Investigation of the Temperature Performance of Bitumen Modified with Egg Shell Waste

Abstract

1. Introduction

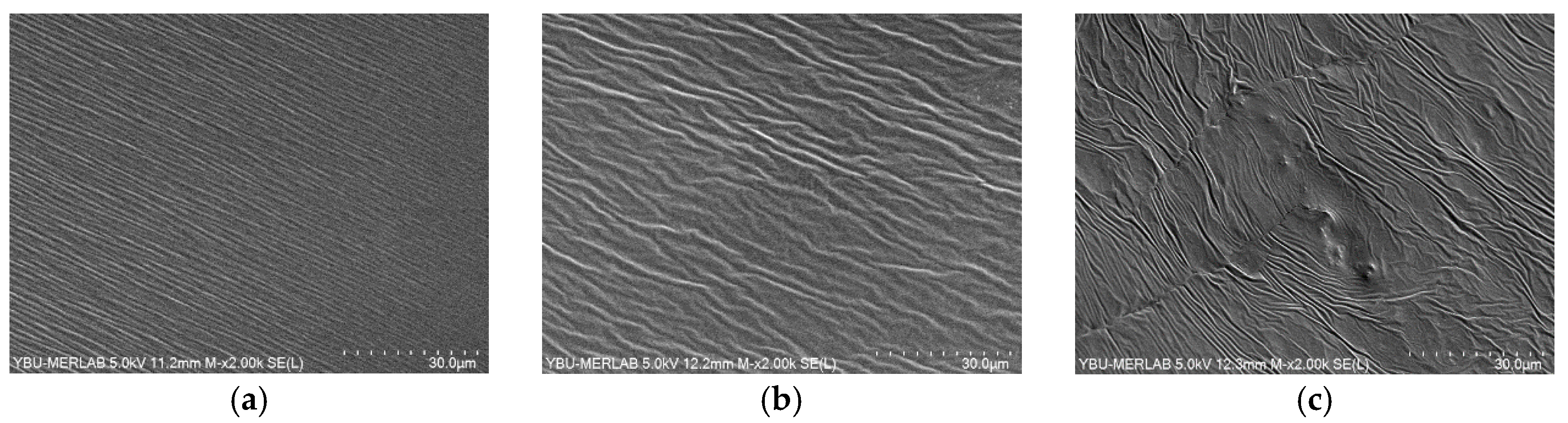

2. Material and Sample Preparation

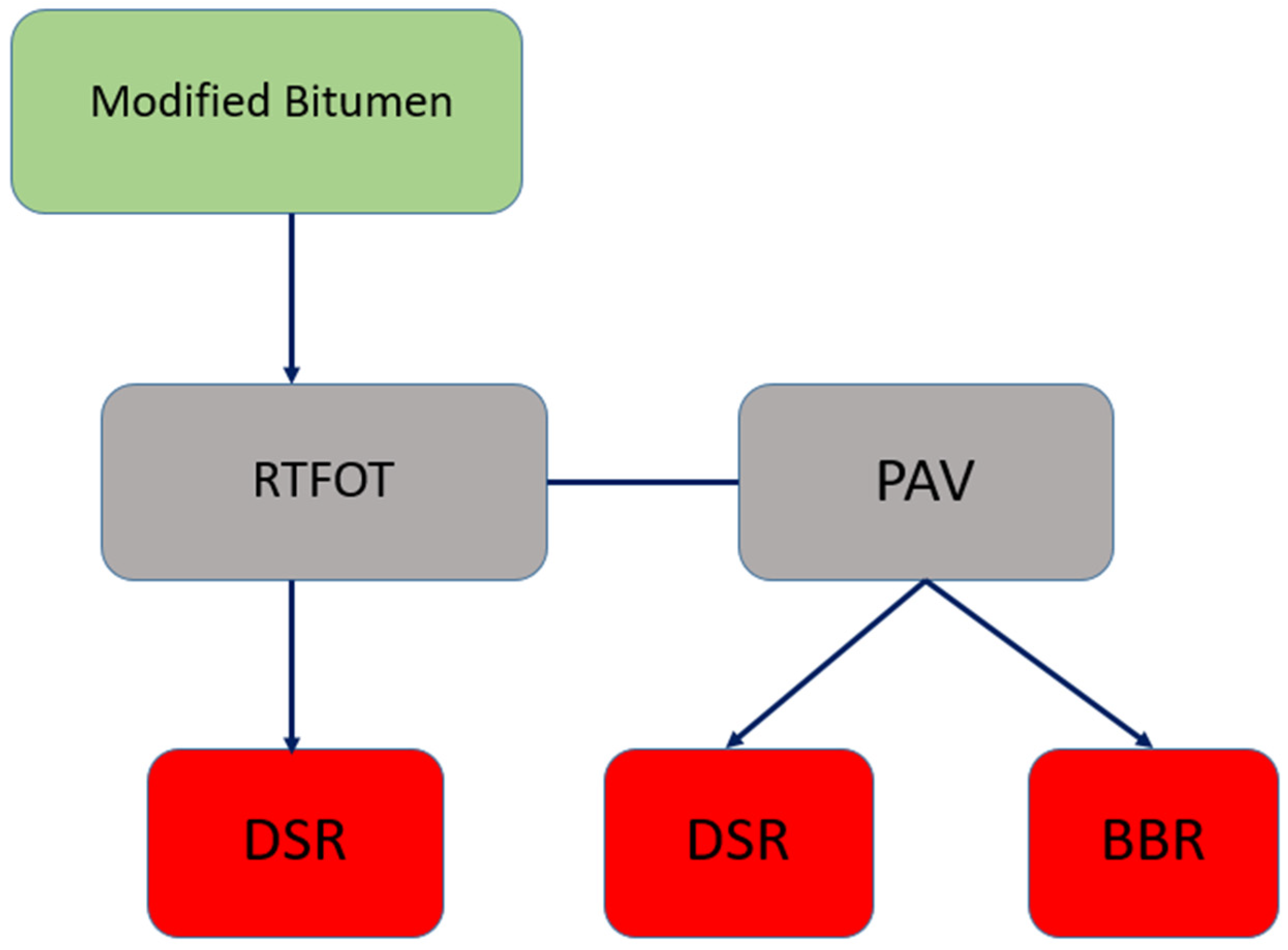

3. Mixture and Test Methods

3.1. Mixture

3.2. Rolling Thin-Film Oven Test (RTFOT)

3.3. Dynamic Shear Rheometer (DSR) Test After RTFOT

3.4. Pressure Aging Vessel (PAV) Test

3.5. Bending Beam Rheometer (BBR) Test After PAV

4. Results Analysis

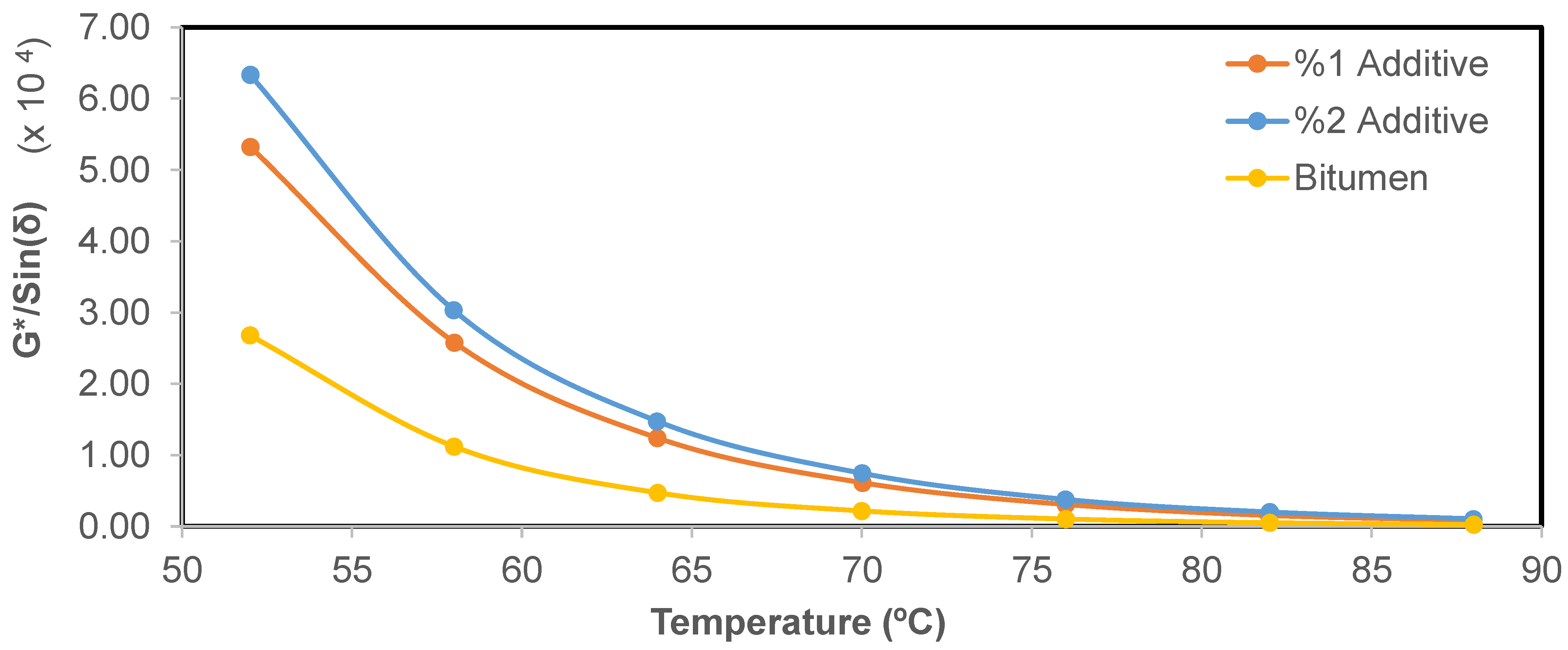

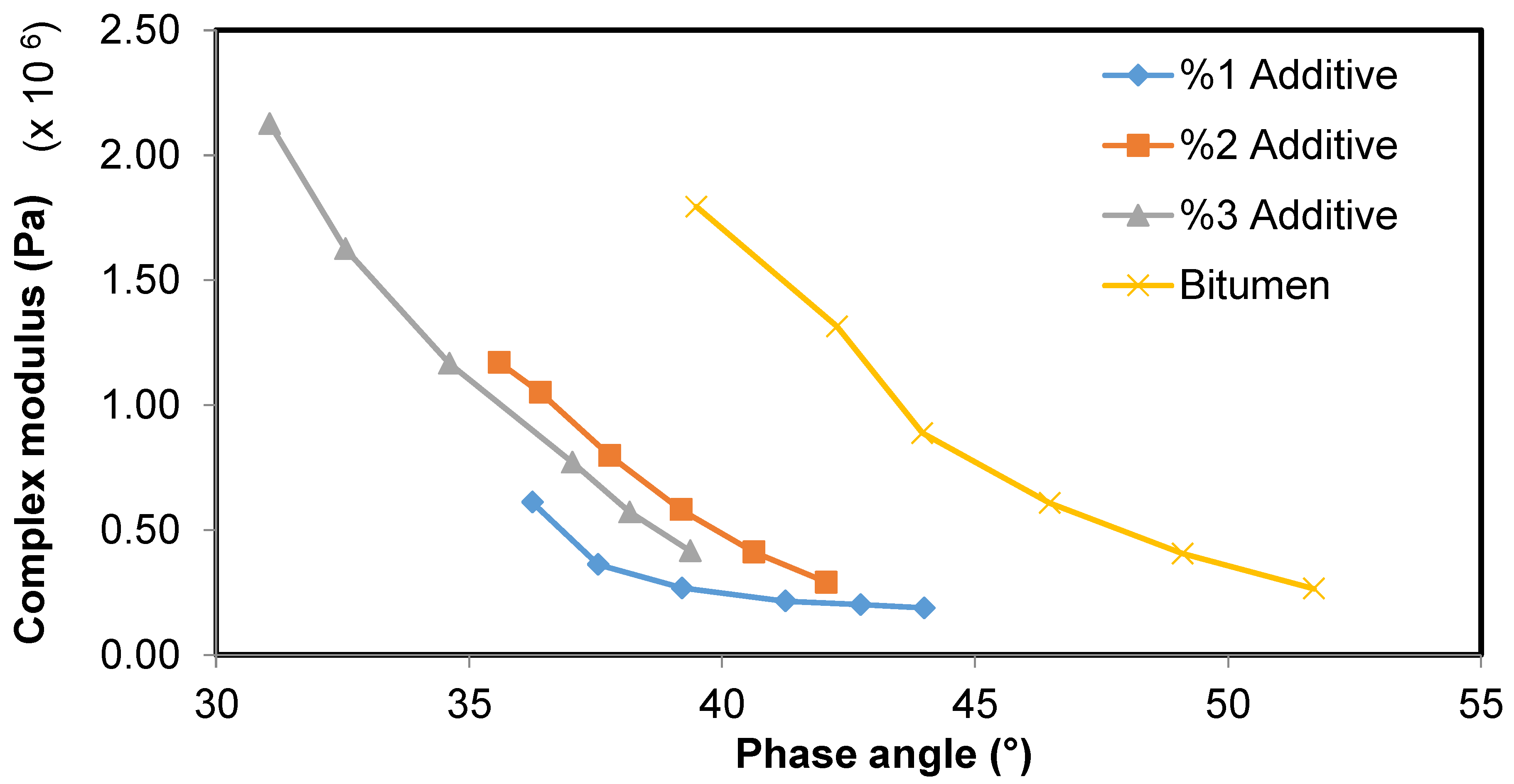

4.1. DSR Test Results After RTFOT

