Study on Damage and Fracture Mechanism and Ontological Relationship of Rock Body in Deep Open Pit in Cold Area

Abstract

1. Introduction

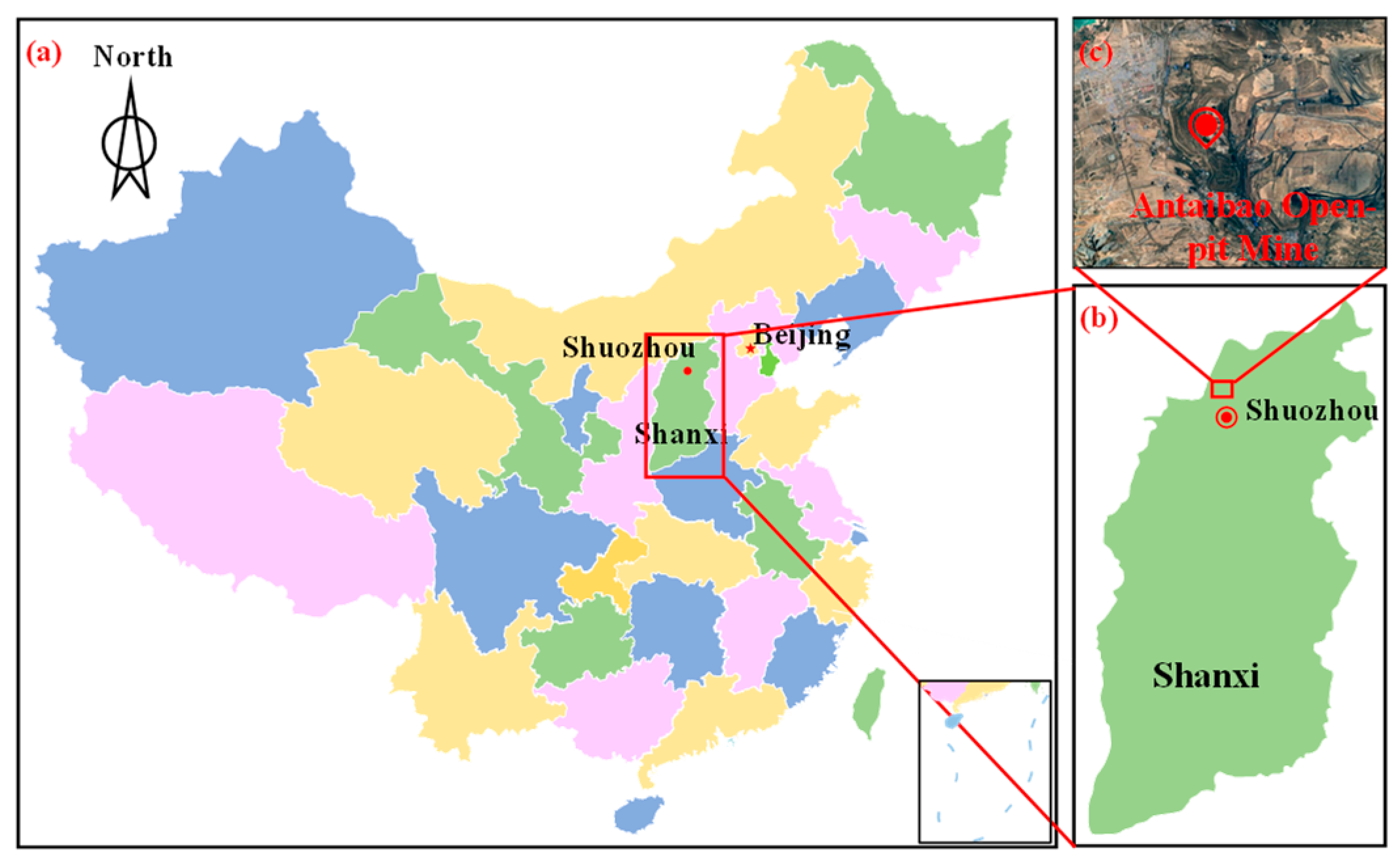

2. Materials and Methods

2.1. Specimen Preparation

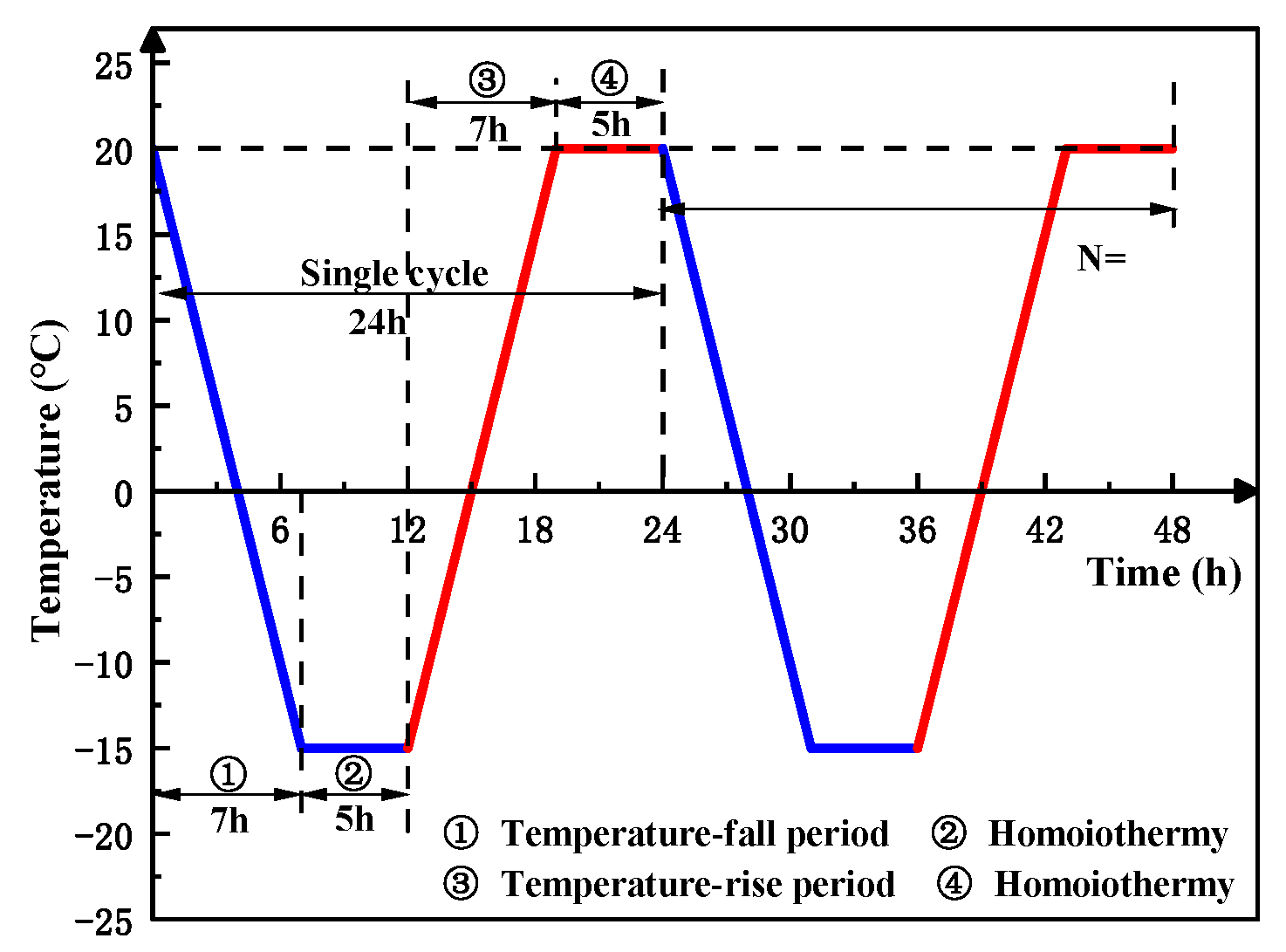

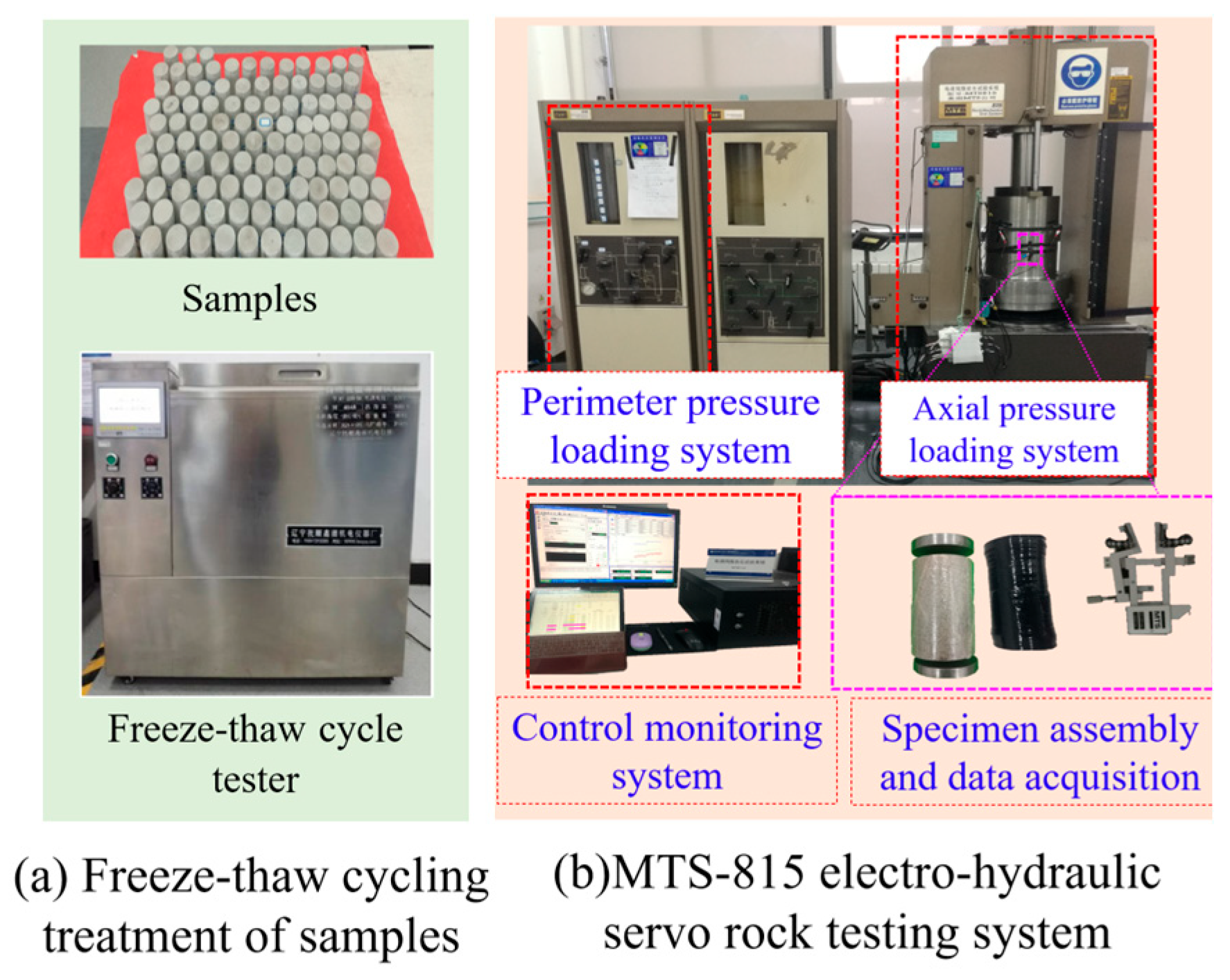

2.2. Test Equipment and Process

3. Test Results and Discussion

3.1. Characteristics of Variation in Mechanical Property Parameters of Sandstone Specimens

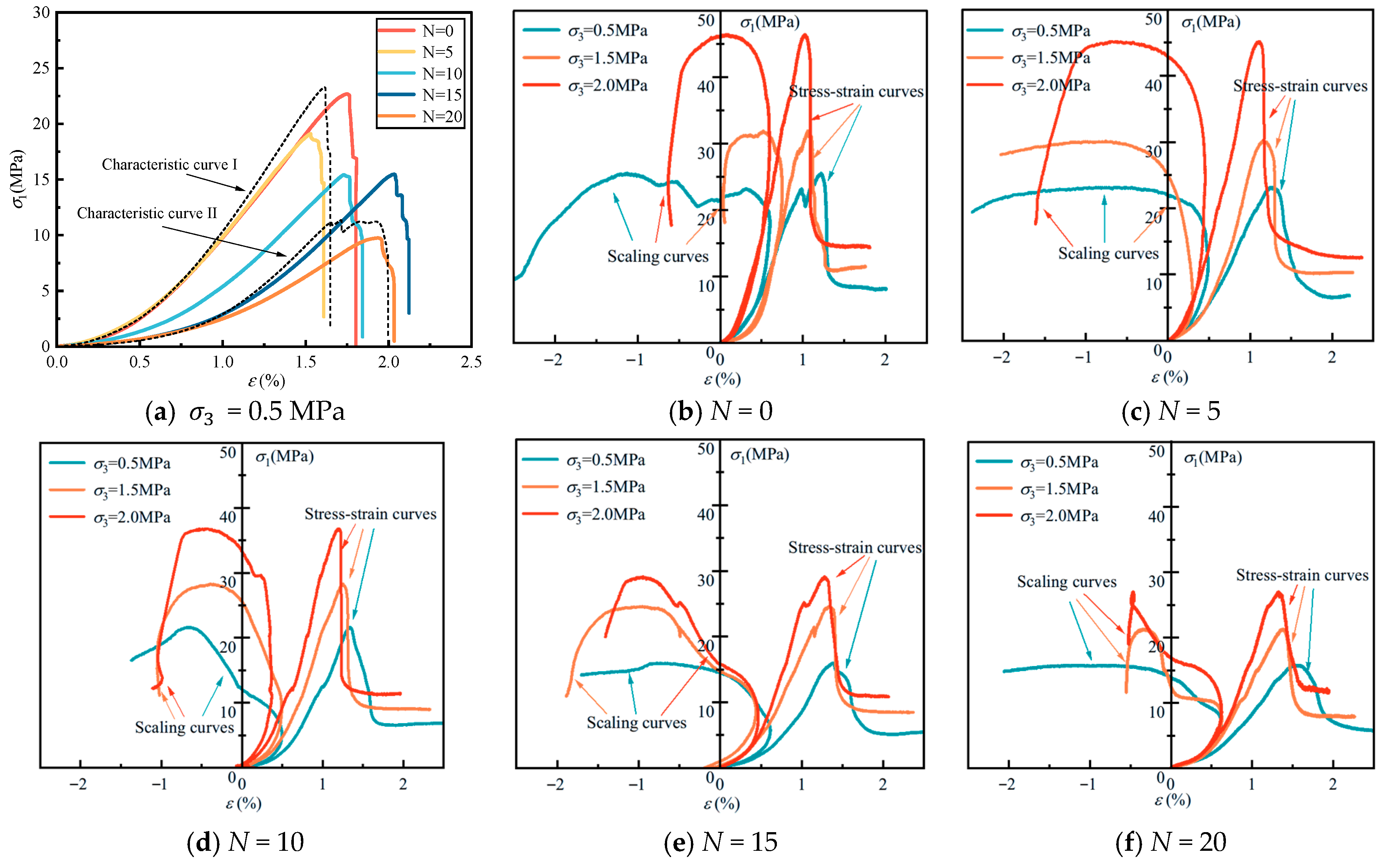

3.1.1. Stress–Strain Curve Characteristics

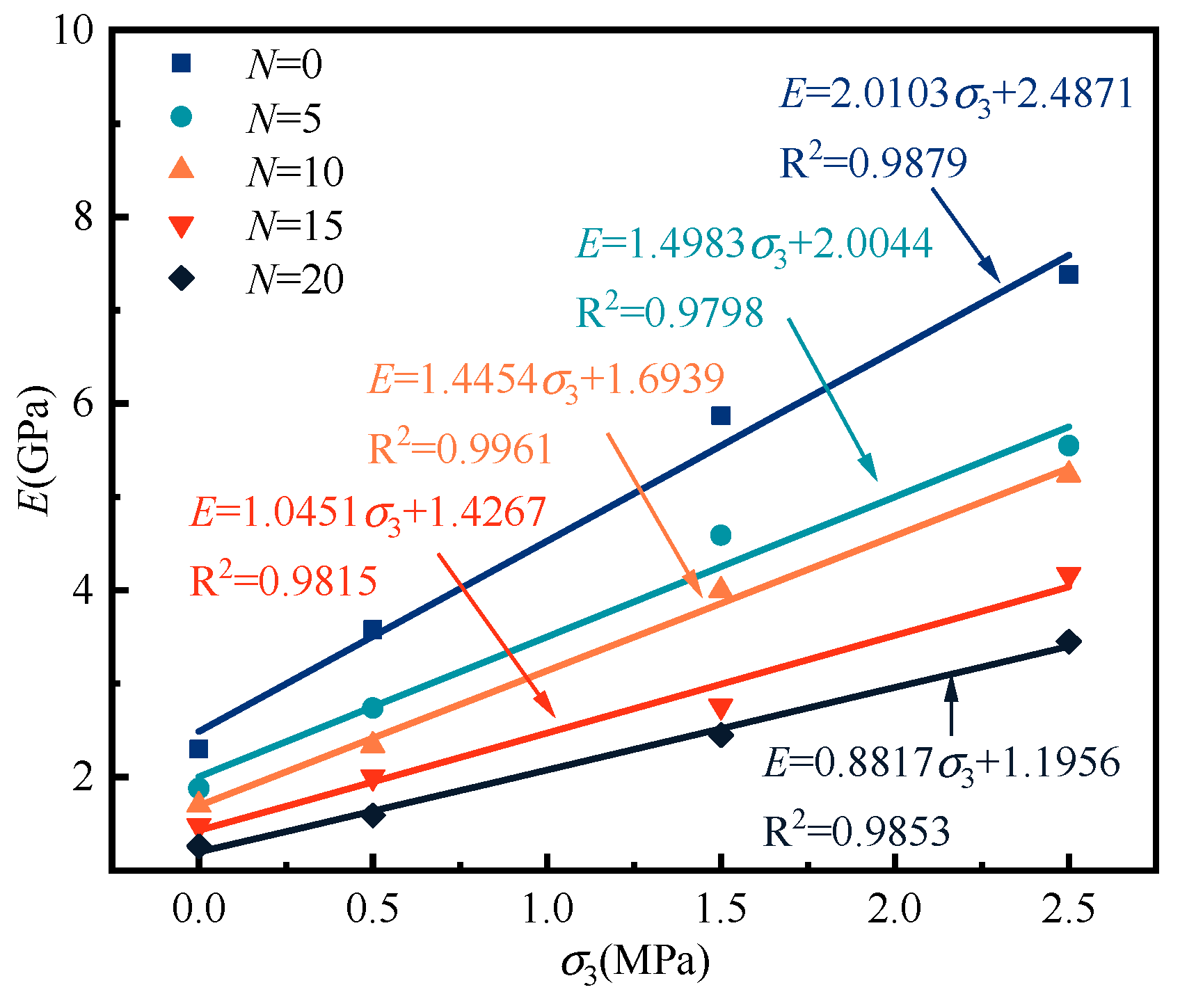

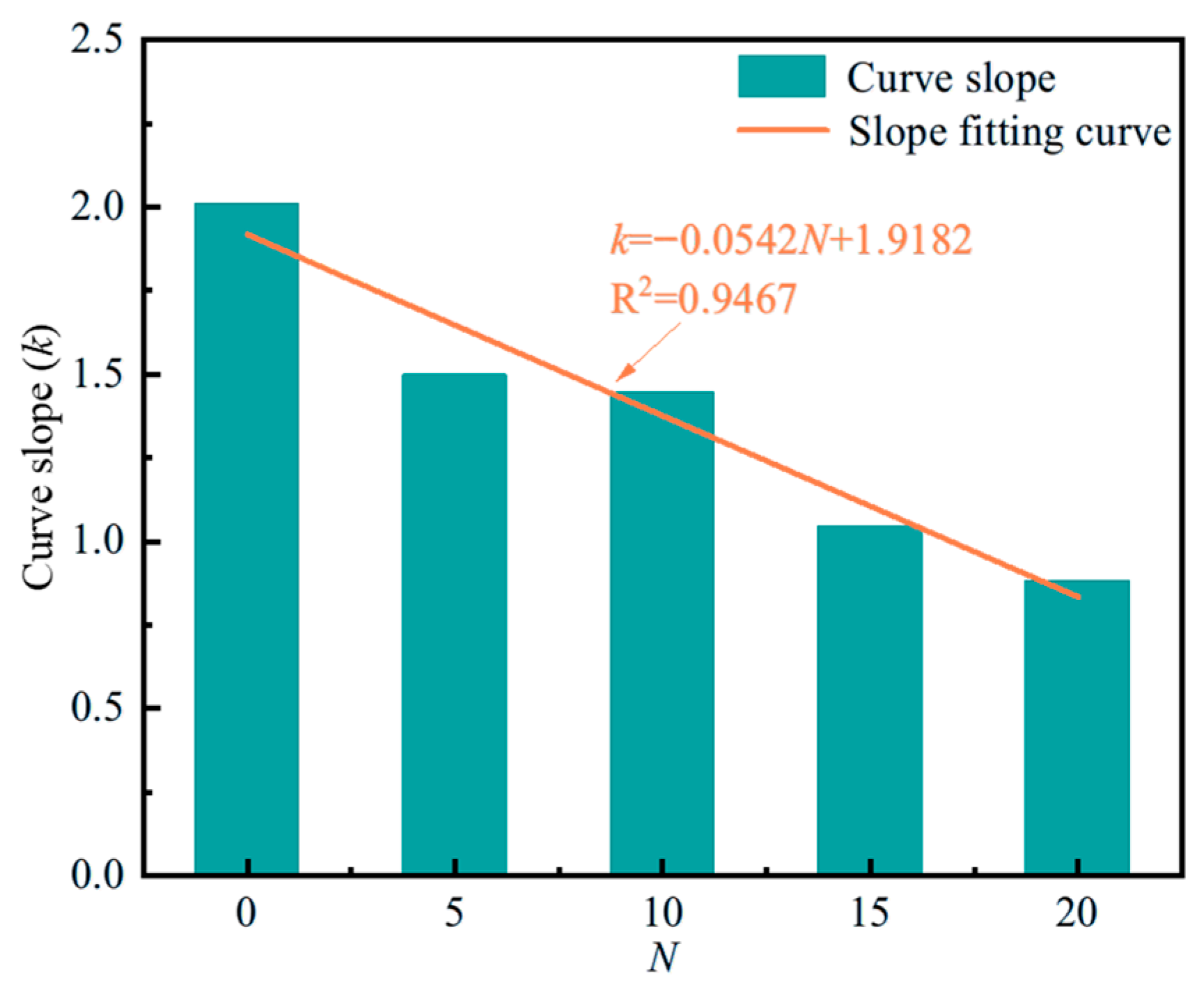

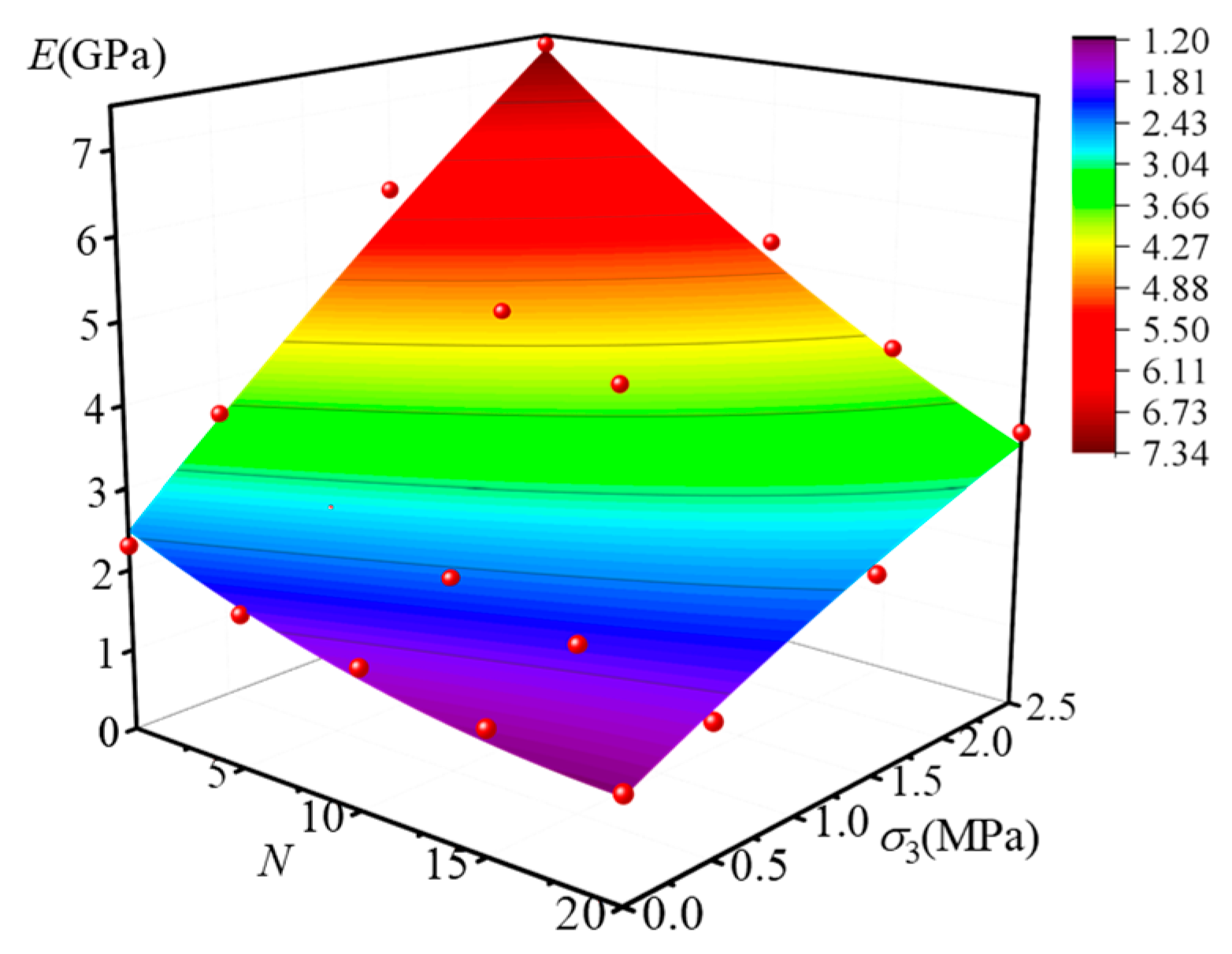

3.1.2. Elastic Modulus

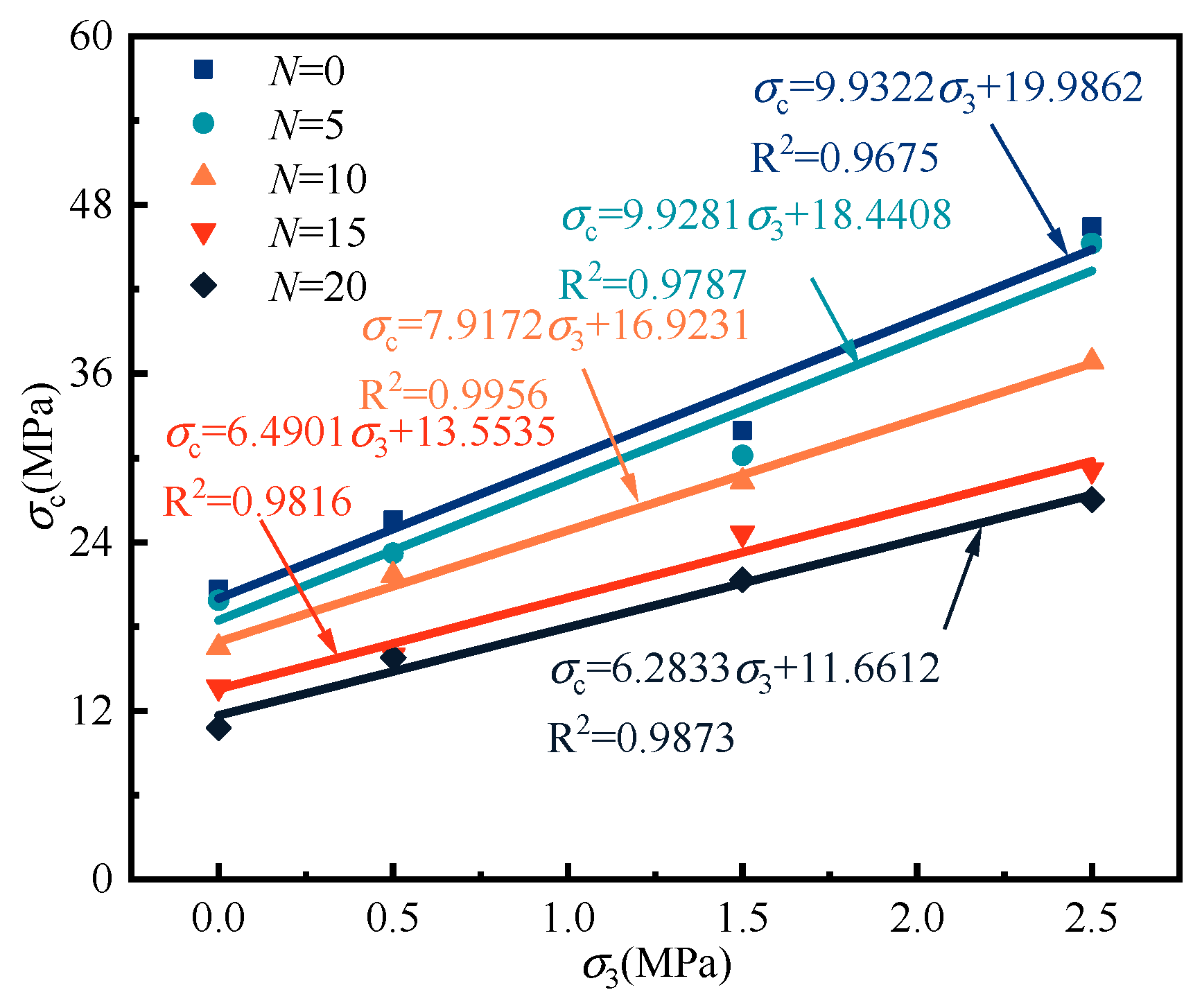

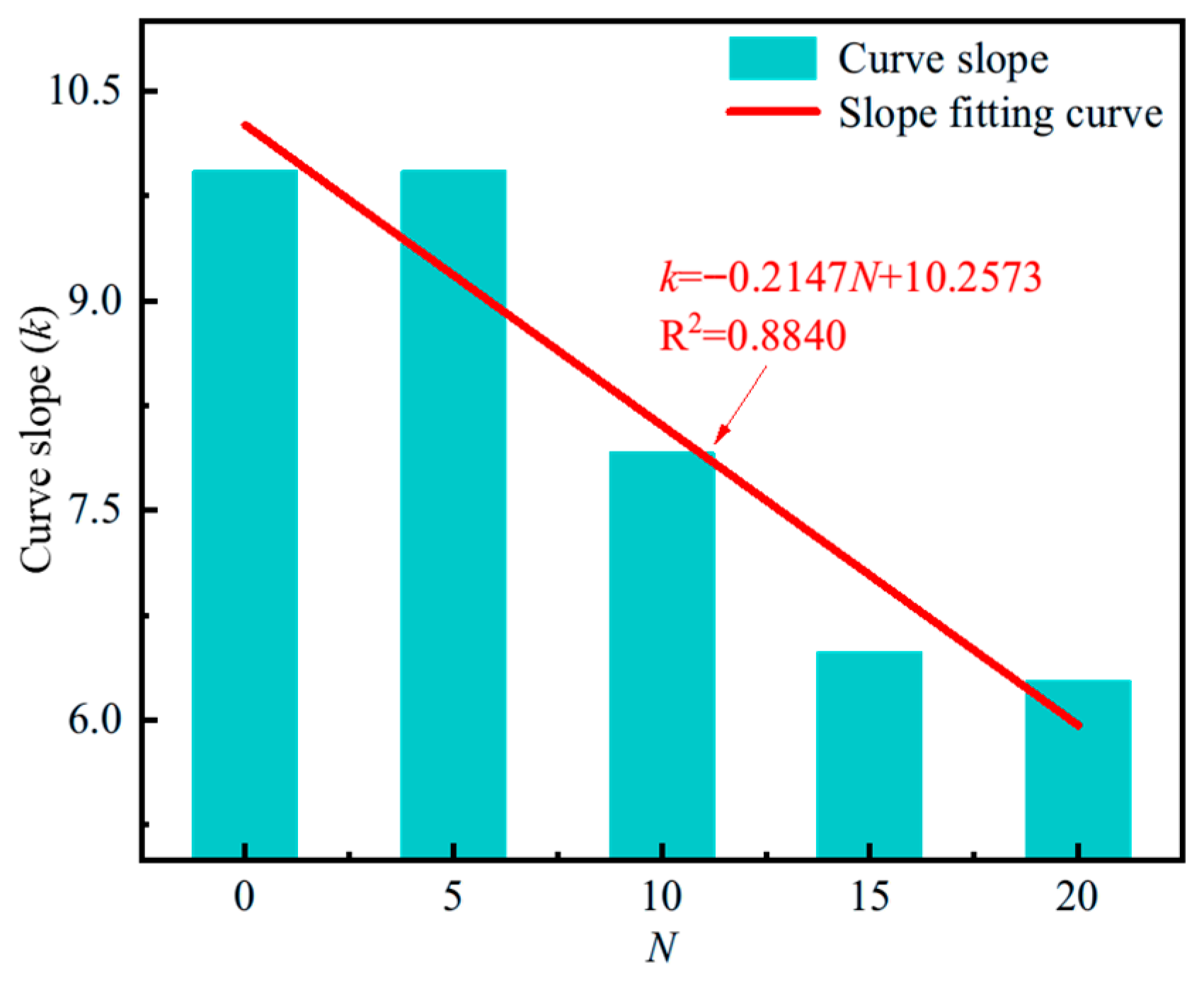

3.1.3. Peak Intensity

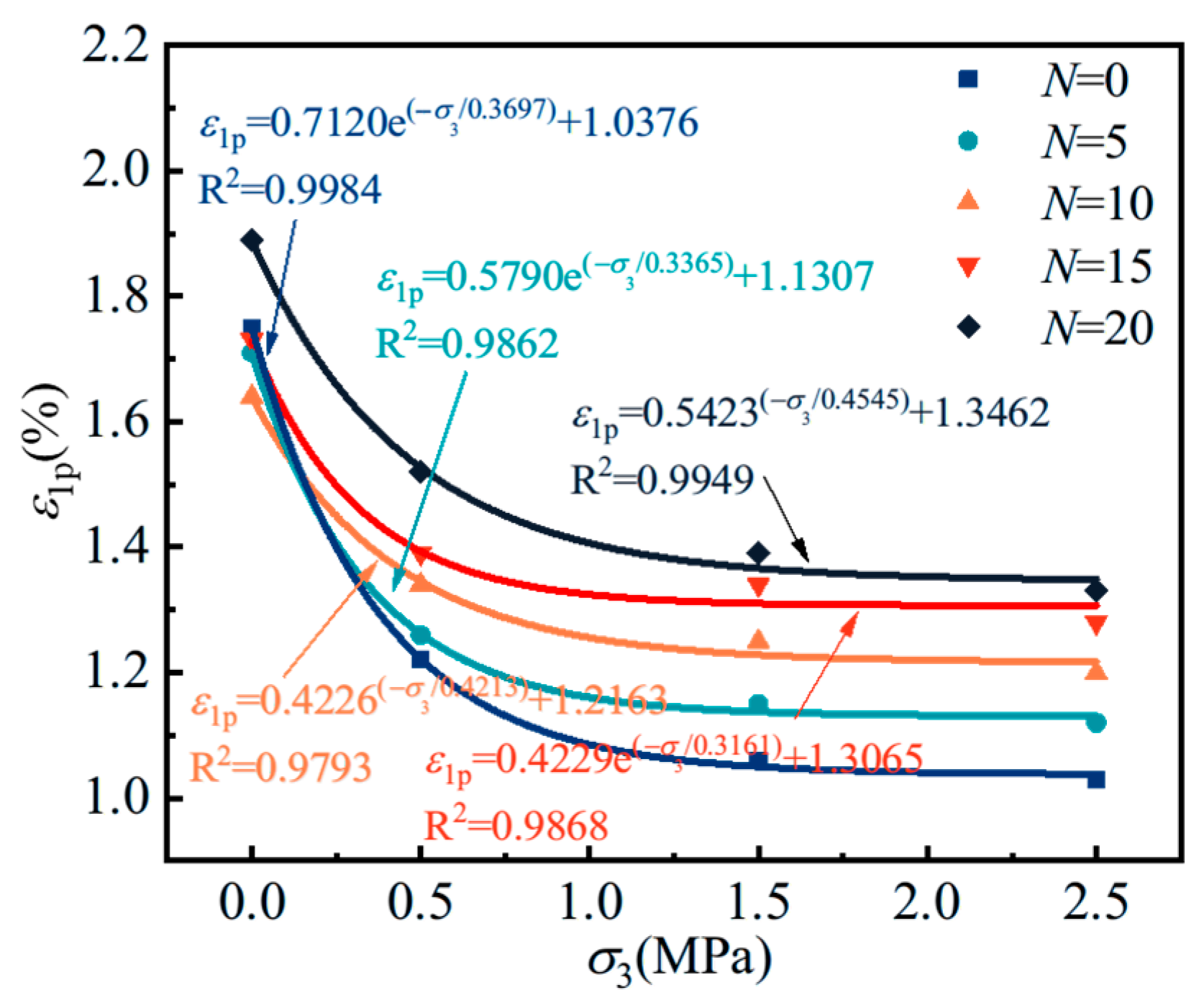

3.1.4. Peak Strain

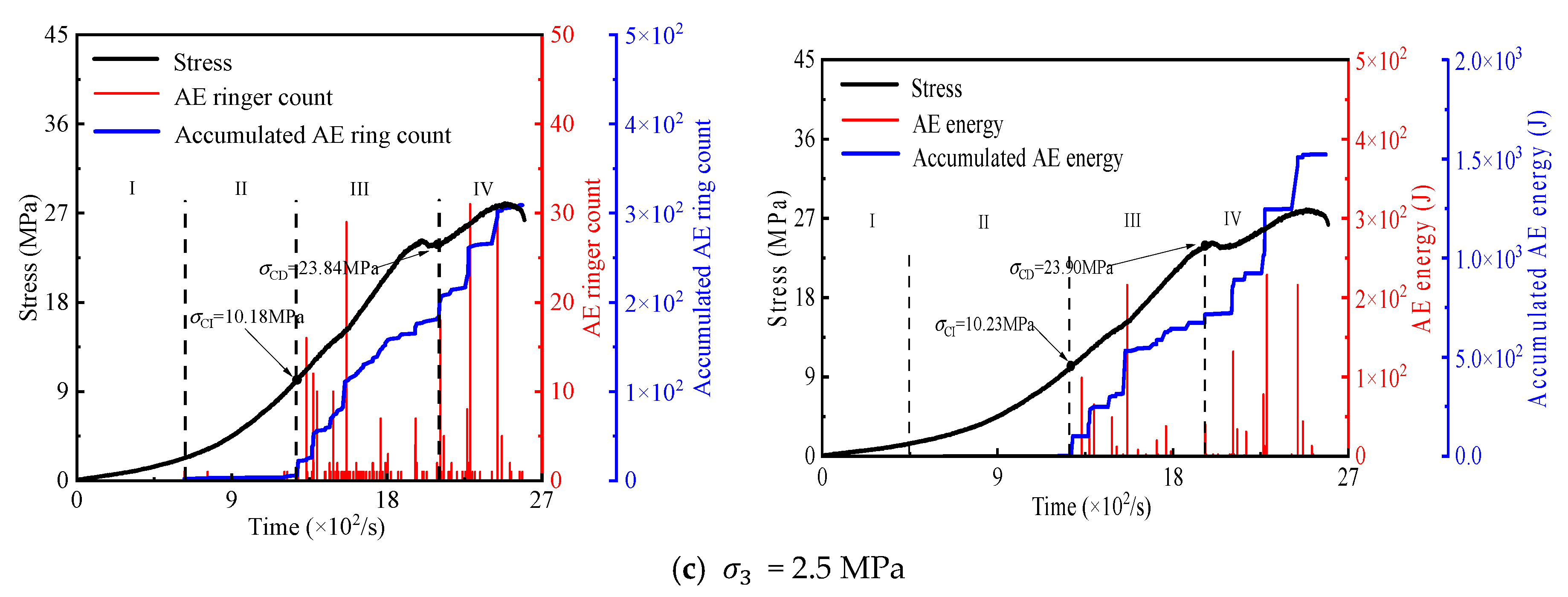

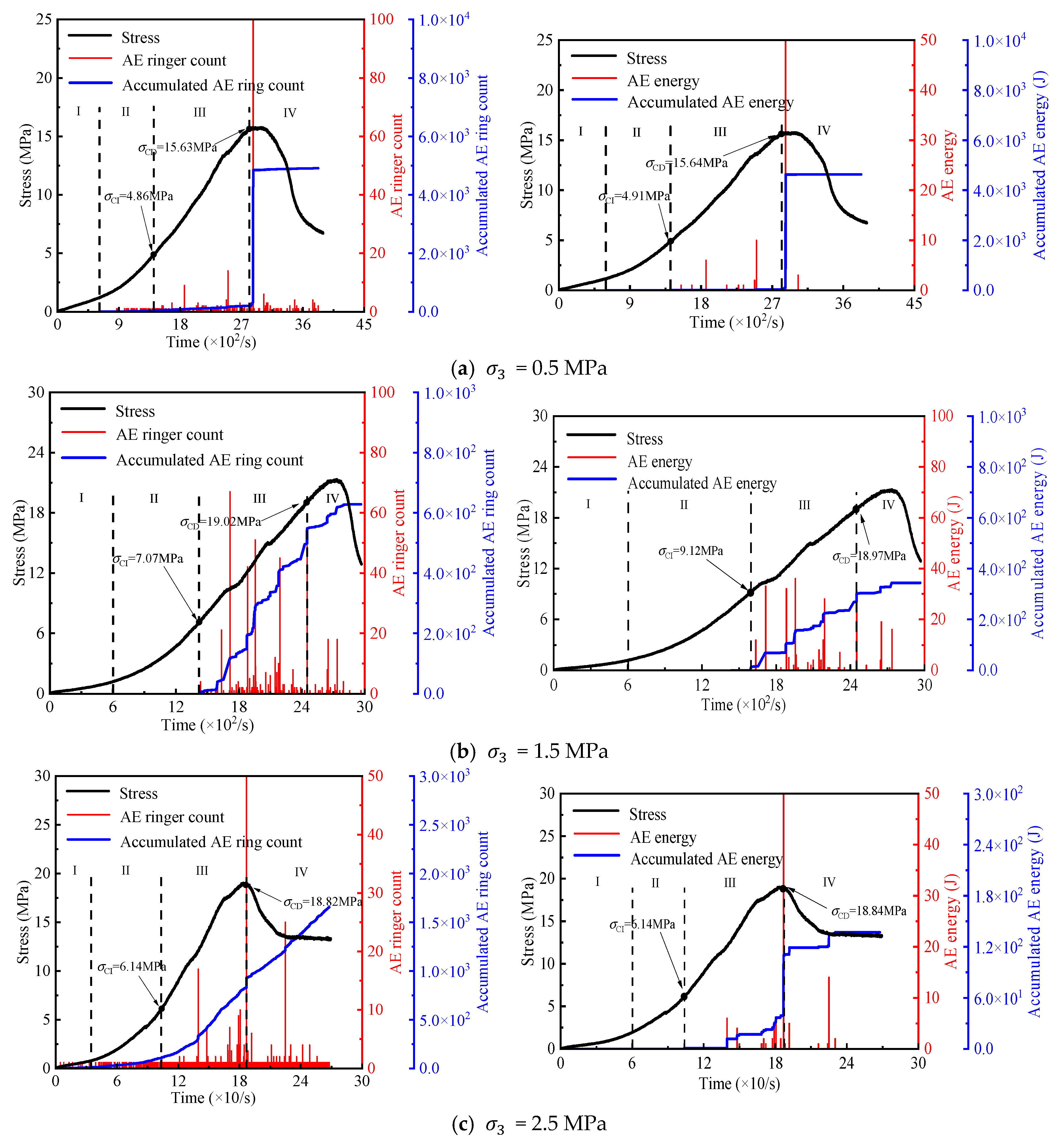

3.2. Acoustic Emission Characterization

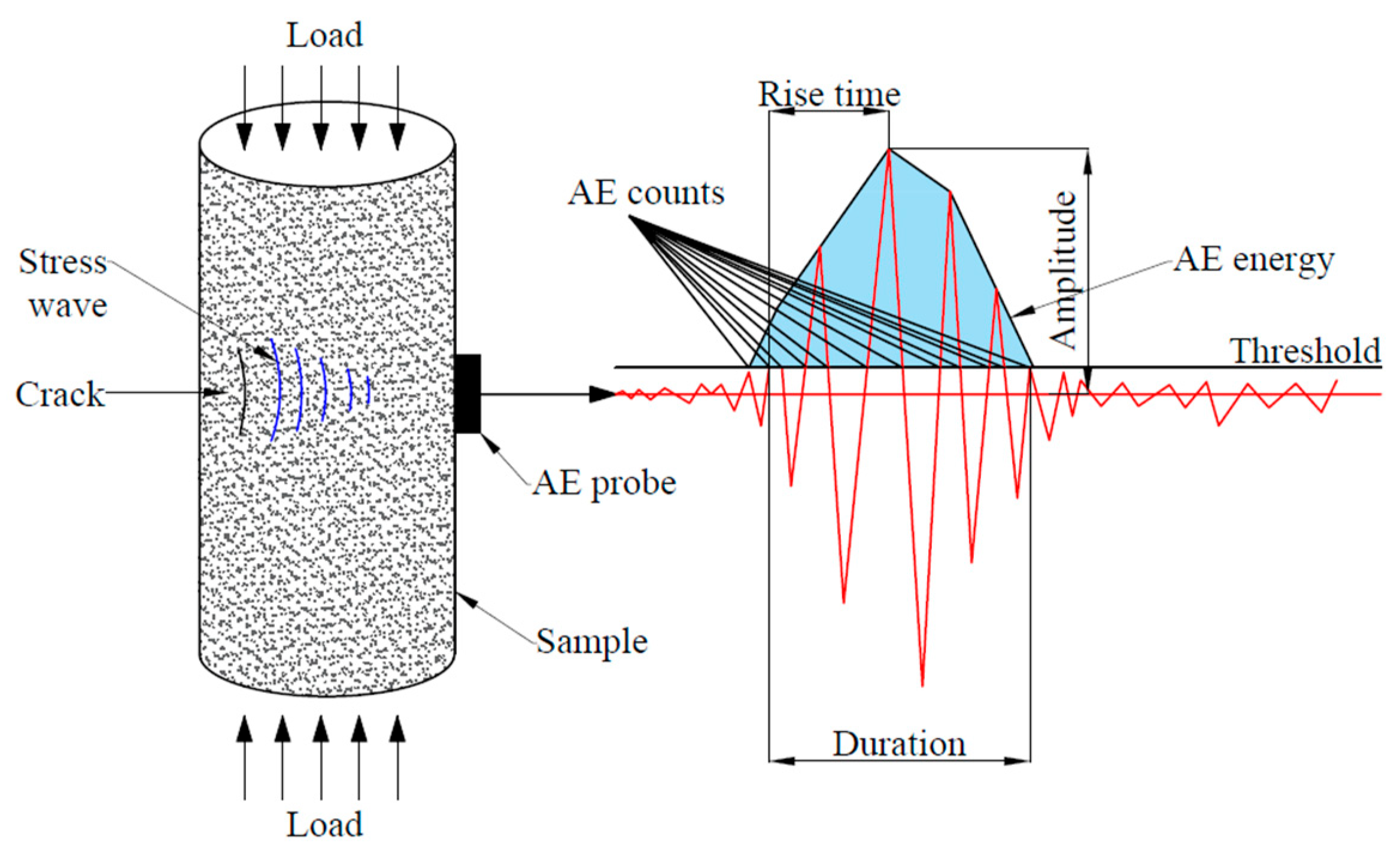

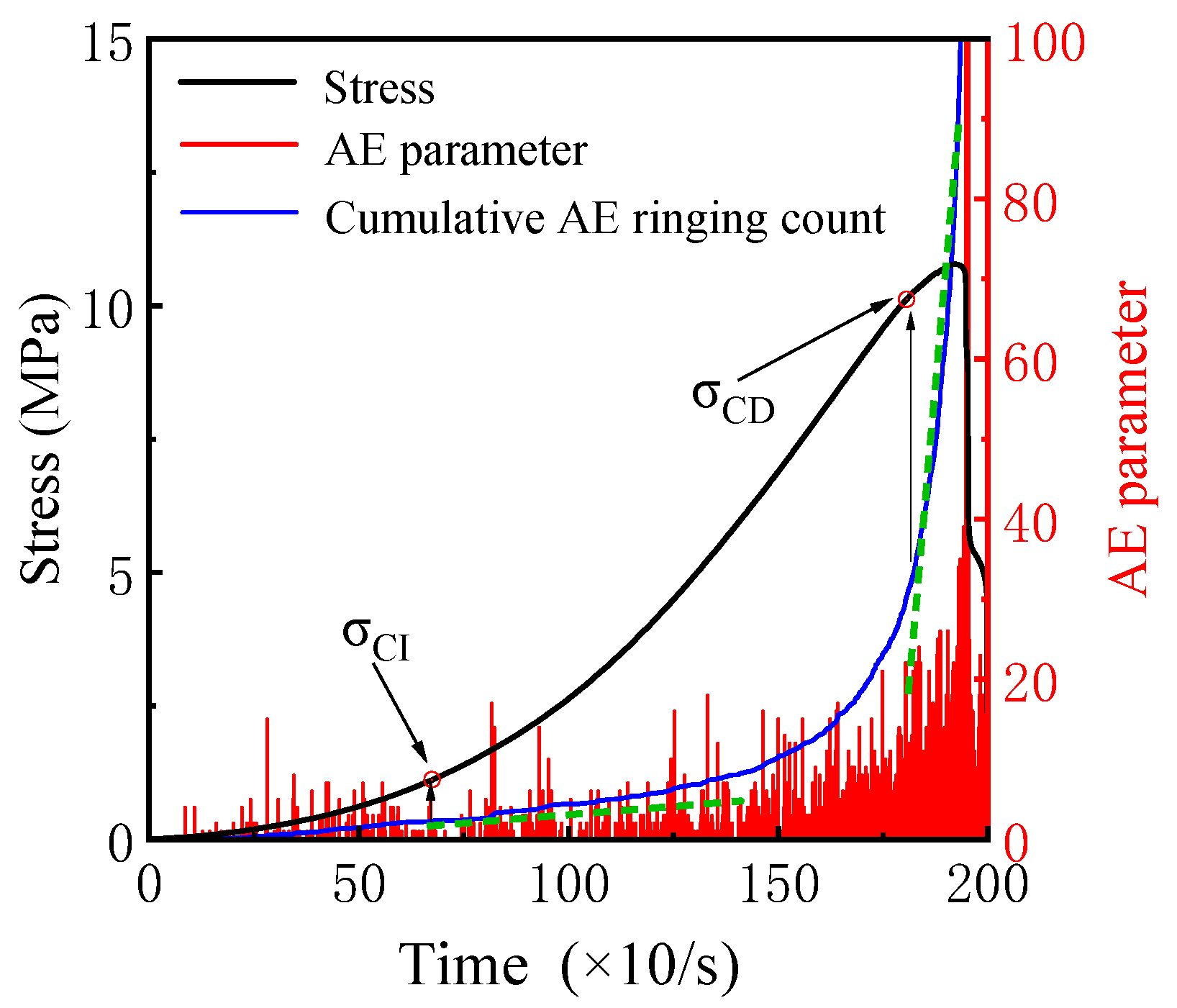

3.2.1. Acoustic Emission Parameter Characterization Methods

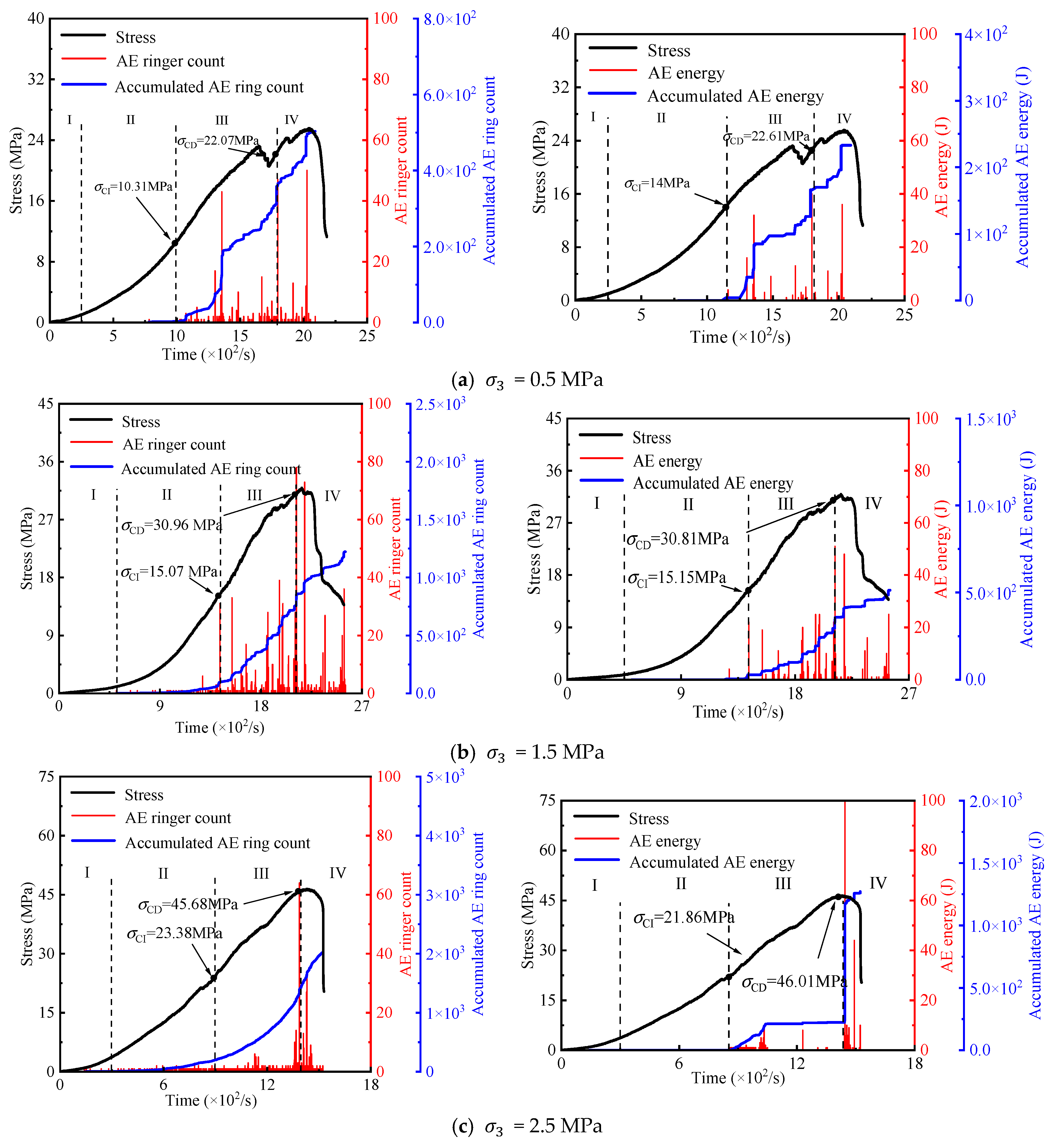

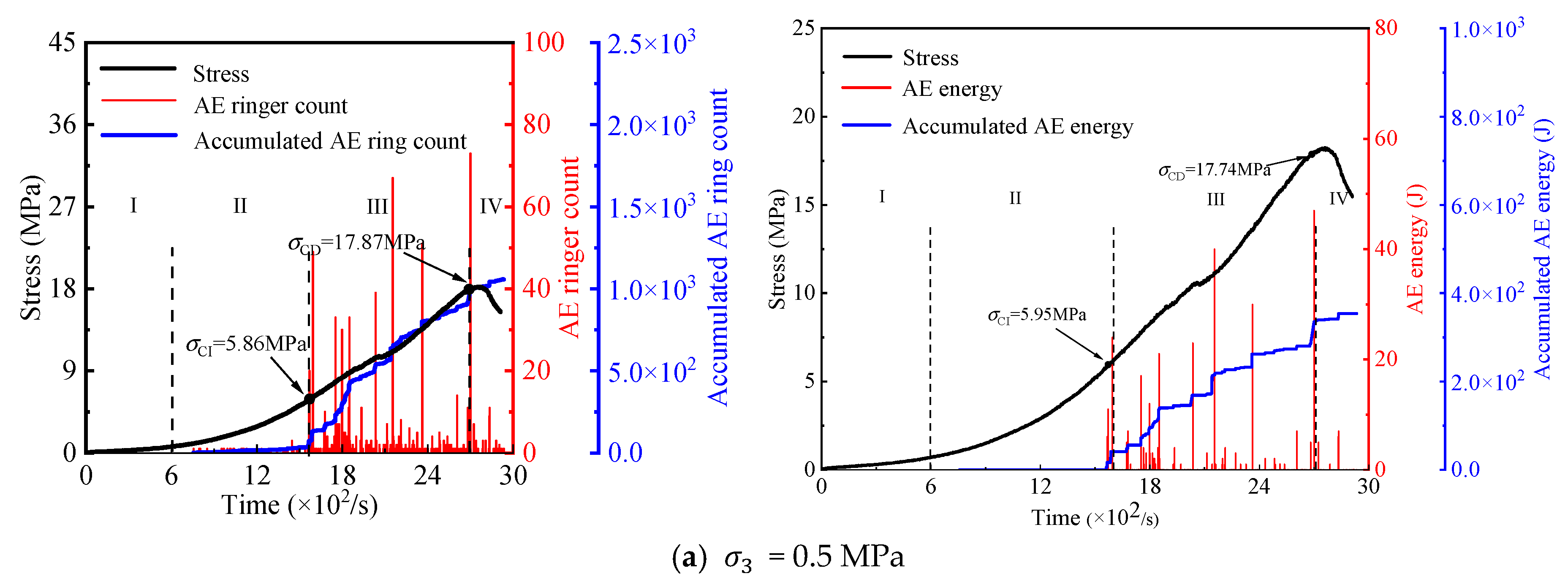

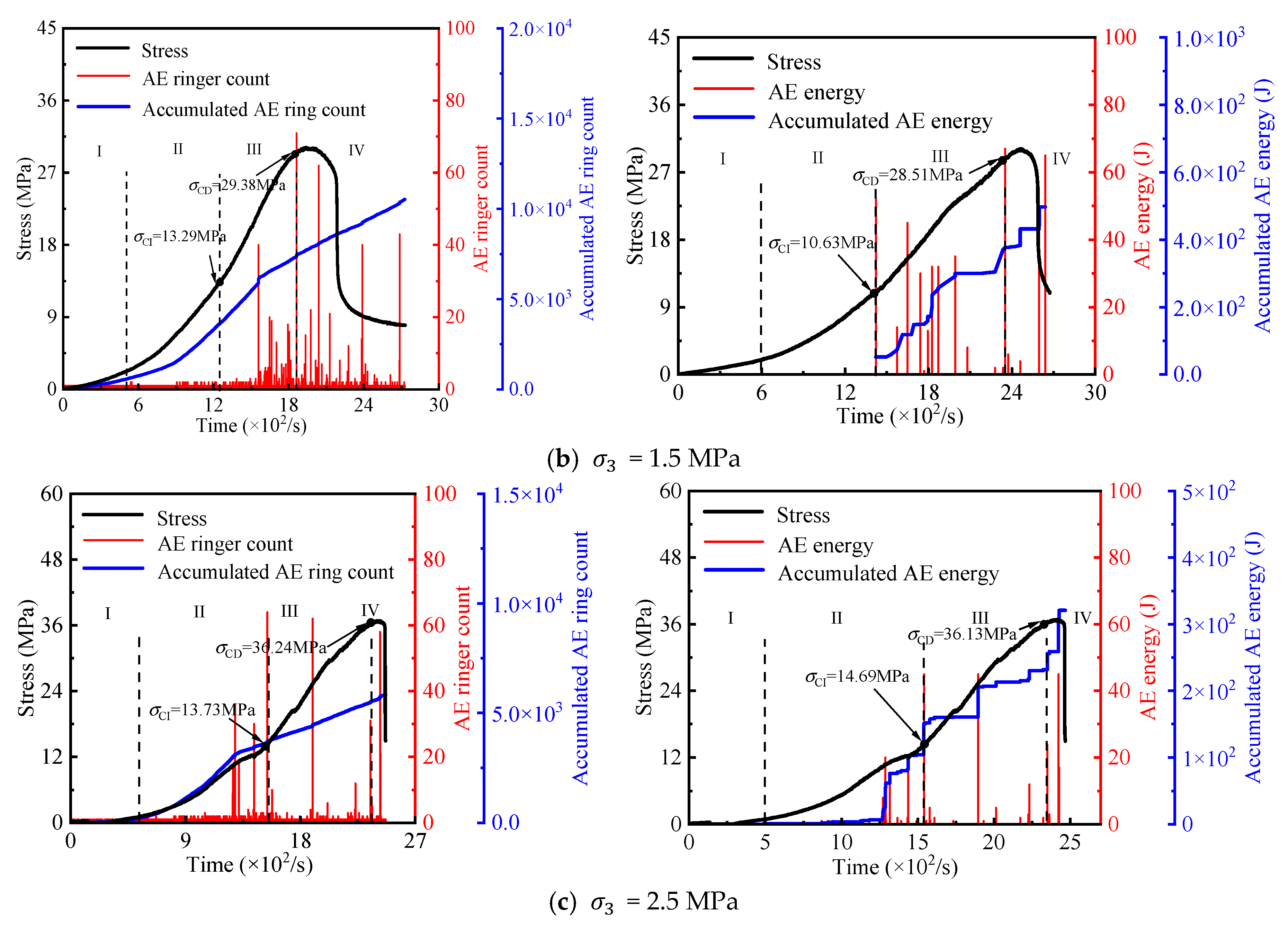

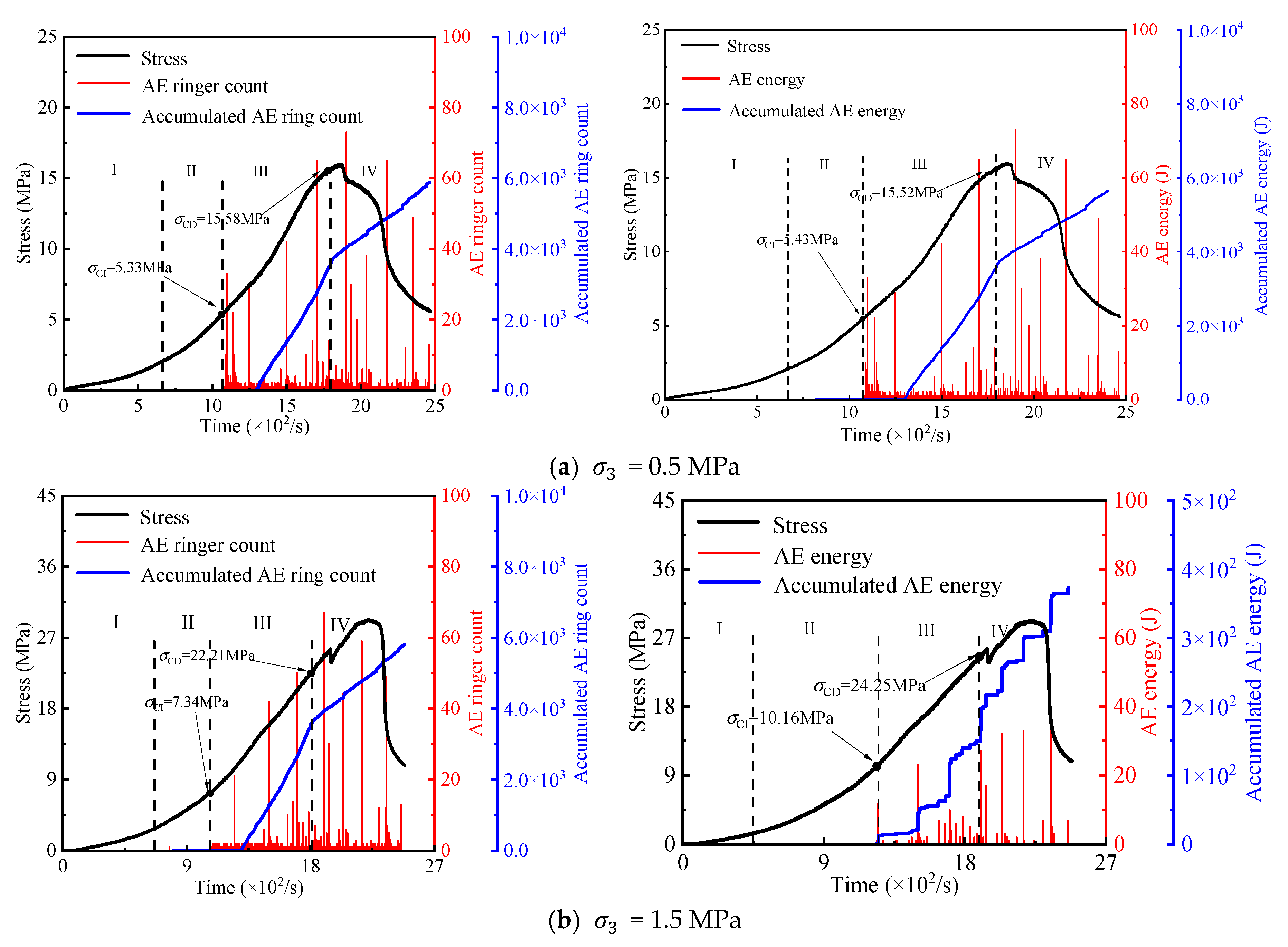

