Effects of Microscopic Properties and Calibration on the Mechanical Behavior of Cohesive Soil-Rock Mixtures Based on Discrete Element Method

Abstract

1. Introduction

2. Laboratory Undrained Triaxial Tests

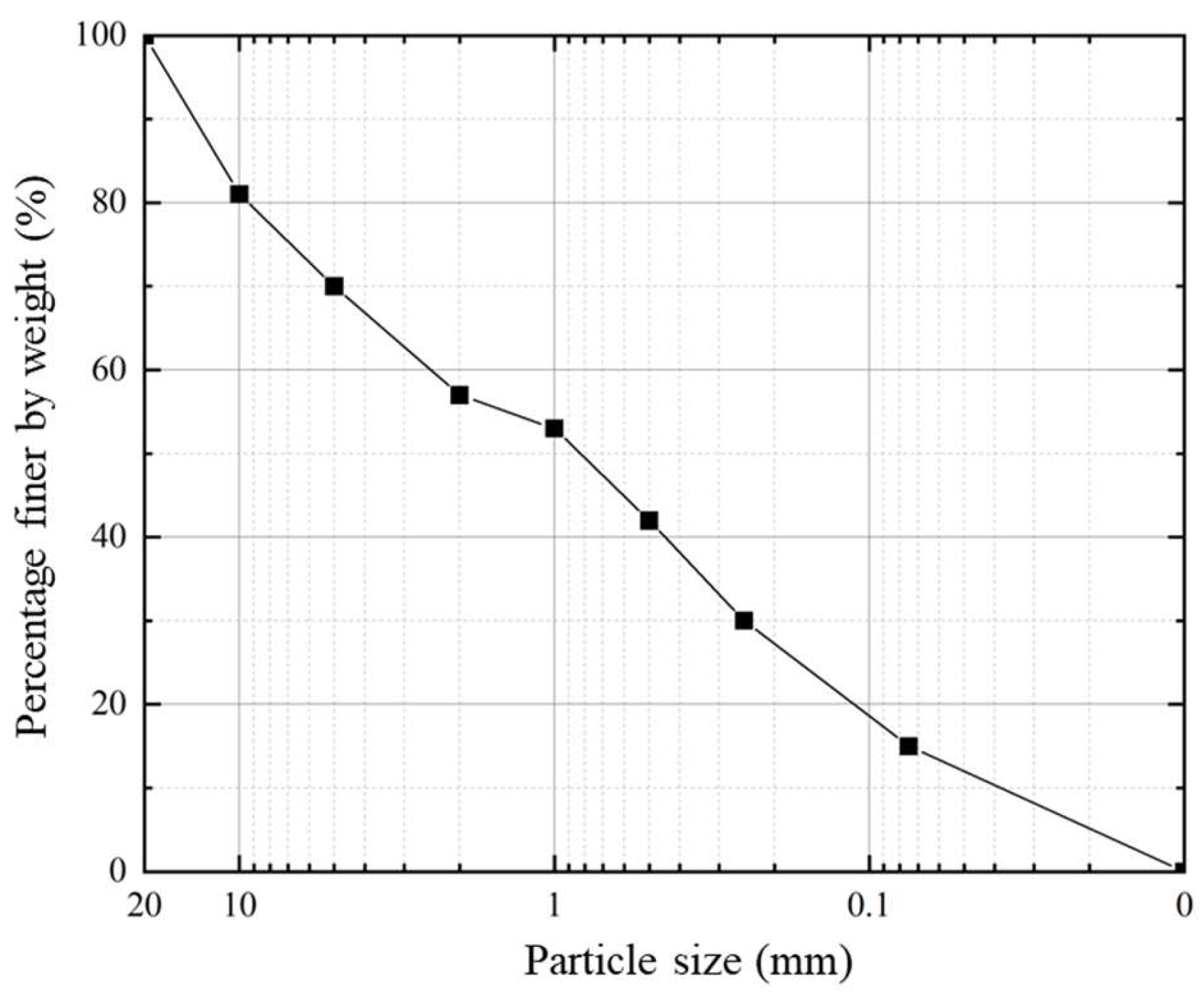

2.1. Test Materials

2.2. Test Method

