Abstract

The subject of this article is tall buildings with a load-bearing layout made of mass timber, erected between 2009 and 2025. The aim of the study is to introduce a typology and to systematise and synthesise knowledge concerning the spatial and material–structural shaping of the load-bearing systems of these buildings. Load-bearing systems were classified according to the type of elements into 1D, 2D, 3D, mixed and hybrid. It was found that the most common types of mass timber tall building construction are 1D, accounting for 47% of the buildings analysed, and 2D accounting for 23%, with the remaining 3D (4%), hybrid (3%) and mixed (1%) used infrequently. A research method based on a case study and data collection with an analysis of the available literature was used. A study of the spatial and material and structural solutions of 109 timber tall buildings was carried out. Conclusions are presented for the most sustainable in terms of material solution, i.e., with an above-ground part made entirely of mass timber in the buildings which represents 10% of the cases studied. Mass timber tall buildings have a low slenderness of 0.66–2.98 for heights up to 50 m and 2.41–4.97 for heights over 50 m.

1. Introduction

1.1. Background

The construction sector is a significant contributor to global CO2 emissions. It is estimated [1] that it is responsible for more than a third of global CO2 emissions, 40% of global energy consumption and 50% of landfill waste production. For these reasons, measures are being taken to reduce the negative environmental impact of the construction industry through, among other things, the sustainable design of cities and living environments, as well as the sustainable use of natural resources [2].

The 2023 report on the evaluation of the implementation of sustainable development measures [3]—based on an analysis over the last 30 years of the development of a selection of 681 cities worldwide—diagnosed a phenomenon negatively affecting urban sustainability. It has been found that their population density is decreasing and urban sprawl is outpacing their population growth.

In Ref. [4], consideration is given to the possibility of using the progressive and inevitable development of urbanisation, but shaped in a sustainable way, as a tool to reduce climate change.

One means of reducing the aforementioned detrimental effects of construction on the environment is the intensification, consolidation and densification of urban development [5,6,7,8], e.g., through the wider introduction of tall buildings and the sustainable use of natural resources through, among other things, the use of renewable, natural materials.

The primary natural building material used in construction is timber. Traditional construction using solid timber has limited development and implementation opportunities due to the disadvantages of this material such as anisotropy, susceptibility to permanent deformation under long-term loads, limited cross-sectional dimensions and limited lengths of wood products (including structural elements), as well as a lack of fire resistance or susceptibility to biological corrosion, etc.

For these reasons, the introduction of mass timber, thanks to the spread of cross-laminated timber technology since 1906 and surface bonding technology since the 1990s has had a significant impact on expanding the possibilities for using a renewable material—wood—in construction [9]. With the term mass timber construction (MTC) capturing the various glulam products [10,11]: cross-laminated timber (CLT), glued laminated timber (glulam), nail laminated timber (NLT), dowel laminated timber (DLT), structural composite lumber (SCL). The term SCL includes laminated veneer lumber (LVL) and laminated strand lumber (LSL).

Initially, glulam was implemented in low- and medium-rise construction; in the late 1980s, it was also employed in high-rise construction [12]. The important advantages of this material that have an impact on the possibility of increasingly widespread implementation in the construction industry include the following: low dead weight and consequently relatively easy assembly of the elements, reduced need for heavy construction equipment and machinery, reduced transport costs due to lower weight compared to traditional materials, the possibility of assembly in various thermal conditions (even in winter), the possibility of prefabricating structural elements (bars, surfaces, volumes) or furnishings, the high quality and aesthetics of the prefabricated elements’ surface finish and consequently the possibility to dispense with finishing layers, as well as the positive impact of natural materials on the well-being of users. The assembly of prefabricated mass timber buildings is characterised by the absence of waste and particle contamination of the air and construction site during the works and, due to rapid assembly, limited nuisance to users of neighbouring buildings or spaces.

Key features that have a decisive impact on increasing interest in the use of mass timber in construction are the pro-environmental aspects, i.e., origin from natural renewable sources, low carbon. The tree absorbs carbon dioxide as it grows. It is estimated [13] that 1 m3 of wood absorbs an average of 0.8–0.9 t of carbon dioxide. For these reasons, products made of timber, e.g., load-bearing structure elements and building equipment, represent a safe and efficient way of storing CO2. In [13], it was determined that a tall building with mass timber construction can absorb significant amounts of CO2, e.g., a 40-storey CLT building (total volume of mass timber used—26,300 m3) can save around 50,000 t of CO2 emissions.

A similar view is expressed in [14,15] indicating that increasing urbanisation with the replacement of conventional building materials by bio-based materials (such as wood or bamboo, which store CO2) may contribute to climate change mitigation.

Many scientific studies include comparisons of the environmental impact during the life-cycle phases of buildings with different material solutions for the load-bearing systems or structural elements of buildings, most often made of concrete (reinforced concrete), steel and timber.

In Ref. [16], analyses were carried out on the primary energy consumption of multi-storey timber buildings with the same architectural solution but constructed according to different timber building systems. The use of a surface element system with CLT was found to provide 16% less primary energy consumption in terms of material production compared to beam-and-post systems and 6% less compared to modular-cubicle systems. In addition, the CLT system also has a lower primary energy consumption over the entire life cycle of the building (which includes material production, building construction, heating and ventilation over a 50-year period and demolition) by 7% and 9%, respectively.

Comparative analyses on the design of the Wälludden multi-storey building showed 60–80% lower primary energy consumption, as well as lower greenhouse gas emissions of carbon dioxide CO2 and methane CH4 for the production of building materials for the construction of the timber-framed building compared to reinforced concrete construction [17]. At the same time, the magnitude of the benefit of the timber structure depends on the expected useful life of the building (50 years, 100 years), as well as the way in which the building materials from the demolition of the building in question will continue to be used once its useful function has been exhausted.

Comparisons [18,19] of the life-cycle GHG emissions of multi-storey buildings with structures, i.e., steel, reinforced concrete and mass timber, have shown that timber buildings have 34–84% lower GHG emissions—relative to steel and reinforced concrete buildings. The greatest benefits in this respect apply to taller buildings of 12–21 storeys above ground, and smaller benefits apply to buildings of 3–12 storeys.

In [20], the results of analyses of greenhouse gas emissions covering selected life phases of two considered comparable residential buildings in Trondheim, Norway, located on a common reinforced concrete underground section are presented. One building is five storeys above ground and of reinforced concrete construction, while the other is eight storeys above ground and made of CLT. As a result of the calculation analyses, emissions in the so-called ‘Cradle to Gate’ phase were found to be 25% lower for a timber-framed building than for a reinforced concrete building, in the use phase (expected to last 60 years), the timber-framed building—built to Passive House standards—had 7% lower greenhouse gas emissions than the reinforced concrete building, and in the transport phase, the timber-framed building had slightly higher emissions. However, it was pointed out that there is quite a lot of uncertainty in the results of the projections for the transport and use phases due to the different energy standards of the implementation of the two buildings and their different heights, among other things.

The paper [21] reports the results of a comparative study of the use phase and, in particular, the energy consumption for the heating and cooling of CLT and reinforced concrete office buildings erected in different climatic zones of China. CLT buildings were found to have—depending on the climatic zone of their location—a lower heating energy requirement in winter of between 11.97% and 30.94% and a lower attractiveness in this respect for summer operation compared to corresponding buildings with reinforced concrete structures. For these reasons, it was considered beneficial to promote this type of solution in regions of China with cold winters, while it was not recommended for temperate or hot climates.

Mass timber buildings are highly sustainable in the procurement and production phase due to the renewable origin of the raw material, typically in the use phase due to the usually lower heating energy requirements and in the disposal phase due to the partial or often complete recyclability of the mass timber components.

They are also characterised by high seismic resistance with a relatively low dead weight of the structure. These properties are confirmed by a number of analytical results relating to multi-storey residential and public buildings erected in seismically active areas and made mainly of CLT [22], as well as by experimental results. In Ref. [23], the results of laboratory tests of a natural-scale erected-test seven-storey building with CLT—subjected under laboratory conditions to an impact corresponding to ten large seismic excitations—are presented. The effect of these impacts was positive; the structure of this building did not suffer any major damage. In [24], the results of test studies and numerical analyses on the seismic behaviour of CLT wall-structured buildings are synthesised, and procedures for their design are included in [25,26], among others.

The lighter weight of tall timber-framed buildings, compared to traditional material solutions—reinforced concrete or steel load-bearing systems—is less advantageous in terms of dynamic wind loads, the possibility of excessive vibration, and consequent discomfort of use. The results of experimental studies of the effects of dynamic wind actions on tall timber buildings are characterised, for example, in Refs. [27,28,29].

Fire safety is one of the issues that has a significant impact on the still-low number of timber high-rise building developments and the legal regulations that exist in many countries limiting the height of this type of development. These topics are generally presented in many publications, including, for example, Refs. [30,31]. On the other hand, the results of experimental studies of specific cases of buildings, e.g., in Ref. [10], where the test results of timber-framed buildings with CLT have been collated. The fire resistance depending on the type of structural elements with CLT ranged from 1 to 3 h, while the fire test of a three-storey building structure with CLT was 1 h. In addition, the trend of designing tall building structures to take into account the charring effect and design section allowances was highlighted [32].

Due to the increasing demand for mass timber and, at the same time, the limited supply of raw material from sustainable forestry, the subject of many scientific studies is the optimisation of the use of the raw material for the production of different ranges of mass timber, as well as the reduction in waste to a necessary minimum and, at the same time, the obtaining of a material with the best desired properties, including strength.

The paper [33] takes a closer look at various wood cutting technologies and points out that the efficiency of raw material utilisation within the product range in question is related to the size of particles in the round timber cutting process and increases along with the decrease in their size. The efficiency of use of timber resources for selected construction materials was determined as follows: LSL (laminated strand lumber)—69%; OSB (oriented strand board)—83%; LVL—52%; PLY (plywood)—52%; GLT—39%; CLT—37%. In the light of the research results presented in [33], it can be concluded that the appropriate choice of construction materials within the available range of products has a significant impact on the rational use of timber resources and the synergy of the achieved pro-environmental effects.

In order to assess the potential for wider implementation of sustainable construction, a comparison of selected timber-framed multi-storey buildings was made [12]. Economic and environmental criteria were adopted for the assessment of the five tallest timber buildings, including the following: height, number of storeys, construction time, investment costs, environmental parameters—reduction in CO2 emission and energy use. As a result of multi-criteria analyses, it was found [12] that the environmental efficiency of the investments studied, as determined by the reduction in CO2 emission and energy consumption, and the economic efficiency are the highest for the tallest buildings under analysis.

