5.1. Freeze–Thaw Rock Mass Hoek–Brown Strength Criterion

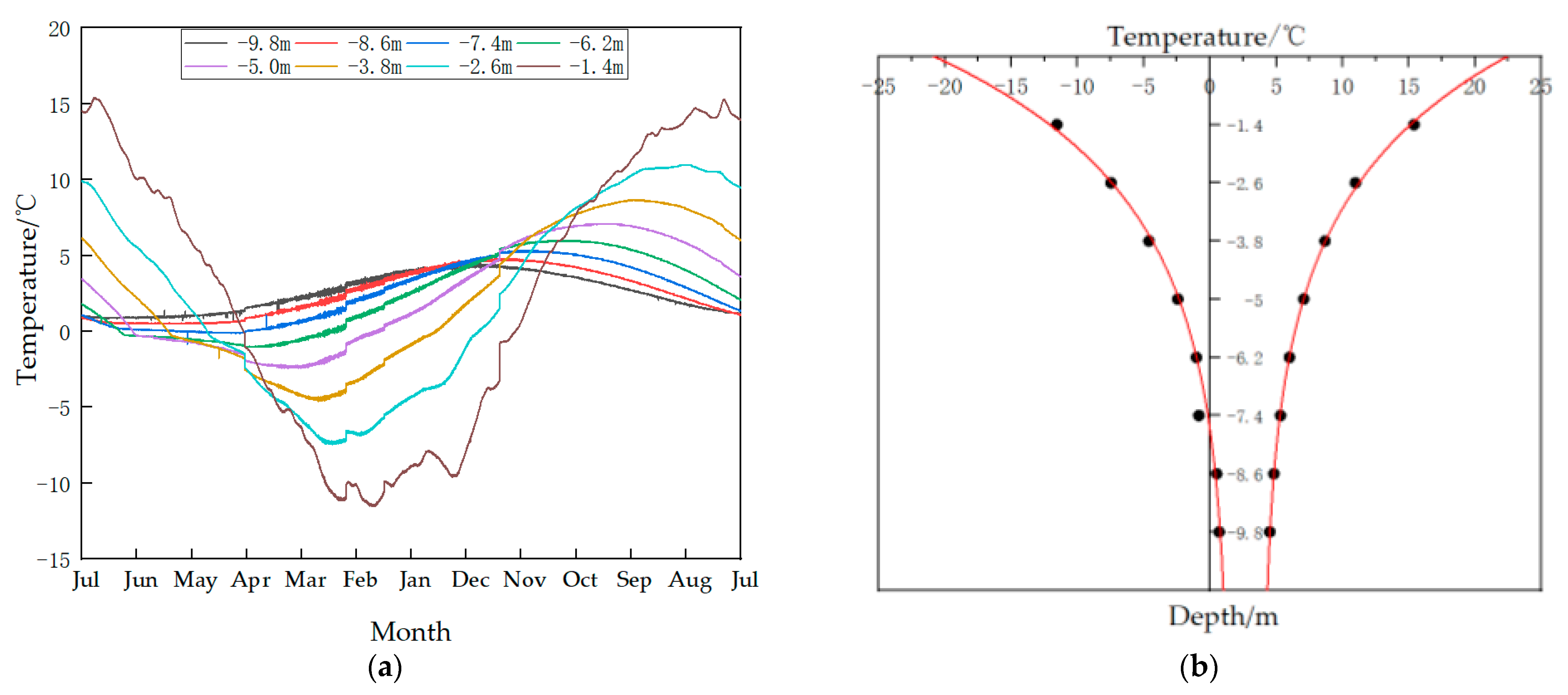

The fundamental assessment of rock mass quality serves as the starting point of the evaluation system. It quantifies the intrinsic stability of the rock mass before it is affected by external disturbances such as freeze–thaw cycles or excavation, by evaluating its natural mechanical properties and structural characteristics. This study adopts conventional rock mass classification systems—such as GSI, RMR, and the Q-system—as key references and applies adaptive modifications based on the characteristics of cold-region slopes.

Although RMR includes indices such as rock strength and , its weighting system is fixed (e.g., accounts for 20%), which limits its flexibility in reflecting dynamic changes caused by freeze–thaw effects. For example, freeze–thaw damage may drastically reduce RQD (due to core fragmentation), but cannot distinguish whether such changes are inherent or induced by freeze–thaw processes. The Q-system, on the other hand, is more tailored for tunnel support design and includes parameters such as the number of joint sets, which may be less applicable to open-pit slopes. Moreover, the Q-system does not explicitly account for temperature field effects, making it difficult to extend directly to cold-region scenarios.

The Geological Strength Index (), proposed by Hoek and Brown, was designed to quantify the overall strength of rock masses based on their structure and discontinuity characteristics. Its key advantage lies in simplifying complex rock mechanical behavior into a quantifiable rating system, applicable across a wide spectrum of rock mass conditions—from intact to heavily fractured. effectively compensates for the limitations of traditional parameters like uniaxial compressive strength when describing the macroscopic mechanical behavior of fractured rock masses, especially those dominated by joints and fissures.

In cold-region slope engineering, rock mass stability depends not only on the intrinsic strength of the rock, but also on dynamic factors such as freeze–thaw cycling, crack propagation, and moisture migration. First, is directly related to structural integrity; for example, volumetric joint count () reflects how fracture density and distribution weaken rock strength. Second, GSI can be dynamically adjusted based on field survey results, such as joint parameters updated in real time via 3D laser scanning or UAV photogrammetry, thus accommodating structural changes caused by freeze–thaw cycles. Finally, GSI is a core parameter in the Hoek–Brown strength criterion, which facilitates mechanical parameter estimation and provides input for numerical simulation and slope stability analysis.

