Preparation of Microlens Array Using Excimer Laser Motion Mask

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Principle Model for the Preparation of Microlens Arrays

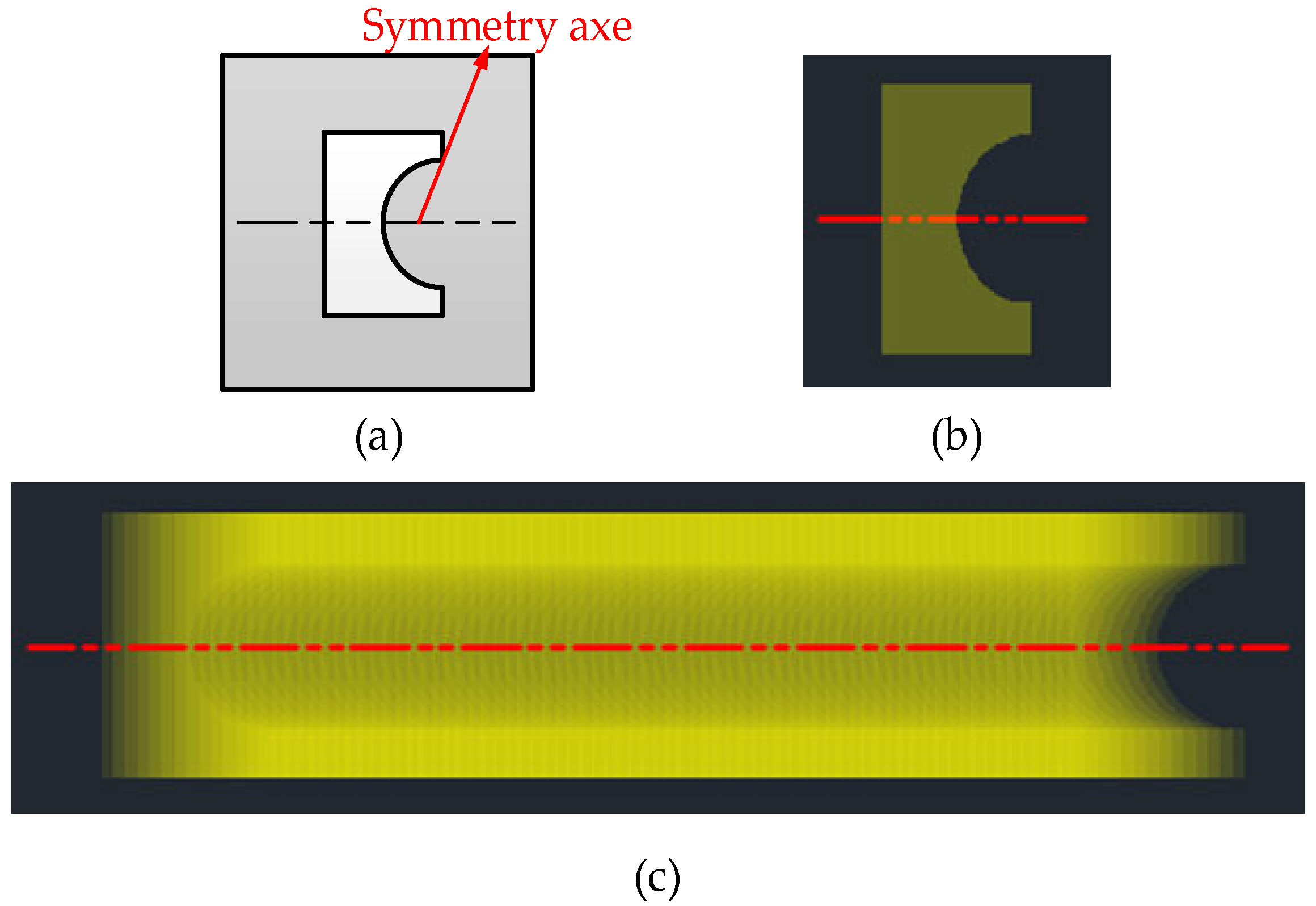

