Research on Leakage Localization in Gaseous CO2 Pipelines Using the Acoustic Emission Method

Abstract

1. Introduction

2. Research Status

2.1. Common Leak Detection Methods for Gas Transmission Pipelines

- (1)

- Infrared imaging detection method

- (2)

- Equipment Wall Detection Method

- (3)

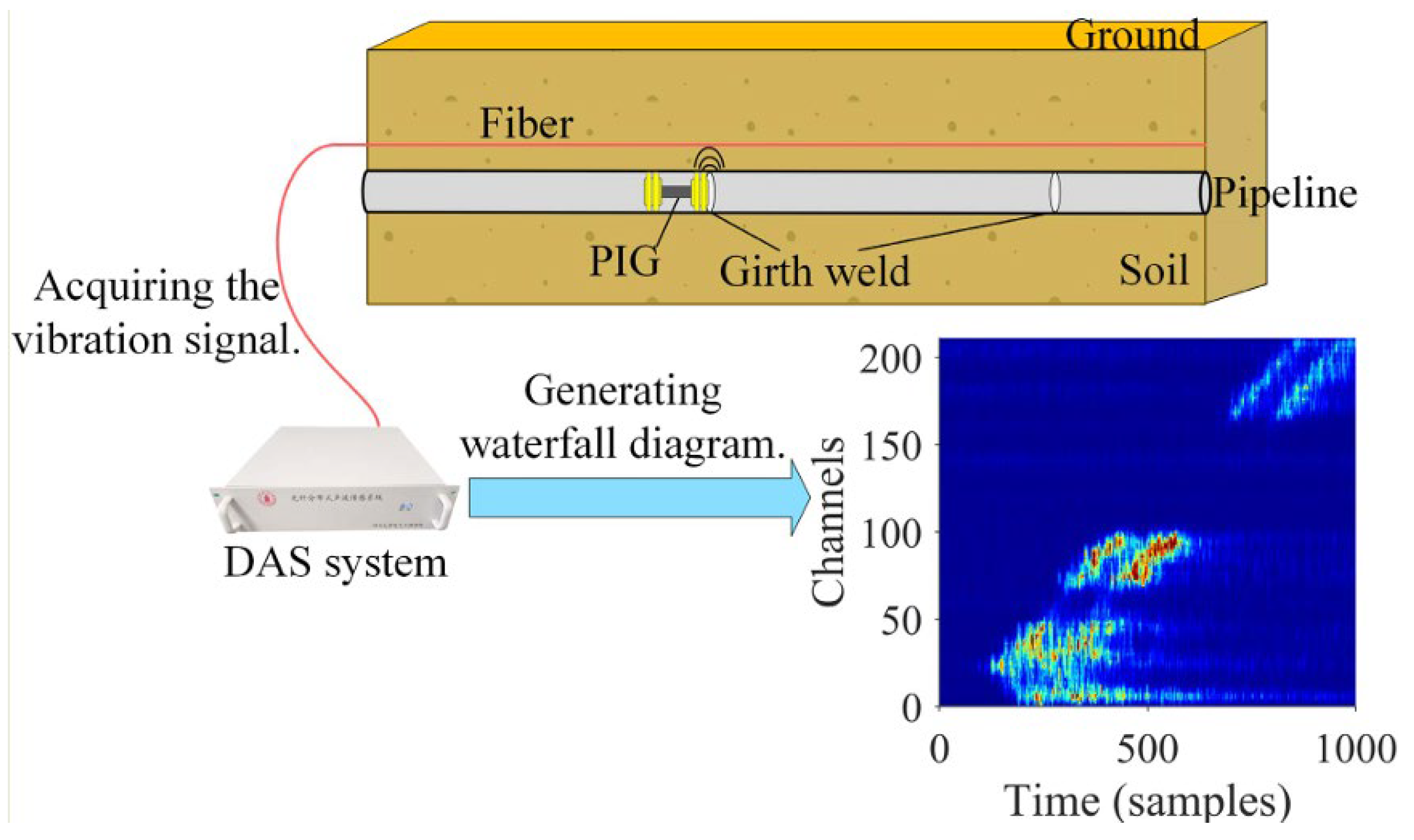

- Distributed Optical Fiber Method

- (4)

- Negative Pressure Wave Detection Method

- (5)

- Acoustic Emission Detection Method

- ①

- Although the infrared imaging method has a relatively wide detection range, its cost is high, and the detection accuracy for buried pipeline leaks is not good.

- ②

- The equipment wall detection method has extremely high detection accuracy and can provide real-time feedback on the pipeline status to achieve leak prediction. However, its cost is relatively high, and it is prone to blockage accidents in pipelines with complex geometric shapes.

- ③

- The distributed optical fiber method has high detection accuracy and can perform real-time detection. However, the cost of laying optical fibers is high, and the maintenance cost and construction volume are large.

- ④

- The negative pressure wave detection method has a low cost. However, under the influence of external noise, false negatives and false positives may occur, and it is not applicable to pipelines transporting multi-phase media.

- ⑤

- The acoustic emission method has obvious advantages in leak detection: Firstly, in terms of hardware equipment, acoustic emission sensors are small in size and easy to install. Meanwhile, during installation and maintenance, only the soil and insulation layer at specific locations need to be dug, which does not affect the normal operation of the pipeline. This greatly reduces the cost of leakage detection and transformation of in-service pipelines [15]. Secondly, in terms of the detection principle, the acoustic emission method belongs to non-destructive testing. During the detection process, it will not damage the internal flow field of the pipeline. It has a fast detection speed and high sensitivity, and can achieve real-time and continuous monitoring of long-distance pipelines. Finally, in terms of detection cost, its system composition is relatively simple. Compared with monitoring technologies such as distributed optical fibers, it has a higher cost-performance ratio [16]. However, the acoustic emission method also has its drawbacks. The propagation of acoustic waves strongly depends on the length and characteristics of the path they travel. The position of the sensors needs to be carefully evaluated based on the geometry of the specimen under analysis