On the other hand, Ref. [34] undertook analyses of the development trends of medium-high- and high-rise timber construction in selected southern European countries. A trend towards the construction of increasingly taller buildings with the use of mass timber, primarily sourced from local forestry—softwood—has been identified. A typology of timber building structures in question was introduced, taking into account five types of structures: a light frame formed from pillars and beams with small cross-sectional dimensions (percentage share of this type of solution in relation to the number of all surveyed buildings—0%); a frame system with beams and pillars formed mainly from GLT or less frequently from LVL or EWP—21%; a wall system with walls and ceilings made from CLT—43%; a mixed system of the aforementioned solutions with EWP—18%; a hybrid system combining elements from mass timber with other construction materials, i.e., steel or concrete—18%. The research reported in [34] shows that the buildings analysed (28 buildings constructed in the southern European region in question were studied) with heights above 30 m are mostly of hybrid construction.

The paper [35] points out that there are still a small number of timber-framed tall buildings. Among the reasons given were the complexity of the design process, the relatively low design experience in this area, the lack of rheological studies of this type of solution, etc.

The paper [36] attempts to present the evolution and directions of development of architectural solutions in contemporary tall timber buildings. The results of a comparative study of 46 buildings designed and constructed in Europe, Australia and North America are given, starting from the pioneering period of the implementation of this type of tall building, i.e., from 2009 to the present. Among other things, it was found that as the height of buildings increases, the proportion of load-bearing systems with an internal reinforced concrete core as one of the elements for ensuring spatial stiffness increases.

Analyses of architectural solutions for functional design [37] and spatial efficiency of tall timber buildings have been undertaken in [38,39,40]. On the other hand, an analysis of the typology and morphology of multi-storey timber buildings, varying in height from low to high, based on 350 completed projects (including 58 tall ones), either under construction or in the design concept phase, was carried out in [41]. Attention was drawn to the predominant layouts of building projections—orthogonal and a few with irregular shapes—which have a direct impact on the spatial solutions of the geometries and the lack of new morphological expressions of this development. The rigid framework of prefabrication and modularity underpinning mass timber developments based on linear or rectangular geometries were cited as reasons for the low architectural variety and limited expression of these developments.

Restrictions in the design of plan, regularity and repeatability of timber building structures result primarily from the prefabrication and standardisation of mass timber elements. The recent scientific research focuses on the design and optimisation of structures or their elements (e.g., slabs) shaped in a ‘flexible’ way to adapt to architectural and functional solutions, as well as modern construction technologies. The paper [42] draws attention to the possibility of implementing integrative computational design and fabrication of mass timber structures using in situ construction robotics. This type of design is currently being tested on structures with free architectural forms but with small spans, such as pavilions.

In Ref. [43], the concept of an agent-based method for designing multi-directional composite timber slab systems in multi-storey buildings was presented, taking into account the individual boundary conditions of the architectural, functional, installation and structural solutions.

The paper [44] presents concepts for the construction of non-standard, freely shaped floor slabs using construction robot systems as future sustainable construction technologies.

The issue of using robotic assembly integrated with BIM and DES simulations for erecting CLT panel structures was characterised in [45]. Significant benefits of using such innovative methods have been identified, including reduced time (by up to 17% compared to traditional methods) and increased accuracy of CLT structure assembly. The mentioned studies and concepts are pioneering in nature and indicate trends and directions in the development of mass timber construction.

In light of the views presented and the examples given, it can be concluded that limiting the negative impact of construction is a key element of environmental protection expressed through a sustainable approach to the design of buildings; the choice of intensive, e.g., high development; and the rational choice of construction materials and a range of building elements capturing the efficient use of the properties of these materials and ensuring susceptibility to reuse (in the event of the original function of the building being exploited) or recycling, limiting the possibility of waste generation, e.g., through the use of prefabricated elements or the implementation of innovative robotic tools integrated with BIM.

1.2. Goals and Scope

The aim of the study is to systematise and synthesise knowledge on the material and structural shaping of load-bearing systems for high-rise buildings made of mass timber. The literature focuses on the functional and structural shaping elements of individual buildings, most often low-rise and mid-rise. However, there is a lack of synthesised information on all timber buildings with a height of at least 25 m that have been completed or are under construction. Also highlighted is the fact that even among designers and investors, there is a lack of knowledge about the possibilities of using mass timber in tall construction. The authors of this analysis believe that the analyses presented in this article fill this gap. These types of buildings represent new, innovative and still rare material and construction solutions. The first tall timber buildings were completed in 2009, i.e., in Seattle, USA, with the Marselle Condos building, and in Sweden, Limnologen in Vaxjo, and Portvakten Söder in Portvakten Söder, and by March 2025, a total of approximately 109 such buildings had been built or were under construction across the world. Tall timber buildings bring together in their spatial and structural solution two important aspects of sustainability in construction, i.e., the use of a natural renewable material—timber—in the shaping of the load-bearing system of the above-ground part of the buildings and the reduction in the negative environmental impact of construction projects through the introduction of intensive high-rise development and consequently smaller building areas and less interference with natural spaces.

2. Materials and Methods

The subject of the study covers tall buildings with a structural system of the above-ground part made of mass timber. In the absence of a generally accepted definition, this article assumes that a tall building has a height of at least 25 m above ground level and, in the case of a building with a residential function, has a height of at least nine storeys above ground.

The period from the first erection of the tall timber building, i.e., 2009 to March 2025, was used as the time period of the study.

This paper presents the results of our own research into spatial and material–structural shaping, introduces a typology of load-bearing systems for this type of building and a typology of material solutions for the above-ground part, and characterises the achievements in the use of mass timber in high-rise construction.

2.1. Stage of the Research

The research was carried out in six stages (Figure 1):

- -

- First stage—based on an analysis of the available literature and internet sources, a dataset of 109 completed and under-construction mass timber tall buildings was compiled; the results of these analyses are summarised in the table attached as Appendix A to this article.

- -

- Second stage—developing a typology of load-bearing systems and material and structural solutions for the above-ground parts.

- -

- Third stage—an analysis of the material and structural solutions of the above-ground parts of the 109 buildings in question with a view to identifying contemporary trends in the construction of these buildings in two separate height groups, i.e., up to 45 m and over 45 m.

- -

- Fourth stage—extracting from the set of all 109 surveyed buildings those whose above-ground structure, comprising the load-bearing system including the structure of the circulation path, is fully made of mass timber. This collection represents 11 buildings. The purpose of these analyses was to determine whether there are opportunities and potential height restrictions for this type of building.

- -

- Fifth stage—determining the spatial trend of the geometries of the buildings in question and the slenderness of selected cases out of 109 buildings for which it was possible to obtain the required dimensional data.

- -

- Sixth stage—final conclusions.

Figure 1.

Scheme of the research process.

2.2. Methodology

A research method based on a case study and dataset was used, including a comprehensive analysis of the available literature, including monographs and peer-reviewed scientific publications, Internet sources, etc.

A survey was carried out of the spatial and material–structural solutions of 109 buildings whose documentation or basic technical parameters—in varying degrees of detail—were available in the literature or online sources and databases. The sources listed in items [20,34,37,39,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80] of the compilation of references were the source of information on the buildings surveyed.

3. Results and Discussion

A research method based on a case study was used, including a comprehensive analysis of the available literature, including monographs and peer-reviewed scientific publications, Internet sources, etc.

3.1. Development of the Dataset—Stage I

Analyses were carried out of material and structural solutions; spatial solutions in terms of the shape of geometries, projections and proportions expressed in terms of slenderness; and the basic parameters of 109 buildings. A summary of the basic building information—which is the result of the Stage I survey—is included in Table A1 of Appendix A.

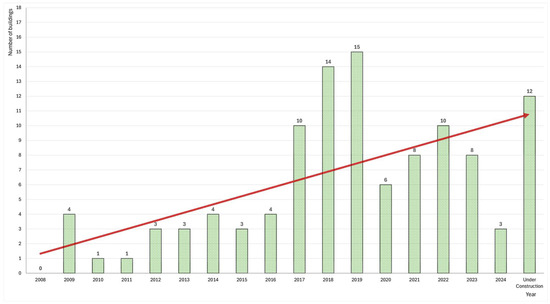

On the basis of the juxtaposed data (Table A1), it can be concluded that the beginning of high-rise timber construction is represented by four buildings put to use in 2009, with a significant increase in their number by 2019. The highest number of such buildings—15—was put to use in 2019. A slight pause in the upward trend occurred in the period 2020–2022, which can be attributed to the constraints of the COVID-19 pandemic period, while the number of these construction projects has now increased again, amounting to 12 in the first quarter of this year (Figure 2). This fact confirms the increased use of structural timber and the interest in the wider implementation of material solutions with limited negative environmental impact in tall buildings.

Figure 2.

Numerical summary of timber tall buildings erected in the period 2009–2024 and under construction in 2025 with an indicated upward trend (red arrow) of this type of construction (cf. Table A1 in Appendix A).

3.2. Typology of Structural Systems—Stage II Studies

The material solutions for the foundations, and if present also for the underground parts of the mass timber tall buildings, are reinforced concrete, while the above-ground parts are differentiated, i.e., the above-ground structure:

- -

- Made entirely of mass timber (one or more different types of mass timber);

- -

- Made of mass timber and reinforced concrete;

- -

- Made of mass timber and steel.

The following solutions are being implemented within the above-ground parts:

- -

- Made entirely of mass timber walls/posts and ceilings—joists and floor panels, circulation paths (lift shafts and staircases) (Figure 3a);

- -

- Made of mass timber walls/posts and ceilings—beams and floor panels, and circulation paths of reinforced concrete (Figure 3b);

- -

- Upper above-ground structures made of mass timber—walls/posts, ceilings, beams and floor panels—and lower above-ground storeys (usually 1 or 2 and in the tallest buildings even 5 or 6 storeys) posts/walls and floor slabs and circulation paths of reinforced concrete (Figure 3c);

- -

- Made of mass timber walls/posts and floor beams, floor slabs made of TCC panels, and circulation paths made of reinforced concrete (Figure 3d);

- -

- Hybrid timber–steel systems, in which the basic elements of the above-ground structure (posts and beams) are steel and ceiling boards are made of mass timber panels (Figure 3e).

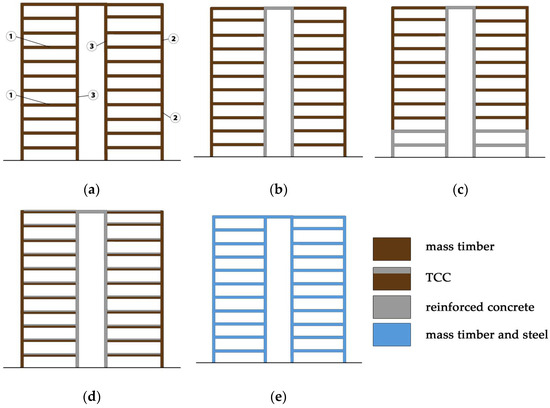

Figure 3.

