Color and Texture of Wheat and Whole Grain Wheat Salty Crackers—Technological Aspects of Cricket Powder Addition

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cracker Manufacturing

2.3. Determination of Crackers Physical Properties

2.3.1. Cracker Color

- As deltaEF, to compare the color of wheat WG flour and the CRPW per contra the WF one.

- As deltaEC4+4, to quantify the color change within a pair of 4-member cracker subsets separately (that is, for WF-5, WF-10, and WF-15 versus WF-0, and for WG-5, WG-10, and WG-15 versus WG-0).

- As deltaEC8, to quantify the color similarity within an 8-member set of crackers independently on the wheat flour type used (WF-5, WF-10, and WF-15 together with WG-0, WG-5, WG-10, and WG-15 versus WF-0 solely).

- As deltaE pairwise, to quantify the color difference in recipe-related pairs WF-0–WG-0, WF-5–WG-5, WF-10–WG-10, and WF-15–WG-15. In general, the deltaEpairwise index could be calculated according to Equation (1), but also simply as a difference “deltaEpairwise (WG-i) − deltaEpairwise (WF-i)”, where i is the CRPW addition level 0, 5, 10, or 15%.

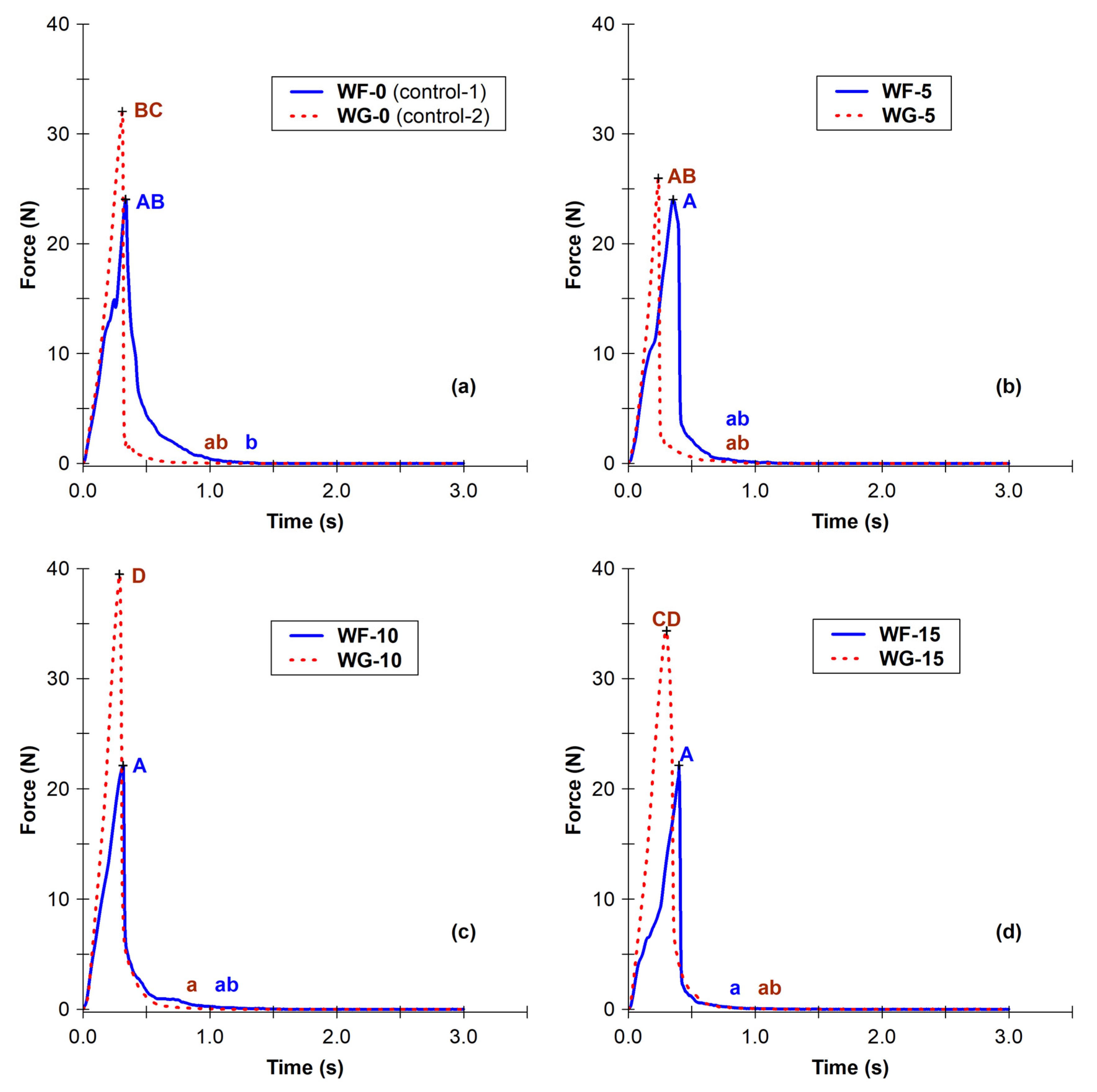

2.3.2. Crackers Texture

- Test mode ‘Compression’;

- Trigger ‘Auto (Force)’, and trigger force 0.049 N;

- Support gap 40 mm (the initial as well as post-test position of the blade edge above the inserted cracker);

- Distance 20 mm (final positions of the blade under the edge of the side supports, to break a sample surely);

- Probe test speed 3 mm/s;

- Calibration by weights of 5000 g before each day of measurement.