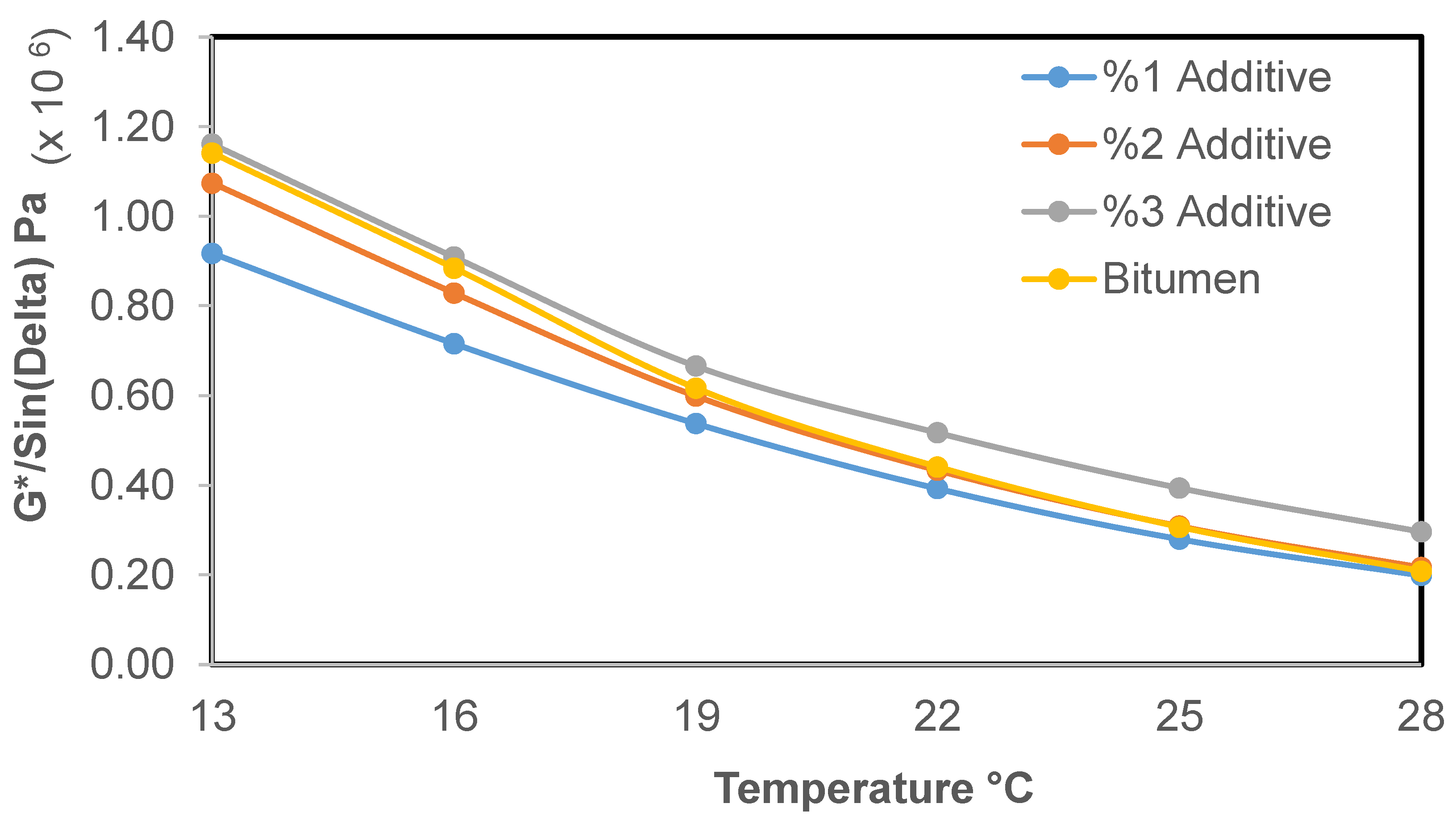

4.2. Dynamic Shear Rheometer (DSR) Test After PAV

4.3. BBR Test Results After PAV

5. Conclusions

- ▪

- It was determined by SEM images that the eggshell waste was homogeneously distributed in the bitumen.

- ▪

- It was observed that modified bitumen has lower phase angle values and higher complex shear modulus values than pure bitumen. This shows that modified bitumen exhibits more elastic behavior than pure bitumen.

- ▪

- DSR tests performed after short-term aging (RTFOT) showed that modified bitumen with 1% and 2% eggshell additives increased the high-temperature performance of pure bitumen.

