1. Introduction

Air quality, both indoors and outdoors, has become an increasing concern in the context of public health, environmental sustainability and the development of smart cities. In the case of enclosed spaces, the situation may be more critical, since it is estimated that people spend approximately 90% of their time indoors [

1], where exposure to atmospheric pollutants such as particulate matter (PM1, PM2.5 and PM10), Carbon Dioxide (CO

2) and Volatile Organic Compounds (VOCs) is common [

2,

3]. The health risks associated with fine and ultrafine particles, present in both outdoor and indoor environments, include respiratory and cardiovascular conditions, as well as long-term effects such as chronic diseases [

4,

5].

Several studies have also shown that concentrations of particles in indoor environments may present significant spatial variations [

6,

7]. This aspect becomes particularly relevant not only in residential, educational or commercial buildings, but also in professional environments, especially kitchens, where peak concentrations have been detected that far exceed the limits considered safe. In this context, understanding the spatial and temporal distribution of environmental pollutants is essential for designing effective mitigation strategies, with sensor placement planning being a critical phase.

Building Information Modelling (BIM) has been consolidated as a reference methodology in the Architecture, Engineering, Construction and Operation (AECO) sector. Its purpose is to generate and manage digital representations of built assets, integrating both their physical and functional characteristics throughout the entire project life cycle. This ability to structure and share information in collaborative environments makes BIM an ideal framework for data-driven decision-making [

8]. The generation of multi-criteria parametric designs in construction projects is enabled by the evolution of computer-based BIM applications, using objects formally defined by their identity, attributes, and relational dependencies [

9].

In parallel, the Internet of Things (IoT) has gained increasing relevance in the construction domain. It is an ecosystem of interconnected devices capable of capturing and transmitting data in real time. In the context of air quality, IoT sensors enable the monitoring of critical environmental variables and provide dynamic information which, when integrated into BIM models, allows the creation of digital twins and the planning of preventive and corrective strategies.

Combined with IoT technologies, BIM not only enables real-time monitoring, predictive maintenance and the development of digital twins, but also offers a suitable environment for the early simulation and planning of strategies related to environmental quality [

10,

11].

Classification systems, on the other hand, constitute a third essential component in this framework. These semantic schemes organise and codify project elements in a standardised manner, ensuring the consistency and traceability of information across disciplines, phases and tools. However, currently available classification systems present significant limitations, as they rarely include specific codes for classifying environmental sensors or IoT devices.

Although there are numerous studies on IoT–BIM integration, no studies have been found that address the application of specific classification systems for air quality sensors in projects where BIM methodology was applied. Despite the evident synergy between BIM and environmental monitoring, current workflows rarely integrate suitable classification systems. Most classification systems used in BIM environments, such as OmniClass, UniClass 2015 or CoClass, offer only limited support for environmental devices [

12,

13]. Even in developed countries, with a mature implementation of BIM methodology, such as Spain (Europe), the national classification systems analysed, including GuBIMClass, AEAS BIM Class and SCFClass, do not currently include structured codes for IoT sensors [

14,

15,

16].

To address this shortcoming, this paper proposes a methodological framework to integrate air quality monitoring in BIM-based projects. The proposal combines two main components: (1) a technical implementation of low-cost sensors for PM1, PM2.5, PM10, gases, temperature and humidity, deployed in a real residential case study; and (2) a structured classification system named AllBIMclass, developed to facilitate the semantic integration of environmental sensors into BIM models. AllBIMclass includes specific codes for sensor typology, installation location (indoor, outdoor or mixed), power supply and data management mode, and is fully compatible with the Industry Foundation Classes (IFC) schema. The framework seeks to improve the capacity of BIM environments to represent, plan and manage environmental monitoring systems throughout the entire building life cycle.

In this work, following the review of the state of the art on low-cost sensors, international BIM classification systems and the IFC standard (

Section 2),

Section 3 describes the design and potential of the sensors developed, while

Section 4 outlines the structure and criteria of AllBIMclass as a specific classification system for environmental monitoring devices.

Section 5 presents a pilot experience in a residential dwelling, where low-cost sensors classified with AllBIMclass were integrated into a BIM-based environmental monitoring workflow.

Section 6 discusses the contributions, limitations and implications of the proposal, and finally,

Section 7 summarises the main conclusions and future research directions.

2. Literature Review

The growing demand for more sustainable, healthy and intelligent buildings, urban environments and infrastructures has driven the development of digital methodologies capable of integrating environmental data throughout all phases of the life cycle of built assets. In this context, sensorisation through IoT technologies, and their integration into BIM environments, represents an emerging research field, with applications ranging from initial planning and simulation to operation and predictive maintenance.

However, the integration of IoT technologies into BIM methodology presents two major challenges. The first is technological, and concerns the difficulty of sensor validation, real-time communication, energy autonomy, and cost reduction. The second is semantic, arising from the absence of suitable classification systems to represent air quality sensors within BIM models, which limits their traceability, interoperability and usability in complex digital environments such as digital twins.

This section reviews previous work related to environmental monitoring using low-cost sensors and the integration of IoT devices into BIM workflows (

Section 2.1). It then analyses the capacity of the main international classification systems, OmniClass, Uniclass 2015 and CoClass, to represent this type of device (

Section 2.2), as well as the role of the IFC standard as a supporting semantic structure (

Section 2.3). Finally, a representative European case, Spain, is presented to illustrate the limitations that may be encountered in certain national frameworks when classifying environmental sensors in BIM projects (

Section 2.4).

2.1. Low-Cost Sensors for Air Quality Monitoring

Indoor Air Quality (IAQ) monitoring increasingly relies on networks of low-cost sensors, which represent an affordable alternative to high-end reference equipment. Various pollutants affect IAQ, including Volatile Organic Compounds (VOCs), Nitrogen Dioxide (NO

2) and Carbon Dioxide (CO

2), although suspended Particulate Matter (PM) remains one of the most relevant due to its direct impact on human health [

1,

2].

Low-cost sensors such as the Plantower PMS5003 (Nanchang, China) and the SDS011 (Nova Technology Co., Ltd., Jinan, China) have gained popularity for measuring PM1, PM2.5 and PM10. These devices employ laser light scattering technology to estimate particle concentrations, offering a favourable balance between accuracy, size and cost [

17,

18]. Their reliability has been extensively studied in different environments, and although their absolute accuracy is lower than that of reference instruments, several calibration strategies have been proposed to correct systematic biases, such as co-location calibration or factory adjustments [

19,

20].

In recent experimental research carried out in a prototype dwelling, PMS5003 optical sensors were designed and assembled with NodeMCU ESP8266 boards (Espressif Systems, Shanghai, China) and DHT22 modules (Aosong Electronic, Guangzhou, China). The total cost per unit was below USD 20, which enabled the deployment of an inexpensive IoT sensor network for real-time indoor particle monitoring, in line with current recommendations on the use of low-cost sensors for air quality control [

4]. The main components of the prototype are shown in

Figure 1.

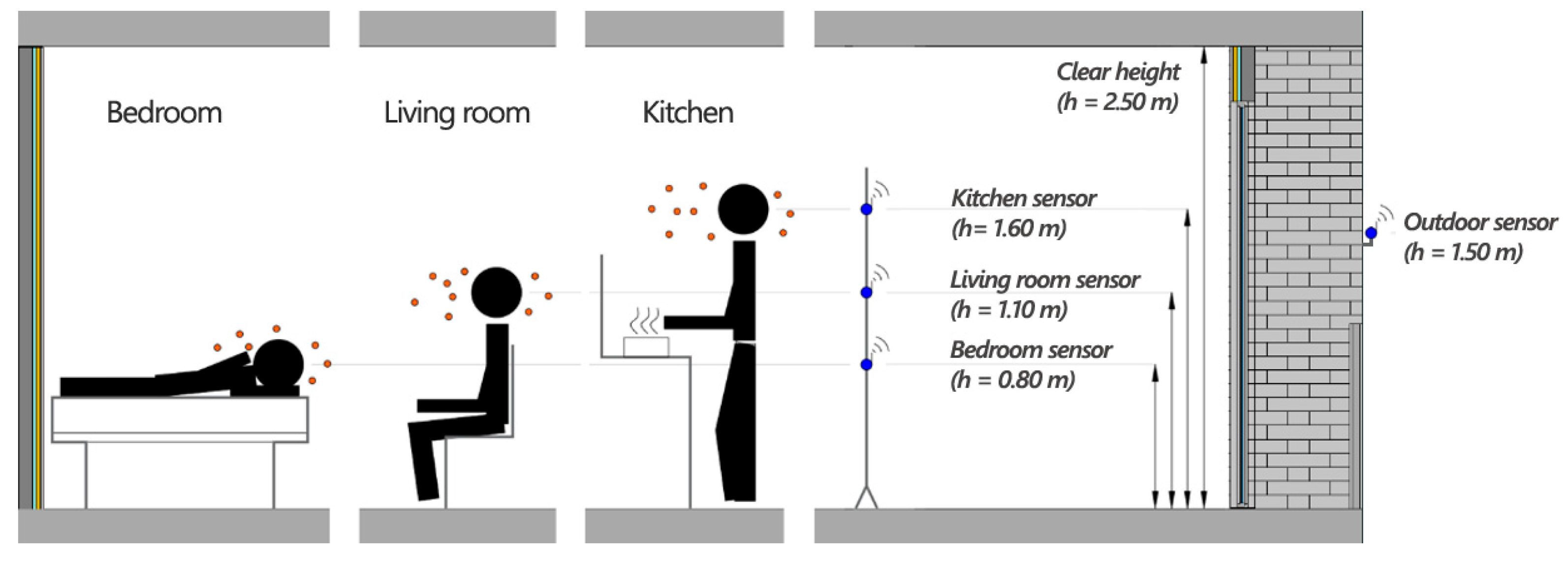

The results revealed statistically significant differences in PM1, PM2.5 and PM10 concentrations as a function of height (0.8 m, 1.1 m and 1.6 m), confirming both the feasibility of these devices for indoor air quality studies and their potential application in BIM-based environmental management contexts [

21]. Nevertheless, the incorporation of such sensors into management systems requires methodological precautions. In particular, the installation height or their position relative to vertical elements (walls) can significantly affect readings, generating deviations from actual exposure in the human breathing zone [

6,

21]. This aspect must be considered when integrating sensors into digital twins, BIM dashboards or other decision-support tools.

