Prediction of Diesel Engine Performance and Emissions Under Variations in Backpressure, Load, and Compression Ratio Using an Artificial Neural Network

Abstract

1. Introduction

1.1. Background

1.2. Related Work

1.3. Research Gap

1.4. Contribution and Novelty

2. Materials and Methods

2.1. Experimental Work for Data Simulation

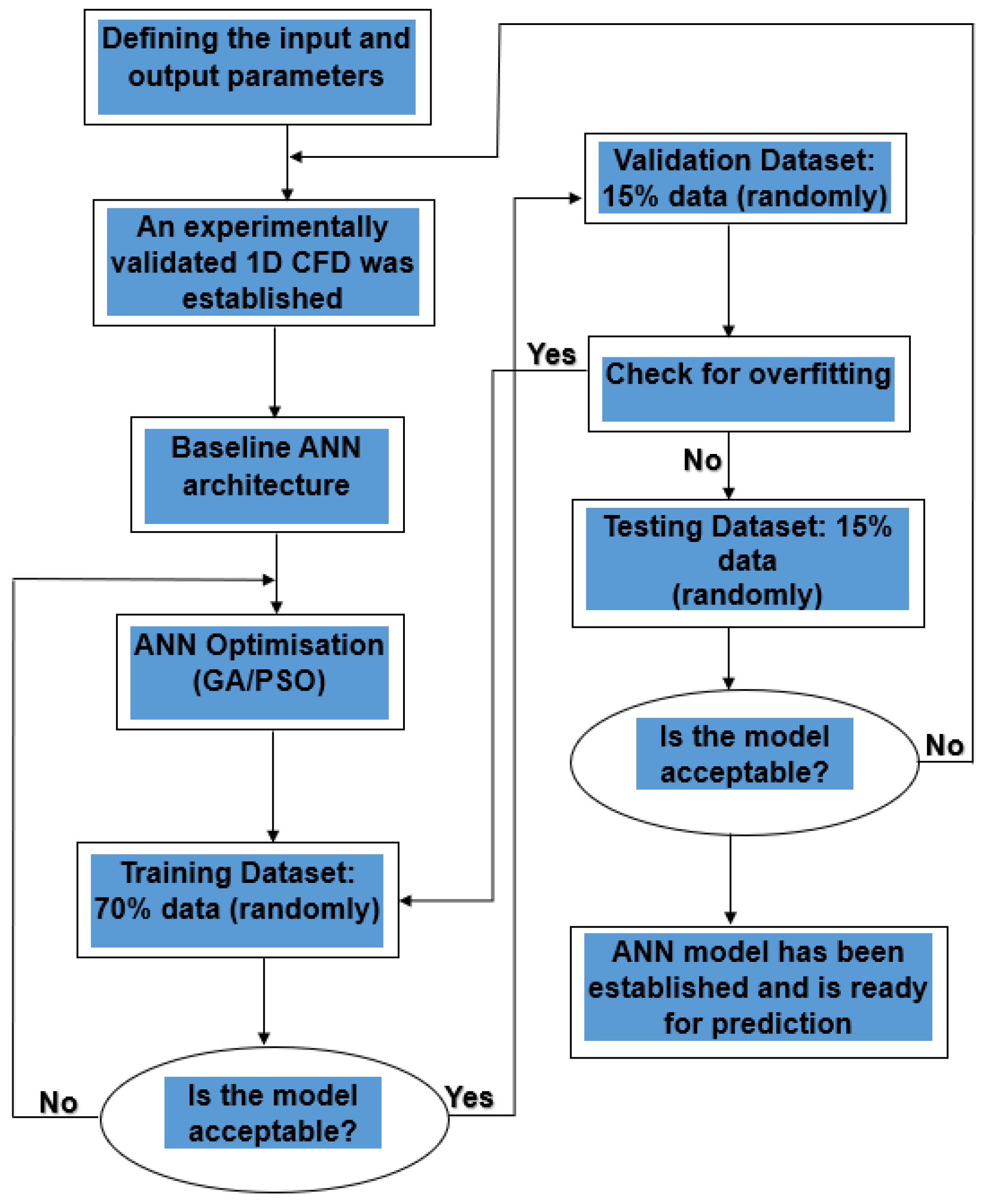

