Reasonable Width of Deteriorated Coal Pillars and Surrounding Rock Control for Roadways in Thick Coal Seams: A Case Study of Datong Coal Mine Area, China

Abstract

1. Introduction

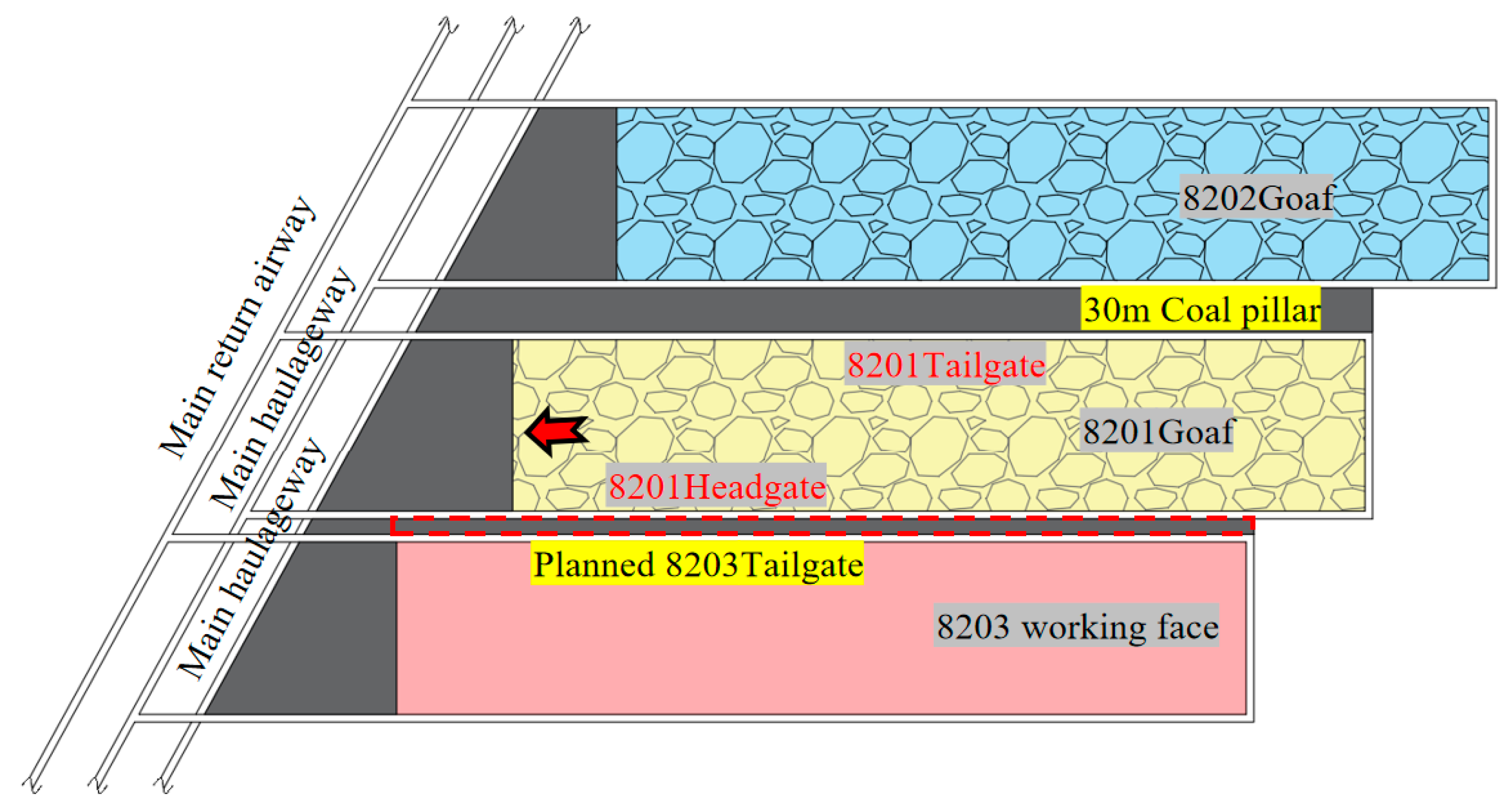

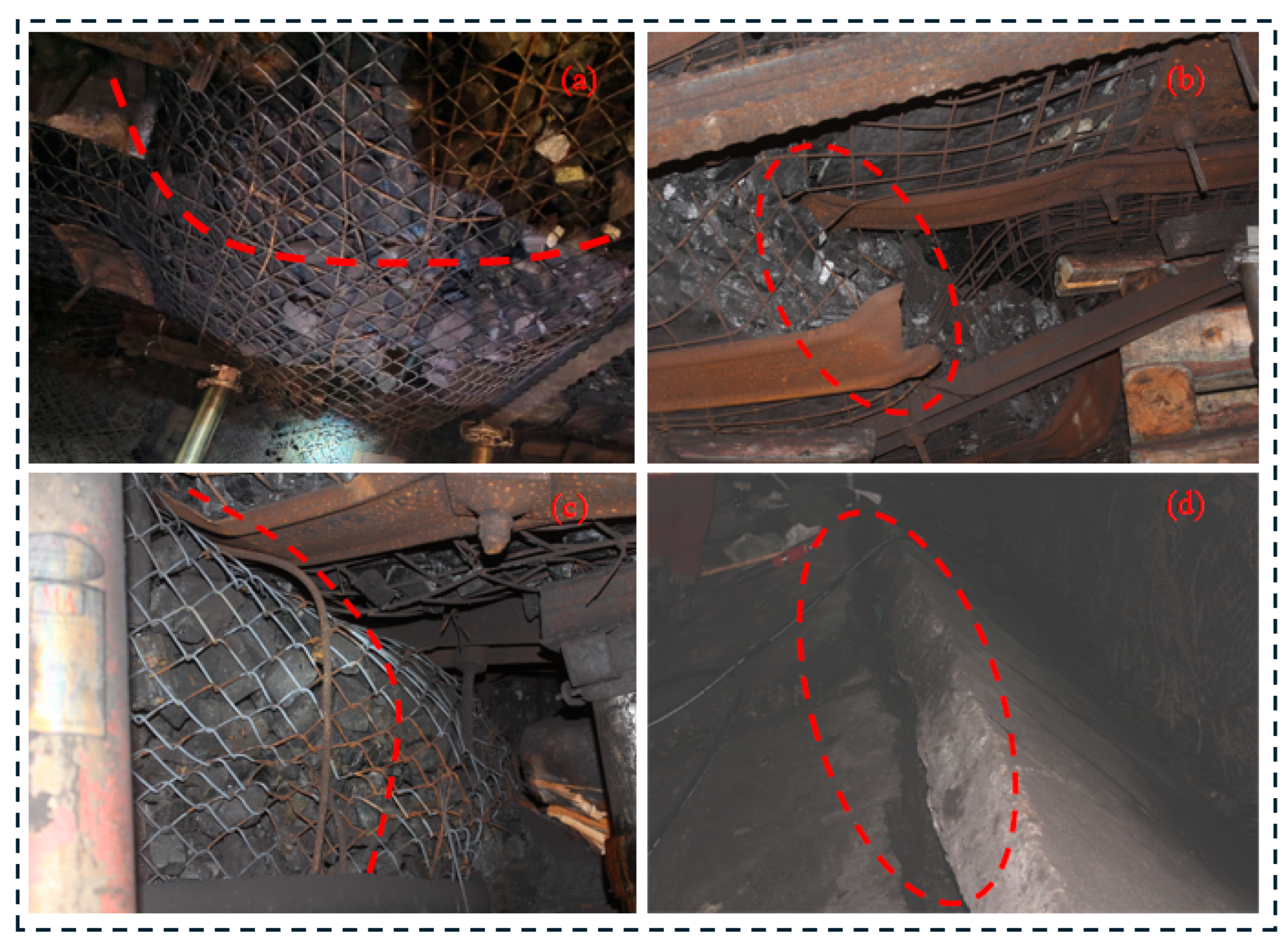

