The Gas Migration During the Drainage Process of Ultra-Long Directional Boreholes in Coal Seams

Abstract

1. Introduction

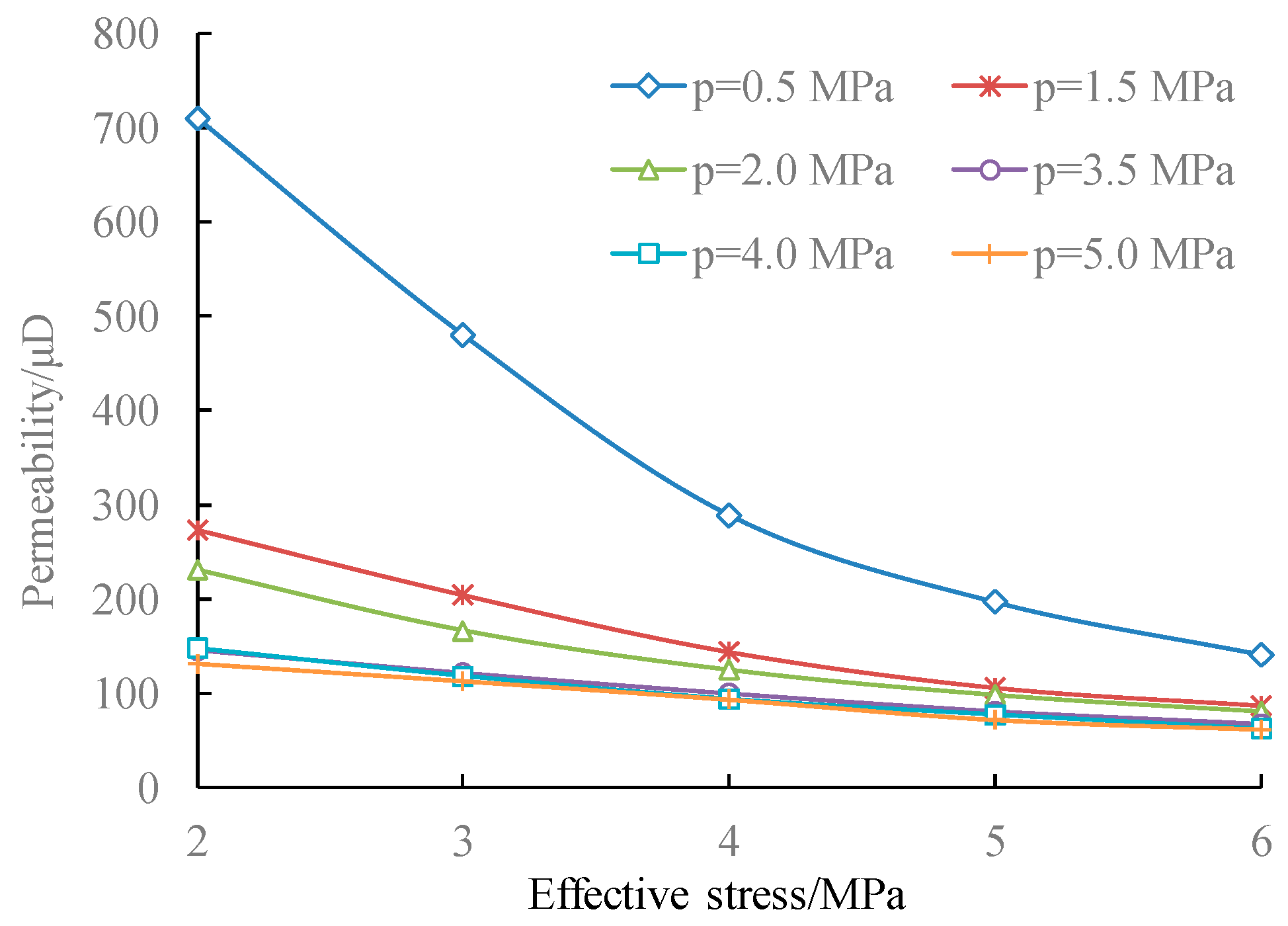

2. Experimental Testing of Dual-Scale Permeability in Coal

3. Theoretical Model of Coal Seam Gas Seepage

3.1. Gas Flow Equation in the Matrix System

3.2. Solid Deformation Control Equation for Coal