- Thickness (height);

- Hardness (force 1 ≈ peak-1 height);

- Flexibility (distance-1 ≈ time < t0; tpeak 1>);

- Breaking work (defined as the area ‘Force Distance 1:2’).

2.4. Summary Data of Sensory Analysis

- Overall appearance;

- Intensity of flavor;

- Pleasantness of flavor;

- Fragility;

- Hardness;

- Pleasantness of texture;

- Pleasantness of overall taste;

- Intensity of fatty taste;

- Pleasantness of fatty taste;

- Intensity of salty taste;

- Pleasantness of salty taste;

- Intensity of bitter taste;

- Off-flavor intensity.

2.5. Statistical Analysis

2.5.1. Analysis of Variance (ANOVA)

- SDR = 0%: Samples are statistically similar (the arithmetic means of the analyzed items are signed by 1 letter solely).

- SDR = 100%: The samples are completely statistically different (a count of the ANOVA letters is equal to the total number of items under evaluation).

2.5.2. Correlation Analysis

- As a linear Pearson correlation coefficient r (rX∙Y), including both variance factors, Wheat flour type and CRPW addition level, into the color, texture, and sensory dataset.

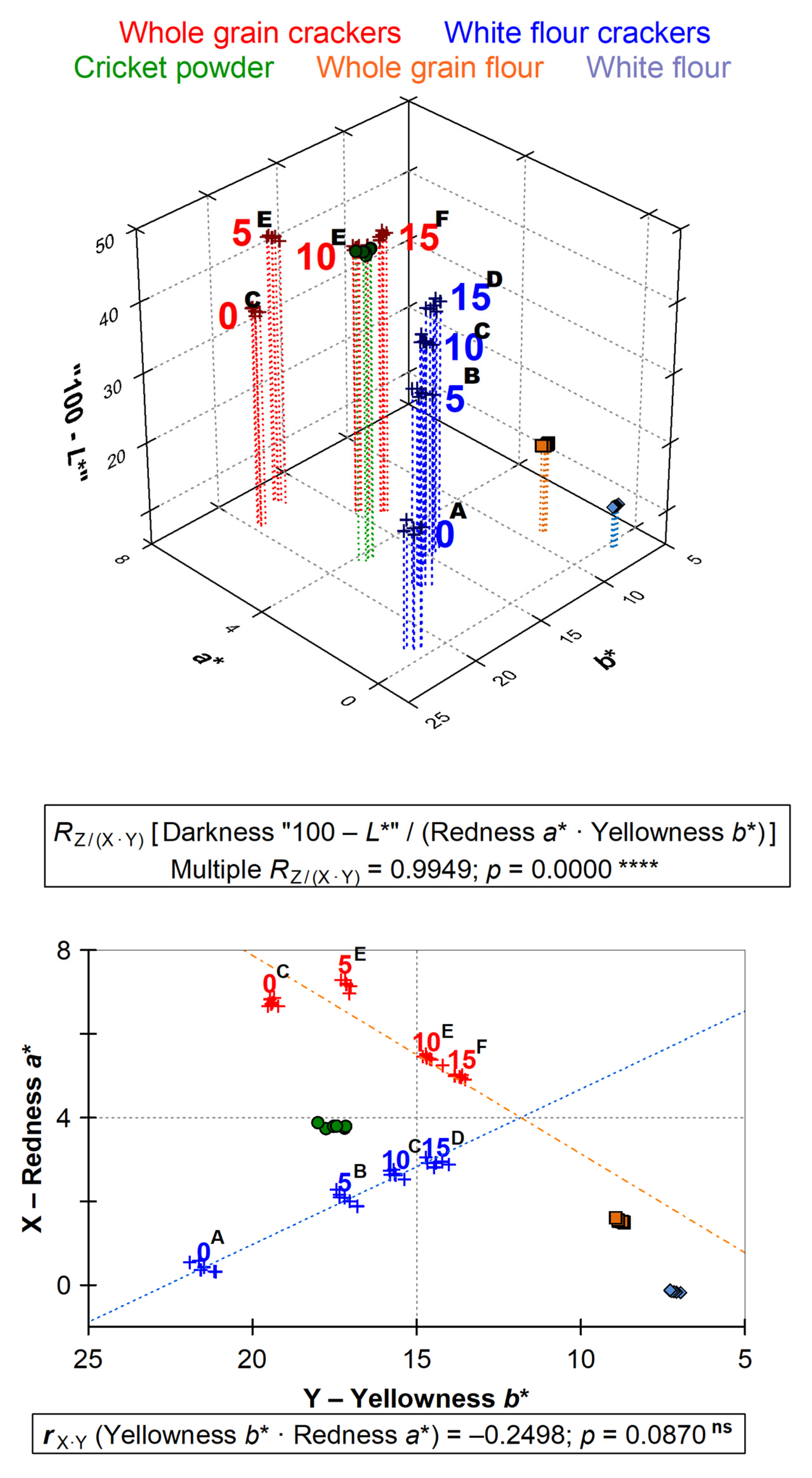

- As a multiple linear Galton–Pearson correlation coefficient RZ/(X∙Y), which combines linear regression and linear correlation for 3 selected variables [20]. The cracker texture parameters of hardness, flexibility, stiffness, and breaking work have been correlated to 3 pairs of the CIE colors: (a) darkness “100 − L*” − redness a*; (b) darkness “100 − L*” − yellowness b*; and (c) redness a* − yellowness b*. The significance of the relationships among 3 tested variables was expressed by the ‘calculated likelihood p’.

