Anti-Sliding Trenches to Enhance Slope Stability of Internal Dumps on Inclined Foundations in Open-Pit Coal Mines

Abstract

1. Introduction

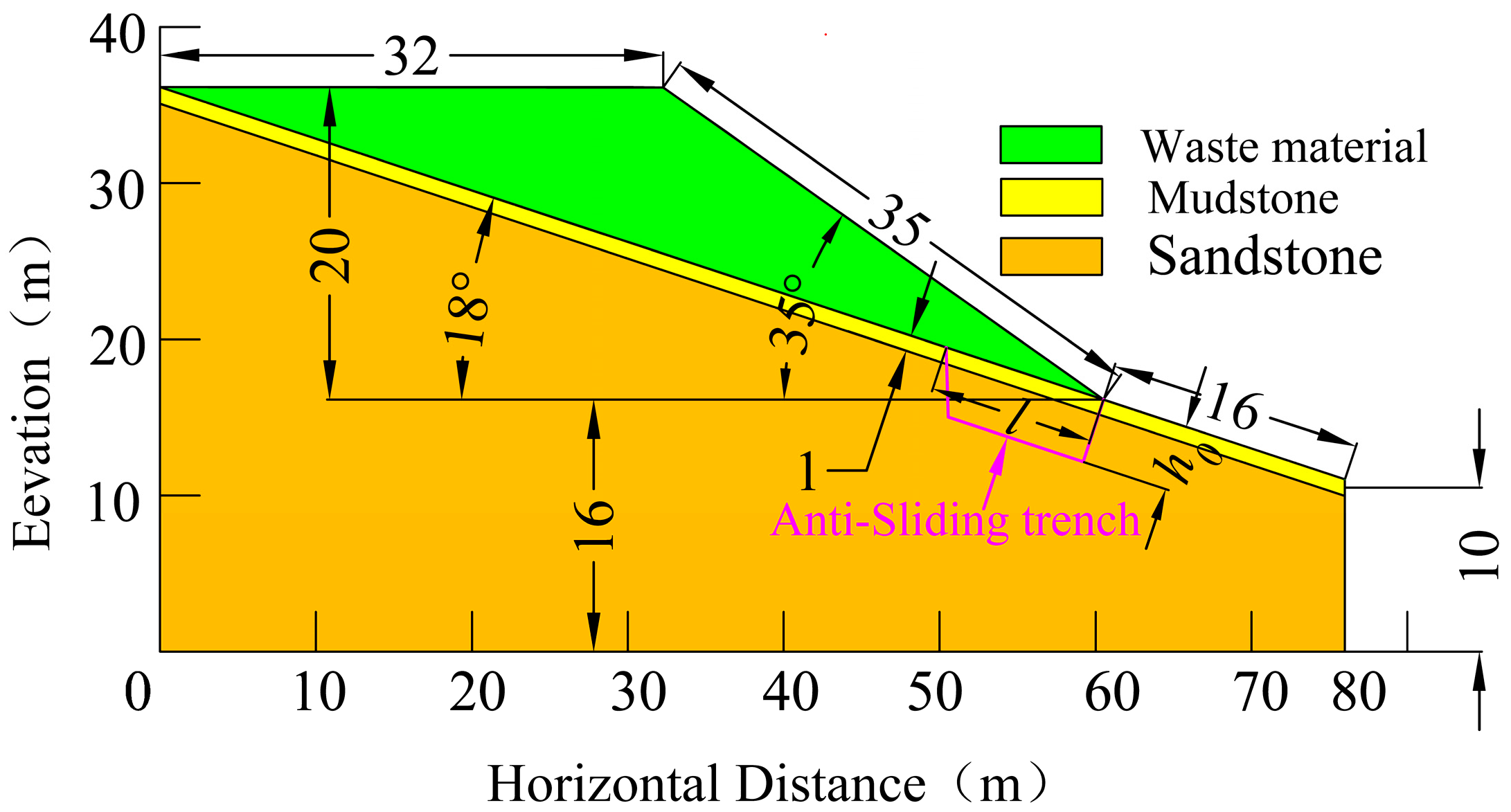

2. Engineering Background

3. Experiments and Methods

3.1. Simulation Experiments

