1. Introduction

Drying is a very important process in the food processing industry. Water is removed from food products to reduce water activity and, consequently, inhibit microbial growth and extend the product’s shelf life. Drying also decreases a product’s mass and volume, leading to lower packaging, transportation, and storage costs [

1].

Milk can be effectively preserved by drying, which is one of the methods of managing surplus raw milk during periods and in areas of high production [

2]. Dry milk ingredients can be used in various branches of the food processing industry. Milk powders have numerous applications in the dairy industry; therefore, the effect of different drying methods on the functional properties of milk powders is an important consideration in the production process.

The physicochemical parameters and functional properties of milk powders with a different composition are usually optimized by choosing the most appropriate technological processes and processing parameters [

3]. Milk powders intended for specific industrial applications should be characterized by the appropriate composition, taste, aroma, reconstitution ability, solubility, wettability, emulsifying ability, surface activity, gelling properties, foaming properties, water-binding capacity, and stability. The functional properties of powders are influenced by the shape, density, and porosity of powder particles, free fat content, surface hydrophobicity of milk particles, hydration properties, and the degree of whey protein denaturation, which is the primary criterion for dividing milk powders into heat classes [

4,

5].

The microstructure of milk powders, including the shape and porosity of powder particles, can be analyzed and compared using microscopic methods [

6,

7]. However, the structures observed under a microscope are often irregular and difficult to describe or compare. This problem can be addressed by calculating fractal dimension in an image analysis. Fractals and fractal dimension are mathematical concepts that have been proposed by Mandelbrot [

8] to describe order in seemingly chaotic or complex systems. Most natural objects exhibit some fractal-like properties to a limited extent (cauliflower, broccoli). However, this does not imply that a fractal dimension cannot be described or that it is not useful. The “apparent” or “natural” fractal dimension well describes the irregularity of an object’s shape [

9]. In classical Euclidean geometry, the dimensions of a point, line, surface, and space correspond to 0, 1, 2 and 3, respectively. In the case of fractal objects, their dimensions can reach values intermediate between those listed above [

10]. When analyzing a two-dimensional image of milk powder particles, the fractal dimension value can range from 1 to 2, which describes the degree of irregularity (or surface filling) of the particle contour.

As previously mentioned, the functional properties of milk powders are affected by their composition and microstructure. In turn, microstructure can be influenced by the applied drying method. Therefore, the aim of this study was to determine the impact of different drying methods on the functional properties and microstructure of milk powders. The novelty of this research lies in the application of fractal dimension analysis to quantitatively characterize the microstructure of milk powders produced by different drying methods. By introducing fractal analysis, this study provides a more objective and mathematically grounded means of describing particle contour complexity and surface irregularity. In doing so, the research establishes a clearer link between drying technology, particle morphology, and functional powder properties, thus extending conventional methods of powder characterization and offering a novel tool for correlating microstructure with performance of dairy powders.

2. Materials and Methods

Raw milk (ca. 100 l) acquired from the Research and Education Station in Bałdy, which is a part of the University of Warmia and Mazury in Olsztyn. Raw milk was centrifuged at a temperature of 45 °C (Spomasz LWG-20 centrifuge, Gniezno, Poland) to obtain skimmed milk. Sweet buttermilk was supplied by a dairy plant (ca. 50 l, Mlekovita, Poland). Skimmed milk was pasteurised at 72 °C for 15 s (Alfa Laval P20-HB plate heat exchanger, Sweden). Whole milk, skim milk, and buttermilk were concentarated in a vacuum evaporator (SPX Flow Technology Denmark A/S, Soeborg, Demark) to dry matter content of ca. 30%.

Whole milk, skim milk, and buttermilk were processed by spray drying (S-d), roller drying (R-d), and freeze drying (F-d). The microstructure and functional properties of the obtained powders were analyzed.

Drying Method

Spray drying was conducted in a Production Minor Spray Dryer (Niro Atomizer, Søborg, Denmark) with inlet and outlet air temperature set to 185 °C and 85 °C, respectively. Freeze drying was carried out in a Christ Alpha 1–2 LD plus freeze dryer (Martin Christ Gefriertrocknungsanlagen GmbH, Osterodeam Harz, Germany) at a temperature of −32 °C and a pressure of 0.34 mBar. Roller drying was performed in a Tape roller dryer (Tape’s Machine General Machinists, Ottawa, ON, Canada) at a temperature of 120 °C and a steam pressure of 0.15 MPa.