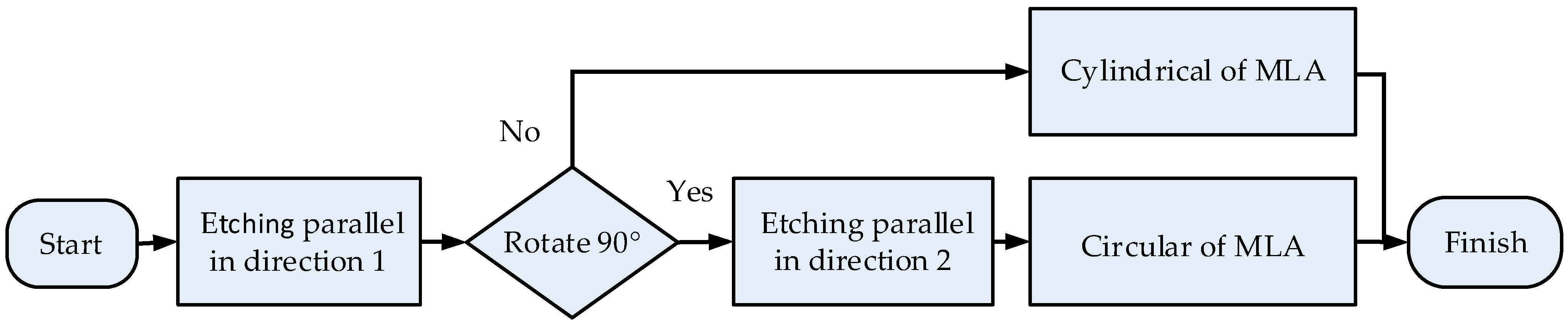

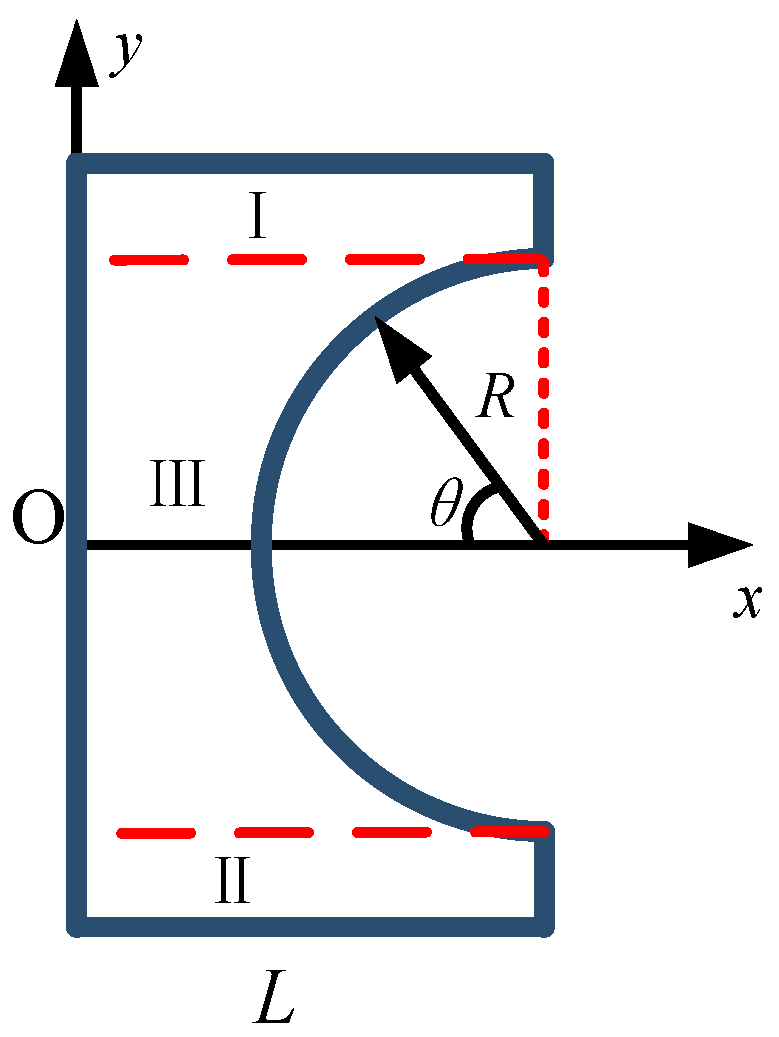

2.1.1. Principle Analysis Model of Excimer Laser Motion Mask Method

2.1.2. Mathematical Model of Excimer Laser Motion Mask Method