Despite the potential of low-cost sensors and their growing adoption in smart environments, their effective integration into BIM models still faces a fundamental limitation: the absence of classification systems capable of representing, in a structured manner, their technical attributes, location, mode of operation or power source. Without a solid classification framework, the traceability, automation and semantic exploitation of these devices within BIM workflows or digital twins remain incomplete or inaccurate. This gap underscores the need to review the main existing classification systems and assess their capacity to address such integration, as discussed in the following sections.

2.2. International Classification Systems in BIM

Over the past decades, several countries have developed their own systems for classifying information in the construction domain. This development has progressively evolved and adapted to current BIM classification systems, which are generally aligned with ISO 12006-2:2015 [

22]. This standard defines a common framework for the organisation of objects, processes and resources related to build assets. Although they share a common normative basis, these systems present significant differences in their structure, level of granularity, coding, accessibility and scope of application, particularly depending on the phase of the project life cycle (planning, design, construction, operation or maintenance).

Among the most recognised at the international level are OmniClass (United States), Uniclass 2015 (United Kingdom) and CoClass (Sweden), currently regarded as the three most consolidated systems in BIM environments [

23], and widely documented in both scientific and technical literature. Their main characteristics are outlined below, together with an analysis of their capacity to classify environmental sensors and integrate IoT devices, the comparison of which is summarised below.

2.2.1. OmniClass

The OmniClass Construction Classification System (OmniClass) was developed by the Construction Specifications Institute (CSI) in the United States. It is structured into 15 thematic tables, each focused on a specific aspect of the built environment, and is based on ISO 12006-2:2015, which ensures coherence with international standards. This classification system builds on MasterFormat, UniFormat and UniFormat II, thereby consolidating decades of experience in the coding and structuring of construction information.

The most relevant table in relation to sensors is OmniClass table 23 (Products), where various technological elements are grouped, including some monitoring devices. In particular, entries such as Air Pollution Monitoring Systems (23.29.39.13.11), Gas Leak Detection Agents (23.29.39.15.13.11), Water Leak Detection (23.29.39.15.13.13), or Built-In Failure Detection (23.29.39.15) can be identified. As shown in

Table 1, these entries are located under the subcategory 23.29.39 Environmental Safety Equipment within OmniClass table 23, and illustrate the generic and fragmented way in which OmniClass addresses monitoring and detection devices. However, the classification is generic and fragmented, with limited granularity and applicability for adequately classifying IoT air quality sensors, or for distinguishing between specific sensor types, such as typology (integrated, particulate, gas, temperature or humidity sensors, among others), data provision method (internal storage or Wi-Fi data transmission), or power supply (battery, solar or direct current connection). Nor does it offer a classification according to sensor location (indoor, outdoor or mobile).

Regarding access, OmniClass is not open access, and downloading its tables in Excel or PDF format requires a commercial licence, which limits its adoption in collaborative or open-access environments.

2.2.2. Uniclass 2015

Uniclass 2015 is the classification system promoted by the National Building Specification (NBS) in the United Kingdom. It represents an evolution from earlier versions such as Uniclass (1997) and Uniclass 2 (2013), and has been designed to address the requirements of BIM methodology in digital environments. Unlike its predecessors, Uniclass 2015 features a more modular, open and updatable structure, with clear alignment to ISO 12006-2:2015, which strengthens its interoperability and applicability throughout the entire life cycle of built assets.

The system is structured into 15 thematic tables, many of them functionally equivalent to the categories established by ISO 12006-2:2015. However, it also incorporates specific tables such as table Zz (CAD), focused on aspects related to digital modelling. One of the most relevant for the classification of environmental devices is table Pr (Products), which includes the group Pr_75_50_76 Sensors and detectors. This group contains a wide range of sensors and detectors, some of them clearly oriented towards environmental control.

Within the aforementioned group, entries include:

Air quality sensors (Pr_75_50_76_02).

Carbon dioxide sensors (Pr_75_50_76_10).

Gas detectors (Pr_75_50_76_33).

Relative humidity sensors (Pr_75_50_76_71).

Room temperature sensors (Pr_75_50_76_73).

Toxic and combustible gas detectors (Pr_75_50_76_88).

Water pressure sensors (Pr_75_50_76_97),

Among many others, demonstrating a higher level of development compared with other international systems in terms of classifying IoT sensors applied to the built environment.

Table 2 presents a selection of Uniclass 2015 entries directly related to environmental monitoring, highlighting their greater specificity compared with OmniClass.

This level of granularity allows for a more precise and differentiated representation of different types of environmental sensors, overcoming the limitations of other systems such as OmniClass, where the relevant entries are more generic and scattered. Nevertheless, Uniclass 2015 does not include specific attributes that would allow environmental sensors to be classified according to their purpose or technology. For instance, it does not distinguish whether they are designed to measure exclusively particulate matter (PM1, PM2.5 and PM10), gases (such as CO2, NO2, SO2, O2 and VOCs), or whether they integrate multiple parameters. Nor does it differentiate key aspects such as the mode of operation (internal logging or IoT transmission), power supply (battery, mains electricity or solar), or device location (indoor, outdoor or mobile), all of which are essential in advanced BIM contexts and digital twin environments.

The Uniclass 2015 tables are available free of charge through its official portal and can be downloaded in XLSX and PDF formats. In addition, the system provides regular updates and feedback mechanisms, which enable continuous improvement and adaptation to new sectoral needs.

2.2.3. CoClass

CoClass, developed by Svensk Byggtjänst (SfB), is the Swedish national classification system for construction, aligned with ISO 12006-2:2015 and the ISO/IEC 81346-1, -2 and -12 series [

24,

25,

26], which introduces a more functional and systems-oriented perspective. The structure of CoClass originates from the evolution of BSAB (72, 83 and 96, respectively) and is designed to be used throughout the entire life cycle of built assets, from planning to maintenance, covering both buildings and infrastructure.

In its latest version 3.16 (2025), CoClass consists of nine tables (eight functional and one under development). Within table KO (Komponenter), CoClass incorporates detection devices under the node BQ_Koncentrationsavkännande objekt (concentration-detection objects), including specific subcategories for sensors and detectors of gases, liquids and solids.

Table 3 presents the main CoClass entries identified under this category, illustrating its limited differentiation of environmental sensor types. This organisation enables the representation of environmental monitoring devices, although with a limited level of detail, like OmniClass and inferior to Uniclass 2015. Sensors are not differentiated by pollutant, technology, location or mode of operation, which hinders their application in models oriented towards advanced environmental control or digital twins. Its tables can be consulted free of charge upon registration on its official website. Information guides in PDF format are also available. However, downloading in digital formats requires a paid subscription.

Building on the previous analyses,

Table 4 provides a comparative summary of the three systems, highlighting their differences in scope, granularity, and applicability for environmental sensor classification.

2.3. IFC Standard as a Support for Classification

The IFC format, maintained by buildingSMART International, constitutes the main open standard for the interoperable representation of BIM models. Its recognition as an international standard was formalised through ISO 16739-1:2018 [

27], and more recently through ISO 16739-1:2024 [

28].

Although IFC is not a classification system in itself, it enables the establishment of semantic links between model elements (such as IfcElement, IfcSpace or IfcSensor) and external classification systems such as OmniClass, Uniclass 2015 or CoClass. This linkage is implemented through entities such as IfcClassification and IfcClassificationReference, which allow the incorporation of attributes such as Identification, Name, ItemReference or Location, all of which are fundamental for traceability and the automated processing of data within digital workflows.

In the specific case of sensors, IFC provides the entities IfcSensor and IfcSensorType within the IfcBuildingControlsDomain. While IfcSensor represents individual instances, IfcSensorType defines the common properties of a sensor type, facilitating the standardisation of templates and the management of multiple instances. Their behaviour in the model is articulated through relationships such as IfcRelDefinesByType, IfcRelAssignsToControl or IfcRelConnectsPorts, which enable sensors to be linked with control objects, construction elements or data flows [

29]. These relationships and linkages are illustrated in

Figure 2, which summarises how IfcSensor and IfcSensorType interact with classification systems, property sets, spatial elements, distribution ports, and complementary ontologies such as SAREF.

Despite these capabilities, IFC presents important limitations. Its generic structure sometimes makes it difficult to distinguish functional or constructive differences between elements; for example, it does not directly differentiate whether a wall has been constructed in situ or corresponds to a prefabricated system, which requires reliance on external systems to provide semantic precision to the model [

13]. Furthermore, although sensors can be represented geometrically through IfcProductDefinitionShape, there is no native taxonomy that classifies environmental or IoT devices according to their nature or function [

29].