2.2. Application of Acoustic Emission Leak Detection Method

3. Basic Methods and Principles of AE

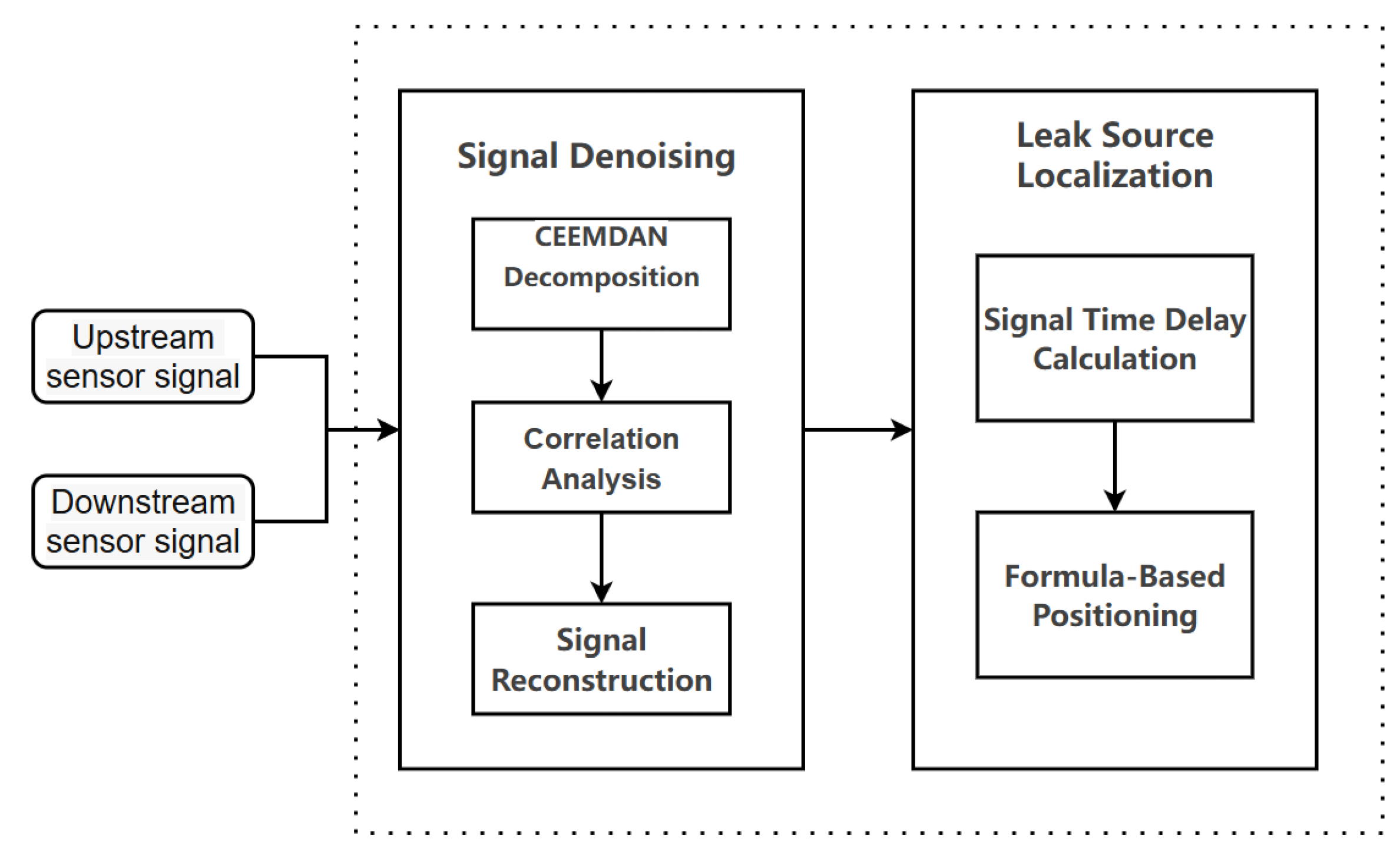

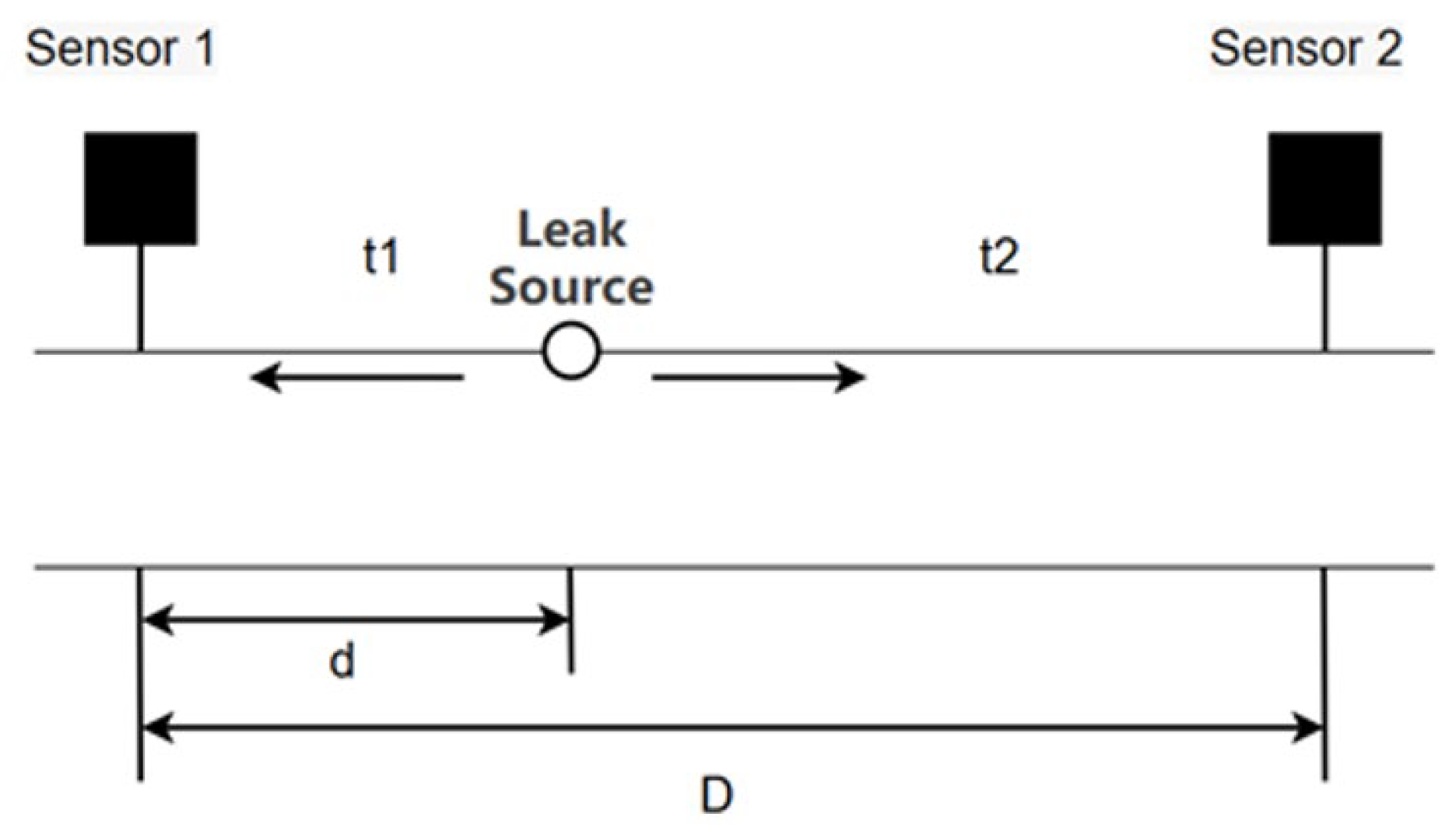

3.1. Method for Determining Pipeline Leak Location

3.2. Denoising Method for Acoustic Emission Signals

- (1)

- Roth weighting: Using the auto-power spectrum of the signal as the weighting function.

- (2)

- SCOT weighting: Using the square root of the auto-power spectrum of the signal as the weighting function.

- (3)

- PHAT: Using the reciprocal of the magnitude of the cross-power spectrum of the signal as the weighting function.

- (4)

- ML weighting: Set large values when the signal-to-noise ratio is high; set small values when the signal-to-noise ratio is low to reduce the influence of environmental noise.

