Study of the Deformation and Instability Characteristics and Treatment of Gentle Tilt-Creeping Open-Pit Mine Slopes Containing Weak Interlayers

Abstract

1. Introduction

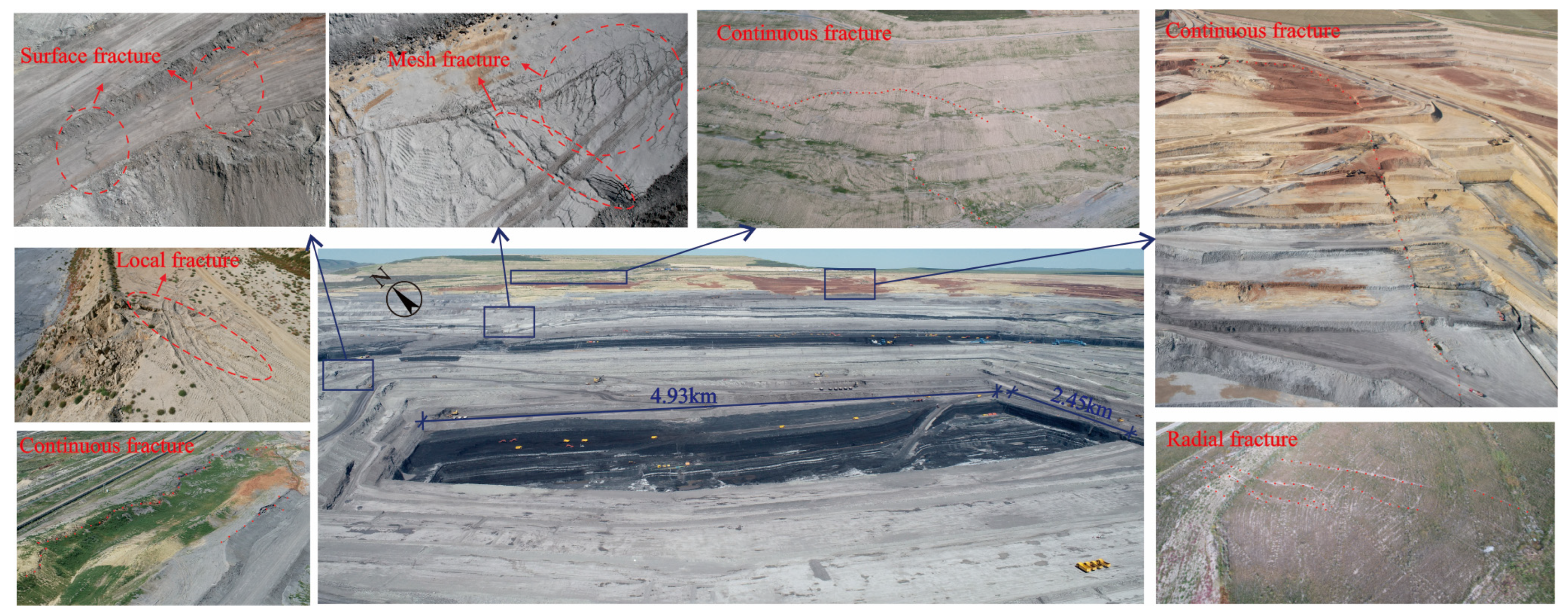

2. Project Overview

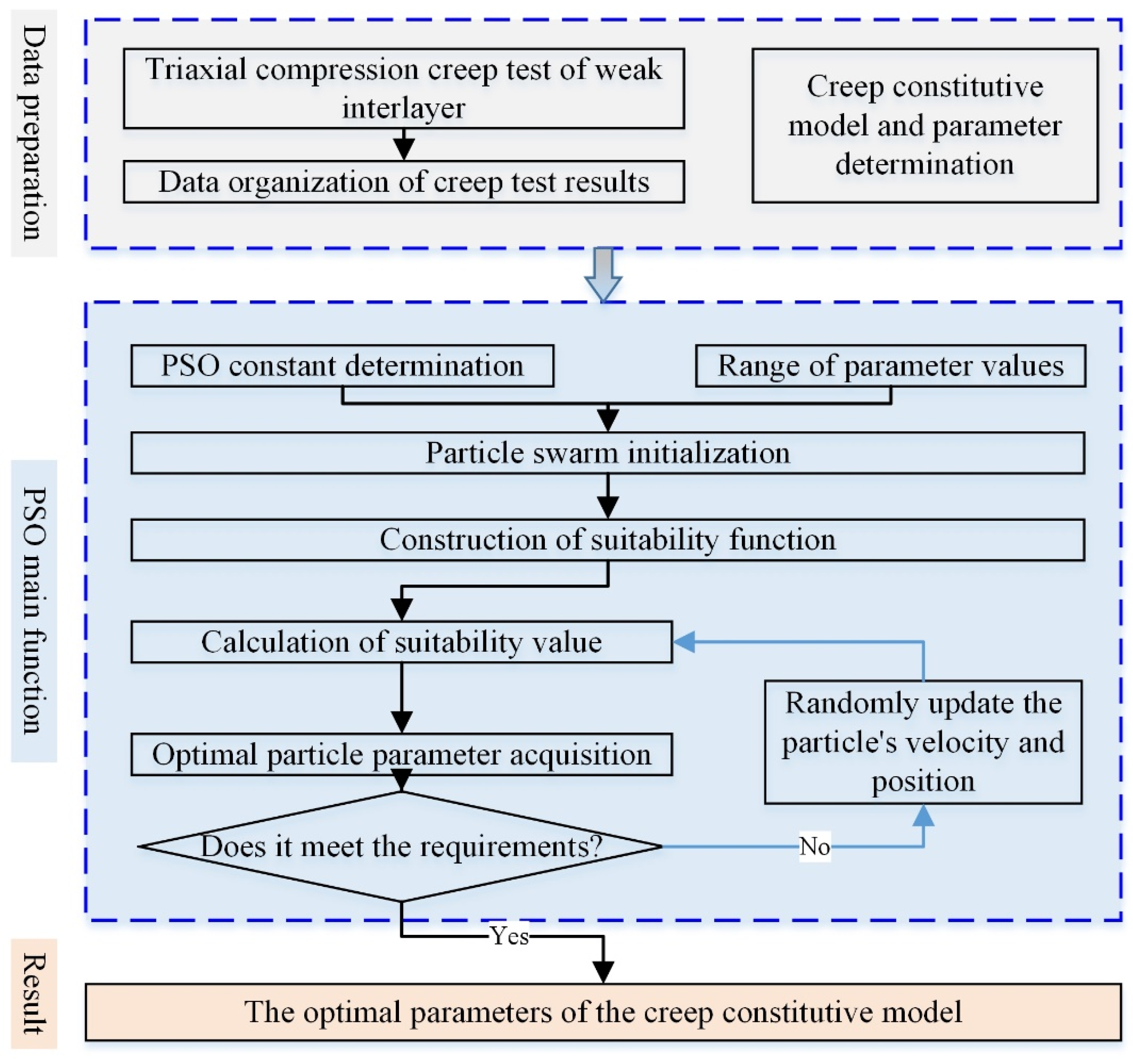

3. Creep Parameter Inversion and Model Construction of Weak Interlayer

3.1. Suitability Function Construction

- is the uniaxial stress;

- , is Young’s modulus;

- is the viscosity coefficient;

- t is the creep time;

- is the yield strength determined using the Mohr–Coulomb strength criterion.

- T is the test time in the whole creep test;

- is the strain theoretical value at time t;

- is the strain experimental data at time t.