2.2. Artificial Neural Network Modelling

3. Results and Discussion

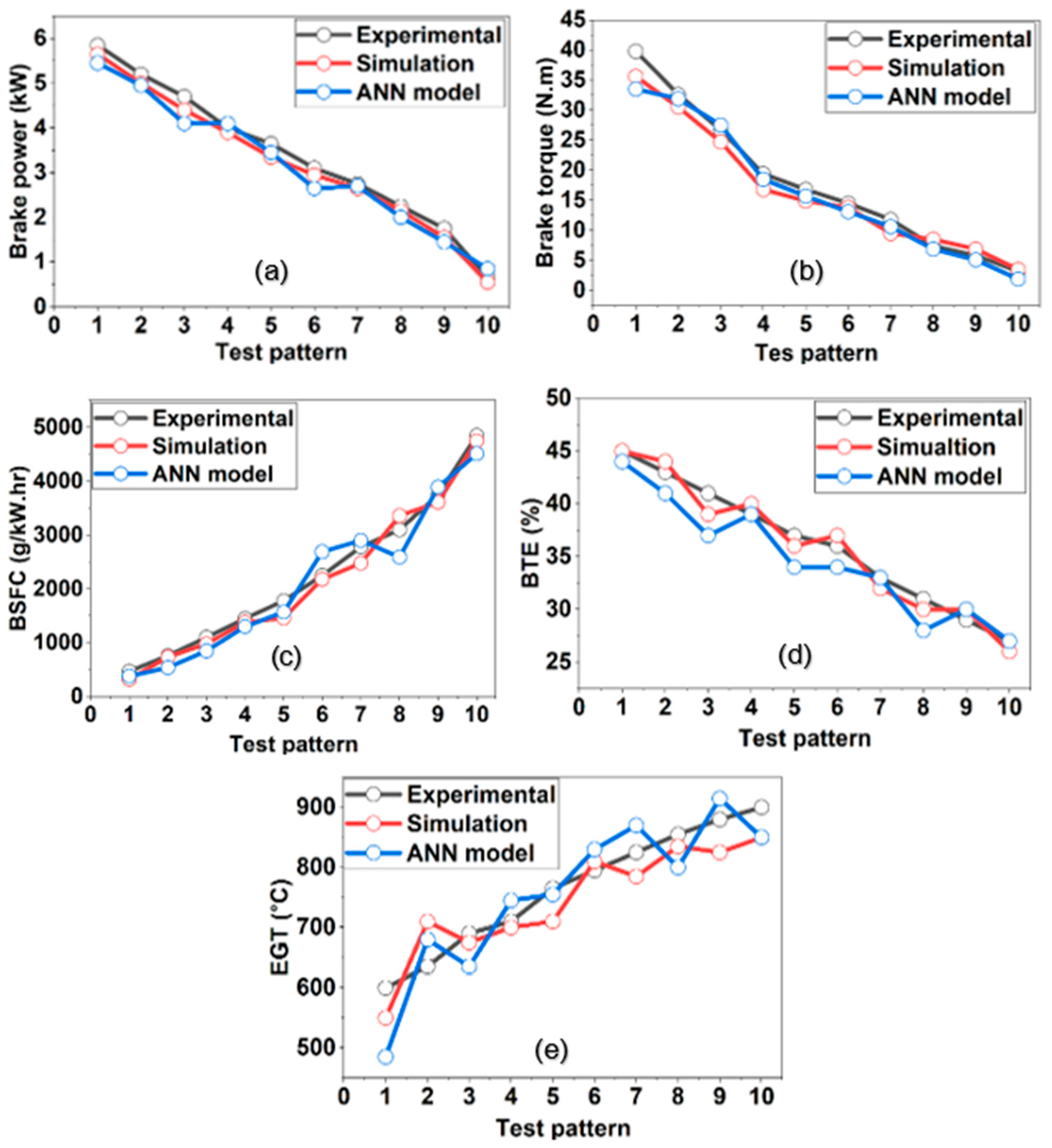

3.1. Performance Parameters

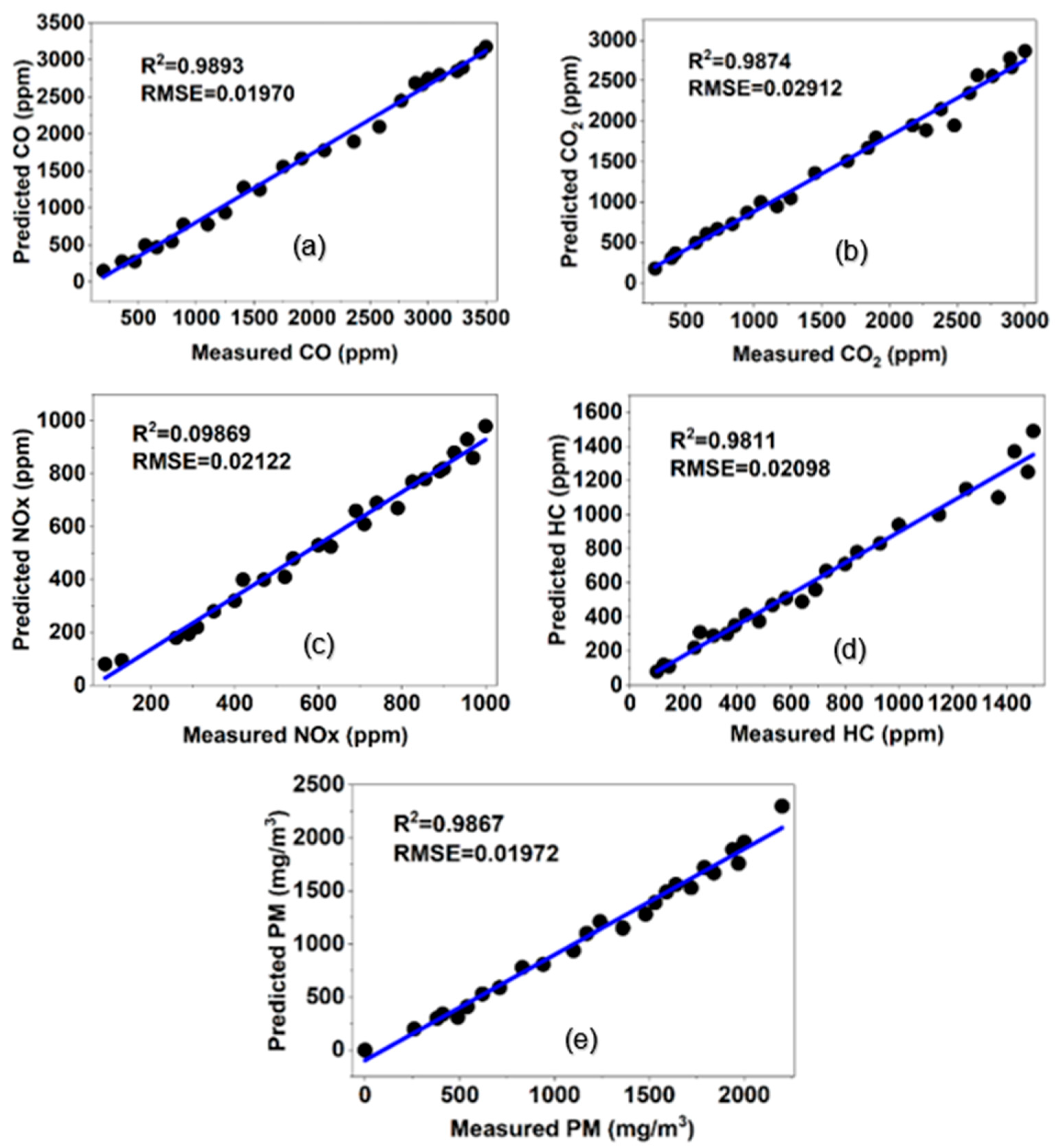

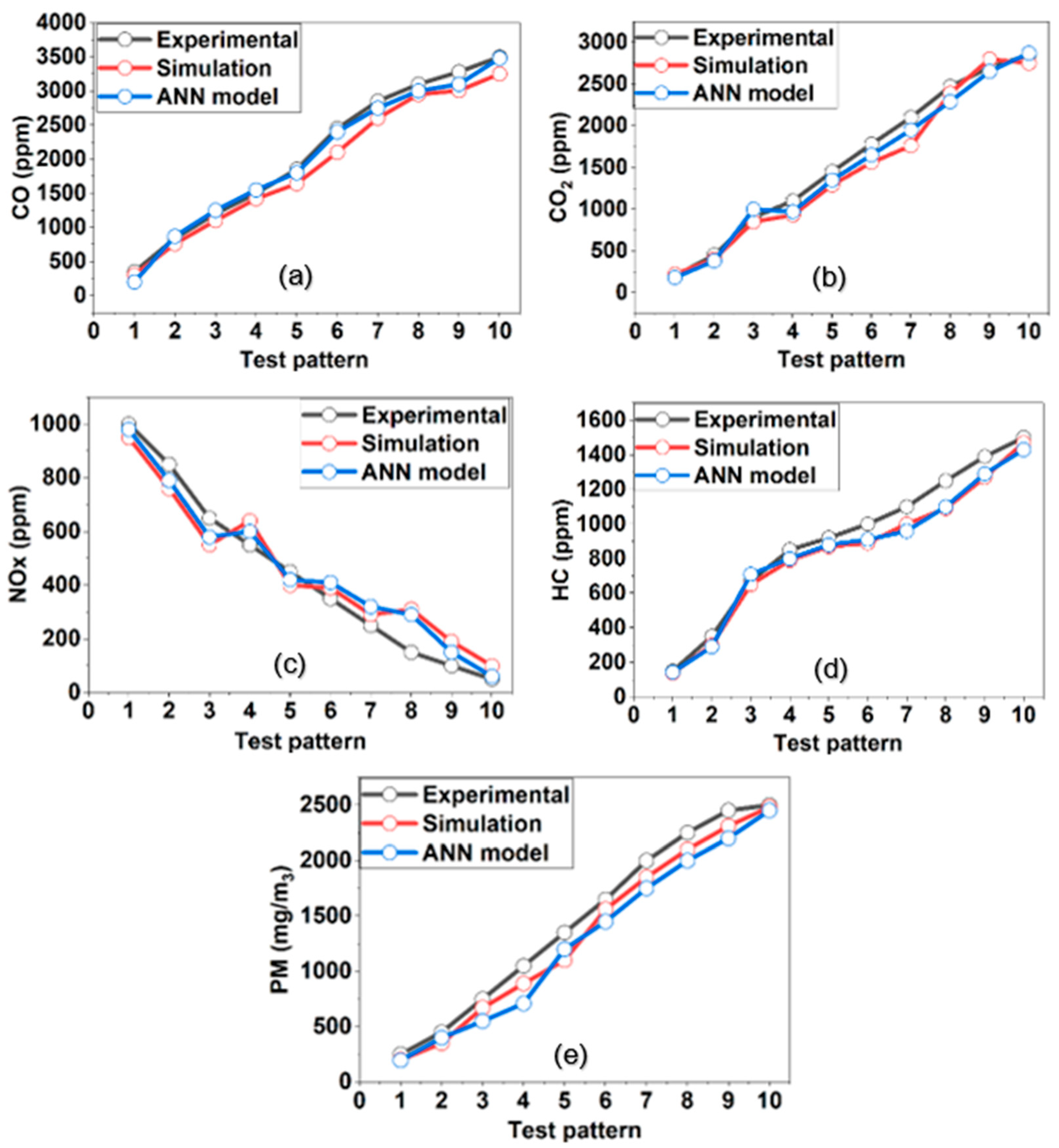

3.2. Emission Characteristics

4. Summary of the Study

4.1. Conclusions

- The findings confirm that excessive EBP adversely influences both performance and emissions, and that these effects are strongly modulated by load and compression ratio variations.

- The model outputs could be used to support emission compliance strategies by forecasting pollutant formation under diverse EBP and load conditions, thus aiding in the development of cleaner diesel technologies.