2. Engineering Background

3. Overlying Strata Structure and Layout Principles of Gob-Side Roadways

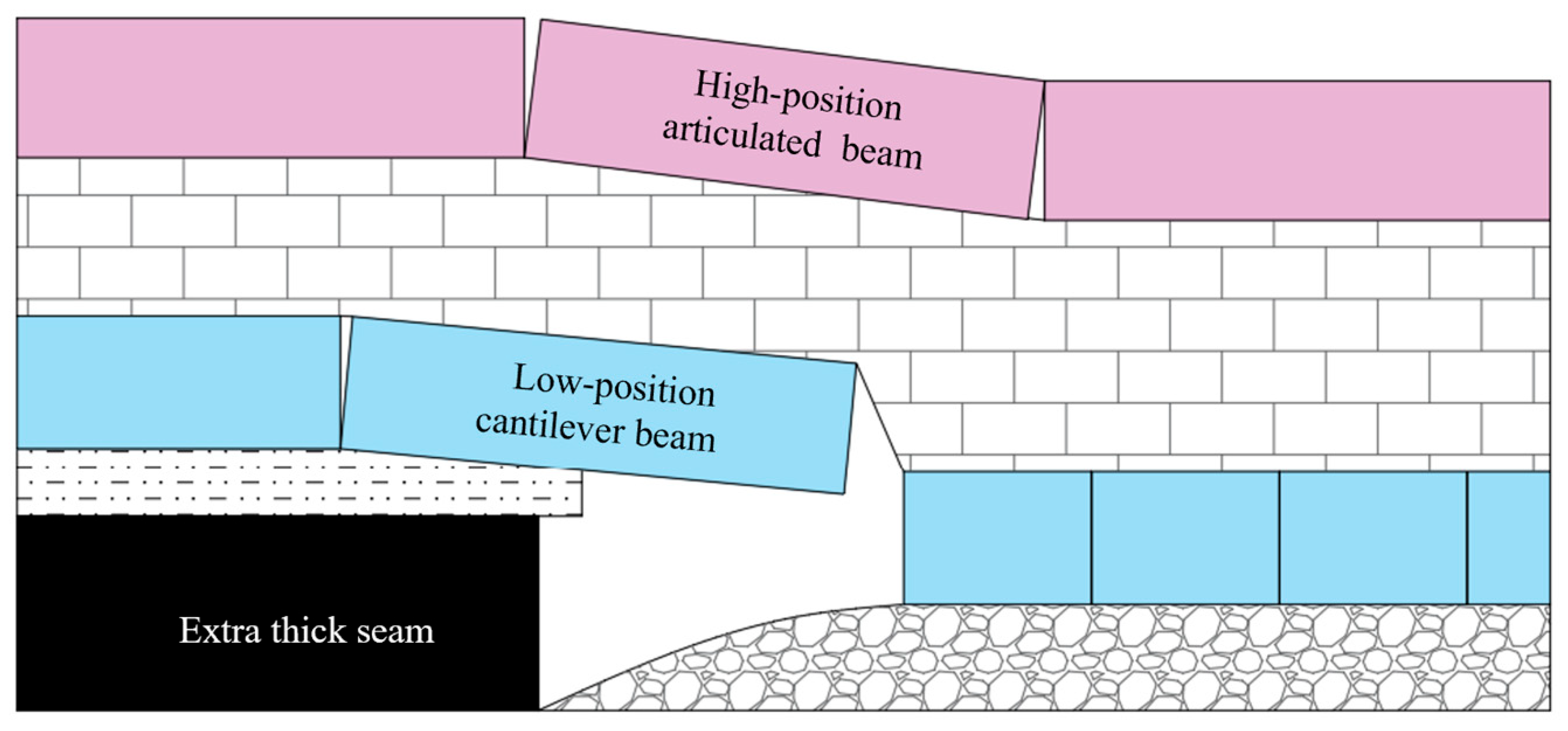

3.1. Overlying Strata Structure in Gob-Side Roadways

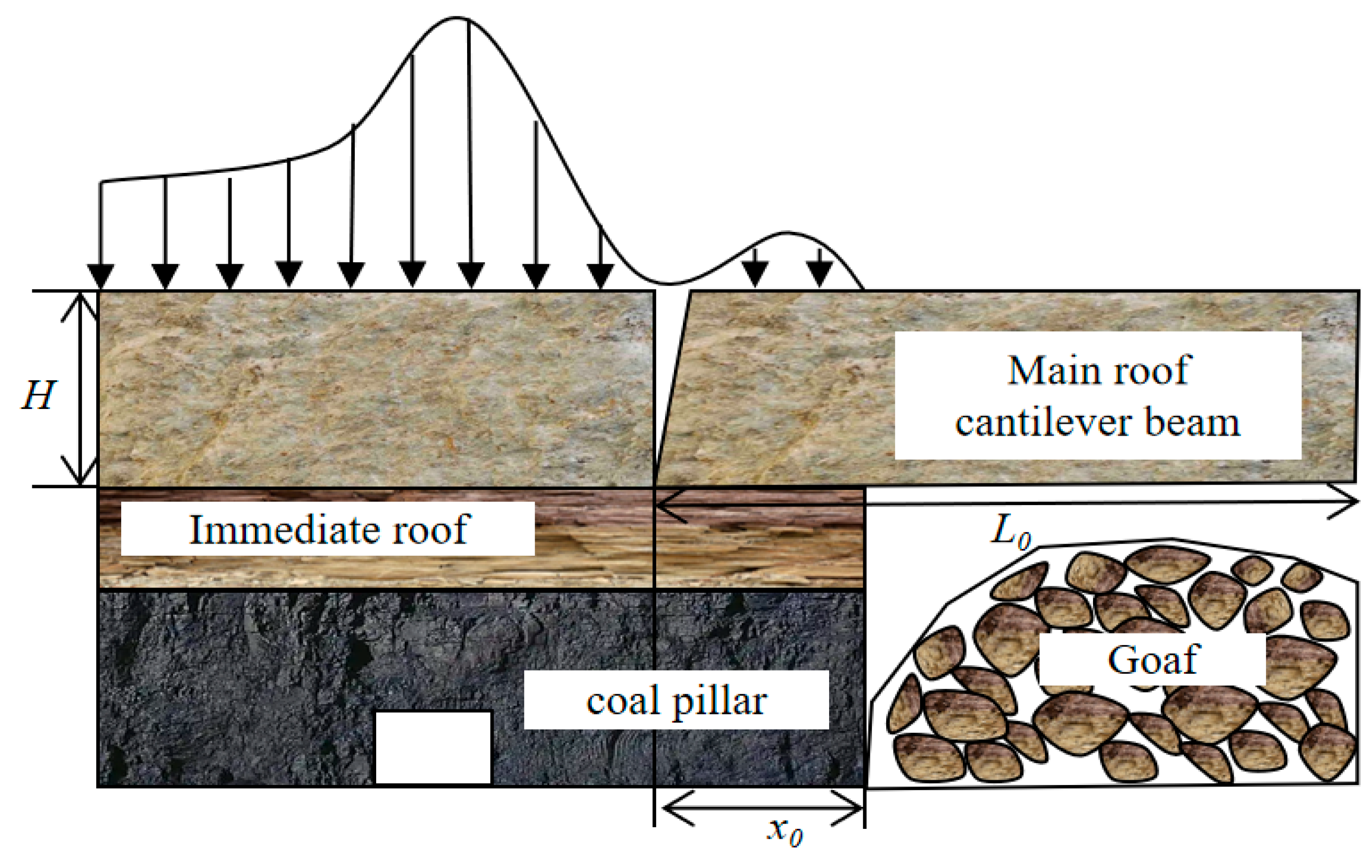