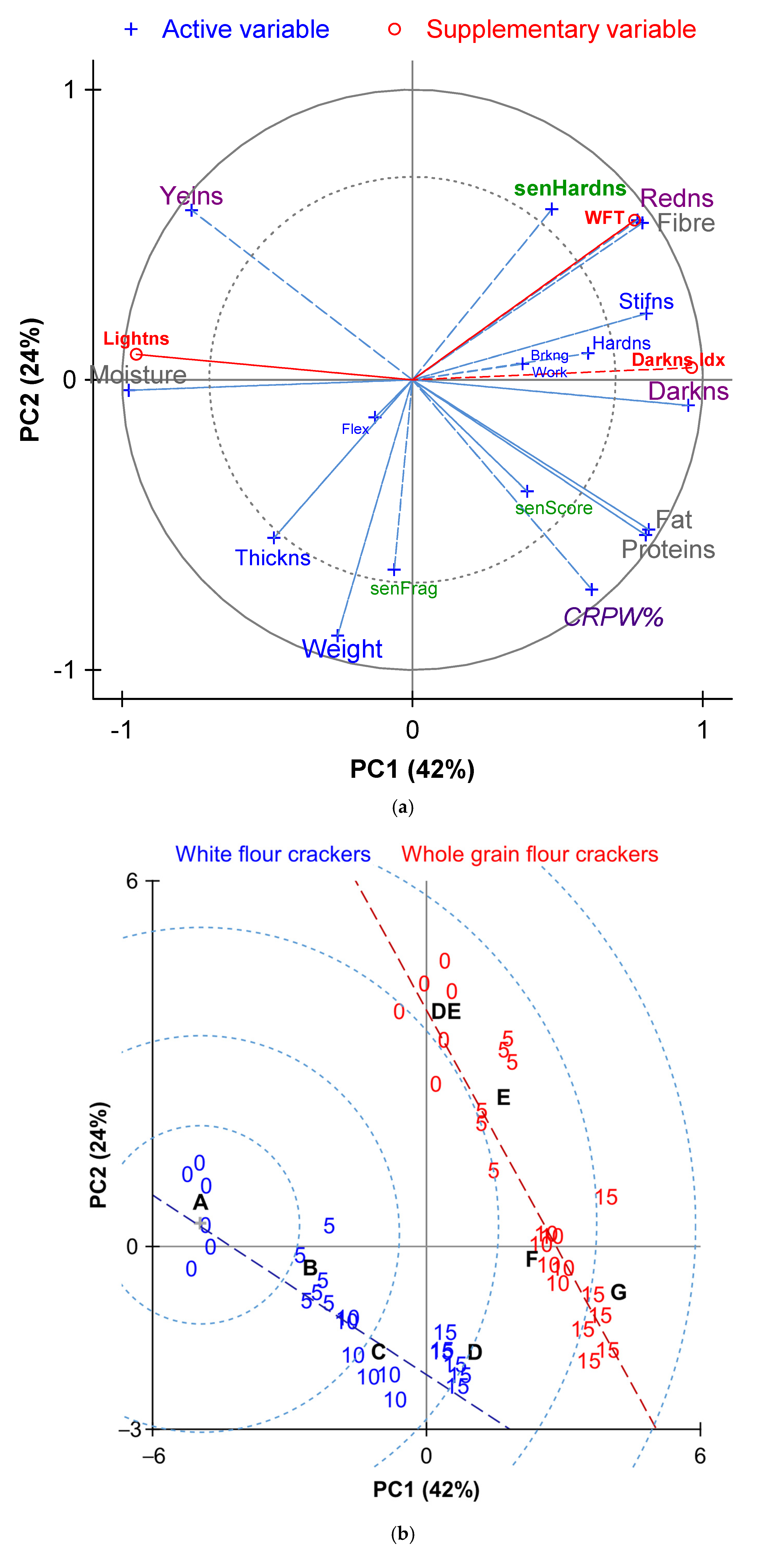

2.5.3. Principal Component Analysis (PCA) and the Euclidean Distances

3. Results and Discussion

3.1. Water Absorption of WF, WG, and CRPW

3.2. Color of Wheat Flour, Cricket Powder, and Non-Enriched Wheat Control Crackers

3.3. Crackers’ Physical Properties

3.3.1. Cracker Color

3.3.2. Crackers Weight and Thickness

3.3.3. Cracker Textural Properties

3.4. Statistical Analysis of Summary Sensory Data

- Overall appearance (64 A–78 A pts.);

- Intensity of flavor (14 A–60 C pts.);

- Pleasantness of flavor (59 A–70 A pts.);

- Fragility (33 A–68 B pts.);

- Hardness (45 A–74 D pts.);

- Pleasantness of texture (55 A–80 B pts.);

- Pleasantness of overall taste (50 A–78 B pts.);

- Intensity of fatty taste (22 A–35 A pts.);

- Pleasantness of fatty taste (55 A–72 A pts.);

- Intensity of salty taste (32 A–55 A pts.);

- Pleasantness of salty taste (59 A–74 A pts.);

- Intensity of bitter taste (4 A–37 C pts.);

- Off-flavor intensity (4 A–30 B pts.).