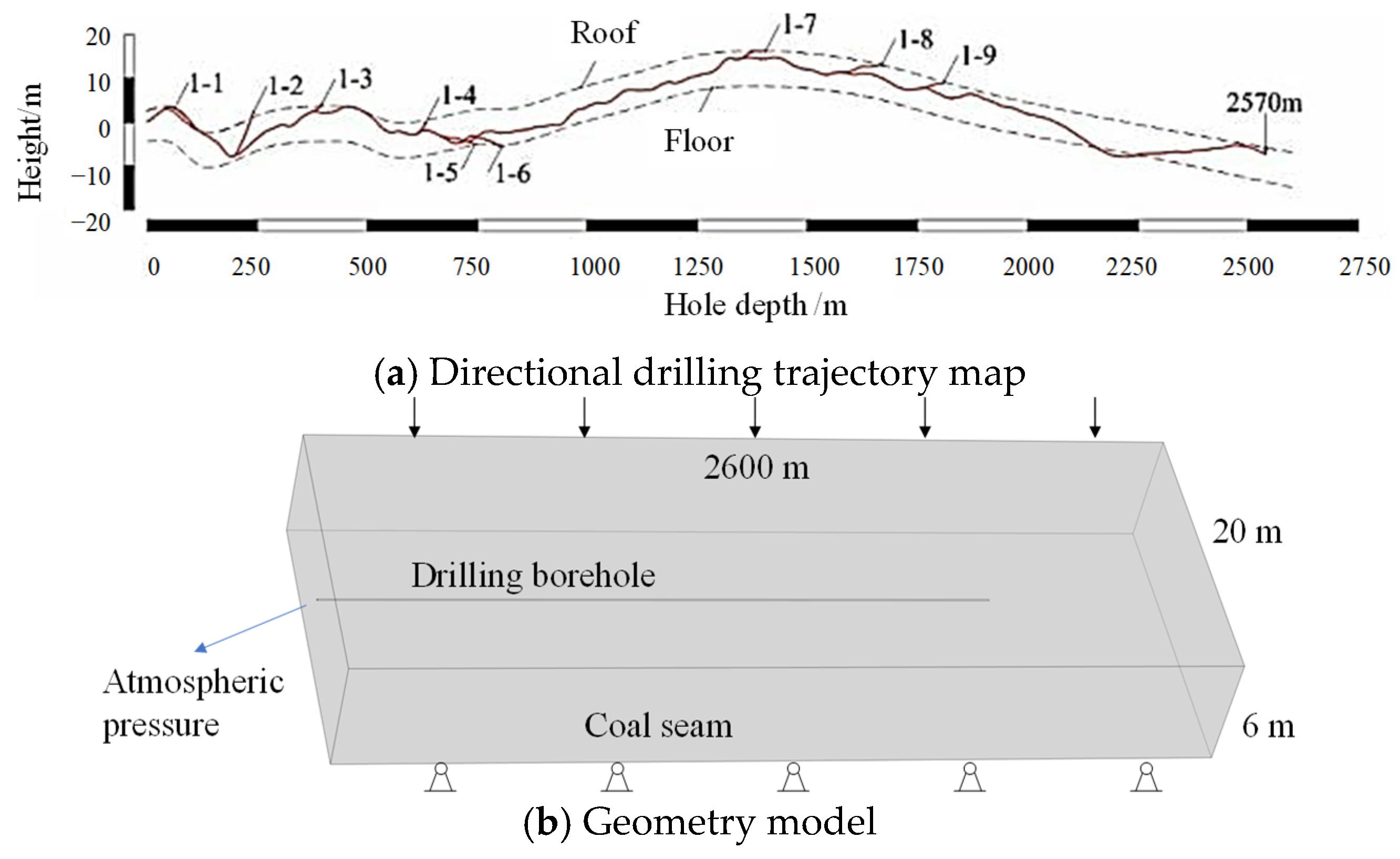

4. Gas Migration Modeling in Ultra-Long Directional Boreholes

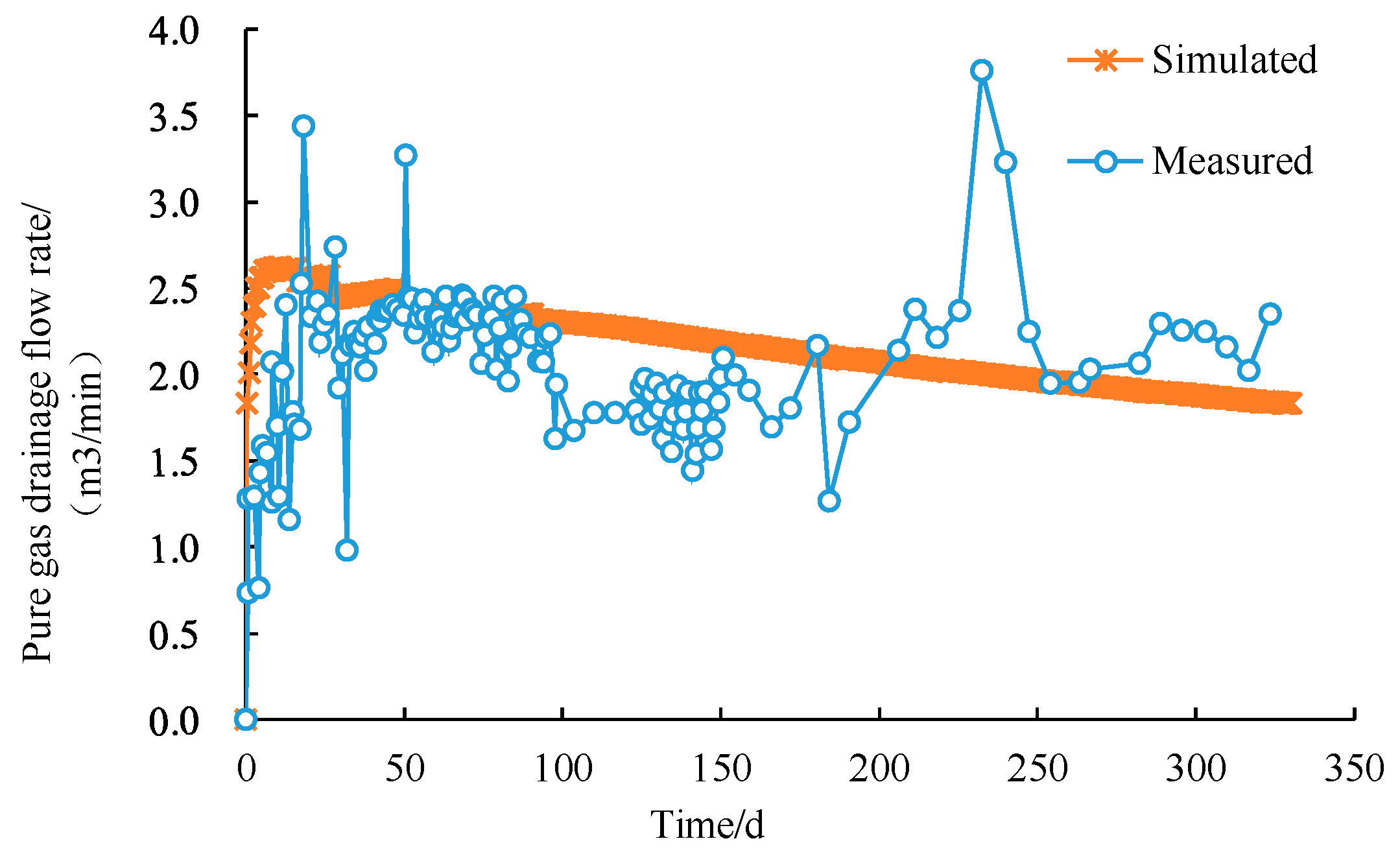

4.1. Theoretical Model Validation

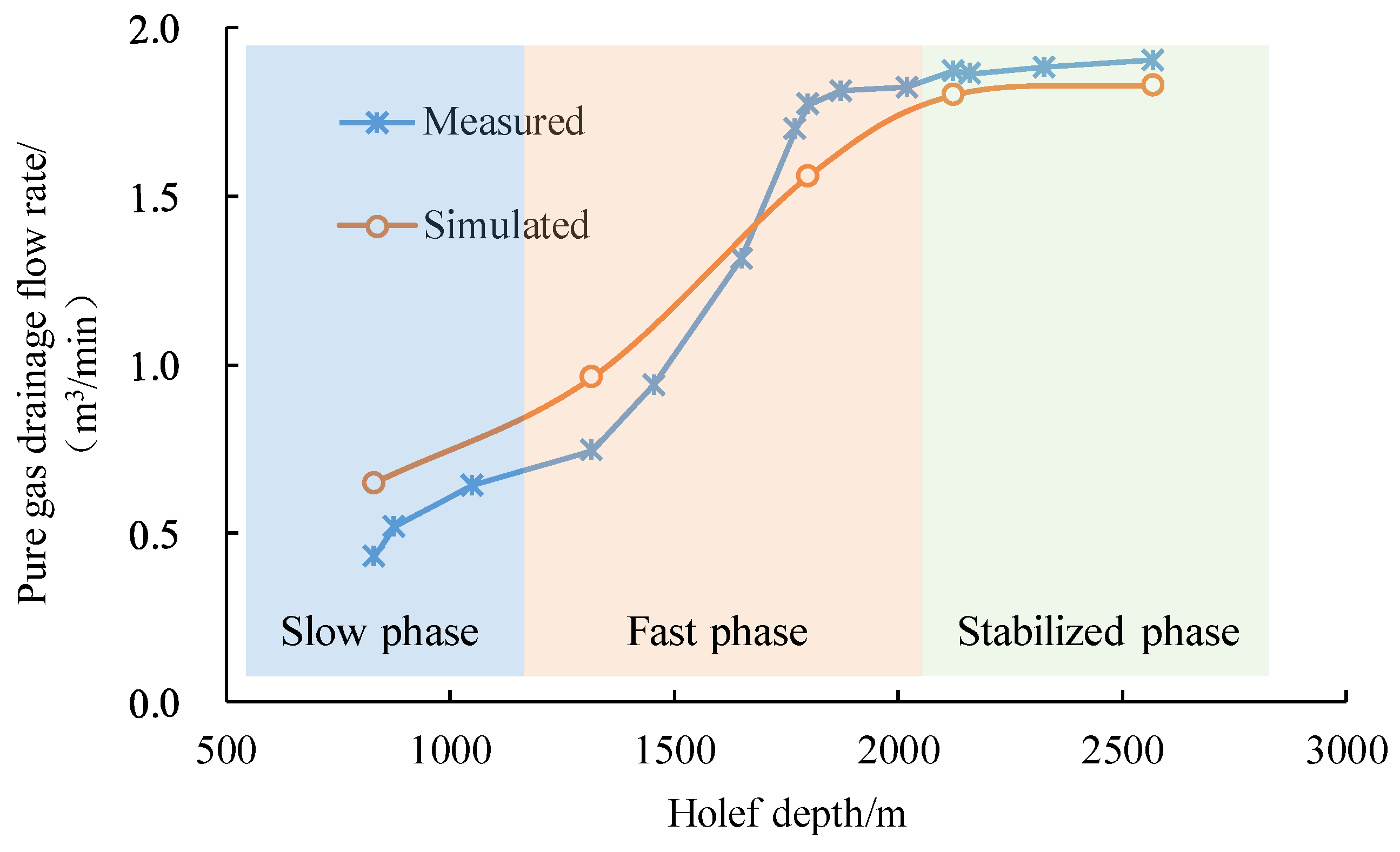

4.2. Influence of Borehole Depth on Gas Extraction

5. Conclusions

- (1)

- The permeability difference between matrix and fracture was found to be smaller in low-rank coal under varying stress and pore pressure conditions. This phenomenon attributed to its larger pore structure. Both matrix and fracture permeability decrease gradually with increasing effective stress, indicating a relatively low stress sensitivity of the tested specimens.

- (2)

- Model predicted real-time gas flow rates at various drilling depths are consistent with the field-measured data. The total borehole gas flow exhibits a linear increasing trend with drilling depth. When the borehole depth is less than 1300 m, the flow rate increases slowly; between 1300 m and 2000 m, the growth rate significantly accelerates; beyond 2000 m, the extraction flow rate tends to stabilize.