4. Preliminary Experiment on Air Pipeline Leakage

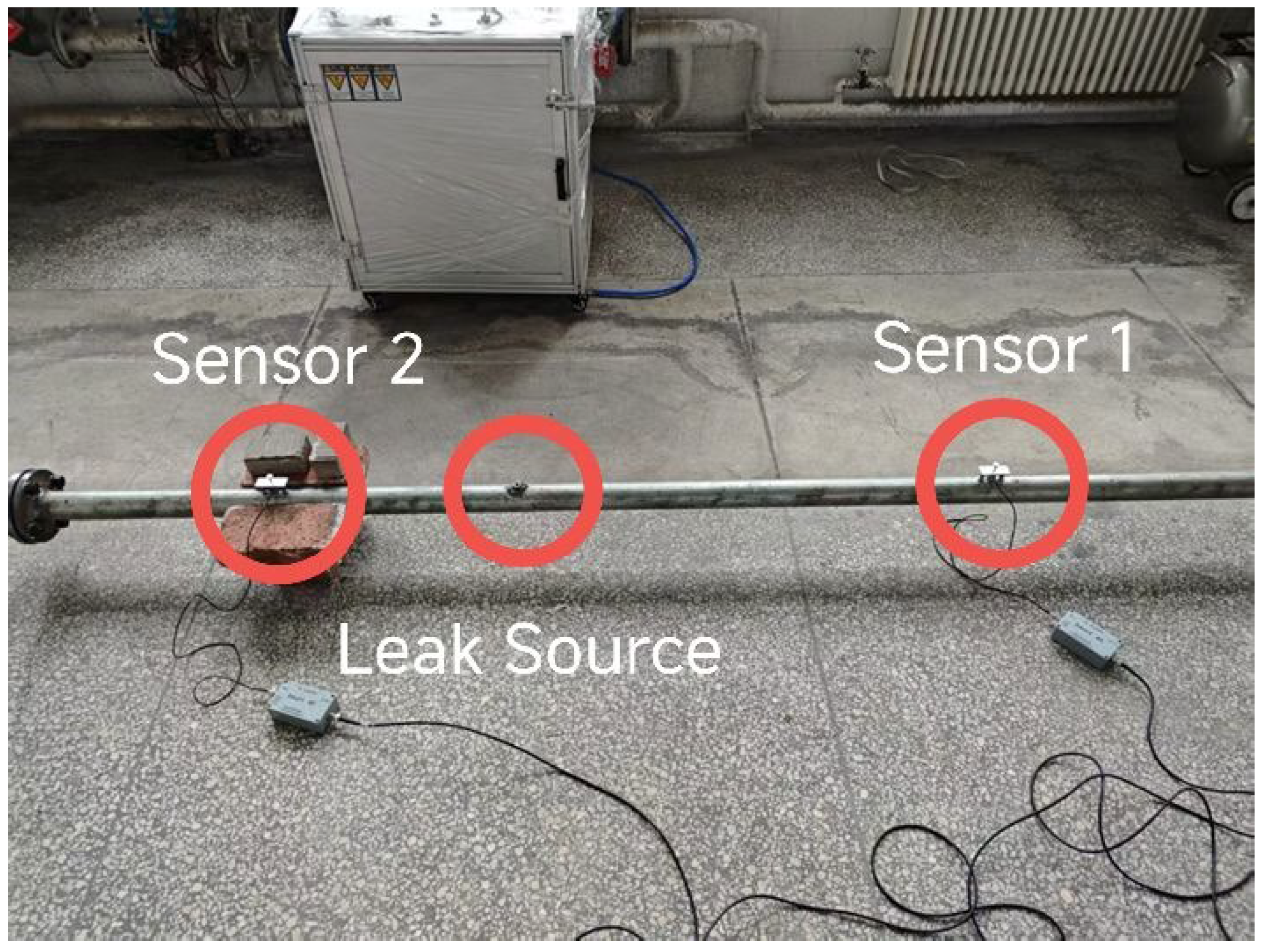

4.1. Experimental Setup

4.1.1. Test Pipeline

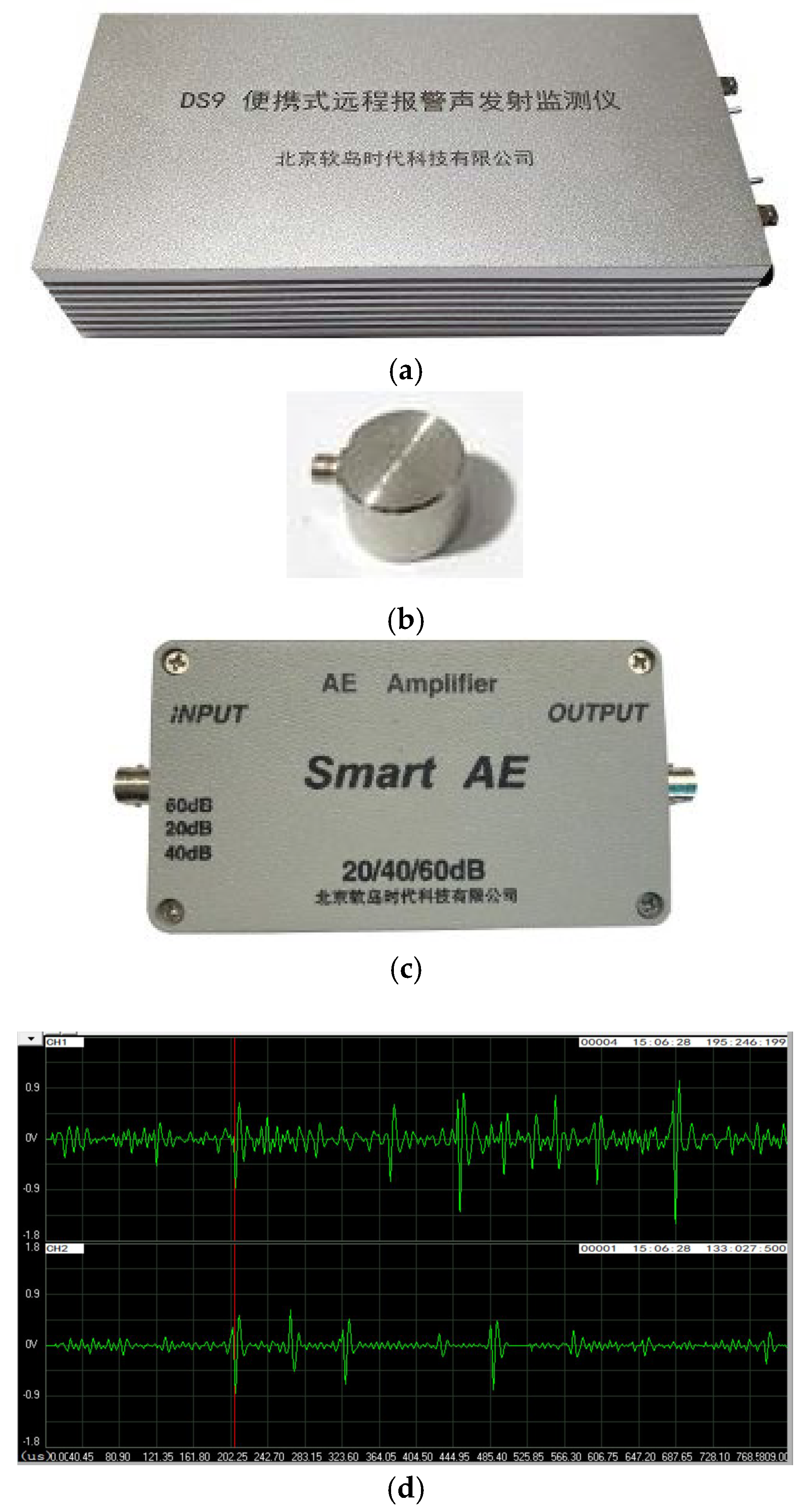

4.1.2. Acoustic Emission Signal Collector

- (1)

- An acoustic emission monitor with a high waveform sampling rate (10 MHz), which can store the acoustic emission waveform at a rate of 10 M (sampling rate is adjustable) sampling points.

- (2)

- An RS-2A sensor with a frequency range of 50 kHz–400 kHz.

- (3)

- A preamplifier with amplification factors of 20/40/60 dB.

- (4)

- Acoustic emission signal acquisition software. Sensor 1 and Sensor 2 are located on both sides of the leak port, and their distances from the leak port are arranged according to the experimental requirements.