3. DEM Simulations

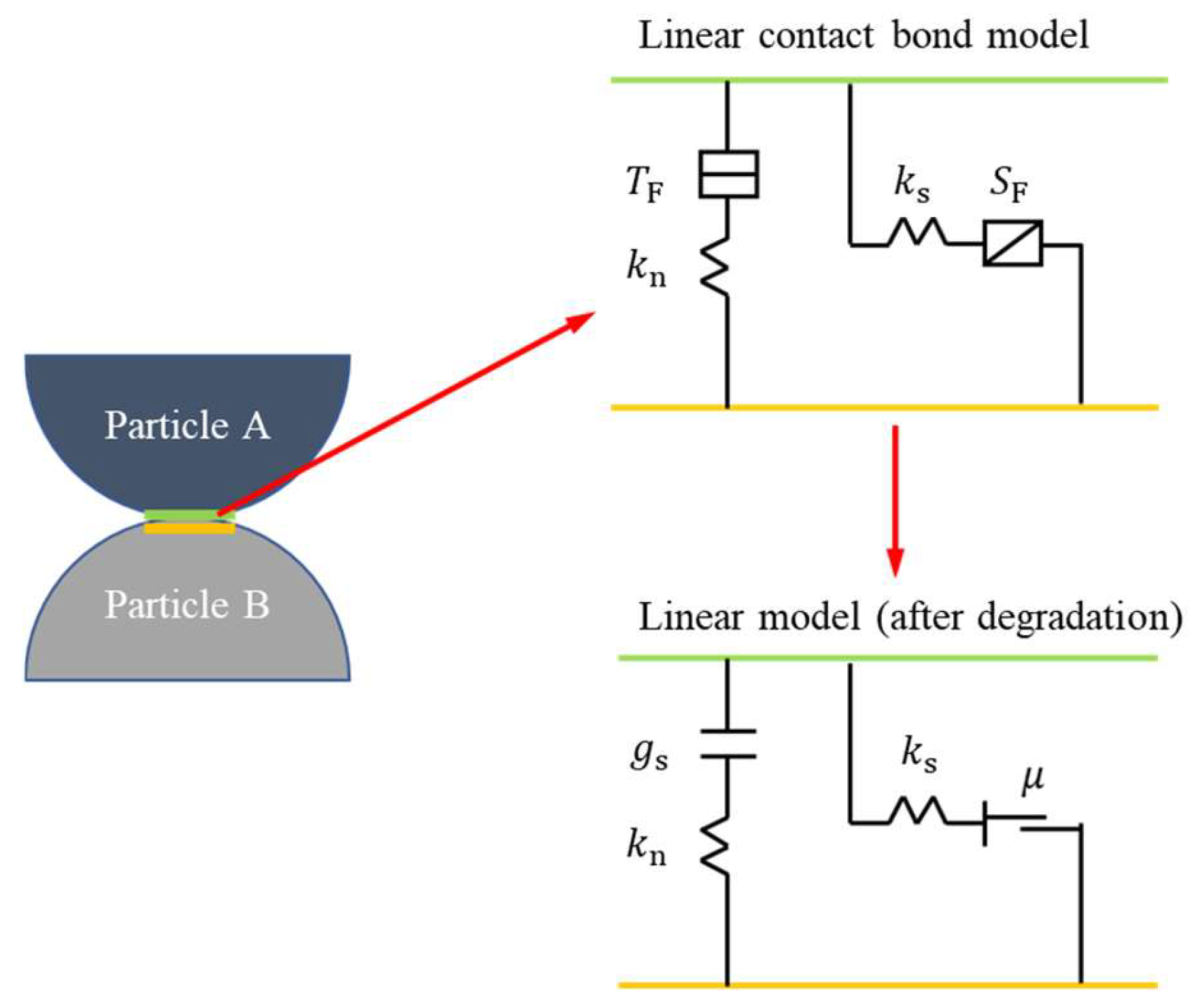

3.1. Contact Model

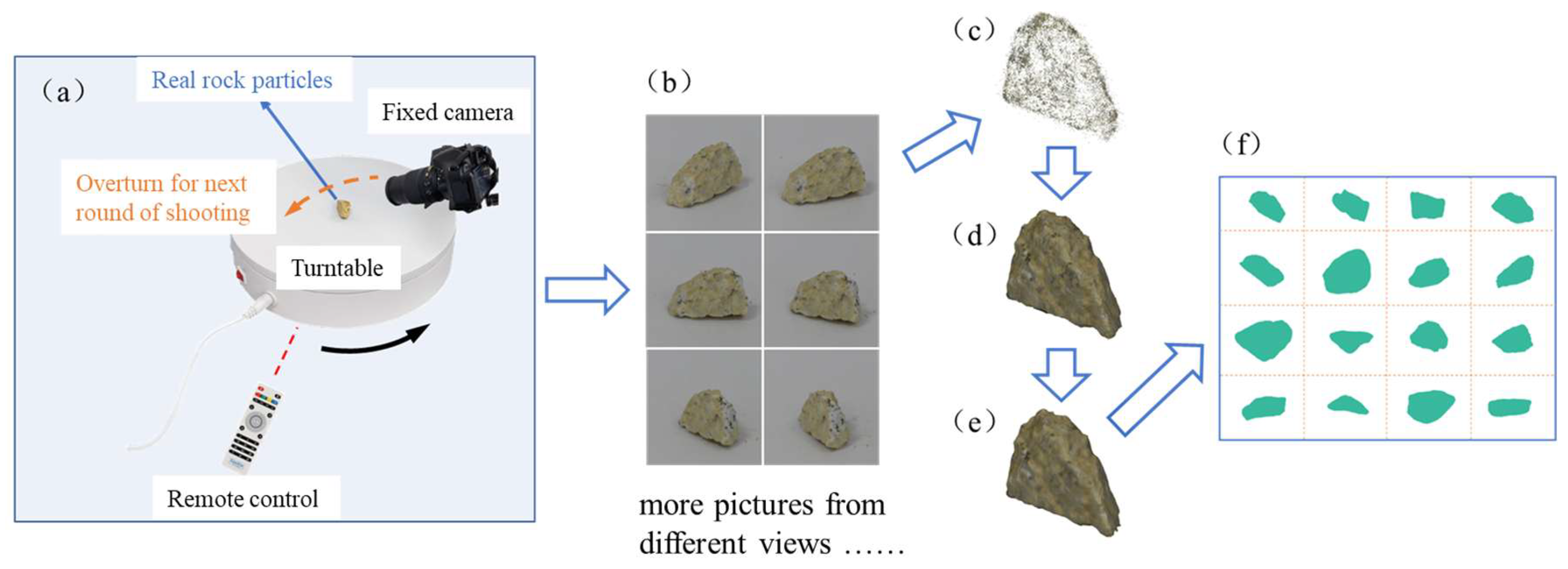

3.2. Acquisition of 2D Realistic Rock Block Contours

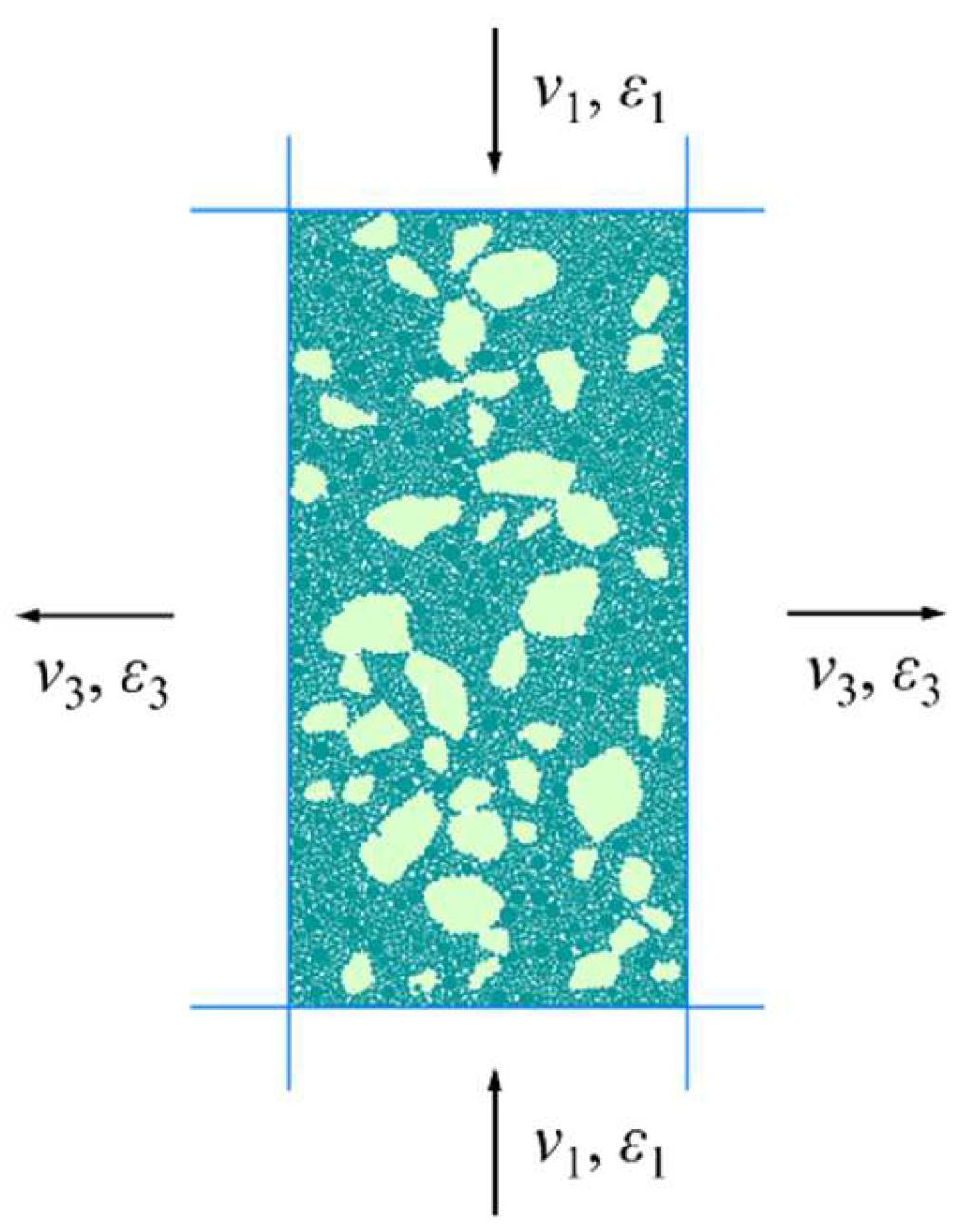

3.3. Numerical Model

3.4. Constant-Volume Method

4. Results and Discussion

