Featured Application

The developed multi-layer sensor network enables real-time, in situ monitoring of temperature distribution during LVL and plywood hot pressing. This technology can be directly applied in the wood-based panel industry to optimize pressing schedules for different panel thicknesses, ensuring complete adhesive curing and consistent bonding quality. By providing precise data on internal thermal gradients, the system supports adaptive process control, reduces the risk of under-cured cores in thicker products, and enhances both the structural performance and production efficiency. Beyond LVL manufacturing, the approach has the potential for broader adoption in smart manufacturing environments where real-time process feedback is critical for quality assurance and energy-efficient operation.

Abstract

Ensuring optimal adhesive curing during plywood and LVL (Layered Veneer Lumber) hot pressing requires accurate knowledge of internal temperature distribution, which is often difficult to assess using conventional surface-based measurements. This study introduces a custom-developed multi-layer smart sensor network capable of in situ, real-time temperature profiling across LVL layers during industrial hot pressing. The system integrates miniature embedded sensors and proprietary data acquisition software, enabling the simultaneous multi-point monitoring of thermal dynamics with a high temporal resolution. Experiments were performed on LVL panels of varying thicknesses, applying industry-standard pressing schedules derived from conventional calculation rules. Despite adherence to prescribed pressing times, results reveal significant core temperature deficits in thicker panels, potentially compromising adhesive gelation and overall bonding quality. These findings underline the need to revisit the pressing time determination for thicker products and demonstrate the potential of advanced sensing technologies to support adaptive process control. The proposed approach contributes to smart manufacturing and the remote-like monitoring of internal thermal states, providing valuable insights for enhancing product performance and industrial process efficiency.

1. Introduction

Plywood and LVL remain among the most widely used engineered wood products, providing mechanical strength, dimensional stability, and versatility that support their use in furniture, construction, and transportation industries [1]. A critical stage in plywood and LVL manufacturing is hot pressing, during which adhesive-bonded veneer stacks are subjected to high temperatures and pressure to achieve curing and bonding integrity. Proper heat transfer into the inner layers of the plywood stack is essential for complete adhesive gelation, which directly affects the final product’s structural performance and long-term durability [2].

The density profile of Laminated Veneer Lumber (LVL) is closely linked to its mechanical properties. Higher density generally improves shear strength, MOE, and bending strength, as observed in carbon-fibre and poplar LVL [3,4], and in denser species such as Kasai compared to Mengkulang [5]. Phenol formaldehyde resin increases the density and compressive strength [6], while greater density uniformity enhances the performance stability [7]. Processing methods, including veneer punching, fibre reinforcement [8], and high-voltage electrostatic fields (HVEF), can further improve the density and strength [9].

In plywood, adhesive joint density is influenced by veneer density, glue spread, adhesive type, and pressing pressure. High-density veneers reduce penetration and bond strength [10,11,12], while polyvinyl acetate outperforms urea-formaldehyde, and modified phenolic resins improve toughness [12]. Adequate pressure ensures uniform bonding [12]. Overall, deeper penetration and even adhesive distribution increase strength [10,12], while veneer density and the adhesive type govern shear and tensile strength [12,13]. Failure modes depend on density, with high-density profiles potentially causing stress concentrations and premature failure [13,14].

Traditionally, hot pressing parameters such as temperature, pressure, and pressing time are determined using empirical or semi-empirical guidelines based on plywood thickness and the adhesive type. While these methods have proven reliable for standard products, they often overlook internal thermal variations, especially in thicker panels. This can result in non-uniform curing, incomplete bonding, and reduced mechanical properties in the finished plywood. Despite the importance of internal temperature monitoring, most existing industrial systems focus on external surface temperatures or rely on indirect calculations, limiting the ability to capture dynamic thermal behaviour inside the veneer stack.

In the woodworking industry, thermocouples and RTD (Resistance Temperature Detector) sensors are commonly used to measure temperature during higher-temperature processes. Thermocouples remain the most popular solution due to their low cost, ease of use, resistance to environmental conditions, and wide operating range—depending on the type, typically up to 850 °C, which meets the requirements of typical woodworking processes (drying, boards manufacturing). RTDs, particularly the Pt100 type, are valued for greater accuracy and long-term stability. Still, they have a lower resistance to thermal shock and vibration, making them primarily used where precision is essential and operating conditions are relatively stable [15,16,17].

If thermocouples or RTDs are not used, more advanced technologies are used, which are not yet common in the woodworking industry but show potential in more challenging or unusual conditions. An example is fibre optic sensors, whose immunity to electromagnetic interference makes them suitable for radio frequency (RFV) drying rooms, where standard sensors can produce erroneous readings. However, due to their high cost and fragility, their use is limited to specialized installations [17,18].

Even more advanced solutions, such as sensors based on silicon carbide (SiC) or LTCC (Low Temperature Co-Fired Ceramics) technology, are currently limited to applications in the energy, automotive, and defence sectors, where extreme operating conditions occur—temperatures exceeding 500 °C or even 1000 °C. SiC sensors offer exceptional resistance to temperature and chemical conditions, making them ideal for use in aggressive environments. LTCC, on the other hand, enables the creation of high-precision sensors with integrated temperature compensation, tested in conditions up to 500 °C and high pressure [19,20].

In the context of the woodworking industry, technologies such as SiC and LTCC exceed current needs and application possibilities. Still, they may find future applications, for example, in highly automated or experimental drying processes. However, the basis remains for proven solutions: thermocouples and RTDs, with the occasional use of optical fibres in environments with strong electromagnetic interference.

Recent advances in sensor technology and smart manufacturing concepts have opened opportunities for the real-time, in situ monitoring of internal processing conditions. Embedded sensor networks and advanced data acquisition and analysis systems have demonstrated potential in various manufacturing sectors, enabling an improved process control and quality assurance. However, in the plywood industry, applications of such advanced sensing methods remain limited, primarily due to challenges associated with sensor integration in high-temperature, high-pressure environments.