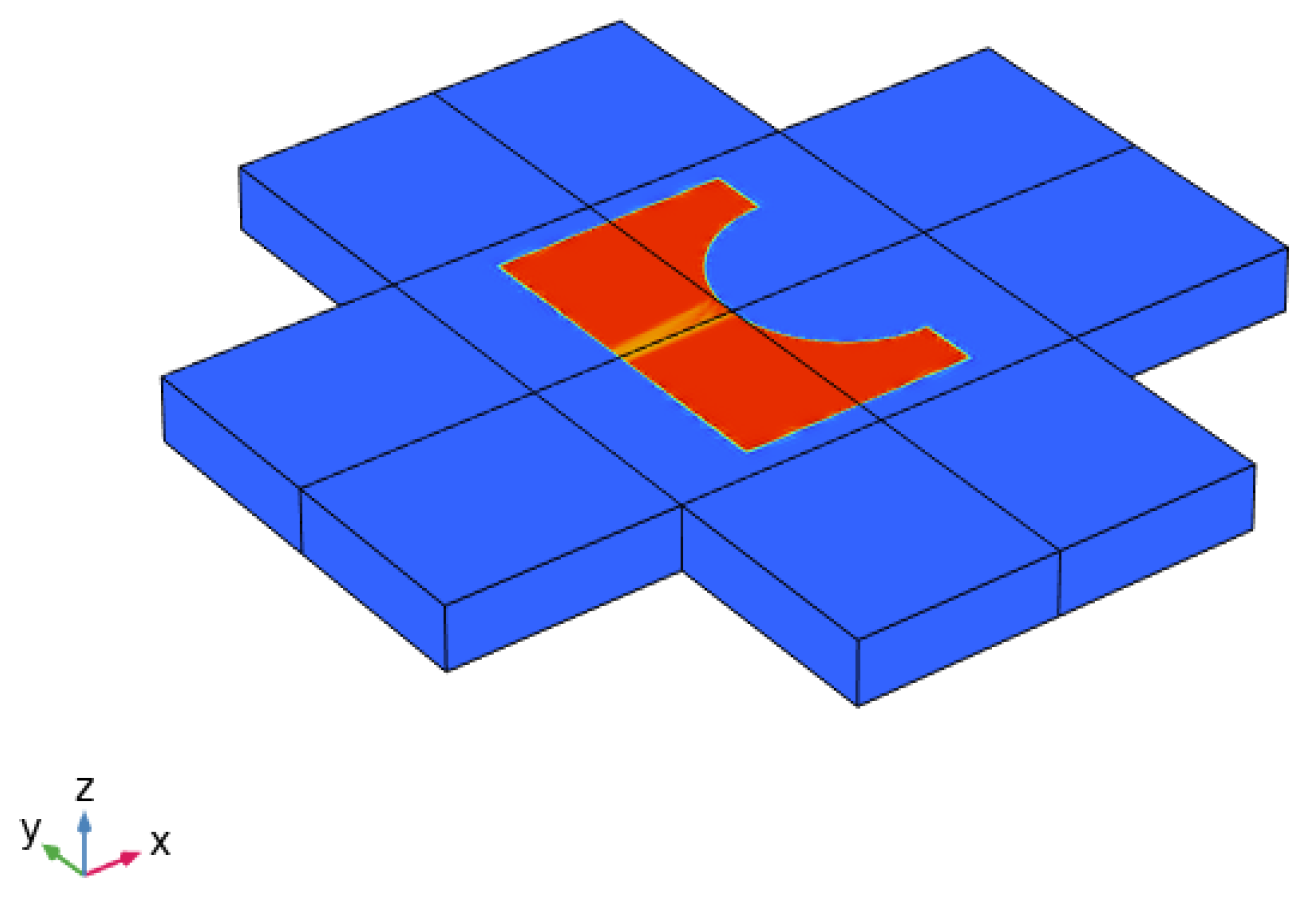

2.2. Numerical Calculation of Microlenses Prepared by Motion Mask Method

2.3. Experimental System and Procedures

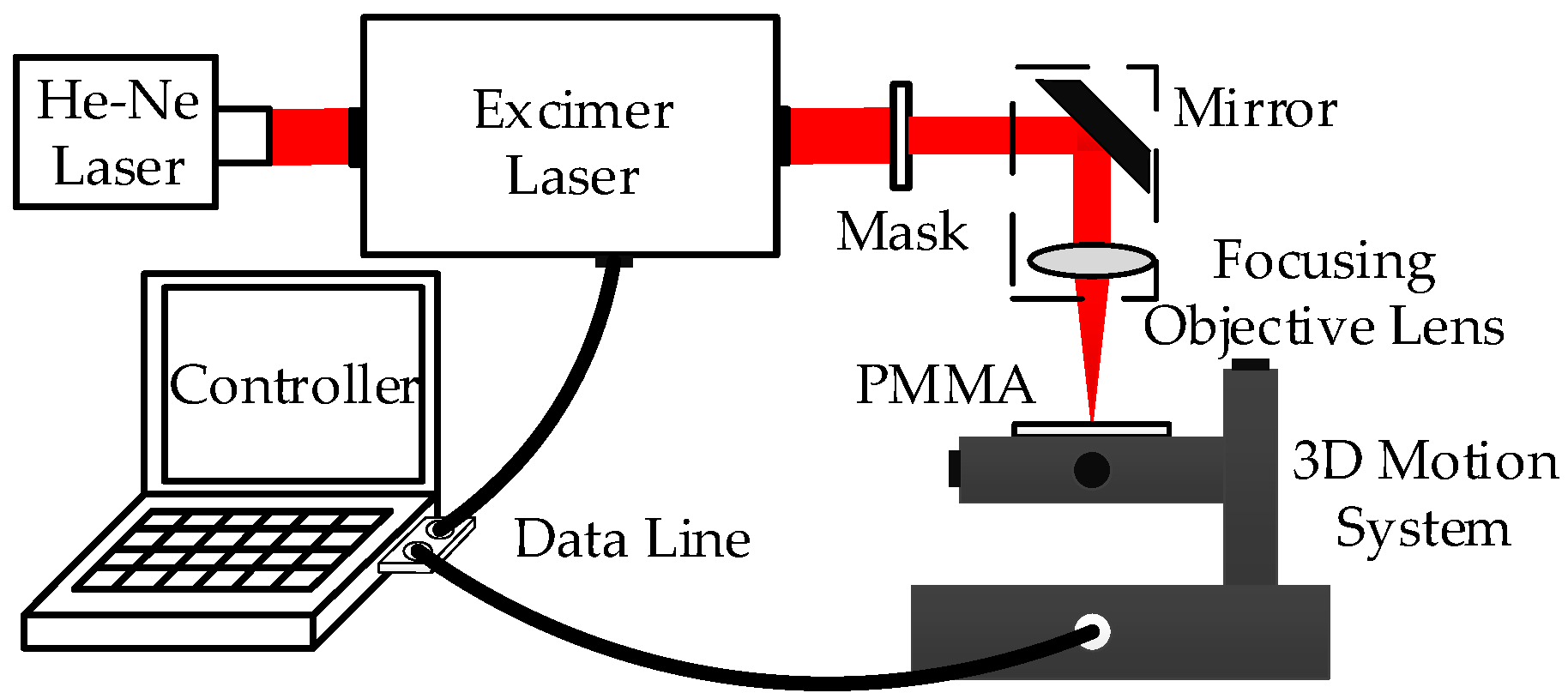