Material solution diagrams for above-ground parts (description in text): (a) made entirely of mass timber walls/posts and ceilings, circulation paths; (b) made of mass timber walls/posts and ceilings, circulation paths of reinforced concrete; (c) upper above-ground structures made of mass timber—walls/posts, ceilings and lower above-ground storeys and circulation paths of reinforced concrete; (d) made of mass timber walls/posts and floor beams, floor slabs made of TCC panels, and circulation paths made of reinforced concrete; (e) hybrid timber–steel systems, in which the basic elements of the above-ground structure are steel and ceiling boards are made of mass timber panels. Legend: 1—ceiling structure (beams, panels); 2—post/wall structure; 3—structure of circulation paths (staircases, lift shafts).

A classification of the load-bearing systems of the above-ground parts of buildings has been introduced with regard to the material solution and the type of prefabricated elements forming the load-bearing system (Figure 4):

- –

- 1D bar elements, with a length much greater than other dimensions’ cross-section; in terms of static work, these are post-beam or frame systems. However, the posts are usually made of GLT (and in the case of the tallest buildings, of LVL) and the floor construction consists of GLT floor beams on which are supported CLT panel slabs or, less commonly in the tallest buildings, TCC.

- –

- 2D surface elements, in which two dimensions are comparable and the third—thickness—is significantly smaller; in terms of static work, these are slab elements and discs forming so-called wall systems in which the main load-bearing system consists of walls and ceilings usually made of CLT panels.

- –

- 3D—prefabricated volume, mostly shaped from CLT.

- –

- Hybrid systems in which the load-bearing system is formed from two materials, steel and timber, i.e., consisting of posts and main beams formed from I-shaped steel sections and CLT ceiling panels.

- –

- Mixed system combining structural elements from 1D and 2D systems.

Figure 4.

Conceptual diagrams of the adopted types of load-bearing systems (colour coding used in subsequent drawings): (a) 1D system, (b) 2D system, (c) 3D system, (d) hybrid system, (e) mixed system.

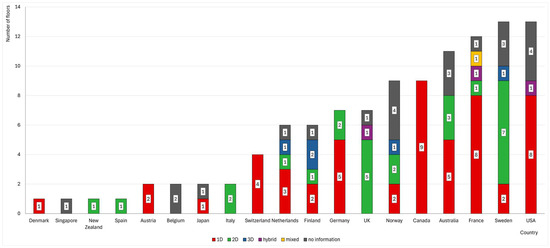

Considering the location of the completed mass timber buildings and their number, it can be concluded that the greatest achievements in the implementation of mass timber high-rise construction are as follows (Figure 5): USA and Sweden—13 buildings each; France—12 buildings; Australia—11 buildings. The significant number of investments concerned in the USA, Sweden and Australia can be attributed, e.g., to the strong tradition of forestry and the timber industry and timber construction in the aforementioned countries and to the advanced production of materials and structural elements from this material.

Figure 5.

Numbers of completed timber tall buildings with an indication of the country of their location. A distinction was made between buildings with a 1D, 2D, 3D, hybrid and mixed structure; where detailed data are missing, ‘no information available’ was entered.

3.3. Material and Construction Solutions for Above-Ground Parts—Stage III of the Study

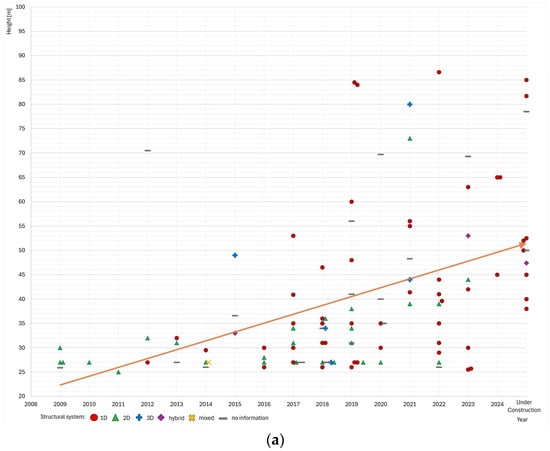

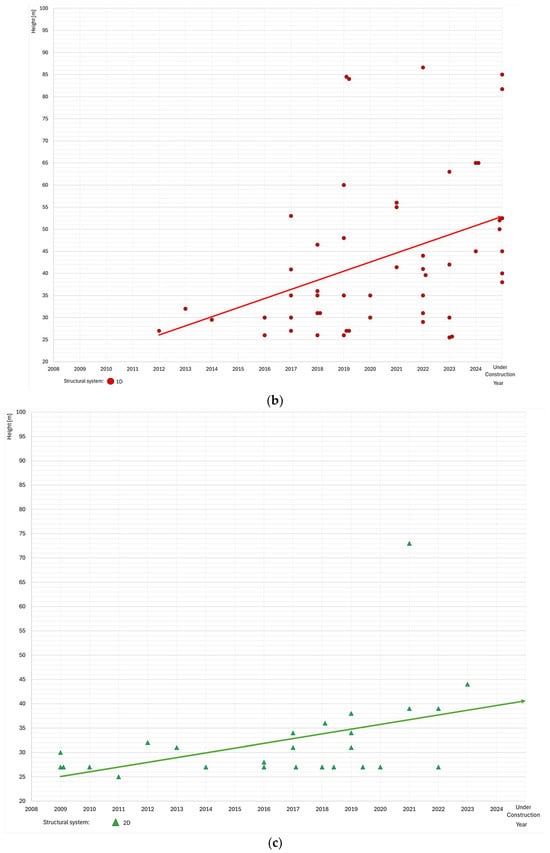

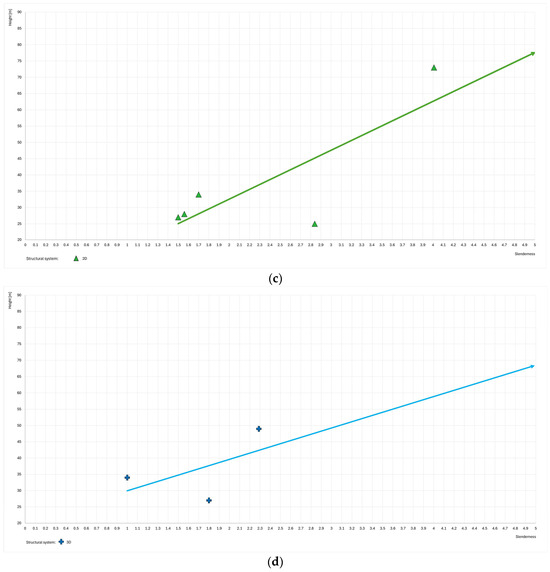

When analysing the height and type of load-bearing system of the buildings in question, we can say (Figure 6) that buildings with heights of up to 35 m (20 out of 23 buildings) were prevalent in the initial period up to 2016, and the most common type of load-bearing system was either the 2D wall-bearing system made of CLT elements (10 out of 23) or a 1D post-and-beam system made of GLT elements (5 out of 23). The structure of 3D volume elements was only used in the case of the Treet building. It should be mentioned that there was also one case of mixed structure and one case of hybrid structure (five cases—no data available).

Figure 6.

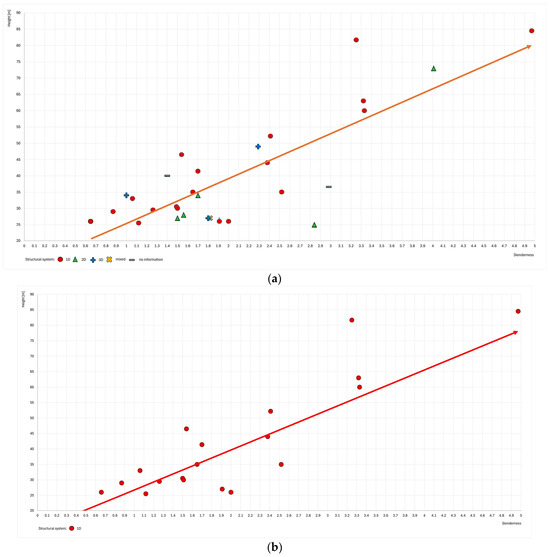

Summary data on the type of load-bearing system, height and time of construction of the buildings concerned with indication of trend lines (colour distinctions in accordance with Figure 4): (a) all types of load-bearing systems, (b) 1D systems, (c) 2D systems, (d) 3D systems, (e) hybrid systems.

In the further period, i.e., from 2017 to March 2025, there is a clear trend of an increase in the number of projects and the number of buildings with heights of more than 35 m; in addition, timber buildings with the greatest heights, i.e., more than 80 m, start to appear—7 such buildings (out of 86) are under construction, including 1 with a record height of 182.6 m: Atlassian Central. Between 2017 and March 2025, 74 buildings were completed and 12 are under construction. In this group of buildings, the predominant structural solution is the post-and-beam or 1D frame system—45 cases (out of 86)—and the 2D wall system—16 cases (out of 86). Three-dimensional volume systems are represented in four buildings and hybrid systems in two buildings.

Among the 109 buildings analysed, the highest each layout are as follows (Table A1 in Appendix A):

- -

- 1D bar elements—the 86.6 m high Ascent MKE erected in Milwaukee (USA) in 2022.

- -

- 2D surface elements from CLT—Haut with a height of 73 m realised in Amsterdam (the Netherlands) in 2021.

- -

- 3D cubic elements—the 80 m high Sara Kulturhus Center erected in Skellefteå (Sweden) in 2021.

- -

- Hybrid—the 53 m high Albizzia built in Lyon (France) in 2023.

- -

- Mixed—the residences J.Ferry with a height of 27 m erected in Saint-Dié-des Vosges, France, in 2014.

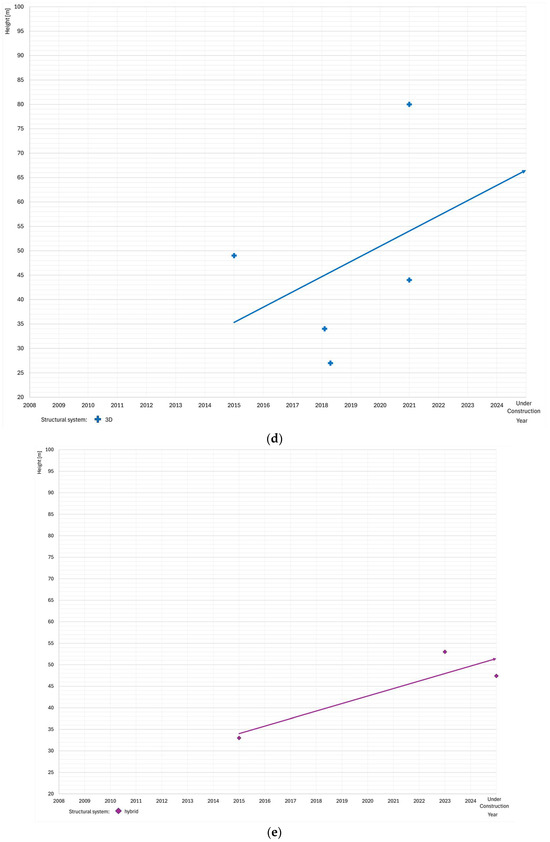

The most common construction type for mass timber tall buildings (Figure 7) is 1D layouts, accounting for 47% (which includes 52 of the 109 buildings analysed), 2D layouts for 24% (respectively, 26), 3D layouts for 4% (respectively, 5), hybrid layouts for 3% (respectively, 3) and mixed layouts for 1% (respectively, 1). It should be mentioned that 20% of cases (22 buildings) did not have a specific type of load-bearing system due to incomplete information in the available documentation.