3.2.2. Acoustic Emission Ring Counts and Energy Characteristics

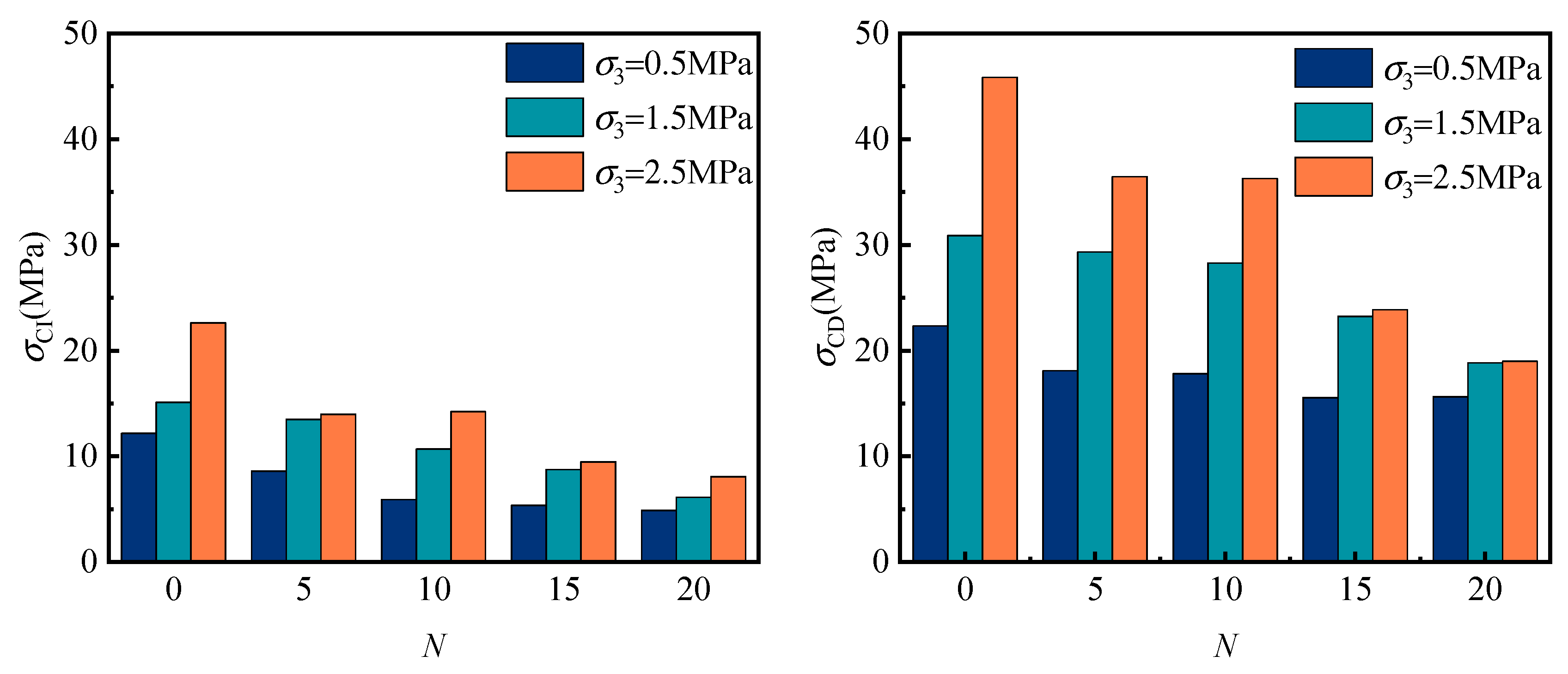

3.3. Correlation Between Crack Initiation, Damage Threshold, and Percentage with Surrounding Pressure

4. Damage Eigenstructure Model and Evolution Equations

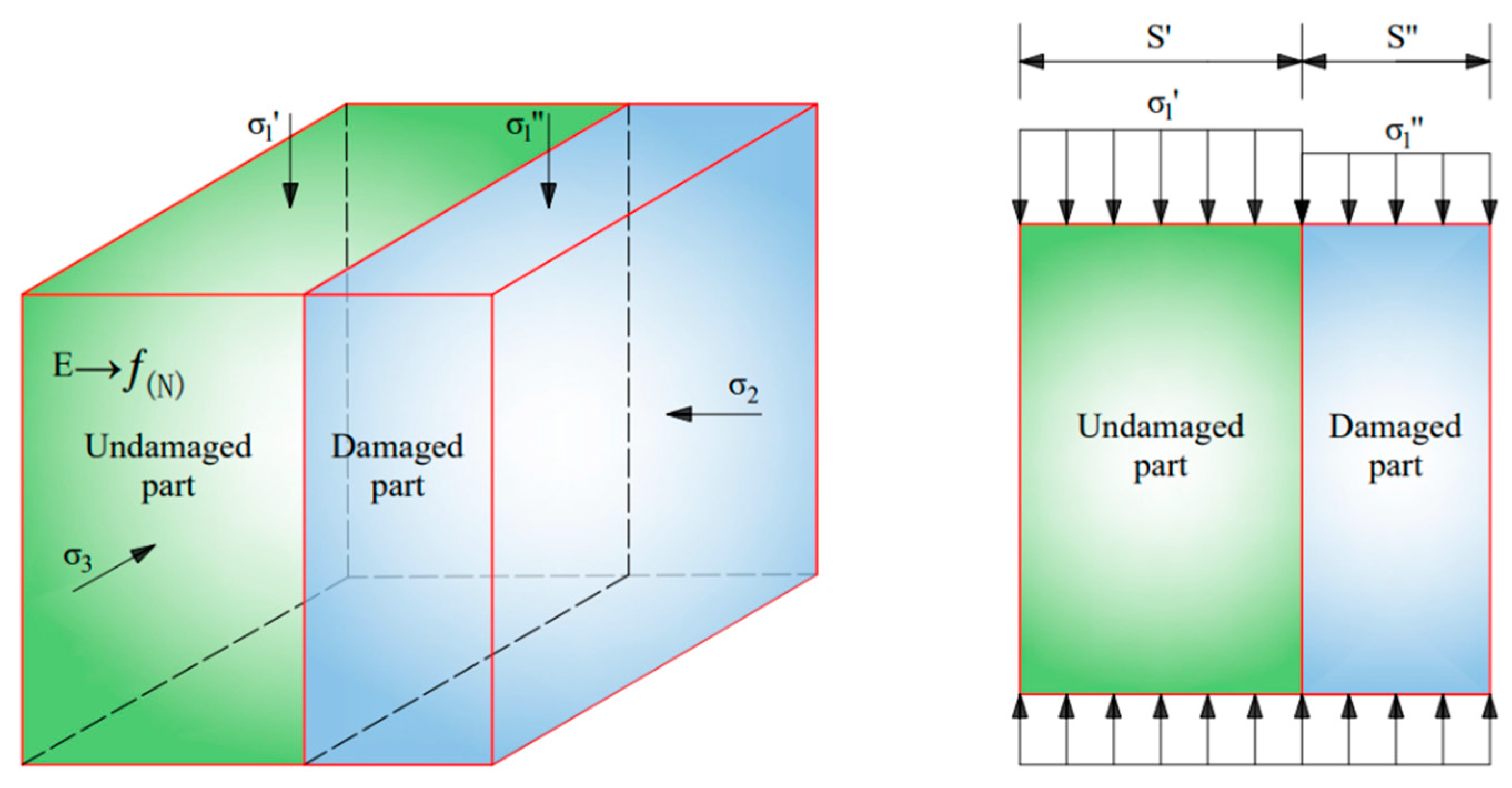

4.1. Establishment of Damage Model

4.2. Damage Evolution Equation

4.2.1. Establishment of Statistical Damage Evolution Equation

4.2.2. Solution of Damage Evolution Equation Parameters

5. Verification of the Accuracy of the Intrinsic Model

6. Conclusions

- (1)

- The stress–strain behavior, elastic modulus, peak strength, and peak strain of coal sandstone under varying freeze–thaw cycles and confining pressures were analyzed. With a fixed confining pressure, increasing freeze–thaw cycles caused the post-peak response to shift from sudden to gradual decline, indicating a transition from brittle to ductile failure. Under the same freeze–thaw conditions, higher confining pressures led to linear increases in elastic modulus and peak strength, while peak strain decreased nonlinearly with a progressively slower rate. The effect of confining pressure on mechanical parameters was strongly dependent on the number of cycles: at fewer cycles, pressure reinforcement was more significant, but with