- (3)

- A reduction in pore pressure increases effective stress, compressing fractures and reducing permeability, whereas gas desorption induces matrix shrinkage, enlarging fracture apertures and enhancing permeability. These mechanisms interact dynamically: pore pressure effects dominate within the first 10 days of drainage, while gas desorption becomes the primary contributor in later stages. In the shallow borehole section (within 10 m of the collar), permeability increased by up to 3.5 times its initial value. At depths exceeding 1500 m, permeability variation was minimal, indicating a limited effectiveness for gas drainage.

- (4)

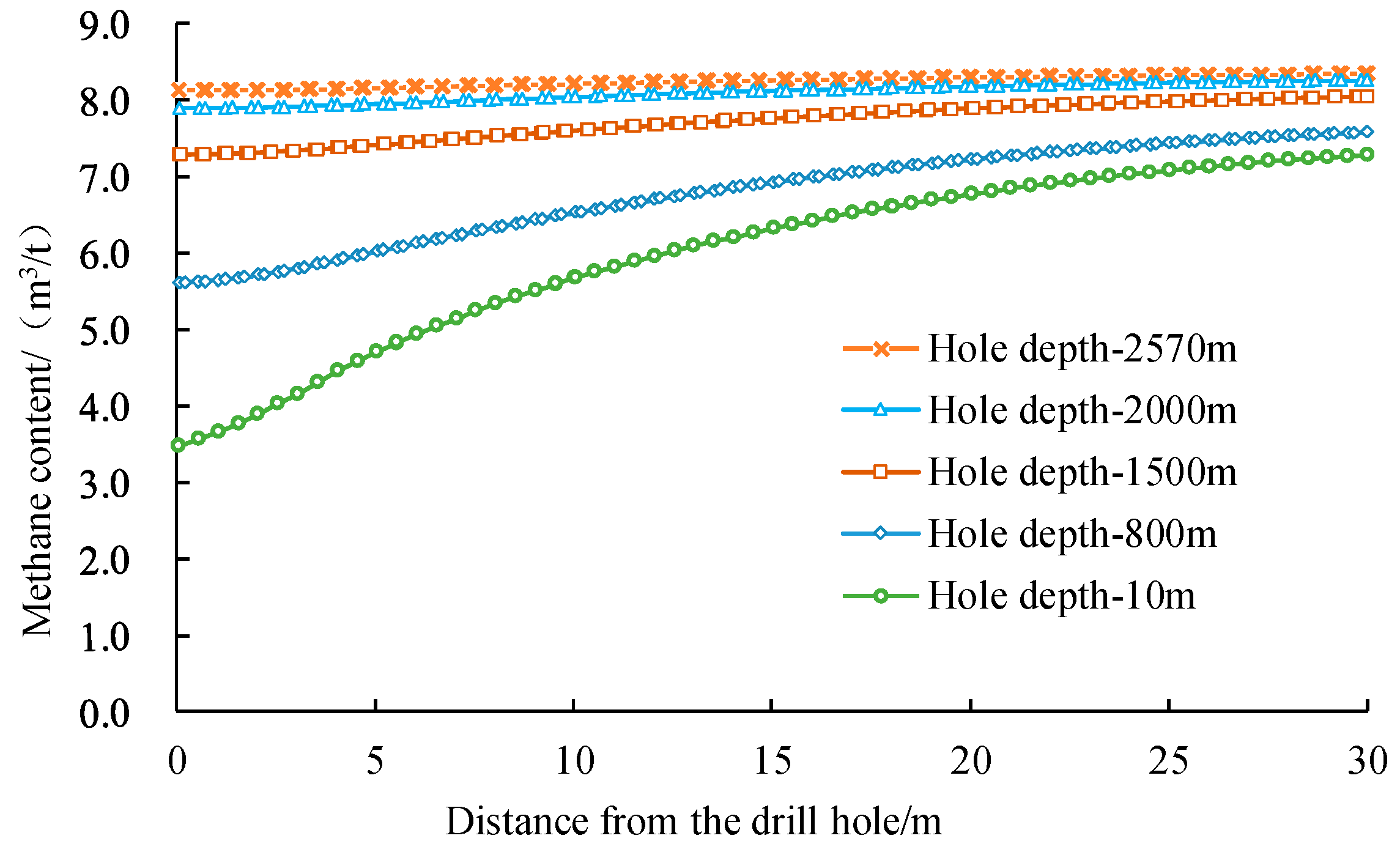

- Field measurements and simulation results show that in shallow sections (<1500 m), a broad pressure drop zone and sufficient desorption lead to significant permeability enhancement and a rapid increase in drainage flow. In deep sections (>2000 m), limited pressure drops propagation and borehole resistance effects slow permeability growth, stabilize drainage rates, and leave gas content above 8 m3/t, indicating a pronounced decline in deep drainage efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, D.; Jia, Q.; Cai, Y. Research progress on coalbed methane reservoir geology and characterization technology in China. Coal Sci. Technol. 2022, 50, 196–203. [Google Scholar]

- Wei, M.; Liu, J.; Elsworth, D. Influence of gas adsorption induced non-uniform deformation on the evolution of coal permeability. Int. J. Rock Mech. Min. Sci. 2019, 114, 71–78. [Google Scholar] [CrossRef]

- Wei, J.; Li, B.; Wang, K. Influencing factors on permeability of loaded gas-bearing coal mass. J. Min. Saf. Eng. 2014, 31, 322–327. [Google Scholar]

- Harpalani, S.; Chen, G. Estimation of changes in fracture porosity of coal with gas emission. Fuel 1995, 74, 1491–1498. [Google Scholar] [CrossRef]

- Wang, K.; Wang, L.; Du, F. Evolutionary mechanism of permeability of coal-rock combination considering interface effect: Model development and analysis. Energy 2023, 284, 129305. [Google Scholar] [CrossRef]

- Zhao, C.; Cheng, Y.; Li, W.; Wang, L.; Lu, Z.; Wang, H. A theoretical investigation of coal fracture evolution with hydrostatic pressure and its validation by CT. Nat. Resour. Res. 2024, 33, 2237–2260. [Google Scholar] [CrossRef]