3.1.1. Objectives

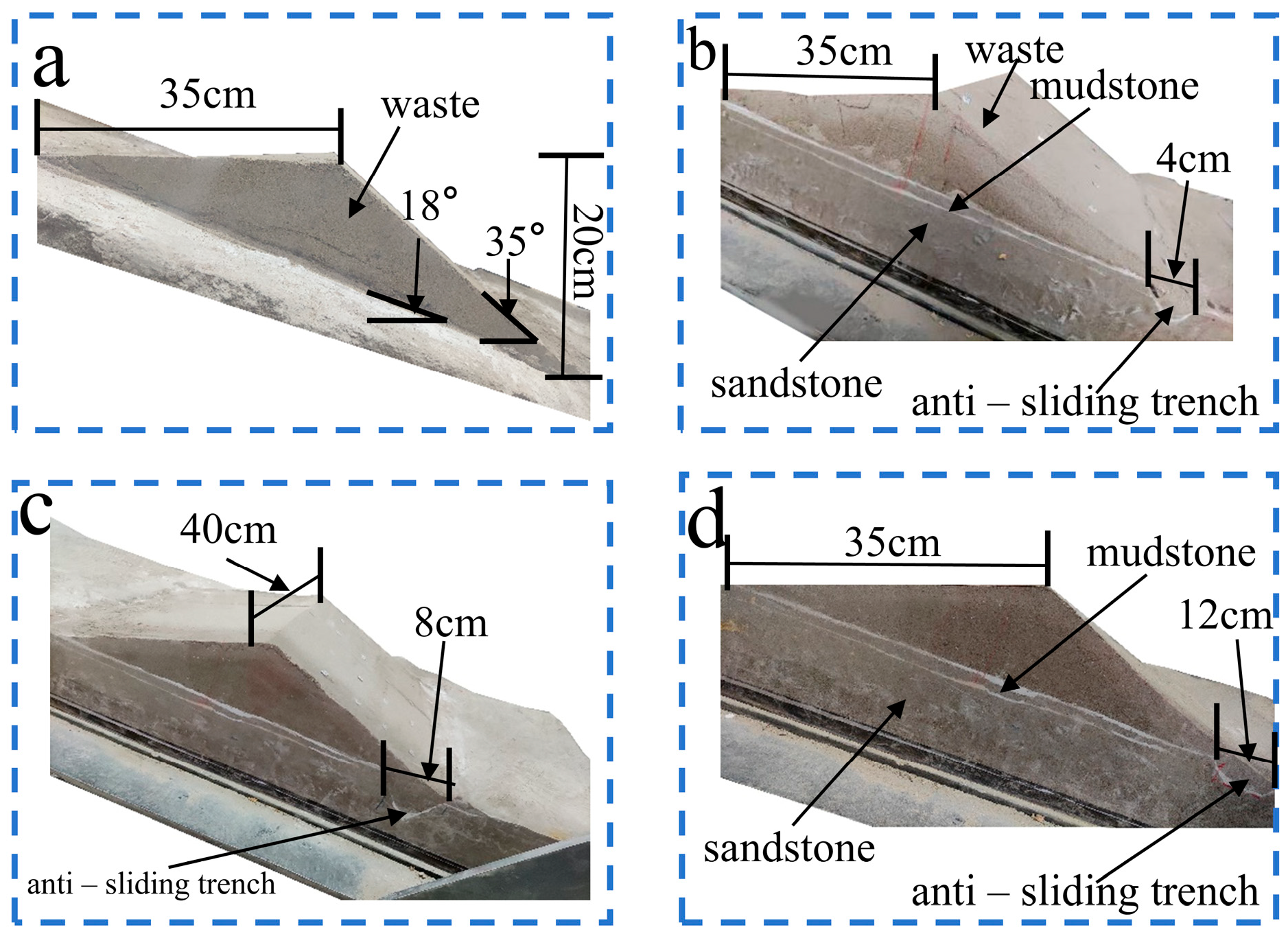

3.1.2. Experimental Setup

3.1.3. Experimental Design and Similarity Ratio

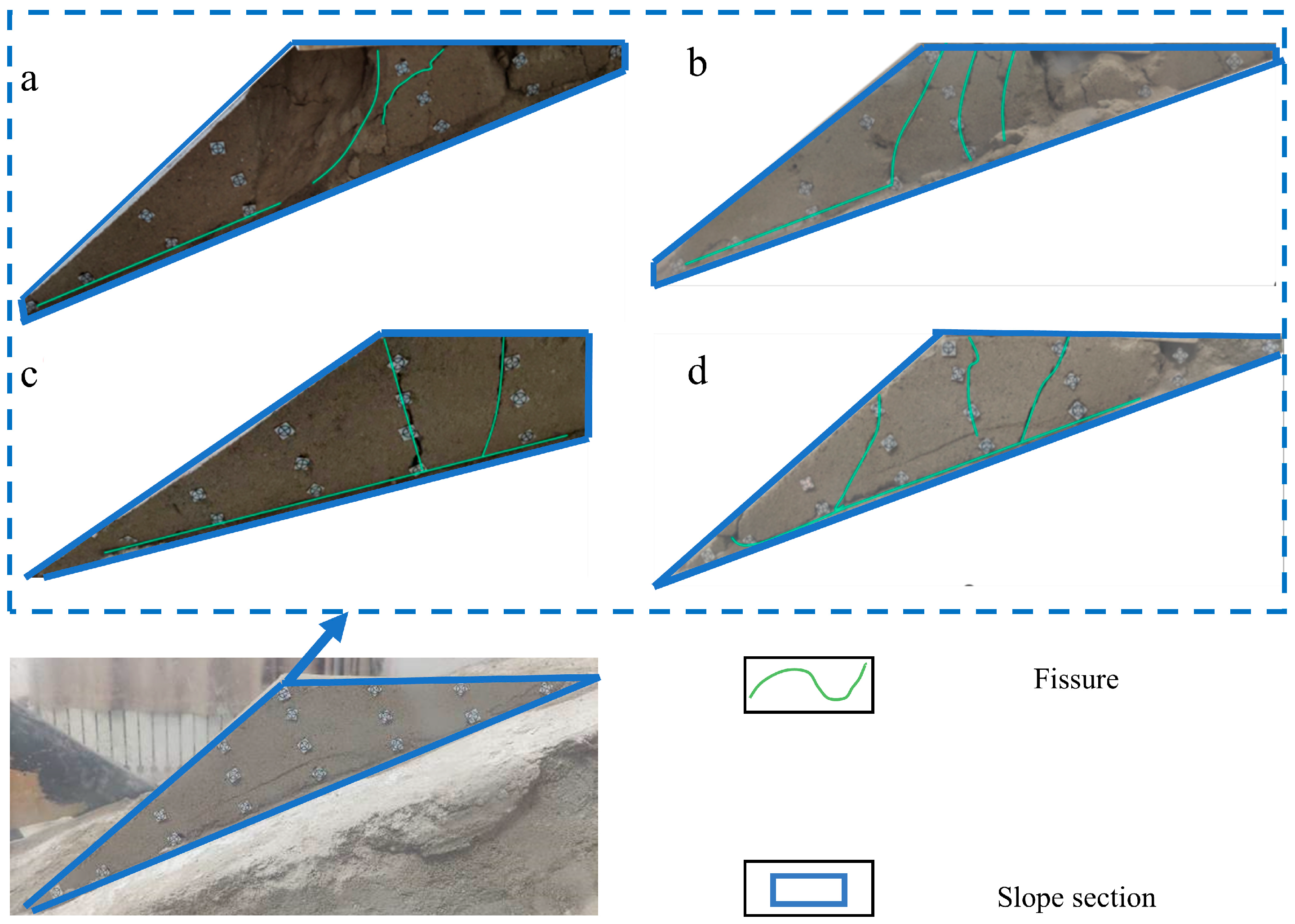

3.1.4. Experimental Results and Analysis