more cycles, internal structural damage accumulated linearly, reducing sensitivity to confinement. Consequently, the fitted slopes of elastic modulus and strength versus confining pressure showed a linear decline, and the capacity of confining pressure to enhance strength weakened markedly at higher freeze–thaw damage levels.

- (2)

- The evolution of acoustic emission (AE) in coal sandstone under freeze–thaw cycles and confining pressure was investigated. Regardless of conditions, AE counts and energy exhibited three stages: quiet, low-amplitude growth, and high-amplitude growth. With increasing freeze–thaw cycles, cumulative AE counts and energy, as well as crack initiation and damage thresholds, decreased, indicating lower stress levels were required for crack initiation and unstable growth, and the material’s deformation resistance and strength weakened. In contrast, higher confining pressure delayed cracking and raised thresholds. Notably, the ratios of crack initiation and damage thresholds to peak stress remained within a specific range, showing these ratios are largely independent of freeze–thaw damage and confining pressure, reflecting an inherent mechanical scaling in the material’s failure process.

- (3)

- Considering the effects of temperature and stress coupling, a local damage model that can describe the post-peak residual strength of coal sandstone specimens was established, combined with the modified Weibull distribution function of the microelement strength, and the damage evolution equation and axial stress damage eigenstructure equation that can characterize the specimen drop were derived; the method of determining the parameters of the model was given, and the comparison between the theoretical and experimental results verified its accuracy. The comparison of theoretical and experimental results verified its accuracy and revealed the intrinsic nature of the freeze–thaw effect on the deformation and strength of coal sandstone from the mechanical point of view.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, Y.; Shao, Z.S.; Shi, G.B.; Dou, Y.; Wang, W.Q.; Zhang, W. Freeze-thaw effects on stability of open pit slope in high-altitude and cold regions. Geofluids 2021, 2021, 8409621. [Google Scholar] [CrossRef]

- Lu, X.; Qi, X.; Tian, Y.; Li, R.; Wang, Z.L.; Tu, L.X.; Zhang, Z.Y. Characterization of freeze-thaw cycle damage to mudstone in open pit in cold regions-based on nuclear magnetic resonance method. Appl. Sci. 2023, 13, 12264. [Google Scholar] [CrossRef]