Earlier versions, such as IFC4, offered insufficient coverage for infrastructure projects. The recent release of IFC 4.3 (ISO 16739-1:2024) significantly improves this situation by extending the standard to civil works [

30], although its implementation is still in early stages.

Recent literature has identified three approaches to addressing the shortcomings in sensor representation: (1) linking with external ontologies such as the Smart Applications REFerence (SAREF), which provide specialised taxonomies; (2) creating custom property sets to add user-defined attributes; and (3) using middleware or APIs to dynamically integrate IFC data with IoT platforms, enabling real-time synchronisation and digital twin applications [

31]. In this regard, while IFC only provides general properties through flexible but non-standardised sets, SAREF natively incorporates detailed attributes such as detection range, sensor type, manufacturer, status, function or measured values, reinforcing the need to complement both frameworks to achieve a complete and interoperable semantics [

29].

Table 5 summarises the complementary coverage of IFC and SAREF in relation to sensor semantics, highlighting how both frameworks can be combined to achieve complete interoperability in IAQ monitoring workflows.

2.4. National-Level Limitations in Sensor Classification: The European Case of Spain

Although this paper focuses on internationally recognised classification systems, a brief analysis of selected national frameworks can illustrate the widespread lack of structured categories for environmental sensors in BIM. Spain has been chosen as a representative example due to the availability of official documentation and recent progress in national classification initiatives.

The example of Spain, as a member of the European Union, helps highlight the structural gaps that may also exist in other countries lacking advanced BIM classification systems, and serves to contextualise the emergence of solutions such as AllBIMclass.

Unlike other European countries that have developed fully structured national classification systems aligned with ISO 12006-2:2015 and ISO/IEC 81346 (such as CoClass in Sweden or CCI in Estonia), the adoption of BIM classification systems in Spain has been more limited and fragmented. Although several initiatives exist, a single official system covering the entire project life cycle and all project typologies has not yet been consolidated.

This section describes the most relevant systems currently in use or under development in Spain, analyses their applicability to the classification of air quality sensors, and presents a comparative synthesis.

2.4.1. GuBIMclass

GuBIMClass is the most widely used BIM classification system in Spain. It was launched by the Grup d’Usuaris BIM de Catalunya (GuBIMCat), in collaboration with Infraestructures.cat, starting in 2014. The current version (v1.2) was published in 2017 and consists of a single table, organised according to the constructive function of the element, structured into nine chapters oriented towards building projects.

Its main characteristics include the following: classification based on the primary function of the element and its constructive sequence; independence from project life cycle phases or BIM uses; and its status as a scalable, homogeneous, and easy-to-apply coding system. Its use has served as the basis for the development of other sectoral systems, such as the railway system SCFClass. However, its coverage is limited for infrastructures and specific sectors such as water [

14], and it does not currently include specific classes for air quality sensors or IoT devices, beyond the generic entry “50.90.50.30—Special sensors.”.

Table 6 presents the GuBIMclass entries under Chapter 50.90.50, which include a generic category for “Special sensors” but without specific differentiation for air quality monitoring devices.

2.4.2. SCFclass (Rail Innovation Hub)

SCFClass is a system developed in 2020 by the Rail Innovation Hub, with a specific focus on railway infrastructures. Its design is based on the structure and logic of GuBIMClass, adapted to the particular needs of the railway sector. Its development drew on regulatory references such as Law 38/2015 of 29 September on the Railway Sector; Royal Decree 2387/2004 of 30 December, which approves the Railway Sector Regulation; and Law 38/1999 of 5 November on Building Regulation.

In its first version (v1), the system employed 12 tables. In its most recent version (v2, 2022), it was expanded to 19 tables, organised into four groups: standard tables, template tables, register tables and support tables. Some of these act more as references or examples than as fully operational classification structures. Nevertheless, as with GuBIMClass, SCFClass does not include specific nodes for the classification of IoT sensors or environmental control devices. Instead, it reproduces almost identically the generic category present in GuBIMClass, under the concept “FUN.ISI.130.030—Special sensor”, within the broader category of control devices.

Table 7 summarises these entries.

The tables can be downloaded free of charge in XLSX, PDF and other supplementary formats, through a ZIP file available on its official website.

2.4.3. AEAS BIM Class

Developed by the Spanish Association for Water Supply and Sanitation (Asociación Española de Abastecimientos de Agua y Saneamiento, AEAS), this system is oriented towards the classification of elements and processes linked to hydraulic networks. It is a multi-table system, structured following the example of classifications such as OmniClass and Uniclass 2015, as well as the recommendations of ISO 12006-2.

In its most recent version, AeasBIMClass.v02 (January 2025), the system is composed of four tables: Objects (classification by typology), Processes (according to the function or stage in which they are involved), Pipe Materials (type of material), and Fluids (type of fluid transported). Although it provides specialised technical nomenclature for the field of the integrated water cycle, it does not currently include the incorporation of environmental sensing devices, nor does it address in detail civil works components, whose classification is instead referred to existing systems such as GuBIMClass or OmniClass [

14].

The tables can be downloaded free of charge in XLSX and PDF format from its official website.

2.4.4. RCEclass

RCEclass is the BIM classification system developed by the Spanish Directorate-General for Roads (Dirección General de Carreteras, DGC), applicable to any phase of the life cycle of contracts implementing BIM methodology in the field of road infrastructure [

16]. The system is structured into 10 tables, the most important of which, entitled Functions, includes 1279 elements that compile, as an inventory, the possible components of a road, based on sectoral regulations, asset management systems and the DGC’s official cost database.

The system does not include designations for sensors related to the monitoring of environmental parameters.

2.4.5. ADIF BIM System

ADIF, as the managing entity of railway infrastructures in Spain, has adopted the classification system proposed by the Railway Innovation Hub (SCFClass) as its BIM classification framework, with the aim of ensuring the standardisation of BIM models in its contracts. This is established in the official document “Anejo de cláusulas BIM para obra” [

15], which specifies that all model objects must be classified according to the tables provided by ADIF, using a function-based structure. The system is intended for internal use and has not been published as an open standard or as a sectoral proposal, which is why it has been excluded from the comparative analysis presented in

Table 8.

Table 8 summarises the main characteristics of the national systems analysed. As can be observed, none of them currently include specific classification structures for IoT sensors related to air quality or other environmental variables. Furthermore, they display limited technological maturity in their development, as they do not include Application Programming Interfaces (APIs). This shortcoming represents a significant limitation considering the growing requirements for sustainability, digitalisation and environmental control in built environments. In this context, proposals such as AllBIMclass are presented as a way to extend and complement existing systems, integrating new categories that address these emerging needs.

3. Low-Cost Sensor Design and Potential

The advance in the availability of low-cost sensors has enabled the development of accessible systems for environmental monitoring in domestic and urban contexts. These devices offer a viable alternative to high-cost commercial equipment, particularly in scenarios where portability, scalability and integration with digital platforms are prioritised. In this work, a prototype monitoring device was designed and evaluated, allowing the recording of PM1, PM2.5 and PM10 concentrations, together with temperature and relative humidity variables.

The sensor design was conceived as a practical case study, demonstrating the ability to obtain environmental data from an inexpensive and easily replicable kit. Beyond experimental validation, this type of solution is particularly relevant for its potential integration into BIM and IoT methodologies, where the generated data can be linked in real time to digital models of buildings and infrastructures, broadening their applications in environmental control projects.

3.1. Sensor Components and Architecture

The monitoring unit was designed to provide an affordable, compact, and autonomous solution for indoor air quality assessment. Its core element is the NodeMCU ESP8266 microcontroller, chosen for its integrated Wi-Fi connectivity, small form factor, and low cost, which make it particularly suitable for IoT-based applications [

3,

4].

Particulate matter was measured using the PMS5003 optical sensor (Plantower), which applies laser scattering to quantify PM1, PM2.5, and PM10 concentrations. This device has been extensively validated in recent studies [

17] and ensures a maximum error of ±10% under standard operating ranges. To complement particle monitoring, temperature and relative humidity were recorded with the DHT22 sensor, selected for its proven accuracy, low energy requirements, and ease of integration with Arduino-based systems.

Power supply was provided through a rechargeable 18,650 lithium battery connected to a protection and management module. This configuration prevents overcharging and excessive current, while enabling autonomous operation for approximately 15 h per cycle. Alternatively, the system can run continuously when powered through a USB connection to the mains.

The resulting kit was lightweight, silent, and inexpensive (around USD 20), aligning with recommendations for the deployment of low-cost indoor monitoring devices [

21,

31]. A preliminary implementation of this design was presented in Renard-Julián et al. [

21]. Furthermore, the modular nature of the platform allows the incorporation of additional sensors, such as those for CO

2, NO

2, SO

2, O

2, or VOCs, without substantially increasing the overall cost.

3.2. Data Capture, Transmission and Storage

The system was programmed using the Arduino IDE environment, incorporating the necessary libraries to establish communication between the NodeMCU board and the PMS5003 and DHT22 sensors. The developed software enabled Wi-Fi configuration, assignment of a unique identifier to each kit with its corresponding location, and programming of the recording interval at 60 s. In each sampling cycle, the identifier, location, date and time, temperature (°C) and relative humidity (%) from the DHT22 sensor were collected, together with PM1, PM2.5 and PM10 concentrations (µg/m3) obtained from the PMS5003.