2.3.1. Experimental System

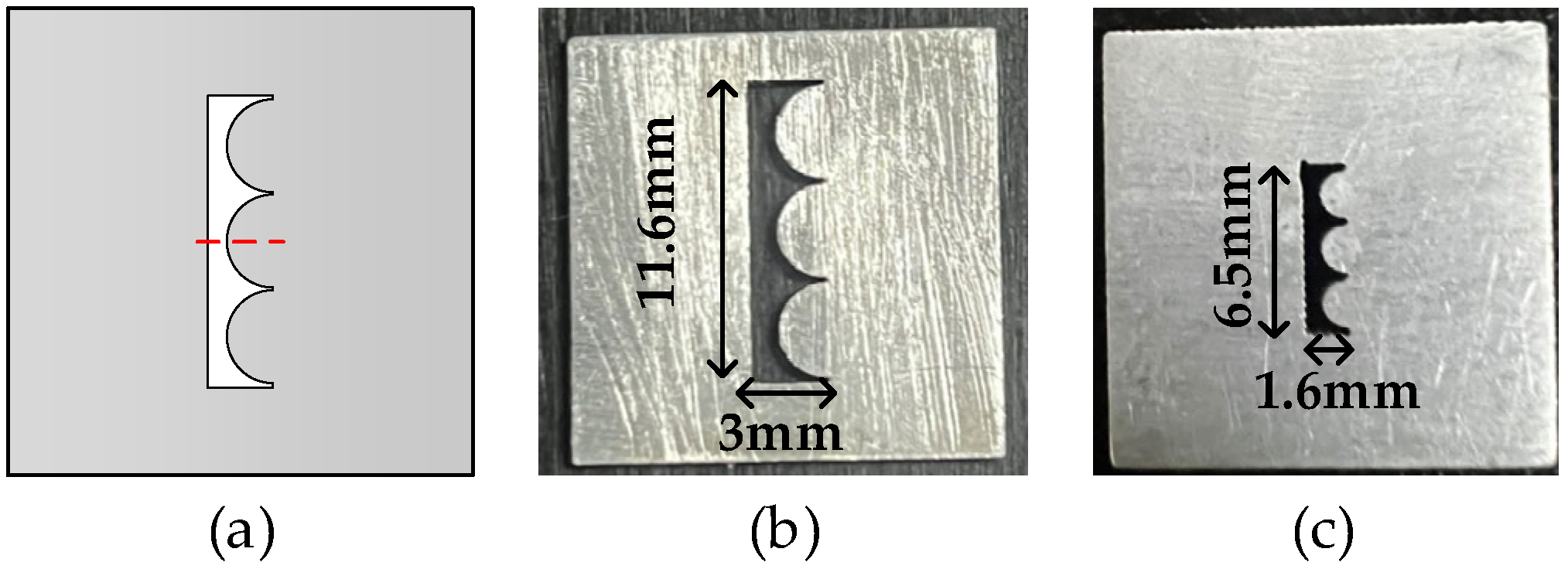

2.3.2. Experimental Method

3. Results and Discussion

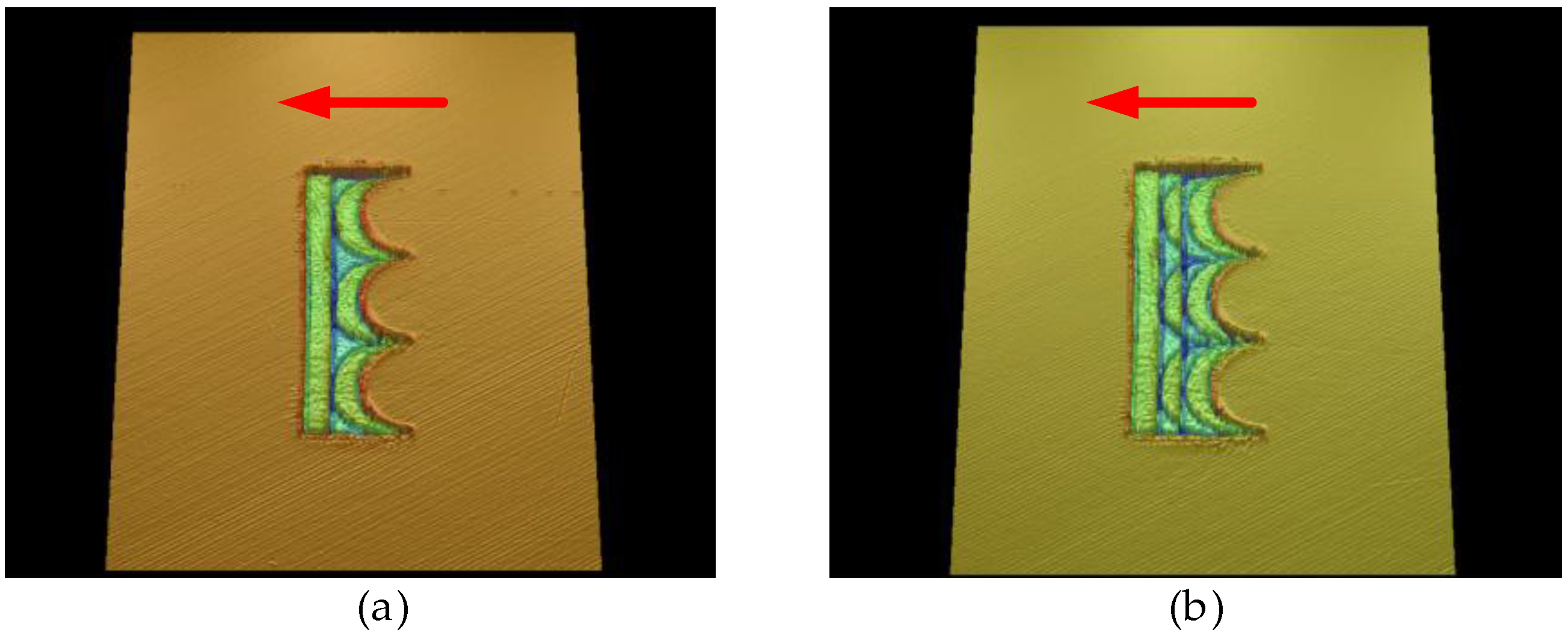

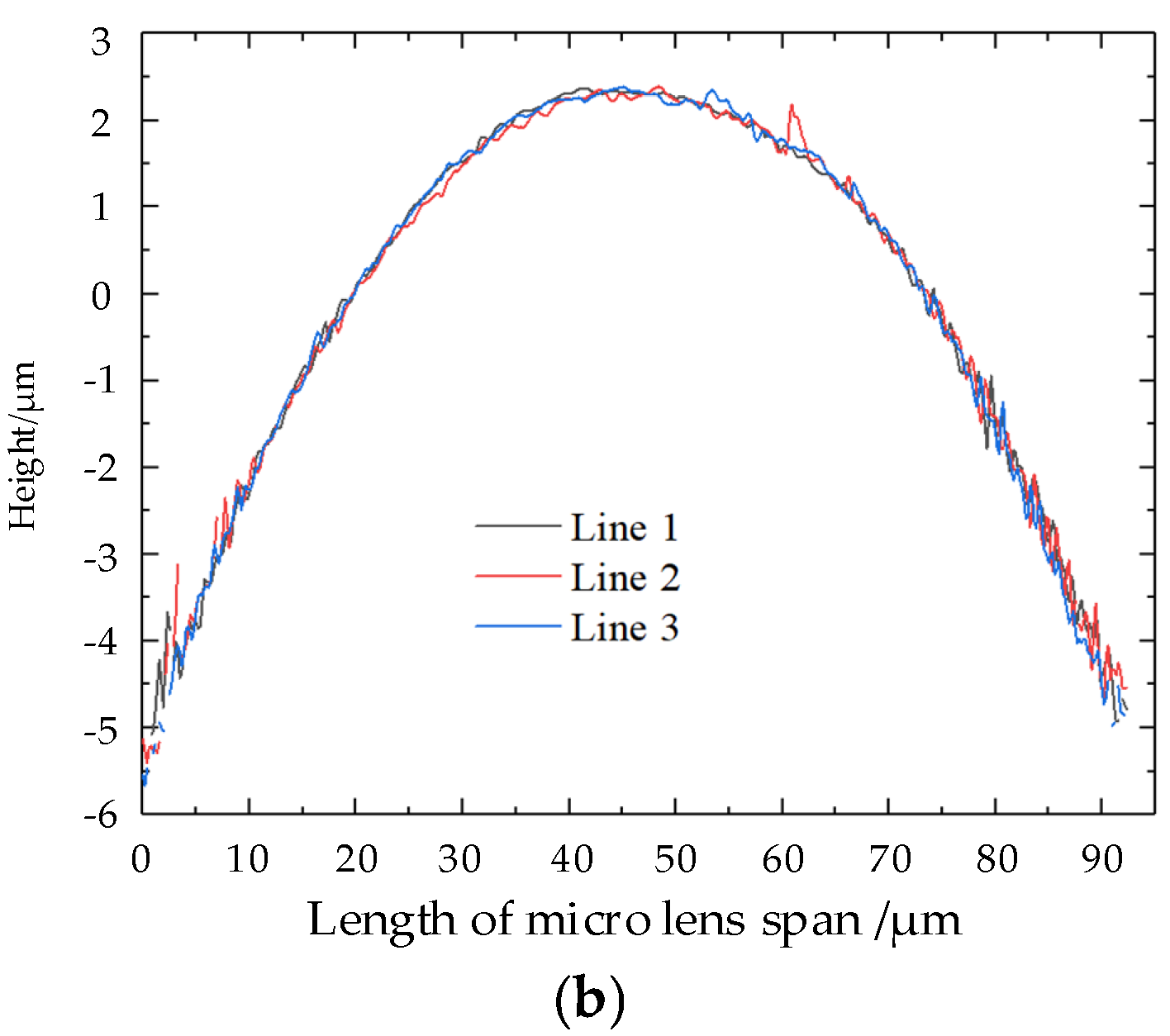