Experimental results demonstrate that, as the panel thickness increases, the core temperature rise is significantly delayed compared to surface layers, raising concerns about adhesive gelation quality and overall bond performance in thicker LVL products.

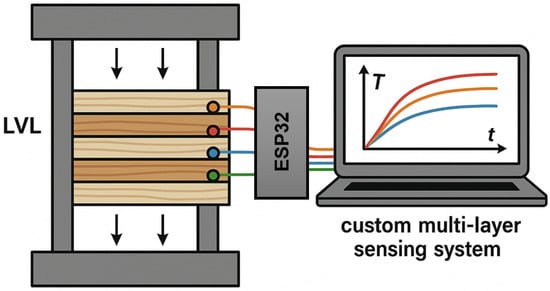

By integrating advanced sensing capabilities into a traditionally empirical process, this study reveals critical thermal behaviour and highlights pathways for optimizing pressing parameters to improve product consistency and quality. Furthermore, the proposed sensing platform (Figure 1) illustrates the potential of embedded measurement systems to contribute to smart manufacturing and remote-like process monitoring in the wood-based panel industry.

Figure 1.

In situ temperature profiling of LVL during hot pressing using a custom multi-layer sensing system.

This study presents a novel custom-developed, multi-layer smart sensor network designed for the in situ measurement of temperature evolution during LVL hot pressing. The developed system consists of miniature embedded temperature sensors strategically positioned across multiple veneer layers, coupled with proprietary data acquisition software capable of simultaneous multi-point measurement and real-time visualization. This unique setup enables the detailed characterization of internal temperature gradients, providing unprecedented insight into how panel thickness influences heat transfer and adhesive curing under standard industrial pressing schedules.

2. Materials and Methods

2.1. Materials

Rotary-cut veneers of Scots pine (Pinus sylvestris L.), about 5% moisture content, were obtained from an industrial producer of wood-layered composites in Poland. The veneers were produced with nominal dimensions of 1000 mm × 1000 mm × 3.20 mm (length × width × thickness). The industrial sheets were trimmed to 220 mm × 220 mm for experimental purposes. Due to the potential effects of natural heterogeneity in the raw material, such as density variation, annual ring orientation, and cross-sectional features, paired specimens were prepared by cutting both sheets parallel to the grain direction of the original veneer. A phenol-formaldehyde (PF) resin (Silekol Sp. z o.o., Kędzierzyn–Koźle, Poland), representative of adhesive systems commonly applied in industrial plywood and composite board production, was selected as the binder. The resin exhibited a solid content of 50%, determined in accordance with [21]. The adhesive formulation was prepared by mixing the PF resin with an aqueous solution of ammonium sulfate ((NH4)2SO4) as a hardener and wheat flour as a filler. The ratio of resin to hardener solution to filler, expressed on a dry-weight basis, was 100:2:10. The adhesive system demonstrated a curing time of approximately 111 s at 100 °C and a dynamic viscosity of about 180 mPa s at 20 °C.

2.2. Samples Preparation

Plywood sheets were prepared with thermocouples placed between the individual layers. The temperature sensors were attached using paper tape, ensuring their stable placement without disturbing the sample’s structure and away from the measuring point so as not to interfere with the reading and heat transfer. The prepared stack (layers in parallel) was placed in a press.

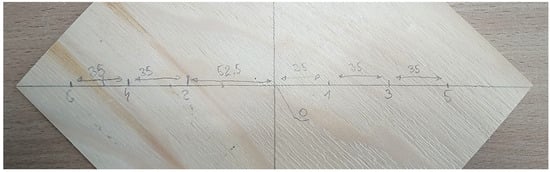

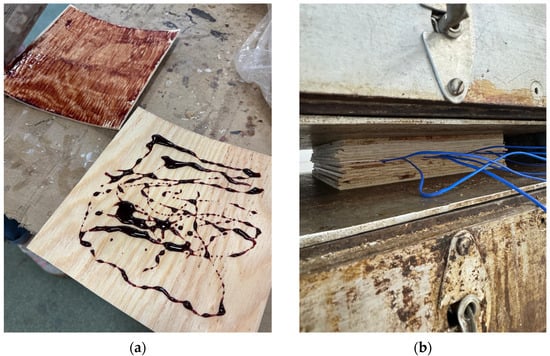

Different test variants were performed: the first, preliminary, was a “dry” test—without glue, but with the use of the same veneers and pressing parameters, aimed at observing only the thermal conductivity of the material. The second test variant was performed on the veneer sets, where the sensors were placed in only one level (in the middle of the veneer set thickness) at various distances (Figure 2) from the centre of the sheet, allowing for an assessment of whether the sensor location affected the obtained temperature results. The third test variant was performed as in industrial panels—the amount of adhesive manually spread (180 g m−2) (Figure 3a) was selected according to the technological recipe, and pressing was performed using a hydraulic press (AKE, Mariannelund, Sweden) (Figure 3b) using parameters derived from Formula (1) for pressing time tp. The maximum pressing pressure was 1.5 MPa, and the press temperature was 140 °C:

where e is the thickness of the pressed material [mm] when measured from the surface to the bonding line nearest the middle of the pressed composite’s thickness.

tp = 4 + e [min]

Figure 2.

Distribution of thermocouples (1–6 correspond to thermocouples T1–T6; distances in mm) in the second and third variants.

Figure 3.

Manual spreading of the adhesive on the veneer surface (a) and the set of veneers with the thermocouples in the hot press (b).