- Sensory score (534 A–631 B pts.);

- Overall sensory acceptability (43 A–50% B).

3.5. Statistical Exploration of Data

3.5.1. Correlation Analysis

3.5.2. Principal Components Analysis (PCA)

- I + II. quadrants: Connection between chemical composition (fat and protein content, and the CRPW addition level) and surface darkness “100 − L*” (or the lightness L* in the IV. quadrant), together with texture parameters; these bio-components, fat and proteins, are responsible for the fragility of the cracker in general, and the CRPW elevated proportion of both.

- Border of the I. and II. quadrant: Darkness “100 − L*”, influenced by or connected with all the primary variables located on the positive PC1 semi-space.

- III. quadrant: Thickness, weight, and the product’s surface lightness L*, dependent on the moisture content in baked crackers.

- IV. quadrant: Pair of lightness–yellowness as an antipode of the CRPW addition level, dependent also on moisture content in baked goods.

- Fragility reflected mainly the cracker’s weight and thickness;

- Sensory hardness corresponded with the fiber content and the product redness as well as with the instrumental hardness;

- The sensory score, as a complex quality indication, depended on the dose of the CRPW presented in the piece just tested (probably interacting with the personal preferences of each assessor).

- Cracker group WF-0 and WF-5: The addition of 5% CRPW in the WF shortened the distance to WG-0 cracker almost to a half, and the texture parameters have been gently modified; this is potentially the most preferred cracker formulation for common consumers (statistical similarity in this pair of products 64%).

- Cracker group WF-10, WG-0, and WG-5: This is likely a compromise of the nutritional enrichment of the WF and the quality of cracker; these two modified formulations would be suitable for semi-industrial production directly (similarities with the WF-0 sample 47%, 30%, and 25%, respectively).

- Cracker group WF-15, WG-10, and WG-15: These formulations are potentially applicable in bakery practice, but a partial modification of the recipe is necessary (similarities to the WF-0 specimen 35%, 13%, and 0%, respectively).

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| (a) | |||||

| Variability descriptor | Darkness “100 −L*” | Redness a* | Yellowness b* | deltaEC4+4 1 | Darkness Index 3 |

| Count of different samples (variability) | 4 (A, B, D, E) | 4 (A, B, C, D) | 4 (B, C, D, F) | 4 (A, E, F, G) | 4 (A, B, C, E) |

| Total count of samples | 4 | ||||

| SDR | 100% | 100% | 100% | 100% | 100% |

| (b) | |||||

| Variability descriptor | Darkness “100 − L*” | Redness a* | Yellowness b* | deltaEC4+4 | Darkness Index |

| Count of different samples (variability) | 3 (C, F, G) | 4 (E, F, G, H) | 4 (A, B, D, E) | 4 (A, B, C, D) | 3 (C, E, F) |

| Total count of samples | 4 | ||||

| SDR | 75% | 100% | 100% | 100% | 75% |

| (c) | |||||

| Variability descriptor | Darkness “100 − L*” | Redness a* | Yellowness b* | deltaEC8 2 | Darkness Index |

| Count of different samples (variability) | 7 (A–G) | 7 (A–G) | 6 (A–F) | 6 (A–F) | 7 (A–G) |

| Total count of samples | 8 | ||||

| SDR | 88% | 88% | 75% | 75% | 88% |

| (a) | ||||||

| Variability descriptor | Weight | Thickness | Hardness | Flexibility | Stiffness 1 | Breaking work 2 |

| Count of different samples (variability) | 2 (B, C) | 2 (BC, DE) | 1 (AB) | 2 (A, B) | 1 (AB) | 1 (AB) |

| Total count of samples | 4 | |||||

| SDR | 50% | 50% | 0% | 50% | 0% | 0% |

| (b) | ||||||

| Variability descriptor | Weight | Thickness | Hardness | Flexibility | Stiffness | Breaking work |

| Count of different samples (variability) | 2 (A, B) | 2 (A, B) | 2 (AB, D) | 1 (AB) | 2 (BC, D) | 2 (A, B) |

| Total count of samples | 4 | |||||

| SDR | 50% | 50% | 50% | 0% | 50% | 50% |

| (c) | ||||||

| Variability descriptor | Weight | Thickness | Hardness | Flexibility | Stiffness | Breaking work |

| Count of different samples (variability) | 3 (A–C) | 5 (A–E) | 4 (A–D) | 2 (A–B) | 2 (A–B) | 4 (A–D) |

| Total count of samples | 8 | |||||

| SDR | 38% | 63% | 50% | 25% | 25% | 50% |

| (a) | ||||

| Variability descriptor | Sensory Fragility | Sensory Hardness | Sensory Score | Sensory Acceptability 1 |

| Count of different samples (variability) | 1 (AB) | 1 (AB) | 1 (AB)p | 1 (AB) |

| Total count of samples | 4 | |||

| SDR | 0% | 0% | 0% | 0% |

| (b) | ||||

| Variability descriptor | Sensory Fragility | Sensory Hardness | Sensory Score | Sensory Acceptability |

| Count of different samples (variability) | 1 (AB) | 1 (BCD) | 1 (AB) | 1 (AB) |

| Total count of samples | 4 | |||

| SDR | 0% | 0% | 0% | 0% |

| (c) | ||||

| Variability descriptor | Sensory Fragility | Sensory Hardness | Sensory Score | Sensory Acceptability |