Figure 7.

Numbers of buildings with load-bearing systems: 1D, 2D, 3D, hybrid, mixed. If no details are given—no information. (a) Column chart; (b) pie chart showing percentage of each type of construction.

One-dimensional load-bearing systems of the above-ground part are usually constructed with GLT posts and GLT floor beams supported by floor slabs made of a variety of mass timbers (cf. Table A1 in Appendix A). These panels are most commonly made of CLT panels (30 building cases); TCC (10 cases); and the rarer floor panel material solutions of DLT (1 case), NLT (nail laminated timber, 1 case), CLT and DLT (dowel laminated timber, 1 case).

There are also buildings with LVL-shaped posts and beams and CLT ceiling panels (4 buildings); GLT and LVL beams and posts and CLT ceiling panels (3 buildings); LVL posts, beams and ceiling panels (1 building); and a building with MPL (mass ply lams) posts and MPL beams on which MPPs (mass ply panels) are supported (1 case). In one case, the material of the load-bearing system was not specified.

The predominant material solution for walls and ceilings in 2D layouts is CLT panels (23 building cases). There is also one case of a building with CLT walls and TCC ceilings (1 building).

Three-dimensional volume load-bearing systems are rare—in the study group of buildings, three cases of prefabricated volume elements formed from CLT, one from LVL and CLT and one from GLT and CLT were found.

Buildings with hybrid systems had steel post and beam structures made of I-shaped sections and ceiling boards formed from CLT panels (three buildings).

Mixed systems concerned only one case of a building that used GLT and CLT glulam in its construction.

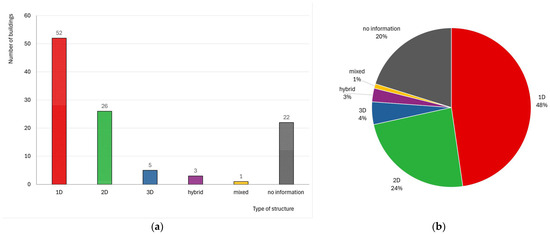

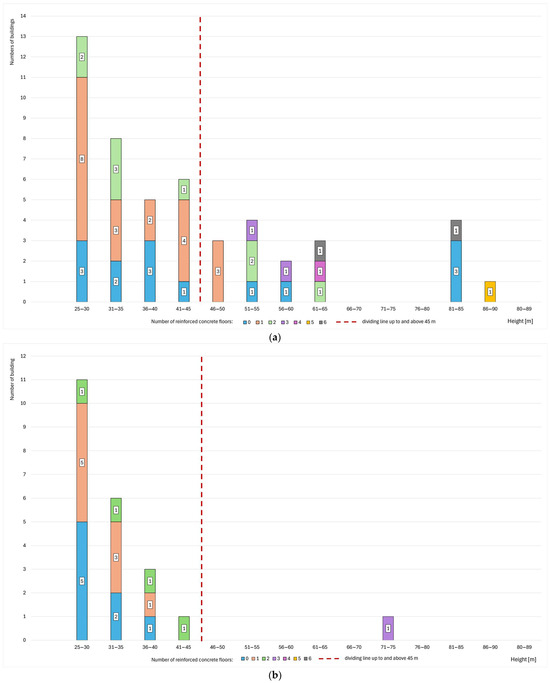

On the basis of the summaries given above, analyses were carried out on the material solutions for the above-ground structure (from ground level) of the basic support system and the circulation path, depending on their height (Figure 8). These concerned the cases of 86 buildings out of a group of 109 buildings, as in the case of 23 buildings there was a lack of information in the surveyed area.

Figure 8.

Number of above-ground reinforced concrete storeys depending on the height of the buildings surveyed.

Conclusions were formulated with regard to the two ranges of building heights identified, i.e., with heights up to 45 m (being the domain of the use of 2D layouts) and over 45 m. On the basis of the analyses carried out, the following conclusions can be drawn (Figure 9, cf. Figure 6):

- (a)

- The number of buildings up to 45 m in height is 62 and the number of lower storeys in these buildings with reinforced concrete construction ranges from 0 to 2. In this group are buildings with the following structures:

- -

- 1D bar elements (32 buildings in total): 8 buildings—no storeys of reinforced concrete construction; 18 buildings—had one storey of reinforced concrete; 6 buildings—two storeys of lower reinforced concrete;

- -

- 2D surface elements (21 buildings in total): 8 buildings—no storeys of reinforced concrete construction; 9 buildings—one storey of reinforced concrete construction; 4 buildings—two storeys of lower reinforced concrete construction;

- -

- 3D volume elements (3 buildings in total): 1 building—no storeys of reinforced concrete construction; and 2 buildings with two lower storeys of reinforced concrete;

- -

- Hybrid (1 building in total): 1 building—no storeys with reinforced concrete construction.

- -

- Mixed use (1 building in total): 1 building—no storeys with reinforced concrete construction.

- -

- No information on the structural solution of the timber part of the buildings (4 buildings in total): 1 building with one storey of reinforced concrete; 3 buildings with two storeys of reinforced concrete.

- (b)

- The number of buildings over 45 m in height is 23, and the number of lower storeys with reinforced concrete construction varies, ranging from 0 to 6. In this group are buildings with the following structures:

- -

- 1D bar elements (17 buildings in total): 5 buildings—no storeys of reinforced concrete construction; 3 buildings—one storey of reinforced concrete; 3 buildings—two storeys of lower reinforced concrete; 2 buildings—three storeys of reinforced concrete; 1 building—four storeys of reinforced concrete; 1 building—five storeys of reinforced concrete; 2 buildings—six storeys of reinforced concrete.

- -

- from 2D surface elements (1 building in total): 1 building with three reinforced concrete storeys.

- -

- 3D volume elements (2 buildings in total): 1 building with no storeys of reinforced concrete construction, and 1 building with two lower storeys of reinforced concrete.

- -

- Hybrid (2 buildings in total): 2 buildings with three storeys of reinforced concrete.

- -

- Mixed structure (0 buildings).

- -

- No information on the structural solution of the timber part buildings (1 building in total): 1 building with four storeys of reinforced concrete.

Figure 9.

Number of above-ground reinforced concrete storeys for buildings with load-bearing layout depending on height: (a) 1D, (b) 2D, (c) 3D.

It is worth noting that in both height ranges there are buildings with above-ground construction from ground level (i.e., at all storey levels) made entirely of mass timber (cf. Figure 9). In the case of buildings with heights of 45 m or less, there are 19 of them, i.e., a percentage of −30% given the total number of buildings surveyed in this height group of 62. In the group of buildings with heights of more than 45 m, there are 6—representing 26% in this height group (comprising 23 buildings).

It should be mentioned that the tallest buildings with the above-ground part (excluding circulation paths) made entirely of timber (cf. Table A1 in Appendix A) in individual types of load-bearing systems are as follows:

- –

- Mjøstårnet with an 1D element structure with a height of 84.5 m;

- –

- Sensation with a 2D element structure with a height of 38 m;

- –

- The Sara Kulturhus Center with a structure made of 3D elements and a height of 80 m;

- –

- The Cube Building with a hybrid structure and a height of 33 m;

- –

- The residences J.Ferry with a mixed structure and a height of 27 m.

The analysis results presented here confirm the implementation of buildings with a structure for the above-ground part (excluding circulation paths) made entirely of mass timber, a natural, renewable material that is beneficial in terms of environmental impact.

3.4. Material Solutions for Circulation Paths—Stage IV

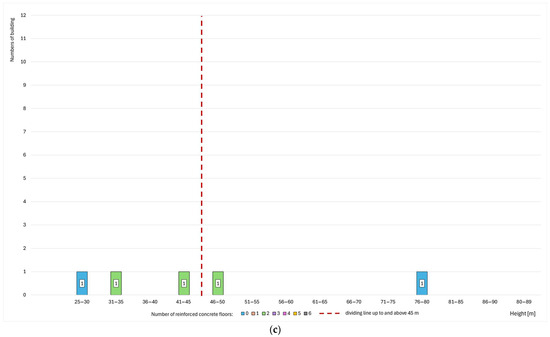

The next stage of the analysis involved the study of material solutions for the construction of circulation paths, which was based on data contained in the literature (Table A1 in Appendix A) related—in this respect—to 78 buildings, out of a total of 109 surveyed.

Three types of material solutions for the structure of circulation paths were found (Figure 10a): hybrid structures combining steel and mass timber elements (5 buildings), structure made fully of mass timber (30 buildings) and reinforced concrete structures (43 buildings). Due to the lack of data in this field, no material solution for the circulation paths has been determined in the case of 31 buildings. The percentage of individual solutions in relation to the total group of analysed buildings is as follows (Figure 10b): for circulation paths made of steel and mass timber—5%; mass timber—28%; reinforced concrete—39%; no data—28%.

Figure 10.

Material solutions for the construction of circulation paths: (a) number of cases, (b) percentage.

From the above summaries, it can be concluded that the proportion of environmentally friendly solutions using sustainable materials—mass timber in both load-bearing system construction and circulation path construction of high-rise buildings—is significant at 28%.

An analysis was made of 30 buildings with a load-bearing layout including circulation paths made of mass timber (Figure 11).

Figure 11.

Number of buildings with mass timber circulation paths under construction over time, indicating trend lines (colour distinctions in accordance with Figure 4): (a) all types of load bearing systems, (b) 1D systems, (c) 2D systems, (d) 3D systems.

These buildings were found to have the following load-bearing systems:

- -

- 1D bar elements—13 buildings; the tallest building in this research group is Mjøstårnet, with 18 above-ground storeys, 84.5 m high, delivered in 2019.

- -

- 2D surface elements—13 buildings, the tallest building in this research group is Cederhusen with 13 above-ground storeys, 44 m high, delivered in 2023.

- -

- 3D volume elements—3 buildings, the tallest building in this group is the Sara Kulturhus Center with 20 above-ground storeys, 80 m high, to be completed in 2021.

- -

- In one case, no data was available to determine the structure of the building.