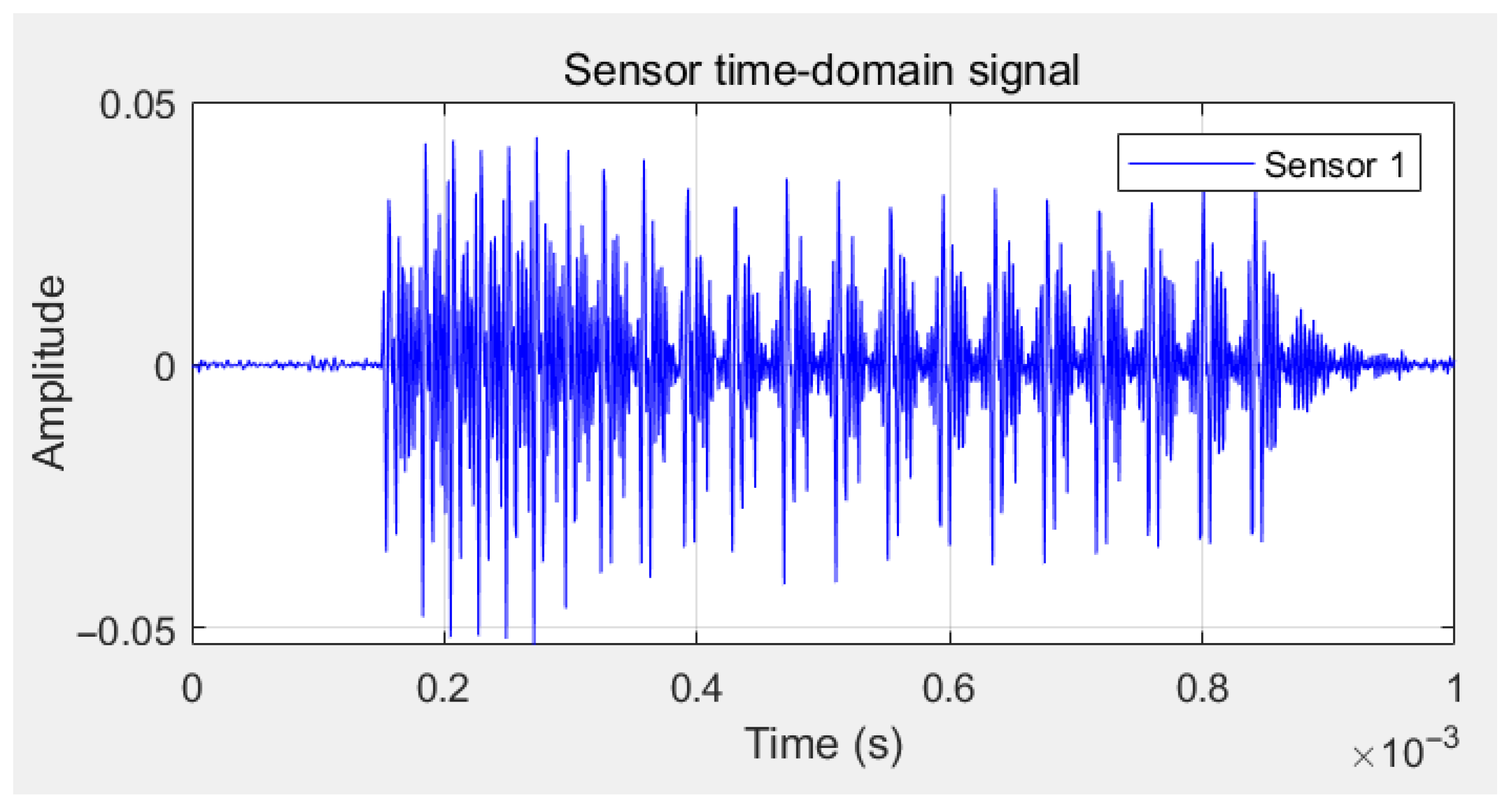

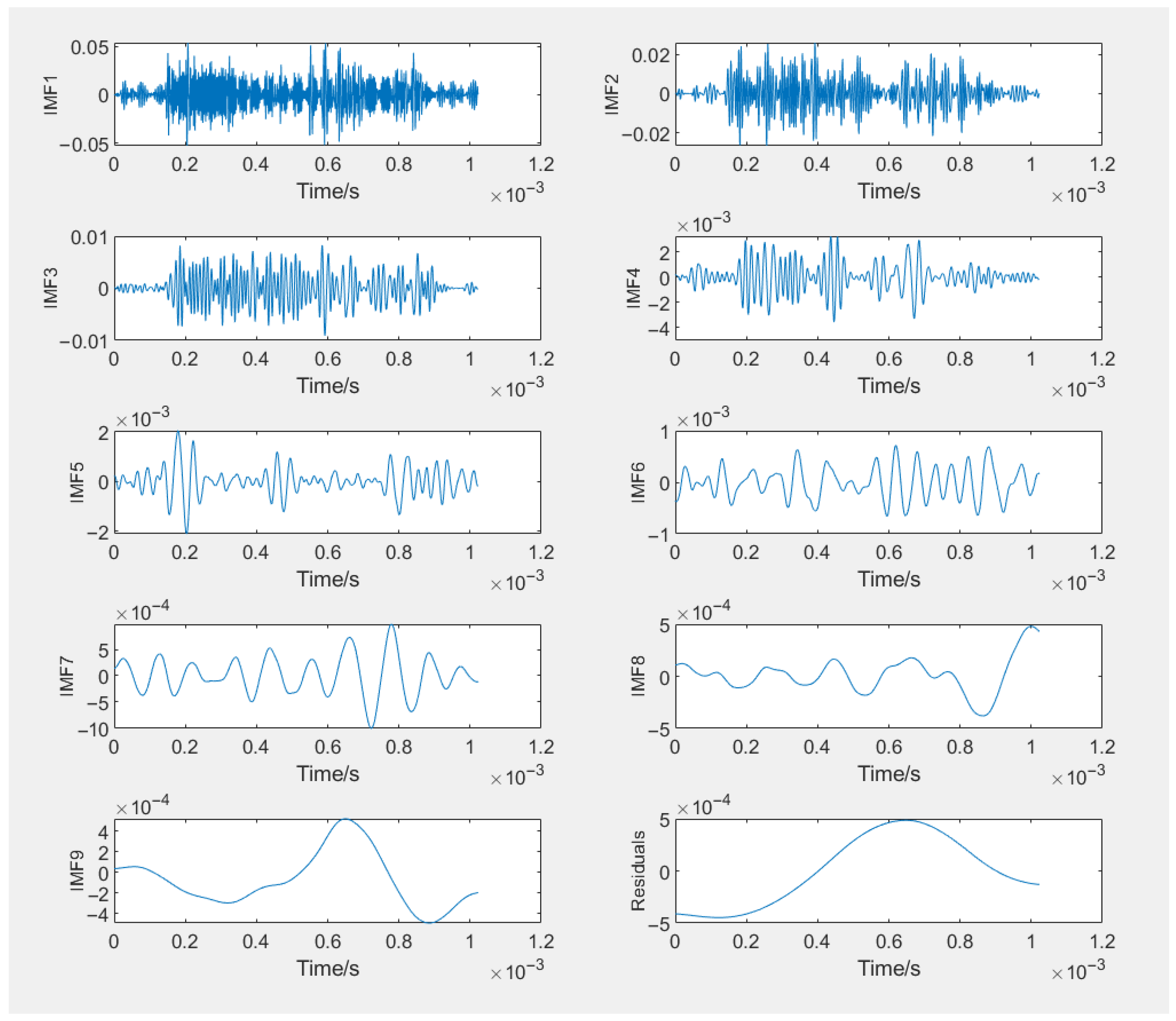

4.2. Signal Acquisition and Processing

4.2.1. Measurement of Pipeline Wave Velocity

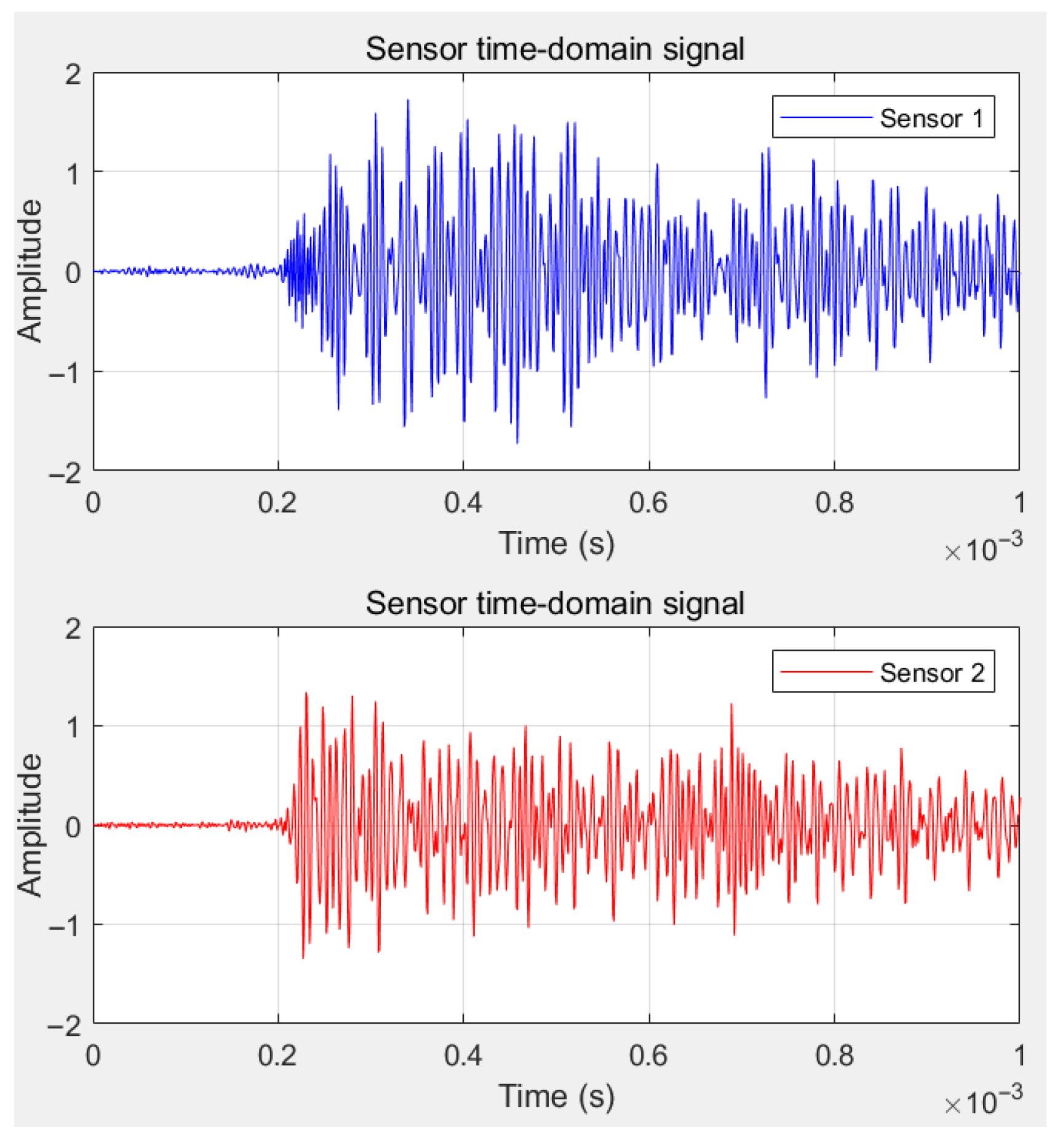

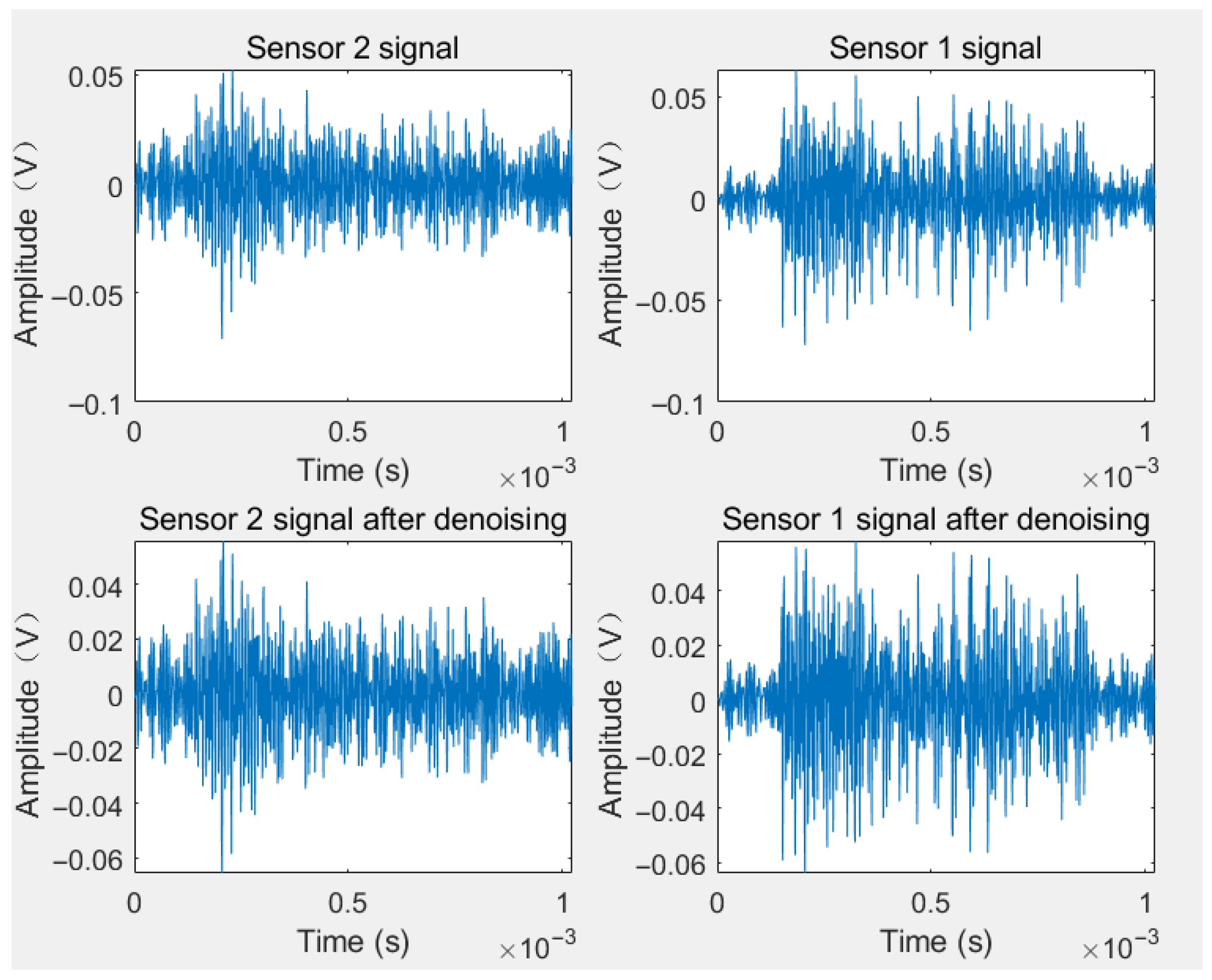

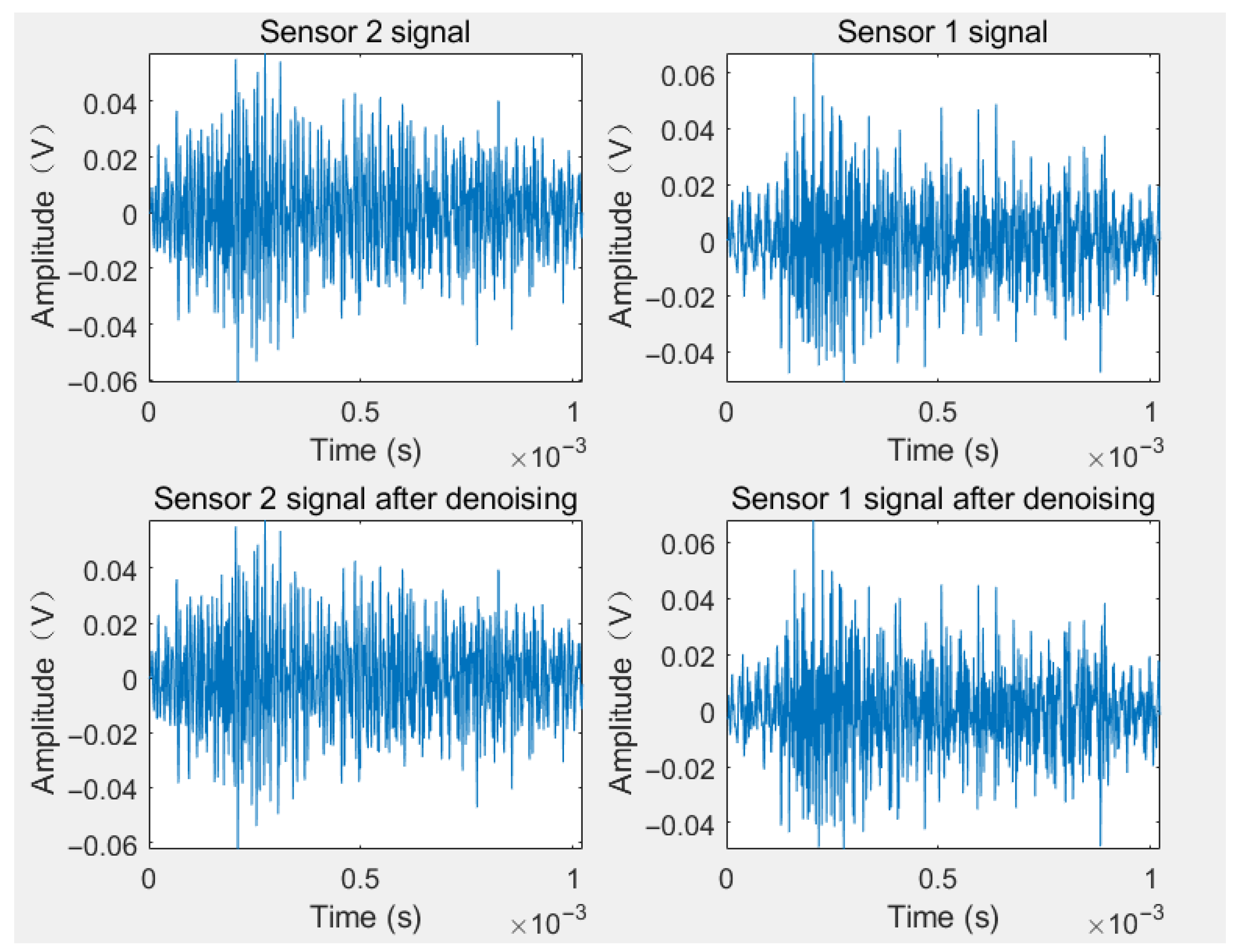

4.2.2. Noise Reduction in Pipeline Leak Signals

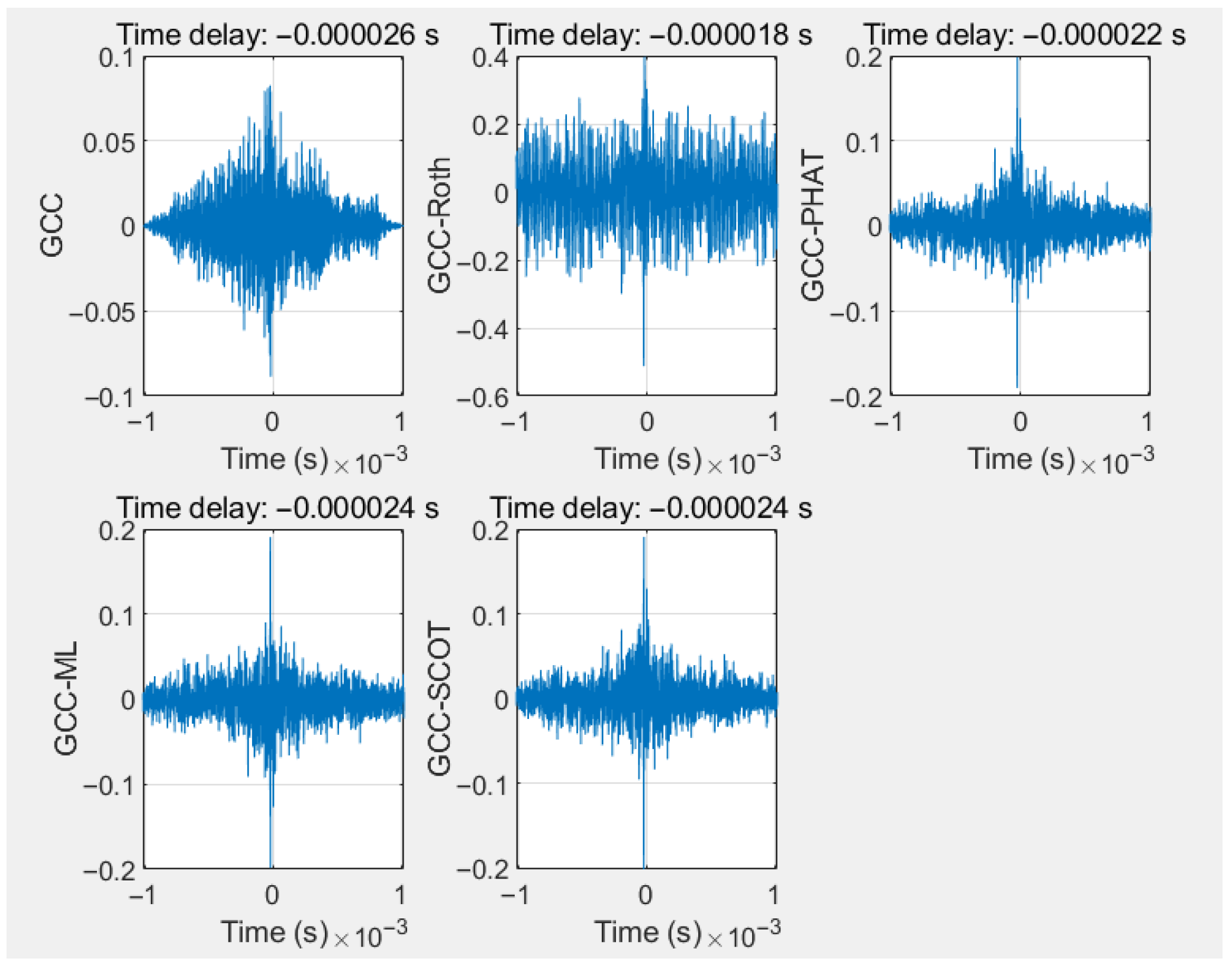

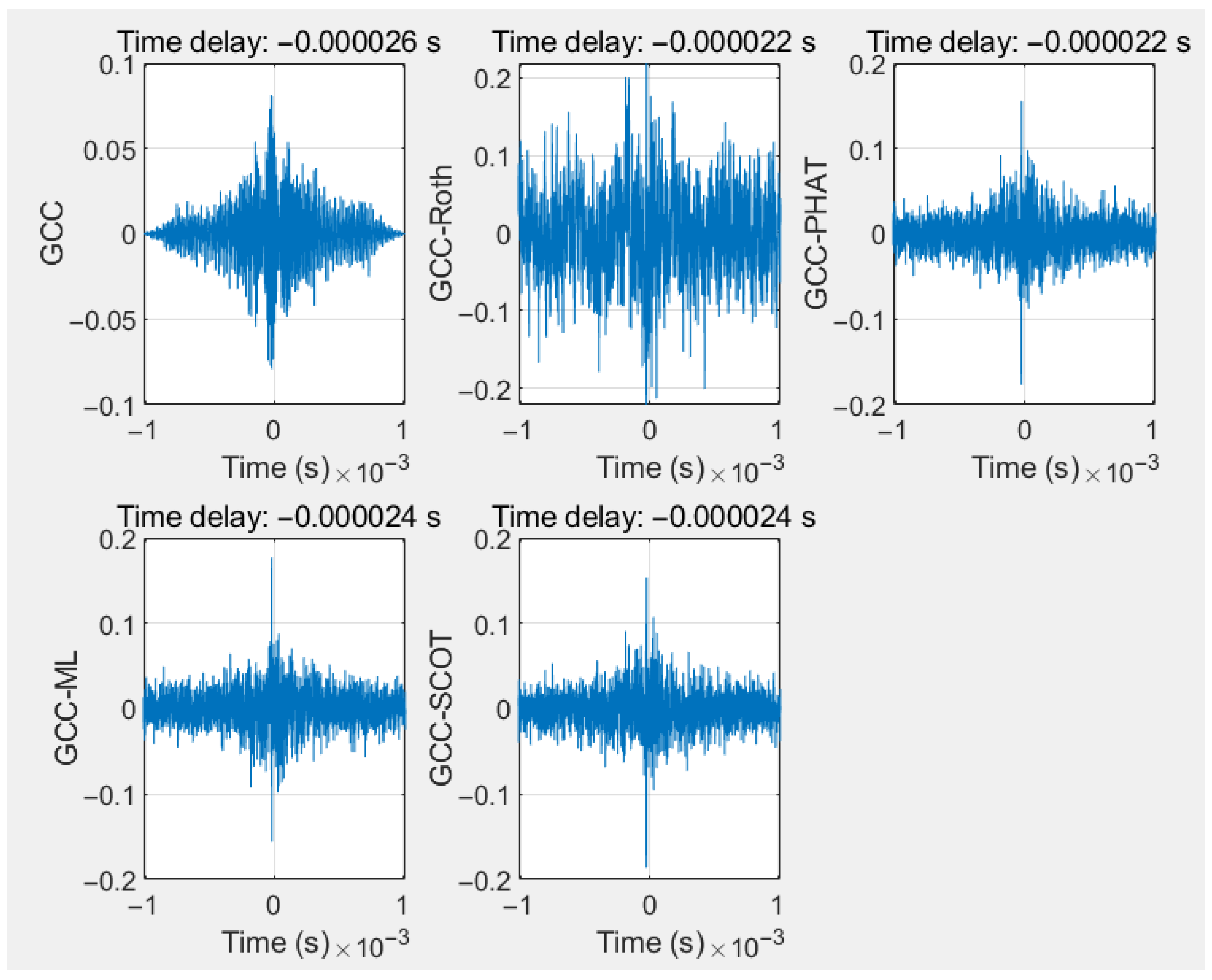

4.3. Pipeline Leak Source Location

5. Gas CO2 Pipeline Leak Location Experiment

5.1. CO2 Test Pipeline and Sensor Arrangement

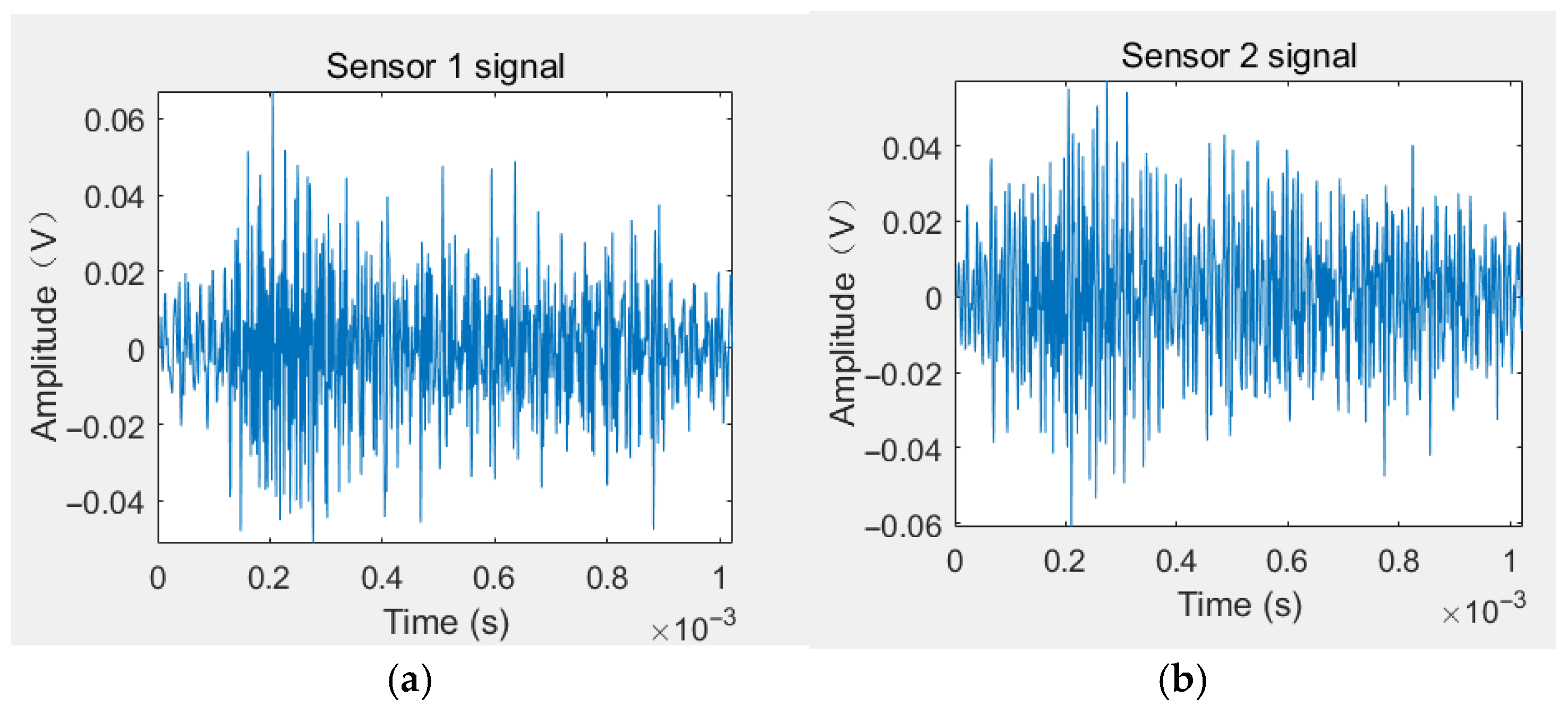

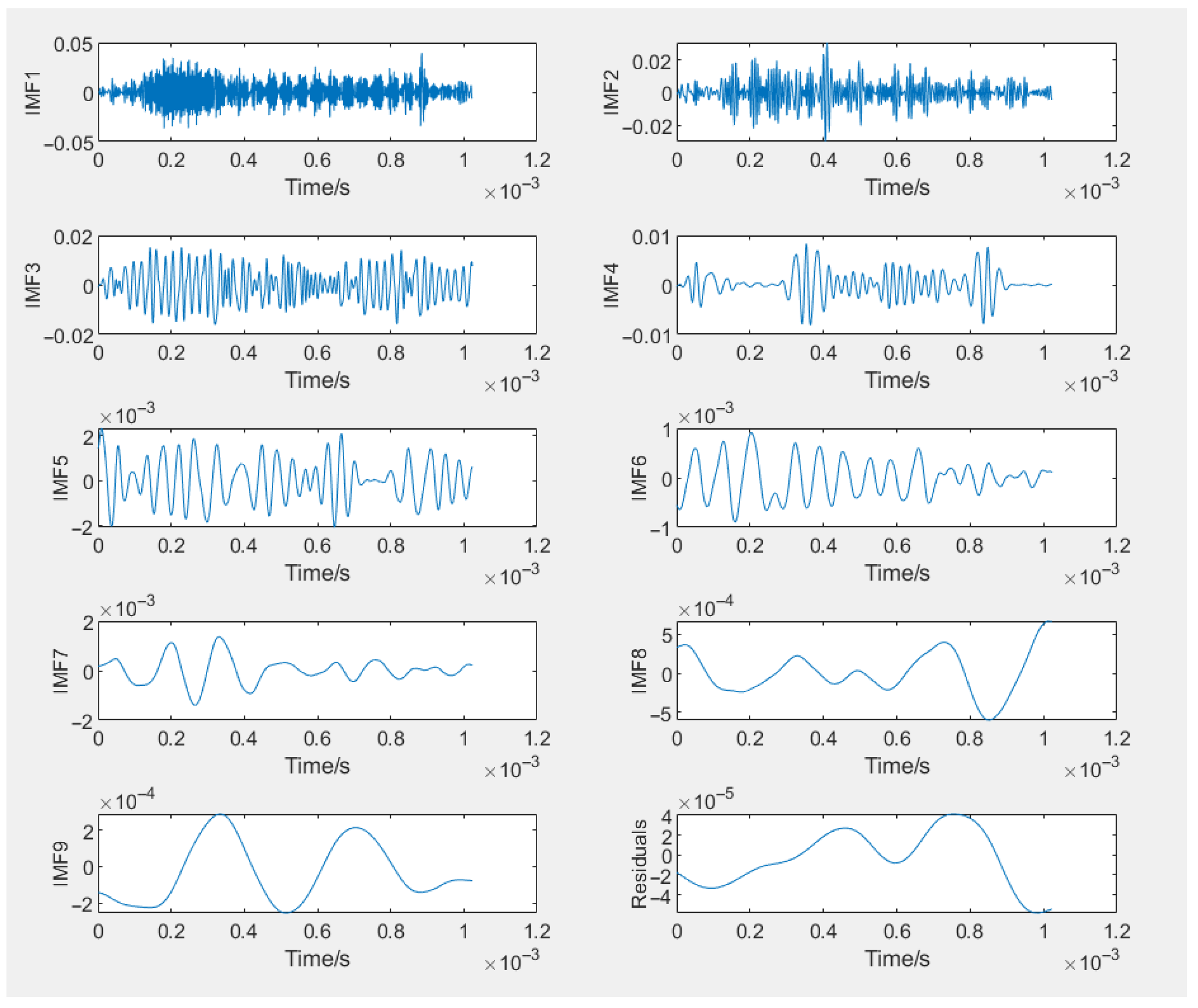

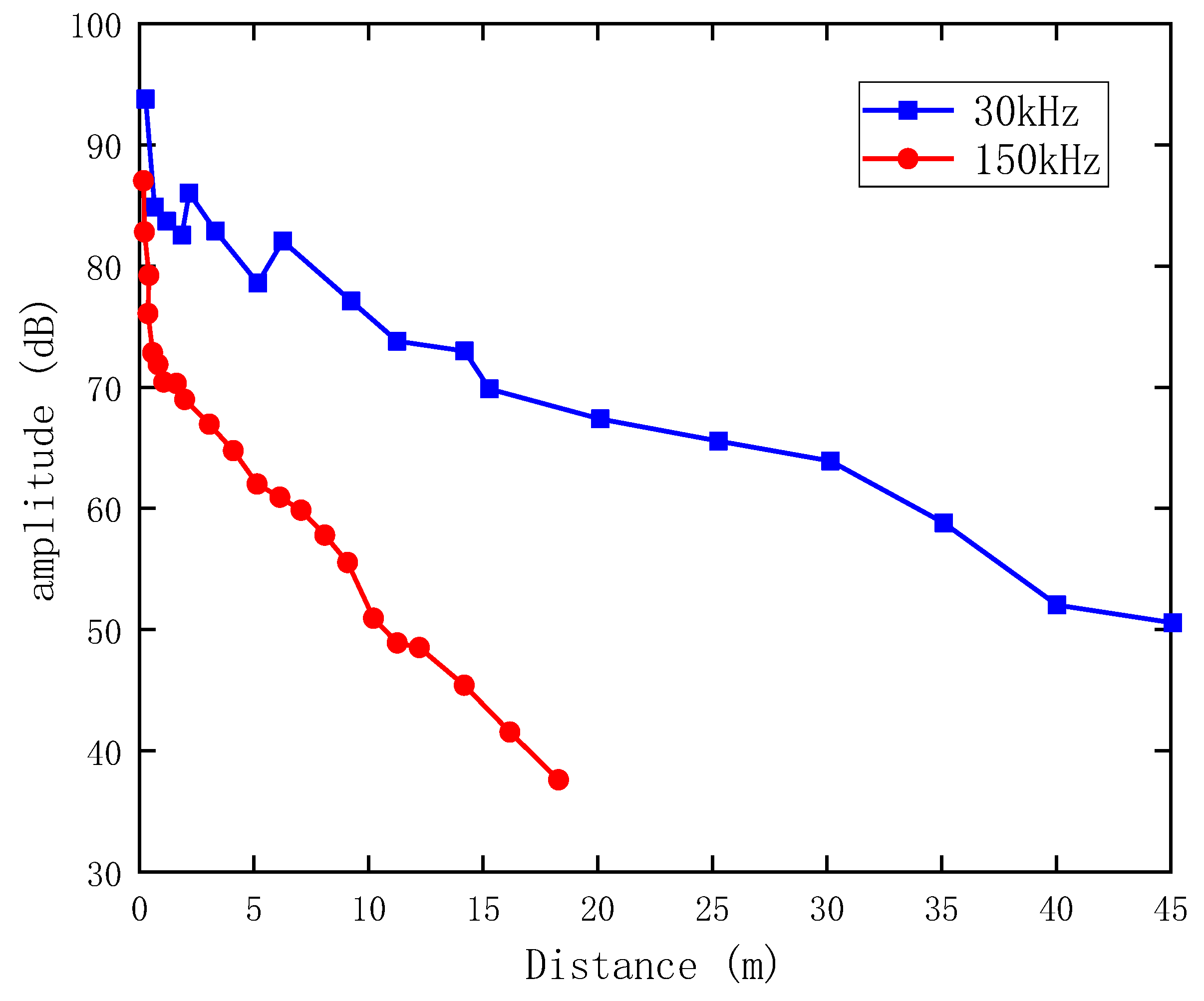

5.2. Leak Signal Processing

5.3. Reconstruction of the Leak Signal

5.4. Calculation of Leak Point Location

5.5. The Prospect of Industrial Pipeline Applications

6. Conclusions

- (1)

- In the preliminary experiment of air pipeline leak location, the SNR values obtained by the CEEMDAN denoising algorithm were 18.46 and 21.16, respectively, while the SNR values obtained by the EEMD algorithm were 15.84 and 18.45, respectively. The RMSE values of both denoising methods were relatively small. This indicates that the CEEMDAN denoising algorithm can enhance the signal decomposition and denoising capabilities, increase the signal-to-noise ratio, better preserve the effective components of the signal, and the reconstructed waveform has a high degree of fit with the original waveform, proving the