Based on the above formula and having the veneer thickness of 3.20 mm, the following press times have been applied: 10, 17, and 30 min, respectively, for 4, 8, and 16-layer composites. As many as 4 repetitions of 220 mm × 220 mm panels have been produced with the following layer numbers: 4, 8, and 16. The LVL core temperature has been measured from the beginning of the pressing through the entire pressing process and during panel cooling until reaching 50 °C.

Before testing, the panels were conditioned in the climatic chamber at 20 °C ± 1 °C and 65% ± 2% relative humidity until they reached a constant mass.

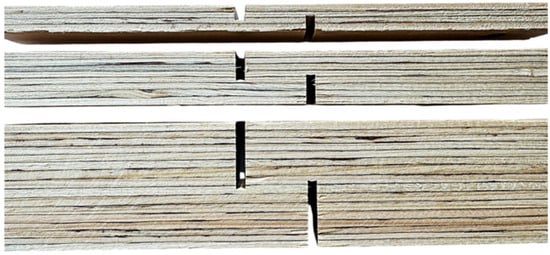

2.3. Samples Testing

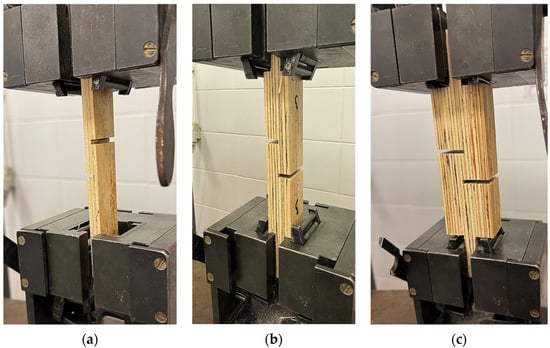

For the produced LVL panels, the bonding quality in the thickness centre of the panels has been estimated according to [22] on a laboratory testing machine custom-made by the Research and Development Centre for Wood-Based Panels Sp. z o. o. in Czarna Woda, Poland. To complete this, the shear strength was measured on the samples in Figure 4, and the in-wood damage ratio was visually evaluated. The nominal dimensions of the sample area subjected to shear forces were 20 mm × 25 mm along and across the sample length, respectively (Figure 5). As many as 10 samples have been measured for every composite type.

Figure 4.

The samples used in bonding quality measurement: 4 layers, 8 layers, and 16 layers (top to bottom).

Figure 5.

The samples during bonding quality measurement: 4 layers (a), 8 layers (b), and 16 layers (c).

The produced samples have also been tested for the density profile. The specimens were prepared by cutting the panels into nominal dimensions of 50 mm × 50 mm × panel thickness. The density profiles were subsequently determined using a Grecon DA-X measuring system (Fagus-GreCon Greten GmbH and Co. KG, Alfeld, Germany) equipped with direct X-ray densitometry, employing a scanning resolution of 0.02 mm across the panel thickness.

2.4. Statistical Analysis

The data for each test were subject to variance analysis (ANOVA), and t-tests were used to determine statistical significance (α = 0.05) of differences between factors and levels (IBM SPSS 20 software, Armonk, NY, USA). A comparison of the means was performed when the ANOVA indicated a significant difference, employing the Duncan test. Wherever possible, the results on the plots represent the average value and ± standard deviation bars. The letters “a” and “b” on the plots indicate the statistically homogeneous groups.

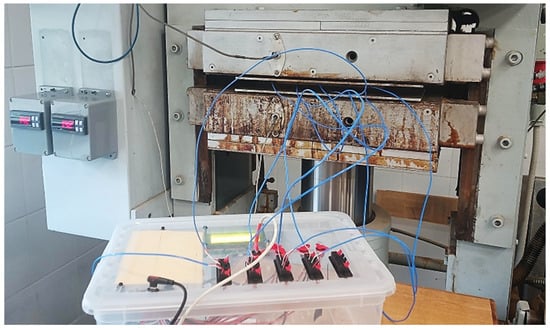

2.5. Temperature Measurement

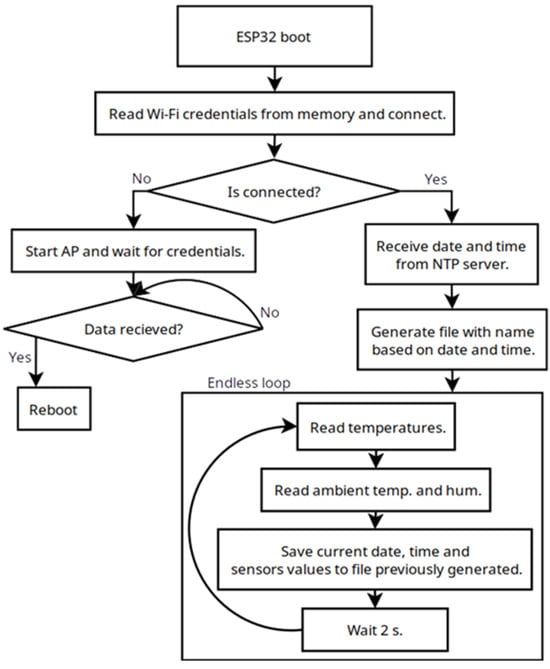

A dedicated device (Figure 6) based on an ESP32 microcontroller measured the temperature with a set of thermocouples connected. Before the measurement, the device was configured by providing the Wi-Fi network information. Once powered on, the ESP32 automatically connects to the network and begins recording sensor data at 2 s intervals. Sensor data is stored in internal memory, containing the device’s startup date and time. Real-time measurement results can be viewed via a web browser and an LCD screen. The recorded data can be downloaded as separate files for further analysis. The procedure performed by the device is shown in Figure 7. The source code (uploaded using PlatformIO, Tallinn, Estonia, on Kubuntu 24.04) is available on GitHub (https://github.com/PMKrol/ThermoScout accessed on 30 August 2025).

Figure 6.