By capturing strong correlations between structural features and mechanical behavior, overcomes the limitations of RMR and the Q-system, while its dynamic scoring system allows flexible incorporation of correction factors such as freeze–thaw, burial depth, etc., making it possible to quantify the cumulative damage effects caused by repeated freeze–thaw cycles.

Based on the findings of previous sections, this chapter proposes a Freeze–Thaw Rock Mass Hoek–Brown Strength Criterion, which incorporates the influence of freeze–thaw effects. This criterion uses as the foundational metric and introduces two correction coefficients: the fracture degradation coefficient () and the infill degradation coefficient (). These are used to obtain a modified GSI that reflects strength deterioration under freeze–thaw conditions. This modified is then combined with the generalized Hoek–Brown strength criterion to calculate rock mass mechanical parameters under different numbers of freeze–thaw cycles, providing a scientific basis for slope design and maintenance in cold regions.

The score ranges from 0 to 100, based on rock mass structure (e.g., block size, fracture development) and joint surface characteristics (e.g., roughness, weathering degree). Its calculation is expressed in Equation (2). The structural rating is determined by the volumetric joint count Jv (joints/m3); the surface condition rating is derived from a combined evaluation of roughness, weathering, and infilling conditions. In this model, is introduced to represent freeze–thaw-induced degradation of through-going fractures, while quantifies the deterioration of infill material under freeze–thaw conditions. Both correction coefficients are normalized into the [0, 1] range to ensure compatibility with the original (0–100) scale. For fractured or infilled rock masses affected by freeze–thaw, the weathering index and the infill condition are multiplied by their respective correction factors (, ) to yield modified scoring inputs

Equations (2)–(5) were proposed in this study to extend the application of the rock mass degradation model to engineering quality indices. The establishment of these equations is based on the experimental results presented earlier and is integrated within the general framework of rock mass classification. It should be emphasized that these equations represent the original contribution of this work. Among them, the GSI [

22] follows the conventional definitions and applications in rock mechanics. By combining such well-established indices with the degradation correction coefficients proposed in this study, the deterioration characteristics of rock mass under freeze–thaw conditions can be evaluated in a more consistent manner.

