1. Introduction

This paper has two main technical motivations. Firstly, to develop a prognostic architecture that dynamically assesses the current deterioration condition of spare parts of machinery, predicts their Remaining Useful Life (RUL), and which could include various methods of deterioration estimation, whether data-based or model-based, that is, a hybrid and flexible prognostics architecture. Secondly, to improve the operational performance of high-power industrial machinery by calculating the Specific Energy Consumption (SEC) in real-time. This approach is intended not only to improve maintenance strategies but also to contribute to energy saving.

The prognostics of the RUL of assets for industrial machinery and its relationship with the reliability of systems is a widely studied topic in Prognostics and Health Management (PHM). PHM is a computation-based paradigm that elaborates physical knowledge, information, and the data of structures, systems and components (SSCs) operation and maintenance, to enable detecting of equipment and process anomalies, diagnosing degradation states and faults, and predicting the evolution of degradation to failure so as to estimate the RUL [

1].

In the literature, several types of models are used to estimate the RUL of components, namely: (i) knowledge-based models, (ii) deterioration models, and (iii) survival models. Knowledge-based models, also known as similarity models, are used for prognostics through an expert system considering various evolution trajectories from a healthy state of the component up to its failure or safety threshold [

2]. Deterioration models are used especially when the final data up to failure are not known but up to a safety threshold, and when the process of deterioration gives significant information on usage, source of variation, faults, etc. [

3,

4]. Survival models are used when there is mainly knowledge about the failure times of several components rather than the process (see some examples in [

4]). In general, RUL estimation models focus on exploiting existing knowledge about resource performance. Various techniques, from statistical applications to applications using Artificial Intelligence (AI), have been developed to accurately estimate the end-of-life time and/or its precision with its respective probability distribution characteristics. In [

5], several algorithms about his topic are considered.

The open challenges in recent years for RUL prognostics modeling [

4,

6] are mainly related to ensuring the robustness, reliability, and applicability of predictive models. Robustness refers to the ability of a model to maintain consistent performance despite inherent variations in input data. Reliability involves the ability of a model to produce accurate and consistent predictions when faced with new or unknown data. Applicability refers to the practical implementation of the prognostic approach within real industrial constraints, including aspects such as failure definition, complexity, computational demands, ease of integration into existing systems, and flexibility. Addressing these challenges simultaneously remains difficult because they are interconnected—enhancing one aspect can sometimes compromise another. Consequently, developing models that are simultaneously robust, reliable, and applicable in diverse and unpredictable industrial environments remains an open and pressing issue in the field of tool wear prognostics.

Conventional model-based methods are hampered by limitations or inability to handle nonlinearities, measurement uncertainty, fault coupling, and other application problems. For example, successful models can be highly complex, and others are too dependent on historical calculations rather than the current system [

7]. New approaches seek to analyze how a few degradation parameters can absorb all possible sources of degradation (see, for instance [

8]). In recent years, other methods have sought to use data-driven technologies to reduce the complexity of RUL prognosis, as in [

9,

10]. Here, hybrid approaches combine all the available sources of knowledge, including model-based and data-driven information (see, for instance, [

10,

11,

12,

13,

14]). They bring the advantages of robustness and interpretability of model-based methods and the specificity and accuracy of data-driven methods.

A common problem lies in the lack of development of global architectures that allow the management of various types of model [

15], i.e., model-based, data-driven, and hybrid methods, so that various techniques can be tested within the same architecture. We can say that such architectures are more adaptable and less method-dependent. See, for example, [

16], where an ensemble prognostics method with degradation-dependent weights is proposed to improve prediction accuracy by combining multiple learning algorithms. See also [

17], which illustrates how the fusion of data from multiple sensors and the combination of different modeling paradigms can lead to more accurate and reliable RUL estimation, demonstrating the flexibility of an architecture that does not rely on a single model type. Furthermore, see [

18], which presents the flexibility of integrating information from multiple sources (sensors) and applying fusion techniques for more robust RUL prediction, which is essential for an architecture less dependent on a single data type or model.

In this paper, the authors intend to address the uncertainties in the framework of an agile enough hybrid architecture focused on on-line prediction, considering the current condition of the deterioration and its dynamic behavior, as well as the current and future operating conditions. The general problem is illustrated in the context of high-power industrial machines. A case study of an industrial shredding machine in a sugarcane mill is used. This shredding machine, or shredder, plays a crucial role in the preparation of harvested sugarcane stalks. Preparation is the first stage of the global production process. It consists of an electric motor coupled to a longitudinal shaft, on which a set of tilting hammers is mounted. These hammers impact the cane stalks at high speed, breaking the cane stalks and facilitating the extraction of juice in the mills. This juice is then processed to produce white sugar, alcohol, energy, and other by-products, such as organic fertilizers. In addition, several sugar mills generate electricity from the combustion of sugarcane waste, which contributes to sustainable energy practices.

Hammers are the most critical spare parts of a shredder, performing the primary work of breaking down materials. Due to their crucial role, they are also subject to the most significant wear. The deterioration of hammers is a process characterized by the progressive loss of their ability to perform their task effectively within a specified range. Deterioration affects the overall performance process and energy consumption of the shredder; therefore, it is essential to monitor and manage the condition of the hammers in real-time.

The operation of industrial shredders, particularly in sugarcane mills, is significantly linked with the SEC, which, in turn, is related to the hammers’ deterioration. Usually, hammers are replaced on the basis of visual observation. However, the evolution of the SEC, calculated from the power required, during the deterioration of hammers appears to follow a consistent increasing pattern, correlating with decreasing hammer lifespan.

Several critical issues highlight the need for improved management and monitoring of the SEC as follows: High impact of SEC usage on maintenance decisions; high cost of spare parts; limited availability; large amount of SEC data not used systematically; low number of frames with complete information linked to maintenance; and not enough plots to perform a statistical analysis.

Therefore, one of the primary goals of shredder management is to extend the lifetime of the hammers, thus prolonging the service time of the shredder while maintaining its nominal performance (see the previous work [

19]). Achieving this goal requires continuous estimation of the hammers’ RUL. RUL is defined as the time remaining from the current moment until the hammers no longer perform their intended function. Accurate, precise, on-line (in-operation), and noninvasive diagnostics of the hammers’ current state of deterioration are essential for predicting their RUL. This type of RUL prognosis can facilitate informed decision-making regarding machine health, with the aim of: extending mean time to failure, improving maintenance strategies, reducing energy costs, minimizing downtime, managing assets more effectively, and increasing profitability and the efficiency of production. These tasks are particularly valuable within the framework of intelligent and sustainable resource management.

Given these challenges, in this paper, a general architecture for RUL estimation is proposed. Several strategies are employed as follows: exploiting incomplete data; real-time comparison of new production information; conservative real testing; simulating input data; probabilistic certification; and progressive data integration. To accurately calculate the SEC linked to the hammers in real-time, we incorporate machine learning techniques into the monitoring and analysis of the shredding process. Dynamic estimation of the current deterioration state of the hammers and dynamic prediction of their future condition are performed. This enables the system to detect possible anomalies and predict the hammers’ RUL.

By analyzing historical data and generating synthetic data through a novel data-driven model, we can characterize zones of behavior and establish a comprehensive mapping of production dynamics. Similarity techniques can be used to perform real-time comparisons of production data with respect to this historical mapping. As an example, the Cumulative Euclidean Distance algorithm is used. In addition, the dynamic feature extraction of production trajectories provides insights into the operating performance and energy consumption of the shredder. As an example, a slope extraction technique is used to represent the extraction process and, at the same time, to monitor the health condition of the spare parts.

The integration of these techniques aims to improve predictive maintenance strategies, optimize energy usage, and improve overall energy production use in sugarcane mills. Using the power of machine learning, we can achieve a more sustainable and cost-efficient industrial process.

To the authors’ knowledge, there has been no similar general schema of such architecture, nor a solution focused on the spare parts of an industrial machine such as a sugarcane shredder, under the framework of the described scenario. The power consumption per ton of cane was understood as an indicator of machine deterioration; however, the corrective maintenance decision was made based on its increase and the preventive satisfaction of the nominal work. Moreover, for the characteristics of the system input, as described, there have been no studies on the type of probabilistic distribution that the RUL would have.

The paper is organized as follows:

Section 1, Introduction;

Section 2, Deterioration considerations on the case study system, which include the general characteristics of the case study, analysis of the deterioration phenomena of an industrial sugarcane shredder, and considerations and definitions for the general problem.

Section 3, Problem statement for the case study: Industrial Shredders, which describes in a general and systematic way the architecture proposed as a solution.

Section 4, Data-driven deterioration model, which describes the data sources for the case study (sugarcane flow and power) that are analyzed. A model is generated, tested, and validated from real data, to estimate the deterioration and subsequently the RUL of hammers. In

Section 5, Hybrid architecture for RUL estimation, in which the blocks and process of the proposed architecture are explained. Finally, in

Section 6, Architecture application for RUL prediction, where by means of a numerical example, the integration of the RUL prognostics architecture is evaluated from real data.

2. Deterioration Considerations on the Case Study System

This paper analyzes the case of an industrial machine that progressively deteriorates as a direct result of raw material being processed, for instance, by the continuous and rotating action of milling, cutting, or crushing of the raw material flow. In this case, it is assumed that there is continuous measurement of the raw material flow and the electrical power used in the process. Thus, the raw material flow is considered as the input to the system. The motion control actions and the characteristics of the input are seen as sources of stress that deteriorate the actuator (see, for instance, refs. [

20,

21,

22]). In a complimentary way, in [

23,

24], the authors assume a relationship between the degradation and the control input of the system to perform Model Predictive Control (MPC) techniques.

Note that these types of approach are based on the component level because the deterioration in the spare parts of the machine that come in contact with the processed material is clearly the cause of the decrease in service time. For other systems where it is necessary to first identify the critical component and how to identify it in a complex dynamic system, recent developments can be found, for instance, in [

25].

In this paper, we take as a case study an electric industrial sugarcane shredding machine, hereafter referred to as the shredder, which by means of a continuous rotary action of a set of hammers prepares the sugarcane flow by progressively hitting the stalks, in order to extract useful juice for successive stages.

In the sugarcane preparation process, the deterioration

D of the hammers can be considered as a measure of the loss of their ability to perform shredding action adequately within a given range. The deterioration

D can then also be considered as an image of the heat and the worn material on the contact surface of the hammers during their lifetime. In this process, the deterioration in the materials is assumed to increase monotonically, i.e., always increasing. The deterioration

D can be modeled as a function of the energy dissipated by the shredder machine and transferred through the hammers to the sugarcane stalks. This assumption is consistent with the Archard equation that is commonly used in the railway industry to predict wear (see, for example, refs. [

26,

27]).

Then, the deterioration process of the spare parts (i.e., the hammers) is related to the increasing SEC of the machine, for a direct mechanical energy transfer process. That is, for an industrial machine, whose spare parts are the ones in charge of coming in direct contact with a given raw material, it can be inferred that the increasing SEC of the machine reflects in some sense its deterioration.

Consider

to be the power required by the sugarcane preparation process when the hammers of the shredder machine impact the cane. Thus, consider the deterioration

to be proportional to the energy consumption of the sugarcane preparation process for a given interval from time 0 to time

t, namely:

where

c is a constant.

Table 1 shows the nomenclature (acronyms, symbols for variables, parameters, units, and their meaning) used in the paper.

The sugarcane flow, , is considered an input to the system and is defined in this case as the mass of sugarcane per unit of time. is assumed to be a random, bounded, exogenous input, assumed to be continuously measured and manipulable at each time step. In this paper, the units used for are tonnes (metric tons) per hour, i.e., [t/h] for convenience within the field of application.

Moreover, according to the initial assumptions and the definition of

, it can be assumed that

is a function of the sugarcane flow

as

Therefore, it is possible to find a function

g that links the derivative of the deterioration in Equation (

1), noted as

with

:

Equation (

3) indicates that the rate of deterioration of the hammers is a function of the sugarcane flow, i.e., by manipulating the sugarcane flow, the rate of deterioration of the hammers can be increased or decreased.

Note also that it is assumed that the power required for the cane preparation process and the cane flow are measured. Therefore, the real deterioration at a current time, can be predicted on-line (i.e., during work) from the measured data.

It is also assumed that can be estimated at any time from the estimation of the current deterioration, here noted as , and its simulated trajectory within a horizon until an acceptable threshold before failure.

For this simulation,

(estimation of current deterioration) and a prediction model are needed. From this point on, the model can run with a regular input such as a step input. This regular input must be a representation of a feature extracted from the data. For example, the amplitude of the step can be the average of the past data, or the minimum value, or the maximum value, or all three values (see the example in [

28]). It is also assumed that, in the prediction of the trajectory of

, the operation conditions remain unvarying along the given horizon from

to

.

At a given current time

, the predicted

, denoted by

, is the predicted remaining period of time from

, until a threshold time

(the estimated threshold time), before the system can no longer perform its intended function. The time

is estimated and

is calculated as

Generally, the RUL is a random variable that can be characterized, for example, by a probability distribution. Variables such as the type of cane fiber, the climate, the type of cane crop terrain, and the humidity of the cane, among others, could influence wear. Consequently, there are several sources of uncertainty in the estimation of deterioration and RUL. However, in this paper, initially RUL is studied from the point of view of control systems theory; therefore, a deterministic analysis of RUL is carried out first. Subsequently, stochastic analysis is performed.