The designed multi-thermocouple measurement device (in front of the press) during measurement.

Figure 7.

The measuring procedure performed by the device.

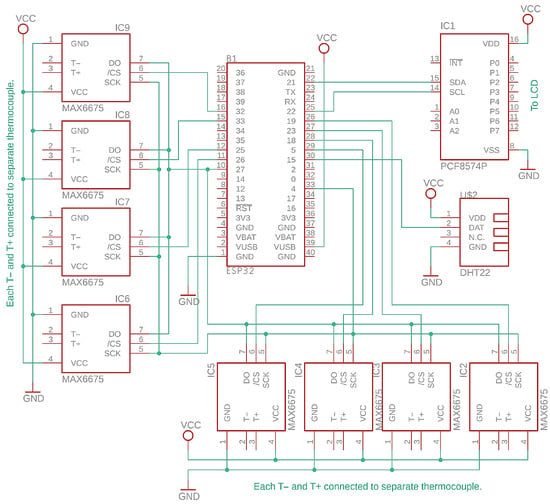

Based on the ESP32 platform (Figure 7), the device utilized the MAX6675 modules for thermocouple data acquisition, the PCF8574 I/O expander for communication with the LCD, and the DHT22 sensor for reading environmental conditions (Figure 8). MAX6675 modules were used to acquire data from thermocouples. The MAX6675 is designed to work with K-type thermocouples, providing digital data output with a measurement error of less than 5% [23].

Figure 8.

Electrical diagram of the measuring device (electronic elements in red; wiring in green; numbers are connectors/ports).

3. Results and Discussion

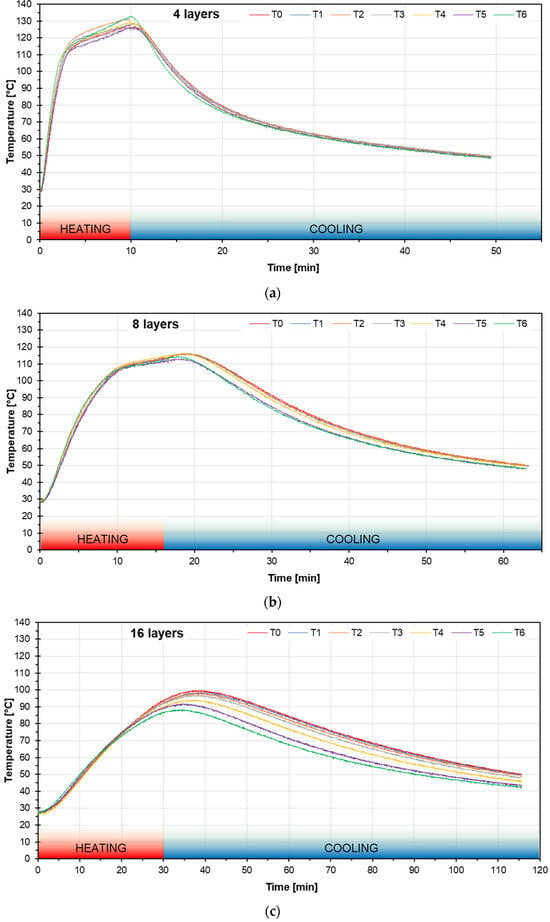

Temperature measurements taken from the tested LVL panels with 4, 8, and 16 layers (Figure 9) demonstrated clear differences in heat transfer across the panel thickness, as well as between the thermocouple positions. It should be highlighted that, in all cases, the panels were pressed under the same platen temperature and pressure, but the pressing duration was adjusted according to the number of layers. Across all configurations, the temperature distribution followed a consistent gradient: thermocouples located near the panel side (T6) reached higher values and did so more rapidly than those closer to the core (T0). This reflects the unidirectional heat transfer from the heated platens toward the centre of the composite. The intermediate thermocouples (T1–T5) showed progressive delays and reductions in the maximum temperature, corresponding to their relative distance from the platen surfaces. During heating, the outer veneers lose moisture, which vaporizes and moves. Steam tends to flow from hotter regions toward cooler ones and also toward free edges and any gaps. When steam migrates and then condenses near cooler surfaces or in crevices, it releases latent heat locally—this can enhance the temperature near edges or intermediate positions. Conversely, in the panel centre, vapour may be trapped longer, and energy is consumed in evaporation rather than raising the temperature, slowing the core temperature rise. For the four-layer panel, the edge warms faster and hotter than the centre (edge reached 120 °C about 36 s earlier than the core, and its measured peak exceeded the core). This demonstrates the strong lateral gradient in thin panels during the early heating stage. For the eight-layer panel, there is still a clear edge-to-core lag (edge reaches 100 °C roughly 24 s earlier than the core). For the 16-layer panel, both the core and edge heat very slowly (60 °C reached only after about 17 min) and neither reached 99 °C during the run—the absolute temperatures are low, and the edge is not strongly hotter than the core in absolute terms (maximum observed edge—core delta is small). This suggests strong overall thermal buffering and that the stack dissipates/consumes incoming heat (latent heat for moisture, larger mass), preventing edge temperatures from rising much above the core.

Figure 9.

The distribution of the temperature in the tested LVL composites: (a) 4 layers, (b) 8 layers and (c) 16 layers. T0–T6 are the thermocouples distributed in the growing distance from the veneer centre with the growing thermocouple number.

Panel thickness strongly influenced the absolute values of the recorded temperatures. In the four-layer LVL, the core thermocouple (T0) reached 127 °C, indicating efficient heat penetration across the relatively thin structure. In the eight-layer LVL, the core temperature was lower at 117 °C, suggesting a slower rate of heat transfer and incomplete thermal equalization during pressing despite the longer pressing time. In the thickest 16-layer variant, the core temperature reached only 99 °C, highlighting significant limitations in heat penetration even after 30 min of pressing.