- Liu, X.; He, T.; Yan, Y.; Meng, L.; Dong, J.; Guo, Y.; Zhou, P. Effects of axial offset and deflection on load-bearing characteristics of the permanent magnet bearing. Eng. Fail. Anal. 2023, 146, 107123. [Google Scholar] [CrossRef]

- Steiakakis, E.; Xiroudakis, G.; Lazos, I.; Vavadakis, D.; Bazdanis, G. Stability analysis of a multi-layered slope in an open pit mine. Geosciences 2023, 13, 359. [Google Scholar] [CrossRef]

- Zheng, M.; Li, S. A non-linear three-dimensional failure criterion based on stress tensor distance. Rock Mech. Rock Eng. 2022, 55, 6741–6760. [Google Scholar] [CrossRef]

- Cao, Y.; Xu, Z.J.; Tai, L.H.; Kong, Z.; Wu, P.; Li, C.; Mao, X.B. Experimental study on the mechanical properties and damage mechanism of saturated coal-measure sandstone in an open pit mine under the freeze-thaw effect. Appl. Sci. 2024, 14, 11381. [Google Scholar] [CrossRef]

- Chu, Y.P.; Zhang, D.M.; Song, S.Q.; Kai, O.Y.; Liu, F. Experimental study on the evolution of pore structure of coal samples under freeze-thaw. Phys. Fluids 2023, 35, 036602. [Google Scholar] [CrossRef]

- Liang, Y.T.; Guo, C.; Zhao, Y.M.; Tian, F.C.; Lu, Z.R. Multi-scale analysis of mudstone freeze-thaw damage mechanism. Environ. Earth Sci. 2024, 83, 298. [Google Scholar] [CrossRef]

- Ma, H.F.; Song, Y.Q.; Yang, J.K.; Zheng, J.J.; Shen, F.X.; Shao, Z.X.; Xia, Z.G. Experimental investigation on physical-mechanical behaviors and macro-micro-structural responses of lignite subjected to freeze-thaw cycles. Nat. Resour. Res. 2023, 32, 543–566. [Google Scholar] [CrossRef]