| Count of different samples (variability) | 2 (A, B) | 2 (A, BCD) | 2 (A, B) | 2 (A, B) |

| Total count of samples | 8 | |||

| SDR | 25% | 25% | 25% | 25% |

| Cracker Characteristics | Principal Component | ||||

|---|---|---|---|---|---|

| – property | – active variable | – PC1 | – PC2 | – PC3 | – Sum PC1–3 |

| Composition | Moisture | 95 *** | 0 ns | 1 ns | 97 |

| Fat | 66 *** | 27 ** | 4 ns | 97 | |

| Proteins | 65 *** | 29 ** | 3 ns | 97 | |

| Fiber | 63 *** | 29 ** | 3 ns | 95 | |

| CRPW% | 38 *** | 52 *** | 5 ns | 96 | |

| Weight | 7 ns | 78 *** | 4 ns | 89 | |

| Thickness | 23 ** | 30 ** | 30 ** | 82 | |

| Texture | Hardness | 37 *** | 1 ns | 56 *** | 93 |

| Flexibility | 2 ns | 2 ns | 75 *** | 78 | |

| Breaking work | 14 * | 0 ns | 76 *** | 90 | |

| Stiffness | 65 *** | 5 ns | 3 ns | 73 | |

| Surface color | Darkness “100 − L*” | 90 *** | 1 ns | 5 ns | 96 |

| Redness a* | 60 *** | 30 ** | 0 ns | 91 | |

| Yellowness b* | 58 *** | 34 ** | 4 ns | 96 | |

| Sensory crispness | 0 ns | 43 ** | 1 ns | 44 | |

| Sensory hardness | 23 ** | 35 ** | 1 ns | 59 | |

| Sensory score | 16 * | 15 * | 13 * | 43 | |

| Average of active variables | 42 | 24 | 17 | 83 | |

| – supplementary variable | – PC1 | – PC2 | – PC3 | – Sum PC1–3 | |

| WFT | 59 *** | 30 *** | 5 ns | 94 | |

| Whiteness L* | 90 *** | 1 ns | 5 ns | 96 | |

| Darkness Index | 93 *** | 0 ns | 3 ns | 96 | |

| Average of supplementary variables | 81 | 10 | 4 | 95 | |

References

- Regulation EU No. 2015/2283. On Novel Foods, Amending Regulation (EU) No 1169/2011 of the European Parliament and of the Council and Repealing Regulation (EC) No 258/97 of the European Parliament and of the Council and Commission Regulation (EC) No 1852/2001. Available online: https://eur-lex.europa.eu/eli/reg/2015/2283/oj/eng (accessed on 1 May 2025).

- Omuse, E.R.; Tonnang, H.E.; Yusuf, A.A.; Machekano, H.; Egonyu, J.P.; Kimathi, E.; Mohamed, S.F.; Kassie, M.; Subramanian, S.; Onditi, J.; et al. The global atlas of edible insects: Analysis of diversity and commonality contributing to food systems and sustainability. Sci. Rep. 2024, 14, 5045. [Google Scholar] [CrossRef] [PubMed]

- Stull, V.J.; Weir, T.L. Chitin and omega-3 fatty acids in edible insects have underexplored benefits for the gut microbiome and human health. Nat. Food 2023, 4, 283–287. [Google Scholar] [CrossRef] [PubMed]

- Kipkoech, C. Beyond proteins—Edible insects as a source of dietary fiber. Polysaccharides 2023, 4, 116–128. [Google Scholar] [CrossRef]

- WHO. Protein and Amino Acid Requirements in Human Nutrition: Report of a Joint WHO/FAO/UNU Expert Consultation; World Health Organization: Geneva, Switzerland, 2007; 284p, ISBN 92-4-1209356. Available online: https://iris.who.int/bitstream/handle/10665/43411/WHO_TRS_935_eng.pdf (accessed on 26 June 2025).

- Orkusz, A. Edible Insects versus meat—Nutritional comparison: Knowledge of their composition is the key to good health. Nutrients 2021, 13, 1207. [Google Scholar] [CrossRef] [PubMed]

- de Gier, S.; Verhoeckx, K. Insect (food) allergy and allergens. Mol. Immunol. 2018, 100, 82–106. [Google Scholar] [CrossRef] [PubMed]

- Bartkiene, E.; Starkute, V.; Katuskevicius, K.; Laukyte, N.; Fomkinas, M.; Vysniauskas, E.; Kasciukaityte, P.; Radvilavicius, E.; Rokaite, S.; Medonas, D.; et al. The contribution of edible cricket flour to quality parameters and sensory characteristics of wheat bread. Food Sci. Nutr. 2022, 10, 4319–4330. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Liu, M.; Li, X.; Pan, F.; Wu, X.; Fang, X.; Zhou, F.; Peng, W.; Tian, W. Applications of insect nutrition resources in animal production. J. Agric. Food Res. 2024, 15, 100966. [Google Scholar] [CrossRef]

- Amoah, I.; Cobbinah, J.C.; Yeboah, J.A.; Essiam, F.A.; Lim, J.J.; Tandoh, M.A.; Rush, E. Edible insect powder for enrichment of bakery products—A review of nutritional, physical characteristics and acceptability of bakery products to consumers. Future Foods 2023, 8, 100251. [Google Scholar] [CrossRef]

- Ardoin, R.; Marx, B.D.; Boeneke, C.; Prinyawiwatkul, W. Effects of cricket powder on selected physical properties and US consumer perceptions of wholewheat snack crackers. Int. J. Food Sci. Technol. 2021, 56, 4070–4080. [Google Scholar] [CrossRef]

- Hradecka, B.; Stara, L.; Kourimsky, T.; Stupak, M.; Svec, I.; Slukova, M.; Skrivan, P.; Hajslova, J. Salty crackers enriched with cricket (Acheta domesticus) powder: A comprehensive quality and safety assessment study. Food Chem. X 2025, 30, 102918. [Google Scholar] [CrossRef] [PubMed]

- Decree No. 18/2020 Coll. Ministry of Agriculture of the Czech Republic. Available online: https://www.e-sbirka.cz/sb/2020/18?zalozka=text (accessed on 25 June 2025). (In Czech).