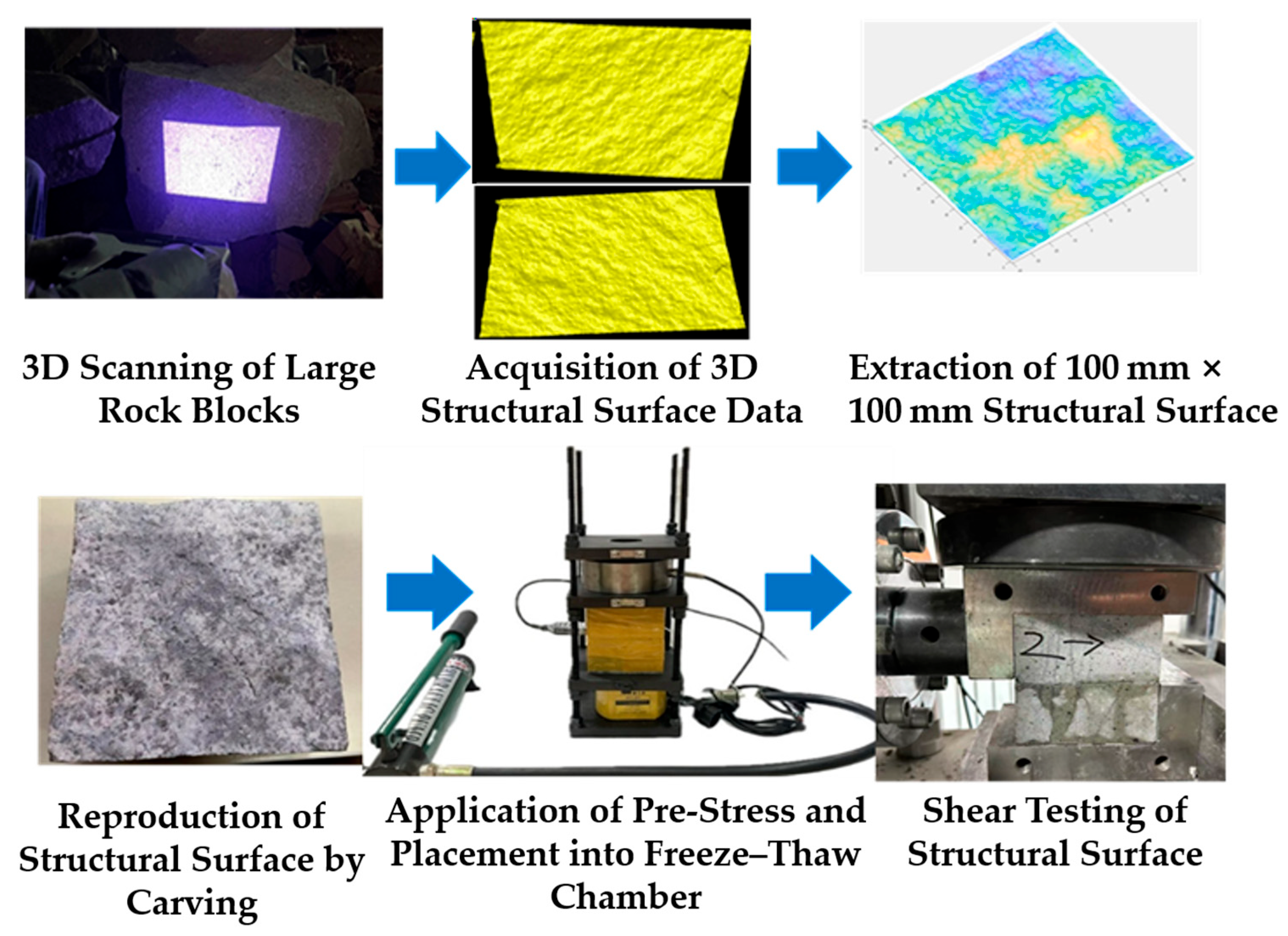

5.1.1. Correction of the Rock Mass Fracture Coefficient

The north slope of the Wushan open-pit mine has developed multiple sets of through-going fractures due to natural geological processes and external disturbances such as blasting and freeze–thaw cycling. These fractures, typically ranging from 3 m to 5 m in trace length, have resulted in a 40% reduction in the safety factor of the shallow rock mass. Through-going fractures are continuous cracks that penetrate entire rock layers or structural planes, significantly weakening the rock mass integrity and its shear strength. Their influence is primarily manifested through stress concentration at the fracture tips, which accelerates crack propagation; increased permeability that allows moisture infiltration and intensifies freeze–thaw damage; and structural instability, as the rock mass tends to fail along these weakened planes.

To quantify the weakening effect of such fractures on shear strength, this study introduces a fracture degradation coefficient,