- ▪

- As a result of short-term aging, 1% and 2% eggshell-modified bitumen exhibited a more elastic behavior than pure bitumen.

- ▪

- DSR tests performed as a result of long-term aging (PAV) have shown that modified bitumen with 1% and 2% eggshell additives increased the high-temperature performance of pure bitumen.

- ▪

- As a result of long-term aging, 3% eggshell-modified bitumen gave the best results in terms of elastic behavior. Additionally, this sample was the modified bitumen with the highest rutting resistance.

- ▪

- According to BBR tests performed at −6 °C and −12 °C, the modified bitumen with the highest m value was the modified bitumen with 3% eggshell additive.

- ▪

- It has been observed that modified bitumen produced with eggshell additives is more resistant to thermal cracks.

- ▪

- The use of waste material eggshells in the modification of bitumen has become an environmentally friendly approach. This study has helped to solve the problem of the storage of eggshell waste.

- ▪

- When all test results were evaluated together, it was seen that the best recommended mixture was modified bitumen created with 2% eggshell.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Redelius, P.; Soenen, H. Relation between bitumen chemistry and performance. Fuel 2015, 140, 34–43. [Google Scholar] [CrossRef]

- Weigel, S.; Stephan, D. Modelling of rheological and ageing properties of bitumen based on its chemical structure. Mater. Struct. 2017, 50, 83. [Google Scholar] [CrossRef]

- Chfat, A.H.Z.; Yaacob, H.; Kamaruddin, N.H.M.; Al-Saffar, Z.H.; Jaya, R.P. Effects of nano eggshell powder as a sustainable bio-filler on the physical, rheological, and microstructure properties of bitumen. Results Eng. 2024, 22, 102061. [Google Scholar] [CrossRef]