3.2. Fracture Location of the Main Roof Cantilever Beam

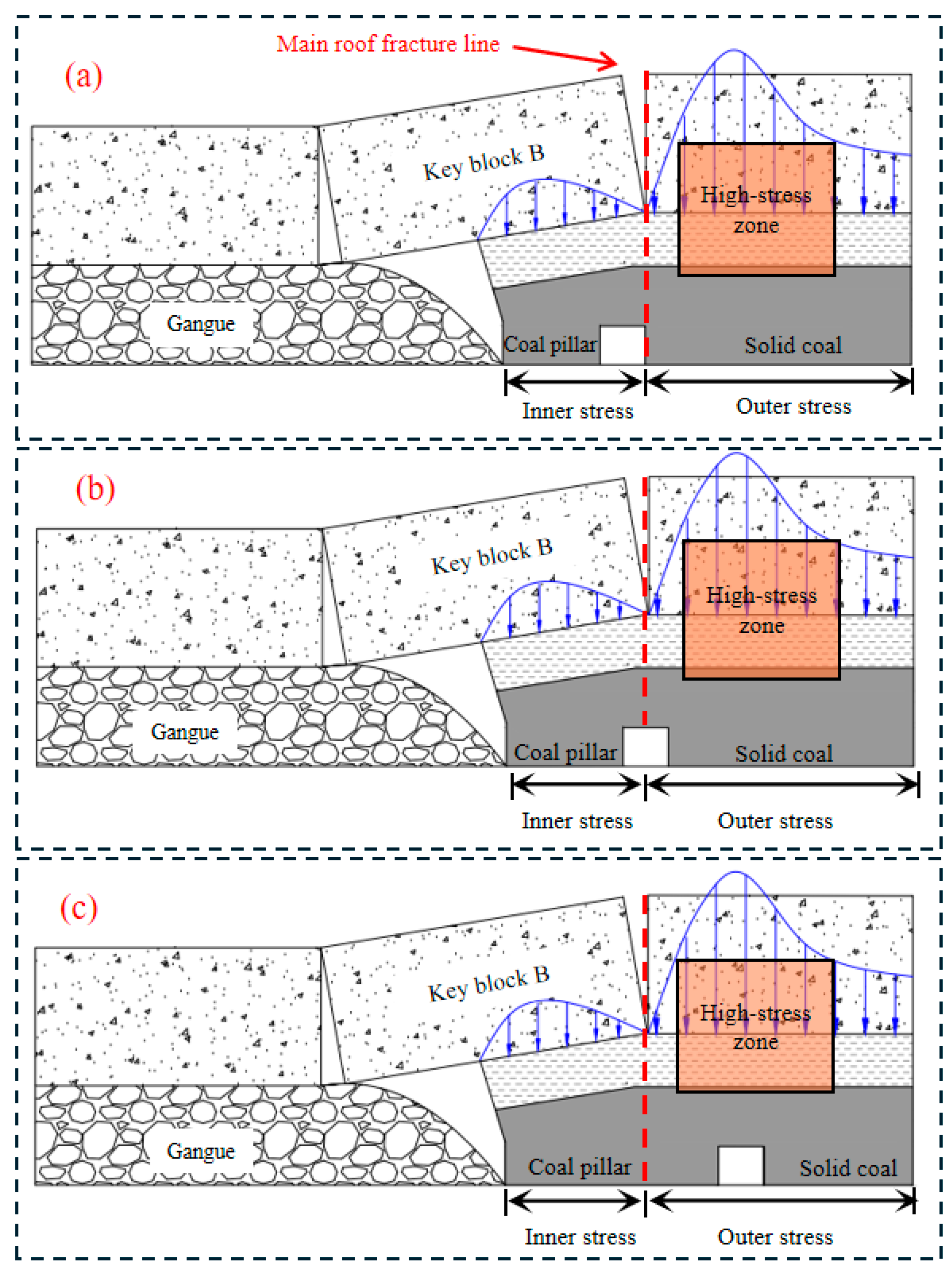

3.3. Layout Principle of Gob-Side Roadways

4. Bearing Characteristics of Deteriorated Coal Pillars in Gob-Side Roadways

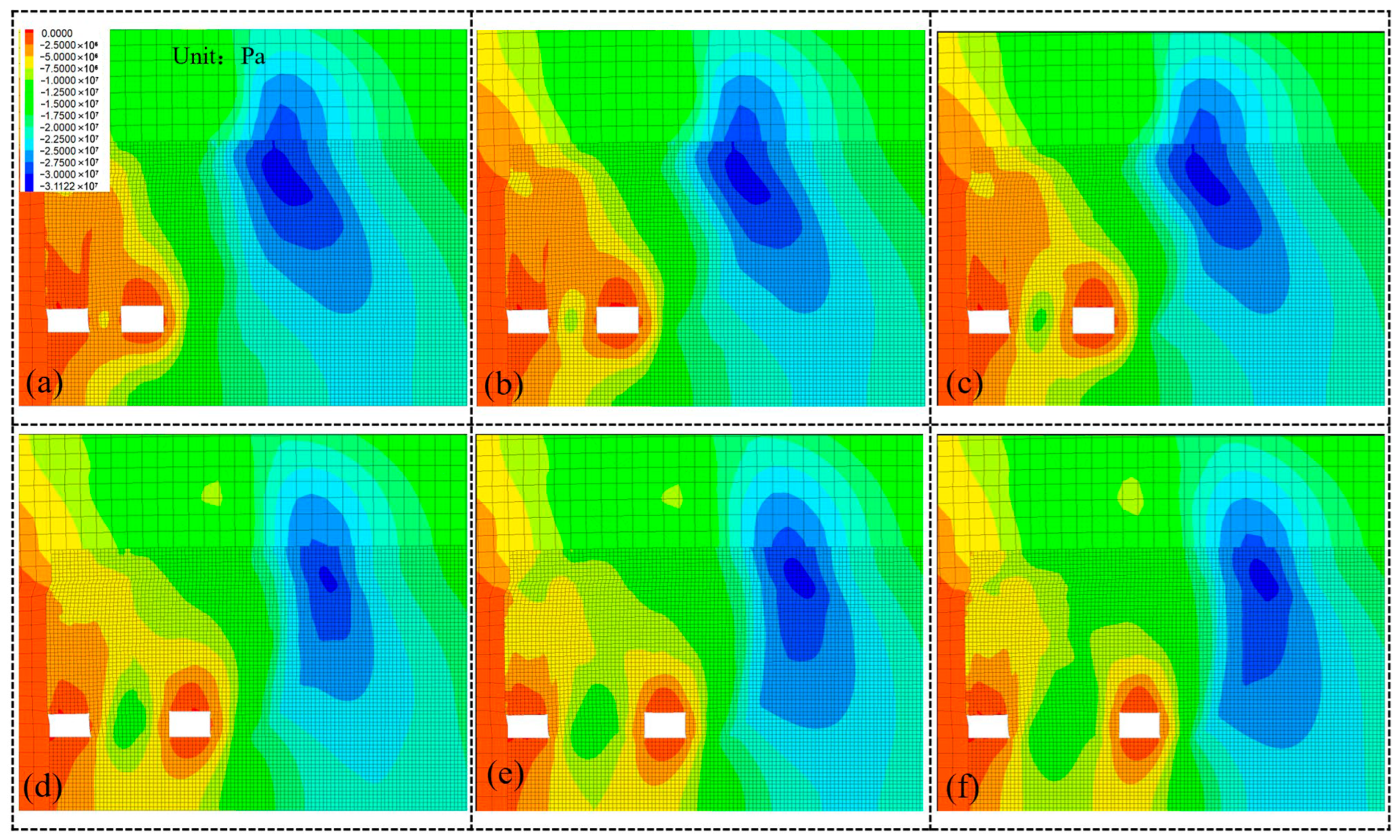