- AACC Method 56-11.01; Solvent Retention Capacity Profile. Approved Methods of the American Association of Cereal Chemists. 10th ed. AACC Press: St. Paul, MN, USA, 2000.

- AACC Method 54-21.01; Solvent Retention Capacity Profile. Approved Methods of the American Association of Cereal Chemists. 10th ed. AACC Press: St. Paul, MN, USA, 2000.

- Robertson, A.R. The CIE 1976 Color-Difference Formulae. Color Res. Appl. 1977, 2, 7–11. [Google Scholar] [CrossRef]

- Shevell, S.K. Color Appearance. In The Science of Color, 2nd ed.; Shevell, S.K., Ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2003; pp. 149–190. ISBN 978-0-444-51251-2. [Google Scholar] [CrossRef]

- Zhu, K.; Kanu, P.J.; Claver, I.P.; Zhu, K.; Qian, H.; Zhou, H. A method for evaluating Hunter whiteness of mixed powders. Adv. Powder Technol. 2009, 20, 123–126. [Google Scholar] [CrossRef]

- Axsom, T.; Villasenor, H. Engineering fundamentals refresh: Strength versus stiffness versus hardness. Fictiv. 17 February 2023. Available online: https://www.fictiv.com/articles/engineering-fundamentals-refresh-strength-vs-stiffness-vs-hardness (accessed on 23 June 2025).

- Meloun, M.; Militký, J. Chapter 7—Correlation. In Statistical Data Analysis: A Practical Guide, 3rd ed.; Meloun, M., Militký, J., Eds.; Woodhead Publishing: New Delhi, India, 2011; pp. 631–666. ISBN 978-0-85709-109-3. [Google Scholar] [CrossRef]

- Chabanet, C. Statistical analysis of sensory profiling data. Graphs for presenting results (PCA and ANOVA). Food Qual. Prefer. 2000, 11, 159–162. [Google Scholar] [CrossRef]

- Roudaut, G.; Dacremont, C.; Vallès Pàmies, B.; Colas, B.; Le Meste, M. Crispness: A critical review on sensory and material science approaches. Trends Food Sci. Technol. 2002, 13, 217–227. [Google Scholar] [CrossRef]

- Man, D.; Olchawa, R. The Possibilities of using BCI technology in biomedical engineering. In Biomedical Engineering and Neuroscience; Hunek, W., Paszkiel, S., Eds.; BCI 2018; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2018; Volume 720, pp. 30–37. [Google Scholar] [CrossRef]

- Hrušková, M.; Vítová, M. Laboratory pasta experiment. Mlynářské Nov. 2007, 2, 7–9. (In Czech) [Google Scholar]

- Kweon, M. USDA 2017. Chemically-Leavened Cracker Baking Procedure. Available online: https://www.ars.usda.gov/midwest-area/wooster-oh/corn-soybean-and-wheat-quality-research/docs/cracker-baking-procedure/ (accessed on 23 July 2025).

- Kim, E.H.-J.; Corrigan, V.K.; Wilson, A.J.; Waters, I.R.; Hedderley, D.I.; Morgenstern, M.P. Fundamental fracture properties associated with sensory hardness of brittle solid foods. J. Texture Stud. 2012, 43, 49–62. [Google Scholar] [CrossRef]

- Mieszkowska, A.; Marzec, A. Structure analysis of short-dough biscuits and its correlation with sensory discriminants. J. Texture Stud. 2015, 46, 313–320. [Google Scholar] [CrossRef]

- Chauvin, M.A.; Ross, C.F.; Pitts, M.; Kupferman, E.; Swanson, B. Relationship between instrumental and sensory determination of apple and pear texture. J. Food Qua. 2010, 33, 181–198. [Google Scholar] [CrossRef]

| Flour Sample 1 | Darkness “100 − L*” | Redness a* | Yellowness b* | deltaEF 2 | Darkness Index 3 |

|---|---|---|---|---|---|

| WF | 11.01 ± 0.09 A | −0.16 ± 0.02 A | 7.17 ± 0.13 A | 0 ± 0 A | 13 ± 0 A |

| WG | 17.77 ± 0.14 B | 1.54 ± 0.04 B | 8.80 ± 0.10 B | 7 ± 0 B | 20 ± 0 B |

| CRPW | 48.70 ± 0.35 C | 3.79 ± 0.05 C | 17.52 ± 0.33 C | 39 ± 0 C | 52 ± 0 C |

| Cracker Sample 1 | Darkness “100 − L*” | Redness a* | Yellowness b* | deltaEC4+4 2 | deltaEC8 3 | deltaEpairwise 4 | Darkness Index 5 |