The collected data were transmitted in real time to a MySQL database hosted on a private server, ensuring structured storage and subsequent querying. To facilitate management, analysis and export of the information in the case study, an application was developed in VS.NET, allowing the download of records and the generation of CSV files. These files could be processed in conventional statistical software such as Microsoft Excel, although the database-resident data could also serve for direct integration into web platforms, dashboards or BIM environments oriented towards digital twins.

3.3. Experimental Validation and Limitations

The prototype was validated in an indoor monitoring case study, analysing particle concentrations in different rooms of a dwelling (kitchen, living room and bedrooms). Additionally, a sensor was installed outdoors (balcony) to contrast the measurements and distinguish between internal sources and external environmental conditions. The devices recorded PM1, PM2.5 and PM10 data at 60 s intervals, together with temperature and humidity values, which enabled the assessment of both stability and the sensors’ capacity to detect spatial and temporal variations in indoor air quality (

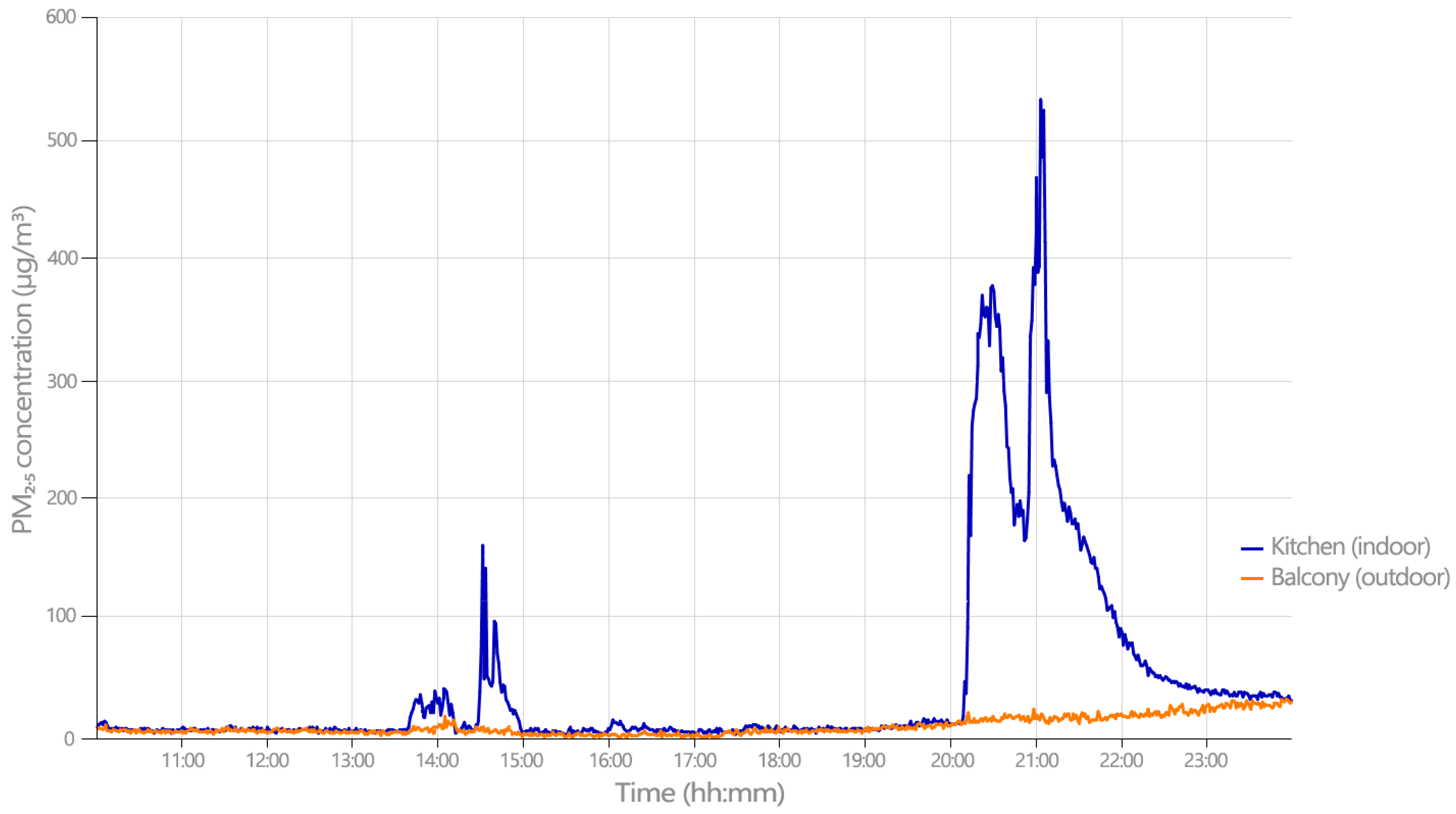

Figure 3).

The results showed relatively low background concentrations (15–20 µg/m3) indoors, with pronounced increases associated with cooking activities. In particular, during oven use, PM2.5 peaks close to 500–600 µg/m3 were observed, coinciding with door opening to insert and remove food. After the door was closed, the values rapidly decreased and, during cooling with the door left ajar, a progressive decline was recorded until background levels were restored. These events were not reflected in the outdoor sensor, which remained stable throughout, confirming the internal origin of the pollution peaks. Analogous results were obtained for PM1 and PM10, reinforcing the consistency of the measurements.

In terms of performance, the system demonstrated sufficient autonomy to cover 24 h observation periods under continuous operation and provided consistent measurements across sessions. Nevertheless, limitations inherent to the use of low-cost sensors were identified: lower accuracy compared with professional reference instrumentation, dependence on Wi-Fi connectivity for transmission, and the need for periodic battery recharging if not continuously connected to the mains. These limitations can be overcome by integrating cellular connectivity via SIM card, as well as USB power supply, without significant increases in unit cost. Overall, the case study validates the feasibility of an economical and replicable system for indoor environmental monitoring; its results should be interpreted as indicative rather than absolute, being particularly useful for preliminary studies, distributed deployments and integration with digital models.

3.4. Potential for Integration with BIM and IoT

The development of low-cost sensors for environmental monitoring should not be considered solely from the perspective of data acquisition, but also in terms of their ability to integrate into broader digital systems. The possibility of transmitting, in real time, information on variables such as temperature, humidity, CO

2, NO

2, SO

2, O

2, PM1, PM2.5, PM10 and VOCs, among others, makes these devices suitable nodes within IoT architectures [

32]. The records generated can be stored on servers or in the cloud, visualised in interactive dashboards and processed through analytical applications. This connectivity facilitates the deployment of distributed monitoring networks, with multiple sensors across different rooms or buildings, capable of generating extensive databases that are useful for decision-making.

In this context, linking sensors with digital models under BIM methodology represents a significant advance. Associating devices with monitored rooms in IFC files allows environmental quality parameters to be directly integrated into the building or infrastructure model. In this way, the data are contextualised within the digital twin, enabling the identification of critical zones, the comparison of ventilation or air-conditioning scenarios, and the generation of early alerts in adverse conditions [

11].

The incorporation of IoT workflows into BIM environments further enhances the development of digital twins, where environmental information is combined with other variables (energy, occupancy, maintenance) to provide a dynamic and up-to-date view of the asset. Within this framework, low-cost sensors become a viable solution to feed digital models in projects of any scale, since their low price enables large-scale deployments and their connectivity flexibility supports integration into web platforms and APIs.

However, significant interoperability challenges remain. Standards such as IFC do not yet include a specific taxonomy for the diversity of environmental sensors, with generic classes such as IfcSensor with customised properties commonly being used instead. Likewise, the main international classification systems do not adequately incorporate specific codes to represent the different types of sensors according to observed parameters (gases, particles, noise, solar radiation), monitoring technologies (internal logging, IoT transmission, direct reading) or application domains (indoor, outdoor, mobile). Even within the European context, some countries, such as Spain, lack specific taxonomies to adequately classify the main typologies of environmental sensors.

The absence of specific classification structures limits automation in the design and maintenance of environmental control systems. To address this gap, the incorporation of specialised nodes is proposed, such as the one developed in the AllBIMClass system, which provides a hierarchical and interoperable classification for IoT sensors aimed at environmental control in both indoor and outdoor environments.

4. AllBIMclass: A Classification System for Environmental Monitoring Devices

The development of the AllBIMclass classification system has been based on a technical and normative approach aimed at ensuring its applicability in real BIM environments. The system is openly and freely available, which facilitates its adoption by researchers and professionals. The main criteria adopted in its definition are presented below.

4.1. Normative Alignment

In designing AllBIMclass, the guiding principles of ISO 12006-2:2015 were adopted to ensure consistency with international classification frameworks in the construction sector. The system applies a functional approach to the built environment, categorised primarily under “Construction results” in line with comparable schemes such as UniFormat. A distinctive feature of AllBIMclass, however, is its extension into the “Resources” domain, explicitly including environmental sensors and monitoring devices. Interoperability has also been prioritised by enabling formal links with the IFC standard (ISO 16739-1:2018) using IfcClassificationReference entities.