These variations in thermal distribution can have direct implications for LVL properties. Higher core temperatures in thinner panels allow for better veneer plasticization, more effective moisture removal, and complete adhesive curing, which supports higher density and stronger bonding. Conversely, in thicker panels, the reduced core temperature may result in incomplete consolidation and a lower density, with negative effects on the shear strength and overall mechanical performance. Extended pressing times, while partially compensating for a slow heat transfer, were not sufficient in the 16-layer variant to achieve thermal conditions comparable to thinner composites.

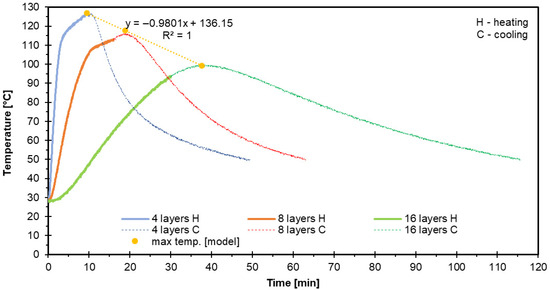

Core temperature measurements during pressing (Figure 10) revealed notable differences among the variants, with maximum values of 127 °C for the 4-layer panels, 117 °C for the 8-layer panels, and 99 °C for the 16-layer panels.

Figure 10.

The real and modelled core zone maximum temperatures of the tested composites.

These variations demonstrate that the core heat penetration decreases with increasing panel thickness and the number of layers, despite the use of the same pressing temperature and pressure. In thinner composites, such as the four-layer panels, heat reaches the panel core more rapidly, leading to higher maximum temperatures. Intermediate 8-layer panels exhibited a moderately lower core temperature (117 °C), while the thickest 16-layer panels reached only 99 °C in the core, indicating that longer pressing times are required to compensate for a slower heat transfer in thicker structures.

The differences in core temperature have direct implications for LVL densification, adhesive curing, and mechanical performance [24]. Higher core temperatures, as observed in the four-layer panels, promote effective plasticization of the wood veneers, moisture removal, and consolidation of the layers, supporting high density and strong adhesive bonding. Conversely, lower core temperatures, as in the 16-layer panels, may result in incomplete veneer plasticization, reduced compaction, and less effective adhesive curing in the inner layers. These effects can lead to lower density, reduced mechanical strength, and potential heterogeneity within the panel.

Pressing duration plays a critical role in compensating for slower heat penetration in thicker LVL composites. While the 16-layer panels were pressed for 30 min—three times longer than the 4-layer panels—the core temperature remained substantially lower. This indicates that pressing time alone may not fully overcome the limitations imposed by the thickness and thermal conductivity of wood, emphasizing the need to optimize both the temperature distribution and pressing duration for uniform densification. The eight-layer panels, pressed for 17 min, achieved a moderate maximum core temperature (117 °C) and the highest density and shear strength, suggesting an optimal balance between pressing time, heat transfer, and panel thickness.

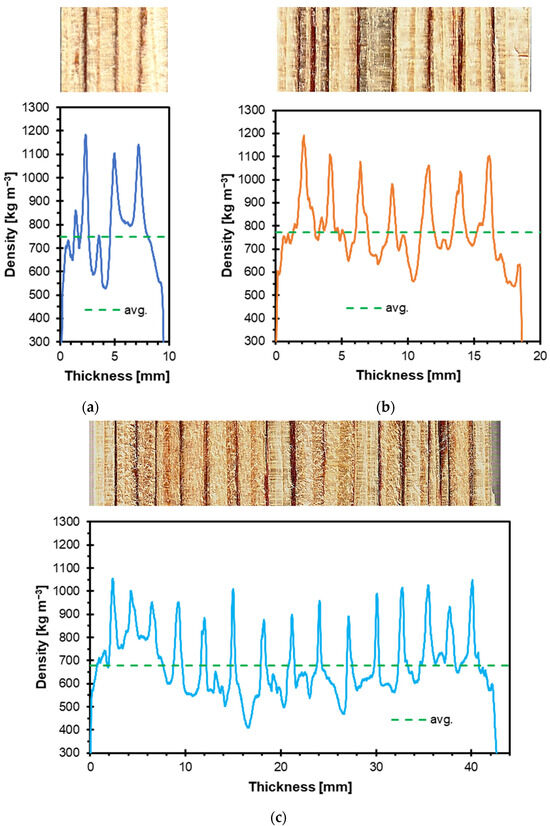

The density profiles (Figure 11) of the tested LVL samples were measured for three different layer configurations—4, 8, and 16 layers—produced from 3.20 mm thick Pinus sylvestris L. veneers. The average density values were 749 kg m−3 for the 4-layer panels, 773 kg m−3 for the 8-layer panels, and 679 kg m−3 for the 16-layer panels. These results demonstrate a notable variation in density, which appears to be influenced by both the number of layers and the pressing conditions applied during manufacture [25]. All panels were pressed under an identical nominal temperature (140 °C) and pressure conditions; however, the pressing duration differed according to the layer count, with 10 min for the 4-layer, 17 min for the 8-layer, and 30 min for the 16-layer variants. Core temperature measurements, mentioned above, indicate that the maximum reached values significantly decreased with the increasing layer number. These data suggest that heat penetration was more limited in thicker, multi-layered composites, likely affecting the degree of densification and moisture removal during pressing.

Figure 11.

The density profiles (curved lines) and the cross-cut scans of the tested LVL composites: (a) 4 layers, (b) 8 layers, and (c) 16 layers.