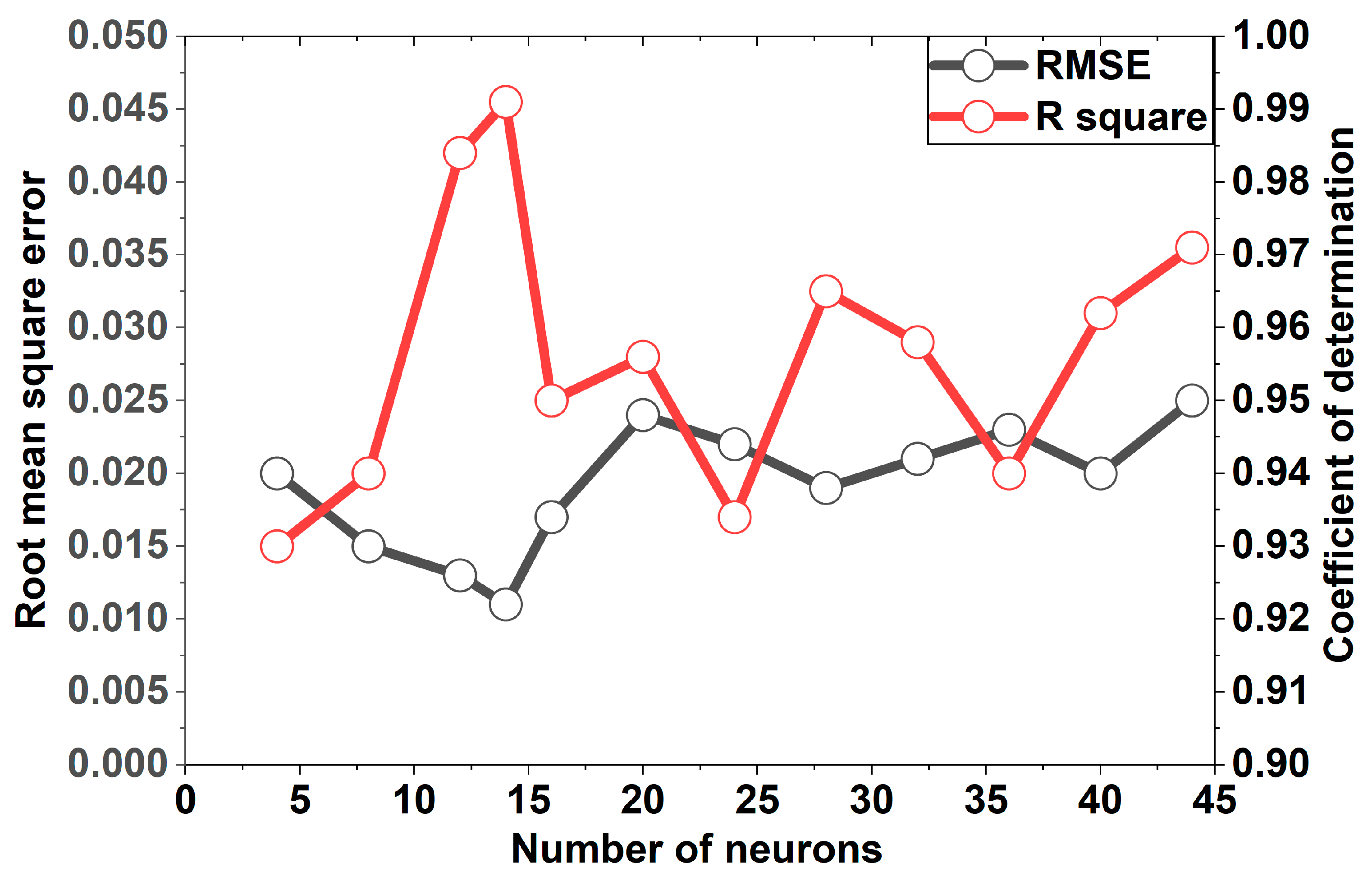

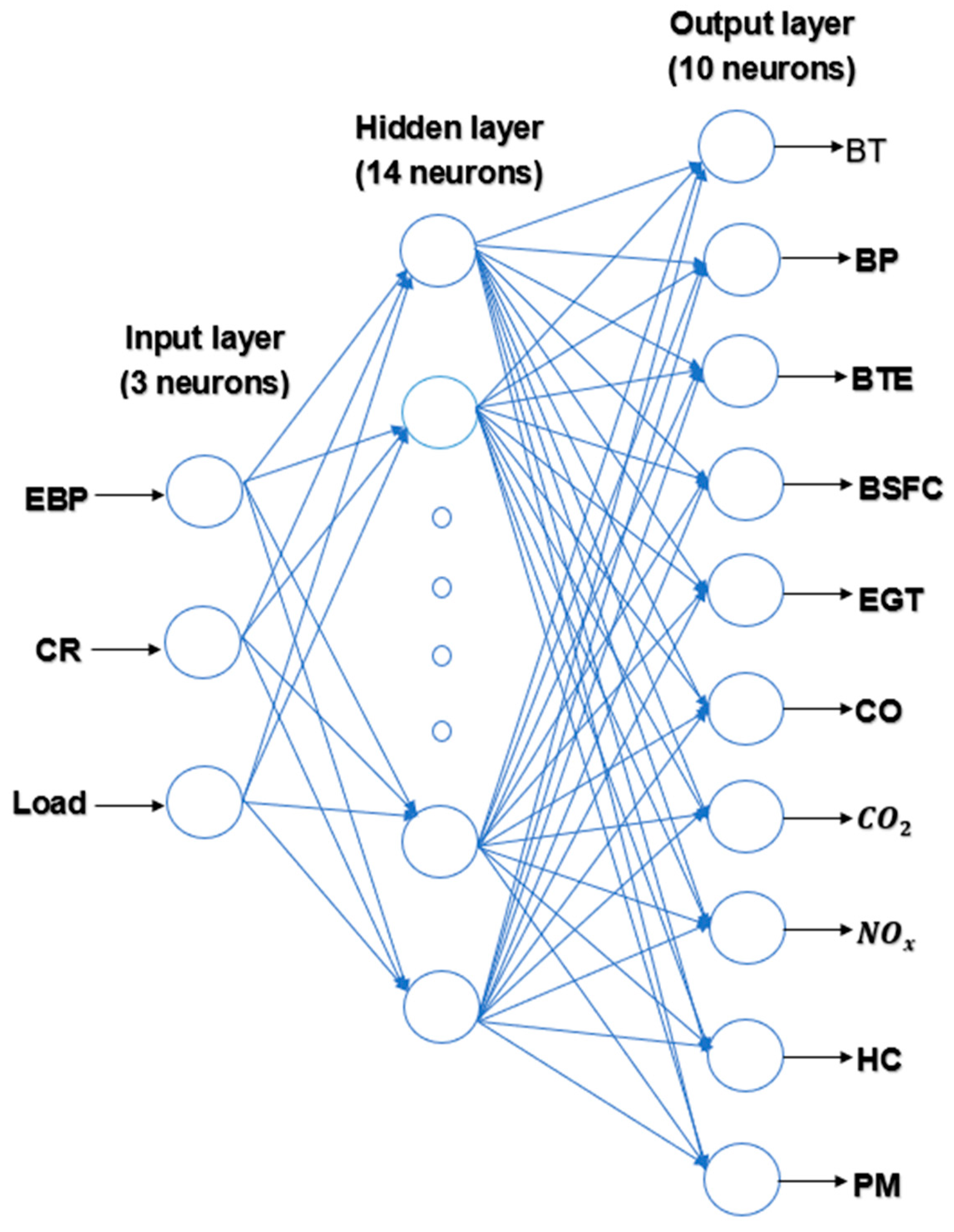

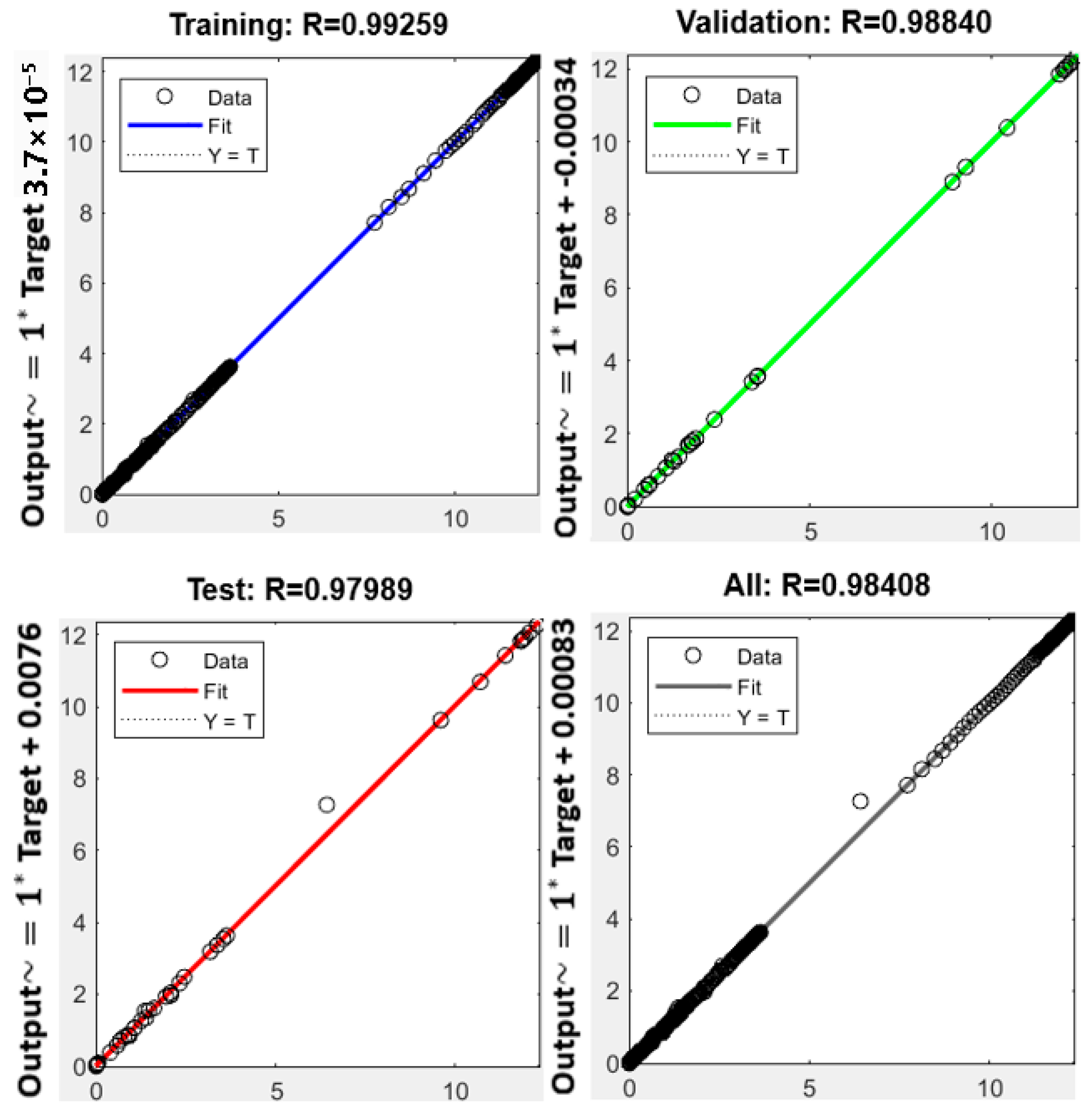

- The predictions obtained from the optimized ANN model, configured with fourteen neurons in the hidden layer, displayed a strong correlation with both the experimental data and the validated simulation results.

- The data point distribution for the optimized ANN model closely resembled that of the experimental and simulation data, achieving an overall value of 0.991. This high indicates that the developed ANN model was proficient in making predictions that aligned well with both experimental and simulated results.

- The overall prediction error percentage for the ANN model was found to range from 1.911% to 2.972%, validating the accuracy and consistency of the model in predicting performance results.

4.2. Recommendations

4.3. Liminations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 1D-CFD | One-dimensional computational fluid dynamics |

| ANN | Artificial neural network |

| GA | Genetic algorithms |

| PSO | Particle swarm optimization |

| EBP | Exhaust backpressure |

| CR | Compression ratio |

| FF | Feedforward |

| IDI | Indirectly injected |

| VCR | Variable compression ratio |

| IC | Internal combustion |

| ML | Machine learning |

| NOX | Nitrogen oxides |

| R2 | Root mean square error |

| RBF | Radial basis function |

| MAPE | Mean absolute percentage error |

| MAE | Mean absolute error |

References