4.1. Stress Distribution Characteristics of Roadway Surrounding Rocks

4.2. Distribution Characteristics of Plastic Zones in Roadway Surrounding Rocks

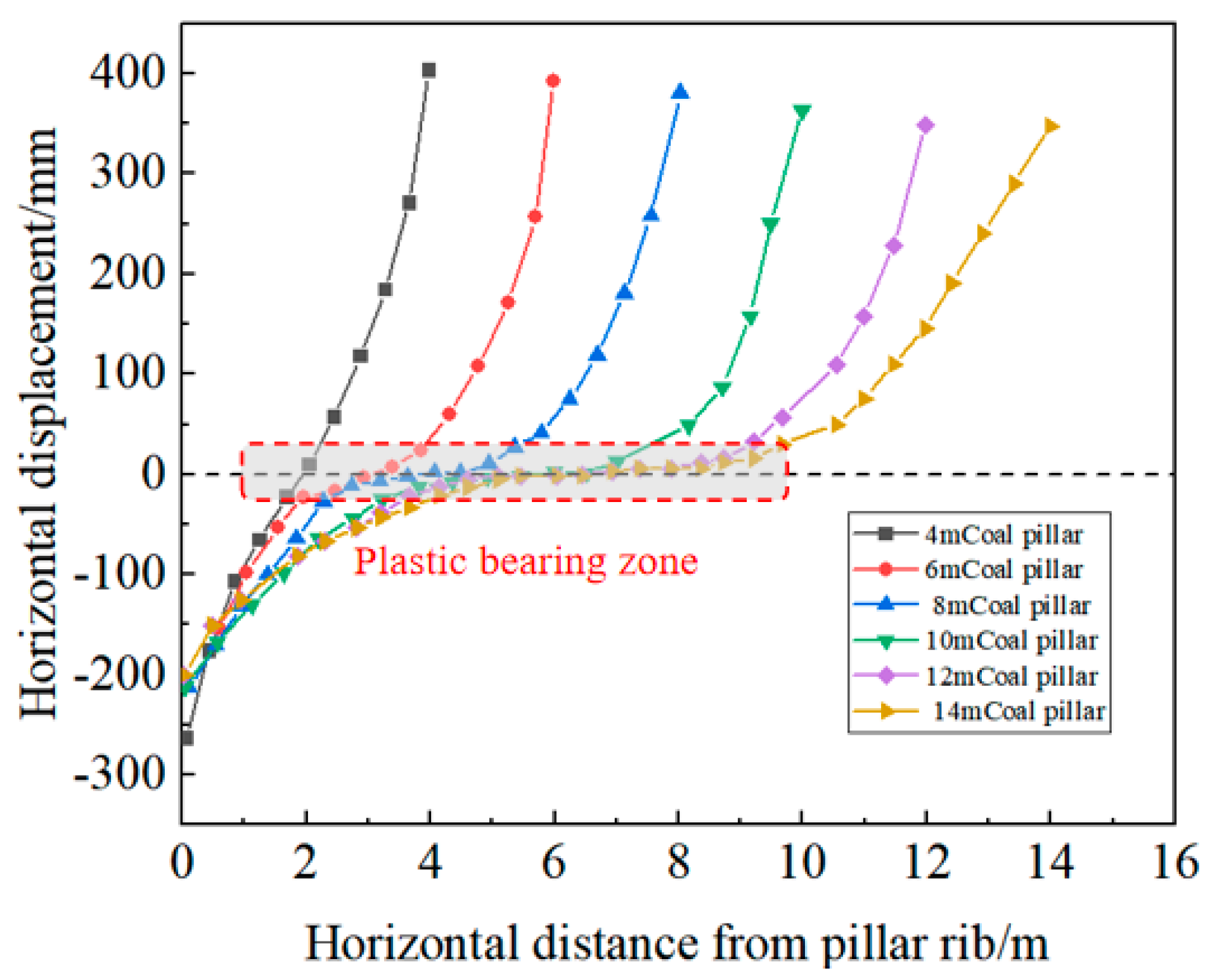

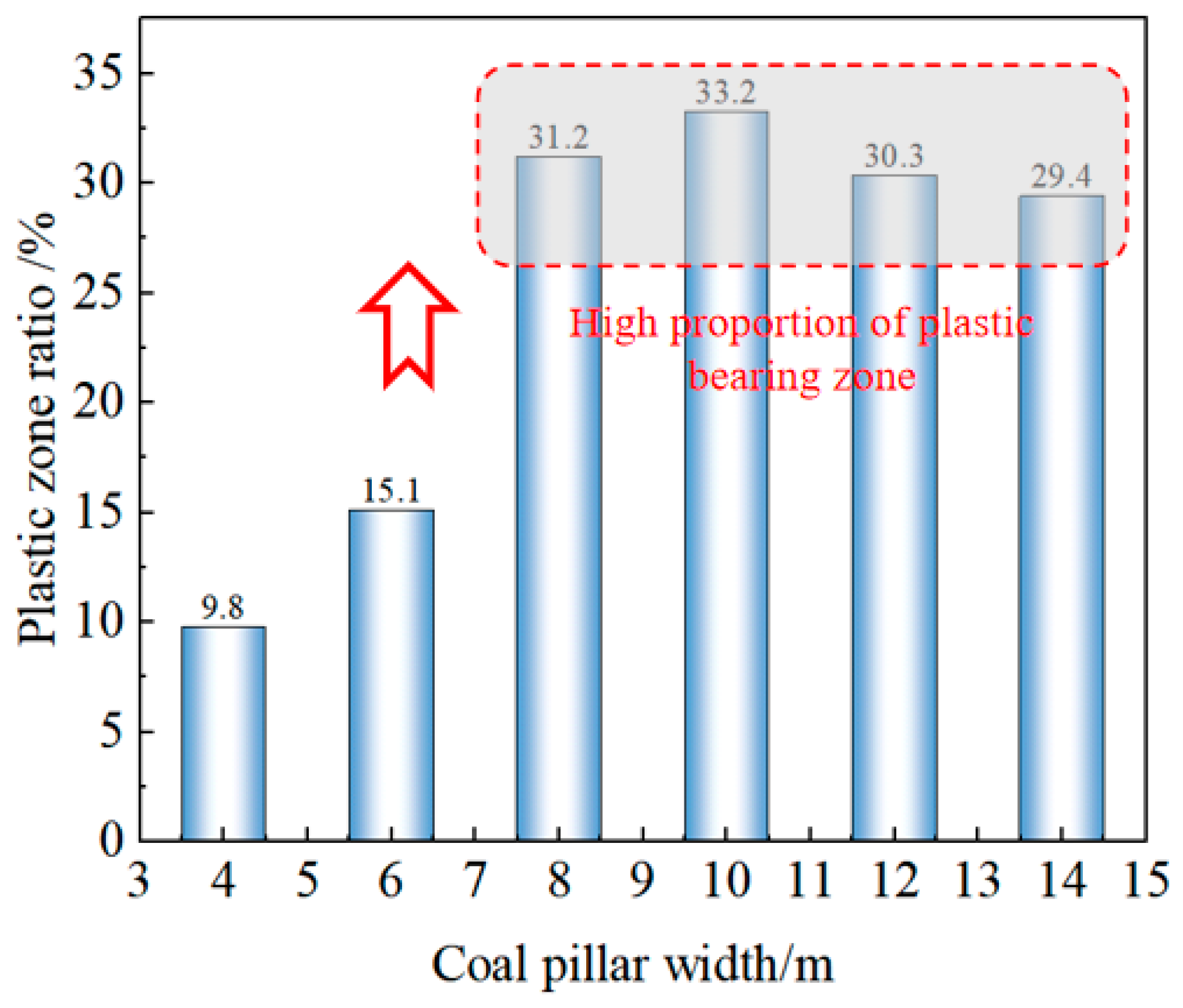