3.2. Creep Model Parameters Inversion

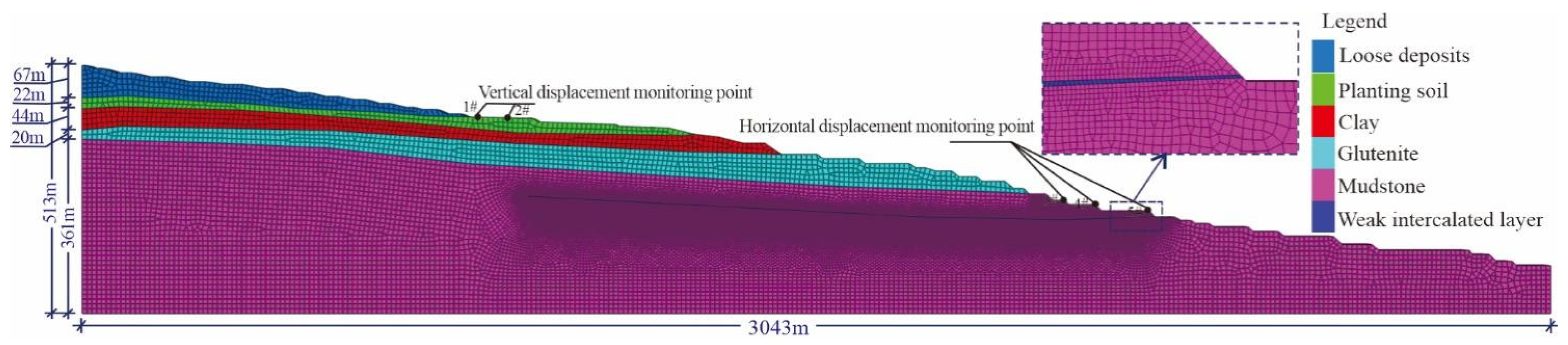

3.3. Typical Profile Model Construction

4. Results

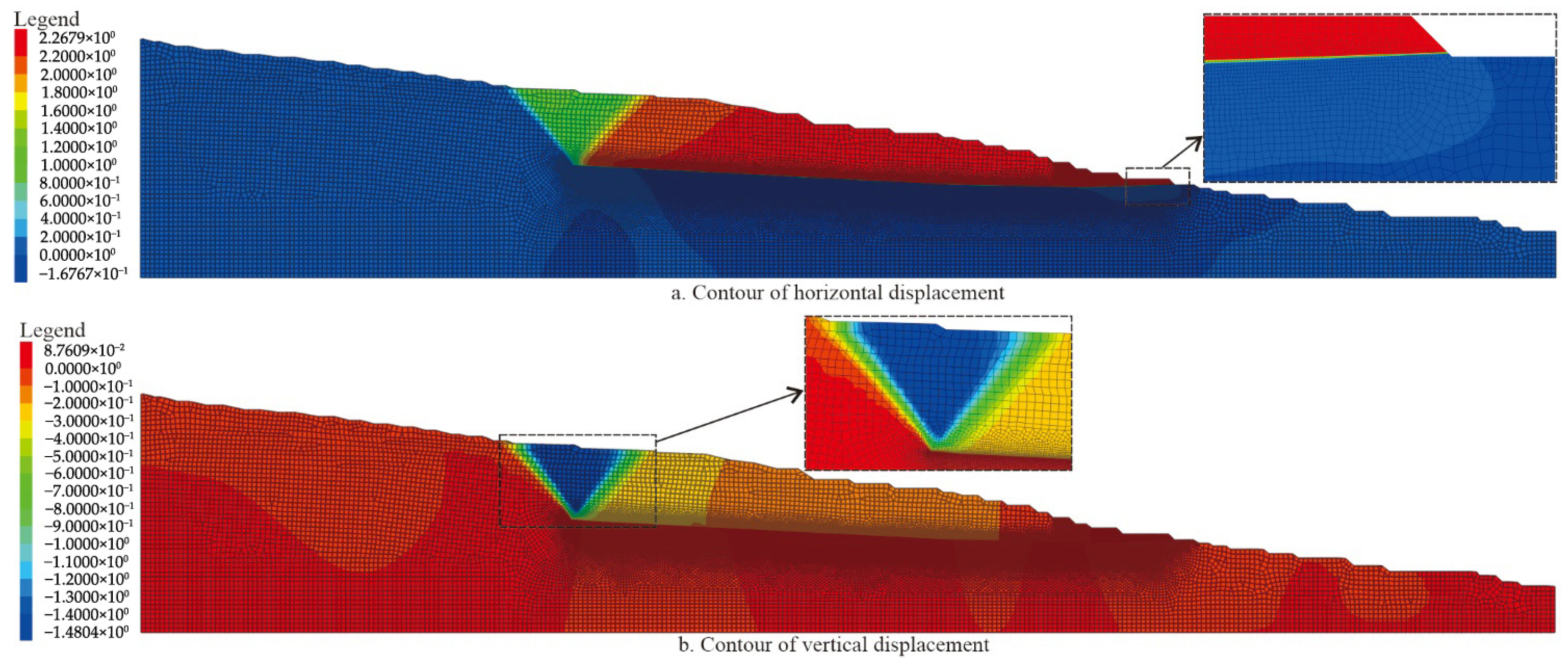

4.1. Slope Deformation

4.2. Distribution of Plastic Zone and Plastic Deformation

4.3. Treatment of Localized Solidification of the Weak Interlayers

5. Discussion

6. Conclusions

- (1)