4.2. Structure and Criteria Used

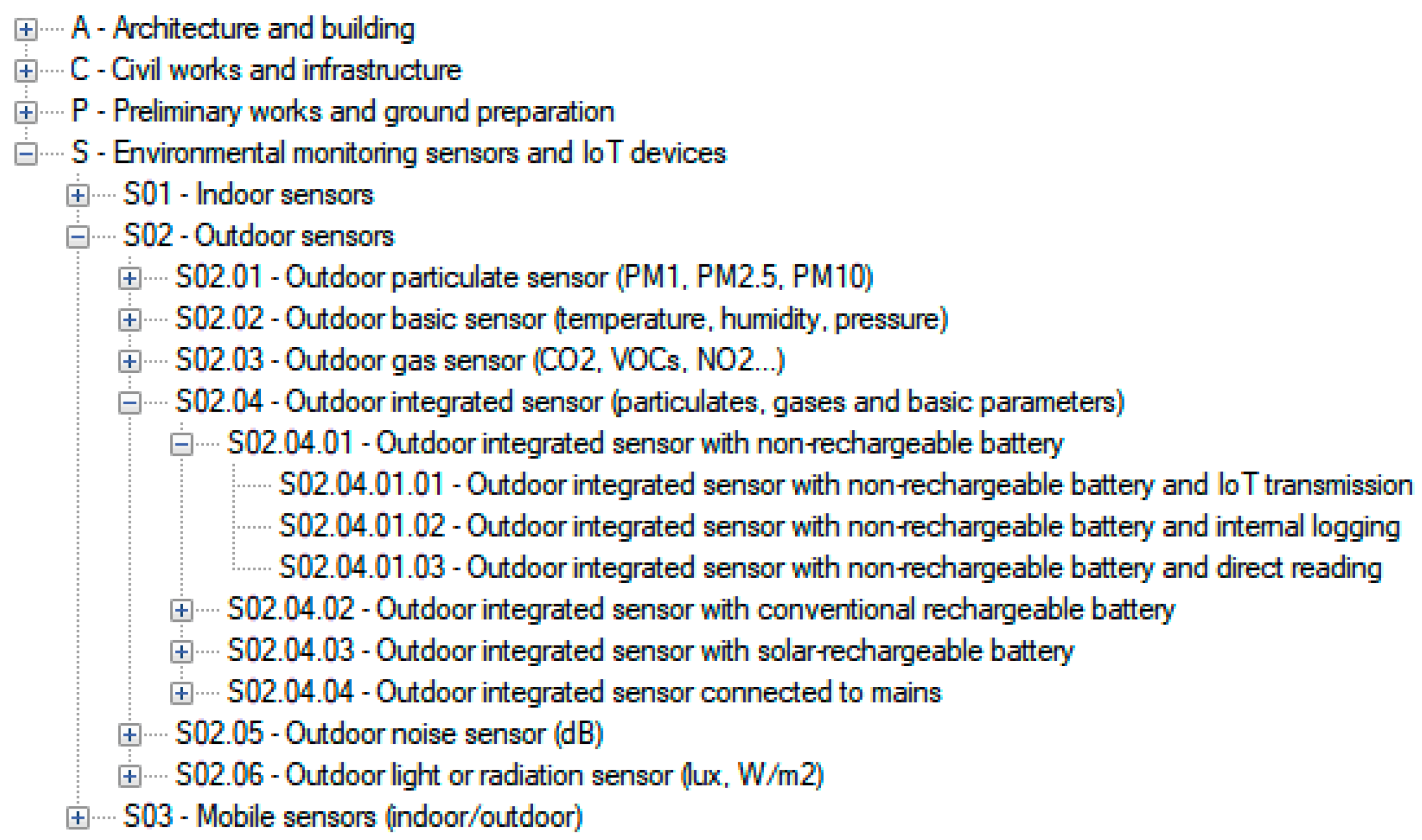

Whereas other classification systems, such as OmniClass, Uniclass 2015, or CoClass, follow a multi-table approach, AllBIMclass was deliberately conceived as a single hierarchical table. This design strategy seeks to maximise structural stability and maintain internal coherence over time, while also reflecting the practical constraints of its development within an independent academic initiative. In its current version, the system encompasses 1306 concepts organised into four thematic nodes. Each node has been aligned with international references analysed in this work, and the coding scheme has been optimised to ensure scalability and interoperability with BIM tools such as Revit and Archicad, while remaining flexible enough to accommodate future sectoral extensions.

Despite being arranged as a single hierarchical table, AllBIMclass brings together nodes with different conceptual roles. This approach resembles the structure of CoClass, where products, processes, and technologies are managed under one integrated framework. AllBIMclass can be regarded as a composite system, as illustrated in

Figure 4, which distinguishes between:

Preliminary works (e.g., earthworks, topographic surveys, and other site preparation tasks);

Architectural components;

Infrastructure-related construction elements;

Technological devices, including IoT sensors and environmental monitoring equipment.

The overall distribution of the 1306 concepts included in AllBIMclass, grouped by thematic blocks and functional categories, as well as their equivalence with international systems, is summarised in

Table 9.

4.3. Node for Environmental Control Sensors and IoT Devices

To overcome a shortcoming identified in international classification systems, a specific node has been developed for sensors and IoT devices for environmental monitoring. This node is organised into four main dimensions, each associated with a hierarchical coding system, ensuring traceability and interoperability. The general structure is shown in

Figure 5:

Location: indoor (S01), outdoor (S02) or mobile (S03).

Typology: particulate (01), basic T/H/P (02), gases (03), integrated (04), noise (05) and radiation/light (06).

Power supply: non-rechargeable battery (01), rechargeable battery (02), solar panel (03), mains connection (04).

Operation method: IoT transmission (01), internal storage (02), direct reading (03).

This node makes it possible to classify a sensor precisely according to its characteristics. For example, an outdoor, integrated sensor (PM, gases and T/H/P), powered by a rechargeable USB battery, with IoT transmission, is classified as S02.04.02.01.

The inclusion of these categories is based on a review of the most widely used sensor typologies in environmental monitoring contexts (dwellings, public buildings and infrastructures), in line with the recommendations of the World Health Organization (WHO) and the Environmental Protection Agency (EPA), as well as recent studies [

10,

11,

21,

32,

33] that identify PM2.5, PM10, CO

2, VOCs, temperature and humidity as monitoring priorities. This review is summarised in

Table 10, which relates each sensor typology to its main applications and supporting normative or scientific references.

Table 10.

Environmental sensor typologies, main applications and supporting normative and scientific references.

Table 10.

Environmental sensor typologies, main applications and supporting normative and scientific references.

| Type of Sensor | Monitoring Purpose | Relevant References |

|---|

| Particulate matter sensors | Air quality in indoor and outdoor environments | [5,30,34] |

| Gas sensor | Environmental surveillance and workplace health | [11,21,35] |

| Basic sensor (temperature, humidity, pressure) | Control of thermal comfort, ventilation, and indoor climate | [11,36] |

| Acoustic sensors | Assessment of noise pollution | [37,38] 1 |

| Light and radiation sensors | Natural and artificial lighting, energy management | [39,40,41] 2 |

4.4. Case Study

To demonstrate its practical applicability, AllBIMclass was tested in Autodesk Revit 2026.1 by importing the classification file in TXT format. This file enables the direct assignment of system codes to object families, including those representing environmental sensors.

As a proof-of-concept, an outdoor device combining particulate and gas measurement was modelled and mounted on a streetlight (

Figure 6). After assigning the classification code S02.04.03.01, the system automatically retrieved the corresponding description (“Outdoor integrated sensor with solar-rechargeable battery and IoT transmission”), confirming the proper implementation of AllBIMclass within Revit.

The model was subsequently exported to IFC4.3 and reviewed using BIMvision 3.0.1, which verified that the classification data were preserved through the IfcClassificationReference entity. This case study highlights the ability of AllBIMclass to ensure semantic consistency across platforms and to support the seamless incorporation of IoT sensors into BIM workflows. The classification files are openly available for download at

https://www.allbimclass.com/ (accessed on 15 August 2025).

5. Pilot Experience: Low-Cost Sensors, AllBIMclass Classification and BIM-Based Environmental Monitoring

This section presents a pilot experience in which an environmental monitoring system was deployed in a single-family dwelling, with the aim of illustrating how the combination of low-cost sensors, standardised classification through AllBIMclass, and integration into BIM models can contribute to the environmental management of indoor and outdoor spaces. The selected dwelling consisted of an entrance hall, a kitchen, a living room, four bedrooms and two outdoor spaces (balcony and gallery). IoT sensors were installed in all rooms except the gallery, bathrooms, and the entrance hall and corridor.

5.1. Sensor Configuration and Data Logging

Seven low-cost environmental monitoring kits, previously described in

Section 3, were used. These were configured through Arduino IDE to assign each a unique identifier and basic operating parameters (Wi-Fi network credentials, sampling interval and data transmission to the database).

During registration on the platform, each sensor was recorded with its identifier, its AllBIMclass classification code, and its XY coordinates obtained from the BIM model of the dwelling. The installation height (Z) was set according to the literature recommendations regarding the optimal elevation for environmental quality sensors [

6], schematically represented in

Figure 7.

The installation included one outdoor sensor and six indoor sensors:

Outdoor: one device located on the balcony, classified through AllBIMclass as “S02.04.01.01”, with the description “Outdoor integrated sensor with non-rechargeable battery and IoT transmission.” This sensor operated on battery power, which was replaced twice a day (morning and evening).