- Jasinge, D.; Ranjith, P.; Choi, S. Effects of effective stress changes on permeability of latrobe valley brown coal. Fuel 2011, 90, 1292–1300. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C.; Tao, Z. Structure deformation of coal induced by gas migration-A case of injecting helium gas into intact coal. Rock Soil Mech. 2015, 36, 3439–3446. [Google Scholar]

- Li, B.; Li, J.; Yang, K. Evolution law of coal permeability based on comprehensive effect of pore pressure and water. J. China Univ. Min. Technol. 2020, 49, 44–53. [Google Scholar]

- Lu, R.; Li, S.; Xue, J. Experimental study on coal seepage characteristics and stress sensitivity. Saf. Coal Mines 2022, 53, 23–30. [Google Scholar]

- Long, Q.; Zhao, X.; Mu, J. Experimental Study on Influence of Pore Gas Pressure upon Gas Permeability of Coal Seam. Min. Saf. Environ. Prot. 2008, 35, 10–12. [Google Scholar]

- Tang, J.; Pan, Y.; Li, C. Experimental study of desorption and seepage of coalbed methane under solid-fluid coupling. J. China Univ. Min. Technol. 2006, 35, 274–278. [Google Scholar]

- Peng, S.; Xu, J.; Yi, G. Experimental analysis of matrix shrinkage’s influence on mechanical permeability of gas-filled coal. J. Chongqing Univ. 2012, 35, 109–114. [Google Scholar]

- Zhu, Z.; Feng, T.; Xie, D. Seepage property of coal containing gas under different paths in laboratory. J. Min. Saf. Eng. 2012, 29, 570–574. [Google Scholar]

- Lin, J.; Ren, T.; Wang, G.; Booth, P.; Nemcik, J. Experimental investigation of N2 injection to enhance gas drainage in CO2-rich low permeable seam. Fuel 2018, 215, 665–674. [Google Scholar] [CrossRef]

- Meng, Y.; Wang, J.Y.; Li, Z.; Zhang, J. An improved productivity model in coal reservoir and its application during coalbed methane production. J. Nat. Gas Sci. Eng. 2018, 49, 342–351. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D. Modelling permeability for coal reservoirs: A review of analytical models and testing data. Int. J. Coal Geol. 2012, 92, 1–44. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, Y.; Liu, Q.; Jiang, J.; Li, W.; Zhang, K. Numerical assessment of CMM drainage in the remote unloaded coal body: Insights of geostress-relief gas migration and coal permeability. J. Nat. Gas Sci. Eng. 2017, 45, 487–501. [Google Scholar] [CrossRef]