Based on the above analysis results, it can be concluded that buildings with mass timber circulation path construction are as follows:

- -

- 1D load-bearing system—12% (13 buildings) of all 109 buildings surveyed;

- -

- 2D load-bearing system—12% (13 buildings) of all 109 buildings surveyed;

- -

- 3D layout—3% (3 buildings) of all 109 buildings surveyed.

It should be mentioned that out of the set of 30 buildings with mass timber circulation paths, the buildings with the greatest use of mass timber, i.e., without lower above-ground reinforced concrete storeys, were singled out. Eleven cases of such buildings were found with a material solution for the construction of the above-ground part including the circulation path structure fully made of mass timber, which represents 10% of all the buildings surveyed. These are the following buildings (the type of load-bearing system, height, country of location and year of completion are given in brackets): Carbon12 (1D, 26 m, USA, 2018), Strandparken Building B (2D, 27 m, Sweden, 2014), Wood Innovation Design Centre (1D, 29.5 m, Canada, 2014), Stadthaus (2D, 30 m, UK, 2009), Cenni di Cambiamento (2D, 31 m, Italy, 2013), Kajstaden (2D, 31 m, Sweden, 2019), Sensations (2D, 38 m, France, 2019), Fyrtornet (1D, 38 m, Sweden, under construction), Obayashi Training Facility/Port Plus (1D, 44 m, Japan, 2022), Sara Kulturhus Center (3D, 80 m, Sweden, 2021), Mjøstårnet (1D, 84.5 m, Norway, 2019).

Based on the above analysis results, it can be concluded that the most sustainable buildings in terms of material solution, i.e., with an above-ground part made entirely of mass timber, were realised with a load-bearing layout as follows:

- -

- 1D bar—representing 4.5% (5 buildings) of the total 109 buildings surveyed;

- -

- 2D surface—4.5% (5 buildings);

- -

- 3D volume—1% (1 building).

a fully mass timber above-ground The tallest among the aforementioned buildings with part including bracing frames are the 1D element Mjøstårnet with a height of 84.5 m, the 2D element Sensations with a height of 38 m and the 3D element Sara Kulturhus Center with a height of 80 m.

The examples presented confirm the possibilities of using solely a sustainable material—mass timber—to erect the above-ground parts of tall buildings.

3.5. Analysis of Spatial Design and Slenderness of Building Geometries

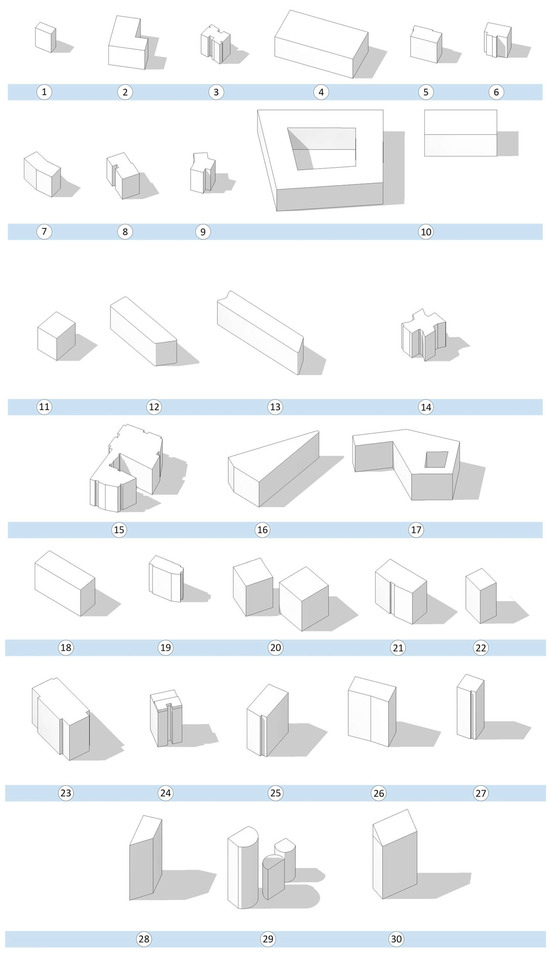

The next stage of the research attempted to analyse the shape of the building geometries, their projections and their slenderness, defined as the quotient of the height of the above-ground part and the smallest dimension of the projection at ground level. These analyses were carried out for 30 buildings for which it was possible to determine the required overall dimensions (Table 1).

Table 1.

Summary of slenderness coefficients of selected buildings.

With regard to the spatial shape of the geometries of the buildings in question, it may be concluded (Figure 12) that the predominant shape of the horizontal projection at ground level is a rectangle (17 buildings)—which accounts for 57% of the surveyed cases; a system of polygons formed from the combination of several rectangles (8 buildings)—27%; as well as rarer examples of buildings with a near-trapezoidal ground plan (3 buildings)—10%; near-triangular (1 building)—3%; or constituting a segment of a circle (1 building)—3%.

Figure 12.

Diagrams of the geometries of the buildings surveyed (numbering as given in Table 1).

The basic type of shapes used in the spatial design of the analysed buildings are cuboid-like geometries (17 buildings)—57%; geometries forming a system of connected cuboids (8 buildings)—27%; or, less frequently, straight prisms with a triangular, trapezoidal or cylindrical base (5 buildings in total)—16%.

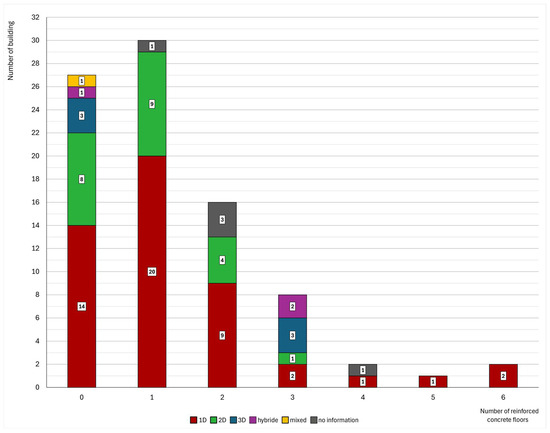

With regard to the proportions in the shaping of the geometries—as expressed by the slenderness ratio—of the listed buildings, it can be stated (Figure 13; cf. Table 1) that mass timber tall buildings are characterised by low slenderness. In the case of buildings up to 50 m in height (24 buildings, accounting for 80% of the buildings under research), this slenderness ranges from 0.66 to around 2.98. It should be mentioned that the largest number of buildings in this height range (16 buildings, or 53% of the buildings analysed in this range) have a slenderness of between 1 and 2. Buildings with heights above 50 m (6 buildings, representing 20% of the buildings analysed in this area) are characterised by higher slenderness values, i.e., between 2.41 and 4.97.

Figure 13.

Diagram showing slenderness in relation to building height (colour distinctions in accordance with Figure 4): (a) all load-bearing systems, (b) 1D systems, (c) 2D systems, (d) 3D systems.

The results of our aforementioned own analyses suggest that the five buildings (17% of those analysed in this respect) with the highest slenderness values (from 3 to 5) have a 1D load-bearing system (4 cases—Arbo, T3 Collingwood, TRÆ, Mjøstårnet) and one building (Haut) has a 2D load-bearing system.

It should be mentioned that the choice of the load-bearing system solution is directly related to the functional solution of the building concerned. Two-dimensional wall systems are usually the primary solution used in the case of residential functions, whereas 1D post-and-beam or frame systems are used for public buildings with larger required areas of rooms without intermediate supports, including educational, commercial, office and other functions.

4. Conclusions

Tall timber buildings bring together in their spatial and structural solution two important aspects of sustainability in construction at the same time, i.e., the use of a natural renewable material—wood—in the shaping of the load-bearing system and, through the introduction of intensive high-rise buildings, less interference with natural spaces.

Mass timber tall buildings are innovative and still rare material and construction solutions, although there is a trend towards more of them and the construction of this type of building with ever greater heights.

The most common types of mass timber tall building construction are 1D bar systems, accounting for 47% of the buildings analysed, and 2D surface element systems accounting for 23%, with the remaining 3D volume (4%), hybrid (3%) and mixed (1%) systems used infrequently.

Buildings of this type have the structure of the underground part and often the lower storeys of the above-ground part and the circulation path made of reinforced concrete, with the rest of the above-ground part made mainly of mass timber.

Buildings up to 45 m in height—which is the domain of the use of 2D layouts—tend to have 0 to 2 lower above-ground storeys of reinforced concrete construction, and over 45 m in height—0 to 6.

Circulation paths are implemented with three types of material solutions, i.e., hybrid combining steel and timber, mass timber and reinforced concrete. The percentage of each of these solutions in relation to the total group of buildings surveyed is as follows: 5%, 28%, 39% (data missing—28%).

The proportion of pro-environmental solutions using sustainable materials—mass timber in both the load-bearing system construction and the circulation path construction of high-rise buildings—is significant at 28%. It should be mentioned that, in addition, 11 cases of such buildings were found with a material solution for the construction of all above-ground storeys, including the structure of the circulation path, made entirely of mass timber, which represents 10% of all the buildings surveyed.

The most sustainable buildings in terms of material solution, i.e., with a fully mass timber above-ground part, were realised with the following load-bearing layout: bar 1D—representing 4.5% of all 109 buildings surveyed; surface 2D—4.5%; volume 3D—1%.

The tallest among the aforementioned buildings with a fully mass timber above-ground part including bracing frames are the 1D element Mjøstårnet with a height of 84.5 m, the 2D element Sensations with a height of 38 m and the 3D element Sara Kulturhus Center with a height of 80 m.

The examples presented confirm the possibilities of using solely a sustainable material—mass timber—to erect the above-ground parts of tall buildings.

The predominant shape of the ground plan of the buildings in question is a rectangle (57%) or a polygon system formed from a combination of rectangles (27%), and less frequently a trapezoid (10%), triangle (3%) or circle (3%). The basic types of shapes used in the spatial design of the analysed buildings are cuboid-like geometries (57%), geometries forming a system of connected cuboids (27%), or, less frequently, straight prisms with a triangular, trapezoidal or cylindrical base (16% in total). The limited variety and flexibility in the design of the shape and layout of tall timber buildings is determined by the technological conditions of the production of prefabricated elements (1D, 2D, 3D) that shape their load-bearing systems, as well as transport requirements.

Mass timber tall buildings are characterised by their low slenderness. Compared to traditional high-rise buildings with a reinforced concrete load-bearing system, this slenderness is typically 2–4-times smaller. For buildings up to 50 m in height (80% of the buildings analysed in this range), this slenderness ranges from 0.66 to around 2.98, while buildings over 50 m in height (20% of the same) have higher slenderness values of 2.41 to 4.97.