3.1. Principle Verification

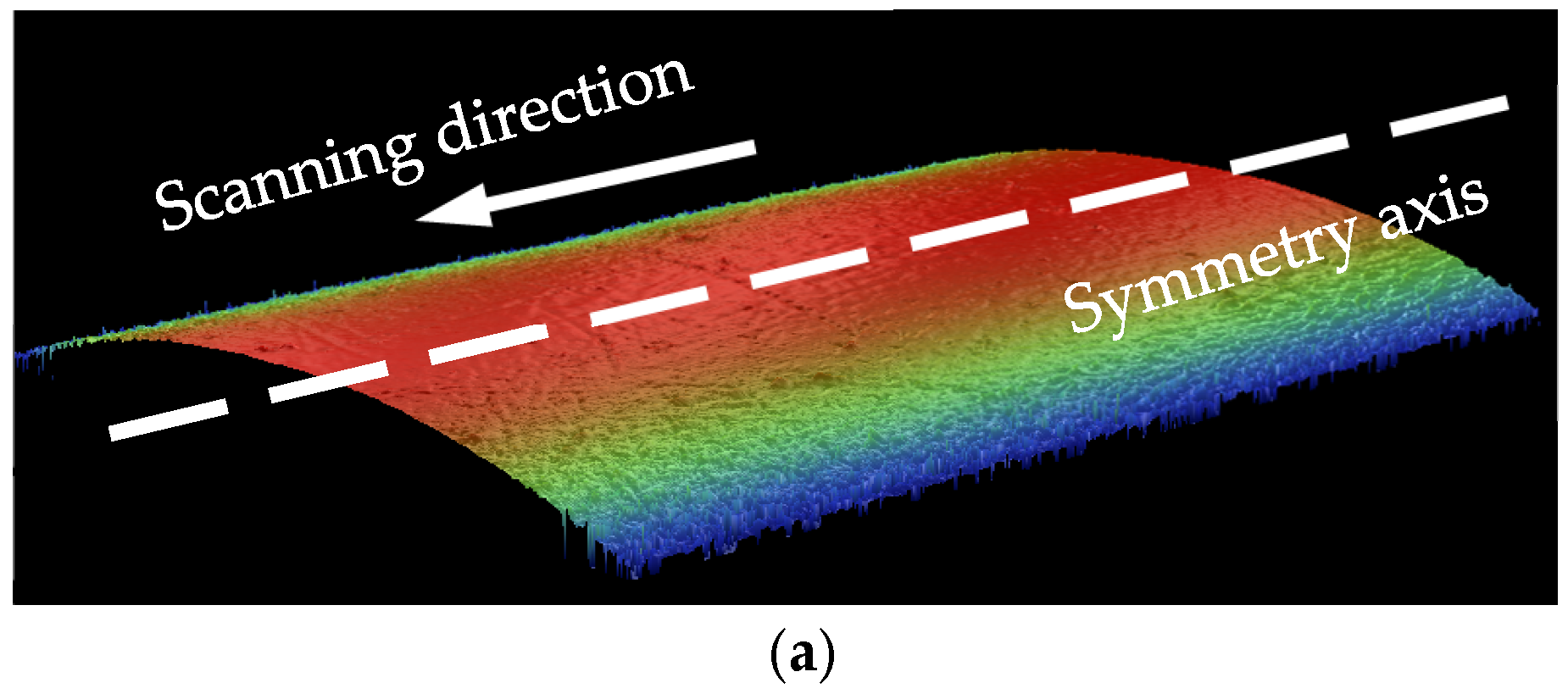

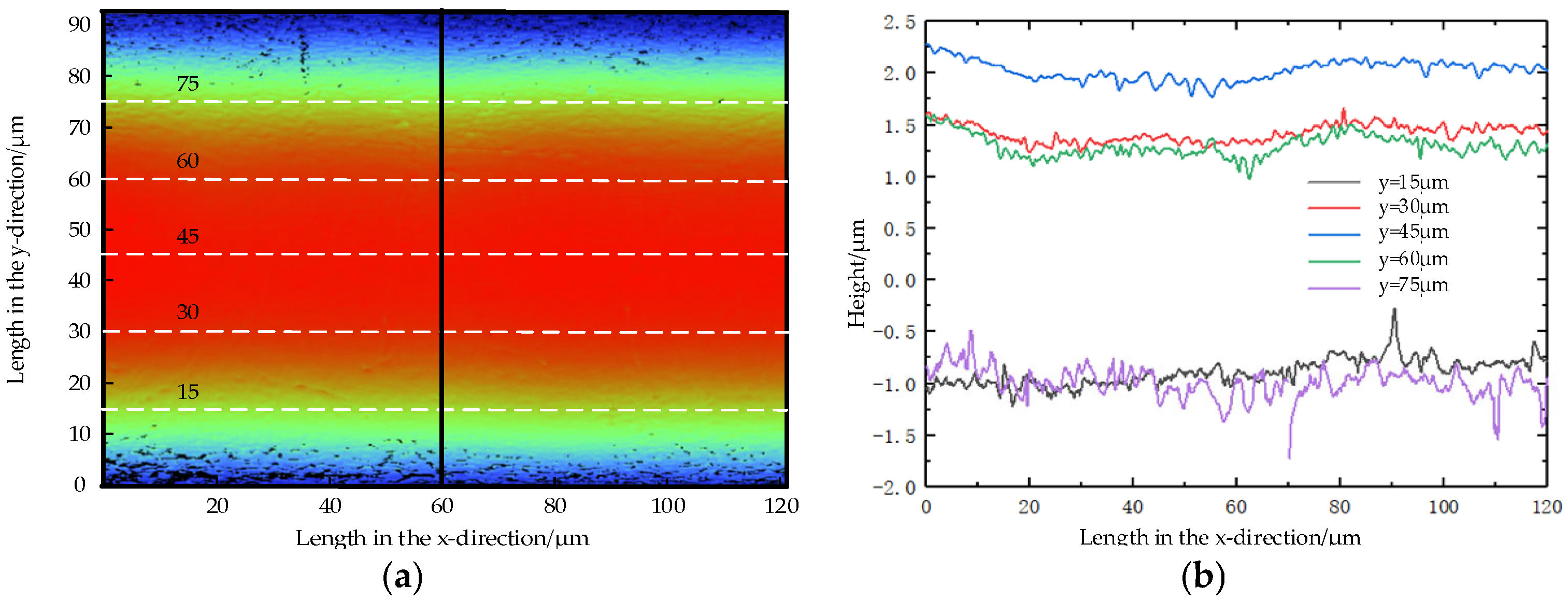

3.2. Measurement of Cylindrical Microlens Morphology

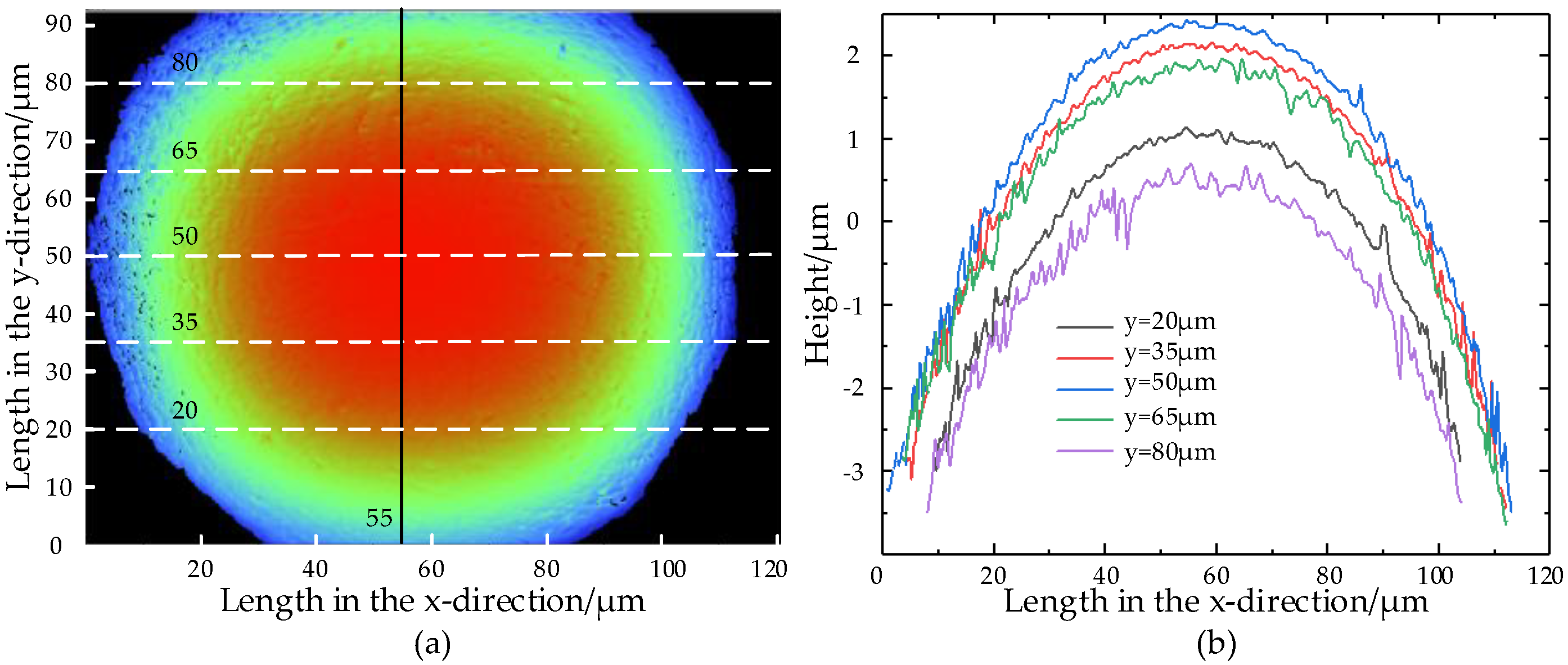