4.1. Parameters Between Soil Particles

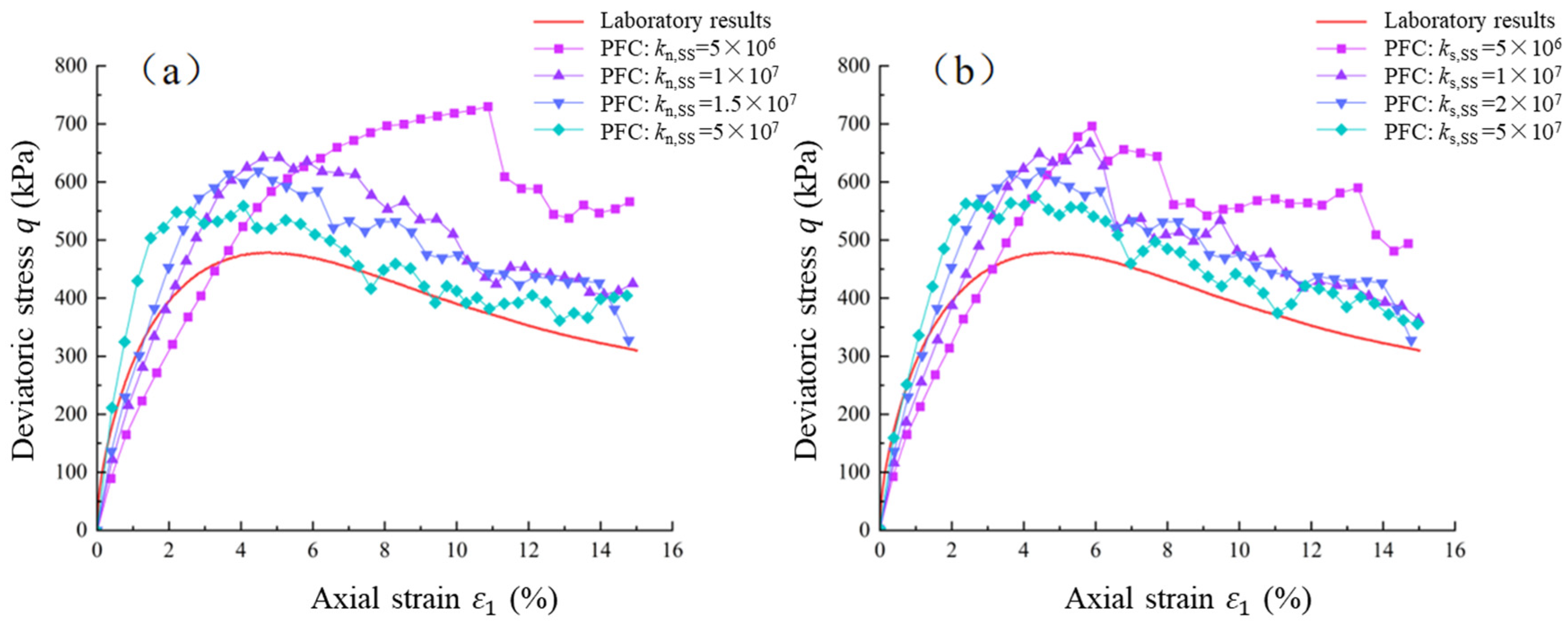

4.1.1. Effect of Contact Stiffness Between Soil Particles

4.1.2. Effect of Inter-Particle Bond Strength Between Soil Particles

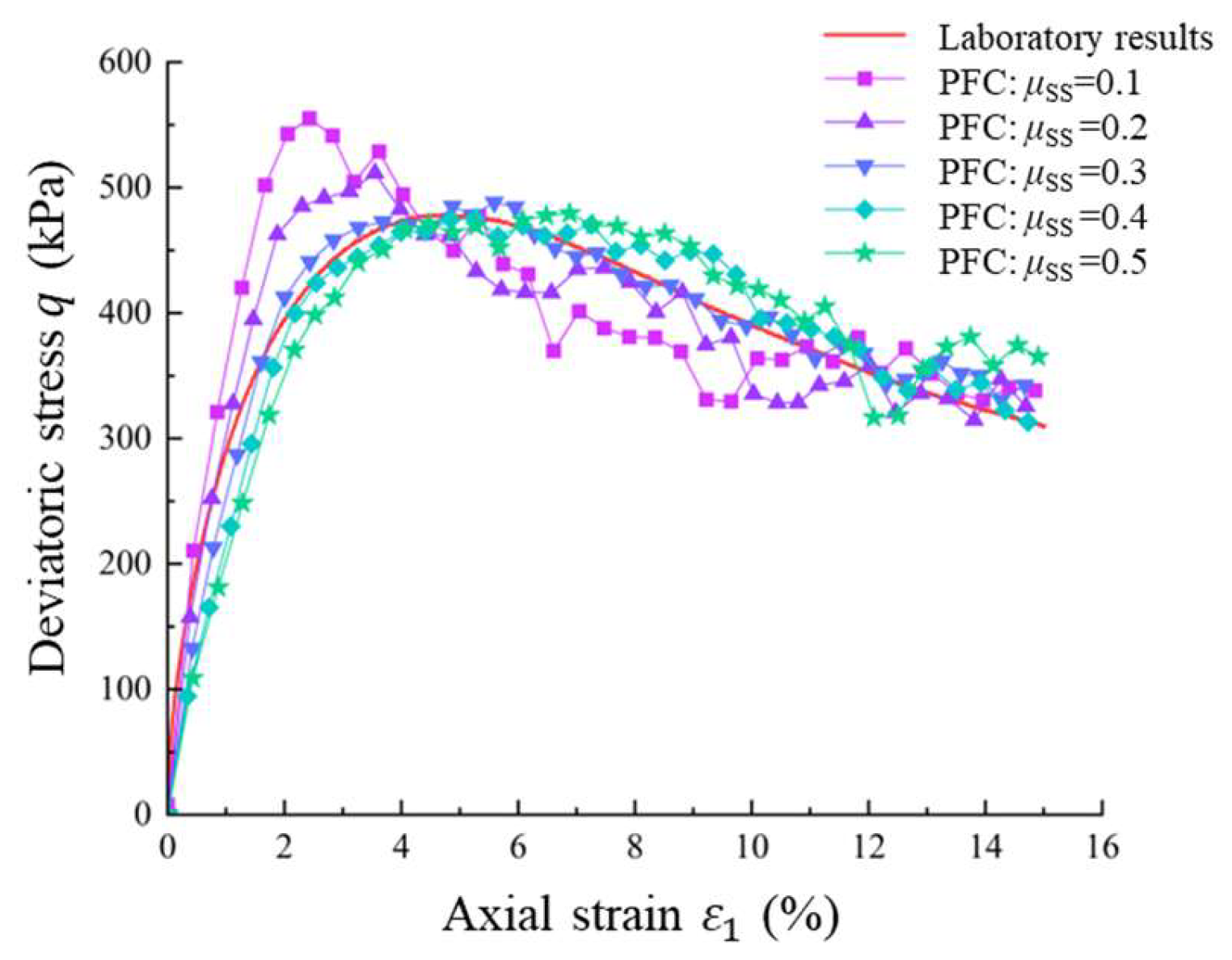