Author Contributions

Conceptualisation, H.M.; methodology, H.M. and K.M.; software, K.M.; validation, H.M.; formal analysis, H.M.; investigation, H.M. and K.M.; resources, H.M. and K.M.; data curation, K.M.; writing—original draft preparation, H.M. and K.M.; writing—review and editing, H.M.; visualisation, K.M.; supervision, H.M.; project administration, H.M.; funding acquisition, H.M. All authors have read and agreed to the published version of the manuscript.

Funding

Research was funded by Warsaw University of Technology within the Excellence Initiative: Research University (IDUB) programme. The grant number 504/04496/1010/45.290021.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Summary of basic data concerning the spatial and material–structural solutions of the buildings under research.

Table A1.

Summary of basic data concerning the spatial and material–structural solutions of the buildings under research.

| No. | Name of Building | Location | Year of Completion (1) | Height (Above Ground Level), [m]. | Number of Floors Above Ground | Number of Floors Above Ground Made of Mass Timber | Number of Floors Above Ground Made of Reinforced Concreate | Type of Load-Bearing Structure of the Above-Ground Part (Acc. to the Classification in Figure 2) | Wall/Post Construction | Ceiling Construction | Structure Material of Vertical Communication and Shafts (2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Holz 8 [41] | Bad Aiblng, Germany | 2011 | 25 | 8 | 8 | 0 | 2D | CLT | CLT | RC |

| 2 | Heartwood [47] | Seattle, USA | 2023 | 25.5 | 8 | 8 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT | Steel and CLT |

| 3 | Cradle [48] | Düsseldorf, Germany | 2023 | 25.7 | 7 | 6 | 1 | 1D | - | - | RC |

| 4 | Marselle Condos [46] | Seattle, USA | 2009 | 25.9 | 7 | - | - | - | - | - | - |

| 5 | Emmons on 3rd [39] | Seattle, USA | 2014 | 26 | 8 | - | - | - | - | - | - |

| 6 | T3 Minneapolis [49] | Minneapolis, USA | 2016 | 26 | 7 | 6 | 1 | 1D | GLT | Beams—GLT, ceiling panels - NLT | RC |

| 7 | Carbon 12 [50] | Portland, USA | 2018 | 26 | 8 | 7 | 1 | 1D | GLT | Beams—GLT, ceiling panels—CLT | GLT, CLT |

| 8 | T3 West Midtown [41] | Atlanta, USA | 2019 | 26 | 7 | 6 | 1 | 1D | GLT | Beams—GLT, ceiling panels - DLT | CLT |

| 9 | Cirrus [41] | Denver, USA | 2022 | 26 | 7 | 5 | 2 | - | - | - | RC |

| 10 | Limnologen [51] | Vaxjo, Sweden | 2009 | 27 | 7 | 6 | 1 | 2D | CLT (locally framed layout with GLT) | Beams—GLT, ceiling panels—CLT | RC |

| 11 | Portvakten Söder [37] | Portvakten Söder, Sweden | 2009 | 27 | 8 | 7 | 1 | 2D | CLT | CLT | - |

| 12 | Bridport House [46] | London, UK | 2010 | 27 | 8 | - | - | 2D | CLT | CLT | - |

| 13 | LCT One [52] | Dunrobin, Austria | 2012 | 27 | 8 | 7 | 1 | 1D | GLT | Beams—GLT, ceiling panels - TCC | RC |

| 14 | Pentagon I [41] | As, Norway | 2013 | 27 | 8 | - | - | - | - | - | - |

| 15 | Strandparken Building B [53] | Stockholm, Sweden | 2024 | 27 | 8 | 8 | 0 | 2D | CLT | CLT | CLT |

| 16 | Residences J.Ferry [46] | Saint-Dié-des Vosges, France | 2014 | 27 | 8 | 8 | 0 | Mixed | Posts—GLT, walls—GLT | Beams—GLT, ceiling panels—CLT | - |

| 17 | Hotel Nautilus [46] | Pesaro, Italy | 2016 | 27 | 8 | - | - | 2D | CLT | CLT | - |

| 18 | Wood City Apartments [46] | Helsinki, Finland | 2017 | 27 | 8 | - | - | 1D | LVL | Beams—LVL, ceiling panels—CLT | - |

| 19 | Dramsvegen [46] | Tromso, Norway | 2017 | 27 | 8 | - | - | - | - | - | - |

| 20 | Highpoint Terrace [46] | London, UK | 2017 | 27 | 8 | 8 | 0 | 3D | CLT | CLT | CLT and steel |

| 21 | Lucien Cornil Student Residence [46] | Marseille, France | 2017 | 27 | 8 | - | - | - | Posts—GLT, walls—CLT | Beams—GLT, ceiling panels—CLT | - |

| 22 | The Gardens Macarthur [46] | Sydney, Australia | 2018 | 27 | 8 | - | - | - | - | - | - |

| 23 | Maskinparken TRE [20] | Trondheim, Norway | 2018 | 27 | 8 | - | - | 2D | CLT | CLT | CLT |

| 24 | Frostaliden [54] | Skövde, Sweden | 2018 | 27 | 8 | 8 | 0 | 2D | CLT | CLT | RC |

| 25 | Puukuokka One, Two, Tree [55] | Jyväskylä, Finland | 2018 | 27 | 8 | 8 | 0 | 3D | CLT | CLT | - |

| 26 | Docenten [46] | Vaxjo, Sweden | 2018 | 27 | 8 | - | - | - | - | - | - |

| 27 | Jo & Joe [46] | Paris, France | 2019 | 27 | 8 | 7 | 1 | 1D | LVL | Beams—LVL - ceiling panels—CLT | RC |

| 28 | Das Kelo [46] | Rovaniemi, Finland | 2019 | 27 | 8 | 7 | 1 | 2D | CLT | CLT | - |

| 29 | Arbora Condominium [50] | Montreal, Canada | 2019 | 27 | 8 | 7 | 1 | 1D | GLT | Beams—GLT, ceiling panels—CLT | CLT |

| 30 | Trummens Strand [46] | Vaxjo, Sweden | 2020 | 27 | 8 | 6, 7—depends on the building | 1/2 | 2D | CLT | CLT | CLT |

| 31 | Cirerers [56] | Barcelona, Spain | 2022 | 27 | 8 | 7 | 1 | 2D | CLT | CLT | CLT |

| 32 | Moholt 50/50 [57] | Trondheim, Norway | 2016 | 28 | 9 | 8 | 1 | 2D | CLT | CLT | CLT |

| 33 | EDGE Suedkreuz [58] | Berlin, Germany | 2022 | 29 | 8 | 7 | 1 | 1D | GLT | Beams—GLT, ceiling panels - TCC | RC |

| 34 | Wood Innovation Design Centre [37] | Prince George, Canada | 2014 | 29.5 | 8 | 8 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT | CLT |

| 35 | Stadthaus [37] | London, UK | 2009 | 30 | 9 | 9 | 0 | 2D | CLT acc. to the KLH system | CLT | CLT panels acc. to the KLH system |

| 36 | Patch 22 [46] | Amsterdam, Netherlands | 2016 | 30 | 7 | 5 | 2 | 1D | GLT | TCC | RC |

| 37 | International House South [46] | Sydney, Australia | 2017 | 30 | 7 | 6 | 1 | 1D | GLT and LVL | Beams—GLT, ceiling panels - CLT | CLT |

| 38 | Daramu House [46] | Sydney, Australia | 2020 | 30 | 7 | - | - | 1D | GLT | Beams—GLT, ceiling panels—CLT | - |

| 39 | Timber Pioneer [46] | Frankfurt am Main, Germany | 2023 | 30 | 8 | 6 | 2 | 1D | GLT | Beams—GLT, ceiling panels—TCC | RC |

| 40 | Cenni di Cambiamento [46] | Milan, Italy | 2013 | 31 | 9 | 9 | 0 | 2D | Mass timber | Mass timber | Mass timber |

| 41 | Press House [46] | London, UK | 2017 | 31 | 8 | 7 | 1 | 2D | CLT | CLT | - |

| 42 | Vallen [37] | Vaxjo, Sweden | 2018 | 31 | 9 | 7 | 2 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 43 | Immeuble ‘Perspective’ [37] | Bordeaux, France | 2018 | 31 | 7 | 7 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 44 | Kajstaden [46] | Vasteras, Sweden | 2019 | 31 | 9 | 9 | 0 | 2D | CLT | CLT | CLT |

| 45 | Botanikern [46] | Uppsala, Sweden | 2019 | 31 | 9 | 7 | 2 | - | Posts—GLT, walls—CLT | CLT | CLT |

| 46 | Caisse d’Epargne Bourgogne-Franche-Comté Headquarters [46] | Dijon, France | 2022 | 31 | 7 | 6 | 1 | 1D | Posts—GLT, walls—CLT | Beams—GLT, ceiling panels—LVL | CLT |

| 47 | Forte [46] | Melbourne, Australia | 2012 | 32 | 10 | 9 | 1 | 2D | GLT | CLT | CLT |

| 48 | Tamedia Office [59] | Zurich, Switzerland | 2013 | 32 | 7 | 7 | 0 | 1D | GLT | CLT | RC |

| 49 | The Cube Building [46] | London, UK | 2015 | 33 | 10 | 10 | 0 | Hybride | Posts—steel, walls—CLT | Beams—steel, ceiling panels—CLT | RC |

| 50 | Dalston Works [60] | London, UK | 2017 | 34 | 10 | 9 | 1 | 2D | CLT | CLT | CLT |

| 51 | Kringsja Studentby [46] | Oslo, Norway | 2018 | 34 | 10 | - | - | - | - | - | - |

| 52 | Hotel Jakarta [46] | Amsterdam, Netherlands | 2018 | 34 | 9 | 7 | 2 | 3D | CLT | CLT | - |

| 53 | Skaio Wooden Apartment Building [41] | Heilbronn, Germany | 2019 | 34 | 10 | 8 | 2 | 2D | CLT | CLT | RC |

| 54 | Opalia [41] | Paris, France | 2017 | 35 | 8 | - | - | 1D | Posts—steel and GLT | Beams—steel and GLT, ceiling panels—CLT | RC |

| 55 | Green Office ENJOY [46] | Paris, France | 2018 | 35 | 8 | 6 | 2 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 56 | Pont de Flandres Batiment 007 [46] | Paris, France | 2019 | 35 | 8 | 7 | 1 | 1D | GLT | Beams—GLT | RC |

| 57 | Palazzo Meridia [46] | Nice, France | 2020 | 35 | 10 | 9 | 1 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 58 | Supercell Headquarters [46] | Helsinki, Finland | 2020 | 35 | 8 | - | - | - | - | - | - |

| 59 | Apex Plaza [46] | Charlottesville, USA | 2022 | 35 | 8 | 6 | 2 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 60 | Suurstoffi 22 [61] | Risch-Rotkreuz, Switzerland | 2018 | 36 | 10 | 10 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT and TCC | RC |