Proximate Analysis

The obtained milk powders were analyzed for the content of protein, fat, ash and moisture using the NIRS DS2500 analyzer (Foss, Hillerød, Denmark) according to the manual instruction of apparatus.

Determination of the Bulk Density and Rheological Properties of Milk Powders

The loose (ρL) and tapped (ρT) bulk density of the examined milk powders was determined according to Standards ISO 8967:2005 and IDF 134:2005 [

11]. Based on bulk density measurements, the Carr index (CI) and the Hausner ratio (HR) were calculated using Equations (1) and (2), respectively [

12]:

Analysis of Insolubility Index

The insolubility index was analyzed based on Standard PN-EN ISO 8156:2014-07 Dried milk and dried milk products [

13].

Determination of Wettability

The wettability of the examined milk powders was determined with the Gea Niro Method No. A5 b. 2009. Wettability IDF Method [

14].

Microstructure Analysis and Fractal Analysis

The micrographs of the studied powders were acquired and analyzed under a QUANTA 200 scanning electron microscope (FEI Company, Hillsboro, OR, USA, Thermo Fisher Scientific). Milk powder samples were placed on a holder (GSED 500 mm detector) and frozen in a microscope chamber (−18 °C). The frozen samples were then analyzed. Micrographs were recorded at 100×, 400×, 800×, and 1600× magnification, and the obtained images were analyzed at different scales. The image analysis involved the determination of the fractal dimension using Nis-Elements Basic Research 3.2 software (Nikon Corporation, Tokyo, Japan). At the beginning of the analysis, the contrast of the images was maximized, and the perimeter (P) and area (A) of approximately 200–250 small, medium, and large powder particles that were fully visible in the micrographs were measured. The obtained data describing the relationship between the values of P and A were used as input data in the calculations.

The fractal dimension was calculated from the logarithmic relationship between the area (lg A), perimeter (lg P), and slope of the obtained line [

15]. The calculated fractal dimension was used to characterize the microtopography of the tested samples.

Color Analysis

The color of the tested milk powders was analyzed with a CM-3500d spectrophotometer (Konica Minolta Sensing, Inc., Osaka, Japan) in the CIE LAB color space. Color was expressed based on the values of color components L* (L* = 0 for black, L* = 100 for white), a* (+ for red and − for green), and b (+ for yellow and − for blue). L*, a* and b* values were used to calculate chromaticity (C*), the whiteness index (WI), and the yellowness index (YI) according to Formulas (3), (4) and (5), respectively [

16]:

Statistical Analysis

Three independent experiments were conducted. The presence of significant differences between variables was determined by one-way analysis of variance (ANOVA) and Fisher’s LSD test. All calculations were performed using the Microsoft Office Excel 2013 package at a significance level of 0.05.

3. Results and Discussion

The proximate composition of whole milk, skim milk, and buttermilk powders is presented in

Table 1. Selected functional properties of milk powders obtained with the use of different drying methods are shown in

Table 2.

The powder composition was found to be dependent on the type of dried raw material. The drying method did not affect the powder composition. The main difference in the chemical composition of the studied powders was their fat content. This is the result of varying fat content in the raw materials subjected to drying (in descending order: whole milk, buttermilk, and skim milk) (p ≤ 0.05). Therefore, the high fat content of whole milk powder was the most pronounced difference in the composition of the analyzed powdered samples. Whole milk powder had the lowest content of protein and lactose. Skim milk powder had a similar composition to buttermilk powder, but buttermilk powder had higher fat content than skim milk powder. Skim milk powder and buttermilk powder were characterized by a higher protein content compared to whole milk powder. Protein content in skim milk powder and buttermilk powder was not different. The lactose content in the analyzed powders increased in the order: whole milk powder < buttermilk < skim milk powder. In turn, no differences in ash content in powdered samples were found.

The functional properties of milk powders that play an important role during storage, transportation, dosing, and reconstitution are presented in

Table 2.