3. Problem Statement for the Case Study: Industrial Shredders

In accordance with

Section 2, this paper addresses the general case of industrial electrical machines that process raw materials and whose spare parts deteriorate due to the main action performed by the machine. This work focuses primarily on deterioration processes due to the progressive loss of material through repetitive or cyclic friction caused by the nominal action of the machine. Here, an industrial sugar cane shredder is used as a case study.

The performance of industrial shredders is significantly related with the SEC, namely, linked to the hammer’s health state. Several critical challenges highlight the need to improve the management and monitoring of the SEC:

Complexity of monitoring. The deterioration of the hammers is not directly measurable; this must be estimated from reliable indicators of the state of health.

High impact of SEC usage on maintenance decisions. Increasing energy consumption directly affects when and how maintenance is performed.

High-cost of spare parts. Hammers are the most critical components and expensive to replace because of the materials, tools, and scale.

Limited availability. Spare sets of hammers are commonly rarely available, leading to potential downtime.

Deficient use of SEC data. Despite the abundance of SEC data, it is often not utilized effectively for maintenance and operational decisions.

Low number of complete information frames. There is a scarcity of comprehensive data sets that link SEC information directly to maintenance activities.

Not enough plots to perform statistical analysis. The limited data available hampers the ability to perform robust statistical analyses.

Based on these challenges and previous assumptions, the following problem question is defined: How can we build an architecture that allows for the inclusion of physics-based and data-based models that has the ability to work with real and synthetic data, and that is flexible enough to estimate the RUL in industrial applications based on power usage and raw material flow data?

Given these challenges, the following criteria to build the global architecture are proposed in this paper:

Maximum exploitation of data. It is crucial to utilize available data as much as possible, even if the datasets are incomplete, given the complexity and cost of obtaining new data outside the production process.

Progressive data integration. Current real production information must be progressively added to the built database to characterize and improve it.

Real-time comparison. Current real production information must be compared with the preceding database in order to identify consistency, to diagnose possible faults or failures, and predict the RUL during operation.

Flexibility. The architecture must be modular and able to adapt to changes in the kind of system, type of deterioration model, data-analysis technique, or user needs.

The architecture must support the inclusion of different types of current methods for: modeling deterioration, using current production data, generating a hybrid real data and synthetic data database, comparing current data with the existing database, and finally, estimating the RUL during system operation.

Moreover, as a validation criterion, Probabilistic certification is proposed. This means that the process can firstly be validated by means of simulation tests to ensure reliability. Conservative real testing is assumed, because real testing would require modifications to current production, which are likely to be significant. Therefore, scenarios should be conservative to minimize costs without affecting the production process.

4. Data-Driven Deterioration Model

This section describes the data sources for the case study machine, a sugarcane industrial shredder, and the resulting deterioration model. In this context, real production data of sugarcane flow , and the power required in the cane preparation process P, are analyzed as input and output signals, respectively. The shredder is driven by two electric motors with a power of 1305 kW each and rotates at a constant speed of 900 RPM. The data were collected using a system that measures the energy consumed by the shredder motor. The current consumed by the motor and the voltage are measured directly, and the power is calculated from there. The original sampling frequency is one data point per minute. The data are then accumulated for each hour for the direct calculation of [kWh] units, so the energy sampling frequency is one data point per hour.

Due to the magnitude of measurement, significant noise sources are not considered, and data smoothing using a moving average is favored as a data preprocessing step. Moreover, outliers and production data different from zero or outside a range of ±30% around the average are suppressed. This last condition is established because it is assumed that there is no deterioration at such periods when there is no incoming raw material.