3.2. Determination of the Anti-Sliding Trench Dimensions

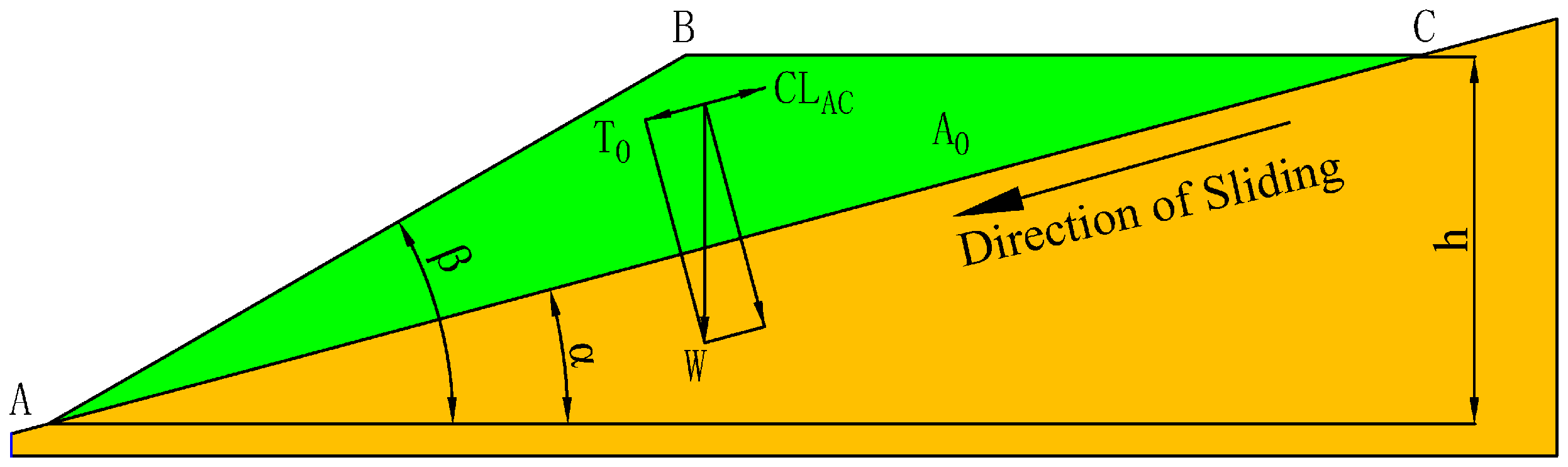

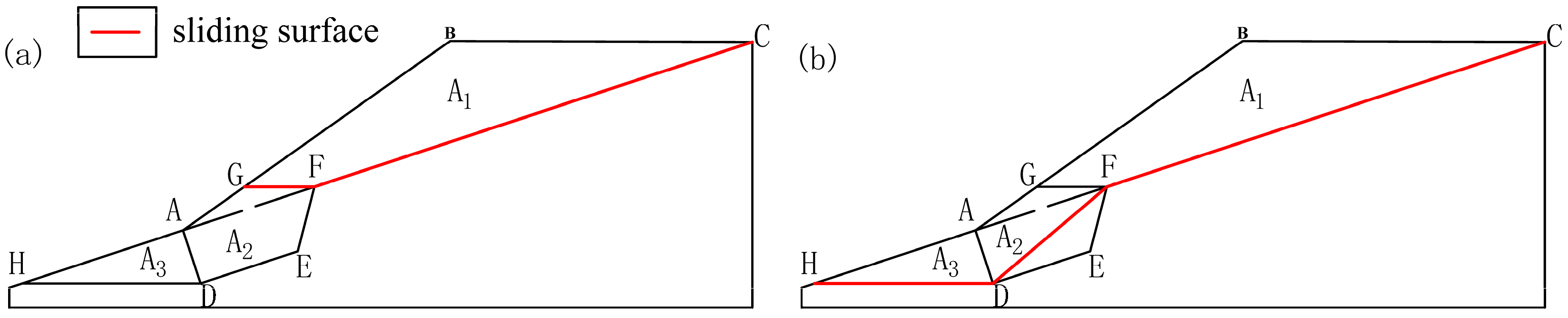

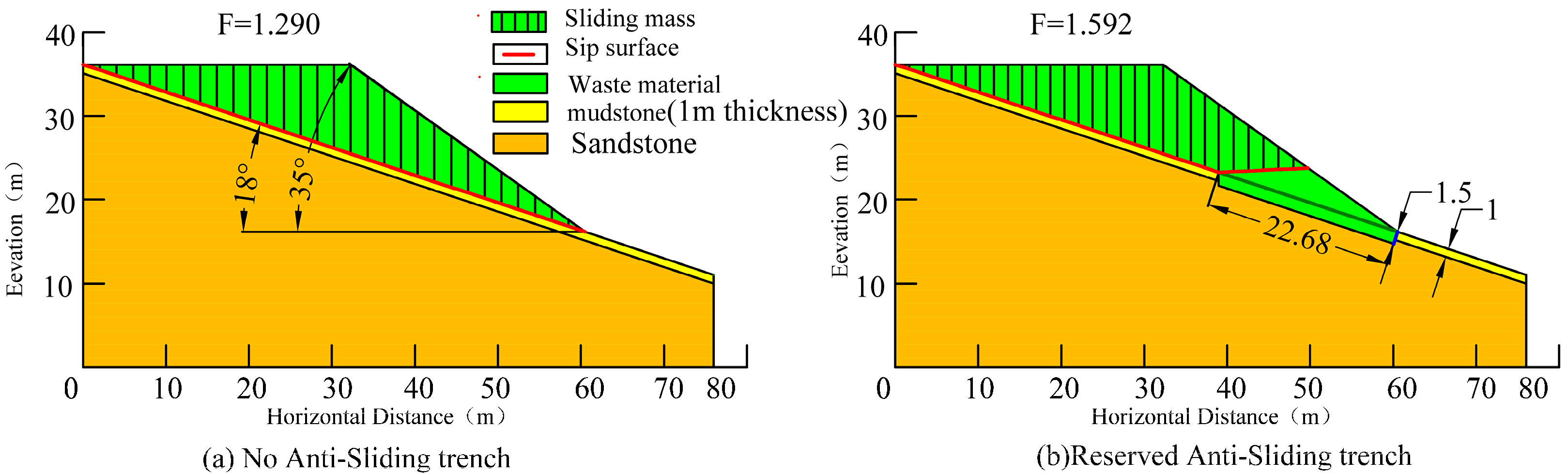

3.2.1. Slope Stability of the Dumping Bench Without Anti-Sliding Trenches

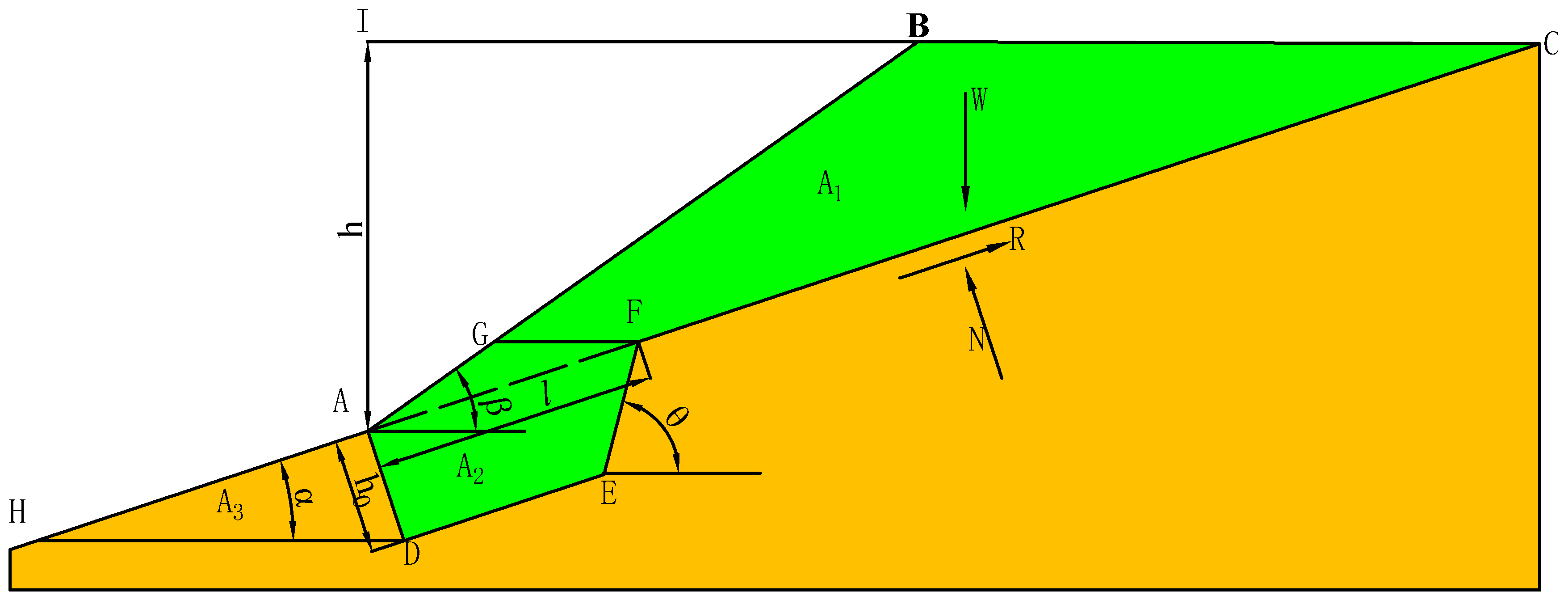