Indoor: one sensor in the kitchen, one in the living room, and one in each of the four bedrooms, classified through AllBIMclass as “S01.04.02.01”, with the description “Indoor integrated sensor connected to mains with IoT transmission.” All of these were connected to mains electricity.

Figure 7.

Illustration of the recommended installation heights for environmental quality sensors in indoor spaces, adapted from previous studies [

7], which were taken as a reference in the pilot experiment.

Figure 7.

Illustration of the recommended installation heights for environmental quality sensors in indoor spaces, adapted from previous studies [

7], which were taken as a reference in the pilot experiment.

This configuration ensured continuous records of particulate matter concentrations (PM1, PM2.5, PM10), temperature and relative humidity in different rooms of the dwelling, generating a dataset with sufficient spatial and temporal granularity for analysis.

As each room was equipped with a dedicated sensor kit, all indoor and outdoor locations were monitored simultaneously, rather than sequentially relocating a single device. This ensured continuous and parallel data collection across the entire dwelling.

5.2. Semantic Layer: The Role of AllBIMclass

Data collection alone does not guarantee integration into digital management environments. Classification through AllBIMclass provided a common semantic scheme to describe each sensor according to its location (indoor/outdoor), typology, power supply and mode of operation. This structuring facilitated the unambiguous identification of devices, their traceability and interoperability across different rooms and usage conditions.

In this way, it was clear that the records from the sensor classified as S02.04.01.01 corresponded to an integrated sensor located outdoors, which required maintenance (in this case, battery replacement). Similarly, the sensors classified as S01.04.02.01 were integrated, located indoors, and required no maintenance.

A key aspect was maintaining hardware simplicity: the sensors only transmitted their identifier and recorded values, while the association with the project, their geometric position and classification code were managed from the web platform and stored in the database. This approach enabled more flexible management, where sensors could be reassigned to different locations without the need for physical reprogramming, and facilitated maintenance tasks such as managing battery replacement for outdoor devices.

Figure 8 illustrates this integration workflow, from the initial identification and configuration of sensors to their registration in the database and linkage with a BIM model through an IFC-compatible plugin or viewer.

5.3. Integration into BIM and Methodological Contribution

The registered and classified sensors were linked to a BIM model of the dwelling through an IFC-compatible plugin. This procedure enabled:

Although the system was not designed for automatic alert generation, the integration facilitated the acquisition of environmental metrics and the management of sensor maintenance, demonstrating the usefulness of AllBIMclass as a semantic layer within digital workflows. It should be noted that the pilot study relied exclusively on real measurements obtained from IoT sensors. No Digital Twin–generated predictions were created for unmonitored areas, although the proposed workflow is fully compatible with such extensions in future developments.

Figure 9 shows a representation of the BIM model corresponding to the dwelling used as the pilot case, in which the rooms are coloured according to PM2.5 concentrations, as an example.

Overall, this pilot experience demonstrates that the combination of low–cost sensors and a structured classification such as AllBIMclass makes it possible to transform a set of isolated records into semantically integrated information within BIM models, opening the door to future applications in dwellings, hospitals, schools and urban infrastructures.

6. Discussion

This discussion addresses the pilot experience presented in this work from a critical and comparative perspective. Similarities and differences with previous research on the integration of environmental sensors and IoT into BIM environments are analysed, highlighting the specific contributions of the developed framework. Its main advantages, limitations and the challenges that still remain are also outlined, as well as the practical and research implications derived from its application in buildings and infrastructures.

6.1. Comparison with Existing Approaches

Several studies have explored the integration of IoT sensors with BIM methodologies for applications in smart buildings and digital twins [

43,

44,

45]. Most of these approaches focus on the development of platforms for energy management, thermal comfort or indoor safety, where sensors transmit environmental data that are visualised in digital models. However, the reviewed literature shows that a major limitation persists: the absence of a standardised system for classifying environmental sensors within BIM models, as well as the insufficiency of the IFC schema to address this gap [

29]. In this context, the application of AllBIMclass in the pilot experience presented in this work represents a significant advance, as it provides a semantic layer capable of unequivocally describing devices of different natures and manufacturers, something not offered by the existing classification systems, as illustrated in

Figure 10.

6.2. Advantages of the Proposed Framework

The pilot experience developed in this work highlights several advantages compared with previous approaches. First, the use of low-cost hardware makes it possible to extend environmental quality monitoring to a wider range of building typologies, including dwellings, schools and hospitals, which typically operate with limited resources. Second, classification through AllBIMclass ensures data interoperability by standardising the description of sensors and facilitating their integration into different digital environments. Third, the scalability of the applied workflow allows it to be transferred from domestic projects to urban infrastructures, where environmental monitoring is equally relevant. Finally, linking the data to BIM models not only facilitates visualisation but also enables the use of digital twins in decision-making processes and long-term planning, as illustrated in

Figure 11.

6.3. Limitations and Challenges

Despite the above advantages, the pilot experience also shows limitations that must be considered. Experimental validation is limited to a residential environment and has not yet been implemented in large-scale projects or complex infrastructures. Sensor connectivity relies on local networks (Wi-Fi) or cellular telephony, which raises difficulties in environments with restricted access or where devices lack coverage and require offline operation, with manual reading or record download processes.

Moreover, AllBIMclass currently remains an initial academic proposal that has not yet been officially adopted in international standards such as IFC, which conditions its immediate practical deployment. Nor have issues related to large-scale data management or cybersecurity been addressed in depth, both of which are critical in real deployment scenarios [

46]. In addition, the present implementation did not include the generation of Digital Twin–based estimations for locations without sensors. The framework was limited to real-world data collected by the deployed devices, which highlights a potential direction for future research.

Other studies have also identified limitations in the real-time integration of IoT sensors with digital platforms, highlighting shortcomings in user interfaces. Furthermore, previous research has revealed aerodynamic phenomena affecting pollutant behaviour, such as the stratification of fine particles (PM1 and PM2.5), or their accumulation near vertical elements away from airflow currents [

6,

21]. This aspect is particularly relevant for the correct placement of sensors and the reliability of results in early warning systems. These limitations are summarised in

Table 11, together with their implications for future research and practical deployment.

6.4. Implications for Research and Practice

From an academic perspective, this work opens new lines of research around the integration of sensor classification into BIM standards and their interoperability with IFC. For professional practice, the pilot experience demonstrates the feasibility of accessible and standardised solutions that enable architects, engineers and managers to implement environmental monitoring systems at low cost and with high integration potential.

Furthermore, the methodology is transferable to other environmental quality parameters beyond particulates (such as CO

2, NO

2, SO

2, O

2, VOCs or hygrothermal comfort), which increases its applicability across different domains. It has also been shown that, despite the growing interest in environmental monitoring, many workplaces still fail to meet the air quality and comfort levels expected by users, with a negative impact on their wellbeing and productivity [

47,

48]. These considerations reinforce the need for interoperable and accessible frameworks, such as the one proposed in this work, to facilitate the transfer of research into applied contexts.

Overall, although the framework still requires validation in broader and more heterogeneous contexts, the combination of low-cost sensors, semantic classification and BIM integration constitutes a technically viable path for the future development of digital twins applied to both buildings and infrastructures.

7. Conclusions

This work demonstrates the technical feasibility and relevance of integrating low-cost sensors together with a semantic classification layer (AllBIMclass) for their incorporation into BIM environments for environmental monitoring purposes. Based on a pilot experience in a residential setting, the ability of these devices to capture pollutants (PM1, PM2.5, and PM10) and basic parameters (temperature and relative humidity) has been evidenced. The assembly of these kits can be extended with additional sensors (e.g., CO2, NO2, SO2, O2, VOCs) without significantly increasing the unit cost.

The application of AllBIMclass, with a specific node for environmental quality, enables this information to be integrated into different stages of the BIM methodology with a sufficient level of detail for rigorous monitoring of environmental parameters. The implemented workflow synthesises the essential steps of the process: (1) sensor configuration, (2) data capture, (3) semantic assignment, and (4) model visualisation.

The results show its potential applicability in the planning and environmental control of architectural and infrastructure projects, opening the door to future research aimed at its validation in larger-scale contexts and its possible alignment with international standards such as IFC.

Author Contributions

Conceptualisation, E.J.R.-J.; methodology, E.J.R.-J.; software, E.J.R.-J.; validation, E.J.R.-J.; formal analysis, E.J.R.-J.; investigation, E.J.R.-J.; data curation, E.J.R.-J.; writing—original draft preparation, E.J.R.-J.; writing—review and editing, M.S.G.-C. and J.M.O.; visualisation, E.J.R.-J.; supervision, M.S.G.-C. and J.M.O.; project administration, M.S.G.-C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analysed in this study. The AllBIMclass classification system used in this study is openly accessible and can be downloaded free of charge at

https://www.allbimclass.com/ (accessed on 15 August 2025).