- Li, Y.X.; Wang, Z.B.; Cao, H.Q.; Wu, T.Y. Constitutive characteristics of rock damage under freeze-thaw cycles. Appl. Sci. 2024, 14, 4627. [Google Scholar] [CrossRef]

- Zhao, T.; Yang, G.; Xi, J.; Shen, Y.; Song, K. Factorial experiment study on the mechanical properties of sandstone-concrete specimens under different freeze-thaw conditions. Front. Phys. 2020, 8, 322. [Google Scholar] [CrossRef]

- Han, X.Z.; Sun, G.C.; Fu, H.L.; Tan, C.; Huang, Z.L.; Yin, P.; Zhang, Q.S.; Fan, W.C.; Yin, S.P. Experimental study on deformation and damage evolution of cracked red sandstone under freeze-thaw cycles. Appl. Sci. 2024, 14, 11174. [Google Scholar] [CrossRef]

- He, Y.; Liu, Y.; Li, J.; Fan, P.; Liu, X.; Chai, R.; Xue, L. Experimental study on the effect of CO2 dynamic sequestration on sandstone pore structure and physical properties. Fuel 2024, 375, 132622. [Google Scholar] [CrossRef]

- Huang, F.; Zhu, T.; Qu, Z.; Gao, X.; Zheng, A. The effect of joint inclination angle on mechanical properties of rock mass studied by model test and DEM simulation. Mech. Based Des. Struct. Mech. 2024, 52, 7122–7137. [Google Scholar] [CrossRef]