The loose and tapped bulk density of milk powders was influenced mainly by the drying method (

p ≤ 0.05). These parameters were lowest in freeze-dried powders, higher in spray-dried powders, and highest in roller-dried powders. The bulk density of powders is determined by their compressibility; loose bulk density describes the volume of the powder and empty spaces between powder particles, whereas tapped bulk density is the maximum bulk density a powder can reach after compaction, when smaller particles move into empty spaces between larger particles, which causes the particles to pack more tightly, decreases the powder’s volume, and increases its density [

17]. These differences can be explained by considering the impact of drying techniques on powder microstructure (dimensions, shapes, and density of the particles). The dominant role of drying methods is in shaping milk powder bulk density through particle microstructure. Roller drying yields compact but irregularly shaped particles with sharp edges without occluded air. However, the final dimensions of the particles are determined by the hammer mill. Powder particles after spray-drying are usually spherical but porous, with air occluded during atomization within particles as vacuoles of varying sizes which decreases the intrinsic particle density. Freeze drying generates fragile, porous, sponge-like structures with the lowest bulk density. The practical implication of low bulk density is undesirable because of higher packaging, storage, and transportation costs per kg of powder. The apparent discrepancy between the two statements likely arises from differences in the relative influence of particle compactness versus particle shape and packing efficiency under specific experimental conditions [

18].

The compressibility of a solid is related to its flowability, and the Carr index (CI) and the Hausner ratio (HR) were calculated based on the loose and tapped bulk density of the analyzed powders. Flowability reflects a powder’s ability to move or flow, and it is a very important parameter during transportation, dosing, and storage [

4]. The values of HR and CI can be used to classify powders based on their flowability and cohesiveness. Powders with low values of CI and HR are characterized by high flowability and low cohesiveness. Higher HR values point to an increase in interparticle forces, and powders with a higher HR are more cohesive. The flowability characteristics of the analyzed powders were influenced by the drying method (

p ≤ 0.05). The highest values of CI and HR were noted in milk powder obtained by spray drying. These parameters were within the range of values indicative of poorly flowing and cohesive powders. Roller-dried powders were characterized by lower cohesiveness and were classified as passable. In turn, freeze-dried powders were described as fair based on their flowability characteristics. The reasons for these phenomena should be sought, as in the case of bulk density, in the varied morphology of powder particles obtained by different drying techniques.

The functional properties of milk powder, including wettability, dispersibility, and sinkability, determine its reconstitution in water, thus affecting the rate at which the powder dissolves and integrates with the liquid [

19]. The amount of undissolved particles remaining after the powder is reconstituted in water is measured by calculating the insolubility index. The wettability and the insolubility index of the studied powders are presented in

Table 2.

The volume of insoluble particles was highest in roller-dried powders (2.0–3.1 cm

3 of sediment in 50 cm

3 of reconstituted milk) and much lower in spray-dried powders, particularly in buttermilk powder, where the insolubility index reached 0.3 cm

3 of sediment in 50 cm

3 of reconstituted milk. Freeze-dried powders were 99.8–99.9% soluble in water. The spray-drying process produces fine, spherical particles with smooth surfaces and a high vacuole volume that facilitate rapid wetting and dissolution, making them more soluble. In contrast, roller-dried powders are denser, irregularly shaped, and lack air pockets, which hinders their rehydration and solubility [

20]. The solubility of milk powders is a critical factor determining their suitability for various food applications, as it directly impacts the powder’s rehydration and functional properties like emulsifying, gelling, and foaming. Poor solubility can lead to difficulties in achieving complete dispersion and a smooth texture, limiting the use of high-protein powders in beverages and other products requiring quick, consistent dissolution. Conversely, powders with high and consistent solubility are essential for smooth rehydration, which is crucial for consumer acceptability and the successful integration of milk solids into a wide range of foods [

21,

22].

The wettability of all spray-dried powders and roller-dried and freeze-dried whole milk powders did not meet standard requirements (>180 s). Wettability is considerably influenced by particle size (including internal porosity) and the size of empty spaces between particles. Small particles and low bed porosity can hinder water penetration [

4,

19]. The wettability of milk powders significantly impacts their food applications by determining how quickly and easily they disperse and rehydrate in water, affecting product quality and consumer acceptance. Poor wettability can lead to lump formation, slow reconstitution, and a “flecking” or poor dispersion in beverages, while good wettability is crucial for instant products like coffee whiteners, infant formula, and baked goods, ensuring a smooth texture and consistent quality [

23].