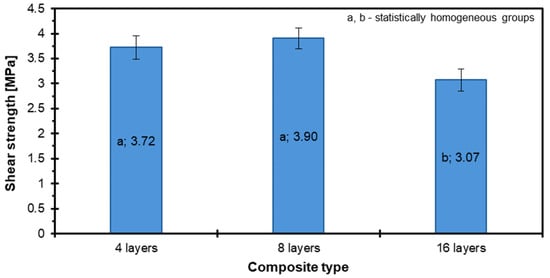

The shear strength of the tested LVL samples was evaluated for three different layer configurations: 4, 8, and 16 layers (Figure 12). The measured values revealed a variation in mechanical performance corresponding to the number of layers in each panel. Specifically, the 4-layer variant exhibited a mean shear strength of 3.72 MPa, the 8-layer variant reached 3.90 MPa, while the 16-layer variant demonstrated a lower value of 3.07 MPa.

Figure 12.

The shear strength of the tested composites.

These results indicate that the shear strength does not increase linearly with the number of layers. The 8-layer samples displayed the highest shear strength among the tested variants, suggesting an optimal balance between the adhesive interface distribution and wood structural integrity. In contrast, the 16-layer panels exhibited a notable reduction in shear strength, which may be attributed to the cumulative effects of internal stress concentrations, potential micro-defects within veneers, or differences in the load transfer efficiency across a higher number of bonded interfaces.

The four-layer variant, while lower than the eight-layer variant in performance, still maintained a substantial shear strength, reflecting the inherent structural capacity of the wood veneers and the quality of adhesive bonding. Across all variants, failure occurred entirely within the wood structure, consistent with observations of 100% in-wood failure during bonding quality assessments, confirming that the adhesive bonds did not constitute a limiting factor in the shear performance. Shear strength tests were conducted on LVL samples with 4, 8, and 16 layers. The results indicated a non-linear relationship between the number of layers and shear strength: 3.72 MPa for the 4-layer variant, 3.90 MPa for the 8-layer variant, and 3.07 MPa for the 16-layer variant. Notably, the 8-layer configuration exhibited the highest shear strength, while the 16-layer variant showed a statistically significant decrease. This effect may also be caused by the average density of the tested composites.

These findings contrast with typical LVL shear strength values reported in the literature. For instance, STEICO LVL R, a commercially available product, has a characteristic shear strength of 2.6 MPa in flatwise loading [26]. Similarly, Kerto LVL, another widely used LVL product, provides design values for the shear strength in accordance with EN 14,374 [27]. While specific numerical values are not detailed in the provided sources, these products are recognized for their consistent performance in structural applications.

The observed shear strength values of the tested samples, particularly the eight-layer variant, align with or exceed these typical literature values [28], suggesting that the tested LVL samples possess a commendable shear performance. The decrease in shear strength with the 16-layer configuration may be attributed to factors such as increased internal stresses, potential micro-defects within the veneers, or variations in adhesive bonding efficiency across a greater number of layers. Another potential shear strength reduction reason can be the lower density in the core zone of the composite, as it has been presented in Figure 11.

Overall, the findings and state of the art [24] demonstrate that the mechanical behaviour of the LVL under shear loading is influenced not only by the number of layers but also by the interaction between veneer thickness, adhesive distribution, and internal stress development [29]. The observed trends suggest that intermediate layer configurations, such as the eight-layer variant, may offer an optimal compromise between structural integrity and panel thickness for shear-critical applications.

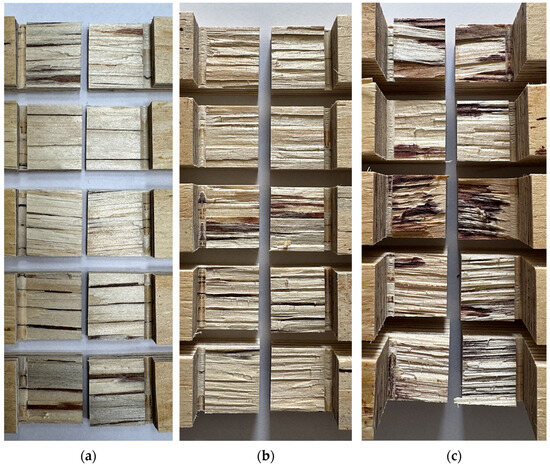

Post-testing evaluation of the produced LVL specimens revealed consistent and uniform failure patterns across all tested variants (Figure 13). No discernible differences in the extent or type of in-wood damage were observed between the specimens regardless of layer configuration. Importantly, all failures occurred exclusively within the wood substrate, with 100% of the fracture located in the veneer structure. This absence of adhesive line failure indicates that the bond strength of the adhesive system surpassed the intrinsic cohesive strength of the wood material itself [30]. Such complete in-wood failure is a strong confirmation of the integrity and effectiveness of the bonding process. It demonstrates that the adhesive interface was not the limiting factor in the structural performance of the LVL panels. Comparable observations have been reported in studies where reliable bonding was achieved, with the wood rather than the adhesive joint governing ultimate failure [8]. In this context, the consistency of the failure mode across all specimens also highlights the homogeneous distribution of stresses within the panels and confirms the uniform quality of adhesion throughout the bonded veneers. These results further substantiate the conclusion that the bonding quality of the tested LVL specimens can be considered optimal. The structural behaviour of the panels is therefore primarily controlled by the inherent mechanical properties of the raw wood material rather than by weaknesses in the adhesive performance or joint formation. This outcome underscores both the suitability of the adhesive system employed and the appropriateness of the bonding methodology applied in manufacturing the LVL panels [8,30].

Figure 13.

The pictures of the damaged samples after the bonding quality test: (a) 4-layer, (b) 8-layer and (c) 16-layer variants.

The above-presented results demonstrate that the temperature distribution in LVL pressing is governed both by the number of layers, pressing time, and by the thermocouple position. Edge regions consistently reach higher temperatures, while the panel core remains the limiting factor, particularly in thick composites. This emphasizes the need for adjusted pressing strategies—such as increased platen temperature, pre-heating, or extended press cycles with steam or microwave assistance—when manufacturing LVL with higher layer counts in order to achieve a uniform bonding quality and mechanical properties.