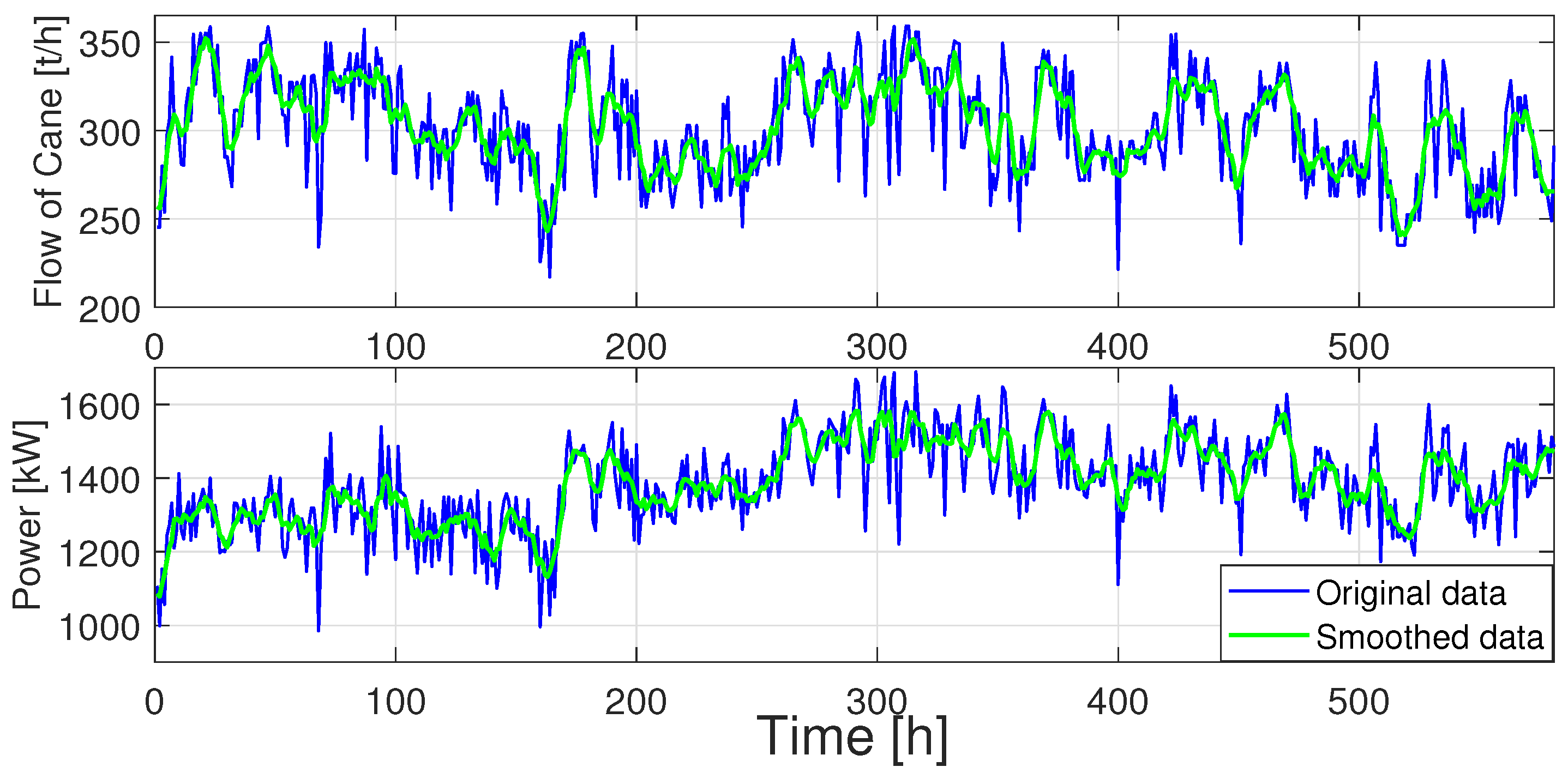

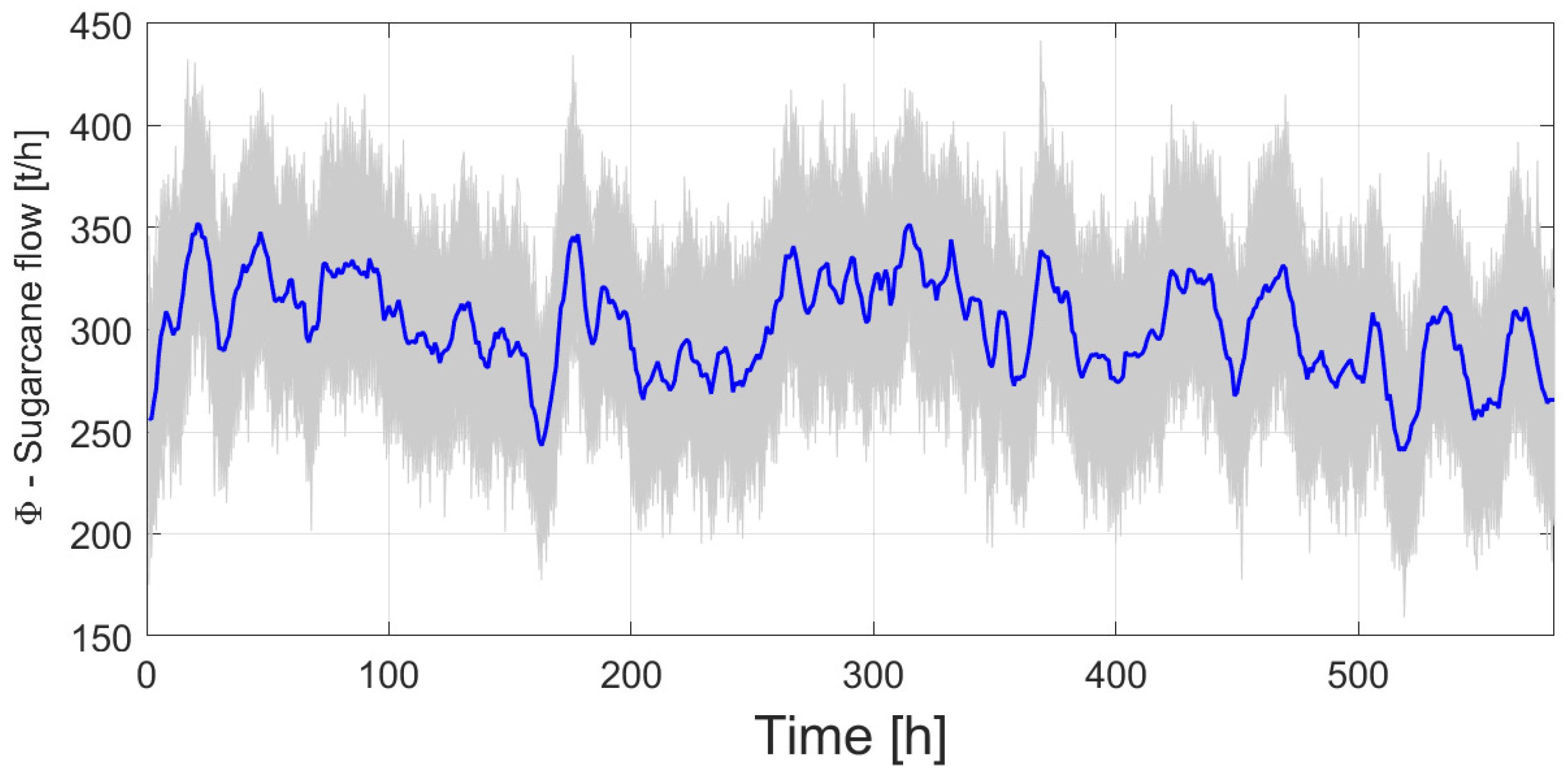

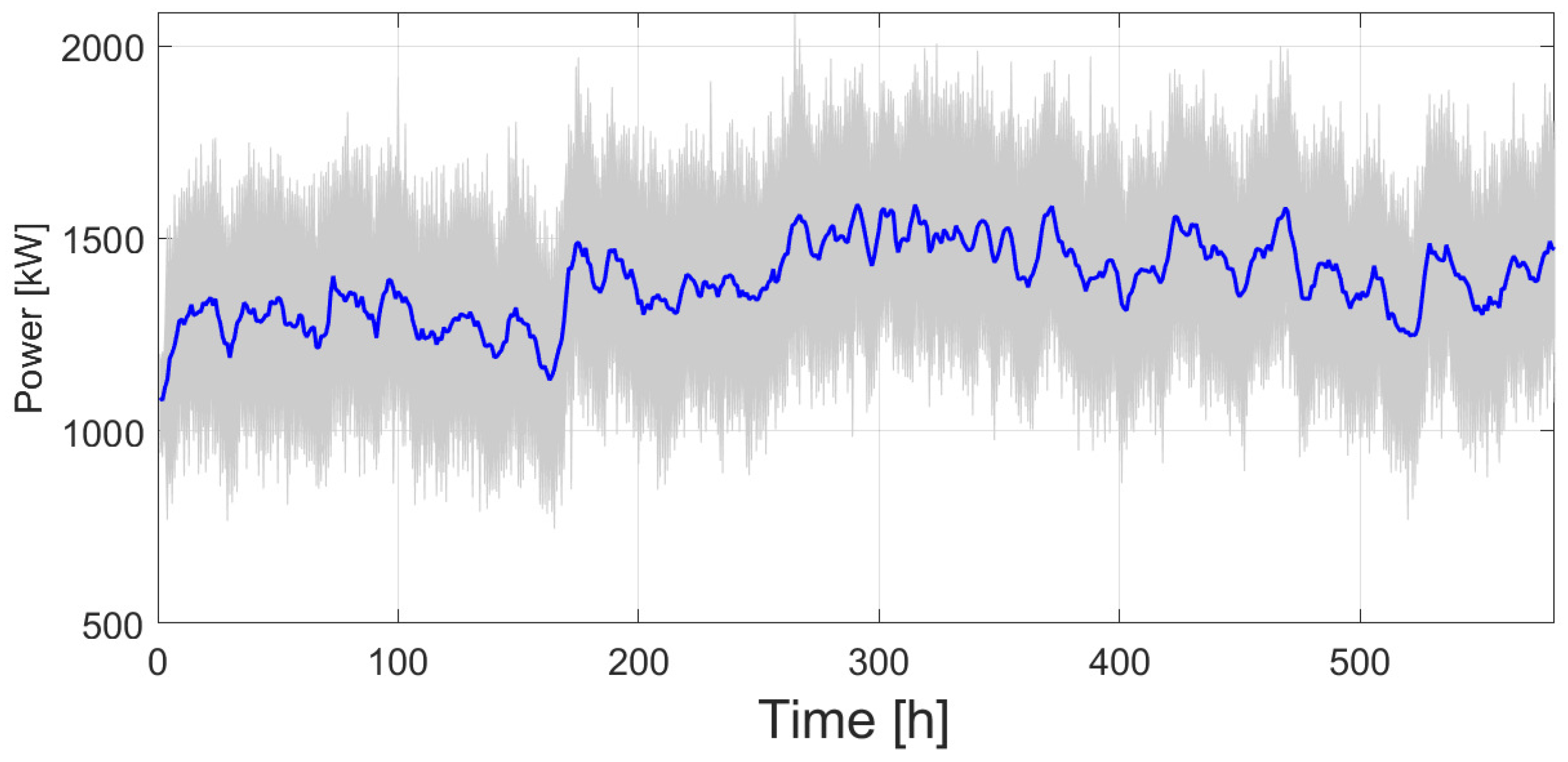

Figure 1 shows the real preprocessed data

and

P (blue lines) for a lifetime of hammers. A moving average of 48 h was used for processing all raw datasets (green lines). This period is considered because in the empirical treatment of the industrial process in the case study, analysis of periods longer than two days is considered useful for evaluating trends or repetitions of events. Therefore, shorter times may be impractical for smoothing processes, and longer times may hide useful dynamics in the data. However, this depends on the specific industrial process.

According to the assumptions to define Equation (

1), power data corresponding to moments where there is no cane flow are removed. The lifetime is defined as the period between the change of shredder hammers. Note that in this case, the life cycle of the hammers is approximately 580 h, which is equivalent to approximately 24 duty days. For empirical and practical reasons, 30 days of useful lifetime is assumed. Note that the 48 h moving average is then equivalent to between 6.7% and 8.3% of the useful life, which is less than 10%, and is therefore considered a representatively small period.

Figure 1 shows the sugarcane flow and the demanded power for the period LT1 (the acronym LT is used for Lifetime). As seen in

Figure 1, the sugarcane flow

is a random variable bounded between 200 t/h and 350 t/h approximately.

P is measured directly using the instrumentation on the shredder motor. The energy consumed by the process is calculated every 1 h. Therefore, 1 h is taken as the step time for data analysis. The cumulative energy consumed by the preparation process stage for the lifetime is approximately 805.51 MWh.

Note that, as mentioned in the introduction, industrial machines have a very specific purpose and their configuration is in practice unique. To replicate the analysis with another type of electrical machine, it is recommended to analyze the same items in this case study but with the electrical characteristics, data acquisition, and deterioration of the specific system.

4.1. Validation of the Deterioration Model

In [

19], an Autoregressive with Exogenous Input (ARX) model is presented and validated from real data for the shredder of the case study. There, the reader can find a detailed explanation of the usefulness of this type of model. It should be noted that, for this article, the model meets the defined requirements; however, other models with similar advantages can be included here, according to the flexibility characteristic of the proposed architecture. For instance, other models like ARMA (Autoregressive Moving Average) are designed for pure time-series analysis where the future value of a variable is predicted solely based on its past values (AR part) and past prediction errors (MA part). Here, we consider the importance of the input. Also, for highly complex, nonlinear systems, more powerful (and less transparent) black-box models like NARX neural networks may be necessary, but they can lack interpretability and entail a high computational cost.

The use of an ARX (AutoRegressive with Exogenous Input) model to represent the relationship between energy used and the amount of raw material offers several advantages, such as: (a) simplicity and ease of implementation, because ARX models are linear models that have a relatively simple structure; (b) they are built directly from historical input–output data of the process (raw material flow and required power), which means that they do not require in-depth knowledge of the underlying physics of the process, which is very important; (c) the autoregressive nature of the ARX model allows it to capture the dependence of the current energy used on the energy used at previous times, which is crucial in industrial processes where energy consumption often has an inertia or “memory” effect; (d) the inclusion of the exogenous input (amount of raw material being processed) allows modeling how this external variable influences energy consumption; (e) consideration of delays; and (f) practicality for inclusion in control systems.

To derive the model, the first half of the real data frame was used, which corresponds to the lifetime of the hammers in the period LT1. The resultant model equations for

and

are, respectively,

According to [

19], from the results of the model validation with the second half of the data batch LT1, an NRMSE (Root Mean Squared Error) of 84.41% was found, which is considered a sufficient fit.

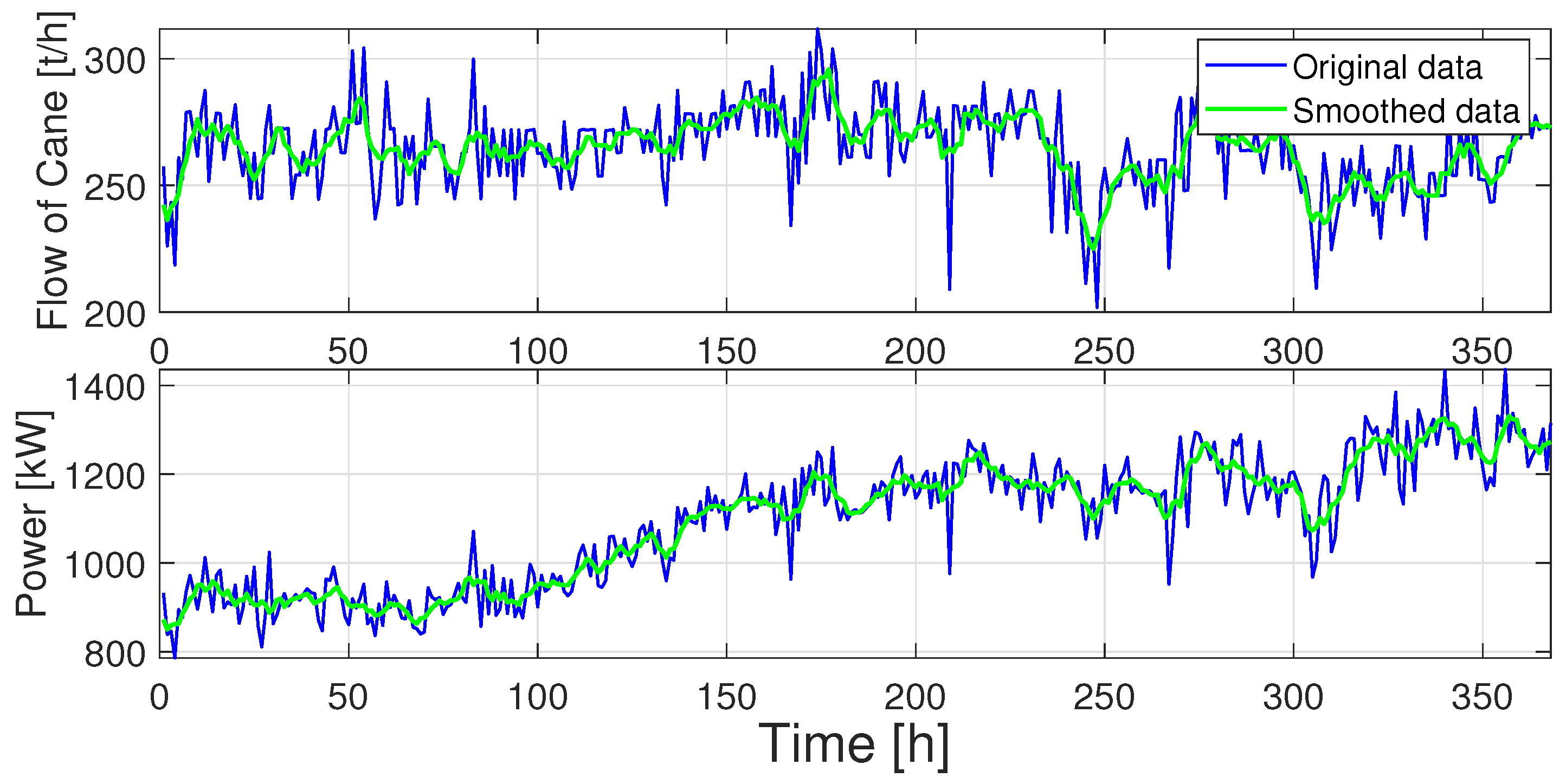

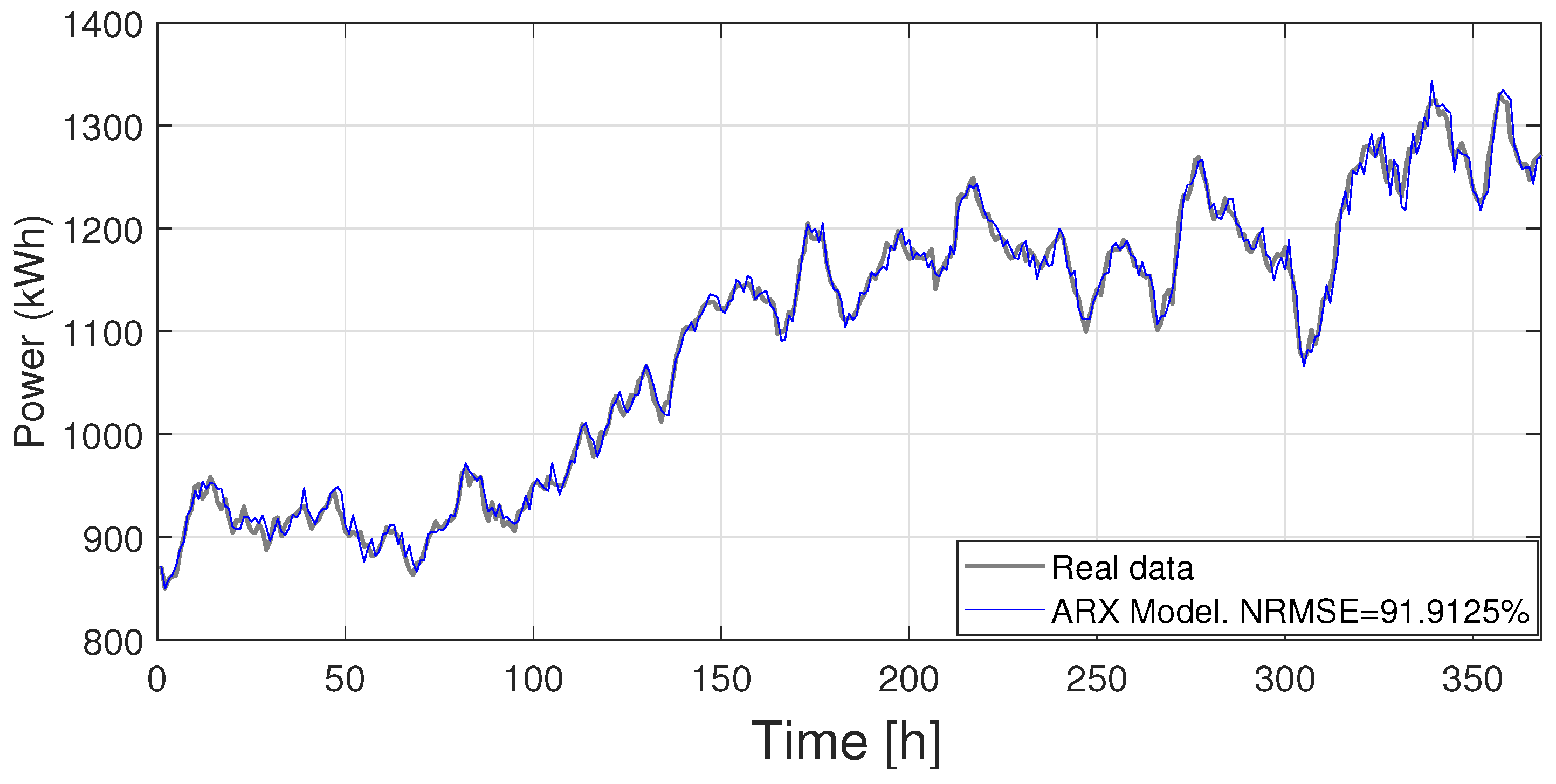

Figure 2 shows the input and output data for the later period LT2. Note that this particular dataset is shorter; however, the overall input and output value characteristics are similar.