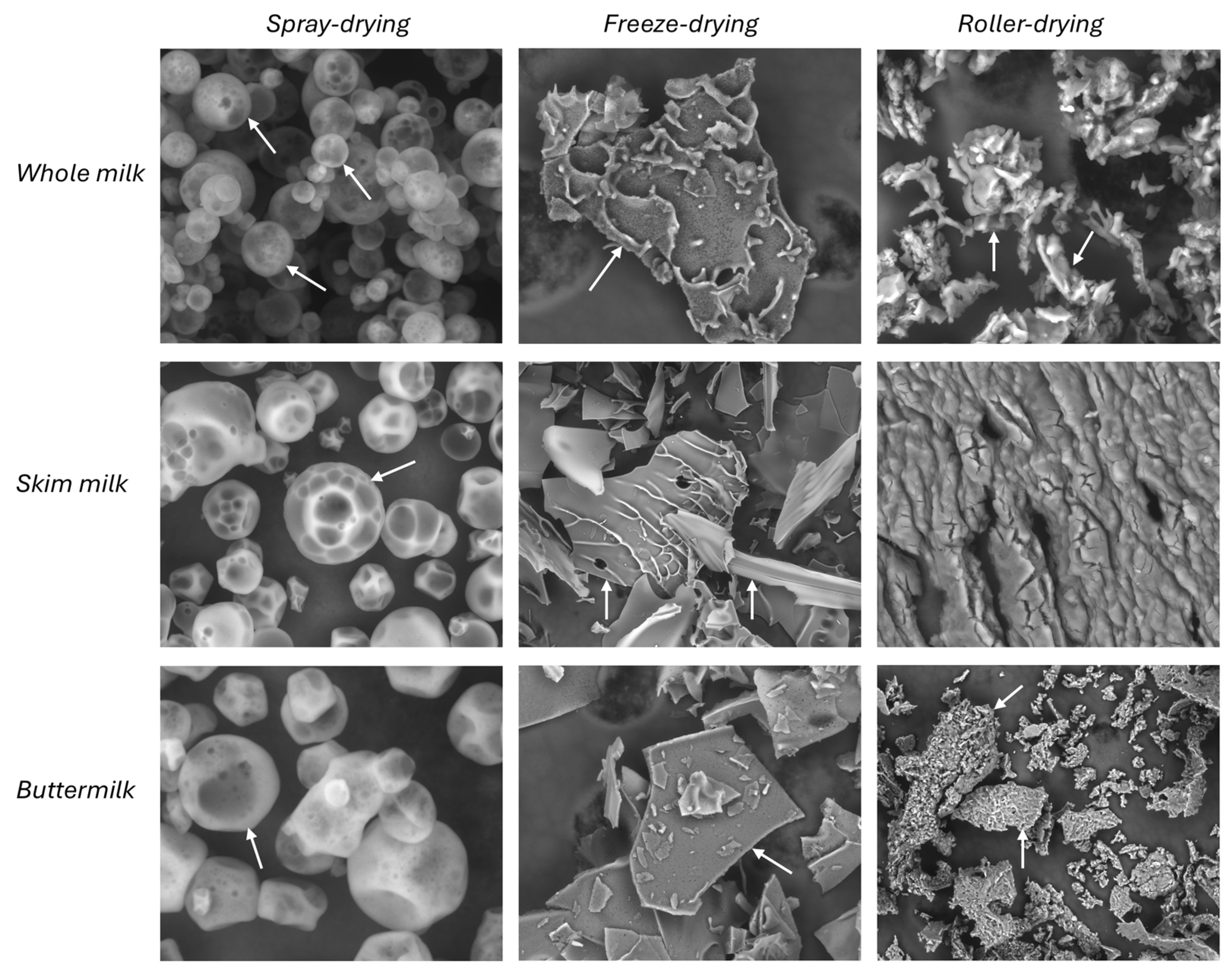

The functional properties of a powder, including its physical, reconstitution, and rheological characteristics are influenced by the microstructure, including the shape and porosity of particles. The morphology of the analyzed powders varied depending on the drying method. The microstructure of milk powders at different levels of magnification is presented in

Figure 1.