reliability of the method. Five time-delay estimation methods, namely GCC, Roth weighting, PHAT weighting, ML weighting, and SCOT weighting, were used for location calculations, and the positioning accuracies were 8.7%, 6.0%, 7.4%, 8.1%, and 8.1% respectively.

- (2)

- In the experiment of CO2 pipeline leak location, after denoising the signal using the CEEMDAN denoising algorithm, based on the principle of acoustic emission location detection, five time-delay estimation algorithms, namely the GCC method, Roth weighting, PHAT weighting, ML weighting, and SCOT weighting, were used to calculate the time difference between the sensors upstream and downstream of the leak source. Combining this with the pipeline sound speed, the specific location of the leak point can be determined. The positioning accuracies of different generalized weighted cross-correlation methods were 10.6%, 6.9%, 6.9%, 8.6%, and 8.6% respectively, all meeting the engineering accuracy requirements. Combining the results of the preliminary experiment on air pipeline leak location, the Roth weighting method has more advantages.

- (3)

- This study verified that the acoustic emission technology has good applicability and engineering feasibility in the leak location of gaseous CO2 pipelines. The positioning error is controlled within 6.9%. However, the current experiment only covers the gaseous CO2 working conditions and has not yet covered the leak location of dense-phase and supercritical CO2 pipelines, which