4.1.3. Effect of Inter-Particle Friction Between Soil Particles

4.1.4. Calibration of Contact Parameters Between Soil Particles

4.2. Parameters Between Soil and Rock Particles

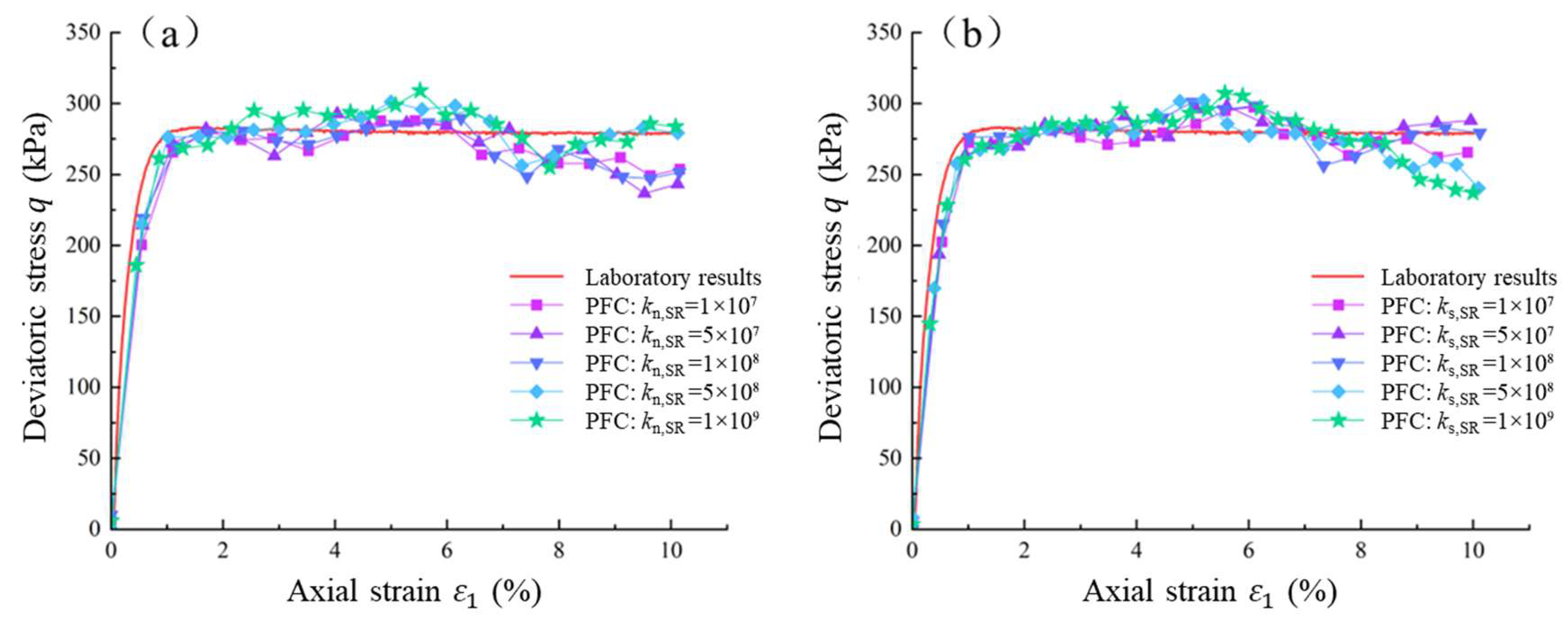

4.2.1. Effect of Contact Stiffness Between Soil and Rock Particles

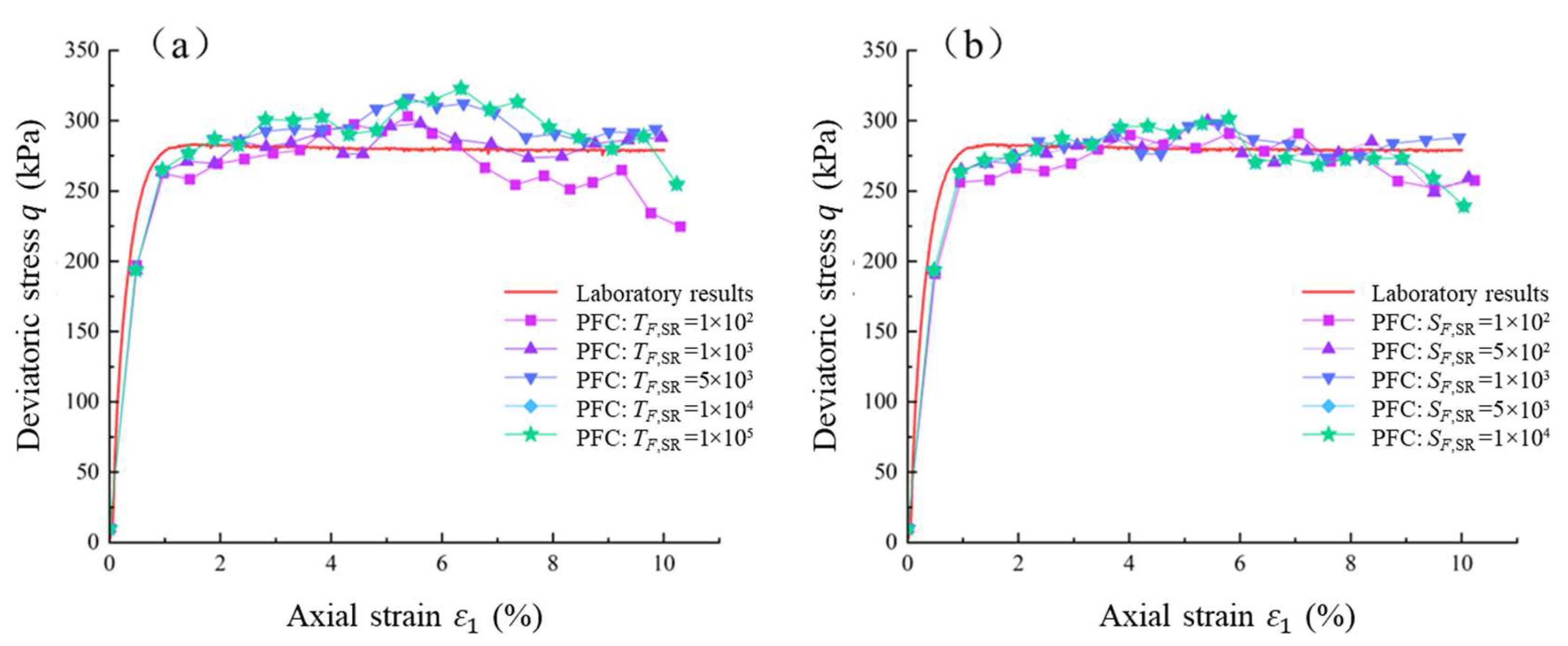