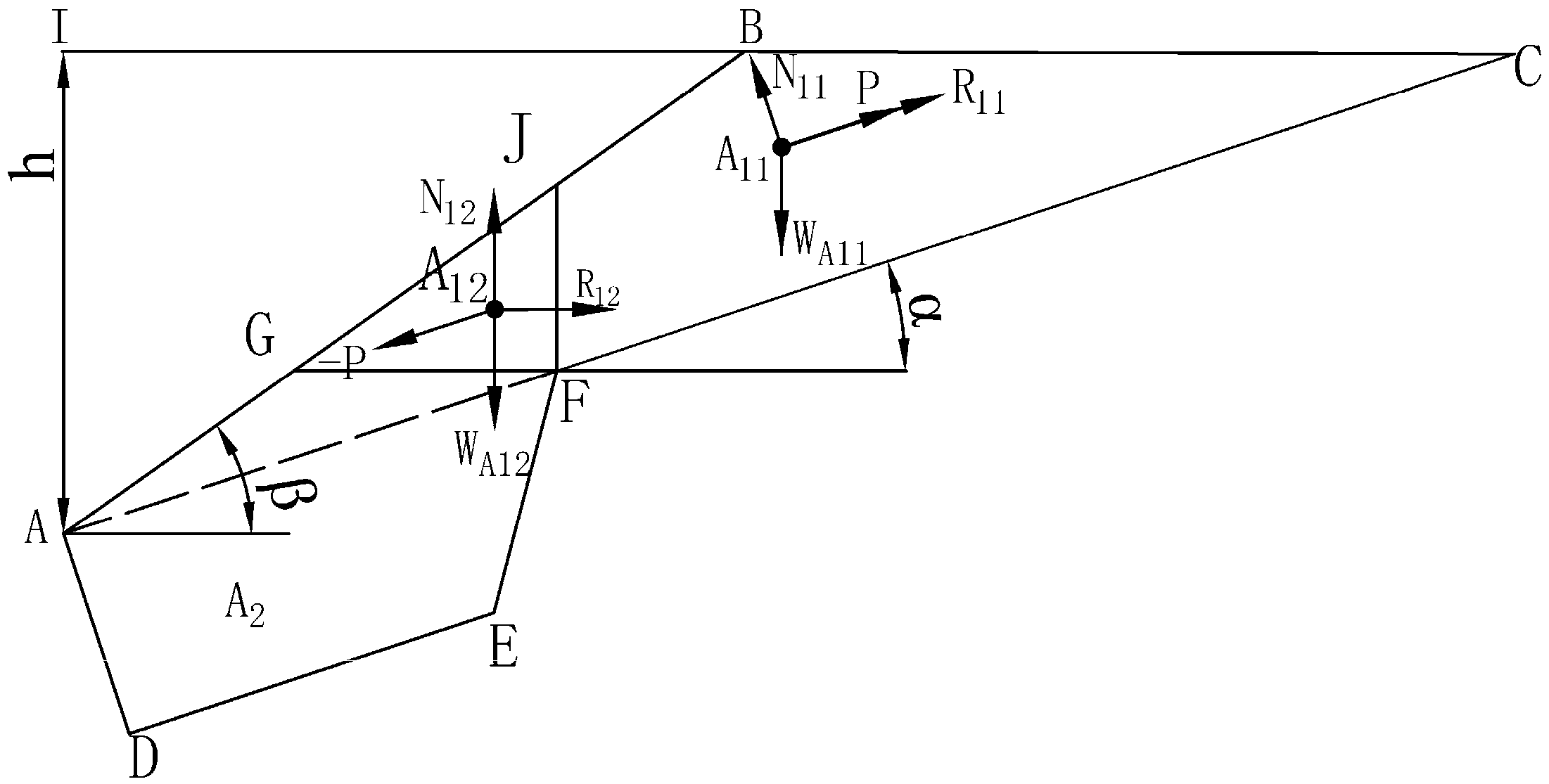

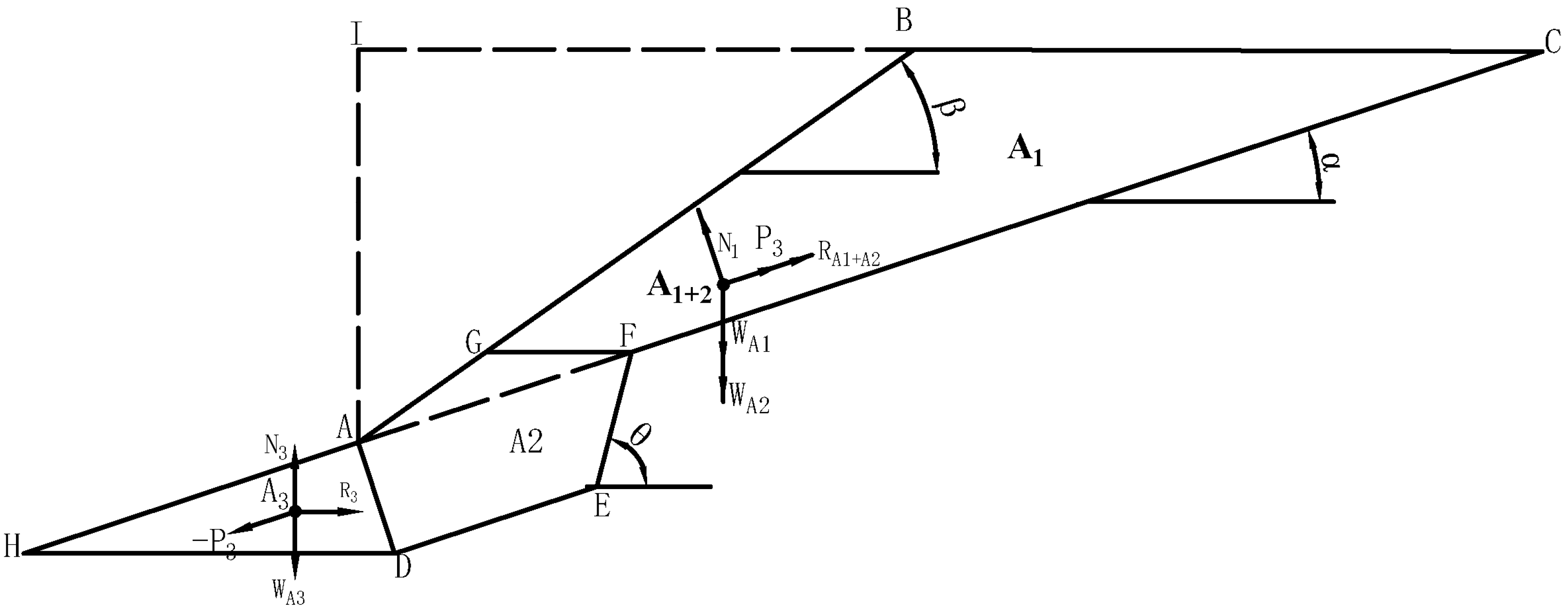

3.2.2. The Slope Stability Relationship of a Dumping Bench with Anti-Sliding Trenches

- is the internal friction angle of the surface , in degrees (°).