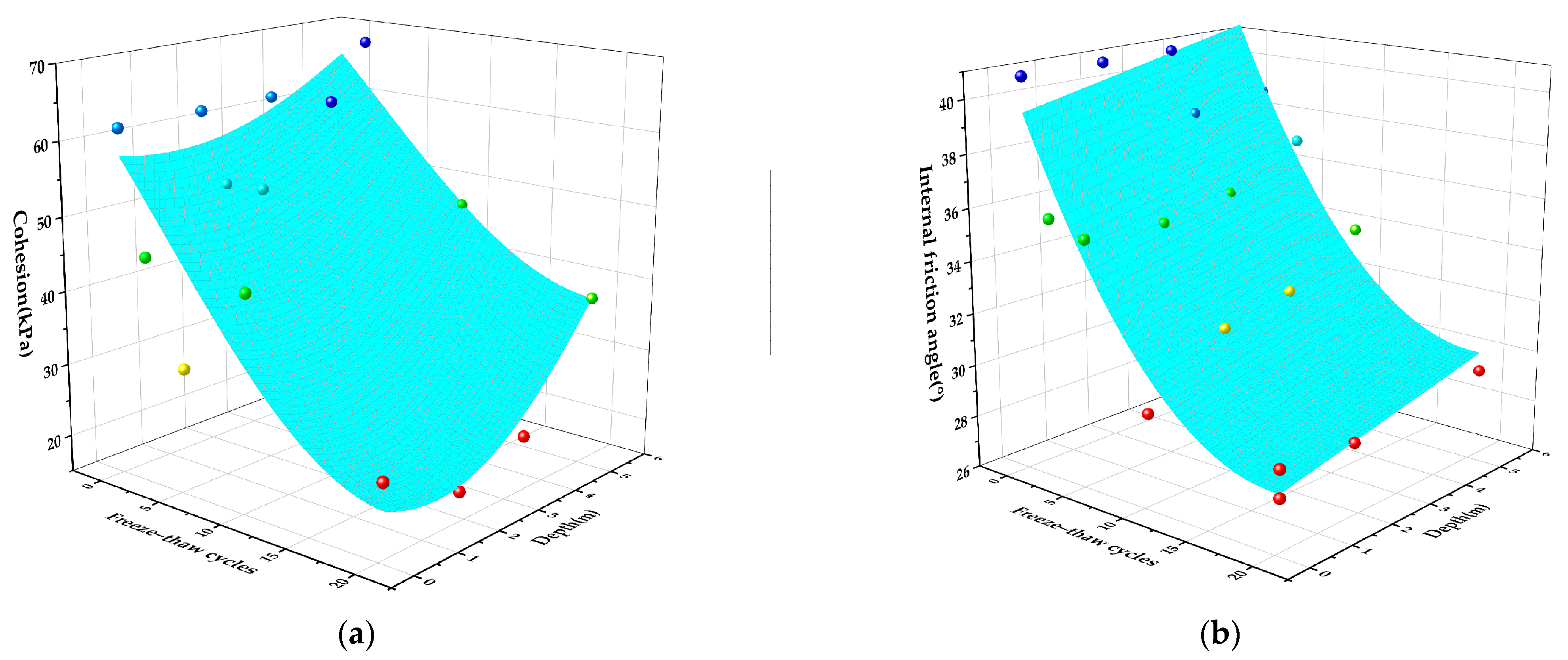

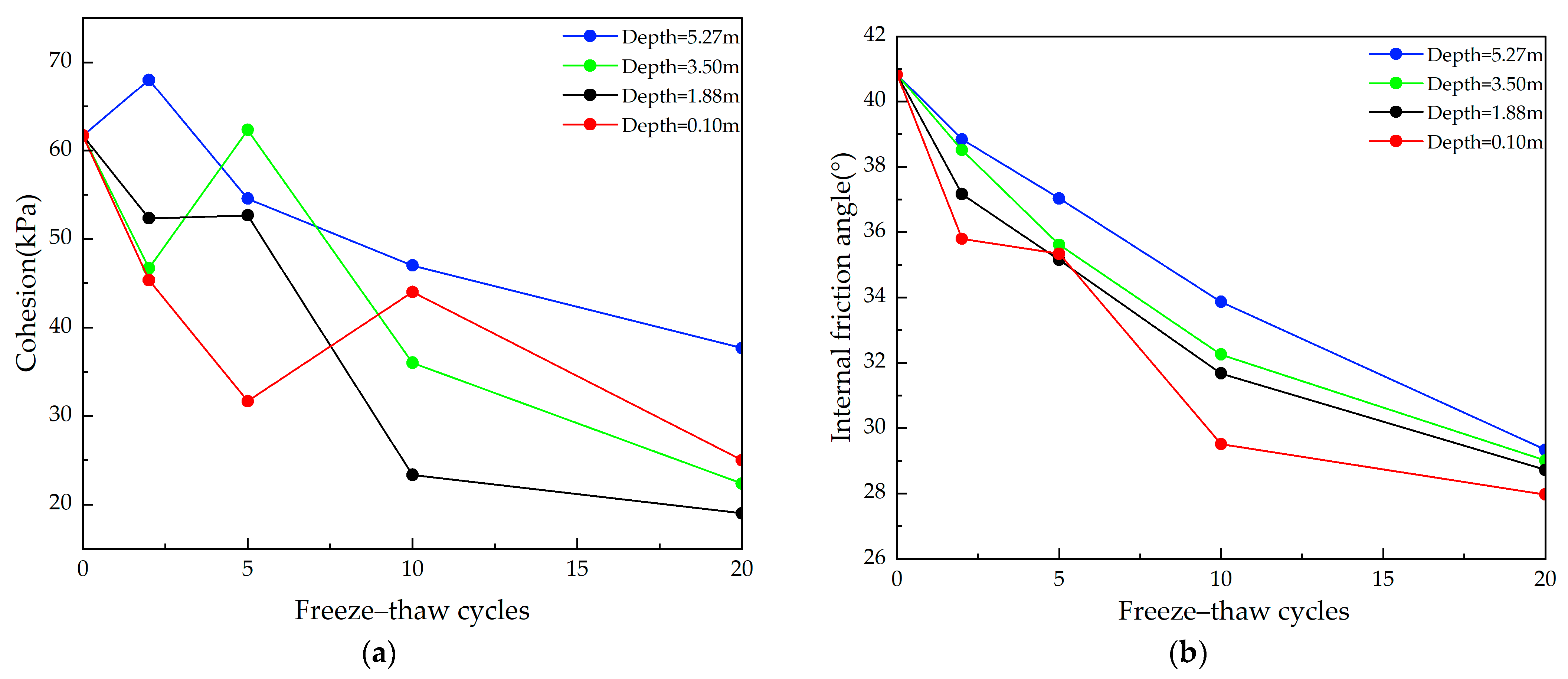

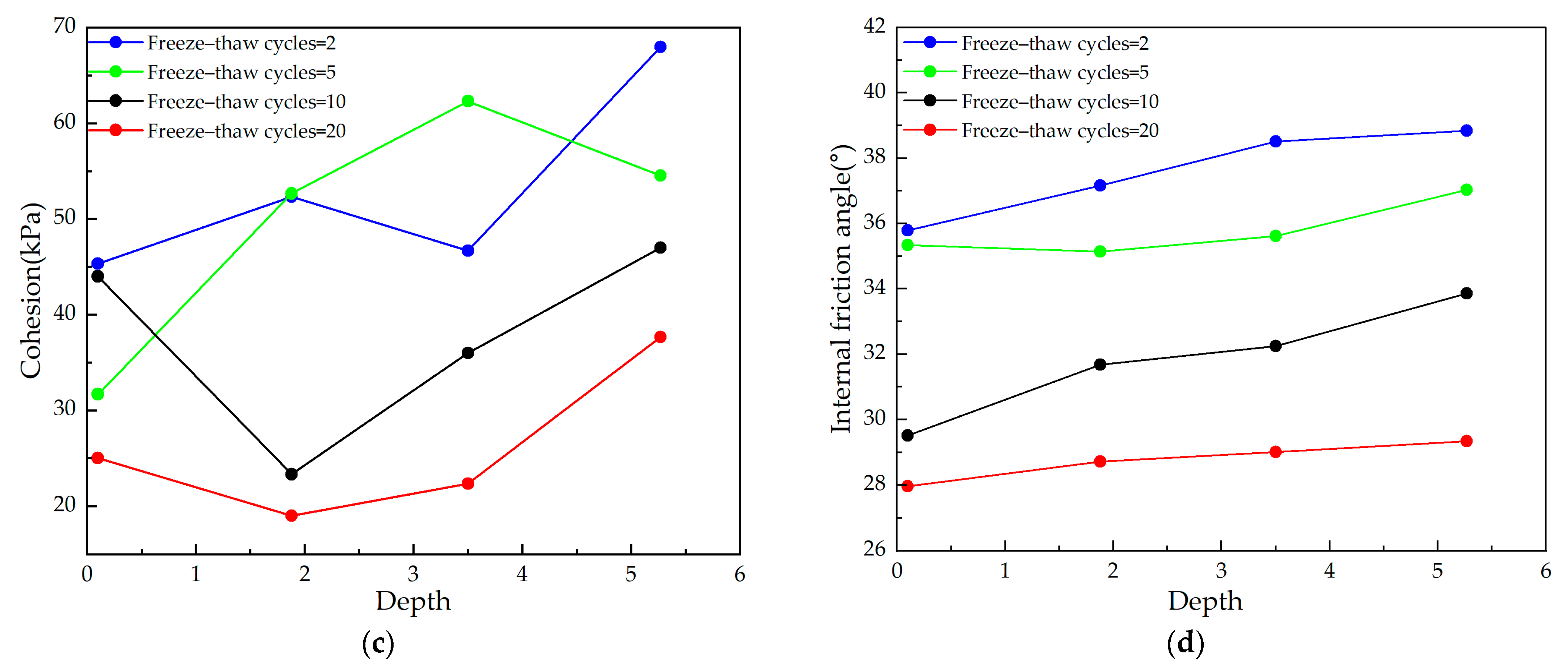

, which reflects the extent to which through-going fractures reduce the mechanical strength of the rock mass. Based on the shear test results for through-going structural planes presented in

Section 4 (

Figure 5), the shear strength of fractured rock masses was observed to decline by approximately 10–30%. Accordingly,

is defined as the ratio of the mechanical parameter of the fractured rock mass to that of the intact rock mass:

In this equation, and represent the cohesion and internal friction angle of the fractured rock mass, while and denote the initial cohesion and internal friction angle of the intact rock mass. The coefficients and are the weighting factors assigned to cohesion and internal friction angle, respectively, satisfying the condition . Their values are determined through iterative computation.