- Zhao, Y.; Qin, W.; Jin, A.; Wu, H.; Chen, Z. Research and analysis of the impact of the pore structure on the mechanical properties and fracture mechanism of sandstone. Mater. Today Commun. 2024, 38, 107753. [Google Scholar] [CrossRef]

- Chen, L.X.; Li, K.S.; Song, G.L.; Zhang, D.; Liu, C.X. Effect of freeze-thaw cycle on physical and mechanical properties and damage characteristics of sandstone. Sci. Rep. 2021, 11, 12315. [Google Scholar] [CrossRef]

- Deprez, M.; De Kock, T.; De Schutter, G.; Cnudde, V. A review on freeze-thaw action and weathering of rocks. Earth-Sci. Rev. 2020, 203, 103143. [Google Scholar] [CrossRef]

- Shi, S.; Zhu, F.; Hu, H. Investigation on the damage model of rock subjected to freeze-thaw cycles considering its fracture voids compaction. Cold Reg. Sci. Tech. 2024, 223, 104222. [Google Scholar] [CrossRef]

- Shu, J.; Deng, Z.; Huang, J.; Wu, B.; Zhang, X.; Ai, H. Stability deterioration analysis of toppling dangerous rock mass under the combined effect of vibration and freeze-thaw cycles. KSCE J. Civ. Eng. 2024, 28, 1729–1738. [Google Scholar] [CrossRef]

- Abdolghanizadeh, K.; Hosseini, M.; Saghafiyazdi, M. Effect of freezing temperature and number of freeze-thaw cycles on mode i and mode II fracture toughness of sandstone. Theor. Appl. Fract. Mech. 2020, 105, 102428. [Google Scholar] [CrossRef]