- is the cohesion of the surface , in kPa.

- is the length of the CF surface, in m.

- is the height of the slope step, in m.

- is the width of the anti-slide trench, in m.

- is the internal friction angle of the GF surface, in degrees (°).

- is the cohesion of the GF surface, in kPa.

- is the length of the GF surface, in m.

- is the unit weight of the waste material in section A12, in kN/m3.

- is the unit weight of the waste material in section A11, in kN/m3.

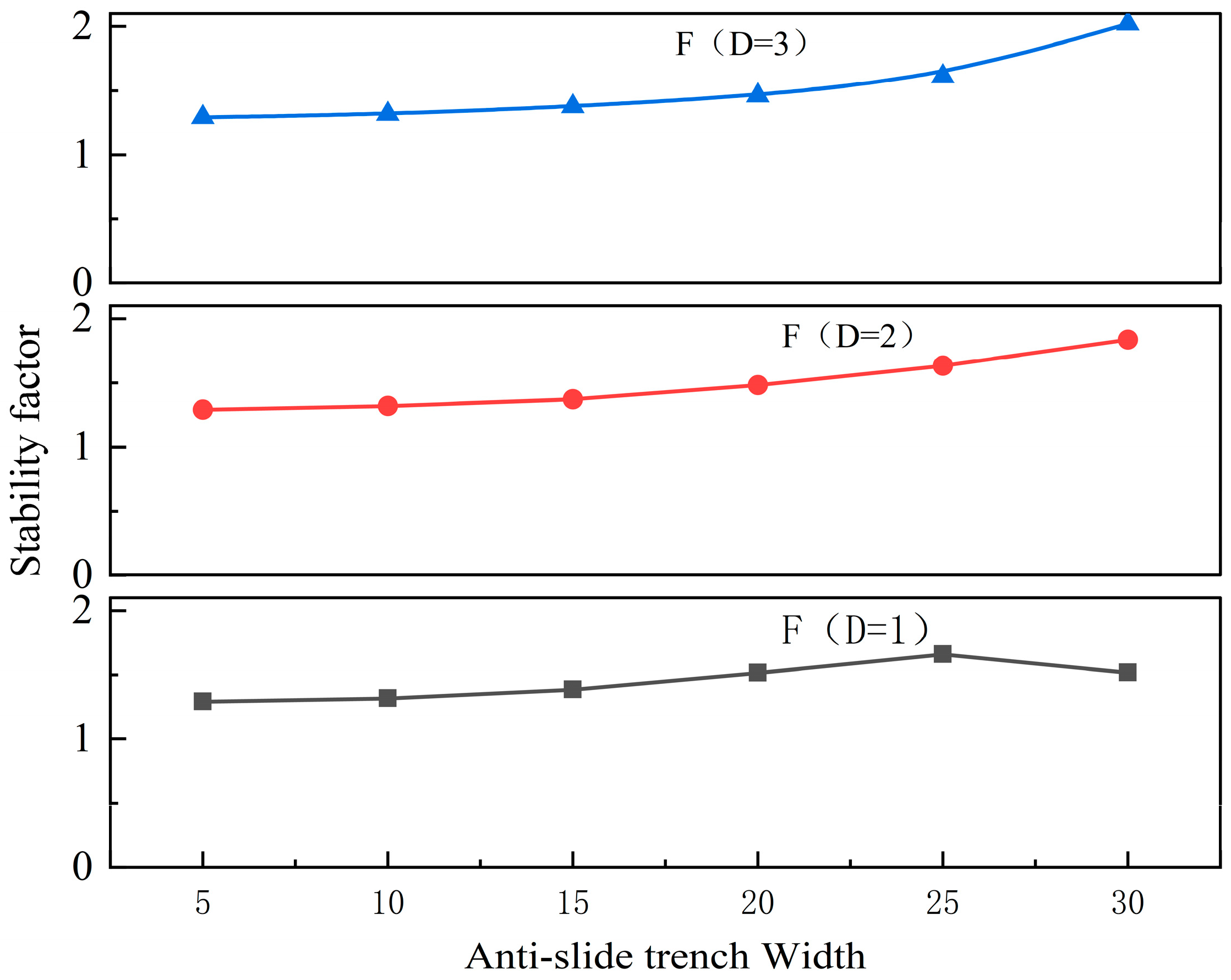

3.2.3. Analysis of the Anti-Sliding Trench Dimensions

- (1)

