Q.; Chen, J.; Wang, J. Solving Multiobjective Combinatorial Optimization via Learning to Improve Method. IEEE Trans. Emerg. Top. Comput. Intell. 2025, 9, 2122–2136. [Google Scholar] [CrossRef]

- Wei, T.; Guo, X.; Zhou, M.; Wang, J.; Liu, S.; Qin, S.; Tang, Y. A Multiobjective Discrete Harmony Search Optimizer for Disassembly Line Balancing Problems Considering Human Factors. IEEE Trans. Hum.-Mach. Syst. 2025, 55, 124–133. [Google Scholar] [CrossRef]

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 emissions of internal combustion engine vehicle and battery electric vehicle using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef]

- Blank, J.; Deb, K. Pymoo: Multi-objective optimization in python. IEEE Access 2020, 8, 89497–89509. [Google Scholar] [CrossRef]

- Zitzler, E.; Thiele, L.; Laumanns, M.; Fonseca, C.M.; Da Fonseca, V.G. Performance assessment of multiobjective optimizers: An analysis and review. IEEE Trans. Evol. Comput. 2003, 7, 117–132. [Google Scholar] [CrossRef]

| Name | Pile Width (m) | Required Power (m3/h) |

|---|---|---|

| Type I | 2.5 | 300 (70 HP) |

| Type II | 3.0 | 500 (80 HP) |

| Type III | 3.5 | 700 (95 HP) |

| Name | Maximum Volume (m3) |

|---|---|

| Type I | |

| Type II | |

| Type III |

| First Scenario | |||

|---|---|---|---|

| # Piles | SMS-EMOA HV | NSGA-II HV | NSGA-III HV |

| 20 | 0.6893 | 0.8077 | 0.7612 |

| std. | 0.1188 | 0.0513 | 0.0977 |

| 22 | 0.5879 | 0.7304 | 0.7099 |

| std. | 0.0946 | 0.0522 | 0.0653 |

| 24 | 0.4812 | 0.6411 | 0.6112 |

| std. | 0.1643 | 0.0538 | 0.0706 |

| 26 | 0.5430 | 0.7917 | 0.7355 |

| std. | 0.2108 | 0.0938 | 0.0967 |

| 28 | 0.5658 | 0.7148 | 0.6843 |

| std. | 0.1478 | 0.0855 | 0.0753 |

| 30 | 0.4381 | 0.6270 | 0.5917 |

| std. | 0.1708 | 0.0718 | 0.0851 |

| 32 | 0.5145 | 0.7598 | 0.5675 |

| std. | 0.2800 | 0.2071 | 0.1037 |

| 34 | 0.4950 | 0.7008 | 0.5788 |

| std. | 0.1593 | 0.0545 | 0.1048 |

| 36 | 0.4899 | 0.6509 | 0.5692 |

| std. | 0.1712 | 0.6824 | 0.0988 |

| 38 | 0.5509 | 0.6954 | 0.5747 |

| std. | 0.1417 | 0.0811 | 0.0687 |

| 40 | 0.5295 | 0.6876 | 0.6017 |

| std. | 0.1416 | 0.0614 | 0.1217 |

| 42 | 0.5087 | 0.6913 | 0.6252 |

| std. | 0.2148 | 0.1106 | 0.1410 |

| 44 | 0.5039 | 0.6821 | 0.6959 |

| std. | 0.2188 | 0.1115 | 0.1188 |

| Second Scenario | |||

| Cases | SMS-EMOA HV | NSGA-II HV | NSGA-III HV |

| 1 | 0.4066 | 0.4704 | 0.1970 |

| std. | 0.2751 | 0.2963 | 0.2405 |

| 2 | 0.4896 | 0.4838 | 0.3351 |

| std. | 0.2190 | 0.2477 | 0.2256 |

| 3 | 0.4762 | 0.5439 | 0.2632 |

| std. | 0.2128 | 0.1613 | 0.2233 |

| First Scenario | |||

|---|---|---|---|

| Piles | SMS-EMOA | NSGA-II | NSGA-III |

| 20 | 0.7979 | 0.6539 | 0.7593 |

| std | 0.0701 | 0.1715 | 0.1075 |

| 22 | 0.7528 | 0.5746 | 0.6947 |

| std | 0.0702 | 0.1422 | 0.0857 |

| 24 | 0.6407 | 0.5039 | 0.6488 |

| std | 0.0695 | 0.1483 | 0.0737 |

| 26 | 0.7765 | 0.5369 | 0.7291 |

| std | 0.0982 | 0.2264 | 0.1120 |

| 28 | 0.7452 | 0.6027 | 0.6725 |

| std | 0.0543 | 0.1194 | 0.0791 |

| 30 | 0.6212 | 0.4296 | 0.6095 |

| std | 0.0751 | 0.1757 | 0.0819 |

| 32 | 0.7581 | 0.5521 | 0.6921 |

| std | 0.1072 | 0.1903 | 0.1095 |

| 34 | 0.7280 | 0.5134 | 0.6908 |

| std | 0.0803 | 0.1775 | 0.0892 |

| 36 | 0.6578 | 0.5066 | 0.6283 |

| std | 0.0768 | 0.1637 | 0.0717 |

| 38 | 0.7164 | 0.5368 | 0.6845 |

| std | 0.0853 | 0.1485 | 0.1012 |

| 40 | 0.6661 | 0.5433 | 0.6559 |

| std | 0.0809 | 0.1317 | 0.0775 |

| 42 | 0.6847 | 0.4822 | 0.6473 |

| std | 0.0868 | 0.2525 | 0.1130 |

| 44 | 0.6959 | 0.6821 | 0.5039 |

| std | 0.1188 | 0.1115 | 0.2188 |

| Second Scenario | |||

| Cases | SMS-EMOA | NSGA-II | NSGA-III |

| 1 | 0.4263 | 0.4327 | 0.3402 |

| std | 0.3099 | 0.3264 | 0.2830 |

| 2 | 0.5123 | 0.4273 | 0.3458 |

| std | 0.2663 | 0.2413 | 0.2657 |

| 3 | 0.5096 | 0.5299 | 0.3588 |

| std | 0.1558 | 0.1853 | 0.2301 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uribe, L.; Andrade-Ibarra, Y.; Trejo-Ramírez, U.; Cuate, O.; Lara, A. Enhancing Machinery-Aided Composting Through Multiobjective Optimization. Appl. Sci. 2025, 15, 10754. https://doi.org/10.3390/app151910754

Uribe L, Andrade-Ibarra Y, Trejo-Ramírez U, Cuate O, Lara A. Enhancing Machinery-Aided Composting Through Multiobjective Optimization. Applied Sciences. 2025; 15(19):10754. https://doi.org/10.3390/app151910754

Chicago/Turabian StyleUribe, Lourdes, Yael Andrade-Ibarra, Uriel Trejo-Ramírez, Oliver Cuate, and Adriana Lara. 2025. "Enhancing Machinery-Aided Composting Through Multiobjective Optimization" Applied Sciences 15, no. 19: 10754. https://doi.org/10.3390/app151910754

APA StyleUribe, L., Andrade-Ibarra, Y., Trejo-Ramírez, U., Cuate, O., & Lara, A. (2025). Enhancing Machinery-Aided Composting Through Multiobjective Optimization. Applied Sciences, 15(19), 10754. https://doi.org/10.3390/app151910754