Spray-dried powders had small, spherical particles that were fairly uniform in size and had smooth surfaces with small indentations (arrows). The particles of spray-dried whole milk and buttermilk powders exhibited a higher number of visible indentations on their surface than the particles of skim milk powder. Roller-dried and freeze-dried powders contained flat and differently sized particles with a very large diameter (arrows). These particles were characterized by numerous irregular cracks and surface indentations. A visual analysis of the micrographs revealed that the surface of particles in roller-dried and freeze-dried powders was not influenced by fat content. Therefore, the microstructure of milk powders is determined mainly by the applied drying method, and the microstructure of spray-dried powders is also influenced by their composition.

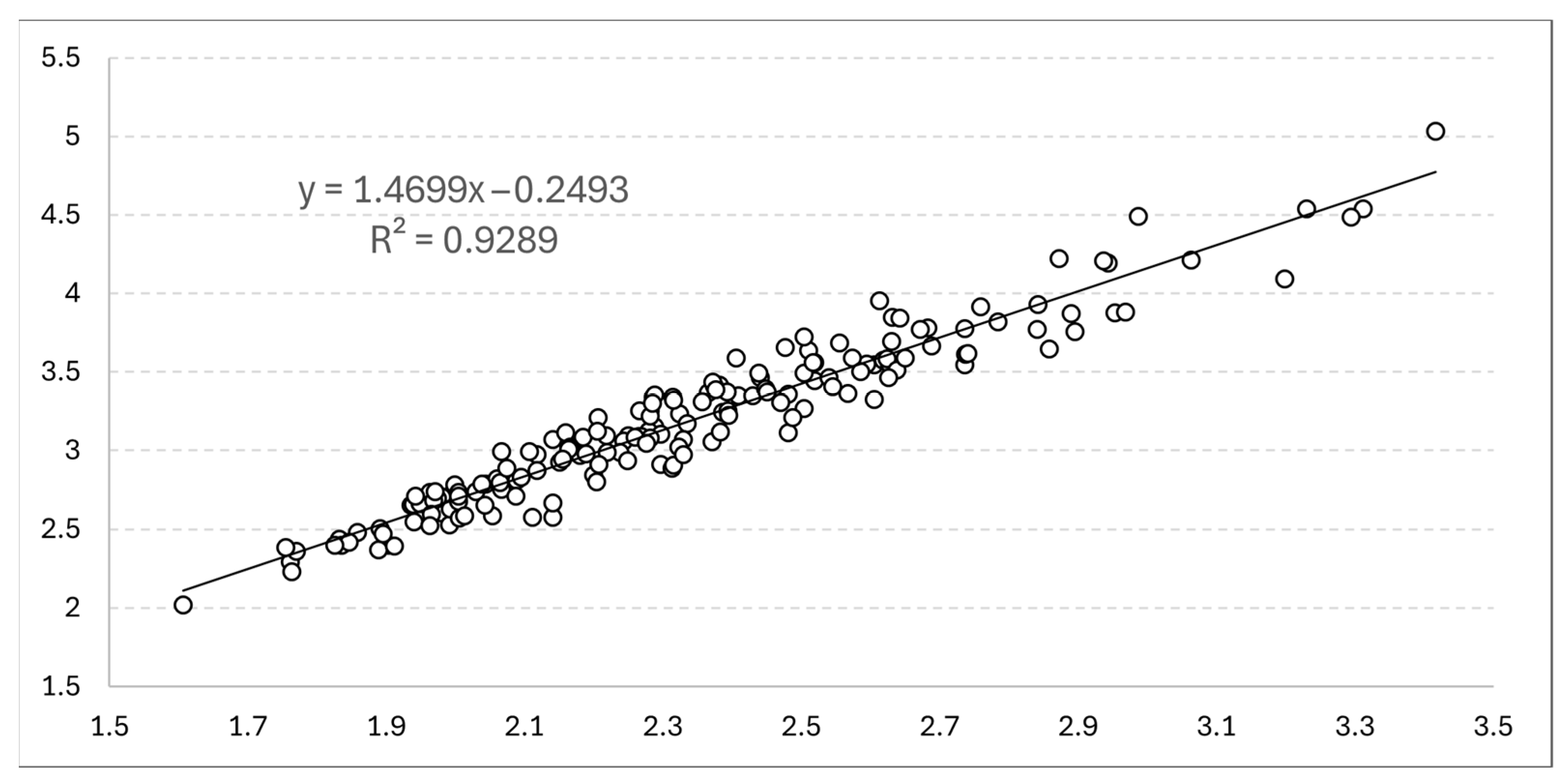

Descriptive analyses of irregular structures tend to be subjective, which is why the microstructure of the studied milk powders was precisely compared by fractal analysis. Fractal analysis is a mathematical tool for comparing microstructures with the use of numerical values, and it supports objective and detailed interpretations of micrographs [

24]. The results of the fractal analysis are presented in

Table 3. An exemplary log(A)~log(P) plot supporting the determination of the fractal dimension is shown in

Figure 2. High values of determination coefficients indicate that the mathematical model fits the data well.

The particles of roller-dried and freeze-dried milk powders were characterized by the highest fractal dimensions. The fractal dimensions of particles were lower in spray-dried powders, which indicates that spray drying led to the formation of particles with the least irregular perimeter and the smoothest and