4.3. Distribution Characteristics of Plastic-Bearing Zones in Coal Pillars

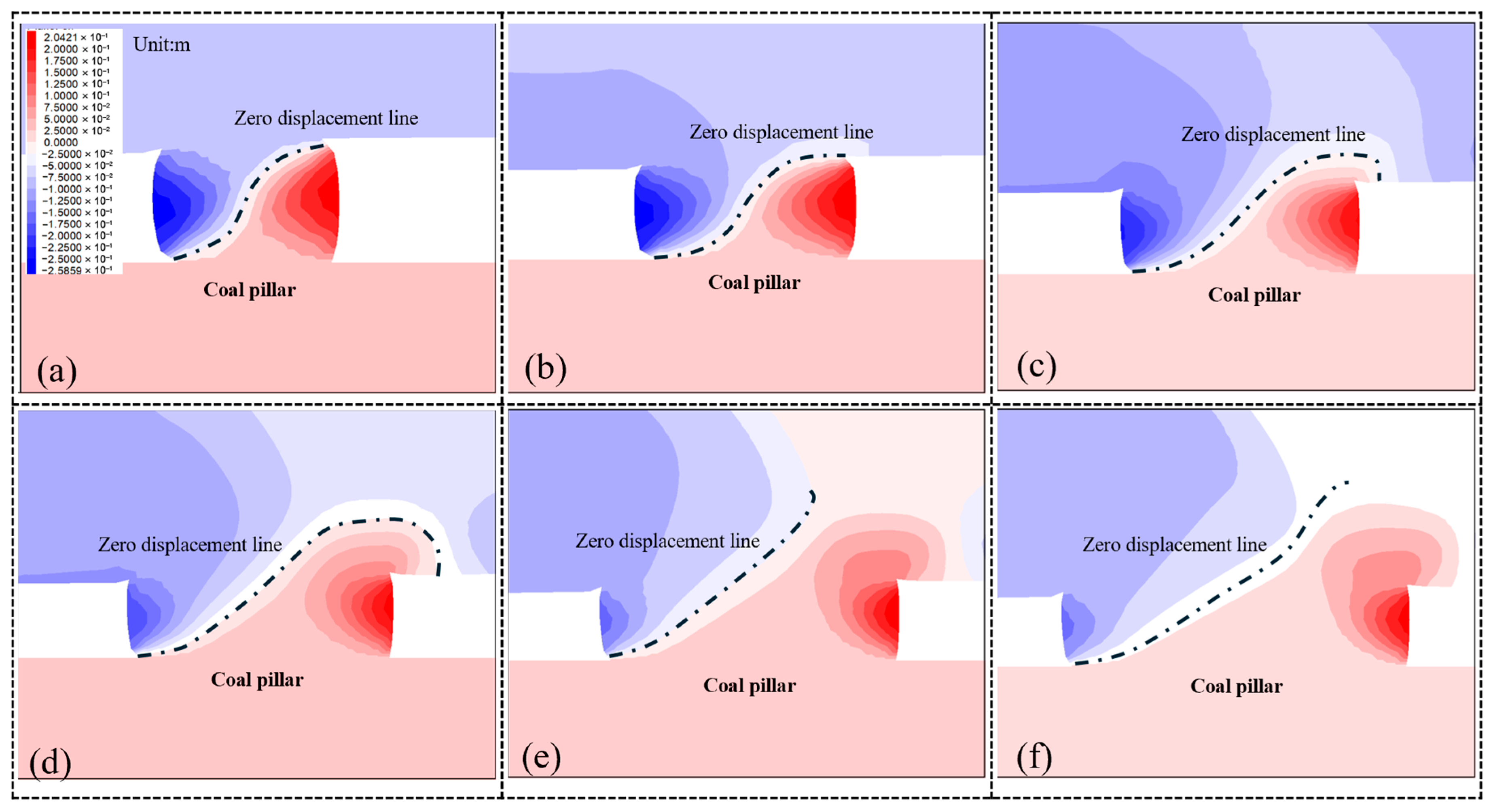

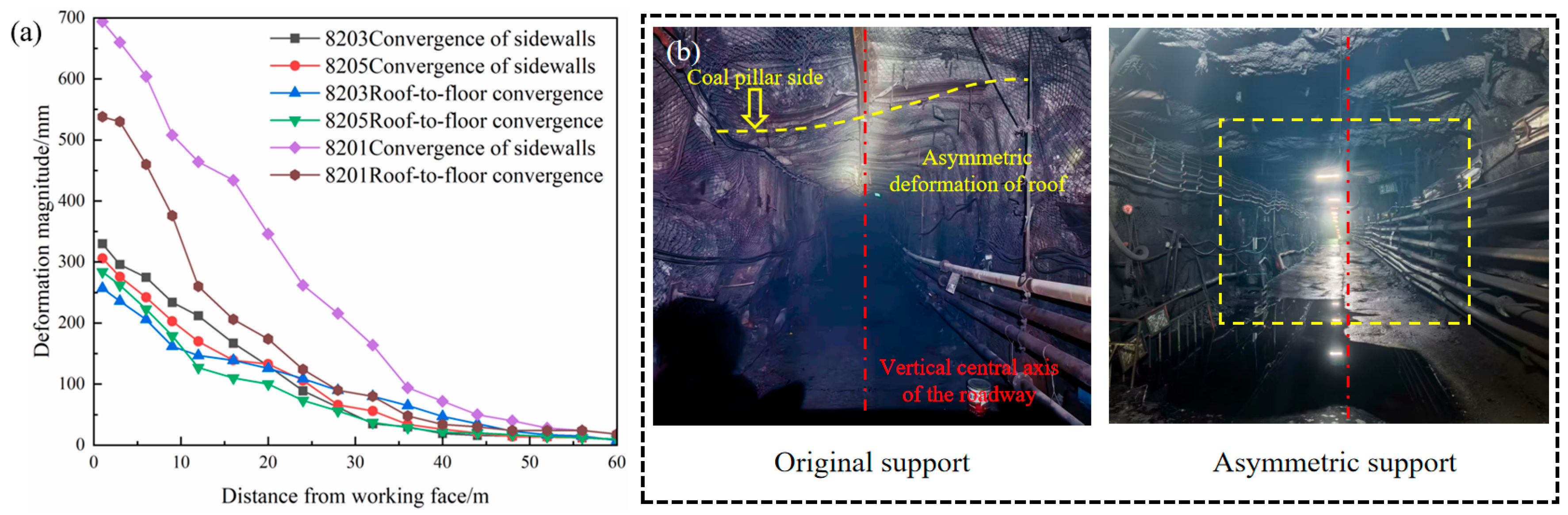

5. Deformation Law of Surrounding Rocks in Gob-Side Roadways

6. Surrounding Rock Control Scheme of the Asymmetric Truss Anchor Cables