- The creep parameters of the weak interlayer soil are a bulk modulus K of 7.35 MPa, shear modulus G1 of 81.20 MPa, shear modulus G2 of 1.02 MPa, viscosity coefficient η1 of 50.36 MPa∙h, viscosity coefficient η2 of 644.65 MPa∙h, and cohesion c of 21.34 kPa, and the internal friction angle is 9.02°.

- (2)

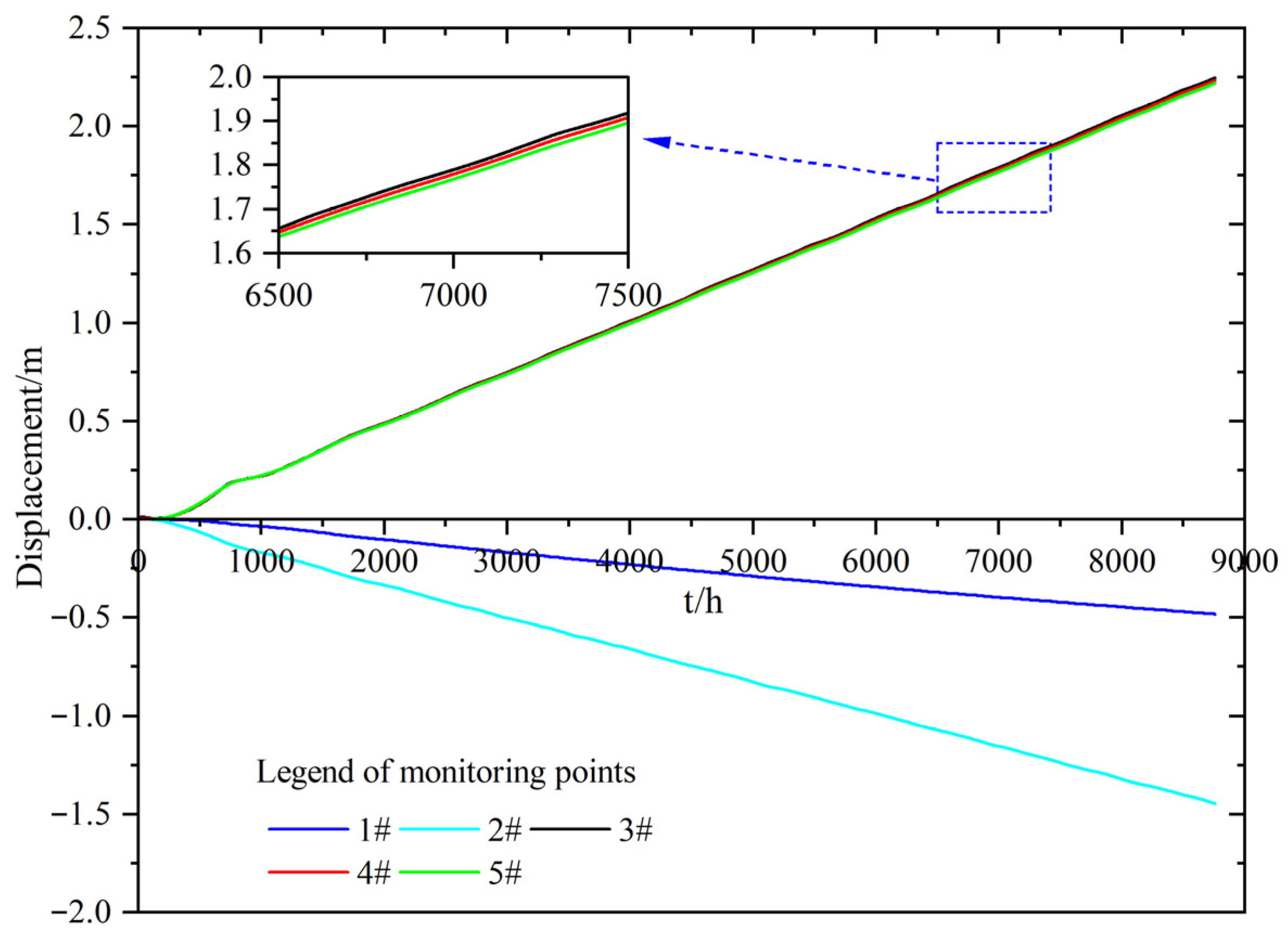

- The deformation and failure of this slope are mainly controlled by the weak interlayer, and the sliding body is mainly the rock and soil body above the interlayer. The deformation of the sliding body is mainly the overall horizontal deformation, and the maximum horizontal displacement after 1 year of free deformation reaches 2.27 m. The trailing edge of the sliding body forms a settlement wedge, and the maximum vertical displacement reaches 1.48 m after 1 year. The leading edge of the sliding belt and the trailing edge of the sliding body produce a penetrating plastic zone.