The results also demonstrate a clear correlation between panel density and shear performance in the LVL. Higher density, achieved through effective compaction and uniform heat penetration, corresponds with improved shear strength, whereas reduced density due to limited heat transfer or excessive panel thickness negatively impacts mechanical properties. Consequently, the eight-layer configuration represents a balanced design, providing an optimal mechanical performance while maintaining sufficient density throughout the cross-section. This highlights the importance of tailoring pressing parameters to the layer configuration to achieve uniform densification and maximize the structural performance in LVL composites. To reach the profits from the potential of the LVL pressing conditions optimization, the knowledge about the real-time temperature variation in the pressed set of veneers is crucial.

4. Conclusions

This study successfully developed and applied a novel, multi-layer smart sensor network to conduct real-time, in situ temperature profiling during the hot pressing of LVL. The research provides critical insights into the internal thermal dynamics of LVL panels of varying thicknesses, highlighting the significant limitations of conventional, empirically derived pressing schedules. The findings demonstrate that, while these schedules may be adequate for thinner products, they fail to ensure complete and uniform heat penetration in thicker panels, leading to significant core temperature deficits and potentially compromising adhesive curing and overall product quality.

The experimental results confirmed that heat transfer from the press platens is progressively delayed as panel thickness increases. For example, the core temperature of the 4-layer panels reached an effective curing temperature of 127 °C, but the 16-layer panels, despite a pressing time three times longer, only reached a core temperature of 99 °C. This finding is particularly important, as it directly correlates with the mechanical properties of the finished product. The eight-layer panels, which achieved an intermediate core temperature of 117 °C, demonstrated the highest shear strength and density, suggesting an optimal balance between panel thickness, heat transfer, and pressing duration. Conversely, the lower core temperature in the 16-layer panels likely contributed to their reduced density and a statistically significant decrease in the shear strength.

The consistent in-wood failure observed in all tested LVL samples, regardless of thickness, confirms that the adhesive bonds were effective, and the adhesive did not constitute a limiting factor in shear performance. This substantiates that the variations in mechanical properties were not due to adhesive failure but rather to the effects of non-uniform densification and incomplete heat penetration in the thicker composites.

In summary, this research underscores the need to move beyond traditional empirical methods for determining hot pressing parameters. The use of a custom, multi-layer sensor network offers a powerful alternative, providing the data necessary to optimize pressing schedules for specific product thicknesses and ensuring consistent quality. The proposed system and the insights it provides pave the way for a smarter, more adaptive approach to manufacturing in the wood-based panel industry, enabling improved process control and enhancing the performance of engineered wood products. Future work could explore the direct correlation between core temperature profiles and specific mechanical properties over time, as well as the integration of this sensing technology into an automated feedback loop for real-time process adjustment.

Author Contributions

S.K. state of the art, formal analysis, investigation, data curation, writing—original draft, writing—review and editing, and resources; P.M.K. conceptualization, methodology, validation, formal analysis, investigation, writing—review and editing, and funding acquisition; G.K. conceptualization, methodology, investigation, writing—original draft, writing—review and editing, project administration, and resources. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original data presented in the study are openly available in RepOD at https://doi.org/10.18150/OQKEBI (created and accessed on 27 August 2025).

Acknowledgments

The mentioned research was conducted with the support of the Student Furniture Scientific Group (Koło Naukowe Meblarstwa) and CNC Machine Tools Student Research Group (Koło Naukowe Obrabiarek CNC), Faculty of Wood Technology, Warsaw University of Life Sciences—SGGW, Warsaw, Poland.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wnorowska, M.; Dziurka, D.; Fierek, A.; Mrozek, M.; Borysiuk, P.; Hikiert, M.A.; Kowaluk, G. Przewodnik Po Płytach Drewnopochodnych. Wydanie II Poprawione; Wnorowska, M., Ed.; Stowarzyszenie Producentów Płyt Drewnopochodnych w Polsce: Poznań, Poland, 2017; ISBN 9788393749348. [Google Scholar]

- Thoemen, H.; Irle, M.; Sernek, M. Wood-Based Panels: An Introduction for Specialists; Brunel University Press: London, UK, 2010; ISBN 9781902316826. [Google Scholar]

- Perçin, O.; Ülker, O. Influence of Carbon Fibre Layers on the Strength of Thermally Modified Laminated Veneer Lumber. Polimeros 2023, 33, e20230007. [Google Scholar] [CrossRef]

- Bal, B.C. Some Physical and Mechanical Properties of Reinforced Laminated Veneer Lumber. Constr. Build. Mater. 2014, 68, 120–126. [Google Scholar] [CrossRef]

- Noh, N.I.F.M.; Kim, T.K.; Bhkari, N.M.; Ahmad, Z.; Chen, L.W.; Lin, N.J.; Chai, L.J.; Razman, R. Static Bending Performance on Flatwise Direction of Mengkulang and Kasai LVL Beam in Structural Size. AIP Conf. Proc. 2023, 2608, 020007. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Z.; Zhou, G.; Kibleur, P.; Mei, C.; Shi, J.; Van Acker, J.; Van den Bulcke, J. The Effect of Structural Changes on the Compressive Strength of LVL. Wood Sci. Technol. 2020, 54, 1253–1267. [Google Scholar] [CrossRef]

- Chen, F.; Deng, J.; Wang, G.; Zhang, D.; Zhao, Q.; Cai, L.; Shi, S.Q. Evaluation of the Uniformity of Density and Mechanical Properties of Bamboo-Bundle Laminated Veneer Lumber (BLVL). BioResources 2014, 9, 554–565. [Google Scholar] [CrossRef]