- Li, R.; Wang, S.W.; Chao, W.W.; Wang, J.C.; Lyu, S.F. Analysis of the transfer modes and dynamic characteristics of reservoir pressure during coalbed methane production. Int. J. Rock Mech. Min. Sci. 2016, 87, 129–138. [Google Scholar] [CrossRef]

- Wei, M.; Huangfu, H.; Lu, C. Experimental measurement method of matrix and fracture permeability of coal and rock mass. J. China Univ. Min. Technol. 2025, 54, 413–422. [Google Scholar]

- Liu, J.; Chen, Z.; Elsworth, D. Evaluation of stress-controlled coal swelling processes. Int. J. Coal Geol. 2010, 83, 446–455. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.; Elsworth, D. Dual poroelastic response of a coal seam to CO2 injection. Int. J. Greenh. Gas Control 2010, 4, 668–678. [Google Scholar] [CrossRef]

- Wei, M.; Liu, J.; Elsworth, D. Impact of equilibration time lag between matrix and fractures on the evolution of coal permeability. Fuel 2021, 290, 120029. [Google Scholar] [CrossRef]

- Robertson, E.P.; Christiansen, R.L. Modeling permeability in coal using sorption-induced strain data. In Proceedings of the 2005 SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Shi, J.; Durucan, S. A model for changes in coalbed permeability during primary and enhanced methane recovery. SPE Reserv. Eval. Eng. 2005, 8, 291–299. [Google Scholar] [CrossRef]

- Wang, W.; Li, W.; Wang, L. Analysis of coal permeability model set and prediction effect based on cubic law and meso-scale deformation law. J. China Coal Soc. 2025, 1–21. [Google Scholar]

- Connell, L.D.; Mazumder, S.; Sander, R. Laboratory characterization of coal matrix shrinkage, cleat compressibility and the geomechanical properties determining reservoir permeability. Fuel 2016, 165, 499–512. [Google Scholar] [CrossRef]

- Lu, S.; Cheng, Y.; Li, W. Model development and analysis of the evolution of coal permeability under different boundary conditions. J. Nat. Gas Sci. Eng. 2016, 31, 129–138. [Google Scholar] [CrossRef]

- Li, R.; Guo, M. Long distance directional drilling technology in Shendong Mining Area. Coal Eng. 2024, 56, 53–58. [Google Scholar]

- Liu, Z.; Chen, D.; Sun, B. Gas control technology in super large area of high gassy mine. Coal Sci. Technol. 2021, 49, 120–126. [Google Scholar]

| Parameter Name | Value | Parameter Name | Value |

|---|---|---|---|

| Shear Modulus of coal, G (MPa) | 380 | Langmuir pressure constant, PL (MPa) | 2.48 |

| Bulk Modulus of coal matrix, K (MPa) | 1143 | Langmuir volume constant, VL (m3/kg) | 0.035 |

| Langmuir volumetric strain, εL | 0.014 | Initial porosity of matrix, фm (%) | 2 |

| Diffusion coefficient of matrix micropores, D (m2/s) | 2.2 × 10−7 | Initial porosity of fractures, фf (%) | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Wei, M.; Liu, Y. The Gas Migration During the Drainage Process of Ultra-Long Directional Boreholes in Coal Seams. Appl. Sci. 2025, 15, 10420. https://doi.org/10.3390/app151910420

He S, Wei M, Liu Y. The Gas Migration During the Drainage Process of Ultra-Long Directional Boreholes in Coal Seams. Applied Sciences. 2025; 15(19):10420. https://doi.org/10.3390/app151910420

Chicago/Turabian StyleHe, Shuaiyin, Mingyao Wei, and Yingke Liu. 2025. "The Gas Migration During the Drainage Process of Ultra-Long Directional Boreholes in Coal Seams" Applied Sciences 15, no. 19: 10420. https://doi.org/10.3390/app151910420

APA StyleHe, S., Wei, M., & Liu, Y. (2025). The Gas Migration During the Drainage Process of Ultra-Long Directional Boreholes in Coal Seams. Applied Sciences, 15(19), 10420. https://doi.org/10.3390/app151910420