5.1.2. Correction of the Infill Degradation Coefficient

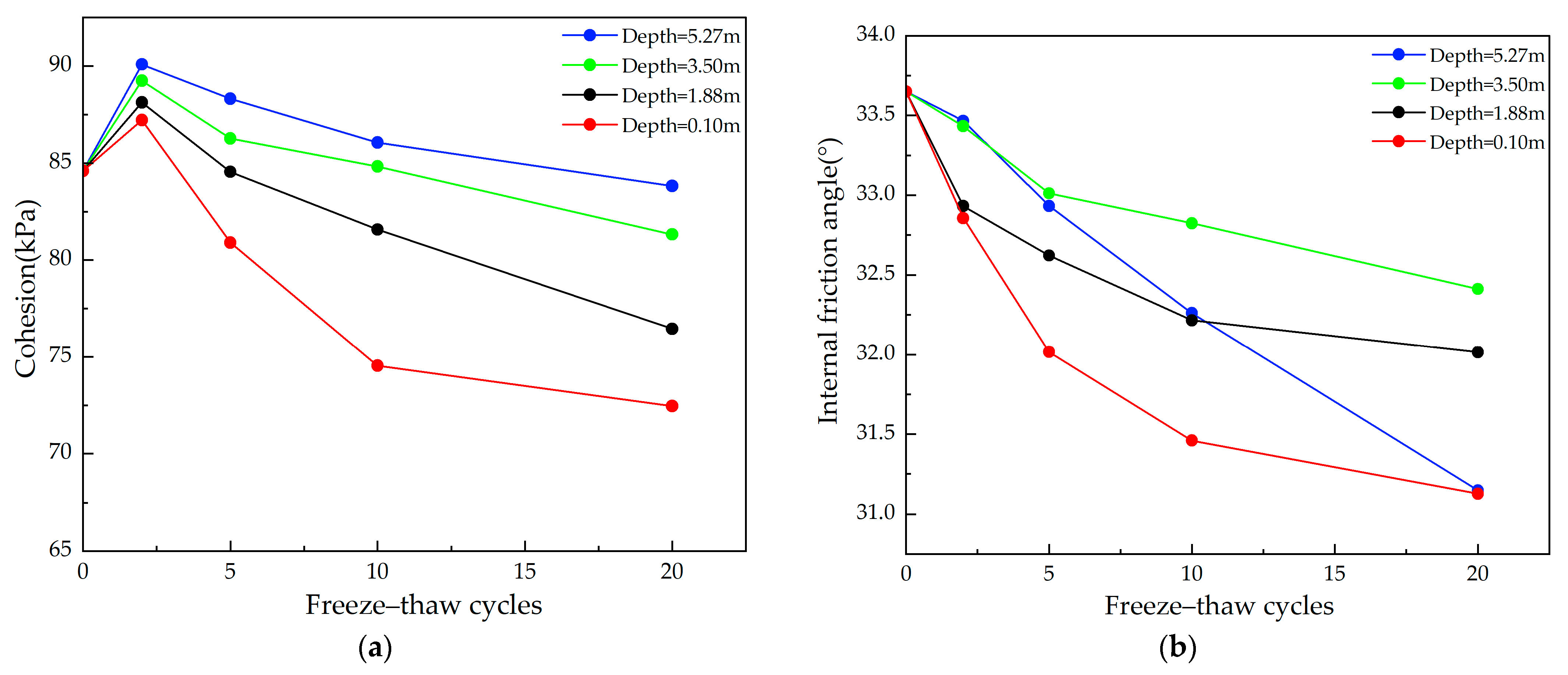

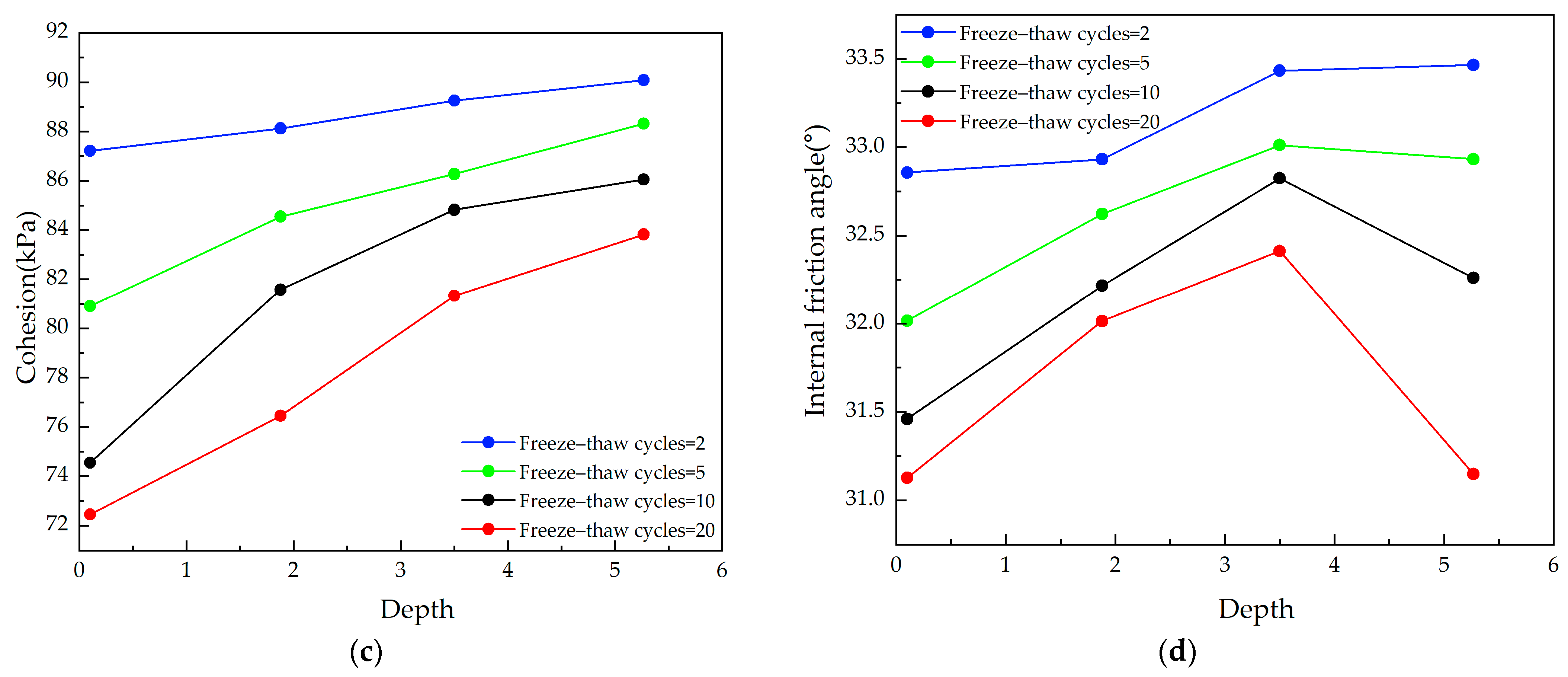

Weak interlayers (e.g., fault gouge) represent zones of reduced strength within a rock mass. Their impacts include strength softening—where the cohesion within the interlayer can be as low as 60% of that in intact rock; creep deformation—manifested as time-dependent strain under long-term loading, which may induce progressive