Figure 3 shows the fitting results for the full period LT2 with the model obtained with the period LT1. The model fits the real data with an NRMSE of 91.91%. This shows that the model is a sufficiently adequate fit to the other datasets. The model was also tested with additional datasets to validate it. Here, as a processing step, moving averages of 48 h are used to smooth curves.

4.2. Specific Energy Consumption (SEC)

Consider the SEC measurable by means of the index

, the ratio of power

P per raw material flow (here sugarcane flow)

, which is equivalent to the energy consumed

to prepare the total mass of raw material (here sugarcane)

Q, which passes through the shredder per hour. Then, the index

can be defined as

where the units of

are [kWh/t], and the units of

are [kWh].

Here, it is assumed that Q is always available and that there are no delays in the weighing process. In this process, it is assumed that the sugarcane is weighted before entering the conveyor as in real life. For this life cycle, the cumulative sum of the mass of cane processed is 175.210 t (tonnes or metric tonnes).

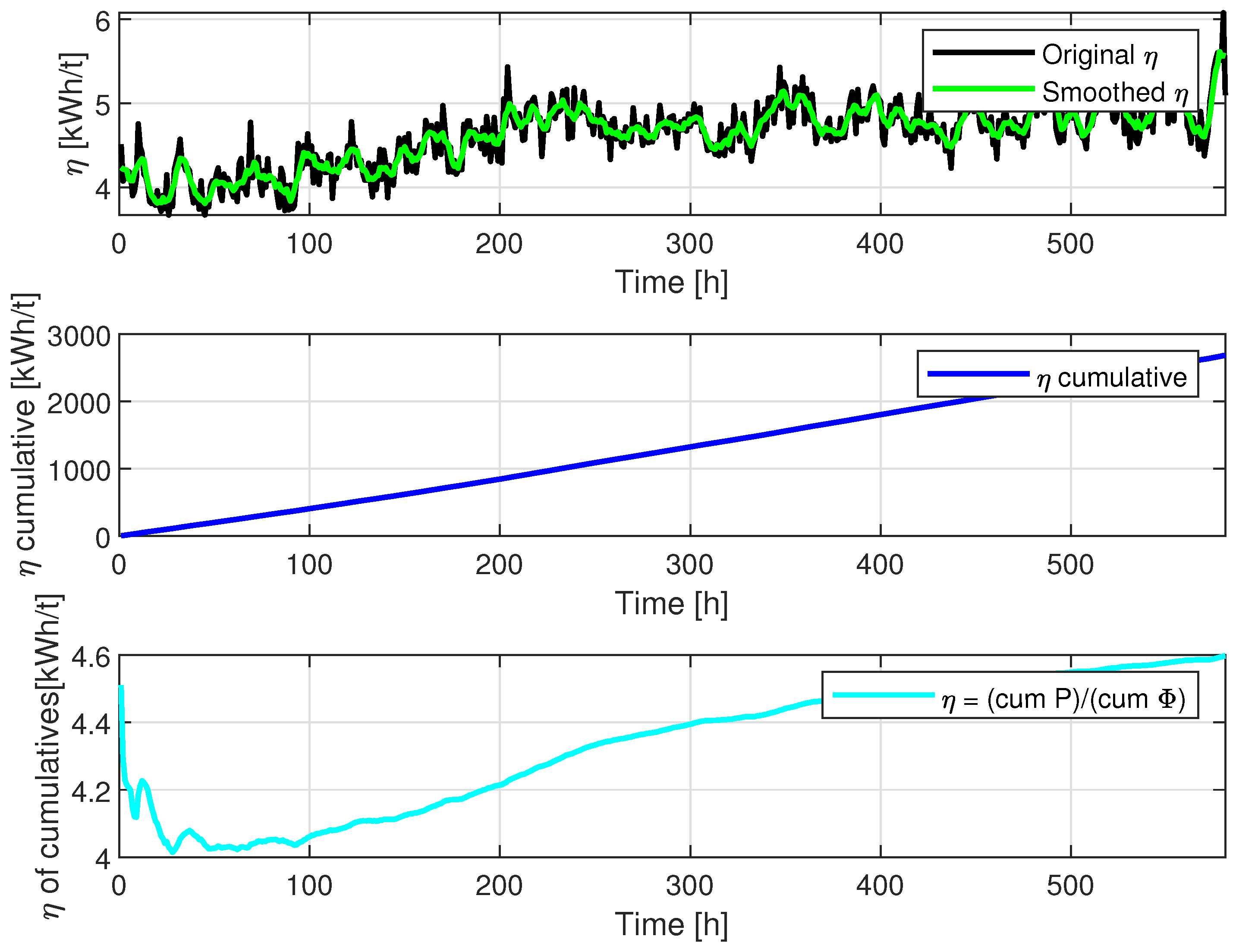

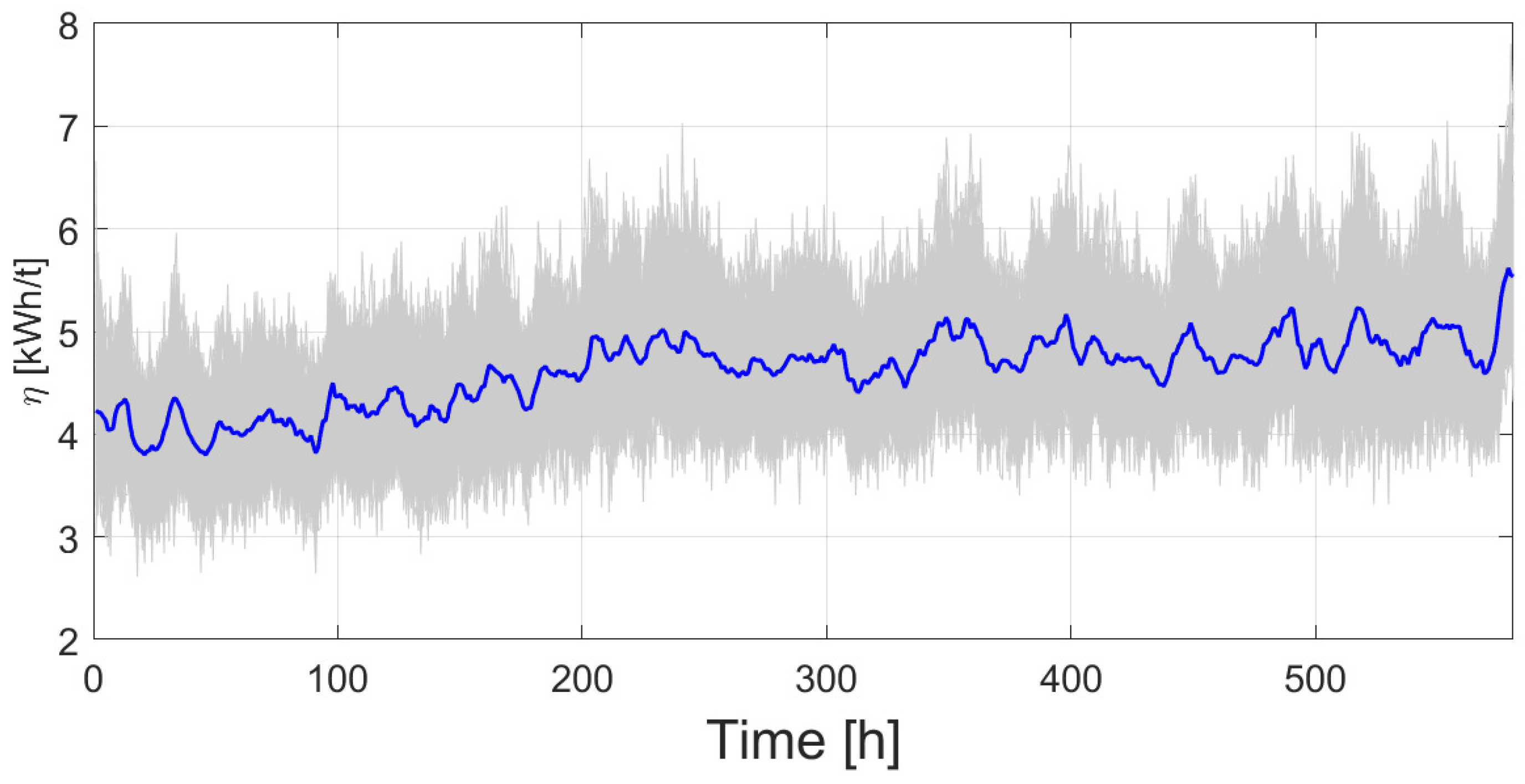

Figure 4 shows the evolution of

throughout the lifetime of the hammers. Variant values can be observed, since the calculation is carried out per hour, and a clear increasing trend is apparent. This means that as resource usage time progresses (and its lifetime decreases), the machine consumes more energy for similar quantities of raw material being processed. The figure also shows the cumulative sum

as a reference. This cumulative value is, of course, monotonically increasing and can be useful to observe the growth slope and reference numerical values to establish a safety threshold.

For the case study, technical operators have empirically identified this threshold to be around 650 MWh (approximately of total consumption, generally around 800 MWh), as it is considered that beyond this point, the process ceases to be cost-efficient. Detecting the threshold serves as a joint strategy with detecting the SEC slope. Therefore, this threshold is only applicable to this case study. However, for each application, a safety threshold can be defined according to its operating conditions.

Furthermore,

Figure 4 shows the calculation

(cyan curve) of the accumulated demanded power, divided by the accumulated processed material up to the current time, as

. This latter figure is useful because it is in the same numerical range of

values, which facilitates its interpretation, and its final value tends to the total value of power demanded divided by the total value of processed material. Finally, its appearance is directly smoothed.

Until now, it has been confirmed that the ARX model of the power demand was validated with an NRMSE of 91.91% for different real datasets of processed material (sugarcane in the case study). This model is useful because it allows the power demand for any given input of processed material to be obtained quickly and directly. In addition, it was verified that the or index of SEC related to spare parts (hammers in the case study) is a consistent and useful indicator of their deterioration. If increases, it might indicate that the machine needs maintenance or that it is operating under less than ideal conditions. In addition to viewing the current absolute value, it is also possible to observe the dynamic aspects linked to the performance behavior.

The increasing data evolution of the SEC of the machine (the shredder, in the case study) is related to index (in the case study, demanded power vs. processed material). Then, the aging process appears to be systematically similar for several datasets. In this type of phenomenon, for which a consistent pattern has been identified, in spite of possible deficiencies in the data recording, there are many data plots that contain useful information, even if this is only partial. It is also emphasized that each data frame for industrial power systems is notoriously expensive, given the costs involved in obtaining it. Thus, it is desirable to exploit the information in the datasets to the maximum, even if the batches are possibly incomplete.

5. Hybrid Architecture for RUL Estimation

In this paper, an architecture is proposed to dynamically estimate the RUL from both real and current data, and from synthetic data.

Section 2 describes how, in terms of SEC treatment and deterioration considerations, the model is applicable to machines whose deterioration (progressive process of material loss) is caused by repetitive cyclic action due to friction, caused by the main useful action of the machine. Nevertheless, the architecture would also be suitable for other types of systems with different types of deterioration, if it is properly modeled.

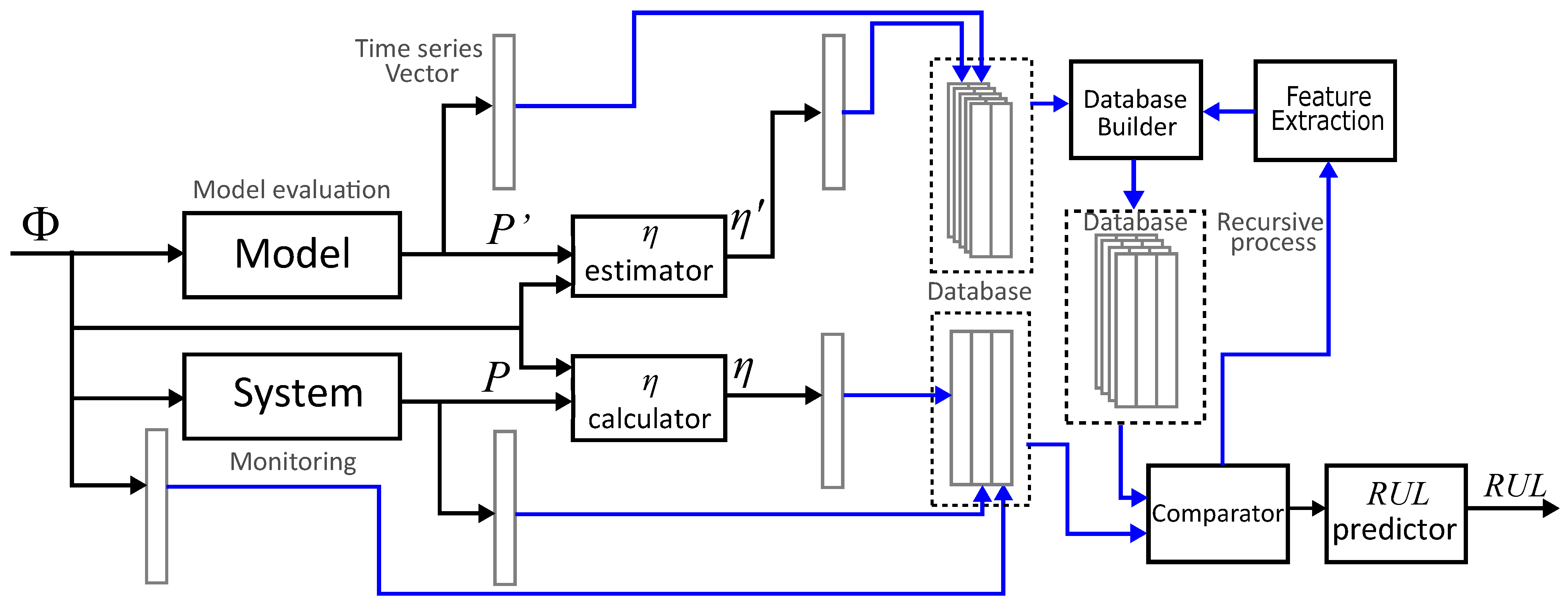

Figure 5 shows the proposed architecture. The architecture design was based on the four criteria described in

Section 3, namely:

C1 Maximum exploitation of data,

C2 Progressive data integration,

C3 Real-time comparison, and

C4 Flexibility.