are more common in actual engineering. This part will be further improved in subsequent research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rui, Z.; Zeng, L.; Dindoruk, B. Challenges in the large-scale deployment of CCUS. Engineering 2025, 44, 17–20. [Google Scholar] [CrossRef]

- Yan, Y.; Borhani, T.N.; Subraveti, S.G.; Pai, K.N.; Prasad, V.; Rajendran, A.; Nkulikiyinka, P.; Asibor, J.O.; Zhang, Z.; Shao, D.; et al. Harnessing the power of machine learning for carbon capture, utilisation, and storage (CCUS)—A state-of-the-art review. Energy Environ. Sci. 2021, 14, 6122–6157. [Google Scholar] [CrossRef]

- Liu, H.J.; Were, P.; Li, Q.; Gou, Y.; Hou, Z. Worldwide status of CCUS technologies and their development and challenges in China. Geofluids 2017, 2017, 6126505. [Google Scholar] [CrossRef]

- Huang, W.H.; Li, Y.X.; Chen, P.C. Development strategy of carbon dioxide pipelines in China under the vision of carbon neutrality. Nat. Gas Ind. 2023, 43, 1–9. (In Chinese) [Google Scholar]

- Lu, S.J.; Zhang, J.J.; Yang, F.; Wang, F.; Liu, M.M.; Gon, Y.P.; Fan, Z.N.; Fang, Q.Q.; Li, Q.F.; Chen, H.F.; et al. Analysis on the progress and future development of CO2 pipeline transportation technology. J. Nanjing Univ. Nat. Sci. 2022, 58, 944–952. (In Chinese) [Google Scholar]

- Siddique, M.F.; Ahmad, Z.; Kim, J. Pipeline leak diagnosis based on leak-augmented scalograms and deep learning. Eng. Appl. Comput. Fluid Mech. 2023, 17, 2225577. [Google Scholar] [CrossRef]