3.3. Measurement of Circular Microlens Morphology

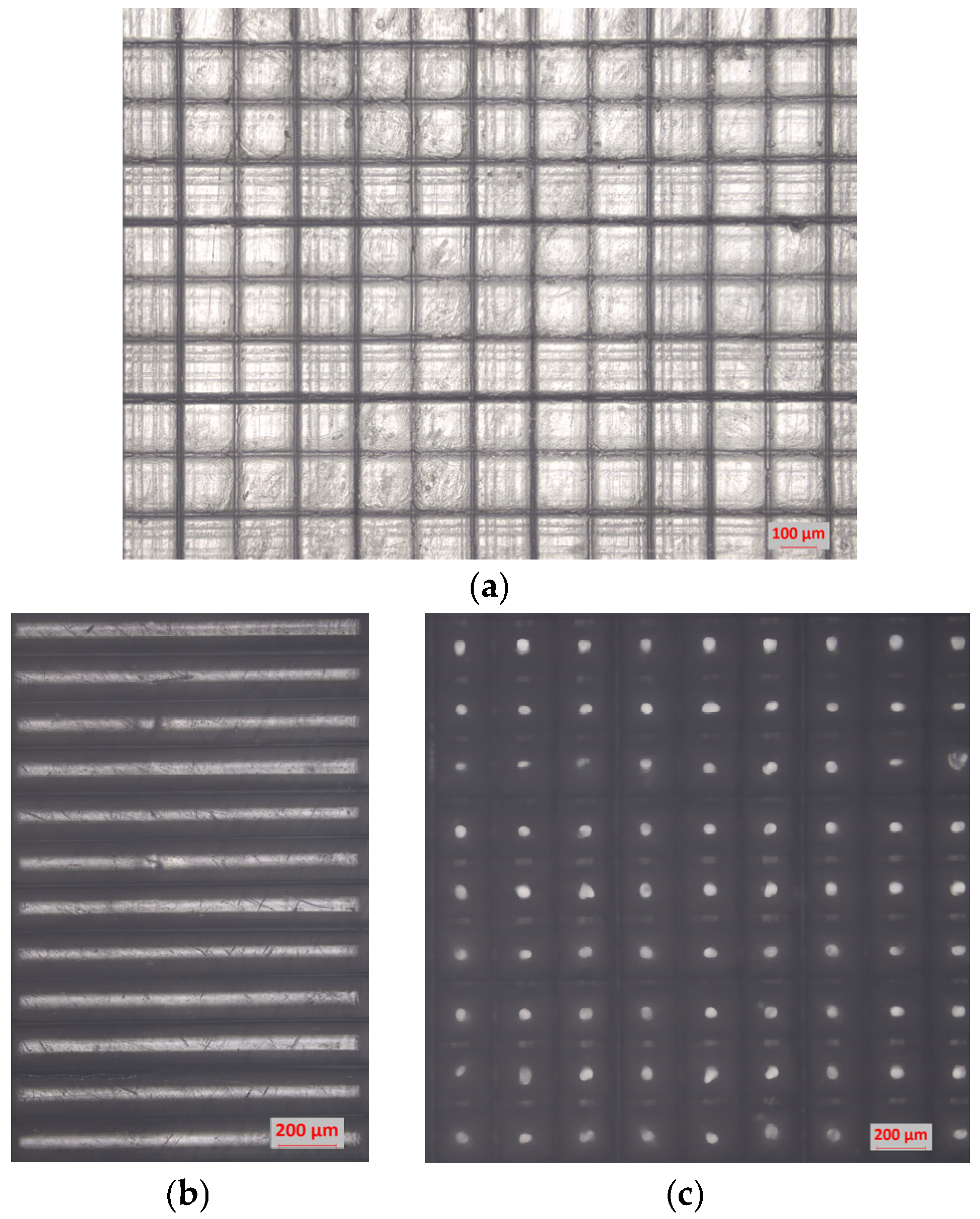

3.4. Morphology of MLA

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MLA | Microlens Array |

| PMMA | Polymethylmethacrylate |

| 2D | Two-Dimensional |

| 3D | Three-Dimensional |

References

- Gu, Z.X.; Zeng, L. Tunable Imaging and Simulation Based on Microlens Array. Acta Photonica Sin. 2025, 54, 0211003. [Google Scholar]