failure; and increased permeability—since the interlayer facilitates moisture migration, exacerbating damage from freeze–thaw cycling.

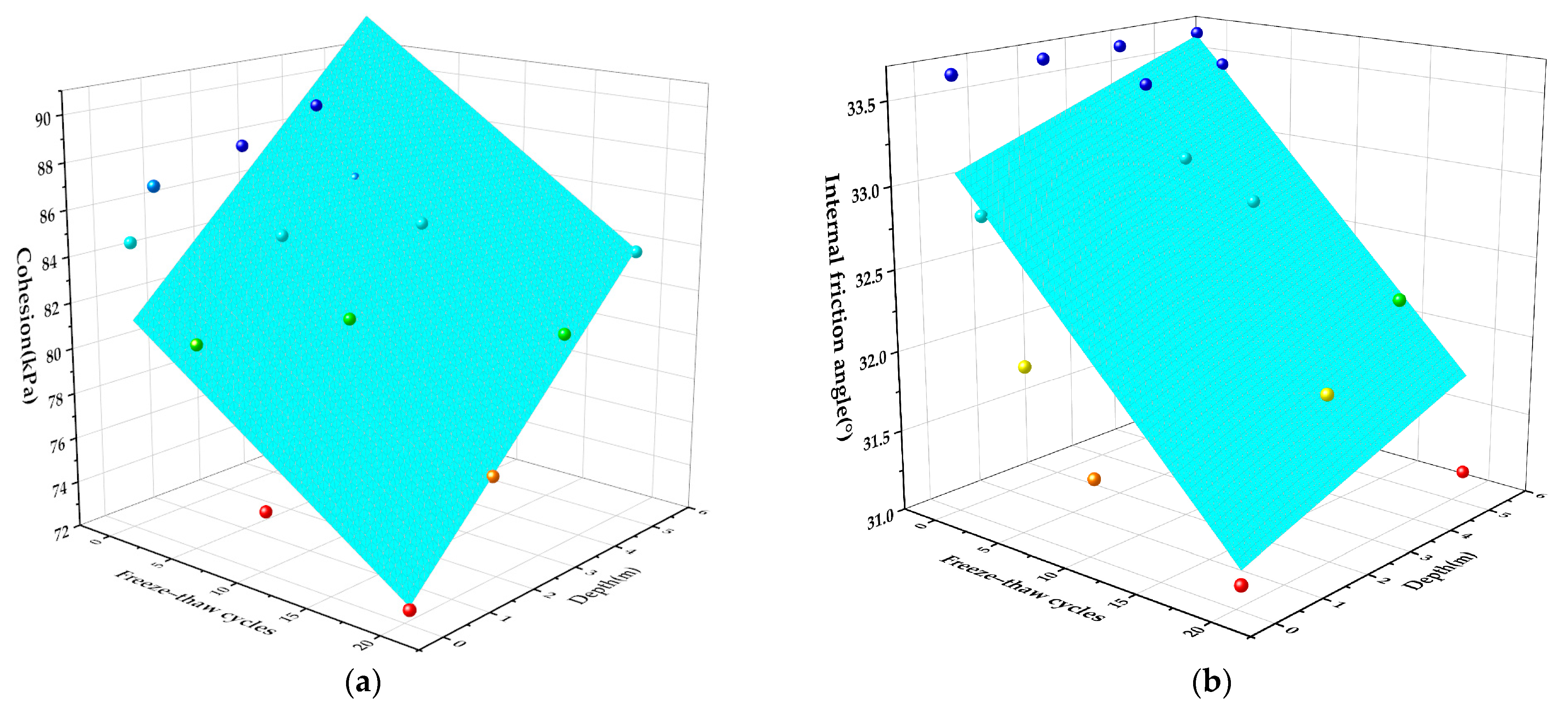

To quantify the weakening effect of such infilled features, the infill degradation coefficient

is introduced. This coefficient reflects the influence of materials such as fault gouge on the mechanical quality of the rock mass. A thicker weak interlayer corresponds to a lower value of