most uniform surface. Particles with a more irregular structure and a more complex surface were observed in roller-dried and freeze-dried powders. Roller-dried and freeze-dried whole milk powders were characterized by the highest fractal dimensions. Taking into account the fat content, the fractal dimension had the highest values for whole milk powders for all drying techniques. The lowest fractal dimension was noted in skim milk powder. The fractal dimension corresponded to the fat content of the tested products. These results suggest that the fractal dimension is influenced by fat content. Milk fat is crystallized during the drying process, and the resulting crystals could increase the overall complexity of a particle’s surface.

Freeze-dried powders were characterized by high fractal dimensions and low loose and tapped bulk density. This inverse relationship indicates that particles with more complex surfaces are less densely packed. These results suggest that the microstructure of milk powders affects their functional properties. A different relationship was observed in roller-dried powders. This difference could be attributed to greater variations in particle shape, which promotes more efficient particle packing and decreases bulk density. At the same time, particles with more complex surfaces are more susceptible to fracture, and the detachment of irregular fragments promotes the formation of particles with a smoother contour.

Fractal dimensions are also correlated with wettability. The lowest fractal dimensions were noted in spray-dried powders, which were also characterized by the lowest wettability. These powders were characterized by a regular microstructure and smooth particles with a smaller surface area, which reduced capillary interactions between particles, leading to decreased wettability.