- (3)

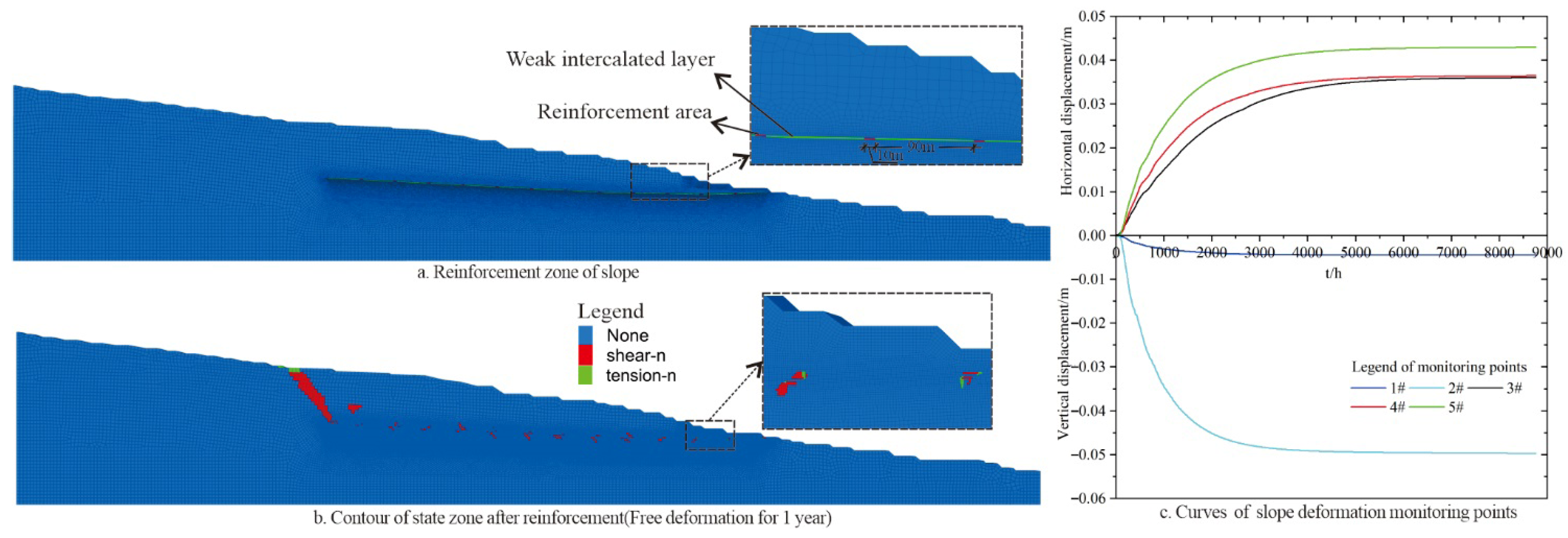

- Local reinforcement of the weak interlayer can effectively control slope deformation. Using the reinforcement scheme of local cement and interlayer soil mixing, the maximum free horizontal deformation and vertical deformation in 1 year are 4.25 cm and 4.95 cm, respectively, and the plastic zone is mainly distributed near the trailing edge of the sliding body and the reinforced soil; it is only partially penetrated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, X.; Ao, Z.; Zhou, W.; Qin, H.; Yang, Z.; An, W.; Li, X.; Liu, H. Geopolymer-based modification of blasting sealing materials and optimization of blasting block size in coal seams of open pit mines. Int. J. Min. Sci. Technol. 2023, 33, 1551–1562. [Google Scholar] [CrossRef]