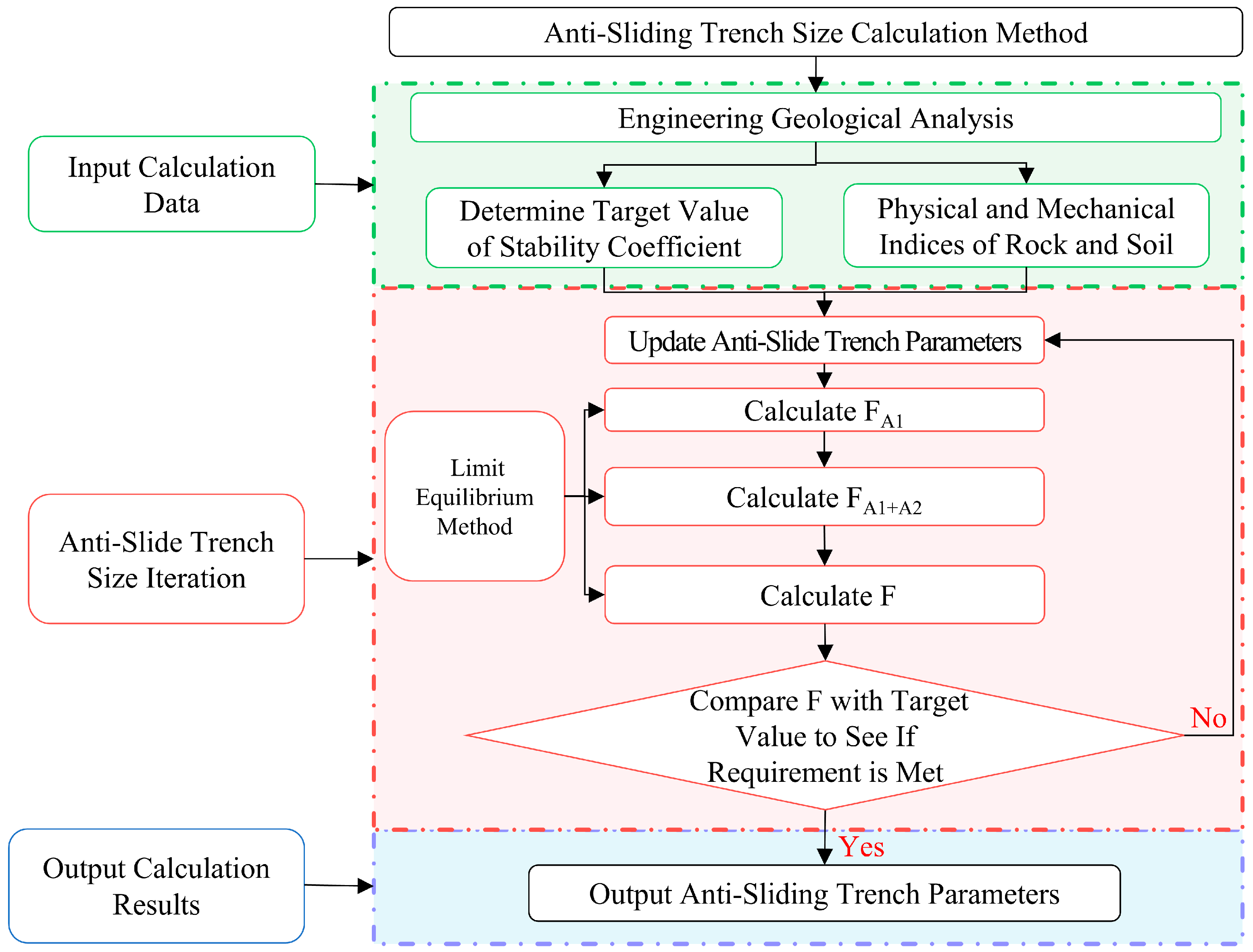

- Analyze the engineering geological characteristics of the waste dump and determine the physical and mechanical parameters of each soil and rock layer.

- (2)

- Based on the sliding surface of the waste dump foundation and relevant standards, determine the target stability factor. Use the limit equilibrium method to calculate whether the slope stability factor of the waste dump meets the target value. If not, add an anti-sliding trench at the slope’s toe.

- (3)

- Determine the initial dimensions of the anti-sliding trench (width and depth).

- (4)

- Use the rock mechanics parameters and anti-sliding trench dimensions as input parameters and apply the limit equilibrium method to calculate the slope stability factor after adding the anti-sliding trench.

- (5)

- Compare the slope stability factor after adding the anti-sliding trench with the targeted slope stability factor. When the value reaches or exceeds the target value, stop further calculation. The corresponding anti-sliding trench parameters represent the designed anti-sliding trench parameters. If the slope stability factor does not meet the target value, continue to increase the dimensions of the anti-sliding trench by a certain increment until the value reaches or exceeds the target value.

- (6)

- Provide the final anti-sliding trench dimensions (width and depth).

3.2.4. Analysis of the Anti-Sliding Effect

3.2.5. Dimensions of the Anti-Sliding Trench in the Anjialing Open-Pit Mine

4. Numerical Verification of Slope Stability

4.1. Establishment of the Numerical Model

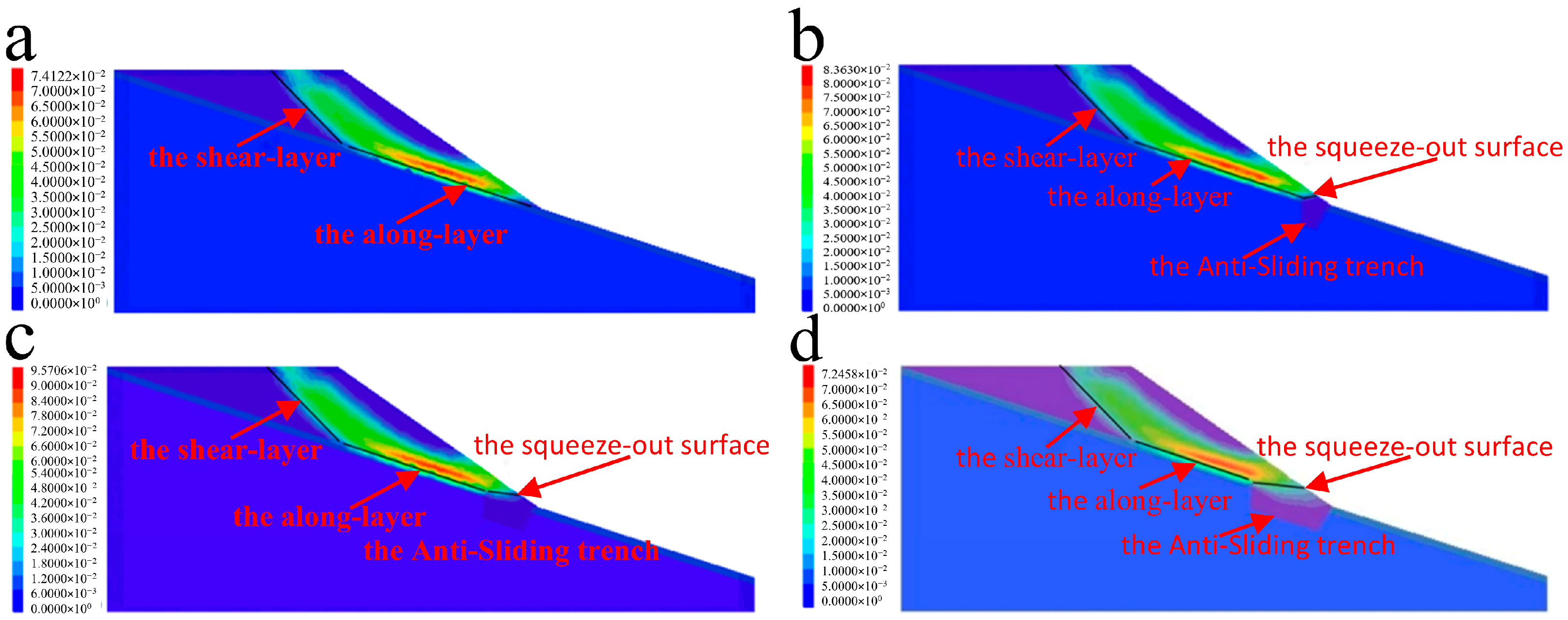

4.2. Numerical Simulation and Experimental Comparison Analysis

4.3. Numerical Calculation of Slope Stability

4.3.1. Model Reliability Analysis

4.3.2. Results and Analysis

5. Discussion

6. Conclusions

- (1)

- The failure modes of the slope in the internal dump with an inclined base of an open-pit coal mine are shear failure along the rear edge of the slope and failure along the base bedding plane. After presetting anti-sliding trenches at the toe of the inclined dump base in the open-pit coal mine, the failure mode is changed from “shear-layer and along-layer failure” to “shear-layer, along-layer, and squeeze-out failures”. The preset anti-sliding trenches alleviate the stress concentration at the slope toe by changing the position of the sliding surface.

- (2)

- After presetting anti-sliding trenches on the slope surface of the inclined base in the internal dump of an open-pit coal mine, the slope stability is not only related to the physical and mechanical parameters of the slope materials but also closely associated with the dimensions of the preset anti-sliding trenches. Within a certain range, the slope stability increases with the anti-sliding trench width, while it is less affected by the anti-sliding trench depth. By using the formula derived in this paper, an analysis was conducted on the dimensions of the preset anti-sliding trenches required to achieve the stability improvement goal for the waste dump steps at Anjialing Coal Mine: when the trench has a depth of 1.5 m and a width of 22.68 m, the stability factor of the step slope increases from 1.3095 to 1.6.

- (3)

- Presetting anti-sliding trenches at the slope toe on the inclined base surface of an open-pit coal mine dump not only alters the stress concentration at the slope toe to enhance slope stability but also effectively drains seepage water from the dump and replaces weak rock layers. This broadens the application spectra of anti-sliding trenches; additionally, it is also highly effective for slopes with larger gradients and weaker base surface layers.