- Gholami, R.; Raza, A.; Iglaurer, S. Leakage risk assessment of a CO2 storage site: A review. Earth-Sci. Rev. 2021, 223, 103849. [Google Scholar] [CrossRef]

- Korlapati, N.V.S.; Khan, F.; Noor, Q.; Mirza, S.; Vaddiraju, S. Review and analysis of pipeline leak detection methods. J. Pipeline Sci. Eng. 2022, 2, 100074. [Google Scholar] [CrossRef]

- Hou, F.; Zhang, Y.; Zhou, Y.; Zhang, M.; Lv, B.; Wu, J. Review on infrared imaging technology. Sustainability 2022, 14, 11161. [Google Scholar] [CrossRef]

- Roh, S.; Choi, H.R. Differential-drive in-pipe robot for moving inside urban gas pipelines. IEEE Trans. Robot. 2005, 21, 1–17. [Google Scholar]

- Ashry, I.; Mao, Y.; Wang, B.; Hveding, F.; Bukhamsin, A.Y.; Ng, T.K.; Ooi, B.S. A review of distributed fiber–optic sensing in the oil and gas industry. J. Light. Technol. 2022, 40, 1407–1431. [Google Scholar] [CrossRef]

- Huang, C.; Peng, F.; Liu, K. Pipeline inspection gauge positioning system based on optical fiber distributed acoustic sensing. IEEE Sens. J. 2021, 21, 25716–25722. [Google Scholar] [CrossRef]

- Li, J.; Zheng, Q.; Qian, Z.; Yang, X. A novel location algorithm for pipeline leakage based on the attenuation of negative pressure wave. Process Saf. Environ. Prot. 2019, 123, 309–316. [Google Scholar] [CrossRef]

- Banjara, N.K.; Sasmal, S.; Voggu, S. Machine learning supported acoustic emission technique for leakage detection in pipelines. Int. J. Press. Vessel. Pip. 2020, 188, 104243. [Google Scholar] [CrossRef]