| 61 | Aveo Bella Vista [46] | Sydney, Australia | 2018 | 36 | 11 | - | - | 2D | CLT | CLT | - |

| 62 | Trafalgar Place [41] | London, UK | 2015 | 36.6 | 10 | 8 | 2 | - | - | - | - |

| 63 | Sensations [62] | Strasbourg, France | 2019 | 38 | 11 | 10 | 1 | 2D | CLT | CLT | CLT |

| 64 | Fyrtornet [46] | Malmo, Sweden | UC | 38 | 11 | 11 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT | CLT |

| 65 | Monterey [63] | Brisbane, Australia | 2021 | 39 | 12 | 10 | 2 | 2D | CLT | CLT | RC |

| 66 | Auckland City Mission [64] | Auckland, New Zealand | 2022 | 39 | 10 | 9 | 1 | 2D | Posts—GLT, walls—CLT | Beams—GLT, ceiling panels—CLT | CLT |

| 67 | INTRO Residential Tower [65] | Cleveland, USA | 2022 | 39.6 | 9 | 8 | 1 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 68 | Klein Veldekens [41] | Geel, Belgium | 2020 | 40 | 10 | 9 | 1 | - | GLT | - | RC |

| 69 | T3 Sterling Road [46] | Toronto, Canada | UC | 40 | 8 | 8 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT and DLT | - |

| 70 | Origine [50] | Quebec, Canada | 2017 | 40.9 | 13 | 12 | 1 | 1D | GLT | Beams—GLT, ceiling panels—CLT | CLT |

| 71 | Blindern Studenthus [46] | Oslo, Norway | 2019 | 41 | 12 | - | - | - | - | - | - |

| 72 | Tallwood I [66] | Langford, Canada | 2022 | 41 | 12 | 11 | 1 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 73 | Spor X [67] | Drammen, Norway | 2021 | 41.4 | 10 | 10 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT | CLT |

| 74 | T3 Bayside [37] | Toronto, Canada | 2023 | 42 | 10 | 9 | 1 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 75 | Hoas Tuuliniitty [46] | Espoo, Finland | 2021 | 42 | 13 | 11 | 2 | 3D | Posts—LVL, walls—CLT | Beams—LVL, ceiling panels—CLT | RC (storeys—0 and 1); above CLT |

| 76 | Obayashi Training Facility /Port Plus [46] | Yokohama, Japan | 2022 | 44 | 11 | 11 | 0 | 1D | LVL | Beams—LVL | LVL |

| 77 | Cederhusen [68] | Stockholm, Sweden | 2023 | 44 | 13 | 11 | 2 | 2D | CLT | CLT | CLT |

| 78 | Holz-Hybrid-Hochhaus CARL [46] | Pforzheim, Germany | 2024 | 48.5 | 14 | 13 | 1 | 1D | GLT | Beams—GLT, ceiling panels—TCC | RC |

| 79 | 2150 Keith Drive The Hive [68] | Vancouver, Canada | UC | 45 | 10 | 8 | 2 | 1D | GLT | Beams—steel, ceiling panels—CLT | Steel |

| 80 | 25 King [68] | Brisbane, Australia | 2018 | 46.5 | 10 | 9 | 1 | 1D | GLT | CLT | CLT |

| 81 | Baker’s Place [46] | Madison, USA | UC | 47.4 | 14 | 11 | 3 | Hybrid | Posts—steel | Beams—steel, ceiling panels—CLT | Steel |

| 82 | Lighthouse Joensu [46] | Joensuu, Finland | 2019 | 48 | 14 | 13 | 1 | 1D | LVL | Ceiling panels—CLT | CLT |

| 83 | Proud Kanda Surugadai [46] | Tokyo, Japan | 2021 | 48.3 | 14 | - | - | - | - | - | - |

| 84 | Treet [69] | Bergen, Norway | 2015 | 49 | 14 | 12 | 2 | 3D | GLT | CLT | CLT |

| 85 | Sawa [46] | Rotterdam, Netherlands | UC | 50 | 16 | 15 | 1 | 1D | GLT | Ceiling panels—CLT | RC |

| 86 | 503 on Tenth [68] | Portland, USA | UC | 50 | 10 | - | - | - | - | - | - |

| 87 | Wurriki Nyal Civic Precinct—Ngytan Koriayo [68] | Greater Geelong, Australia | UC | 52 | 11 | 9 | 2 | 1D | GLT and LVL | Beams—GLT and LVL, ceiling panels—CLT | RC |

| 88 | Limberlost Place [70] | Toronto, Canada | UC | 52.5 | 10 | 10 | 0 | 1D | GLT | Ceiling panels—CLT | Steel |

| 89 | Albizzia [71] | Lyon, France | 2023 | 53 | 16 | 13 | 3 | Hybrid | CLT | CLT | RC |

| 90 | Brock Commons Tallwood House [66] | Vancouver, Canada | 2017 | 53 | 18 | 17 | 1 | 1D | GLT | Beams—GLT | RC |

| 91 | Hyperion [34] | Bordeaux, France | 2021 | 55 | 16 | 13 | 3 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 92 | Eunoia Junior College [68] | Singapore, Singapore | 2019 | 56 | 12 | - | - | - | - | - | - |

| 93 | Stories [46] | Amsterdam, Netherlands | 2021 | 56 | 13 | 10 | 3 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 94 | Arbo [72] | Lucerne, Switzerland | 2019 | 60 | 15 | 15 | 0 | 1D | GLT and LVL | Beams—GLT, ceiling panels—TCC | RC |

| 95 | T3 Collingwood [73] | Melbourne, Australia | 2023 | 63 | 15 | 9 | 6 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 96 | ANDYS at 1510 Webster Street [46] | Oakland, USA | 2024 | 65 | 19 | 17 | 2 | 1D | MPL | Ceiling panels—MPP | RC |

| 97 | Roots [46] | Hamburg, Germany | 2024 | 65 | 19 | 15 | 4 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 98 | Brunfaut Tower [46] | Brussels, Belgium | 2023 | 69.3 | 22 | - | - | - | - | - | - |

| 99 | 55 Southbank [41] | Melbourne, Australia | 2020 | 69.7 | 19 | - | - | - | - | - | - |

| 100 | De Karel Doorman [74] | Rotterdam, Netherlands | 2012 | 70.5 | 22 | - | - | - | - | - | - |

| 101 | Haut [75] | Amsterdam, Netherlands | 2021 | 73 | 21 | 19 | 2 | 2D | CLT | TCC | RC |

| 102 | Kaj16 [46] | Goteborg, Sweden | UC | 78.5 | 16 | 12 | 4 | - | - | - | - |

| 103 | Sara Kulturhus Center [76] | Skellefteå, Sweden | 2021 | 80 | 20 | 20 | 0 | 3D | CLT | CLT | CLT |

| 104 | TRÆ [41] | Aarhus, Denmark | UC | 81.7 | 20 | 20 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT | RC |

| 105 | HoHo Vienna [77] | Vienna, Austria | 2019 | 84 | 24 | 24 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT and TCC | RC |

| 106 | Mjøstårnet [78] | Brumunddal, Norway | 2019 | 84.5 | 18 | 18 | 0 | 1D | GLT | Beams—GLT, ceiling panels—CLT (storeys 2–11) and Tra8 (storeys 12–18) | CLT |

| 107 | Tilia Tower [46] | Lausanne, Switzerland | UC | 85 | 28 | 22 | 6 | 1D | GLT | Beams—GLT, ceiling panels—TCC | RC |

| 108 | Ascent MKE [79] | Milwaukee, USA | 2022 | 86.6 | 25 | 20 | 5 | 1D | GLT | Ceiling panels—CLT | RC |

| 109 | Atlassian Central [80] | Sydney, Australia | UC | 182.6 | 42 | - | - | - | - | - | - |

(1) UC—under construction, (2) RC—reinforced concrete.

References

- Min, J.; Yan, G.; Abed, A.M.; Elattar, S.; Khadimallah, M.A.; Jan, A.; Ali, H.E. The effect of carbon dioxide emissions on the building energy efficiency. Fuel 2022, 326, 124842. [Google Scholar] [CrossRef]

- United Nations. Department of Economic and Social Affairs, Sustainable Development. The 17 Goals. Available online: https://sdgs.un.org/goals (accessed on 28 July 2025).

- United Nations, Department of Economic and Social Affairs. The Sustainable Development Goals Report 2023: Special Edition. Available online: https://unstats.un.org/sdgs/report/2023 (accessed on 28 July 2025).

- Angelo, H.; Wachsmuth, D. Why does everyone think cities can save the planet? Urban Stud. 2020, 57, 2201–2221. [Google Scholar] [CrossRef]

- Kjærås, K. Towards a relational conception of the compact city. Urban Stud. 2020, 58, 1176–1192. [Google Scholar] [CrossRef]

- Bibby, P.; Henneberry, J.; Halleux, J.-M. Incremental residential densification and urban spatial justice: The case of England between 2001 and 2011. Urban Stud. 2020, 58, 2117–2138. [Google Scholar] [CrossRef]

- Burton, E. The Compact City: Just or Just Compact? A Preliminary Analysis. Urban Stud. 2020, 37, 1969–2006. [Google Scholar] [CrossRef]

- Holgersson, H. Skies over Frölunda: ‘Mixed city’ densification and the lived space of a stigmatised Modernist suburb in Sweden. Urban Stud. 2025, 27, 00420980251342942. [Google Scholar] [CrossRef]

- Harte, A.M. Mass timber—The emergence of a modern construction material. J. Struct. Integr. Maint. 2017, 2, 121–132. [Google Scholar] [CrossRef]

- Abed, J.; Rayburg, S.; Rodwell, J.; Neave, M. A Review of the Performance and Benefits of Mass Timber as an Alternative to Concrete and Steel for Improving the Sustainability of Structures. Sustainability 2022, 14, 5570. [Google Scholar] [CrossRef]

- Green, M. The Case for Tall Wood Buildings. How Mass Timber Offers a Safe, Economical, and Environmentally Friendly Alternative for Tall Building Structures. Second Edition, MGA I Michael Green Architecture+ Design. 2012. Available online: https://cwc.ca/wp-content/uploads/2020/06/Second-Edition-The-Case-for-Tall-Wood-Buildings.pdf (accessed on 20 February 2025).