- Li, H.; Wu, Z.; Liu, S.; Gu, C.; Zhang, X.; Xu, P.; Zhang, L.; Meng, J.; Hao, Z. Rock fracturing mechanism and arrangement of fracturing holes using hydro-mechanical splitters. Eng. Fract. Mech. 2024, 301, 110055. [Google Scholar] [CrossRef]

- Cao, J.; Hu, J.; Wang, X.; Yang, Y.; Xia, Z.; Wang, H.; Yang, B. Numerical simulation of the meso-mechanical properties of double cruciform fissures rocks after freeze-thaw cycles. Comput. Part. Mech. 2025, 12, 1549–1564. [Google Scholar] [CrossRef]

- Gang, M.; Nonaka, S.; Utashiro, K.; Kodama, J.; Nakamura, D.; Fujii, Y.; Fukuda, D.; Wang, S. Impacts of frost heave susceptibility and temperature-changing conditions on freeze-thaw deterioration of welded tuffs. Cold Reg. Sci. Tech. 2024, 225, 104270. [Google Scholar] [CrossRef]

- Li, M.; Yu, H.; Zhang, J.Z.; Lin, G.; Zhang, L.Y.; Chen, Y.L.; Zhu, F.Q.; Mao, Y.W.; Chen, H.; Ding, Z.B.; et al. Study on dynamic mechanical response characteristics and fracture energy dissipation mechanism of sandstones with different saturations under real-time low temperature. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 77. [Google Scholar] [CrossRef]

- Cao, H.; Zhu, D.; Bao, T.; Sun, P.; Li, J.; Erneste, H. Applicability of rock damage model based on power law distribution. Acta Geophys. 2024, 72, 3021–3036. [Google Scholar] [CrossRef]

- Liang, H.; He, M.; Zhao, H.; Zhang, Y.; Lu, Q.; Hao, S.; Gong, Z.; Guan, H. A macro-meso damage coupling rock mass damage model based on improved internal crack analysis. PLoS ONE 2025, 20, e0326786. [Google Scholar] [CrossRef]

- Li, T.; Liu, F.; Shan, K.; Zhu, H.; Liao, Z. Numerical and experimental study of fracture evolution in layered sandstone and mudstone above the cavity. Environ. Earth Sci. 2024, 83, 347. [Google Scholar] [CrossRef]

- Shi, S.; Zhu, F.J.; Zhu, J.C. Investigation on damage creep constitutive model of rock under the coupled effect of freeze-thaw cycles and loading. Fatigue Fract. Eng. Mater. Struct 2024, 47, 1281–1299. [Google Scholar] [CrossRef]

- Xiao, C.; Yang, R.; Zhao, Z.; You, S.; He, S.; Zhang, Y. Blasting damage control of slit charge structure. Mech. Adv. Mater. Struct. 2024, 31, 6848–6862. [Google Scholar] [CrossRef]

- GB/T50266-2013; Standard for Test Methods of Engineering Rock Mass. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT50266-2013 (accessed on 10 September 2025).

- Jia, Z.Q.; Xie, H.P.; Zhang, R.; Li, C.B.; Wang, M.; Gao, M.Z.; Zhang, Z.P.; Zhang, Z.T. Acoustic emission characteristics and damage evolution of coal at different depths under triaxial compression. Rock Mech. Rock Eng. 2020, 53, 2063–2076. [Google Scholar] [CrossRef]

- Liang, B.; Yang, G.S.; Yu, J.J. Study on acoustic emission and damage mechanical properties of freeze-thaw sandstone under uniaxial compression. Geofluids 2022, 2022, 3961317. [Google Scholar] [CrossRef]

- Wang, C.Y.; You, R.; Lv, W.Y.; Sui, Q.R.; Yan, Y.H.; Zhu, H.J. Damage evolution and acoustic emission characteristics of sandstone under freeze-thaw cycles. ACS Omega 2024, 9, 4892–4904. [Google Scholar] [CrossRef]

- Feng, Q.; Hou, S.J.; Liu, W.W.; Zhang, S.; Li, W.S.; Tian, M.L. Study on the simulation method and mesoscopic characteristics of rock freeze-thaw damage. Comput. Geotech. 2023, 153, 105038. [Google Scholar] [CrossRef]

- Feng, Q.; Jin, J.C.; Zhang, S.; Liu, W.W.; Yang, X.X.; Li, W.T. Study on a damage model and uniaxial compression simulation method of frozen-thawed rock. Rock Mech. Rock Eng. 2022, 55, 187–211. [Google Scholar] [CrossRef]

- Li, J.L.; Zhou, K.P.; Liu, W.J.; Zhang, Y.M. Analysis of the effect of freeze-thaw cycles on the degradation of mechanical parameters and slope stability. Bull. Eng. Geol. Environ. 2018, 77, 573–580. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, X.Z.; Zhang, H.M.; Shen, Y.J. Correction method of mohr-coulomb strength criterion for rock based on freeze-thaw and residual effects. Sci. Rep. 2024, 14, 31005. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.J.; Miao, S.J.; Li, K.S.; Shang, X.F.; Li, P.L.; Cai, M.F. The fractal dimension, structure characteristics, and damage effects of multi-scale cracks on sandstone under triaxial compression. Fractal Fract. 2025, 9, 51. [Google Scholar] [CrossRef]

- Liang, M.; Miao, S.; Cai, M.; Huang, Z.; Yang, P. A damage constitutive model of rock with consideration of dilatation and post-peak shape of the stress-strain curve. Chin. J. Rock Mech. Eng. 2021, 40, 2392–2401. [Google Scholar]

- Lan, Y.W.; Gao, H.M.; Zhao, Y.L. Pore structure characteristics and strength variation of red sandstone under freeze-thaw cycles. Materials 2022, 15, 3856. [Google Scholar] [CrossRef]

- Zhou, Z.J.; Zhan, H.C.; Hu, J.Y.; Ren, C.N. Characteristics of unloading creep of tuffaceous sandstone in east tianshan tunnel under freeze-thaw cycles. Adv. Mater. Sci. Eng. 2019, 2019, 7547564. [Google Scholar] [CrossRef]

- Cai, X.; Zhou, Z.L.; Tan, L.H.; Zang, H.Z.; Song, Z.Y. Fracture behavior and damage mechanisms of sandstone subjected to wetting -drying cycles. Eng. Fract. Mech. 2020, 234, 107109. [Google Scholar] [CrossRef]

- Li, J.L.; Zhu, L.Y.; Zhou, K.P.; Chen, H.; Gao, L.; Lin, Y.; Shen, Y.J. Non-linear creep damage model of sandstone under freeze-thaw cycle. J. Cent. South Univ. 2021, 28, 954–967. [Google Scholar] [CrossRef]

- Shi, Z.M.; Li, J.T.; Wang, J.; Chen, J.C.; Lin, H.; Cao, P. Experimental and numerical study on fracture characteristics and constitutive model of sandstone under freeze-thaw-fatigue. Int. J. Fatigue 2023, 166, 107236. [Google Scholar] [CrossRef]

- Yang, X.B.; Cheng, H.M.; Hou, X.; Nie, C.G.; Lv, J.Q. Research on characteristic stress and constitutive equation of confined sandstone during damage evolution based on energy evolution analysis. Adv. Mater. Sci. Eng. 2019, 2019, 4145981. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, X.; Guo, Q.F.; Zhang, Z.H.; Cai, M.F.; Tian, L.M. Research on the mechanical properties and damage constitutive model of multi-shape fractured sandstone under hydro-mechanical coupling. Minerals 2022, 12, 436. [Google Scholar] [CrossRef]

| Samples | Natural Density (kg/m3) | Dry Density (kg/m3) | Porosity (%) | Natural Water Content (%) | Saturated Water Content (%) |

|---|---|---|---|---|---|

| Coal sandstone | 2437.0 | 2417.1 | 11.14 | 0.897 | 3.161 |

| N | (MPa) | (MPa) | (MPa) | (MPa) | ||

|---|---|---|---|---|---|---|

| 0 | 0.5 | 12.16 | 22.34 | 25.56 | 47.562% | 87.416% |

| 0 | 1.5 | 15.11 | 30.89 | 32.06 | 47.132% | 96.338% |

| 0 | 2.5 | 22.62 | 45.85 | 46.46 | 48.685% | 98.672% |

| 5 | 0.5 | 8.61 | 18.09 | 18.28 | 47.073% | 98.933% |

| 5 | 1.5 | 13.50 | 29.33 | 30.07 | 44.895% | 97.522% |

| 5 | 2.5 | 14.19 | 36.46 | 45.19 | 31.401% | 80.683% |

| 10 | 0.5 | 5.91 | 17.81 | 18.22 | 32.409% | 97.722% |

| 10 | 1.5 | 10.69 | 28.28 | 29.16 | 36.660% | 96.982% |

| 10 | 2.5 | 14.23 | 36.28 | 36.81 | 38.644% | 98.547% |

| 15 | 0.5 | 5.38 | 15.55 | 15.95 | 33.730% | 97.492% |

| 15 | 1.5 | 8.75 | 23.23 | 27.98 | 31.272% | 83.024% |

| 15 | 2.5 | 9.50 | 23.87 | 28.02 | 33.887% | 85.189% |

| 20 | 0.5 | 4.89 | 15.64 | 15.77 | 30.977% | 99.144% |

| 20 | 1.5 | 6.14 | 18.83 | 18.95 | 32.401% | 99.367% |

| 20 | 2.5 | 8.10 | 18.99 | 21.28 | 38.040% | 89.262% |

| Formulas | Variant | A1 | A2 | A3 | A4 | A5 | A6 |

|---|---|---|---|---|---|---|---|

| (7) | (N,) | 1.30 × 10−3 | −3.77 × 10−2 | −2.41 × 10−2 | −5.25 × 10−2 | 0.937 | 1.079 |

| N | (MPa) | Damage Modeling Parameters | Goodness-of-Fit R2 | ||

|---|---|---|---|---|---|

| 5 | 0.5 | 29.42 | 5.10 | 2.72 | 0.98 |

| 1.5 | 35.98 | 5.28 | 10.65 | 0.98 | |

| 2.0 | 46.10 | 19.20 | 1.00 | 0.99 | |

| 20 | 0.5 | 19.88 | 4.41 | 3.96 | 0.97 |

| 1.5 | 22.35 | 7.15 | 4.21 | 0.97 | |

| 2.0 | 30.53 | 18.09 | 0.23 | 0.98 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Zhu, F.; Kong, Z.; Chen, L.; Fan, F.; Wu, B.; Deng, J.; Guo, S. Study on Damage and Fracture Mechanism and Ontological Relationship of Rock Body in Deep Open Pit in Cold Area. Appl. Sci. 2025, 15, 10021. https://doi.org/10.3390/app151810021

Li M, Zhu F, Kong Z, Chen L, Fan F, Wu B, Deng J, Guo S. Study on Damage and Fracture Mechanism and Ontological Relationship of Rock Body in Deep Open Pit in Cold Area. Applied Sciences. 2025; 15(18):10021. https://doi.org/10.3390/app151810021

Chicago/Turabian StyleLi, Ming, Fuqiang Zhu, Zheng Kong, Liang Chen, Fangwei Fan, Boyuan Wu, Jishuo Deng, and Shuai Guo. 2025. "Study on Damage and Fracture Mechanism and Ontological Relationship of Rock Body in Deep Open Pit in Cold Area" Applied Sciences 15, no. 18: 10021. https://doi.org/10.3390/app151810021

APA StyleLi, M., Zhu, F., Kong, Z., Chen, L., Fan, F., Wu, B., Deng, J., & Guo, S. (2025). Study on Damage and Fracture Mechanism and Ontological Relationship of Rock Body in Deep Open Pit in Cold Area. Applied Sciences, 15(18), 10021. https://doi.org/10.3390/app151810021