- Yan, J.; Xing, X.; Li, Z.; Ni, W.; Zhao, L.; Zhu, C.; He, Y. Development of a DFN-based probabilistic block theory approach for bench face angle design in open pit mining. J. Rock Mech. Geotech. Eng. 2024, 16, 3047–3062. [Google Scholar] [CrossRef]

- Tao, Y.; Zhang, R.; Du, H. Failure Prediction of Open-Pit Mine Landslides Containing Complex Geological Structures Using the Inverse Velocity Method. Water 2024, 16, 430. [Google Scholar] [CrossRef]

- Raza, I.; Ullah, H.; Ehsan, M.I.; Khalid, P.; Iqbal, M.Z.; Rasheed, S. An integrated geophysical and geotechnical solutions for assessing slope instability challenges in open-pit mining: Safeguarding mining operations. Bull. Eng. Geol. Environ. 2025, 84, 83. [Google Scholar] [CrossRef]

- Li, G.; Hu, Z.; Wang, D.; Wang, L.; Wang, Y.; Zhao, L.; Jia, H.; Fang, K. Instability mechanisms of slope in open-pit coal mines: From physical and numerical modeling. Int. J. Min. Sci. Technol. 2024, 34, 1509–1528. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, Y.; Ren, H.; He, T.; Sun, Y. A Novel Approach to Automatically Identify Open-Pit Coal Mining Dynamics Based on Temporal Satellite Images. Remote Sens. 2025, 17, 1029. [Google Scholar] [CrossRef]

- Rezaei, M.; Mousavi, S.Z.S.; Esmaeili, K. Combination of Monte Carlo Simulation and Bishop Technique for the Slope Stability Analysis of the Gol-E-Gohar Iron Open Pit Mine. J. Min. Environ. 2025, 16, 613–632. [Google Scholar]

- Wang, C.; Min, H.; Zhu, T.; Wang, H.; Qin, W.; Zhang, G. Failure mechanism and stability analysis of the landslide: A case study for open pit iron mine in Xichang, Sichuan, China. Nat. Hazards 2022, 116, 663–691. [Google Scholar] [CrossRef]

- Lashgari, M.; Ozturk, C.A. Slope failure and stability investigations for an open pit copper mine in Turkey. Environ. Earth Sci. 2022, 81, 5. [Google Scholar] [CrossRef]

- Wang, F.; Ren, Q.; Jiang, X.; Niu, J.; Chen, B. Engineering geology and mechanism of multiple landslides in a large open-pit mine: The case of the Copper Mine in Qinghai Province, China. Bull. Eng. Geol. Environ. 2023, 82, 147. [Google Scholar] [CrossRef]

- Perumalla, R.; Kumar, R.S.; Govindaraj, M. Review of Slope Stability Analysis under Drawdown Conditions for Mine Slopes. Disaster Adv. 2025, 18, 222–227. [Google Scholar] [CrossRef]

- Zheng, H.; Jiang, P. The optimal control problem for stability analysis of general slopes. Eng. Geol. 2025, 352, 108089. [Google Scholar] [CrossRef]

- Ma, X.; Tao, Y.; Lu, M.; Sharma, A.; Zhang, J. Reliability analysis of soil slopes stabilized with piles under rainfall. J. Rock Mech. Geotech. 2025; in press. [Google Scholar] [CrossRef]

- Park, D. Stability analysis of earth slopes with counterweight fill: Kinematic limit analysis. Eng. Geol. 2025, 351, 108027. [Google Scholar] [CrossRef]

- He, Z.; Wang, B. Instability Process Model Test for Bedding Rock Slope with Weak Interlayer under Different Rainfall Conditions. Adv. Civ. Eng. 2018, 2018 Pt 2, 8201031. [Google Scholar] [CrossRef]

- Yang, H.; Pei, X.; Cui, S.; He, Z.; Lei, J. Effects of weak interlayers on seismic performance of bedding slopes based on shaking table tests. J. Rock Mech. Geotech. Eng. 2025; in press. [Google Scholar] [CrossRef]

- Li, J.; Hu, B.; Sheng, J.; Zhang, Z. Failure mechanism and treatment of mine landslide with gently-inclined weak interlayer: A case study of Laoyingzui landslide in Emei, Sichuan, China. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 61. [Google Scholar] [CrossRef]