The architecture includes a continuous reading of the current information from the raw material flow , (sugarcane flow for the case study). The calculator block provides that it is also possible to calculate progressively, under the assumption that it is possible to measure the electrical power P demanded by the machine. The information for , P, and is stored in a database. All individual databases are represented by a rectangle. Here, The black arrows represent current real-time data; the blue arrows represent data vectors or data matrices.

In parallel, P′ can be estimated with the model from the information of the current flow . The estimator block obtains from P′ and the current flow . The model is used to predict the behavior in an agile way from the first instants of time of real information. This information is also stored and symbolized by the multiple rectangles.

In the Database Builder block, the previously developed model data are useful for building a synthetic database. The model is useful for replicating the current behavior of and could be improved to increase its accuracy against real data. However, in this work, we prefer to evaluate how real data (changing and diverse) affect the system and the model. This architecture design criterion is preferred because the variability in real data could provide process characteristics that can be progressively included in the collected information. Similarly, conclusions are more reliable with different sets of real data. Then, reliable current data from a few cycles can serve as a basis for creating various scenarios. It is worth remembering that real tests would not be feasible because they involve modifying current production. In the latter case, the scenarios would have to be very conservative or would be too costly. Summarizing, the Database Builder block manages the synthetic database with which the current actual information is compared in the Comparator block.

The Comparator block, determines with which of the existing deterioration trajectories in the database the current deterioration trajectory is temporally most similar.

Moreover, the Comparator action enables the condition monitoring of the current data, because if a significant difference is found, this could be interpreted as an alarm or fault detection.

The Feature Extraction block, takes the information of the Comparator, and is responsible for extracting particular features from the current frame which are useful for the database builder.

Feature extraction can be structured or unstructured and can include features such as progressive slope, amplitude, and frequency, among others. Feature extraction helps to improve the construction of the comparison database. This database will then initially have a mostly synthetic weight and over time will be enriched with information from the real system. This means that the database becomes more reliable over time. This information could be useful to define, for instance, working zones. In that sense, feature extraction can be considered an adaptive process.

The Database Builder block internally takes information of the Feature Extraction block to recursively improve the process. Then, the synthetic data can be progressively compared and fed with the new measured data to build a more reliable database.

This new database can be used recurrently to compare current production data and estimate the RUL and particular characteristics of the deterioration process. Thus, model performance can be probabilistically certified from a database that progressively includes current and possibly better obtained data.

Finally, the RUL Predictor block, uses the information of the Comparator for prognosis of the RUL. From the information of the Comparator, it is assumed that the final time

of the components will temporarily be the one corresponding to this stored trajectory. The RUL is then calculated with Equation (

4). If over time the trajectory becomes more similar to another stored trajectory, according to the Comparator, the prognosis is updated. In this case, the RUL can be predicted in a deterministic way or including some criteria in confidence bounds.

Generally speaking, note that the global architecture proposed in this

Section 5 is therefore hybrid in two senses: First, in terms of diversity of techniques, since various data analysis techniques can be used in feature extraction and in comparing the historical dataset with the current one, performing a continuous evaluation of current production on the system and on the model. Second, the architecture is also hybrid in the topological sense, as it involves the parallel use of input information (with the model and with the system), and a feature extraction feedback loop. This latter loop is intended to use all existing historical information to improve the prognosis. For instance, the architecture is useful for involving similarity models in the comparison for RUL prognosis, as well as a physics-based deterioration model for generating synthetic data.

6. Architecture Application for RUL Estimation

This section explains how the architecture works by means of a numerical example. As a model, we choose the one described in

Section 4; as a comparator technique, we use the Cumulative Euclidean Distance; as an example of feature extraction, we take the slope of

on a moving horizon; and in the construction of the database, synthetic data are created by means of a normal distribution around a real dataset, all new information is assumed to be better than the previous information and is added to the synthetic data, and the previously extracted slopes are stored. The previous work [

19] demonstrated that both the flow of raw material and the power used by the engines, for the case study, have a normal distribution.

6.1. Synthetic Database Generation

As suggested in [

29,

30], the number of simulations

which guarantee a confidence parameter

= 0.001 (i.e., 99.9% of the reliability of the estimation procedure) can be computed as

where

, in this case chosen equal to 95%, represents the complement percentage of the time series population that fails to meet the condition (e.g., 5% of the time series population cannot be considered as enough).

Figure 6 shows the synthetic data created for the incoming raw material flow

. In [

19], a normal distribution of

was found. The gray lines are the synthetic data and the blue line is a real dataset of

. A standard deviation of 23.7 was used.

Figure 7 shows the resultant power

for synthetic data. The gray lines are the calculated synthetic data

, and the blue line is the

corresponding to the real

dataset.

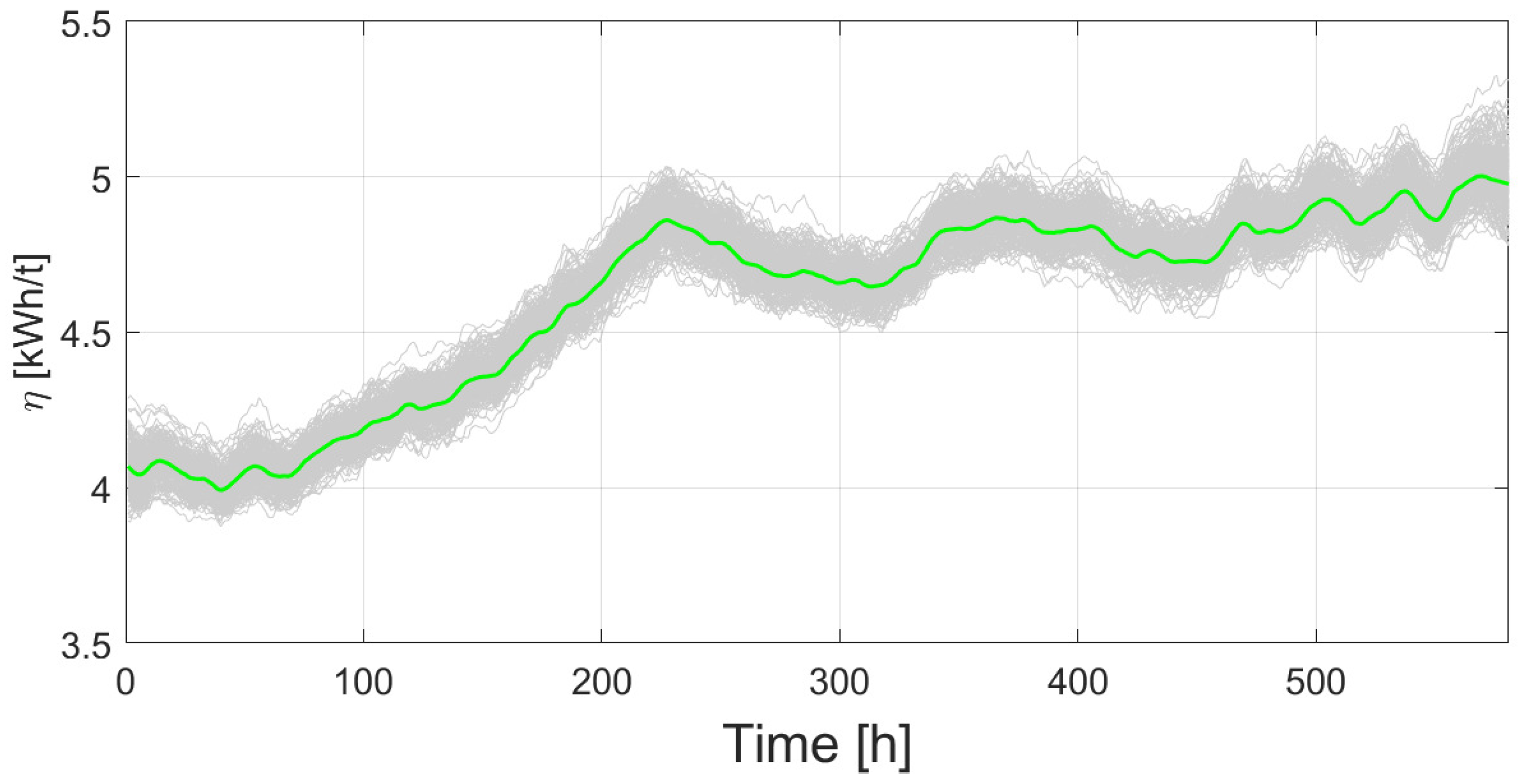

Figure 8 is the resultant

dataset. The figure shows a typical increasing evolution of

for the real trajectory (blue line) and for the synthetic ones (gray lines), from around 4 kWh/t to around 5.5 kWh/t.

Generally, the

data vary considerably, and the same is expected for

. A smoothing process is recommended for

, mainly because the slope estimation of the dataset is defined.

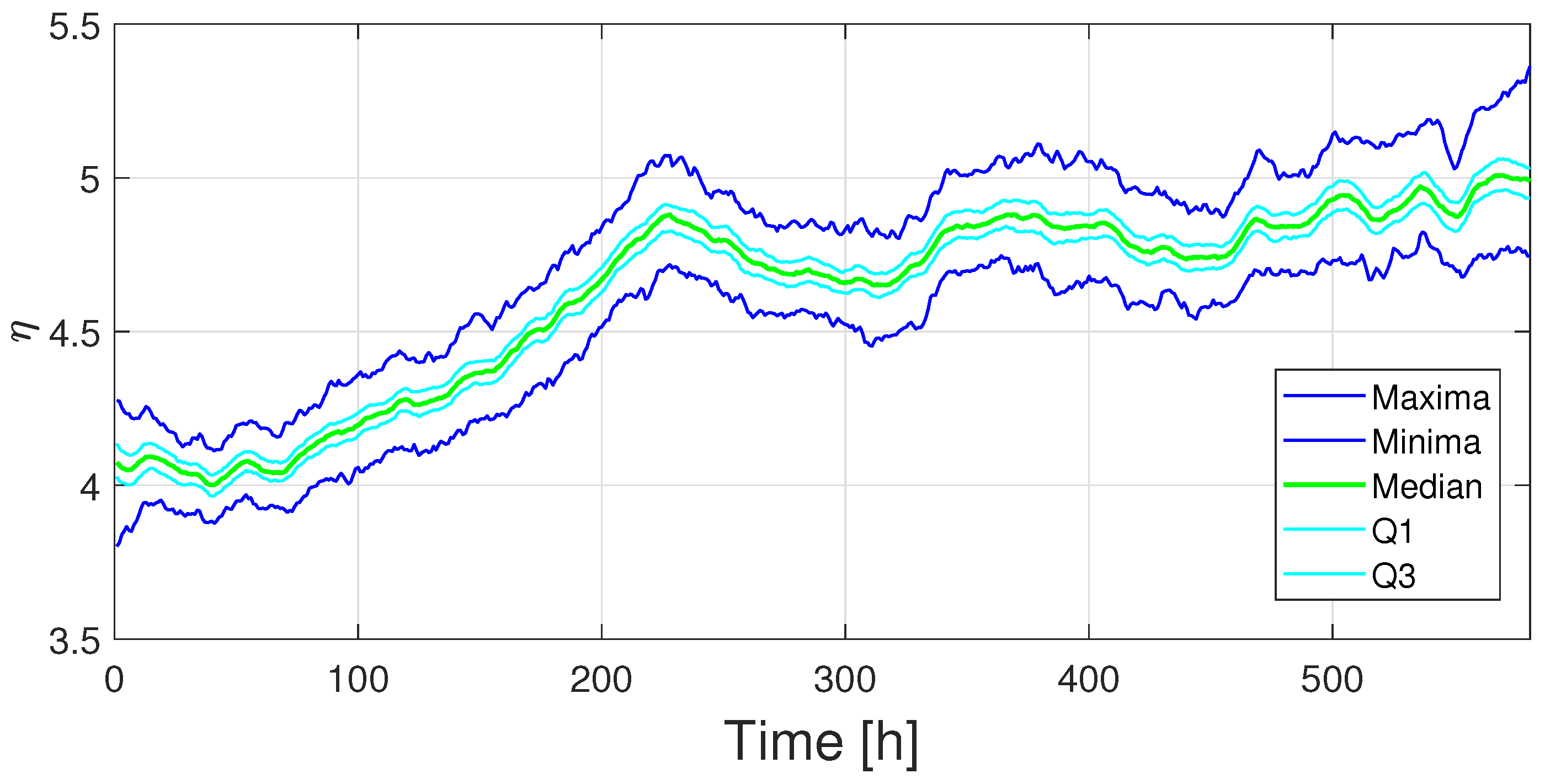

Figure 9 shows the smoothed trajectories of

using a moving average of 48 h, which is considered as an appropriate window for the case study. The gray trajectories are the evolution of synthetic

, and the green one is the real trajectory.