4.2.2. Effect of Inter-Particle Bond Strength Between Soil and Rock Particles

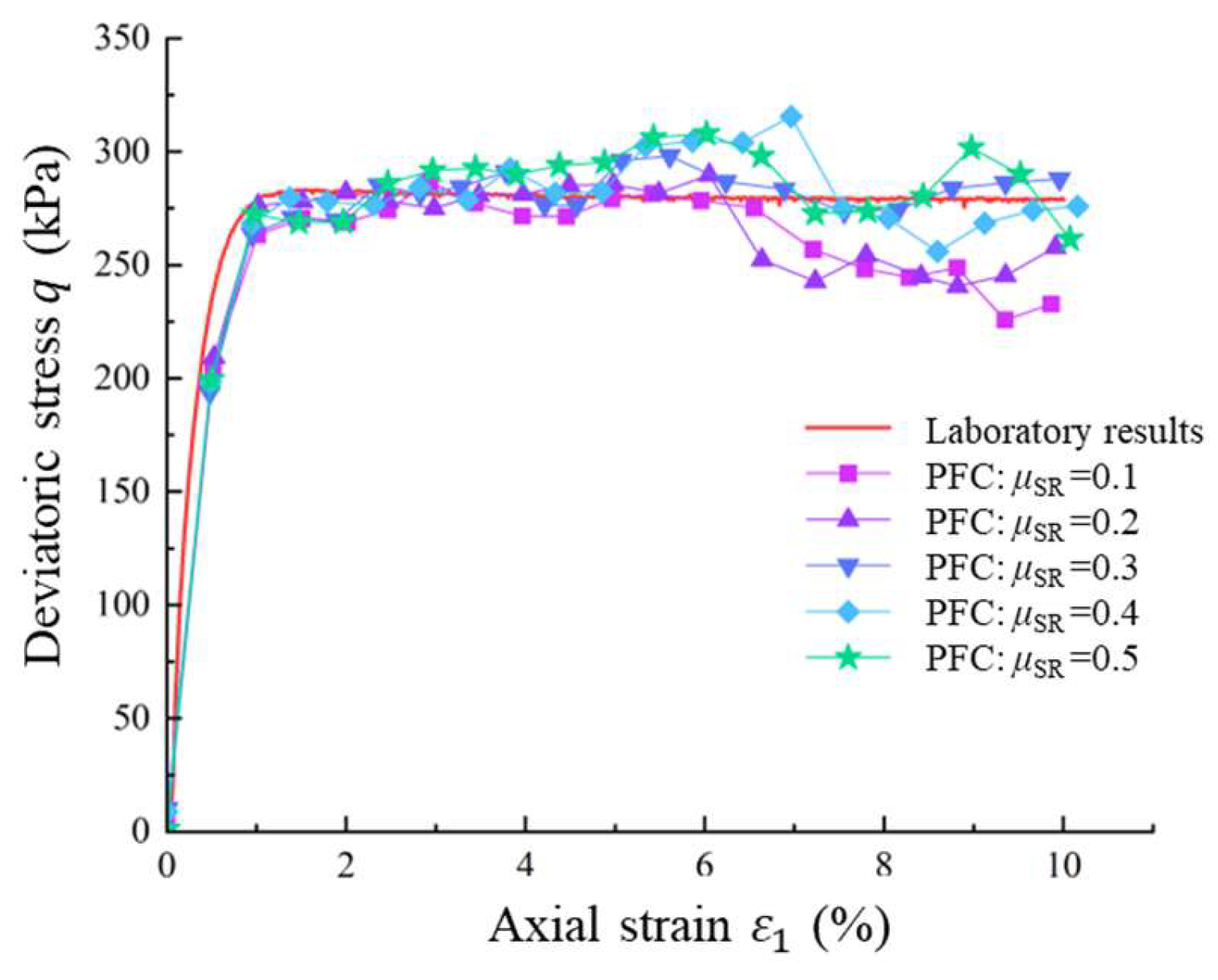

4.2.3. Effect of Inter-Particle Friction Between Soil and Rock Particles

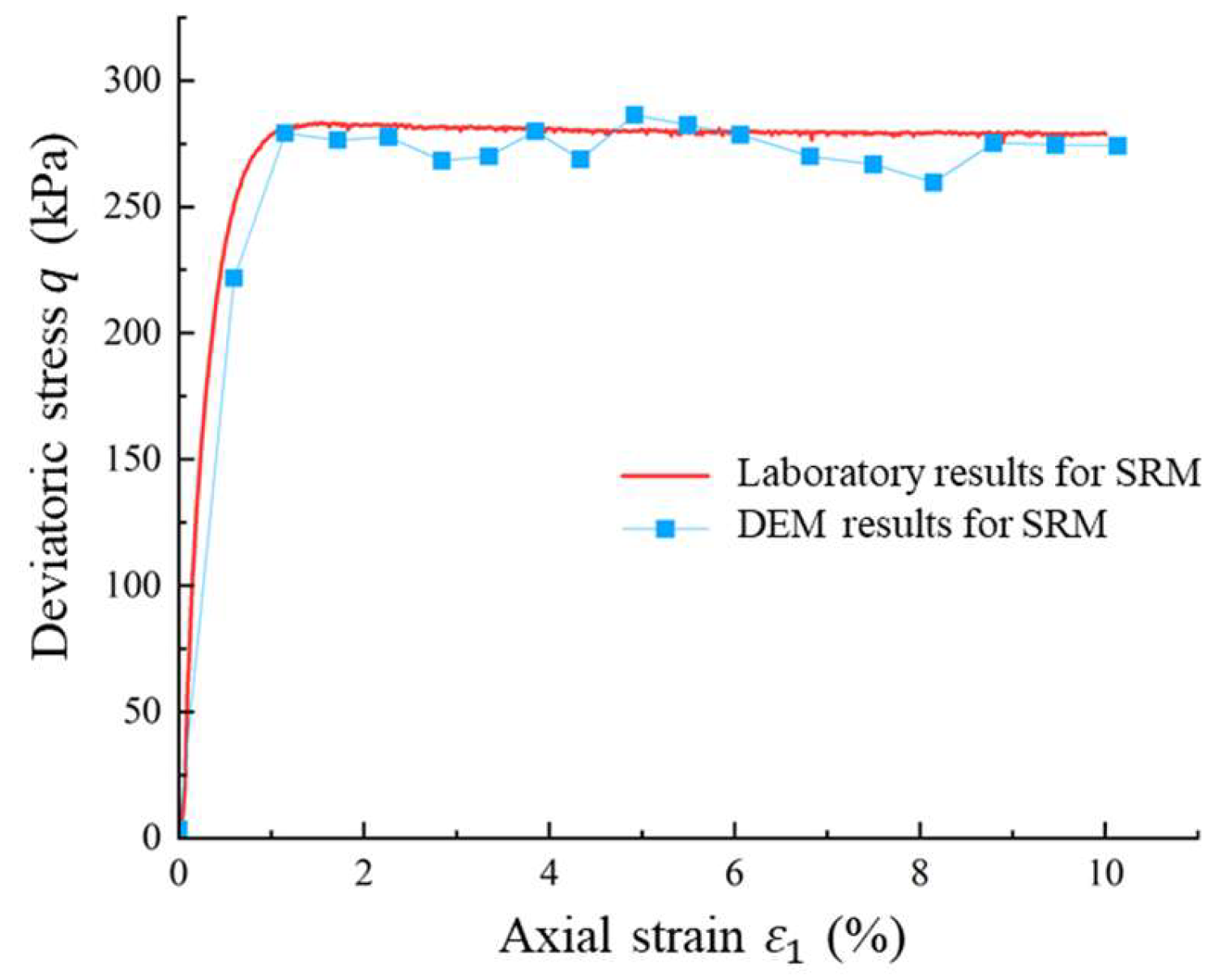

4.2.4. Calibration of Contact Parameters Between Soil and Rock Particles

4.3. Discussion

5. Conclusions

- (1)

- A different set of contact models, which assign separate mechanical properties to soil–soil and soil–rock contacts, is essential for realistically capturing the complex behavior of CSRM in DEM simulations.