. Based on shear tests on structural planes containing fault gouge (

Section 4,

Figure 6), it was observed that a 10 mm thick layer of fault gouge can reduce cohesion by approximately 30%. Accordingly, the expression for

is provided in Equation (5):

In this equation, and represent the cohesion and internal friction angle of the rock mass containing infill materials, while and denote the initial cohesion and internal friction angle of the fractured (non-infilled) rock mass. The coefficients and n are the weighting factors corresponding to cohesion and internal friction angle, respectively, and satisfy the constraint . Their values are determined through iterative computation.

5.2. Application of Freeze–Thaw Rock Mass Hoek–Brown Strength Criterion

5.2.1. Example of Application of Freeze–Thaw Rock Mass Hoek–Brown Strength Criterion

Due to the presence of multiple faulted and fractured zones and the long-term influence of freeze–thaw cycling, the shallow rock mass on the north slope of the Wushan open-pit mine has experienced significant degradation, posing a potential sliding risk. By applying the proposed strength criterion, high-risk zones can be accurately identified, and targeted mitigation measures can be developed. This section uses the north slope of the Wushan open-pit mine as a case study to verify the practicality and accuracy of the Freeze–Thaw Rock Mass Hoek–Brown Strength Criterion.

Based on the engineering characteristics of the north slope and the design of correction coefficients in the proposed criterion, the application process is as follows:

- (1)

First, the weathering degree and infill condition of the fractured rock mass and infilled rock mass under freeze–thaw conditions are modified by multiplying them with the correction coefficients and , respectively. This adjustment yields a revised structural surface rating (), which is then used to obtain a modified .

- (2)

Next, the modified

values, combined with the rock material constant

obtained from

Section 3, are substituted into the generalized Hoek–Brown strength criterion to calculate the mechanical parameters (

) of rock masses at different depths and under different numbers of freeze–thaw cycles.

- (3)

Finally, the calculated values of c and φ are compared with those obtained from laboratory tests (

Appendix A), and the error between the two is used to assess the accuracy of the proposed method.

For the correction coefficients and , the weighting coefficients of cohesion and internal friction angle (a, b, m, and n) were determined by iterative calculation within the range (0, 0.1, …, 1). The optimal values were identified as those minimizing the total error between the corrected and measured mechanical parameters (), and these values were taken as the contribution coefficients. The final results of the iteration yielded a = b = 0.5 and m = 0.4, n = 0.6.