Figure 10 shows the distributions of the synthetic

data. The maxima, minima, median, quartile 1, and quartile 3 trajectories of the full dataset are shown. This information could be useful for the data analysis of the database.

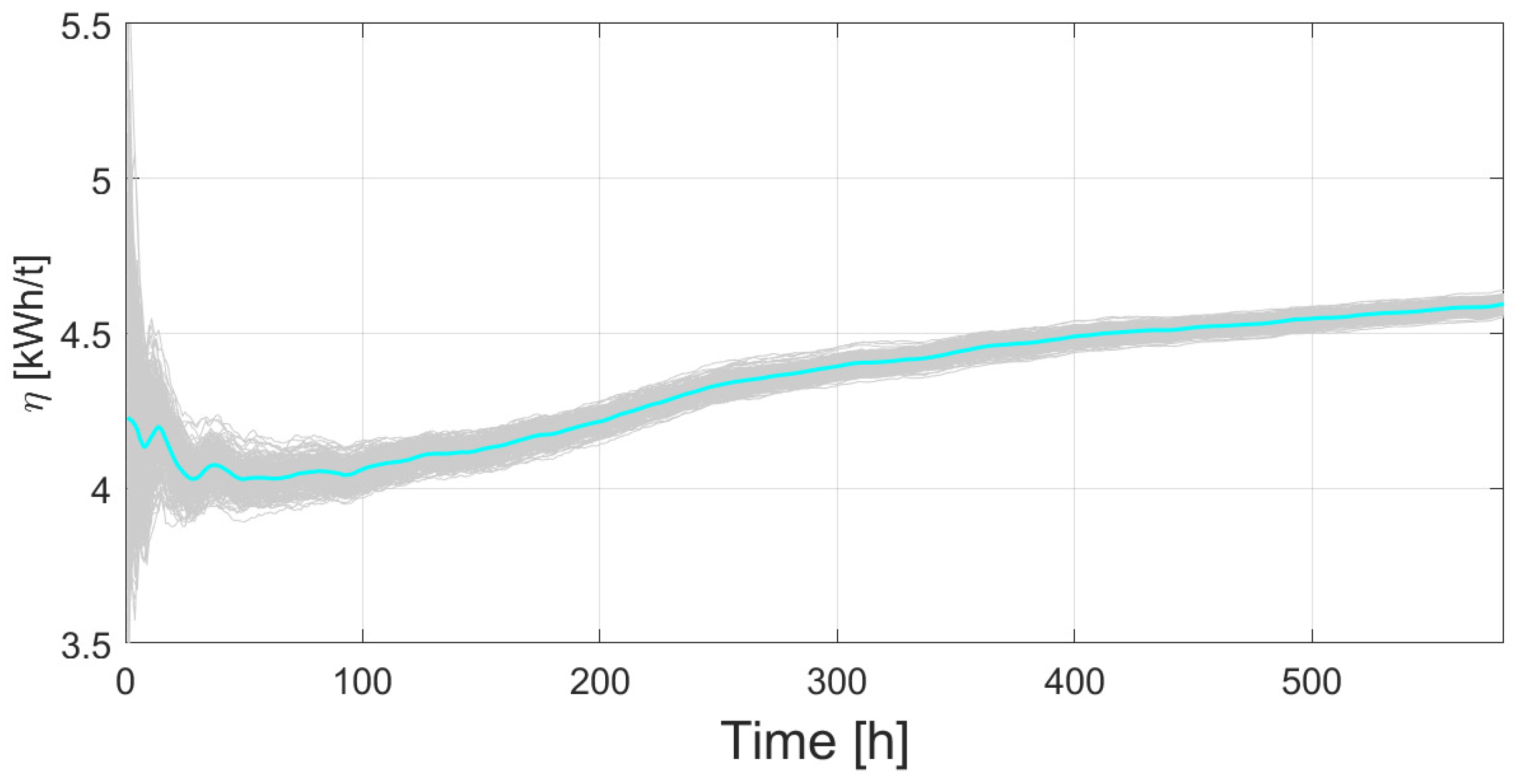

Figure 11, shows the resultant

data. Synthetic data (gray lines) show more dispersion at the very beginning of the trajectories and the dispersion decreases with time. The trajectories merge to around

= 4.6 kWh/t at the end of life. As expected, this is considered a useful progressive deterioration metric that converges to the final total average in a naturally smooth way.

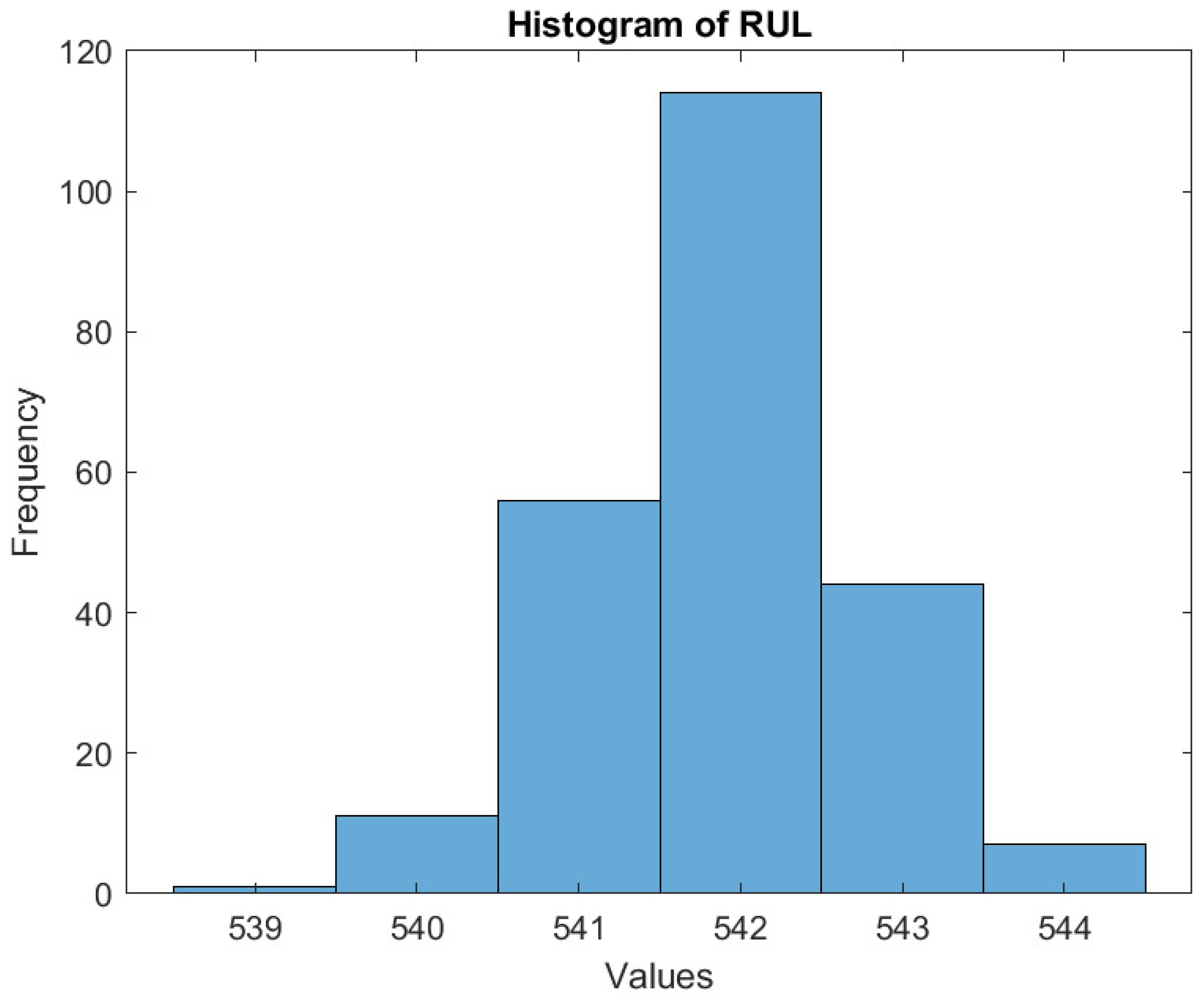

Figure 12 shows the histogram of the corresponding RUL values for the synthetic dataset. For the numerical example, the RUL is estimated from the current state up to a threshold of 700 MW. A mean value of 541 h was found.

6.2. Comparator

Progressive comparison of a new behavioral trajectory to a set of time series can be carried out using the Cumulative Euclidean Distance between given current new data and a continuously updated dataset of .

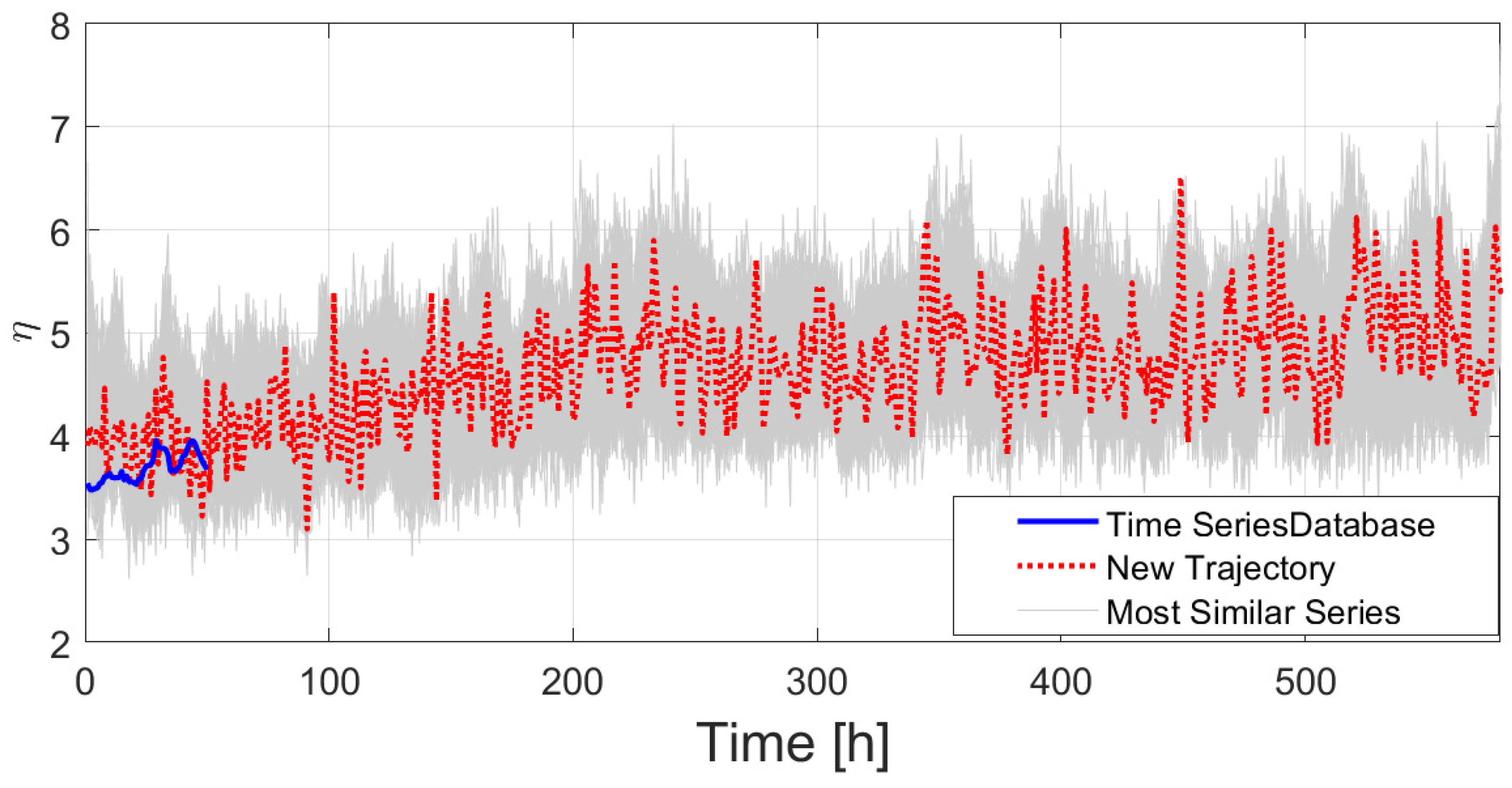

Figure 13 shows the dynamic comparison between a new real trajectory of

of a period labeled as LT3 (blue line) until 50 h, with respect to the database constructed previously. For the first 50 h, the most similar trajectory (red dotted line) is chosen from the database. At this point, it can be assumed that the useful lifetime of the current trajectory will be the one of the most similar series until a given threshold or condition defined by operator. Then, the RUL can be calculated with Equation (

4).