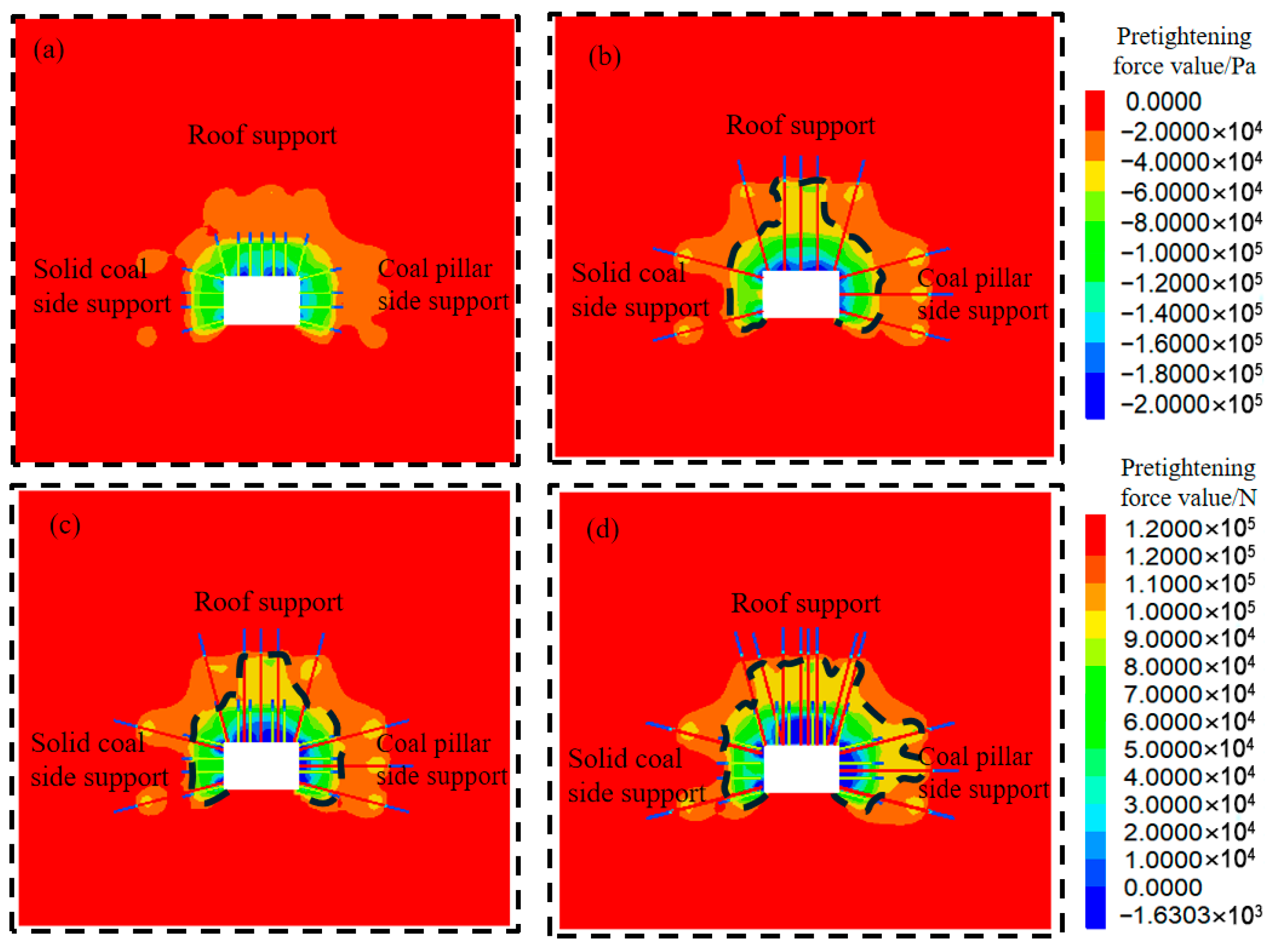

6.1. Roadway Support Parameters

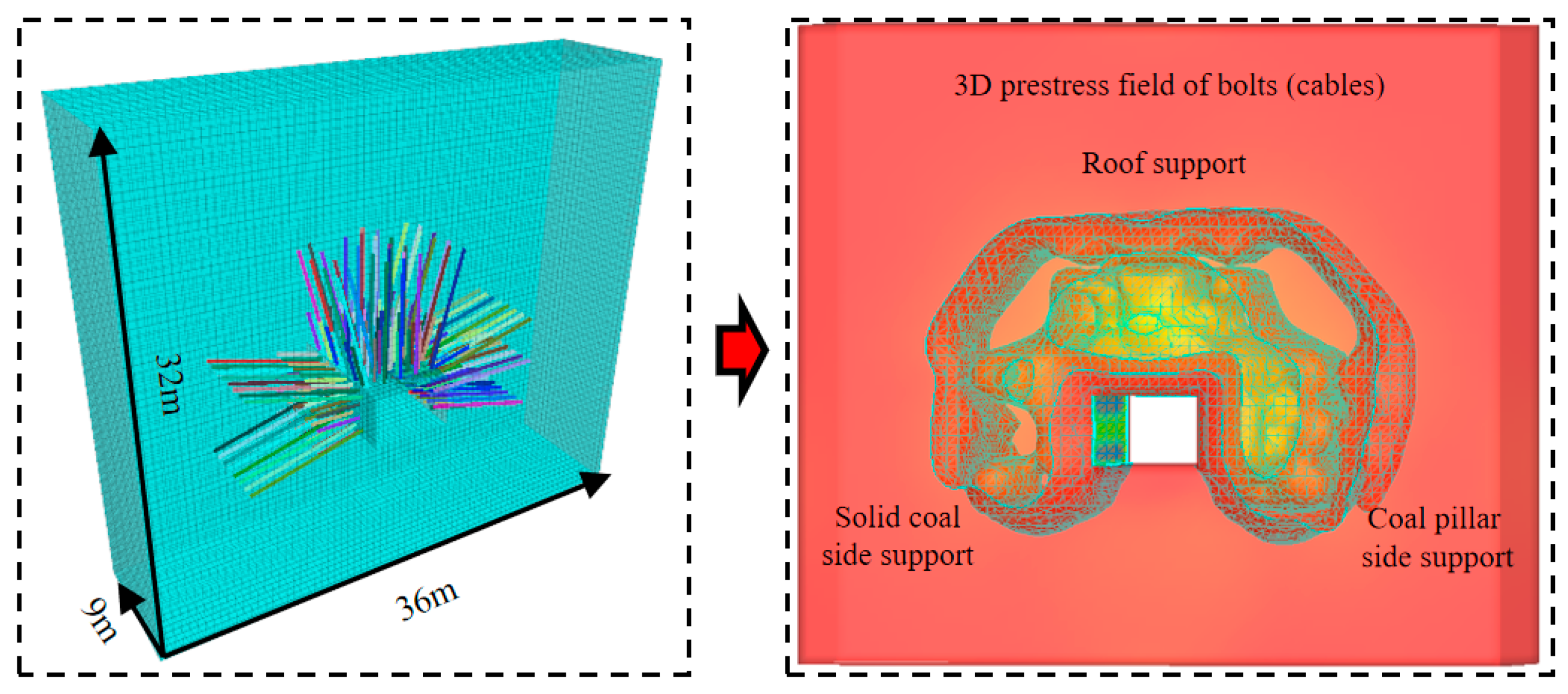

6.2. Characteristics of the Support Structure’s Prestress Field

7. Engineering Practice

8. Conclusions

- (1)