- (2)

- For the pure clay matrix, contact stiffness and the friction coefficient were found to govern the initial tangent modulus, peak stress, and residual strength. In contrast, the bond strength parameters (normal and shear) primarily influenced the peak and residual strengths without affecting the initial stiffness, confirming their role in defining the material’s cohesive strength. A reliable set of mesoscopic parameters for the clay matrix was successfully calibrated against experimental data.

- (3)

- In the CSRM model with a 30% rock content, the initial tangent modulus was predominantly controlled by the pre-calibrated soil–soil contact parameters. The soil–rock contact parameters had a negligible effect on the initial elastic response but became significant in the plastic stage. Specifically, the normal bond strength and friction coefficient at the soil–rock interface played a crucial role in the development of shear stress post-yield. An interesting threshold effect was observed where, beyond a certain value, further increases in soil–rock bond strength did not alter the stress–strain curve, indicating a limit to its contribution in this particular granular structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, W.J.; Hu, R.L.; Yue, Z.Q.; Tan, R.J. Genesis and stability of the Zhoujiawan landslide, Three Gorges, China. Bull. Eng. Geol. Environ. 2009, 68, 47–54. [Google Scholar] [CrossRef]

- Geertsema, M.; Clague, J.J.; Schwab, J.W.; Evans, S.G. An overview of recent large catastrophic landslides in northern British Columbia, Canada. Eng. Geol. 2006, 83, 120–143. [Google Scholar] [CrossRef]

- Gao, W.; Hu, R.; Oyediran, I.A.; Li, Z.; Zhang, X. Geomechanical characterization of Zhangmu soil-rock mixture deposit. Geotech. Geol. Eng. 2014, 32, 1329–1338. [Google Scholar] [CrossRef]

- Xu, W.J.; Zhang, H.Y. Research on the effect of rock content and sample size on the strength behavior of soil-rock mixture. Bull. Eng. Geol. Environ. 2021, 80, 2715–2726. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Z. Study of Material Composition Effects on the Mechanical Properties of Soil-Rock Mixtures. Adv. Civ. Eng. 2018, 2018, 3854727. [Google Scholar] [CrossRef]

- Qian, J.; Yao, Y.; Li, J.; Xiao, H.; Luo, S. Resilient properties of soil-rock mixture materials: Preliminary investigation of the effect of composition and structure. Materials 2020, 13, 1658. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Xu, W.J.; Yu, Y.Z. Triaxial tests of soil–rock mixtures with different rock block distributions. Soils Found. 2016, 56, 44–56. [Google Scholar] [CrossRef]

- Zhong, W.; Liu, H.; Gu, D.; Zhang, W.; Yang, C.; Gao, X. Development of a preparation method of transparent soil-rock mixture for geotechnical laboratory modeling. Eng. Geol. 2022, 301, 106622. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; Li, S.D.; Duan, Y.T. A laboratory study of the effect of confining pressure on permeable property in soil-rock mixture. Environ. Earth Sci. 2016, 75, 284. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Thornton, C. Numerical simulations of deviatoric shear deformation of granular media. Géotechnique 2000, 50, 43–53. [Google Scholar] [CrossRef]

- Sitharam, T.G.; Dinesh, S.V.; Shimizu, N. Micromechanical modelling of monotonic drained and undrained shear behaviour of granular media using three-dimensional DEM. Int. J. Numer. Anal. Methods Geomech. 2002, 26, 1167–1189. [Google Scholar] [CrossRef]

- Gu, X.; Huang, M.; Qian, J. DEM investigation on the evolution of microstructure in granular soils under shearing. Granul. Matter 2014, 16, 91–106. [Google Scholar] [CrossRef]

- Gong, J.; Nie, Z.; Zhu, Y.; Liang, Z.; Wang, X. Exploring the effects of particle shape and content of fines on the shear behavior of sand-fines mixtures via the DEM. Comput. Geotech. 2019, 106, 161–176. [Google Scholar] [CrossRef]

- Zhao, L.; Deng, M.; Zhang, S.; Huang, D.; Qiao, N.; Gong, J. Effects of particle shape on triaxial compression behaviours of realistic ballast particles based on MAVL particle shape evaluation system. Granul. Matter 2023, 25, 4. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, M.; Li, S.; Wang, J.G. Stochastic structural model of rock and soil aggregates by continuum-based discrete element method. Sci. China Ser. E Eng. Mater. Sci. 2005, 48, 95–106. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, N.; Zhang, J. Random gravel model and particle flow based numerical biaxial test of solid backfill materials. Int. J. Min. Sci. Technol. 2013, 23, 463–467. [Google Scholar] [CrossRef]

- Yao, Y.; Li, J.; Ni, J.; Liang, C.; Zhang, A. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 2022, 141, 104476. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Y.T.; Zheng, H. Numerical study of soil-rock mixture: Generation of random aggregate structure. Sci. China Technol. Sci. 2018, 61, 359–369. [Google Scholar] [CrossRef]

- Jin, L.; Zeng, Y.; Xia, L.; Ye, Y. Experimental and numerical investigation of mechanical behaviors of cemented soil–rock mixture. Geotech. Geol. Eng. 2017, 35, 337–354. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Belheine, N.; Plassiard, J.P.; Donzé, F.V.; Darve, F.; Seridi, A. Numerical simulation of drained triaxial test using 3D discrete element modeling. Comput. Geotech. 2009, 36, 320–331. [Google Scholar] [CrossRef]

- Fakhimi, A. Application of slightly overlapped circular particles assembly in numerical simulation of rocks with high friction angles. Eng. Geol. 2004, 74, 129–138. [Google Scholar] [CrossRef]

- Salazar, A.; Sáez, E.; Pardo, G. Modeling the direct shear test of a coarse sand using the 3D Discrete Element Method with a rolling friction model. Comput. Geotech. 2015, 67, 83–93. [Google Scholar] [CrossRef]

- Nguyen, D.; Chen, Y.; Martinez, A. A DEM sensitivity study on the effects of contact parameters on triaxial response for the development of a calibration method. Comput. Geotech. 2025, 184, 107241. [Google Scholar] [CrossRef]

- Momeni, A.; Eshiet, K.I.-I.I.; Sheng, Y. The sensitivity of micro—Macro mechanical behaviour of sand to the inter-particle properties. Geotechnics 2023, 3, 416–445. [Google Scholar] [CrossRef]