|---|---|---|---|---|---|---|---|

| WF-0 (control-1) | 22.22 ± 0.53 A | 0.42 ± 0.11 A | 21.48 ± 0.30 F | 0 ± 0 A | 0 ± 0 A | – | 31 ± 0 A |

| WF-5 | 32.74 ± 0.39 B | 2.08 ± 0.13 B | 17.19 ± 0.24 D | 11 ± 1 E | 11 ± 1 B | – | 37 ± 0 B |

| WF-10 | 37.07 ± 0.44 D | 2.65 ± 0.08 C | 15.67 ± 0.16 C | 16 ± 1 F | 16 ± 1 C | – | 40 ± 0 C |

| WF-15 | 40.19 ± 0.46 E | 2.92 ± 0.08 D | 14.42 ± 0.27 B | 19 ± 1 G | 19 ± 1 D | – | 43 ± 0 E |

| WG-0 (control-2) | 36.02 ± 0.26 C | 6.74 ± 0.08 G | 19.39 ± 0.11 E | 0 ± 0 A | 15 ± 0 C | 15 ± 0 D | 41 ± 0 D |

| WG-5 | 43.25 ± 0.10 F | 7.17 ± 0.12 H | 17.14 ± 0.10 D | 8 ± 0 B | 23 ± 1 E | 12 ± 0 C | 47 ± 0 G |

| WG-10 | 43.22 ± 0.20 F | 5.41 ± 0.09 F | 14.59 ± 0.21 B | 9 ± 0 C | 23 ± 1 E | 7 ± 1 B | 46 ± 0 F |

| WG-15 | 44.92 ± 0.40 G | 4.98 ± 0.04 E | 13.69 ± 0.12 A | 11 ± 0 D | 24 ± 0 F | 5 ± 1 A | 47 ± 0 G |

| WF-set average (N = 24) | 33.1 ± 7.0 | 2.02 ± 1.00 | 17.19 ± 2.73 | 12 ± 8 | 12 ± 8 | – | 38 ± 5 |

| WG-set average (N = 24) | 41.9 ± 3.5 | 6.07 ± 0.93 | 16.20 ± 2.28 | 7 ± 4 | 21 ± 4 | – | 45 ± 2 |

| Cracker Sample 1 | Weight (g) | Thickness (mm) | Stiffness 2 (N/mm) | Breaking Work 3 (N.mm) |

|---|---|---|---|---|

| WF-0 (control-1) | 10.39 ± 0.28 BC | 6.66 ± 0.43 E | 20.77 ± 2.07 A | 19.54 ± 2.63 AB |

| WF-5 | 10.20 ± 0.25 B | 6.26 ± 0.47 CDE | 25.24 ± 2.49 AB | 14.29 ± 3.32 A |

| WF-10 | 10.81 ± 0.19 C | 6.49 ± 0.39 DE | 22.14 ± 2.40 A | 12.92 ± 1.84 A |

| WF-15 | 10.05 ± 0.28 B | 5.67 ± 0.26 BC | 25.61 ± 2.03 AB | 11.56 ± 2.43 A |

| WG-0 (control-2) | 6.96 ± 0.19 A | 5.58 ± 0.20 B | 30.86 ± 2.46 CD | 19.95 ± 5.32 AB |

| WG-5 | 7.05 ± 0.30 A | 4.56 ± 0.47 A | 28.28 ± 2.10 BC | 16.02 ± 4.79 A |

| WG-10 | 10.01 ± 0.43 B | 5.93 ± 0.25 BCD | 34.85 ± 1.41 D | 26.21 ± 3.90 B |

| WG-15 | 10.08 ± 0.24 B | 5.97 ± 0.25 BCD | 33.71 ± 1.26 D | 25.09 ± 4.34 B |

| WF-set average (N = 24) | 10.36 ± 1.70 | 6.27 ± 0.53 | 23.44 ± 3.43 | 14.58 ± 4.14 |

| WG-set average (N = 24) | 8.53 ± 1.58 | 5.51 ± 0.65 | 31.93 ± 3.51 | 21.82 ± 6.80 |

| Cracker Sample 1 | Sensory Fragility (pts.) * | Sensory Hardness (pts.) * | Sensory Score (pts.) | Sensory Acceptability 2 (–) |

|---|---|---|---|---|

| WF-0 (control-1) | 57 ± 26 AB | 45 ± 12 A | 534 ± 91 A | 43 ± 7% A |

| WF-5 | 65 ± 28 B | 48 ± 7 AB | 610 ± 47 AB | 49 ± 4% AB |

| WF-10 | 68 ± 21 B | 47 ± 5 AB | 606 ± 98 AB | 49 ± 8% AB |

| WF-15 | 66 ± 16 B | 54 ± 7 AB | 626 ± 63 AB | 50 ± 5% AB |

| WG-0 (control-2) | 33 ± 24 A | 74 ± 17 C | 553 ± 88 AB | 44 ± 7% AB |

| WG-5 | 43 ± 22 AB | 63 ± 15 CD | 631 ± 80 B | 50 ± 6% B |

| WG-10 | 52 ± 26 AB | 61 ± 15 BCD | 616 ± 76 AB | 49 ± 6% AB |

| WG-15 | 50 ± 31 AB | 63 ± 14 CD | 612 ± 100 AB | 49 ± 8% AB |

| WF-set average (N = 24) | 64 ± 23 | 44 ± 26 | 594 ± 84 | 48 ± 7% † |

| WG-set average (N = 24) | 50 ± 31 | 65 ± 17 | 603 ± 89 | 48 ± 7% †† |

| (a) | |||||||

|---|---|---|---|---|---|---|---|

| Variance Factor 1 | Color Component, Index | Physical Traits | |||||

| Darkness “100 − L*” | Redness a* | Yellowness b* | deltaEC8 | Darkness Index | Weight | Thickness | |