- Pangh, H.; Doosthoseini, K. Optimization of Press Time and Properties of Laminated Veneer Lumber Panels by Means of a Punching Technique. BioResources 2017, 12, 2254–2268. [Google Scholar] [CrossRef][Green Version]

- He, Q.; Zhan, T.; Ju, Z.; Zhang, H.; Hong, L.; Wang, Z.; Brosse, N.; Lu, X. Highly Mechanical Performance of Laminated Veneer Lumber Induced by High Voltage Electrostatic Field. In Proceedings of the 2019 Modular and Offsite Construction (MOC) Summit, Banff, AB, Canada, 21–24 May 2019; pp. 67–75. [Google Scholar] [CrossRef]

- Apsari, A.N.; Tanaka, T. Effects of Glue Spreading Rate and Veneer Density on Sugi (Cryptomeria Japonica) Plywood Adhesive Penetration. Maderas Cienc. Tecnol. 2023, 8, 1–10. [Google Scholar] [CrossRef]

- Follrich, J.; Teischinger, A.; Gindl, W.; Müller, U. Adhesive Bond Strength of End Grain Joints in Softwood with Varying Density. Holzforschung 2008, 62, 237–242. [Google Scholar] [CrossRef]

- do Nascimento, A.M.; Garcia, R.A.; Lucia, R.M. Della Adhesion Quality of Glued Joints from Different Commercial Wood Species. Cerne 2013, 19, 593–601. [Google Scholar] [CrossRef]

- Zhu, C.; Tian, F.; Wu, Y.; Jin, Y.; Xu, X. Chemical Structure and Bonding Performance of CTBN-toughened Phenol Formaldehyde Resin. J. For. Eng. 2024, 9, 36–43. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Li, Y.S.; Liu, R. Failure Behavior of Adhesive Bonded Interface between Steel and Bamboo Plywood. J. Adhes. Sci. Technol. 2016, 30, 2081–2099. [Google Scholar] [CrossRef]

- McGovern, B. The ABCs of RTDs: This short tutorial will bring you up to speed on the operating principle of resistance temperature detectors. Sensors 2003, 20, 37–39. [Google Scholar]

- Cigoy, D. Resistance Temperature Detectors. Control Eng. 2005, 52, 73–74. [Google Scholar]

- Sargent, R. Measurement of Board Temperatures during Kiln Drying Using Fiber Optic Sensors. J. Test. Eval. 2009, 37, 306–309. [Google Scholar] [CrossRef]

- Melnyk, I.; Montgomery, D.; Short, D. Fibre-Optic Temperature Sensors in a Lumber Kiln. Mill Prod. News 2004, 15, 12. [Google Scholar]

- Griffin, B.A.; Habermehl, S.D.; Clews, P.J. Development of an Aluminum Nitride-Silicon Carbide Material Set for High-Temperature Sensor Applications. In Sensors for Extreme Harsh Environments, Proceedings of the SPIE Sensing Technology + Applications, Baltimore, MD, USA, 5–9 May 2014; SPIE: Bellingham, WA, USA, 2014; Volume 9113, p. 91130A. [Google Scholar] [CrossRef]

- Pandey, P.; Goldberg, A.; Ziesche, S. LTCC Based Passive Compensation Circuits for High Temperature Sensors. In Proceedings of the 2022 45th International Spring Seminar on Electronics Technology (ISSE), Vienna, Austria, 11–15 May 2022. [Google Scholar] [CrossRef]

- EN 827; Adhesives—Determination of Conventional Solids Content and Constant Mass Solids Content. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 314-1; Plywood—Bonding Quality—Part 1: Test Methods. European Committee for Standardization: Brussels, Belgium, 2004.

- Septiana, R.; Roihan, I.; Koestoer, R.A. Testing a Calibration Method for Temperature Sensors in Different Working Fluids. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 68, 84–93. [Google Scholar] [CrossRef]

- Gumowska, A.; Wronka, A.; Borysiuk, P.; Robles, E.; Sala, C.M.; Kowaluk, G. Production of Layered Wood Composites with a Time- Saving Layer-by-Layer Addition. BioResources 2018, 13, 8089–8099. [Google Scholar] [CrossRef]

- Bal, B.C. Flexural Properties, Bonding Performance and Splitting Strength of LVL Reinforced with Woven Glass Fiber. Constr. Build. Mater. 2014, 51, 9–14. [Google Scholar] [CrossRef]

- Design Guide STEICO LVL/Laminated Veneer Lumber. Available online: https://www.steico.com/fileadmin/user_upload/importer/downloads/planungs-_und_konstruktionshefte/STEICO_Construction_Guide_LVL_en_i.pdf (accessed on 24 August 2025).

- Metsä KERTO LVL Manual Mechanical Properties. Available online: https://www.metsagroup.com/globalassets/metsa-wood/attachments/kerto-lvl-manual/en/metsa_kertolvl_mechanical_properties.pdf (accessed on 24 August 2025).

- Jeżo, A.; Wronka, A.; Dębiński, A.; Kristak, L.; Reh, R.; Rizhikovs, J.; Kowaluk, G. Influence of Upcycled Post-Treatment Bark Biomass Addition to the Binder on Produced Plywood Properties. Forests 2023, 14, 110. [Google Scholar] [CrossRef]

- Réh, R.; Krišťák, Ľ.; Sedliačik, J.; Bekhta, P.; Božiková, M.; Kunecová, D.; Vozárová, V.; Tudor, E.M.; Antov, P.; Savov, V. Utilization of Birch Bark as an Eco-Friendly Filler in Urea-Formaldehyde Adhesives for Plywood Manufacturing. Polymers 2021, 13, 511. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. Upcycling of Wood Dust from Particleboard Recycling as a Filler in Lignocellulosic Layered Composite Technology. Materials 2023, 16, 7352. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).