- Li, S.; Wen, Y.; Li, P.; Yang, J.; Yang, L. Leak detection and location for gas pipelines using acoustic emission sensors. In Proceedings of the 2012 IEEE International Ultrasonics Symposium, Dresden, Germany, 7–10 October 2012; pp. 957–960. [Google Scholar]

- Quy, T.B.; Muhammad, S.; Kim, J. A reliable acoustic emission based technique for the detection of a small leak in a pipeline system. Energies 2019, 12, 1472. [Google Scholar] [CrossRef]

- Idachaba, F.; Rabiei, M. Current technologies and the applications of data analytics for crude oil leak detection in surface pipelines. J. Pipeline Sci. Eng. 2021, 1, 436–451. [Google Scholar] [CrossRef]

- Kaiser, J. Untersuchungen über das Auftreten von Geräuschen beim Zugversuch (An Investigation into the Occurrence of Noises in Tensile Tests or a Study of Acoustic Phenomena in Tensile Tests). Ph.D. Thesis, Technische Hochschule München, Munich, Germany, 1950. (In German). [Google Scholar]

- Grabec, I. Application of correlation techniques for localization of acoustic emission sources. Ultrasonics 1978, 16, 111–115. [Google Scholar] [CrossRef]

- Jiao, J.P.; He, C.F.; Wu, B.; Fei, R.Y. A new acoustic emission localization technique for pipeline leakage based on guided wave theory. J. Mech. Eng. 2004, 40, 77–81. (In Chinese) [Google Scholar] [CrossRef]

- Hao, Y.M.; Xing, Z.X.; Shao, H.; Wang, K.Q.; Wang, X.J. Experimental study on acoustic emission source localization for pressure pipeline leakage. J. Saf. Sci. Technol. 2011, 7, 140–144. (In Chinese) [Google Scholar]

- Ozevin, D.; Harding, J. Novel leak localization in pressurized pipeline networks using acoustic emission and geometric connectivity. Int. J. Press. Vessel. Pip. 2012, 92, 63–69. [Google Scholar] [CrossRef]

- Li, Z.L.; Zhang, H.F.; Xia, G.H. Quantitative detection of gas internal leakage in valves based on acoustic emission theory. J. Vib. Shock 2013, 32, 77–81. (In Chinese) [Google Scholar]

- Kong, D.L.; Huo, Z.; Yang, Y.Q.; Hu, B.; Peng, Z.J. Application of acoustic emission technology in on-line monitoring of valve leakage. In Proceedings of the 15th Chinese Acoustic Emission Symposium, Beijing, China, 3 June 2016; pp. 138–144. (In Chinese). [Google Scholar]

- Quy, T.B.; Kim, J. Leak detection in a gas pipeline using spectral portrait of acoustic emission signals. Measurement 2020, 152, 107403. [Google Scholar] [CrossRef]

- Ullah, N.; Ahmed, Z.; Kim, J. Pipeline leakage detection using acoustic emission and machine learning algorithms. Sensors 2023, 23, 3226. [Google Scholar] [CrossRef]

- Cui, J.; Zhang, M.; Qu, X.; Zhang, J.; Chen, L. An improved identification method of pipeline leak using acoustic emission signal. J. Mar. Sci. Eng. 2024, 12, 625. [Google Scholar] [CrossRef]

- Saleem, F.; Ahmad, Z.; Siddique, M.F.; Umar, M.; Kim, J.-M. Acoustic emission-based pipeline leak detection and size identification using a customized one-dimensional DenseNet. Sensors 2025, 25, 1112. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Liu, H. TDOA localization with unknown signal propagation speed and sensor position errors. IEEE Commun. Lett. 2020, 24, 1024–1027. [Google Scholar] [CrossRef]

- Teja, K.; Tiwari, R.; Mohanty, S. Adaptive denoising of ECG using EMD, EEMD and CEEMDAN signal processing techniques. J. Phys. Conf. Ser. 2020, 1706, 012077. [Google Scholar] [CrossRef]

- Bennia, F.; Moussaoui, S.; Boutalbi, M.C.; Messaoudi, N. Comparative study between EMD, EEMD, and CEEMDAN based on de-noising bioelectric signals. In Proceedings of the 2024 8th International Conference on Image and Signal Processing and Their Applications (ISPA), Biskra, Algeria, 21–22 April 2024; pp. 1–6. [Google Scholar]

- Cui, X.W. Research on Leakage Detection and Localization of CO2 Transportation and Storage Equipment Based on Acoustic Emission. Ph.D. Thesis, North China Electric Power University (Beijing), Beijing, China, 2017. (In Chinese). [Google Scholar]

| No. | Detection Method | Advantages | Disadvantages |

|---|---|---|---|

| 1 | Infrared Imaging Method | Wide detection range, relatively high accuracy | Unable to detect buried pipelines. High cost for long-term use of low-altitude aircraft. |

| 2 | Equipment Wall Detection Method | Theoretically has very high detection accuracy and can even give early warnings before a leak occurs | Relatively expensive. Prone to blockage accidents at bends, vertical sections, and pipe diameter changes. |

| 3 | Distributed Optical Fiber Method | Can achieve all-round real-time detection | High equipment cost, high maintenance cost, and large construction volume. |

| 4 | Negative Pressure Wave Detection Method | Relatively accurate positioning, low cost | Prone to false alarms. Unable to detect leaks that have already occurred. |

| 5 | Acoustic Emission Detection Method | Wide application range, high reliability, moderate price | Difficult signal analysis, vulnerable to noise interference. The propagation of acoustic waves strongly depends on the length and characteristics of the path they travel. |

| Characteristic Component | IMF1 | IMF2 | IMF3 | IMF4 | IMF5 | IMF6 | IMF7 | IMF8 | IMF9 | IMF10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Cross-correlation Coefficient | 0.993 | 0.119 | 0.117 | 0.062 | 0.017 | 0.002 | 0.005 | 0.001 | 0.001 | 0.001 |

| Denoising Method | Source of Acoustic Emission Signal | SNR | RMSE |

|---|---|---|---|

| EEMD | Sensor 1 | 15.84 | 0.01173 |

| EEMD | Sensor 2 | 18.45 | 0.01592 |

| CEEMDAN | Sensor 1 | 18.46 | 0.01311 |

| CEEMDAN | Sensor 2 | 21.16 | 0.01165 |

| Positioning Method | Time Difference (ms) | Distance Difference (m) | Absolute Error (m) | Sensor Spacing (m) | Relative Error (%) |

|---|---|---|---|---|---|

| Cross-correlation Positioning | 0.026 | 0.087 | 0.087 | 1 | 8.7 |

| Roth Weighting | 0.018 | 0.060 | 0.060 | 1 | 6.0 |

| PHAT Weighting | 0.022 | 0.074 | 0.074 | 1 | 7.4 |

| ML Weighting | 0.024 | 0.081 | 0.081 | 1 | 8.1 |

| SCOT Weighting | 0.024 | 0.081 | 0.081 | 1 | 8.1 |

| Characteristic Component | IMF1 | IMF2 | IMF3 | IMF4 | IMF5 | IMF6 | IMF7 | IMF8 | IMF9 | IMF 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Cross-correlation Coefficient | 0.7274 | 0.6639 | 0.2758 | 0.0755 | 0.0167 | 0.0045 | 0.0001 | 0.0003 | 0.0006 | 0.0005 |

| Denoising Method | Acoustic Emission Signal | SNR | RMSE |

|---|---|---|---|

| CEEMDAN | Sensor 1 | 18.07 | 0.00221 |

| CEEMDAN | Sensor 2 | 15.05 | 0.00297 |

| Location Method | Time Difference (ms) | Distance Difference (m) | Absolute Error (m) | Sensor Spacing (m) | Relative Error (%) |

|---|---|---|---|---|---|

| Cross-correlation Location | 0.026 | 0.087 | 0.037 | 0.35 | 10.6 |

| Roth Weighting | 0.022 | 0.074 | 0.024 | 0.35 | 6.9 |

| PHAT Weighting | 0.022 | 0.074 | 0.024 | 0.35 | 6.9 |

| ML Weighting | 0.024 | 0.081 | 0.031 | 0.35 | 8.6 |

| SCOT Weighting | 0.024 | 0.081 | 0.031 | 0.35 | 8.6 |

| Sensor Center Frequency | Pre-Amplifier Gain | Theoretical Maximum Detection Distance | Application Scope |

|---|---|---|---|

| 30 kHz | 40 dB | Approximately 30–70 m | Suitable for short-distance and high-precision leakage monitoring within the station yard or laboratory research. |

| 20 kHz | 60 dB | Approximately 100–150 m | Suitable for high-consequence areas. Install sensors at ≤150 m intervals. Low-frequency operation requires robust noise reduction algorithms due to susceptibility to interference. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Ma, Y. Research on Leakage Localization in Gaseous CO2 Pipelines Using the Acoustic Emission Method. Appl. Sci. 2025, 15, 10501. https://doi.org/10.3390/app151910501

Li X, Ma Y. Research on Leakage Localization in Gaseous CO2 Pipelines Using the Acoustic Emission Method. Applied Sciences. 2025; 15(19):10501. https://doi.org/10.3390/app151910501

Chicago/Turabian StyleLi, Xinze, and Yao Ma. 2025. "Research on Leakage Localization in Gaseous CO2 Pipelines Using the Acoustic Emission Method" Applied Sciences 15, no. 19: 10501. https://doi.org/10.3390/app151910501

APA StyleLi, X., & Ma, Y. (2025). Research on Leakage Localization in Gaseous CO2 Pipelines Using the Acoustic Emission Method. Applied Sciences, 15(19), 10501. https://doi.org/10.3390/app151910501