- (4)

- In the design of anti-sliding trenches for the slope of an internal dump with an inclined base in an open-pit coal mine, multiple anti-sliding trenches can also be designed on the slope surface of the base to improve slope stability, besides arranging an anti-sliding trench at the base of the slope toe. The quantitative calculation of slope stability can be conducted using the method proposed in this paper. However, it should also be noted that although the installation of anti-sliding trenches can enhance slope stability, their application in engineering practice is relatively limited and has not been well verified in engineering practice. During the application process, it is essential to strengthen the monitoring and early warning mechanisms to prevent the occurrence of slope disasters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, H.Z. Key Mining Technology Research and Application in Surface Mine from Flat Seam to Inclined Seam. Ph.D. Dissertation, China University of Mining and Technology (Beijing), Beijing, China, 2012. [Google Scholar]

- Cao, B. The Optimization Research and Application of Surface Mine Transition Alternative Mode of Mining Area and Transportation Dumping Engineering Under Complicated Geological Conditions. Ph.D. Dissertation, China University of Mining and Technology (Beijing), Beijing, China, 2012. [Google Scholar]

- Wang, D.; Li, G.H.; Cao, L.Z.; Bai, R.C.; Song, Z.L.; Zhao, J.C. Method for arranging the working line of internal waste dump in surface coal mining based on maximizing utilization. J. China Coal Soc. 2020, 45, 3150–3156. [Google Scholar] [CrossRef]

- Zhou, W.; Han, L.; Cai, Q.X. Influence of inner dump on end-slope stability. J. Min. Saf. Eng. 2015, 32, 671–676. [Google Scholar] [CrossRef]

- Liu, F.M.; Cai, Q.X.; Zhou, W.; Fang, J. Experimental study on the rainfall infiltration rule in the dump slope of surface mines. J. China Coal Soc. 2015, 40, 1534–1540. [Google Scholar] [CrossRef]

- Zhao, H.Z.; Wang, D.Y.; Ma, M.; Zheng, K.H. Parameter inversion and location determination of evolutionary weak layer for open-pit mine slope. Int. J. Coal Sci. Technol. 2020, 7, 714–724. [Google Scholar] [CrossRef]

- Song, Z.L.; Liu, W.F.; Fan, J.F.; Yang, X.C.; Cao, L.Z. Analysis of the inner dumping slope stability with inclining basement. Met. Mine 2018, 179–183. [Google Scholar] [CrossRef]

- Zhao, H.Z.; Du, H.R.; Tao, Z.G.; Lin, Z.C. Method and mechanism of dump overlying the bedrock with large dip angle in opencast mine. Adv. Civ. Eng. 2021, 2021, 6632944. [Google Scholar] [CrossRef]

- Cao, L.Z.; Zhang, J.F.; Wang, D. Instability mechanism and control of the dump slope with soft inclined composite basement. Met. Mine 2019, 43–47. [Google Scholar] [CrossRef]

- Shiau, J.; Lai, V.Q.; Keawsawasvong, S. Multivariate adaptive regression splines analysis for 3D slope stability in anisotropic and heterogenous clay. J. Rock Mech. Geotech. Eng. 2023, 15, 1052–1064. [Google Scholar] [CrossRef]

- Lann, T.S.; Bao, H.; Lan, H.X.; Zheng, H.; Yan, C.G.; Peng, J.B. Hydro-mechanical effects of vegetation on slope stability: A review. Sci. Total Environ. 2024, 926, 171691. [Google Scholar] [CrossRef]

- Kardani, N.; Zhou, A.; Nazem, M.; Shen, S.-L. Improved prediction of slope stability using a hybrid stacking ensemble method based on finite element analysis and field data. J. Rock Mech. Geotech. Eng. 2021, 13, 188–201. [Google Scholar] [CrossRef]

- Shi, S.H.; Guo, Z.Z.; Ding, P.; Tao, Y.B.; Mao, H.; Jiao, Z.C. Failure mechanism and stability control technology of slope during open-pit combing underground extraction: A case study from Shanxi Province of China. Sustainability 2022, 14, 8939. [Google Scholar] [CrossRef]

- Dong, F.L.; Zhang, G.Q. A study on the application of the bumpy surface blasting method. J. Fuxin Min. Inst. 1988, 2, 95–102. [Google Scholar]

- Bi, J.W.; Gao, G.Y.; Zhang, J.J. Centrifuge model test of soft soil for pile-net composite foundation with overlying sloping base reinforced by inclined piles. J. Tongji Univ. (Nat. Sci.) 2020, 48, 953–961. [Google Scholar] [CrossRef]

- Wang, D.; Li, G.H.; Cao, L.Z.; Bai, R.C.; Song, Z.L. Mechanical effect of supporting and retaining coal pillar on internal waste dump with weak basement. J. China Coal Soc. 2019, 44, 934–941. [Google Scholar] [CrossRef]

- Mahanta, A.; Bhowmik, R.; Datta, M. Stabilization of hazardous solid waste landfill on sloping ground with variable base inclination. In Proceedings of the Eighth International Conference on Case Histories in Geotechnical Engineering, Austin, TX, USA, 24–27 March 2019; pp. 62–71. [Google Scholar]

- Kumar, A.; Das, S.K.; Nainegali, L.; Reddy, K.R. Phytostabilization of coalmine overburden waste rock dump slopes: Current status, challenges, and perspectives. Bull. Eng. Geol. Environ. 2023, 82, 130. [Google Scholar] [CrossRef]

- Bhowmik, R.; Sukumar, R.; Datta, M.; Shahu, J.T. The Use of Geosynthetic Reinforcement for Enhancing the Stability of the Geomembrane–Soil Interface along the Slopes of Cover Systems of MSW Landfills. In Proceedings of the Geo-Chicago 2016, Chicago, IL, USA, 26–29 August 2016; pp. 307–318. [Google Scholar]

- Bao, H.; Liu, L.; Lan, H.; Peng, J.; Yan, C.; Tang, M.; Guo, G.; Zheng, H. Evolution of high-filling loess slope under long-term seasonal fluctuation of groundwater. Catena 2024, 238, 107898. [Google Scholar] [CrossRef]

- Li, Z.G.; Li, W.L.; Xu, Q.; Lu, H.Y.; Fu, H.; Guo, P.Y.; Zhao, J.J.; Yu, C.W. Preliminary analysis of the catastrophic February 22nd 2023 Xinjing open-pit mine landslide, Inner Mongolia, China. Landslides 2024, 21, 1053–1067. [Google Scholar] [CrossRef]

- Jia, L.; Wang, J.; Gao, S.; Fang, L.; Wang, D. Landslide risk evaluation method of open-pit mine based on numerical simulation of large deformation of landslide. Sci. Rep. 2023, 13, 15410. [Google Scholar] [CrossRef]

- Yang, Y.S.; Yi, X.; Hu, P.; Dong, Q. The optimized design for groove parameters based on cement pavement materials performance. Adv. Mater. Res. 2011, 213, 613–617. [Google Scholar] [CrossRef]

- Jiang, S.Z. Case analysis of the impact of anti-slide trenches on the stability of gravity dams on gently inclined downstream bedrock. Water Conserv. Sci. Technol. Econ. 2015, 21, 54–56. [Google Scholar] [CrossRef]