- Bao, M.; Chen, Z.; Nian, G.; Zhang, L.; Zhu, T. Study on creep properties of weak layer rock of slope under damage coupling. Bull. Eng. Geol. Environ. 2024, 83, 154. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, T.; Li, S. Investigation on stability of large bedding slope affected by weak interlayer creep deformation. Mech. Time-Depend. Mater. 2023, 27, 227–250. [Google Scholar] [CrossRef]

- Yan, H.; Yu, F.; Zhu, C.; Yuan, J.; Wang, Q.; Wu, J. A new swelling—Creep model for red-bed mudstone and its application. Front. Earth Sci. 2025, 13, 1577262. [Google Scholar] [CrossRef]

- Liu, F.; Chen, W.; Yang, Z.; Deng, W.; Li, H.; Yang, T. Landslide Characteristics and Stability Control of Bedding Rock Slope: A Case Study in the Sijiaying Open-Pit Mine. Min. Metall. Explor. 2024, 41, 3007–3022. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, W.; Xu, H.; Huo, Y.; Wang, Y.; Li, S. Damage creep model and application for sandy mudstone considering the effect of immersion deterioration. J. Mech. 2024, 40, 325–335. [Google Scholar] [CrossRef]

- Su, Y.; Cai, G.; Yin, F.; Shan, Y.; Wang, H. Investigation of the creep behavior and time-dependent constitutive model of red-stratum mudstone fill material in high-fill subgrade. Constr. Build. Mater. 2025, 458, 139560. [Google Scholar] [CrossRef]

- Chai, B.; Yin, K.; Du, J.; Xiao, L. Correlation between incompetent beds and slope deformation at Badong town in the Three Gorges reservoir, China. Environ. Earth Sci. 2012, 69, 209–223. [Google Scholar] [CrossRef]

- Zhang, S.-L.; Zhu, Z.-H.; Qi, S.-C.; Hu, Y.-X.; Du, Q.; Zhou, J.-W. Deformation process and mechanism analyses for a planar sliding in the Mayanpo massive bedding rock slope at the Xiangjiaba Hydropower Station. Landslides 2018, 15, 2061–2073. [Google Scholar] [CrossRef]

- Li, J.; Hu, B.; Sheng, J.; Huang, L. A Fractional-Order Creep-Damage Model for Carbonaceous Shale Describing Coupled Damage Caused by Rainfall and Blasting. Fractal Fract. 2024, 8, 459. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, B.; Li, J.; Chen, K.; Zhong, Z.; Zhang, X. Analysis of dynamic disturbance and multistage shear creep damage evolution law of the weak intercalated layers in slope under the influence of coupled damage effect. Int. J. Damage Mech. 2024, 34, 236–269. [Google Scholar] [CrossRef]

- Xue, F.; Hu, B.; Zhong, Z.X.; Zhang, H.; Li, H. Study on shear creep characteristics of carbonaceous mud shale at different moisture contents under temperature cycling. Water 2025, 17, 567. [Google Scholar] [CrossRef]

- Han, G.; Zhang, C.; Singh, H.K.; Liu, R.; Chen, G.; Huang, S.; Zhou, H.; Zhang, Y. Characterizing large-scale weak interlayer shear zones using conditional random field theory. J. Rock Mech. Geotech. Eng. 2023, 15, 2611–2625. [Google Scholar] [CrossRef]

- Liu, D.; Shan, R.L.; Wang, H.; Li, Z.; Tong, X.; Zhao, Y.; Han, T.Y.; Zhao, X.P.; Li, Y.Z.; Bai, H.B.; et al. Study on triaxial creep mechanical properties and creep model of sandy mudstone with initial radial depth damage. Constr. Build. Mater. 2025, 483, 141772. [Google Scholar] [CrossRef]

- Liu, G.; Lei, J.; Guo, Z.; Chai, S.; Ren, C. Light weight obstacle detection for unmanned mining trucks in open-pit mines. Sci. Rep. 2025, 15, 9028. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of ICNN’95—International Conference on Neural Networks; IEEE: New York, NY, USA, 1995; Volume 4, pp. 1941–1948. [Google Scholar]