- Yu, T.; Li, K.; Wu, Q.; Yao, P.; Ke, J.; Wang, B.; Wang, Y. Diesel engine emission aftertreatment device aging mechanism and durability assessment methods: A review. Atmosphere 2023, 14, 314. [Google Scholar] [CrossRef]

- Pierce, D.; Haynes, A.; Hughes, J.; Graves, R.; Maziasz, P.; Muralidharan, G.; Shyam, A.; Wang, B.; England, R.; Daniel, C. High temperature materials for heavy duty diesel engines: Historical and future trends. Prog. Mater. Sci. 2019, 103, 109–179. [Google Scholar] [CrossRef]

- Liu, Z.G.; Munnannur, A. Future Diesel Engines. In Design and Development of Heavy Duty Diesel Engines: Energy, Environment, and Sustainability; Lakshminarayanan, P., Agarwal, A., Eds.; Springer: Cham, Switzerland, 2009; pp. 887–914. [Google Scholar] [CrossRef]

- Xu, G.; Jia, M.; Li, Y.; Chang, Y.; Liu, H.; Wang, T. Evaluation of variable compression ratio (VCR) and variable valve timing (VVT) strategies in a heavy-duty diesel engine with reactivity controlled compression ignition (RCCI) combustion under a wide load range. Fuel 2019, 253, 114–128. [Google Scholar] [CrossRef]

- Karvounis, P.; Theotokatos, G. Performance improvement and emissions reduction of methanol fuelled marine dual-fuel engine with variable compression ratio. Fuel Process. Technol. 2025, 272, 108208. [Google Scholar] [CrossRef]

- Aydın, M.; Uslu, S.; Çelik, M.B. Performance and emission prediction of a compression ignition engine fueled with biodiesel-diesel blends: A combined application of ANN and RSM based optimization. Fuel 2020, 269, 117472. [Google Scholar] [CrossRef]