- Zhong, Y.; Yu, H.B. Novel Optofluidic Imaging System Integrated with Tunable Microlens Arrays. ACS Appl. Mater. Interfaces 2023, 15, 11994–12004. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.X.; Ng, S.W.L. Dynamic nano-imaging via a microsphere compound lens integrated microfluidic device with a 10× objective lens. Lab. Chip 2023, 23, 3070–3079. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.J.; Bian, Q. Technical Study of Microlens Arrays for Gaussian Beam Homogenization Shaping. Chin. J. Lasers 2025, 52, 0105002. [Google Scholar]

- Hou, Z.J.; Wang, X.D. Preparation and Performance of Integration Device between Si Microlens Array and Infrared Focal Plane Array (Invited). Acta Photonica Sinica 2024, 53, 0753304. [Google Scholar]

- Huang, S.Q.; Song, Z.Y. Rapid fabrication and characteristics analysis of high-filling-factor microlens array. Infrared Laser Eng. 2021, 50, 329–333. [Google Scholar]

- Shao, J.Z.; Liang, X. Excimer laser marking—A precise patterning technique for material surfaces. Opt. Laser Technol. 2024, 176, 110974. [Google Scholar] [CrossRef]

- Qin, D.; Guo, J. Surface Characterization and Tribology Behavior of PMMA Processed by Excimer Laser. Chin. J. Mech. Emg. 2023, 36, 60–76. [Google Scholar] [CrossRef]

- Kong, D.J.; Sun, X.Y. Superhydrophobic quasi-periodic concave microlens array on fused silica prepared by spatially modulated picosecond laser parallel processing. Ceram. Int. 2024, 50, 42922–42932. [Google Scholar] [CrossRef]

- Ottevaere, H.; Cox, R. Comparing glass and plastic refractive microlenses fabricated with different technologies. J. Opt. A Pure Appl. Op. 2006, 8, 407–429. [Google Scholar] [CrossRef]

- Liu, X.; Yu, L. Optical Nanofabrication of Concave Microlens Arrays. Laser Photonics Rev. 2019, 13, 1800272. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Lei, H.Q. Fabrication of high-quality microlens arrays on fused silica based on combined rapid evaporative ablation and precision melting polishing of CO2 lasers. J. Mater. Res. Technol. 2024, 33, 3928–3943. [Google Scholar] [CrossRef]

- Li, Q.K.; Liu, X.Q. Fabrication of glass microlens arrays by laser-based technology. Laser Technol. 2021, 45, 131–136. [Google Scholar]

- Zolfaghari, A.; Zhang, L. Replication of plastic microlens arrays using electroforming and precision compression molding. Microelectron. Eng. 2021, 239–240, 111529. [Google Scholar] [CrossRef]

- Yi, J.H.; Baek, C.H. Fabrication of a light screen-aperture integrated flexible thin film micro-lens array for a biomimetic superposition compound eye. Opt. Express 2021, 29, 39214–39226. [Google Scholar] [CrossRef] [PubMed]

- An, H.; Qian, Y.F. Unveiling the effects of laser scanning direction and processing parameters on heat transfer and ablation behavior of CFRP. Compos. Part. B Eng. 2025, 298, 112407. [Google Scholar] [CrossRef]

- Xing, H.X.; Wang, S. Gold film suppresses ablation damage of CVD polycrystalline diamond by sub-nanosecond pulsed laser processing: Experimental and theoretical investigation. Diam. Relat. Mater. 2025, 153, 112100. [Google Scholar] [CrossRef]

- Zhao, J.G.; Han, X. Innovative multiscale simulation with experimental validation of ultrafast laser processing in silicon carbide (4H-SiC). J. Manuf. Process. 2025, 137, 252–262. [Google Scholar] [CrossRef]

- Liu, Y.; Ouyang, P.F. Multi-energy field simulation and experimental research on backside water assisted laser processing for thin-walled irregular metal micro-holes. Opt. Laser Technol. 2025, 187, 112790. [Google Scholar] [CrossRef]

- Lin, Z.J.; Ji, L.F. Surface defects state analysis of laser induced graphene from 4H-SiC. J. Mater. Res. Technol. 2020, 9, 5934–5941. [Google Scholar] [CrossRef]

| Entry | Material | Attribute | ||

|---|---|---|---|---|

| Index | PMMA | Density | Heat capacity | Thermal conductivity |

| Parameter | (C5O2H8)n | 1190 kg/m3 | 1420 J/(kg·K) | 0.2 W/(m·K) |

| Entry | Laser Irradiation Parameters | ||||

|---|---|---|---|---|---|

| Index | Wavelength | Energy | Pulse width | Frequency | Scanning speed |

| Parameter | 248 nm | 720 mJ | 30 ns | 25 Hz | 0.02 mm/s |

| Type | Mask | Focusing Objective Lens | Etching Morphology | ||

|---|---|---|---|---|---|

| Index | Length | Width | Magnification | Length | Width |

| Parameter | 11.6 mm | 3 mm | 0.053× | 605 μm | 158 μm |

| 6.5 mm | 1.6 mm | 0.053× | 346 μm | 84 μm | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Chen, T. Preparation of Microlens Array Using Excimer Laser Motion Mask. Appl. Sci. 2025, 15, 10664. https://doi.org/10.3390/app151910664

Wang L, Chen T. Preparation of Microlens Array Using Excimer Laser Motion Mask. Applied Sciences. 2025; 15(19):10664. https://doi.org/10.3390/app151910664

Chicago/Turabian StyleWang, Libin, and Tao Chen. 2025. "Preparation of Microlens Array Using Excimer Laser Motion Mask" Applied Sciences 15, no. 19: 10664. https://doi.org/10.3390/app151910664

APA StyleWang, L., & Chen, T. (2025). Preparation of Microlens Array Using Excimer Laser Motion Mask. Applied Sciences, 15(19), 10664. https://doi.org/10.3390/app151910664