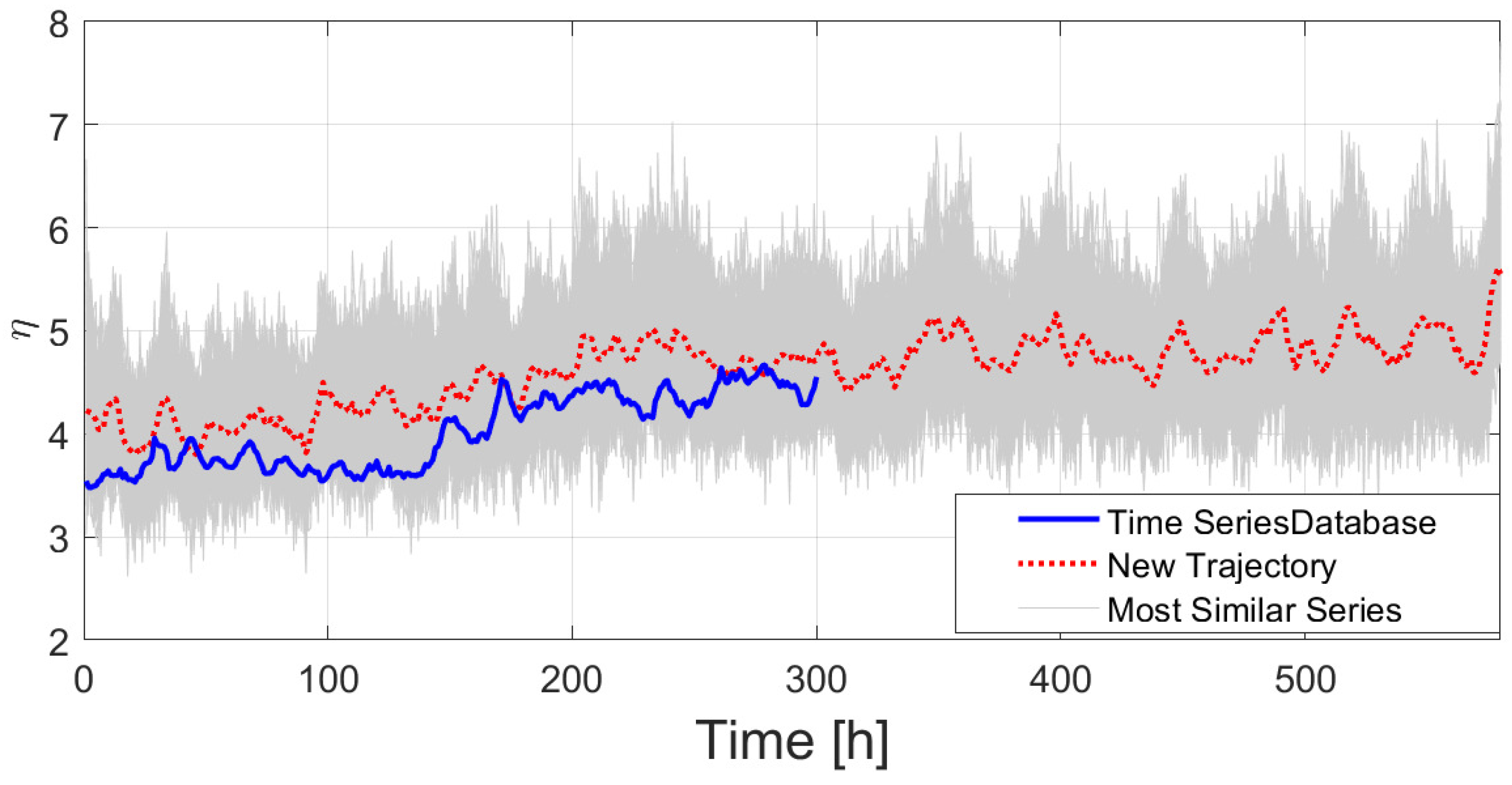

Figure 14, in the same way for

Figure 13, shows the comparison until 300 h. Here, a new most-similar trajectory is found. This shows the updating capability of the architecture.

The database contains the growth trajectories of . The total useful life associated with each trajectory can be established after meeting a threshold condition; for example, in this paper, it is established as an example that the useful life is taken when 622 MW is reached. This value can be established based on historical behavior. Alternatively, the indices described in the figure could be used. Then, the progressive comparison of current data with the database results in finding the most similar trajectory and its associated total useful lifetime value. This value is then considered as the spare parts RUL from the current moment.

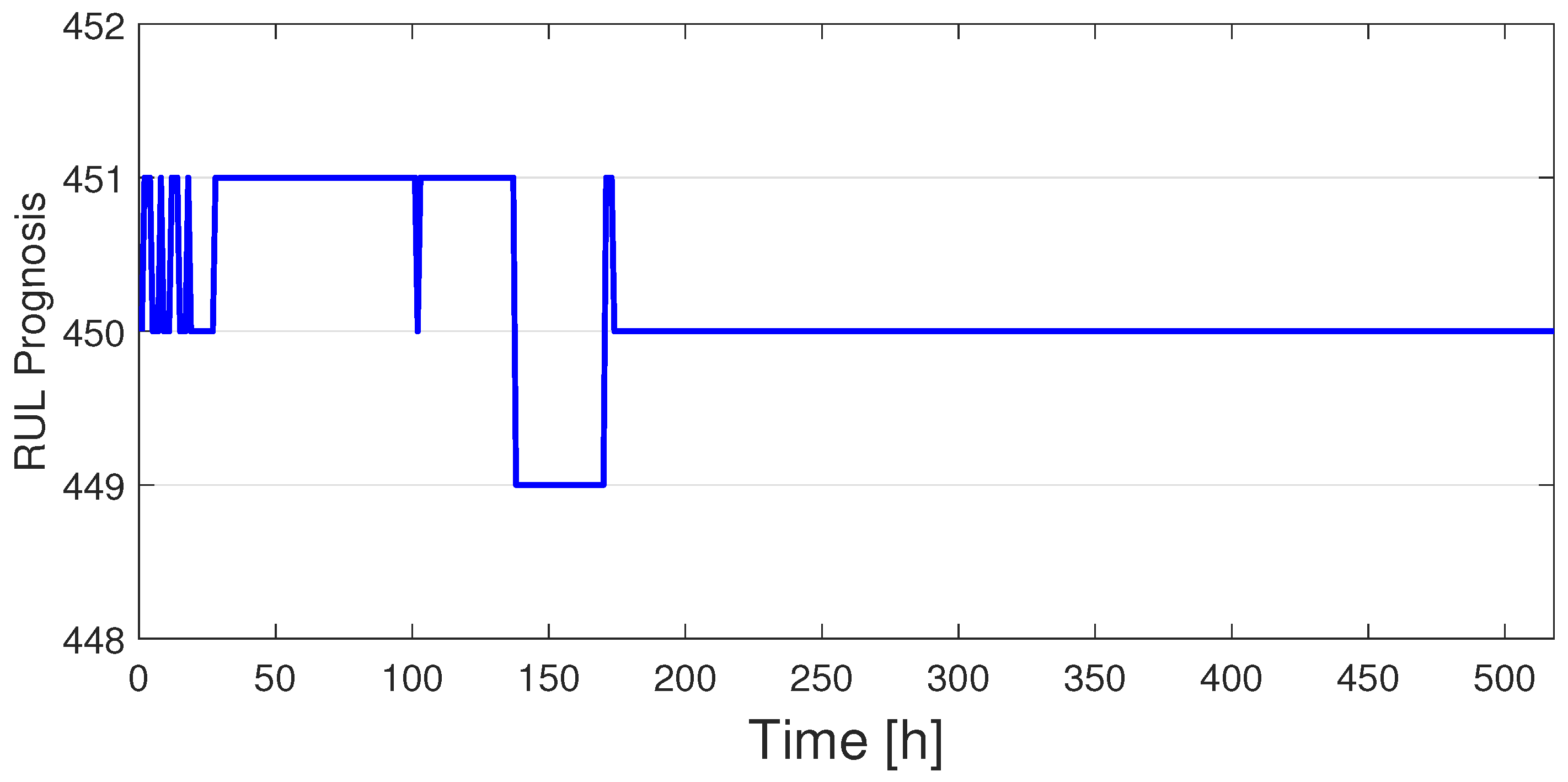

Figure 15 shows that using continuous similarity analysis, the RUL prognosis successfully converges toward the mean value of the database after approximately 180 h, which represents around 31% of a typical total useful life. This shows that, from a certain early point onward, the comparator identifies that the trajectory most similar to the new one is the one considered the mean one in the previous database. This suggests that, from that point onward, the prognosis is more reliable with respect to the recursive database.

Summarizing, the RUL prognostics are successfully determined by means of a similarity analysis based on historical data and, at the same time, on the fulfillment of a state condition, in this case, the defined energy threshold of the most similar trajectory.

6.3. Feature Extraction

As an example of feature extraction, we use here the slope of on a moving horizon. Although other characteristics can be chosen (for instance, amplitude, frequency, among others), for this example, the progressive extraction of the slope is used since the positive variation in the slope is linked to increases in the deterioration processes.

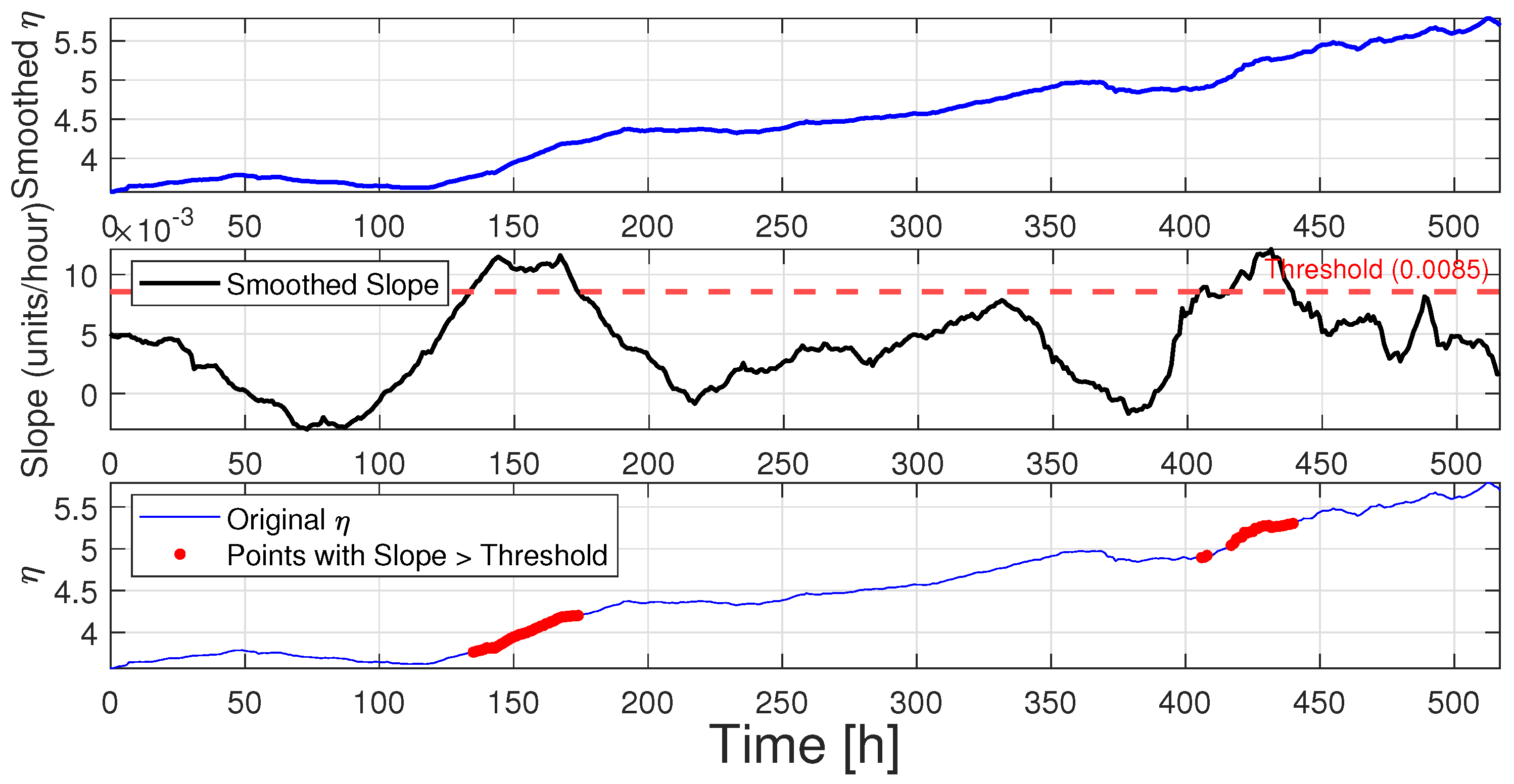

Figure 16 shows at the top, the evolution of a real

trajectory. The feature extraction block in this case is designed to extract the slope over a 1 h moving horizon. To do this, the

trajectory is smoothed over a 48 h moving horizon as explained in

Section 4. Here, each time a slope threshold is exceeded, the system generates an alert. The middle part of the figure shows the 1 h moving average slope (black line) and a chosen threshold, which in this case corresponds to twice the total slope of evolution (4.3 ×