- Key strata above the goaf of the fully mechanized caving face in the extra-thick coal seam formed a structure of low-level cantilever beam and high-level articulated rock beam. The calculated breaking position of the main roof cantilever beam was 15.4 m from the coal wall of the goaf. The optimal location for the roadway was within the inner stress field inside the main roof fracture line. Therefore, the maximum width of the reserved coal pillar should not exceed 9.9 m.

- (2)

- When the coal pillar width ranged from 4 to 14 m during roadway excavation, each width exhibited a stress peak. This peak increased as the coal pillar widened. When the pillar width reached 8 m, the internal stress exceeded the in situ rock stress. In addition, the entire coal pillar entered a fully plastic failure state.

- (3)

- The occupancy rate of the plastic-bearing zone was higher than that in pillars with other widths within the 8–10 m of deteriorated coal pillars. Considering safety and economic factors, the optimal width for the gob-side roadway was determined to be 8 m. Roof subsidence and deformation on the coal pillar side were greater than those on the solid coal side, demonstrating obvious asymmetric deformation in the roadway.

- (4)

- An asymmetric support scheme using truss-anchor cables was proposed. Numerical simulations confirmed that the selected support system established a prestressed field in the surrounding rocks. Field practice further verified the rationality and effectiveness of the designed deteriorated coal pillar width and the asymmetric support system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, L.Z.; Song, H.R.; Lu, Y.L. Research on mechanical mechanism and control technology of mine pressure appearance in gob-side entry driving of extra-thick coal seam. Coal Technol. 2025, 44, 87–93. [Google Scholar]

- Cheng, K.H.; Wang, P.F.; Zhai, L.W. Research and application of anchor cable support technology for whole coal roadway in isolated working face of extra-thick coal seam. Saf. Coal Mines 2021, 52, 106–114. [Google Scholar]

- Xing, X.D. Application research on key technology of reasonable arrangement of small coal pillar in extra-thick coal seam. Coal Technol. 2025, 44, 46–50. [Google Scholar]

- Wang, X.G.; He, H.; Zang, S.F.; Xue, S.H.; He, Y.K.; Niu, X.; Luo, Y. Integrated pressure relief technology for rock burst and gas outburst coordinated control in ultra-thick coal seams under spatially isolated rock pillar areas. Saf. Coal Mines 2025, 56, 69–77. [Google Scholar]

- Feng, J.; Wang, K.; Chen, J.; Liu, Y.; Zheng, X.; Niu, K. Design of the Appropriate Width of the Filling Body for Gob-side Entry Retaining in Hard and Thick Top Coal with Gangue Concrete. Acad. J. Archit. Geotech. Eng. 2025, 7, 39–49. [Google Scholar]

- Pan, K.; Ju, J.W.; Hou, B.; Jia, H.-S. An exploration of improving stability of gob-side entry retained with graded and zoned pressure relief technology: A case study. Sci. Rep. 2024, 14, 29440. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q. Mechanism and control of asymmetric floor heave in gob-side entry under dynamic pressure in ultra-thick coal seams. Coal Eng. 2025, 57, 44–53. [Google Scholar]

- Li, H.M.; Wang, W.Q.; Wang, Z.G.; Sun, H. Surrounding rock control technology with synergetic support and pressure relief for gob-side entry driving in extra-thick coal seam. Coal Eng. 2024, 56, 45–51. [Google Scholar]

- Liu, Y.; Yang, Y.; Wang, X.; Wang, W.Q.; Wu, X.S.; Cao, X.Y.; Lu, Z.J.; Yang, T.; Wei, Z.Q. Instability mechanism of coal pillar in steeply dipping ultra-thick coal seam “segmented and stratified” combined mining. Saf. Coal Mines 2025, 56, 146–154. [Google Scholar]

- Chen, Z.M.; Li, Z.L.; Zhong, T.P.; Song, D.Z.; Liu, X.D.; Hu, X.C. Numerical simulation study on mining method for anti rock burst in different steeply inclined extra-thick coal seam. Saf. Coal Mines 2025, 56, 117–127. [Google Scholar]

- Zhao, W.Z.; Xi, B.P.; Han, F.Z.; Fan, Q.; Jiang, Y.C. Research on the coal pillar width of gob-side entry driving in fully mechanized caving face in extra thick coal seam. China Coal 2024, 50, 140–147. [Google Scholar]

- Liu, Y.; Guo, W.; Fan, G.; Yu, W.; Chai, Y.; Yue, X.; Han, X. Research on Key Roof-Cutting Parameters for Surrounding Rock Stability Control in Gob-Side Entry Retention without Coal Pillars in Karst Mountainous Area. Appl. Sci. 2024, 14, 8118. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Zhu, L.; Huang, Q.X.; Xu, K.; Wu, Y.; Gu, W. Research on Roof Fracture Characteristics of Gob-Side Entry Retaining with Roof Cutting and Non-pillar Mining in Thick Coal Seam, China. Geotech. Geol. Eng. 2021, 40, 1–20. [Google Scholar] [CrossRef]

- Guo, H.J.; Liu, H. Research on the reasonable width of coal pillar in fully mechanized caving mining section in extra-thick coal seam. China Coal 2024, 50, 231–237. [Google Scholar]

- Zhao, G.Z.; Ma, Z.G.; Sun, K.; Fan, J.-Q.; Li, K. Research on deformation controlling mechanism of the narrow pillar of roadway driving along next goaf. J. Min. Saf. Eng. 2010, 27, 517–521. [Google Scholar]

- Bai, J.B.; Hou, C.J.; Huang, H.F. Numerical simulation study on stability of narrow coal pillar of roadway driving along goaf. Chin. J. Rock Mech. Eng. 2004, 23, 3475–3479. [Google Scholar]

- Zheng, X.G.; Yao, Z.G.; Zhang, N. Stress Distribution of coal pillar with gob-side entry driving in the process of excavation & mining. J. Min. Saf. Eng. 2012, 29, 459–465. [Google Scholar]

- Chen, Z.W.; Zhang, Y.D. Research and application of coordinated control technology for surrounding rock stability of gob-side entry driving with narrow coal pillar. Min. Saf. Environ. Prot. 2023, 50, 65–70. [Google Scholar]

- Zhang, G.C.; He, F.L. Rock and soil mechanics pillar width determination and surrounding rocks control of gob-side entry with large cross-section and fully-mechanized mining. Rock Soil Mech. 2016, 37, 1721–1728+1736. [Google Scholar]