- Erfen, Y.B.; Tun, U.; Onn, H. The appropriateness of eggshell as filler in hot mix asphalt. J. Teknol. Malays. 2015. [Google Scholar] [CrossRef]

- Masued, G.G. Investigating the ability of using eggshell powder as a filler in hot mix asphalt mixture. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 518, p. 022047. [Google Scholar]

- Razzaq, A.K.; Yousif, R.A.; Tayh, S.A. Characterization of hot mix asphalt modified by egg shell powder. Int. J. Eng. Res. Technol. 2018, 11, 481–492. [Google Scholar]

- Oluwatuyi, O.E.; Adeola, B.O.; Alhassan, E.A.; Nnochiri, E.S.; Modupe, A.E.; Elemile, O.O.; Obayanju, T.; Akerele, G. Ameliorating effect of milled eggshell on cement stabilized lateritic soil for highway construction. Case Stud. Constr. Mater. 2018, 9, e00191. [Google Scholar] [CrossRef]

- Chee, G.H.; Ramadhansyah, P.J. The Influence of Eggshell Powder as Additive on the Physical and Mechanical Properties of Stone Mastic Asphalt. Construction 2022, 2, 79–87. [Google Scholar] [CrossRef]

- Masri, K.A.; Ganesan, E.; Ramadhansyah, P.J.; Doh, S.I.; Syafiqah, S.N.; Jaafar, Z.M.; Mashros, N. Stress and strain characteristic of stone mastic asphalt incorporating eggshell powder. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 682, p. 012056. [Google Scholar]

- Wang, X.; Ji, G.; Zhang, Y.; Guo, Y.; Zhao, J. Research on high-and low-temperature characteristics of bitumen blended with waste eggshell powder. Materials 2021, 14, 2020. [Google Scholar] [CrossRef] [PubMed]

- Kumandaş, E.Ç.; Pancar, E.B.; Oruç, Ş. Investigation of rheological properties of vegetable waste oil, RET, and PPA Composite Modified Bitumen Using DSR and BBR. IES 2020, 20, 5–6. [Google Scholar]

- Yılmaz, M.; Kök, B. Determining the high temperature performance grade and workability of styrene-butadiene-styrene modified bituminous binders according to superpave system. Gazi Univ. Fac. Eng. Archit. J. 2008, 23, 811–819. [Google Scholar]

- Wu, G.; Zhang, H.; Sun, J.; Yu, T. Comparative analysis on rheological characteristics of different modified asphalt based on DSR and BBR evaluation. J. Eng. Des. Technol. 2023, 21, 1568–1587. [Google Scholar] [CrossRef]

- Fakhri, M.; Kianfar, A. Comparison of BBR results of EVA polymer and nano-CaCO3-modified bitumen using burger model, relaxation modulus, dissipation energy ratio, ANOVA, and artificial neural networks. Int. J. Pavement Res. Technol. 2021, 14, 85–97. [Google Scholar] [CrossRef]

- Dehnad, M.H.; Damyar, B.; Farahani, H.Z. Rheological evaluation of modified bitumen by EVA and crumb rubber using RSM optimization. Adv. Mater. Sci. Eng. 2021, 2021, 9825541. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, H.; Wu, J.; Oeser, M. A Temperature-independent methodology for bitumen modification evaluation based on DSR measurement. In Green and Intelligent Technologies for Sustainable and Smart Asphalt Pavements; CRC Press: Boca Raton, FL, USA, 2021; pp. 567–573. [Google Scholar]

- Çalışıcı, M. Increasing the Ageing Resistance of Bitumen with Synthetic Metal and Polymer Additives. Ph.D. Thesis, Gazi University, Ankara, Turkey, 2009. [Google Scholar]

- AASHTO T 240; Standard Method of Test for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film Oven Test). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO TP70-09; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO: Washington, DC, USA, 2009.