), equivalent to 8.5 ×

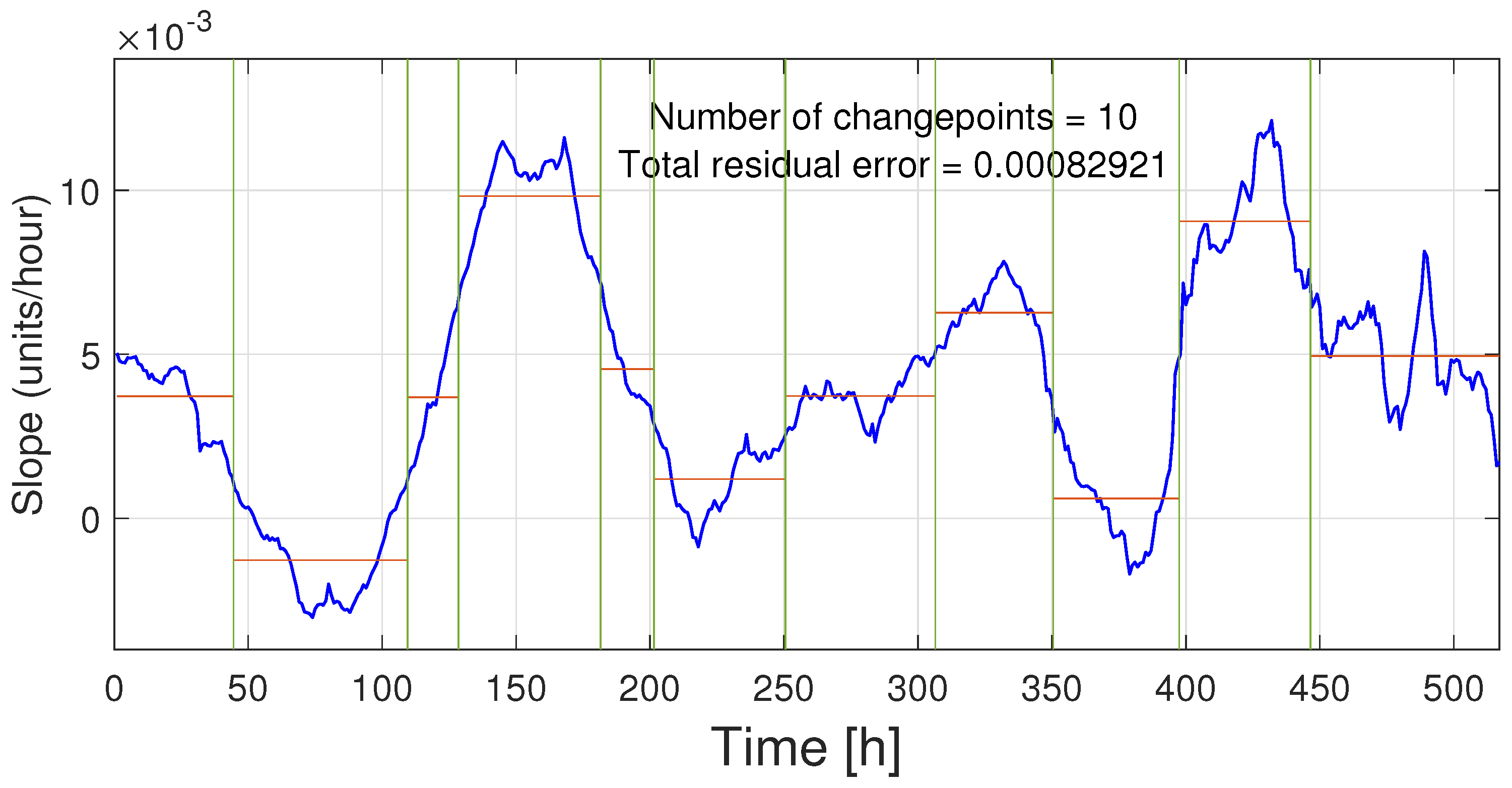

, which can also be derived from the analysis of previous real trajectories, i.e., an adaptive process. The bottom part of the figure shows the points at which the slope exceeds the threshold. Furthermore, there are 67 data points where the slope exceeds the threshold. Here, the first alert occurs around 134 h.

Figure 17 shows the changepoints for which the slope has significant changes. The used metric is the RMSE. In this case, 10 changepoints are chosen. Significant slope changes were detected at hours: 44, 109, 128, 181, 201, 250, 306, 350, 397, and 446 (See green lines).

Using this tool, the operator can identify how the SEC slopes have changed over time using the database under construction. High variability in slope behavior would indicate discontinuous and intense work. In an industrial process, less variability and greater regularity may be required.

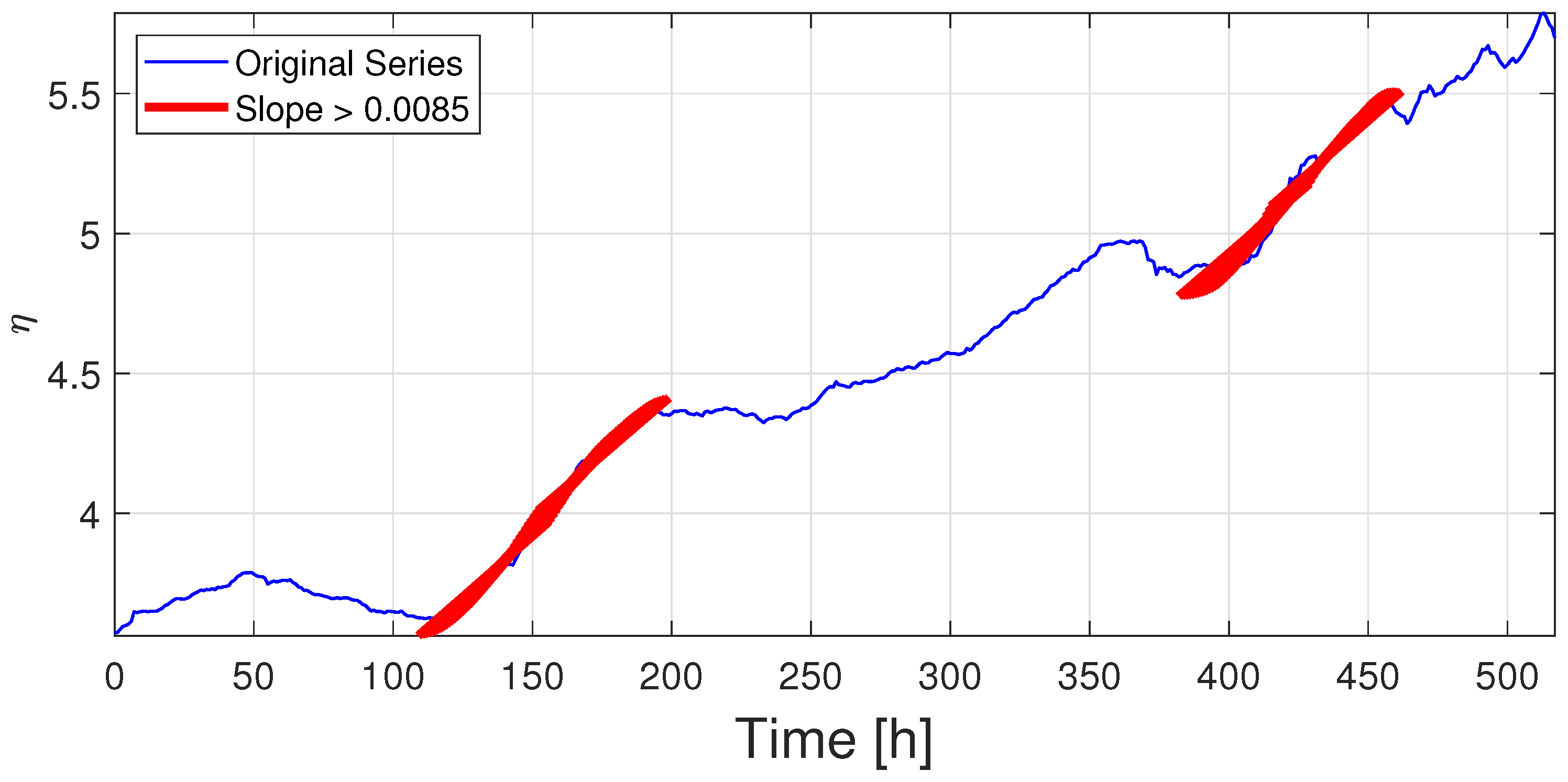

Figure 18 also shows estimation of the slope for a moving window of 48 h. Each time a slope threshold is exceeded, the system generates an alert. The threshold is the same as for the slope of 1 h. In this case, significant positive changes in the slope are shown (red lines). Finally, all extracted slopes are stored in the database and could be used by the database generator. The feature extractor is exemplified by a slope extraction. The results show 471 windows of 48 h each were analyzed; 78 windows where the slope exceeded the threshold of 0.0036 were found.

One of the advantages of this figure is that the overlapping slopes on the analysis horizon create areas of regular steep slopes linked to the moving average. These changes coincide with the areas defined by points in

Figure 16.

Note that there are two areas where critical slope windows (red areas) are detected. Note in particular, the final window between 400 h and 450 h, where the threshold is consistently exceeded. The latter process reflects decreasing performance. This critical persistence at the end may alert the operator to the need for an earlier change of hammers, which is consistent with the previous prognosis that established a useful life of 450 h.

The numerical example shown in

Section 6 shows that the similarity of new growth trajectories of

progressively converge on the most representative one in the database, reflecting the consistency of the architecture, which enables a reliable prognosis. It can also be observed that extraction of a single characteristic from the growth trajectory of

allows to characterize objectively and dynamically the deterioration in the components or, equivalently, their increasing energy consumption. These two processes are carried out during the service of the machine. Then, for the case study, current SEC data in real-time can help identify high-production and low-energy consumption zones.

Note that the recursive part of the architecture resembles the Generative Adversarial Network (GAN) approach (see, for instance, the description in [

31]). A GAN can be used to overcome the scarcity of failure data. For the GAN method, the Generator (for the architecture near in function to the Database Builder block) aims to create new data that are as similar as possible to the actual deterioration data. Meanwhile, the discriminator (for the architecture near in function to the Comparator block) acts as a judge that attempts to distinguish between actual degradation data and synthetic data created by the generator. In contrast, for the architecture proposed, weight is given to the RUL prediction objective rather than to the creation of synthetic data. Furthermore, in terms of architecture, the database has direct access to real data, which in the case of GAN only comes through its interaction with the discriminator.

The specific methods used in the paper for the blocks are only examples to explain the architecture, yet the results are encouraging. For instance, Recurrent Neural Network (RNN) models, Long Short Term Memory (LSTM), and Transformers, represent recent advances in PHM as point methods whose memory effect is useful for evaluating historical information (see, for instance, [

32,

33]). The proposed global architecture in this paper can flexibly include such methods, for example, for better feature extraction, with the stated benefit of on-line comparison of a physics-based model with incoming real data. It is suggested that work on this issue be carried out by adopting this global architecture.

7. Conclusions

The proposed hybrid architecture successfully predicts the Remaining Useful Life (RUL) of sugarcane shredder spare parts, the industrial electric machine used as a case study. The architecture enables the recursive use of SEC data (Specific Energy Consumption per quantity of sugarcane processed), even though these data may be incomplete or show differences in terms of their length between successive periods. The ARX deterioration model used, which is based on physics and its association with energy consumption, fits new time series with an NRMSE over 91%. These data correctly feed a recursive database that contains both synthetic and real data. From the numerical example, the similarity analysis, which uses the Cumulative Euclidean Distance method, shows that the RUL prognosis successfully converges toward the mean value of the database after approximately 180 h, which represents around 31% of a typical total useful life and is considered an early detection. The calculation of the RUL of the case study machine is probabilistically certified with a confidence margin of 95%. In addition, the slope extraction enables the characterization of work zones. Here, 78 windows, i.e., 10.8% of the total windows, were found with slopes that exceeded the threshold of 8.5 × . Work zones where analysis windows with high slopes persist, i.e., more power used to process the material flow, suggest a detrimental effect on spare parts performance. The model-based feature analysis shows lower performance, namely, at the end of the useful life, with values close to the prognosis of the similarity analysis. The architecture presented is flexible, i.e., can be configured for other types of model than the ones used in this paper, such as Recurrent Neural Network (RNN) and/or Long Short-Term Memory (LSTM) methods. In general, the results show that a hybrid analysis can provide a consistent basis for early RUL prognostics, and in turn, support operator decision-making on the replacement of spare parts for an industrial machine.