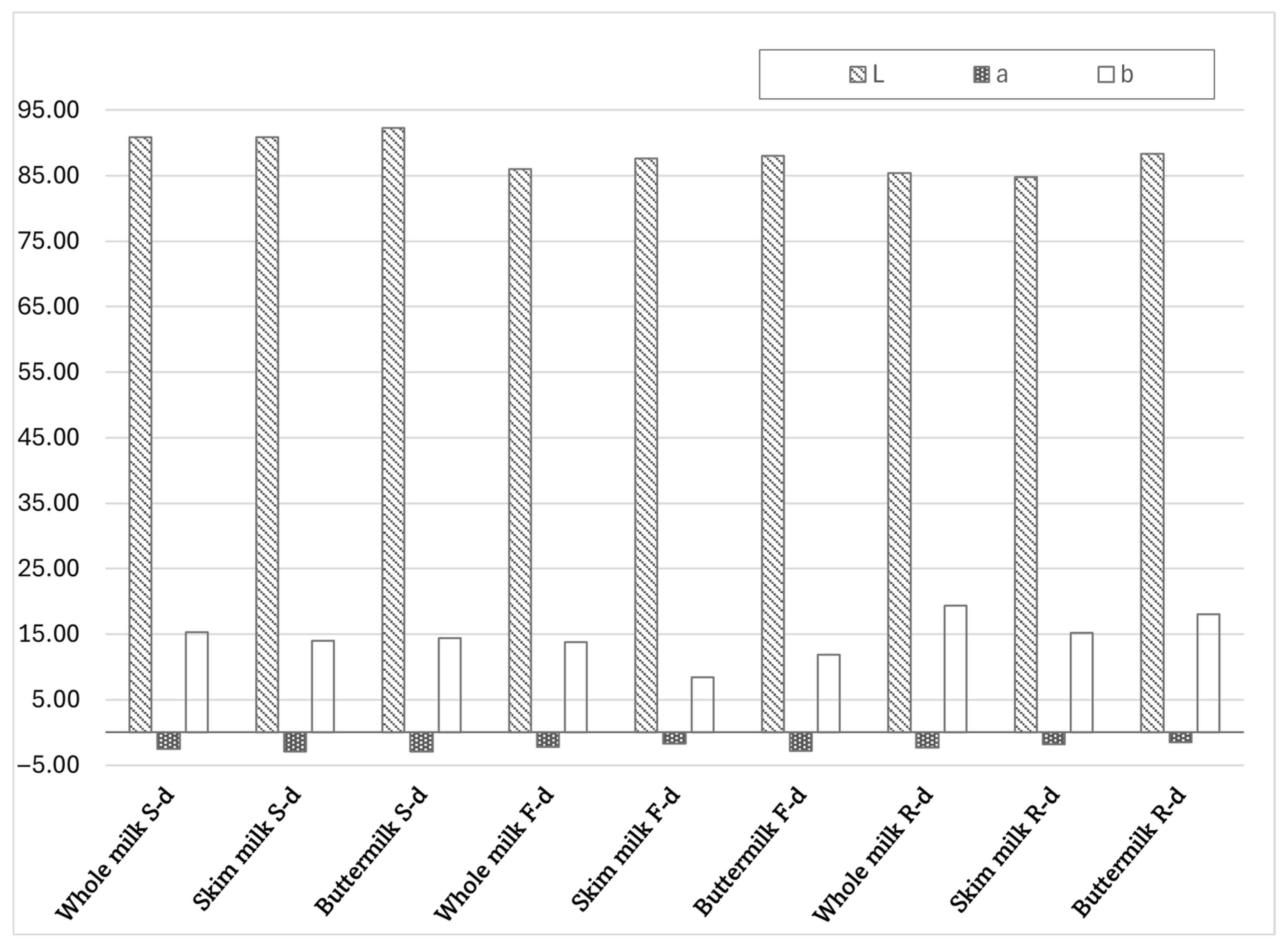

The color analysis revealed that the color parameters of milk powders were influenced by the drying method and the type of raw material. The results of the color analysis are presented in

Figure 3.

The value of parameter L* was highest in buttermilk powders, regardless of the drying method. All milk powders obtained by roller drying were darker, as indicated by lower values of L*. All analyzed samples were characterized by negative values of a*, which denotes a color shift towards green, and positive values of b*, which denotes a color shift towards yellow. The color parameters of whole milk powder were influenced by its high fat content. In turn, the high content of lactose and protein in buttermilk and skim milk powders contributed to Maillard reactions, which are initiated during processing and continue to progress during storage [

25,

26]. The values of C*, WI, and YI of the analyzed powders were calculated based on the results of color measurements (

Table 4).

The values of color parameters C*, WI, and YI in whole milk, skim milk, and buttermilk powders varied depending on the drying method and the type of raw material (

p ≤ 0.05). The values of C* and YI were highest and WI values were lowest in roller-dried powders. Spray drying and freeze drying led to a decrease in C* and YI values. Regardless of the drying method, the examined powders were arranged in the following ascending order based on their C* values: skim milk powder < buttermilk powder < whole milk powder. Whole milk powder was characterized by lower values of WI and higher values of YI in comparison with skim milk powder and buttermilk powder. Spray-dried skim milk powder and buttermilk powder did not differ in the values of WI or YI (

p > 0.05). No unequivocal trends in WI or YI values were found for roller-dried and freeze-dried skim milk powder and buttermilk powder. Color, an aspect of the appearance of food, is one of the attributes that affect the consumer perception of quality. The color in foods is the result of colored natural products associated with raw material and/or colored compounds generated as a result of processing. The development of color in foods is an obvious feature of the extent of the advance of Maillard reaction. Many factors influence the extent of the Maillard reaction, such as temperature, water activity, pH, moisture content, and chemical composition of food systems [

27].