- Rezaei, J.; Shahbakhti, M.; Bahri, B.; Aziz, A.A. Performance prediction of HCCI engines with oxygenated fuels using artificial neural networks. Appl. Energy 2015, 138, 460–473. [Google Scholar] [CrossRef]

- Baioletti, M.; Bari, G.D.; Poggioni, V.; Tracolli, M. Can Differential Evolution Be an Efficient Engine to Optimize Neural Networks? Lect. Notes Comput. Sci. 2017, 10710, 401–413. [Google Scholar] [CrossRef]

- Pham, H.; Hasegawa, H. Adaptive Plan System of Swarm Intelligent using Differential Evolution with Genetic Algorithm. J. Adv. Mech. Des. Syst. Manuf. 2019, 7, 458–473. [Google Scholar] [CrossRef][Green Version]

- Baioletti, M.; Di Bari, G.; Milani, A.; Poggioni, V. Differential Evolution for Neural Networks Optimization. Mathematics 2020, 8, 69. [Google Scholar] [CrossRef]

- Çay, Y.; Korkmaz, I.; Çiçek, A.; Kara, F. Prediction of engine performance and exhaust emissions for gasoline and methanol using artificial neural network. Energy 2019, 50, 177–186. [Google Scholar] [CrossRef]

- Prasada Rao, K.; Victor Babu, T.; Anuradha, G.; Appa Rao, B.V. IDI diesel engine performance and exhaust emission analysis using biodiesel with an artificial neural network (ANN). Egypt. J. Pet. 2017, 26, 593–600. [Google Scholar] [CrossRef]

- Noor, C.W.M.; Mamat, R.; Najafi, G.; Mat Yasin, M.H.; Ihsan, C.K.; Noor, M.M. Prediction of marine diesel engine performance by using artificial neural network model. J. Mech. Eng. Sci. 2021, 10, 1917–1930. [Google Scholar] [CrossRef]