- Li, W.; Bai, J.; Peng, S.; Wang, X.; Xu, Y. Numerical modeling for yield pillar design: A case study. Rock Mech. Rock Eng. 2015, 48, 305–318. [Google Scholar] [CrossRef]

- Shen, B. Coal mine roadway stability in soft rock: A case study. Rock Mech. Rock Eng. 2014, 47, 2225–2238. [Google Scholar] [CrossRef]

- Wu, W.; Wang, T.; Bai, J.; Liu, J.; Wang, X.; Xu, H.; Feng, G. Failure characteristics and cooperative control strategies for gob-side entry driving near an advancing working face: A case study. Processes 2024, 12, 1398. [Google Scholar] [CrossRef]

- Huang, W.; Zhao, T.; Zhang, C.; Liu, Y.; Sui, L.; Hou, T.; Jiang, D. Assessment of pillar stability and its control in a double roadway layout. Energy Sci. Eng. 2024, 12, 4192–4209. [Google Scholar] [CrossRef]

- Tomiczek, K. A brief analysis of behaviour possibility of a jointed rock mass near to longwall excavation face simulation using Distinct Elements Method (DEM) in the context of the Beam on Elastic Foundation (BEF) theory. In Proceedings of the E3S Web of Conferences, EDP Sciences, Milan, Italy, 13–15 February 2019; Volume 106, p. 01015. [Google Scholar]

- Wang, D.; He, F.; Wu, Y.; Lv, K.; Zhang, J.; Shi, S.; Guo, J.; Xu, X.; Tao, K.; Zhang, Y.; et al. Study on stability and control of surrounding rock in the large section stopping space with extra-thick coal seam. Alex. Eng. J. 2025, 117, 205–220. [Google Scholar] [CrossRef]

- Yan, S.H.; Yin, X.W.; Xu, H.J.; Xu, G.; Liu, Q.-M.; Yu, L. Roof structure of short cantilever-articulated rock beam and calculation of support resistance in full-mechanized face with large mining height. J. China Coal Soc. 2011, 36, 1816–1820. [Google Scholar]

- Yu, M.L.; Wang, Z.W.; Liu, Y.; Li, C.; Li, Z.; Wang, L. Mechanical mechanism of key strata fracturing under different water pressures in the fourth aquifer of loose layers. J. Min. Strat. Control. Eng. 2024, 6, 132–147. [Google Scholar] [CrossRef]

- Yu, M.L. Fracture Mechanics and Zoning Movement Model of Medium-Thick Strata in Coal Mines; China University of Mining and Technology: Beijing, China, 2023. [Google Scholar] [CrossRef]

- Zheng, Z.; Yang, Z.Q.; Zhu, H.Z.; He, F.L.; Du, C.Y.; Liu, B.Q. Study on reasonable coal-pillar width and surrounding-rock control of gob-side irregular roadway in inclined seam. J. Min. Saf. Eng. 2019, 36, 223–231. [Google Scholar]

- Zhang, G.C.; He, F.L. Asymmetric failure and control measures of large cross-section entry roof with strong mining disturbance and fully-mechanized caving mining. Chin. J. Rock Mech. Eng. 2016, 35, 806–818. [Google Scholar] [CrossRef]

- Wang, D.; He, F.; Wu, Y.; Xu, X.; Zhang, J.; Lv, K.; Li, L.; Zhai, W.; Song, J. Study on surrounding rock failure mechanism and rational coal pillar width of the gob-side coal roadway under influence of intense dynamic pressure. Energy Sci. Eng. 2023, 11, 1716–1733. [Google Scholar] [CrossRef]

- Xu, X.H.; He, F.L.; Li, X.B.; He, W. Research on mechanism and control of asymmetric deformation of gob side coal roadway with fully mechanized caving mining. Eng. Fail. Anal. 2021, 120, 105097. [Google Scholar] [CrossRef]

- Jiang, Z.S.; Chen, D.D.; Xie, S.R. A novel asymmetric stress unloading technology in two sides of coal roadway in deep mine: A case study. Tunn. Undergr. Space Technol. 2023, 142, 105452. [Google Scholar] [CrossRef]

- Zuo, J.P.; Ma, Z.Y. Asymmetric deformation and failure behavior of roadway subjected to different principal stress based on biaxial tests. Tunn. Undergr. Space Technol. 2025, 155, 106174. [Google Scholar] [CrossRef]

- Xie, S.R.; Ren, Y.X.; Chen, D.D.; Guo, W.; Li, S.; Li, Y.; Ma, X.; Ye, Q.; Chang, J.; Liang, D.; et al. A case study on coordinated asymmetric support-relief control for roadway surrounding rock under multiple dynamic pressures in thick coal seams. Eng. Fail. Anal. 2025, 179, 109821. [Google Scholar] [CrossRef]

- Qin, Z.; Liu, Y.; Zhang, F.; Liu, N. Stability Assessment of Gob Side Entry at the Steeply Inclined Mining Face. Appl. Sci. 2025, 15, 3244. [Google Scholar] [CrossRef]

- Zhang, H.; Wen, Y.; Wu, W.; Wen, H.; Hu, Y.; Wang, B.; Shao, J.; Li, Z.; Niu, J. Study on the Width of a Narrow Coal Pillar for Gob-Side Entry Driving near an Advancing Working Face in a Shallow Coal Seam. Energies 2025, 18, 4303. [Google Scholar] [CrossRef]

| Rock Stratum | Density ρ/kg/m3 | Internal Friction Angle φ/° | Bulk Modulus K/GPa | Shear Modulus G/GPa | Cohesion c/MPa |

|---|---|---|---|---|---|

| Siltstone | 2455 | 32 | 10.2 | 7.7 | 3.98 |

| Medium-coarse sandstone | 2780 | 35.9 | 12.4 | 8.51 | 9.10 |

| Mudstone | 2102 | 30.1 | 3.8 | 2.53 | 2.58 |

| Coal | 1521 | 27 | 4.8 | 0.42 | 2.1 |

| Sandy mudstone | 2380 | 30.9 | 4.4 | 3.41 | 3.2 |

| Siltstone | 2580 | 32.7 | 10.5 | 7.51 | 8.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J.; Wang, Y.; Jin, X.; Qiao, F. Reasonable Width of Deteriorated Coal Pillars and Surrounding Rock Control for Roadways in Thick Coal Seams: A Case Study of Datong Coal Mine Area, China. Appl. Sci. 2025, 15, 10110. https://doi.org/10.3390/app151810110

Jin J, Wang Y, Jin X, Qiao F. Reasonable Width of Deteriorated Coal Pillars and Surrounding Rock Control for Roadways in Thick Coal Seams: A Case Study of Datong Coal Mine Area, China. Applied Sciences. 2025; 15(18):10110. https://doi.org/10.3390/app151810110

Chicago/Turabian StyleJin, Junyu, Yu Wang, Xufeng Jin, and Fang Qiao. 2025. "Reasonable Width of Deteriorated Coal Pillars and Surrounding Rock Control for Roadways in Thick Coal Seams: A Case Study of Datong Coal Mine Area, China" Applied Sciences 15, no. 18: 10110. https://doi.org/10.3390/app151810110

APA StyleJin, J., Wang, Y., Jin, X., & Qiao, F. (2025). Reasonable Width of Deteriorated Coal Pillars and Surrounding Rock Control for Roadways in Thick Coal Seams: A Case Study of Datong Coal Mine Area, China. Applied Sciences, 15(18), 10110. https://doi.org/10.3390/app151810110