- Tupėnaitė, L.; Žilėnaitė, V.; Kanapeckienė, L.; Sajjadian, S.M.; Gečys, T.; Sakalauskienė, L.; Naimavičienė, J. Multiple criteria assessment of high-rise timber buildings. Eng. Struct. Technol. 2019, 11, 87–94. [Google Scholar] [CrossRef]

- Ahmed, S.; Arocho, I. Mass timber building material in the U.S. construction industry: Determining the existing awareness level, construction-related challenges, and recommendations to increase its current acceptance level. Clean. Eng. Technol. 2020, 1, 100007. [Google Scholar] [CrossRef]

- Pomponi, F.; Hart, J.; Arehart, J.H.; D’Amico, B. Buildings as a Global Carbon Sink? A Reality Check on Feasibility Limits. One Earth 2020, 3, 157–161. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schelinhuber, H.J. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Lifecycle primary energy analysis of low-energy timber building systems for multi-storey residential buildings. Energy Build. 2014, 81, 84–97. [Google Scholar] [CrossRef]

- Börjesson, P.; Gustavsson, L. Greenhouse gas balances in building construction: Wood versus concrete from life-cycle and forest land-use perspectives. Energy Policy 2000, 28, 575–588. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Buildings. In Climate Change 2014: Mitigation of Climate Change: Working Group III Contribution to the IPCC Fifth Assessment Report; Cambridge University Press: Cambridge, UK, 2015; pp. 671–738. [Google Scholar]

- Skullestad, J.L.; Bohne, R.A.; Lohne, J. High-rise Timber Buildings as a Climate Change Mitigation Measure—A Comparative LCA of Structural System Alternatives. Energy Procedia 2016, 96, 112–123. [Google Scholar] [CrossRef]

- Eliassen, A.R.; Faanes, S.; Bohne, R.A. Comparative LCA of a concrete and steel apartment building and a cross laminated timber apartment building. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012017. [Google Scholar] [CrossRef]

- Dong, Y.; Cui, X.; Yin, X.; Chen, Y.; Guo, H. Assessment of Energy Saving Potential by Replacing Conventional Materials by Cross Laminated Timber (CLT)—A Case Study of Office Buildings in China. Appl. Sci. 2019, 9, 858. [Google Scholar] [CrossRef]

- Sandoli, A.; D’Ambra, C.; Ceraldi, C.; Calderoni, B.; Prota, A. Sustainable Cross-Laminated Timber Structures in a Seismic Area: Overview and Future Trends. Appl. Sci. 2021, 11, 2078. [Google Scholar] [CrossRef]

- Ceccotti, A.; Sandhaas, C.; Okabe, M.; Yasumura, M.; Minowa, C.; Kawai, N. SOFIE Project–3D Shaking Table Test on a Seven-Storey Full-Scale Cross-Laminated Timber Building. Earthq. Eng. Struct. Dyn. 2013, 42, 2003–2021. [Google Scholar] [CrossRef]

- Izzi, M.; Casagrande, D.; Bezzi, S.; Pasca, D.; Follesa, M.; Tomasi, R. Seismic behaviour of Cross-Laminated Timber structures: A state-of-the-art review. Eng. Struct. 2018, 170, 42–52. [Google Scholar] [CrossRef]

- Stepinac, M.; Šušteršič, I.; Gavrić, I.; Rajčić, V. Seismic Design of Timber Buildings: Highlighted Challenges and Future Trends. Appl. Sci. 2020, 10, 1380. [Google Scholar] [CrossRef]

- Iezzi, S.; Savini, F.; Trizio, I.; Fabbrocino, G.; Sandoli, A. On the Role of Seismic Damage Tolerance on Costs and Life Cycle of CLT Buildings. Appl. Sci. 2023, 13, 9113. [Google Scholar] [CrossRef]

- Bezabeh, M.A.; Bitsuamlak, G.T.; Popovski, M.; Tesfamariam, S. Probabilistic Serviceability-Performance Assessment of Tall Mass-Timber Buildings Subjected to Stochastic Wind Loads: Part II—Structural Reliability Analysis. J. Wind. Eng. Ind. Aerodyn. 2018, 181, 112–125. [Google Scholar] [CrossRef]

- Bezabeh, M.A.; Bitsuamlak, G.T.; Popovski, M.; Tesfamariam, S. Dynamic Response of Tall Mass-Timber Buildings to Wind Excitation. J. Struct. Eng. 2020, 146, 04020199. [Google Scholar] [CrossRef]

- Bezabeh, M.A.; Gairola, A.; Bitsuamlak, G.T.; Popovski, M.; Tesfamariam, S. Structural Performance of Multi-Story Mass-Timber Buildings under Tornado-like Wind Field. Eng. Struct. 2018, 177, 519–539. [Google Scholar] [CrossRef]

- Muszyński, L.; Gupta, R.; hyun Hong, S.; Osborn, N.; Pickett, B. Fire Resistance of Unprotected Cross-Laminated Timber (CLT) Floor Assemblies Produced in the USA. Fire Saf. J. 2019, 107, 126–136. [Google Scholar] [CrossRef]

- Östman, B.; Brandon, D.; Frantzich, H. Fire Safety Engineering in Timber Buildings. Fire Saf. J. 2017, 91, 11–20. [Google Scholar] [CrossRef]

- Frangi, A.; Fontana, M.; Knobloch, M. Fire Design Concepts for Tall Timber Buildings. Struct. Eng. Int. 2008, 18, 148–155. [Google Scholar] [CrossRef]

- Pramreiter, M.; Nenning, T.; Huber, C.; Müller, U.; Kromoser, B.; Mayencourt, P.; Konnerth, J. A review of the resource efficiency and mechanical performance of commercial wood-based building materials. Sustain. Mater. Technol. 2023, 38, e00728. [Google Scholar] [CrossRef]

- Basterra, L.-A.; Baño, V.; López, G.; Cabrera, G.; Vallelado-Cordobés, P. Identification and Trend Analysis of Multistorey Timber Buildings in the SUDOE Region. Buildings 2023, 13, 1501. [Google Scholar] [CrossRef]

- Žegarac Leskovar, V.; Premrov, M. A Review of Architectural and Structural Design Typologies of Multi-Storey Timber Buildings in Europe. Forests 2021, 12, 757. [Google Scholar] [CrossRef]

- Kuzmanovska, I.; Gasparri, E.; Tapias Monné, D.; Aitchison, M. Tall Timber Buildings: Emerging trends and typologies. In Proceedings of the 2018 World Conference on Timber Engineering, Seoul, Republic of Korea, 20–23 August 2018. [Google Scholar]

- Michalak, H.; Michalak, K. Selected Aspects of Sustainable Construction—Contemporary Opportunities for the Use of Timber in High and High-Rise Buildings. Energies 2024, 17, 1961. [Google Scholar] [CrossRef]

- Ilgın, H.E.; Aslantamer, Ö.N. Spatial Effectiveness in High-Rise Timber Towers: A Global Perspective. Buildings 2024, 14, 2713. [Google Scholar] [CrossRef]

- Ilgın, H.E. High-Rise Residential Timber Buildings: Emerging Architectural and Structural Design Trends. Buildings 2024, 14, 25. [Google Scholar] [CrossRef]

- Ilgın, H.E. Analysis of the Main Architectural and Structural Design Considerations in Tall Timber Buildings. Buildings 2024, 14, 43. [Google Scholar] [CrossRef]

- Svatoš-Ražnjević, H.; Orozco, L.; Menges, A. Advanced Timber Construction Industry: A Review of 350 Multi-Storey Timber Projects from 2000–2021. Buildings 2022, 12, 404. [Google Scholar] [CrossRef]

- Chai, H.; Wagner, H.J.; Guo, Z.; Qi, Y.; Menges, A.; Yuan, P.F. Computational design and on-site mobile robotic construction of an adaptive reinforcement beam network for cross-laminated timber slab panels. Autom. Constr. 2022, 142, 104536. [Google Scholar] [CrossRef]

- Luis, O.; Krtschil, A.; Wagner, H.J.; Simon, B.; Amtsberg, F.; Skoury, L.; Knippers, J.; Menges, A. Design methods for variable density, multi-directional composite timber slab systems for multi-storey construction. In Proceedings of the International Conference on Education and Research in Computer Aided Architectural Design in Europe (eCAADe 39), Novi Sad, Serbia, 8–10 September 2021; Volume 1, pp. 303–312. [Google Scholar] [CrossRef]

- Wagner, H.; Hua, C.; Guo, Z.; Menges, A.; Yuan, P. Towards an On-site Fabrication System for Bespoke, Unlimited and Monolithic Timber Slabs. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS)—Workshop on Construction and Architecture Robotics, Las Vegas, NV, USA, 25–29 October 2020. [Google Scholar] [CrossRef]

- Forcael, E.; Mata, R.; González, B.; Opazo-Vega, A.; García-Alvarado, R.; González, M.; Núñez, E.; Padilla, J. Enhanced robotic cross-laminated timber panel assembly process. Dev. Built Environ. 2025, 22, 10066. [Google Scholar] [CrossRef]

- CTBUH Council on Tall Buildings and Urban Habitat. Tall Timber Center, The Mass Timber Database of CTBUH; CTBUH Council on Tall Buildings and Urban Habitat: Chicago, IL, USA, 2025; Available online: https://www.ctbuh.org (accessed on 16 December 2024).

- Chapagain, A.; Crovella, P. Building Sustainable Futures: Evaluating Embodied Carbon Emissions and Biogenic Carbon Storage in a Cross-Laminated Timber Wall and Floor (Honeycomb) Mass Timber Building. Sustainability 2025, 17, 5602. [Google Scholar] [CrossRef]

- Scheible, F.; Peter, B. Freie Wahl—Das Projekt bestimmt die Planungsmethode. Bautechnik 2019, 96, 939–944. [Google Scholar] [CrossRef]

- Brown, J.J. T3 Minneapolis—America’s largest modern mass timber building. In Engineering the Future—Report. In Proceedings of the IABSE Conference, Vancouver, BC, Canada, 19–23 September 2017; Structural Engineers Association of British Columbia: Vancouver, BC, Canada, 2017; Volume 109, pp. 3237–3244. [Google Scholar] [CrossRef]

- Pei, S.; Rammer, D.; Popovski, M.; Williamson, T.; Line, P.; van de Lindt, J.W. An Overview of CLT Research and Implementation in North America. USDA Forest Products Laboratory. 2016. Available online: https://www.fpl.fs.usda.gov/documnts/pdf2016/fpl_2016_pei001.pdf (accessed on 20 December 2024).

- Landel, P. RISE Research Institutes of Sweden Report 2018 Swedish Technical Benchmarking of Tall Timber Buildings. Tech. Rep. 2018, 11, 67. [Google Scholar]

- Professner, H.; Mathis, C. LifeCycle Tower—High-Rise Buildings in Timber. In Structures Congress 2012; American Society of Civil Engineers: Reston, VA, USA, 2012. [Google Scholar] [CrossRef]

- Lundgren, J. The Impact of Life Expectancy in LCA of Concrete and Massive Wood Structures: A Case Study of Strandparken in Sundbyberg. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2014. Available online: https://odr.chalmers.se/bitstreams/66c45e13-9945-4083-829d-427f17b8d0bd/download (accessed on 22 December 2024).