- Boruah, D.; Thakur, P.K.; Baruah, D. Artificial neural network based modelling of internal combustion engine performance. Int. J. Eng. Res. Technol. 2019, 5, 568–576. [Google Scholar] [CrossRef]

- Muralidharan, K.; Vasudevan, D. Applications of artificial neural networks in prediction of performance, emission and combustion characteristics of variable compression ratio engine fuelled with waste cooking oil biodiesel. J. Braz. Soc. Mech. Sci. Eng. 2015, 37, 915–928. [Google Scholar] [CrossRef]

- Karthickeyan, V.; Balamurugan, P.; Rohith, G.; Senthil, R. Developing of ANN model for prediction of performance and emission characteristics of VCR engine with orange oil biodiesel blends. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 2877–2888. [Google Scholar] [CrossRef]

- Behera, B.N.; Hotta, T.K. Influence of copper oxide nano-particles on the performance, emission, and combustion measures of a VCR engine using palm biodiesel blended with N-butanol: A combined experimental and ANN-GA-based study. Fuel 2024, 381, 133504. [Google Scholar] [CrossRef]

- Kakati, D.; Roy, S.; Banerjee, R. Development of an artificial neural network based virtual sensing platform for the simultaneous prediction of emission-performance-stability parameters of a diesel engine operating in dual fuel mode with port injected methanol. Energy Convers. Manag. 2019, 184, 488–509. [Google Scholar] [CrossRef]

- Manimaran, R.; Mohanraj, T.; Venkatesan, M. ANN modeling for forecasting of VCR engine performance and emission parameters fuelled with green diesel extracted from waste biomass resources. Environ. Sci. Pollut. Res. 2022, 29, 51183–51210. [Google Scholar] [CrossRef]

- Saravanamuthu, M.; Thulasiram, R.; Ramasamy, D.; Sundaramoorthy, S. Optimization of engine parameters using NSGA II for the comprehensive reduction of emissions from VCR engine fuelled with ROME biodiesel. Environ. Sci. Pollut. Res. 2022, 30, 61162–61176. [Google Scholar] [CrossRef]

- Hosamani, B.R.; Abbas Ali, S.; Katti, V. Assessment of performance and exhaust emission quality of different compression ratio engine using two biodiesel mixture: Artificial neural network approach. Alex. Eng. J. 2020, 60, 837–844. [Google Scholar] [CrossRef]

- Kumar, T.A.; Musthafa, M.M.; Chandramouli, R.; Kandavel, T.K.; Raj, T.M.; Sridharan, G. Performance characteristics of a variable compression ratio CI engine simulation using artificial neural network. Energy Sources Part A 2019, 44, 1912–1922. [Google Scholar] [CrossRef]

- Taye, M.M. Understanding of Machine Learning with Deep Learning: Architectures, Workflow, Applications and Future Directions. Computers 2023, 12, 91. [Google Scholar] [CrossRef]

- Yang, F.; Cho, H.; Zhang, H.; Zhang, J.; Wu, Y. Artificial neural network (ANN) based prediction and optimization of an organic Rankine cycle (ORC) for diesel engine waste heat recovery. Energy Conver. Manag. 2018, 164, 15–26. [Google Scholar] [CrossRef]

- Yellapragada, D.B.; Budda, G.R.; Vadavelli, K. Optimization of injection parameters for ethanol blends of plastic oil in VCR engine using RSM and ANN. World J. Eng. 2021, 18, 906–919. [Google Scholar] [CrossRef]

- Kajale, T.; Hole, J.; Pawar, A.; Dubal, S. Optimizing performance and emissions of VCR diesel engines using grey-taguchi methods and ANN with biodiesel from waste cooking soybean oil. Int. J. Heat Technol. 2025, 43, 228–240. [Google Scholar] [CrossRef]

- Thodda, G.; Madhavan, V.R.; Thangavelu, L. Predictive modelling and optimization of performance and emissions of acetylene fuelled CI engine using ANN and RSM. Energy Sources Part A 2020, 45, 1–19. [Google Scholar] [CrossRef]

- Fernoaga, V.; Sandu, V.; Balan, T. Artificial intelligence for the prediction of exhaust back pressure effect on the performance of diesel engines. Appl. Sci. 2020, 10, 7370. [Google Scholar] [CrossRef]

- Yan, Z.; Cui, Z.; Gu, M.; Zhong, S.; Lin, L. Double regulation Levenberg–Marquardt neural networks: An aero-engine fuel flow prediction method. Nonlinear Dyn. 2023, 111, 18129–18147. [Google Scholar] [CrossRef]

- Shalahuddin, L.; Fajar, R.; Bismantoko, S. Review of artificial neural network applications for prediction of internal combustion engine performance. AIP Conf. Proc. 2023, 2646, 040043. [Google Scholar] [CrossRef]

- Jadidi, M.; Kostic, S.; Zimmer, L.; Dworkin, S.B. An artificial neural network for the low-cost prediction of soot emissions. Energies. 2020, 13, 4787. [Google Scholar] [CrossRef]

- Yousif Mawlood, A.; Salih, H.; Hummadi, R.; Hasan, A.; Ibrahim, H. Comparison of artificial neural network (ANN) and linear regression modeling with residual errors to predict the unconfined compressive strength and compression index for Erbil City soils, Kurdistan-Iraq. Arab. J. Geosci. 2021, 14, 485. [Google Scholar] [CrossRef]