Acknowledgments

The first author would like to thank M. Socorro García-Cascales and José Manuel Olmos for their supervision and guidance during the preparation of this work. The support of the Universidad Politécnica de Cartagena (UPCT) within the framework of the Doctoral Program in Technology and Modelling in Civil, Mining and Environmental Engineering is also gratefully acknowledged.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| AECO | Architecture, Engineering, Construction and Operation |

| API | Application Programming Interface |

| BIM | Building Information Modelling |

| BQA | Building Quantity Attribute (CoClass) |

| CAD | Computer-Aided Design |

| CO2 | Carbon Dioxide |

| COVs | Volatile Organic Compounds |

| IAQ | Indoor Air Quality |

| IFC | Industry Foundation Classes |

| IoT | Internet of Things |

| O2 | Oxygen |

| PM1 | Particulate Matter with aerodynamic diameter ≤1 µm |

| PM2.5 | Particulate Matter with aerodynamic diameter ≤2.5 µm |

| PM10 | Particulate Matter with aerodynamic diameter ≤10 µm |

| SAREF | Smart Applications REFerence ontology |

| SIM | Subscriber Identity Module |

| SO2 | Sulphur Dioxide |

| NO2 | Nitrogen Dioxide |

| T | Temperature |

| H | Humidity |

| P | Pressure |

| VS.NET | Visual Studio .NET |

References

- Farmer, D.K.; Vance, M.E.; Abbatt, J.P.D.; Abeleira, A.; Alves, M.R.; Arata, C.; Boedicker, E.; Bourne, S.; Cardoso-Saldaña, F.; Corsi, R.; et al. Overview of HOMEChem: House observations of microbial and environmental chemistry. Environ. Sci. Process. Impacts 2019, 21, 1280–1300. [Google Scholar] [CrossRef]

- Mebrahtu, T.F.; Santorelli, G.; Yang, T.C.; Wright, J.; Tate, J.; McEachan, R.R.C. The effects of exposure to NO2, PM2.5 and PM10 on health service attendances with respiratory illnesses: A time-series analysis. Environ. Pollut. 2023, 333, 122123. [Google Scholar] [CrossRef]

- Schieweck, A.; Uhde, E.; Salthammer, T.; Salthammer, L.C.; Morawska, L.; Mazaheri, M.; Kumar, P. Smart homes and the control of indoor air quality. Renew. Sustain. Energy Rev. 2018, 94, 705–718. [Google Scholar] [CrossRef]

- Kumar, P.; Skouloudis, A.N.; Bell, M.; Viana, M.; Carotta, M.C.; Biskos, G.; Morawska, L. Real-time sensors for indoor air monitoring and challenges ahead in deploying them to urban buildings. Sci. Total Environ. 2016, 560–561, 150–159. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization (WHO). WHO Global Air Quality Guidelines: Particulate Matter (PM2.5 and PM10), Ozone, Nitrogen Dioxide, Sulfur Dioxide and Carbon Monoxide; World Health Organization: Geneva, Switzerland, 2021; Available online: https://www.who.int/publications/i/item/9789240034228 (accessed on 9 October 2024).

- Ma, Y.; Jiang, Y.; Li, L. Numerical simulation of PM2.5 distribution in indoor air. Procedia Eng. 2015, 121, 1939–1947. [Google Scholar] [CrossRef]

- Renard, E.J.; Olmos, J.M. Training and teaching available for BIM modeling software: Archicad, Revit and Allplan. In Proceedings of the 26th International Congress on Project Management and Engineering (CIDIP 2022), Terrassa, Spain, 5–8 July 2022; AEIPRO: Terrassa, Spain, 2022. Available online: http://dspace.aeipro.com/xmlui/handle/123456789/3322 (accessed on 14 August 2023).

- Salzano, A.; Zitiello, E.P.; Nicolella, M.; Gragnaniello, C. Digital evolution: From BIM to Digital Twin. In Proceedings of the 11th International Conference of Ar.Tec. (Scientific Society of Architectural Engineering), Colloqui.AT.e 2024; Corrao, R., Campisi, T., Colajanni, S., Saeli, M., Vinci, C., Eds.; Lecture Notes in Civil Engineering. Springer: Cham, Switzerland, 2025; Volume 612, pp. 681–693. [Google Scholar] [CrossRef]

- Valinejadshoubi, M.; Moselhi, O.; Iordanova, I.; Valdivieso, F.; Shakibabarough, A.; Bagchi, A. The Development of an Automated System for a Quality Evaluation of Engineering BIM Models: A Case Study. Appl. Sci. 2024, 14, 3244. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, S.; Cai, J.; Chen, J.; Li, S. A large language model-based platform for real-time building monitoring and occupant interaction. J. Build. Eng. 2025, 100, 111488. [Google Scholar] [CrossRef]

- Cui, W.; Chen, Y.; Xu, B. Application research of intelligent system based on BIM and sensors monitoring technology in construction management. Phys. Chem. Earth 2024, 134, 103546. [Google Scholar] [CrossRef]

- Construction Specifications Institute (CSI). OmniClass: A Strategy for Organizing Construction Information. Available online: https://www.csiresources.org/standards/omniclass (accessed on 12 September 2024).

- buildingSMART International. How Does IFC Work with Existing Classification Systems Such as Omniclass, Uniformat, etc.? Forum Post. 2019. Available online: https://forums.buildingsmart.org/t/how-does-ifc-work-with-existing-classification-systems-such-as-omniclass-uniformat-etc/804 (accessed on 18 September 2024).

- Asociación Española de Abastecimientos de Agua y Saneamiento (AEAS). Manual del Sistema de Clasificación BIM de AEAS—AeasBIMClass.v02; AEAS: Madrid, Spain, 2025; Available online: https://www.aeas.es/documentos/manuales-y-guias (accessed on 11 February 2025).

- Administrador de Infraestructuras Ferroviarias (ADIF). Anejo de Cláusulas BIM Para Obra; ADIF: Madrid, Spain, 2023; Available online: https://www.adif.es/empresas-y-contratacion/contratacion (accessed on 12 February 2025).

- Dirección General de Carreteras (DGC). Orden Circular OC 5/2024 Sobre el Sistema de Clasificación RCEclass (Versión 1.0); Ministerio de Transportes y Movilidad Sostenible: Madrid, Spain, 2024; Available online: https://www.transportes.gob.es/carreteras/rceclass (accessed on 13 February 2025).

- Patel, M.Y.; Vannucci, P.F.; Kim, J.; Berelson, W.M.; Cohen, R.C. Towards a hygroscopic growth calibration for low-cost PM2.5 sensors. Atmos. Meas. Tech. 2024, 17, 1051–1060. [Google Scholar] [CrossRef]

- Plantower. PMS5003 Particulate Matter Sensor. Available online: https://www.plantower.com/products_16/10.html (accessed on 1 March 2024).

- deSouza, P.; Kahn, R.; Stockman, T.; Obermann, W.; Crawford, B.; Wang, A.; Crooks, J.; Li, J.; Kinney, P. Calibrating networks of low-cost air quality sensors. Atmos. Meas. Tech. 2022, 15, 6309–6328. [Google Scholar] [CrossRef]

- González Rivero, R.A.; Morera Hernández, L.E.; Schalm, O.; Hernández Rodríguez, E.; Alejo Sánchez, D.; Morales Pérez, M.C.; Nuñez Caraballo, V.; Jacobs, W.; Martinez Laguardia, A. A low-cost calibration method for temperature, relative humidity, and carbon dioxide sensors used in air quality monitoring systems. Atmosphere 2023, 14, 191. [Google Scholar] [CrossRef]

- Renard-Julián, E.J.; Olmos, J.M.; García-Cascales, M.S. Evaluation of vertical stratification of PM1, PM2.5, and PM10 in residences using IoT sensors: Implications for BIM methodology. In Proceedings of the 28th International Congress on Project Management and Engineering (CIDIP 2024), Jaen, Spain, 2–5 July 2024; AEIPRO: Jaen, Spain, 2024. [Google Scholar] [CrossRef]

- ISO 12006-2:2015; Building Construction, Organization of Information About Construction Works, Part 2: Framework for Classification. International Organization for Standardization: Geneva, Switzerland, 2015.

- Royano, V.; Gibert, V.; Serrat, C.; Rapinski, J. Analysis of classification systems for the built environment: Historical perspective, comprehensive review and discussion. J. Build. Eng. 2023, 67, 105911. [Google Scholar] [CrossRef]

- ISO/IEC 81346-1:2022; Industrial Systems, Installations and Equipment and Industrial Products—Structuring Principles and Reference Designations—Part 1: Basic Rules. IEC/ISO: Geneva, Switzerland, 2022.

- ISO/IEC 81346-2:2019; Industrial Systems, Installations and Equipment and Industrial Products—Structuring Principles and Reference Designations—Part 2: Classification of Objects and Codes for Classes. IEC/ISO: Geneva, Switzerland, 2019.

- ISO/IEC 81346-12:2018; Industrial Systems, Installations and Equipment and Industrial Products—Structuring Principles and Reference Designations—Part 12: Construction Works and Building Services. IEC/ISO: Geneva, Switzerland, 2018.

- ISO 16739-1:2018; Industry Foundation Classes (IFC) for Data Sharing in the Construction and Facility Management Industries—Part 1: Data Schema. ISO: Geneva, Switzerland, 2018.

- ISO 16739-1:2024; Industry Foundation Classes (IFC) for Data Sharing in the Construction and Facility Management Industries—Part 1: Data Schema. ISO: Geneva, Switzerland, 2024.