- Hazzar, L.; Nuth, M.; Chekired, M. DEM simulation of drained triaxial tests for glass-beads. Powder Technol. 2020, 364, 123–134. [Google Scholar] [CrossRef]

- Cheng, K.; Wang, Y.; Yang, Q.; Mo, Y.; Guo, Y. Determination of microscopic parameters of quartz sand through tri-axial test using the discrete element method. Comput. Geotech. 2017, 92, 22–40. [Google Scholar] [CrossRef]

- Yan, Y.; Chang, D.; Liu, J.; Xu, A.; Feng, L. Multiscale mechanical analysis of Frozen Clay: Triaxial testing and discrete element modeling. Cold Reg. Sci. Technol. 2024, 224, 104250. [Google Scholar] [CrossRef]

- Wu, M.; Zhou, F.; Wang, J. DEM modeling of mini-triaxial test on soil-rock mixture considering particle shape effect. Comput. Geotech. 2023, 153, 105110. [Google Scholar] [CrossRef]

- Hu, Y.; Lu, Y. A novel framework for calibrating DEM parameters: A case study of sand and soil-rock mixture. Comput. Geotech. 2024, 174, 106619. [Google Scholar] [CrossRef]

- Jiang, C.; Zeng, L.; Liu, Y.; Mu, Y.; Dong, W. A DEM Study on the Macro-and Micro-Mechanical Characteristics of an Irregularly Shaped Soil–Rock Mixture Based on the Analysis of the Contact Force Skeleton. Appl. Sci. 2025, 15, 7978. [Google Scholar] [CrossRef]

- Ovalle, C.; Dano, C. Effects of particle size–strength and size–shape correlations on parallel grading scaling. Géotech. Lett. 2020, 10, 191–197. [Google Scholar] [CrossRef]

- Xu, W.J.; Xu, Q.; Hu, R.L. Study on the shear strength of soil–rock mixture by large scale direct shear test. Int. J. Rock Mech. Min. Sci. 2011, 48, 1235–1247. [Google Scholar] [CrossRef]

- Paixão, A.; Resende, R.; Fortunato, E. Photogrammetry for digital reconstruction of railway ballast particles–A cost-efficient method. Constr. Build. Mater. 2018, 191, 963–976. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, S.; Deng, M.; Wang, X. Statistical analysis and comparative study of multi-scale 2D and 3D shape features for unbound granular geomaterials. Transp. Geotech. 2021, 26, 100377. [Google Scholar] [CrossRef]

- Asahina, D.; Taylor, M.A. Geometry of irregular particles: Direct surface measurements by 3-D laser scanner. Powder Technol. 2011, 213, 70–78. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, J.; Zhao, B. Micromorphology characterization and reconstruction of sand particles using micro X-Ray tomography and spherical harmonics. Eng. Geol. 2015, 184, 126–137. [Google Scholar] [CrossRef]

- Itasca Consulting Group. Particle Flow Code in Two Dimensions: User’s Manual; Version 5.0; Itasca Consulting Group: Minneapolis, MN, USA, 2015. [Google Scholar]

- Jensen, R.P.; Bosscher, P.J.; Plesha, M.E.; Edil, T.B. DEM simulation of granular media—Structure interface: Effects of surface roughness and particle shape. Int. J. Numer. Anal. Methods Geomech. 1999, 23, 531–547. [Google Scholar] [CrossRef]

- Shafipour, R.; Soroush, A. Fluid coupled-DEM modelling of undrained behavior of granular media. Comput. Geotech. 2008, 35, 673–685. [Google Scholar] [CrossRef]

- Keishing, J.; Hanley, K.J. Improving constant-volume simulations of undrained behaviour in DEM. Acta Geotech. 2020, 15, 2545–2558. [Google Scholar] [CrossRef]

- Wang, M.; Lu, Z.; Zhao, Y.; Wan, W. Calibrating microparameters of DEM models by using CEM, DE, EFO, MFO, SSO algorithms and the optimal hyperparameters. Comput. Part. Mech. 2024, 11, 839–852. [Google Scholar] [CrossRef]

| Parameter Name | Value |

|---|---|

| Specific gravity, | 2.61 |

| Liquid limit, (%) | 24.87 |

| Plastic limit, (%) | 13.70 |

| Plastic index, (%) | 11.17 |

| Parameter Name | Value |

|---|---|

| Normal contact stiffness, (N/m) | 1.5 × 107 |

| Tangential contact stiffness, (N/m) | 2 × 107 |

| Normal tensile bond strength, (N) | 5 × 102 |

| Shear bond strength, (N) | 3.3 × 102 |

| Friction coefficient, | 0.3 |

| Parameter Name | Value |

|---|---|

| Normal contact stiffness, (N/m) | 5 × 108 |

| Tangential contact stiffness, (N/m) | 5 × 107 |

| Normal tensile bond strength, (N) | 8 × 103 |

| Shear bond strength, (N) | 5 × 103 |

| Friction coefficient, | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Deng, M.; Yao, F.; Luo, W.; Zhao, L. Effects of Microscopic Properties and Calibration on the Mechanical Behavior of Cohesive Soil-Rock Mixtures Based on Discrete Element Method. Appl. Sci. 2025, 15, 10529. https://doi.org/10.3390/app151910529

Huang Y, Deng M, Yao F, Luo W, Zhao L. Effects of Microscopic Properties and Calibration on the Mechanical Behavior of Cohesive Soil-Rock Mixtures Based on Discrete Element Method. Applied Sciences. 2025; 15(19):10529. https://doi.org/10.3390/app151910529

Chicago/Turabian StyleHuang, Yong, Min Deng, Fei Yao, Wei Luo, and Lianheng Zhao. 2025. "Effects of Microscopic Properties and Calibration on the Mechanical Behavior of Cohesive Soil-Rock Mixtures Based on Discrete Element Method" Applied Sciences 15, no. 19: 10529. https://doi.org/10.3390/app151910529

APA StyleHuang, Y., Deng, M., Yao, F., Luo, W., & Zhao, L. (2025). Effects of Microscopic Properties and Calibration on the Mechanical Behavior of Cohesive Soil-Rock Mixtures Based on Discrete Element Method. Applied Sciences, 15(19), 10529. https://doi.org/10.3390/app151910529