| Element | Apparent Concentration | k Ratio | Wt% | Wt% Sigma | Factory Standard |

|---|---|---|---|---|---|

| C | 0.43 | 0.00435 | 90.40 | 0.09 | Yes |

| O | 0.01 | 0.00006 | 2.40 | 0.06 | Yes |

| Si | 0.00 | 0.00001 | 0.09 | 0.02 | Yes |

| S | 0.05 | 0.00051 | 6.13 | 0.06 | Yes |

| Ca | 0.00 | 0.00003 | 0.98 | 0.03 | Yes |

| Total: | 100.00 |

| Element | Apparent Concentration | k Ratio | Wt% | Wt% Sigma | Factory Standard |

|---|---|---|---|---|---|

| C | 0.43 | 0.00435 | 88.62 | 0.08 | Yes |

| O | 0.01 | 0.00006 | 2.56 | 0.06 | Yes |

| Si | 0.00 | 0.00001 | 0.11 | 0.02 | Yes |

| S | 0.05 | 0.00051 | 6.70 | 0.05 | Yes |

| Ca | 0.00 | 0.00003 | 2.01 | 0.02 | Yes |

| Total: | 100.00 |

| Element | Apparent Concentration | k Ratio | Wt% | Wt% Sigma | Factory Standard |

|---|---|---|---|---|---|

| C | 0.43 | 0.00435 | 88.55 | 0.08 | Yes |

| O | 0.01 | 0.00006 | 2.63 | 0.04 | Yes |

| Si | 0.00 | 0.00001 | 0.08 | 0.01 | Yes |

| S | 0.05 | 0.00051 | 5.67 | 0.03 | Yes |

| Ca | 0.00 | 0.00003 | 3.07 | 0.05 | Yes |

| Total: | 100.00 |

| Bitumen | Temperature (°) | Complex Modulus (Pa) | Phase Angle (°) | G*/Sin(δ) Pa |

|---|---|---|---|---|

| Bitumen | 70 | 2138 | 83.25 | 2200 |

| %1 Additive | 79.36 | 2148 | 77.89 | 2200 |

| %2 Additive | 81.36 | 2144 | 77.45 | 2200 |

| %3 Additive | - | - | - | - |

| Measured Stiffness | Estimated Stiffness | m-Value | |

|---|---|---|---|

| Bitumen | 79.78 | 80.56 | 0.356 |

| %1 Additive | 82.32 | 79.25 | 0.355 |

| %2 Additive | 73.31 | 73.17 | 0.392 |

| %3 Additive | 56.83 | 56.69 | 0.412 |

| Measured Stiffness | Estimated Stiffness | m-Value | |

|---|---|---|---|

| Bitumen | 158.68 | 159.79 | 0.294 |

| %1 Additive | 178.71 | 178.38 | 0.324 |

| %2 Additive | 177.84 | 177.68 | 0.330 |

| %3 Additive | 155.27 | 155.66 | 0.344 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erginer, İ.; Cansız, Ö.F.; Özyılmaz, A.T.; Karaca, N.; Taşar, B. Investigation of the Temperature Performance of Bitumen Modified with Egg Shell Waste. Appl. Sci. 2025, 15, 10500. https://doi.org/10.3390/app151910500

Erginer İ, Cansız ÖF, Özyılmaz AT, Karaca N, Taşar B. Investigation of the Temperature Performance of Bitumen Modified with Egg Shell Waste. Applied Sciences. 2025; 15(19):10500. https://doi.org/10.3390/app151910500

Chicago/Turabian StyleErginer, İbrahim, Ömer Faruk Cansız, Ali Tuncay Özyılmaz, Nurullah Karaca, and Bestami Taşar. 2025. "Investigation of the Temperature Performance of Bitumen Modified with Egg Shell Waste" Applied Sciences 15, no. 19: 10500. https://doi.org/10.3390/app151910500

APA StyleErginer, İ., Cansız, Ö. F., Özyılmaz, A. T., Karaca, N., & Taşar, B. (2025). Investigation of the Temperature Performance of Bitumen Modified with Egg Shell Waste. Applied Sciences, 15(19), 10500. https://doi.org/10.3390/app151910500