- Okonta, E.D.; Rahimian, F.; Vukovic, V.; Rodriguez, S. Semantic interoperability on IoT: Aligning IFC and Smart Application Reference (SAREF) sensor data models. Autom. Constr. 2025, 177, 106328. [Google Scholar] [CrossRef]

- El-Amraoui-Farssi, A.; Gómez-Jauregui, V.; Manchado, C.; Otero, C. IFC for infrastructures: New open standards for intelligent data. In Advances in Design Engineering II, Proceedings of the INGEGRAF 2021, Valencia, Spain, 24–25 June

2021; Cavas Martínez, F., Peris-Fajarnes, G., Morer Camo, P., Lengua Lengua, I., Defez García, B., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2022; pp. 38–45. [Google Scholar] [CrossRef]

- Hasan, M.W. Building an IoT temperature and humidity forecasting model based on long short-term memory (LSTM) with improved whale optimization algorithm. Memories 2023, 6, 100086. [Google Scholar] [CrossRef]

- Salzano, A.; Cascone, S.; Zitiello, E.P.; Nicolella, M. HVAC system performance in educational facilities: A case study on the integration of digital twin technology and IoT sensors for predictive maintenance. J. Archit. Eng. 2025, 31, 04025004. [Google Scholar] [CrossRef]

- Clements, A.; Duvall, R.; Greene, D.; Dye, T. The Enhanced Air Sensor Guidebook; EPA/600/R-22/213; U.S. Environmental Protection Agency, Office of Research and Development: Washington, DC, USA, 2022. Available online: https://www.epa.gov/air-sensor-toolbox/how-use-air-sensors-air-sensor-guidebook (accessed on 20 June 2025).

- World Health Organization (WHO). WHO Guidelines for Indoor Air Quality: Selected Pollutants; WHO Regional Office for Europe: Copenhagen, Denmark, 2010; Available online: https://www.who.int/publications/i/item/9789289002134 (accessed on 20 June 2025).

- ANSI/ASHRAE Standard 55-2023; Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE): Peachtree Corners, GA, USA, 2023. Available online: https://www.ashrae.org/technical-resources/bookstore/standard-55-thermal-environmental-conditions-for-human-occupancy (accessed on 1 July 2025).

- ISO 7730:2021; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organization for Standardization (ISO): Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/85803.html (accessed on 1 July 2025).

- World Health Organization (WHO). Environmental Noise Guidelines for the European Region; WHO Regional Office for Europe: Copenhagen, Denmark, 2018; Available online: https://www.who.int/europe/publications/i/item/9789289053563 (accessed on 1 July 2025).

- European Parliament and Council. Directive 2002/49/EC of the European Parliament and of the Council of 25 June 2002 Relating to the Assessment and Management of Environmental Noise; Official Journal of the European Communities: Luxembourg, 2002; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:32002L0049 (accessed on 3 July 2025).

- EN 12464-1:2021; Light and Lighting—Lighting of Work Places—Part 1: Indoor Work Places. European Committee for Standardization (CEN): Brussels, Belgium, 2021.

- ISO/CIE 8995-1:2025; Lighting of Work Places—Part 1: Indoor. ISO: Geneva, Switzerland, 2025. Available online: https://www.iso.org/standard/76342.html (accessed on 4 July 2025).

- U.S. Green Building Council (USGBC). LEED v4 for Building Design and Construction; USGBC: Washington, DC, USA, 2013; Available online: https://www.usgbc.org/resources/leed-reference-guide-homes-design-and-construction (accessed on 1 July 2025).

- U.S. Environmental Protection Agency (EPA). Technical Assistance Document for the Reporting of Daily Air Quality Index (AQI); U.S. Environmental Protection Agency: Washington, DC, USA, 2018. Available online: https://www.airnow.gov/publications/air-quality-index/technical-assistance-document-for-reporting-the-daily-aqi/ (accessed on 15 April 2025).

- Kaewunruen, S.; Lin, Y.-H.; Guo, Y. BIM-Driven Digital Twin for Demolition Waste Management of Existing Residential Buildings. Sci. Rep. 2025, 15, 28989. [Google Scholar] [CrossRef]

- Elrifaee, M.; Zayed, T. Smart IoT-BIM Framework with Modified Zonal Safety Analysis (ZSA) for Real-Time Safety Monitoring in Construction. Autom. Constr. 2025, 178, 106431. [Google Scholar] [CrossRef]

- Ma, T.; Xiao, F.; Zhang, C.; Zhang, J.; Zhang, H.; Xu, K.; Luo, X. Digital Twin for 3D Interactive Building Operations: Integrating BIM, IoT-Enabled Building Automation Systems, AI, and Mixed Reality. Autom. Constr. 2025, 176, 106277. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-Data Mining Integrated Digital Twin Framework for Advanced Project Management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Liu, X.; Antwi-Afari, M.F.; Li, J.; Zhang, Y.; Manu, P. BIM, IoT, and GIS integration in construction resource monitoring. Autom. Constr. 2025, 174, 106149. [Google Scholar] [CrossRef]

- Piras, G.; Agostinelli, S.; Muzi, F. Smart Buildings and Digital Twin to Monitoring the Efficiency and Wellness of Working Environments: A Case Study on IoT Integration and Data-Driven Management. Appl. Sci. 2025, 15, 4939. [Google Scholar] [CrossRef]

Figure 1.

Components of the low-cost sensor kit used for air quality monitoring: PMS5003 optical particle sensor (PM1, PM2.5, PM10); DHT22 temperature and humidity sensor; NodeMCU ESP8266 microcontroller with Wi-Fi connectivity; 18,650 lithium battery; and battery charging and protection module (TP4056, NanJing Top Power ASIC Corp., Nanjing, China).

Figure 1.

Components of the low-cost sensor kit used for air quality monitoring: PMS5003 optical particle sensor (PM1, PM2.5, PM10); DHT22 temperature and humidity sensor; NodeMCU ESP8266 microcontroller with Wi-Fi connectivity; 18,650 lithium battery; and battery charging and protection module (TP4056, NanJing Top Power ASIC Corp., Nanjing, China).

Figure 2.

Schematic representation of IFC entities supporting sensor classification and integration. The central entity (IfcSensor/IfcSensorType) links to external classification systems (e.g., OmniClass, UniClass, CoClass, AllBIMclass) through IfcClassification, to geometry and location through IfcSpace/IfcElement, and to descriptive templates through Property Sets (e.g., Pset_SensorTypeCommon, Pset_PHistory). Connectivity with other systems is modelled by IfcRelConnectsPorts, which associates the sensor with an IfcDistributionPort and subsequently with an IfcElement (connected system or device). Complementary semantics can be added through ontology extensions such as SAREF, which introduce attributes like sensing range, value, timestamp or state.

Figure 2.

Schematic representation of IFC entities supporting sensor classification and integration. The central entity (IfcSensor/IfcSensorType) links to external classification systems (e.g., OmniClass, UniClass, CoClass, AllBIMclass) through IfcClassification, to geometry and location through IfcSpace/IfcElement, and to descriptive templates through Property Sets (e.g., Pset_SensorTypeCommon, Pset_PHistory). Connectivity with other systems is modelled by IfcRelConnectsPorts, which associates the sensor with an IfcDistributionPort and subsequently with an IfcElement (connected system or device). Complementary semantics can be added through ontology extensions such as SAREF, which introduce attributes like sensing range, value, timestamp or state.

Figure 3.

Hourly evolution of PM2.5 concentrations measured in kitchen (indoor) and balcony (outdoor) during one day of monitoring (sampling interval: 60 s). Significant indoor peaks are observed around 14:00 (cooking) and between 20:00 and 21:00 (oven use), absent in the outdoor measurements, confirming the indoor origin of these events. Concentrations gradually decrease to background levels (15–20 µg/m3) during oven cooling.

Figure 3.

Hourly evolution of PM2.5 concentrations measured in kitchen (indoor) and balcony (outdoor) during one day of monitoring (sampling interval: 60 s). Significant indoor peaks are observed around 14:00 (cooking) and between 20:00 and 21:00 (oven use), absent in the outdoor measurements, confirming the indoor origin of these events. Concentrations gradually decrease to background levels (15–20 µg/m3) during oven cooling.

Figure 4.

General hierarchical index of AllBIMclass v.1.0, structured into four main nodes: Architecture and Building, Civil Works and Infrastructure, Preliminary Works, and Environmental Sensors and IoT Devices. This overall organisation reflects the decision to adopt a single composite table, ensuring stability, coherence, and compatibility with BIM workflows.

Figure 4.

General hierarchical index of AllBIMclass v.1.0, structured into four main nodes: Architecture and Building, Civil Works and Infrastructure, Preliminary Works, and Environmental Sensors and IoT Devices. This overall organisation reflects the decision to adopt a single composite table, ensuring stability, coherence, and compatibility with BIM workflows.

Figure 5.

Hierarchical structure of the AllBIMclass v.1.0 node dedicated to environmental monitoring sensors and IoT devices. The classification unfolds into four levels (location, sensor type, power supply, and operation mode), providing semantic precision and interoperability for BIM-based environmental monitoring.

Figure 5.

Hierarchical structure of the AllBIMclass v.1.0 node dedicated to environmental monitoring sensors and IoT devices. The classification unfolds into four levels (location, sensor type, power supply, and operation mode), providing semantic precision and interoperability for BIM-based environmental monitoring.

Figure 6.

Integration of AllBIMclass in Autodesk Revit 2026.1. The test case illustrates an outdoor environmental sensor mounted on a streetlight, with the classification code and description correctly assigned.

Figure 6.

Integration of AllBIMclass in Autodesk Revit 2026.1. The test case illustrates an outdoor environmental sensor mounted on a streetlight, with the classification code and description correctly assigned.

Figure 8.