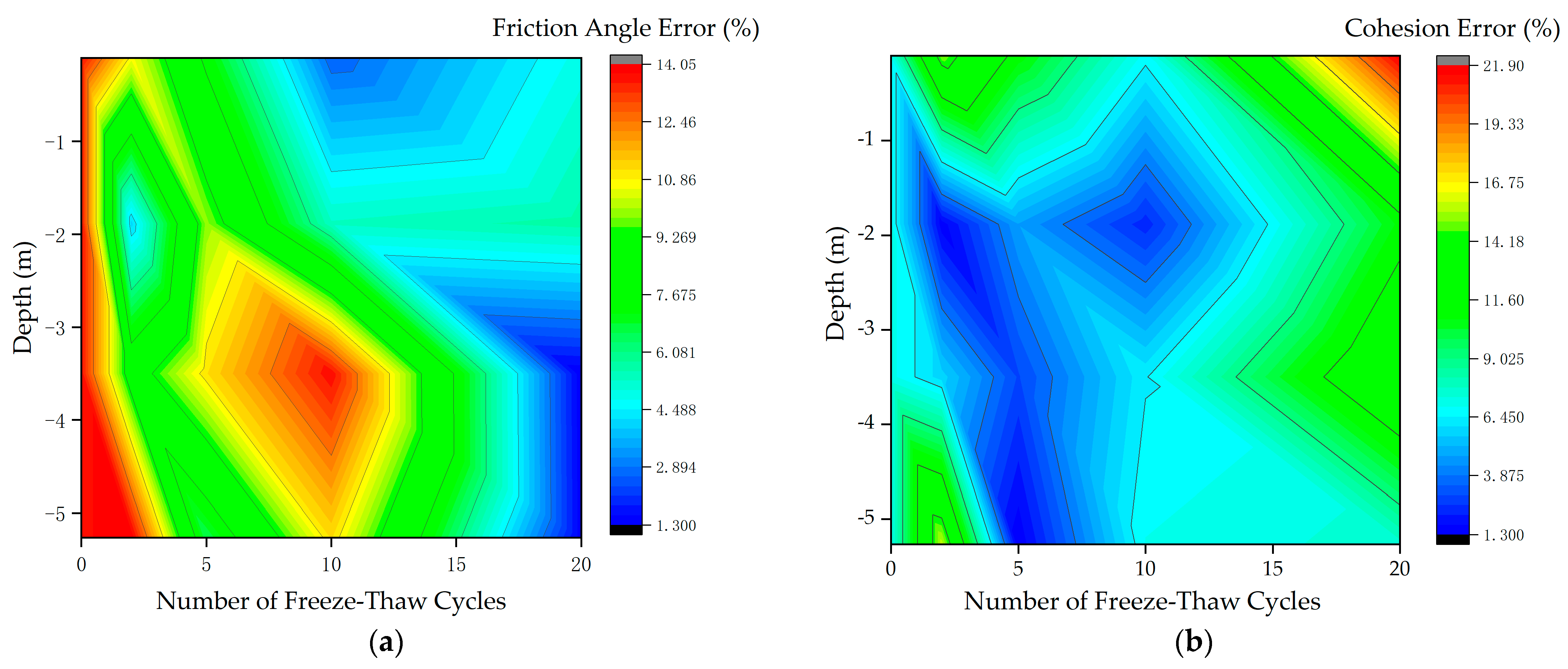

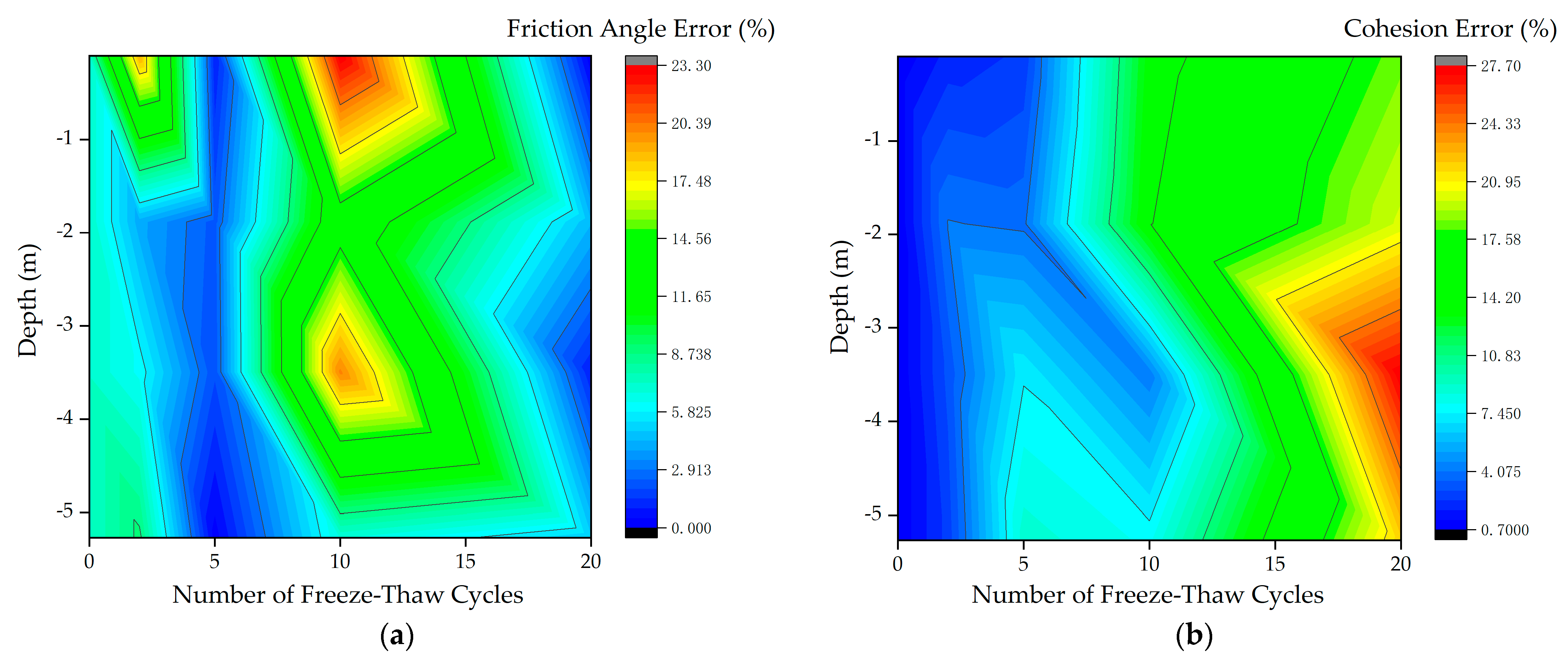

The freeze–thaw corrected mechanical parameters and associated error analysis for fractured rock masses are presented in

Table 7, and those for infilled rock masses are shown in

Table 8. The corresponding error distribution cloud maps are illustrated in

Figure 7 and

Figure 8.

It was found that the mean correction errors for the internal friction angle and cohesion of fractured rock masses were 7.78% and 8.33%, respectively, while for infilled rock masses the values were 7.36% and 9.59%, respectively. These results indicate that the Freeze–Thaw Rock Mass Hoek–Brown Strength Criterion provides reliable predictions with high accuracy.

5.2.2. Engineering Implications

To enhance the practical applicability of the research outcomes, this study proposed a Freeze–thaw Rock Mass Hoek–Brown Strength Criterion incorporating correction coefficients and with calibrated weights. This criterion enables quantitative evaluation of the degradation of rock mass mechanical parameters under in situ freeze–thaw conditions, thus providing a more scientific basis for engineering design in cold regions. The potential applications include:

- (1)

In slope stability analysis, the method allows for more accurate estimation of the long-term reduction in cohesion and internal friction angle due to freeze–thaw effects, thereby improving the reliability of stability assessments.

- (2)

In underground excavation projects, the framework can be applied to evaluate the reliability of filling materials, assisting in the selection of suitable reinforcement measures.

- (3)

It should be noted that the correction coefficients obtained in this study were calibrated for granite and a specific filling material, and further validation is required for other lithologies or different engineering environments.