- Qian, G.P.; Li, S.J.; Yu, H.N.; Gong, X.B. Interlaminar bonding properties on cement concrete deck and phosphorous slag asphalt pavement. Materials 2019, 12, 1427. [Google Scholar] [CrossRef]

- Hou, C.H. Analysis and control of slope stability of end wall coal mining in Anjialing open-pit mine. Saf. Coal Mines 2022, 53, 235–240. [Google Scholar] [CrossRef]

- Yang, X. Study on the Stability of South Slope In-Pit Dump of Anjialing Open Pit Mine. Master’s Thesis, Liaoning Technical University, Fuxin, China, 2012. [Google Scholar]

- Zhu, J.M.; Liu, X.Q.; Feng, J.Y.; Wu, J.P. Study on slope stability and optimization of boundary parameters under condition of combined open-underground mining. Chin. J. Rock Mech. Eng. 2009, 28, 3971–3977. [Google Scholar] [CrossRef]

- Li, C.H.; Xiao, Y.G.; Wang, Y.; Bu, L.; Hou, Z.Q. Review and prospects for understanding deformation and failure of rock slope in cold regions with high altitude. Chin. J. Eng. 2019, 41, 1374–1386. [Google Scholar] [CrossRef]

- Ma, L.; Jin, X.Y.; Zhang, Q.F.; Jiang, K.S.; Li, M.B.; Hu, Y. Stability analysis of the inner dump with inclined base considering anti-slip pillar. Coal Sci. Technol. 2024, 52, 181–188. [Google Scholar] [CrossRef]

- GB/T 37573-2019; Technical Specification for Annual Evaluation of the Stability of Open-Pit Coal Mine Slopes. State Administration for Market Regulation, Standardization Administration of China: Beijing, China, 2019.

- Wang, J.C.; Sun, S.W. Slope Engineering in Open-Pit Mines; Science Press: Beijing, China, 2016. [Google Scholar]

- Tu, L.X.; Tian, Y.; Wang, Z.L.; Zhou, W.; Cai, Q.X.; Lu, X. Study on slope stability under different weak layer replacement parameters in open-pit mines. Coal Mine Saf. 2023, 54, 214–220. [Google Scholar] [CrossRef]

- Bang, V.S.; Wang, Y.; Vu, T.; Zhou, W.; Liu, X.; Ao, Z.C.; Nguyen, D.; Pham, H.; Nguyen, H. The influence of rainfall and evaporation wetting–drying cycles on the open-pit coal mine dumps in Cam Pha, Quang Ninh Region of Vietnam. Appl. Sci. 2024, 14, 1711. [Google Scholar] [CrossRef]

| Rock Layer | Density/ g/cm3 | Cohesion/kPa | Internal Friction Angle, φ/° | Elastic Modulus/104 MPa | Poisson’s Ratio |

|---|---|---|---|---|---|

| Waste | 1.99 | 9.7 | 18 | 0.017 | 0.39 |

| Mudstone | 2.23 | 154.4 | 28.5 | 1.21 | 0.31 |

| Sandstone | 2.3 | 361.5 | 27.1 | 1.95 | 0.22 |

| Name of the Rock Layer | Sand (%) | Lime (%) | Plaster (%) |

|---|---|---|---|

| Sandstone | 87.5 | 6.25 | 6.25 |

| Mudstone | 88.89 | 8.89 | 2.22 |

| Waste | 90.9 | 9.1 | 0 |

| Physical Parameter | Similarity Ratio | Model Value and Unit | Actual Engineering Value and Unit | |

|---|---|---|---|---|

| Slope Model and Dimensions | Slope Length (along the slope) | 100 | 35 cm | 35 m |

| Slope Height (vertical) | 100 | 20 cm | 20 m | |

| Slope Angle | 1 | 18° | 18° | |

| Base Rock Slope Angle | 1 | 35° | 35° | |

| Anti-sliding Trench Dimensions | Anti-sliding Trench Depth | 100 | 4 cm | 4 m |

| Anti-sliding Trench Width | 4 cm/8 cm/12 cm | 4 m/8 m/12 m | ||

| Load | Stress | 150 | 10.62 Pa/16.82 Pa | 1592.5 Pa/2523.5 Pa |

| Materials (Waste, Mudstone, Sandstone) | Density | 1.5 | See values in Table 1 for actual engineering values; model values are the actual values divided by the similarity ratio. | |

| Cohesion | 150 | |||

| Internal Friction Angle | 1 | |||

| Elastic Modulus | 150 | |||

| Poisson’s Ratio | 1 | |||

| h0 (m) | F (l = 5 m) | F (l = 10 m) | F (l = 15 m) | F (l = 20 m) | F (l = 25 m) | F (l = 30 m) |

|---|---|---|---|---|---|---|

| 0.5 | 1.312 | 1.342 | 1.404 | 1.455 | 1.452 | 1.449 |

| 1 | 1.312 | 1.342 | 1.404 | 1.513 | 1.590 | 1.582 |

| 1.5 | 1.312 | 1.342 | 1.404 | 1.513 | 1.699 | 1.710 |

| 2 | 1.312 | 1.342 | 1.404 | 1.513 | 1.699 | 1.833 |

| 2.5 | 1.312 | 1.342 | 1.404 | 1.513 | 1.699 | 1.953 |

| 3 | 1.312 | 1.342 | 1.404 | 1.513 | 1.699 | 2.040 |

| D | F (W = 5) | F (W = 10) | F (W = 15) | F (W = 20) | F (W = 25) | F (W = 30) |

|---|---|---|---|---|---|---|

| 1 | 1.291 | 1.316 | 1.384 | 1.514 | 1.658 | 1.516 |

| 2 | 1.290 | 1.320 | 1.372 | 1.482 | 1.633 | 1.837 |

| 3 | 1.291 | 1.316 | 1.375 | 1.460 | 1.610 | 2.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Wei, H.; Qin, B.; Du, H.; Shao, Z. Anti-Sliding Trenches to Enhance Slope Stability of Internal Dumps on Inclined Foundations in Open-Pit Coal Mines. Appl. Sci. 2025, 15, 10510. https://doi.org/10.3390/app151910510

Zhao H, Wei H, Qin B, Du H, Shao Z. Anti-Sliding Trenches to Enhance Slope Stability of Internal Dumps on Inclined Foundations in Open-Pit Coal Mines. Applied Sciences. 2025; 15(19):10510. https://doi.org/10.3390/app151910510

Chicago/Turabian StyleZhao, Hongze, Hong Wei, Binde Qin, Hairui Du, and Zhiben Shao. 2025. "Anti-Sliding Trenches to Enhance Slope Stability of Internal Dumps on Inclined Foundations in Open-Pit Coal Mines" Applied Sciences 15, no. 19: 10510. https://doi.org/10.3390/app151910510

APA StyleZhao, H., Wei, H., Qin, B., Du, H., & Shao, Z. (2025). Anti-Sliding Trenches to Enhance Slope Stability of Internal Dumps on Inclined Foundations in Open-Pit Coal Mines. Applied Sciences, 15(19), 10510. https://doi.org/10.3390/app151910510