- Gan, L.; Shen, X.; Zhang, H. New deformation back analysis method for the creep model parameters using finite element nonlinear method. Clust. Comput. 2017, 20, 3225–3236. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, B.; Yu, X.; Xu, N.; Ye, J. Long-term stability and deformation behaviour of anhydrite mine-out for crude oil storage. Rock Mech. Rock Eng. 2020, 53, 1719–1735. [Google Scholar] [CrossRef]

- Aydan, Ö.; Ito, T.; Özcan, N.T.; Özkan, İ.; Rassouli, F. Impression creep tests as index creep testing technique in rock mechanics and rock engineering. Rock Mech. Rock Eng. 2024, 1–26. [Google Scholar] [CrossRef]

- Jose, D.; Kolathayar, S.; Nayak, S. 3D finite element analysis of anti-slide pile performance for slope stabilization. Geotech. Geol. Eng. 2025, 43, 74. [Google Scholar] [CrossRef]

- Han, C.; Zu, F.; Du, C.; Shi, L. Analysis of excavation stability and reinforcement treatment of the cutting slope under the influence of old goaf. Appl. Sci. 2022, 12, 8698. [Google Scholar] [CrossRef]

- Volanis, G.; Galanakis, D.; Bolanakis, N.; Maravelakis, E.; Borg, R.P.; Stavroulakis, G.E. Modelling and Stability Assessment of the Rock Cliffs and Xrobb l-Ġħaġin Neolithic Structure in Malta. Heritage 2024, 7, 2944–2958. [Google Scholar] [CrossRef]

| Confining Stress | Axial Stress (kPa) | Confining Stress | Axial Stress (kPa) | Confining Stress | Axial Stress (kPa) | Duration (h) |

|---|---|---|---|---|---|---|

| 50 kPa | 10 | 100 kPa | 20 | 200 kPa | 30 | ≥20 h |

| 20 | 40 | 50 | ≥20 h | |||

| 30 | 60 | 80 | ≥20 h | |||

| 40 | 80 | 100 | ≥20 h | |||

| 45 | 100 | 130 | ≥20 h | |||

| 50 | 120 | 150 | ≥20 h |

| Parameters | c/kPa | ||||||

|---|---|---|---|---|---|---|---|

| Value (suitability function 1) | 7.35 | 81.20 | 1.02 | 50.39 | 644.65 | 21.34 | 9.02 |

| Value (suitability function 2) | 16.47 | 0.92 | 38.60 | 734.82 | 60.77 |

| Parameters | μ | c/kPa | φ | ||

|---|---|---|---|---|---|

| Loose deposits | 1870 | 290 | 0.27 | 30 | 45 |

| Cultivated soils | 1910 | 51 | 0.26 | 41.1 | 35.6 |

| Clays | 1950 | 67 | 0.26 | 44.5 | 37.5 |

| Gravel | 1970 | 1050 | 0.25 | 223 | 36.6 |

| Mudstones | 2040 | 1480 | 0.23 | 205.6 | 35.7 |

| Parameters | μ | c/kPa | φ | ||

|---|---|---|---|---|---|

| Reinforcement | 2140 | 350 | 0.21 | 5000 | 45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wang, G.; Wang, M.; Wang, H. Study of the Deformation and Instability Characteristics and Treatment of Gentle Tilt-Creeping Open-Pit Mine Slopes Containing Weak Interlayers. Appl. Sci. 2025, 15, 9960. https://doi.org/10.3390/app15189960

Wang X, Wang G, Wang M, Wang H. Study of the Deformation and Instability Characteristics and Treatment of Gentle Tilt-Creeping Open-Pit Mine Slopes Containing Weak Interlayers. Applied Sciences. 2025; 15(18):9960. https://doi.org/10.3390/app15189960

Chicago/Turabian StyleWang, Xiaojie, Guihe Wang, Meimei Wang, and Hanxun Wang. 2025. "Study of the Deformation and Instability Characteristics and Treatment of Gentle Tilt-Creeping Open-Pit Mine Slopes Containing Weak Interlayers" Applied Sciences 15, no. 18: 9960. https://doi.org/10.3390/app15189960

APA StyleWang, X., Wang, G., Wang, M., & Wang, H. (2025). Study of the Deformation and Instability Characteristics and Treatment of Gentle Tilt-Creeping Open-Pit Mine Slopes Containing Weak Interlayers. Applied Sciences, 15(18), 9960. https://doi.org/10.3390/app15189960