| WFT | 0.632 *** | 0.907 *** | −0.196 ns | 0.634 *** | 0.731 *** | −0.633 *** | −0.547 *** |

| CRPW% | 0.682 *** | 0.025 ns | −0.942 *** | 0.677 *** | 0.588 *** | 0.458 ** | −0.017 ns |

| Variance factor | Texture parameters | Sensory attribute | |||||

| Hardness | Flexibility | Stiffness | Breaking work | Fragility | Hardness | Score | |

| WFT | 0.691 *** | 0.051 ns | 0.781 *** | 0.549 *** | −0.392 ** | 0.625 *** | 0.223 ns |

| CRPW% | 0.126 ns | −0.218 ns | 0.273 ns | 0.002 ns | 0.366 * | −0.053 ns | 0.498 *** |

| (b) | |||||||

| Variable | Weight | Thickness | Hardness | Flexibility | Stiffness | Breaking work | |

| Darkness “100 − L*” | −0.240 ns | −0.543 *** | 0.386 ** | −0.291 * | 0.652 *** | 0.170 ns | |

| Redness a* | −0.785 *** | −0.727 *** | 0.456 ** | −0.164 ns | 0.676 *** | 0.270 ns | |

| Yellowness b* | −0.302 * | 0.138 ns | −0.252 ns | 0.258 ns | −0.442 ** | −0.073 ns | |

| deltaEC4+4 | 0.482 ** | −0.023 ns | −0.287 * | −0.373 ** | −0.092 ns | −0.386 ** | |

| deltaEC8 | −0.242 ns | −0.530 *** | 0.399 ** | −0.281 ns | 0.658 *** | 0.177 ns | |

| Darkness Index | −0.355 * | −0.613 *** | 0.432 ** | −0.254 ns | 0.687 *** | 0.222 ns | |

| (c) | |||||||

| Sensory Attribute | Weight | Thickness | Hardness | Flexibility | Stiffness | Breaking work | |

| Fragility | 0.457 ** | 0.270 ns | −0.124 ns | 0.048 ns | −0.169 ns | −0.236 ns | |

| Hardness | −0.519 *** | −0.328 * | 0.428 ** | 0.083 ns | 0.462 *** | 0.348 * | |

| Score 2 | 0.045 ns | −0.112 ns | 0.237 ns | −0.035 ns | 0.320 * | 0.146 ns | |

| Predicted Z-Variable (Texture Parameter) | X- and Y-Variable Multiplication ‘X ∙ Y’ (Predictors—Color Components) | Multiple Correlation Coefficient RZ/(X∙Y) | Calculated Probability p |

|---|---|---|---|

| Hardness | (Redness a* ∙ Yellowness b*) | 0.4782 ** | 0.00290 |

| Flexibility | 0.2779 ns | 0.16380 | |

| Stiffness | 0.7321 *** | 0.00000 | |

| Breaking work | 0.2701 ns | 0.18180 | |

| Hardness | (Darkness “100 − L*” ∙ Redness a*) | 0.4629 ** | 0.00440 |

| Flexibility | 0.2995 ns | 0.12080 | |

| Stiffness | 0.7143 *** | 0.00000 | |

| Breaking work | 0.2731 ns | 0.17470 | |

| Hardness | (Darkness “100 − L*” ∙ Yellowness b*) | 0.4073 * | 0.01690 |

| Flexibility | 0.2921 ns | 0.13440 | |

| Stiffness | 0.6790 *** | 0.00000 | |

| Breaking work | 0.2108 ns | 0.35960 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Švec, I.; Hradecká, B.; Skřivan, P.; Sluková, M.; Štětina, J.; Beňo, F.; Hajšlová, J. Color and Texture of Wheat and Whole Grain Wheat Salty Crackers—Technological Aspects of Cricket Powder Addition. Appl. Sci. 2025, 15, 9914. https://doi.org/10.3390/app15189914

Švec I, Hradecká B, Skřivan P, Sluková M, Štětina J, Beňo F, Hajšlová J. Color and Texture of Wheat and Whole Grain Wheat Salty Crackers—Technological Aspects of Cricket Powder Addition. Applied Sciences. 2025; 15(18):9914. https://doi.org/10.3390/app15189914

Chicago/Turabian StyleŠvec, Ivan, Beverly Hradecká, Pavel Skřivan, Marcela Sluková, Jiří Štětina, Filip Beňo, and Jana Hajšlová. 2025. "Color and Texture of Wheat and Whole Grain Wheat Salty Crackers—Technological Aspects of Cricket Powder Addition" Applied Sciences 15, no. 18: 9914. https://doi.org/10.3390/app15189914

APA StyleŠvec, I., Hradecká, B., Skřivan, P., Sluková, M., Štětina, J., Beňo, F., & Hajšlová, J. (2025). Color and Texture of Wheat and Whole Grain Wheat Salty Crackers—Technological Aspects of Cricket Powder Addition. Applied Sciences, 15(18), 9914. https://doi.org/10.3390/app15189914