- Wahidna, A.; Sookia, N.; Ramgolam, Y.K. Performance evaluation of artificial neural network and hybrid artificial neural network based genetic algorithm models for global horizontal irradiance forecasting. Sol. Energy Adv. 2024, 4, 100054. [Google Scholar] [CrossRef]

- Jierula, A.; Wang, S.; OH, T.M.; Wang, P. Study on Accuracy Metrics for Evaluating the Predictions of Damage Locations in Deep Piles Using Artificial Neural Networks with Acoustic Emission Data. Appl. Sci. 2021, 11, 2314. [Google Scholar] [CrossRef]

- Seo, J.; Park, S. Optimizing model parameters of artificial neural networks to predict vehicle emissions. Atmos. Environ. 2023, 294, 119508. [Google Scholar] [CrossRef]

- Li, Y.; Jia, M.; Han, X.; Bai, X.-S. Towards a comprehensive optimization of engine efficiency and emissions by coupling artificial neural network (ANN) with genetic algorithm (GA). Energy 2021, 225, 120331. [Google Scholar] [CrossRef]

- Di Mauro, A.; Chen, H.; Sick, V. Neural network prediction of cycle-to-cycle power variability in a spark-ignited internal combustion engine. Proc. Combust. Inst. 2019, 37, 4937–4944. [Google Scholar] [CrossRef]

- Sharma, P. Artificial intelligence-based model prediction of biodiesel-fueled engine performance and emission characteristics: A comparative evaluation of gene expression programming and artificial neural network. Heat Transf. 2021, 50, 5563–5587. [Google Scholar] [CrossRef]

- Yang, R.; Yan, Y.; Sun, X.; Wang, Q.; Zhang Fu, J.; Lu, Z. An artificial neural network model to predict efficiency and emissions of a gasoline engine. Processes 2022, 10, 204. [Google Scholar] [CrossRef]

- Dahham, R.Y.; Wei, H.; Pan, J. Improving Thermal Efficiency of Internal Combustion Engines: Recent Progress and Remaining Challenges. Energies 2022, 15, 6222. [Google Scholar] [CrossRef]

| Performance Parameter | Emission Characteristic |

|---|---|

| Brake power (BP) | Carbon monoxide (CO) |

| Brake torque (BT) | Carbon dioxide (CO2), |

| Brake specific fuel consumption (BSFC) | Nitrogen oxides (NOX) |

| Brake thermal efficiency (BTE) | Hydrocarbons (HC), |

| Exhaust gas temperature (EGT) | Particulate matter (PM) |

| Engine Parameters | Units | Values |

|---|---|---|

| Make | Kirloskar | |

| Type | 1-cylinder, 4-stroke, VCR diesel | |

| Cooling system | Water cooled | |

| Rated power | kW | 3.5 |

| Speed | Rpm | 1500 |

| Bore diameter | Mm | 87.5 |

| Stroke | Mm | 110 |

| Connecting rod | Mm | 234 |

| Compression ratio | Variable (12–18) | |

| Displacement | Cc | 661 |

| Loading | Eddy current dynamometer |

| Parameter | Specification |

|---|---|

| Input layer neuron | 3 |

| Hidden layer (single) neuron | 4 to 44 |

| Output layer neuron | 10 |

| Training function | Levenberg–Marquardt |

| Performance function | Mean square error |

| Activation function | Log-sigmoid, Linear |

| Performance goal |

| Model Configuration | RMSE | MAE | Convergence Epochs | |

|---|---|---|---|---|

| ANN (baseline, neuron variation only) | 0.013 | 0.984 | 0.017 | 640 |

| ANN + GA optimization | 0.0128 | 0.989 | 0.012 | 520 |

| ANN + PSO optimization | 0.011 | 0.991 | 0.010 | 500 |

| Model Configuration | RMSE | MAE | MAPE (%) | |

|---|---|---|---|---|

| Support Vector Machine (SVM) | 0.026 | 0.965 | 0.020 | 3.5 |

| Random Forest (RF) | 0.022 | 0.972 | 0.018 | 3.1 |

| Deep Neural Network (DNN) | 0.018 | 0.978 | 0.013 | 2.7 |

| ANN (GA/PSO optimized) | 0.011 | 0.991 | 0.010 | 2.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanyi, N.; Inambao, F.; Stopforth, R. Prediction of Diesel Engine Performance and Emissions Under Variations in Backpressure, Load, and Compression Ratio Using an Artificial Neural Network. Appl. Sci. 2025, 15, 10588. https://doi.org/10.3390/app151910588

Khanyi N, Inambao F, Stopforth R. Prediction of Diesel Engine Performance and Emissions Under Variations in Backpressure, Load, and Compression Ratio Using an Artificial Neural Network. Applied Sciences. 2025; 15(19):10588. https://doi.org/10.3390/app151910588

Chicago/Turabian StyleKhanyi, Nhlanhla, Freddie Inambao, and Riaan Stopforth. 2025. "Prediction of Diesel Engine Performance and Emissions Under Variations in Backpressure, Load, and Compression Ratio Using an Artificial Neural Network" Applied Sciences 15, no. 19: 10588. https://doi.org/10.3390/app151910588

APA StyleKhanyi, N., Inambao, F., & Stopforth, R. (2025). Prediction of Diesel Engine Performance and Emissions Under Variations in Backpressure, Load, and Compression Ratio Using an Artificial Neural Network. Applied Sciences, 15(19), 10588. https://doi.org/10.3390/app151910588