Finite Element Modeling and Analysis for Creep Buckling of a Cylindrical Shell Subjected External Lateral Pressure with Local Wall Thinning

Abstract

1. Introduction

2. The Cylindrical Shell Structure and Finite Element Modeling

2.1. Geometry Description of the Cylindrical Shell Structure with Imperfections

2.2. Material Properties

2.3. Loading and Boundary Conditions

2.4. Finite Element Modeling

3. Results and Discussions

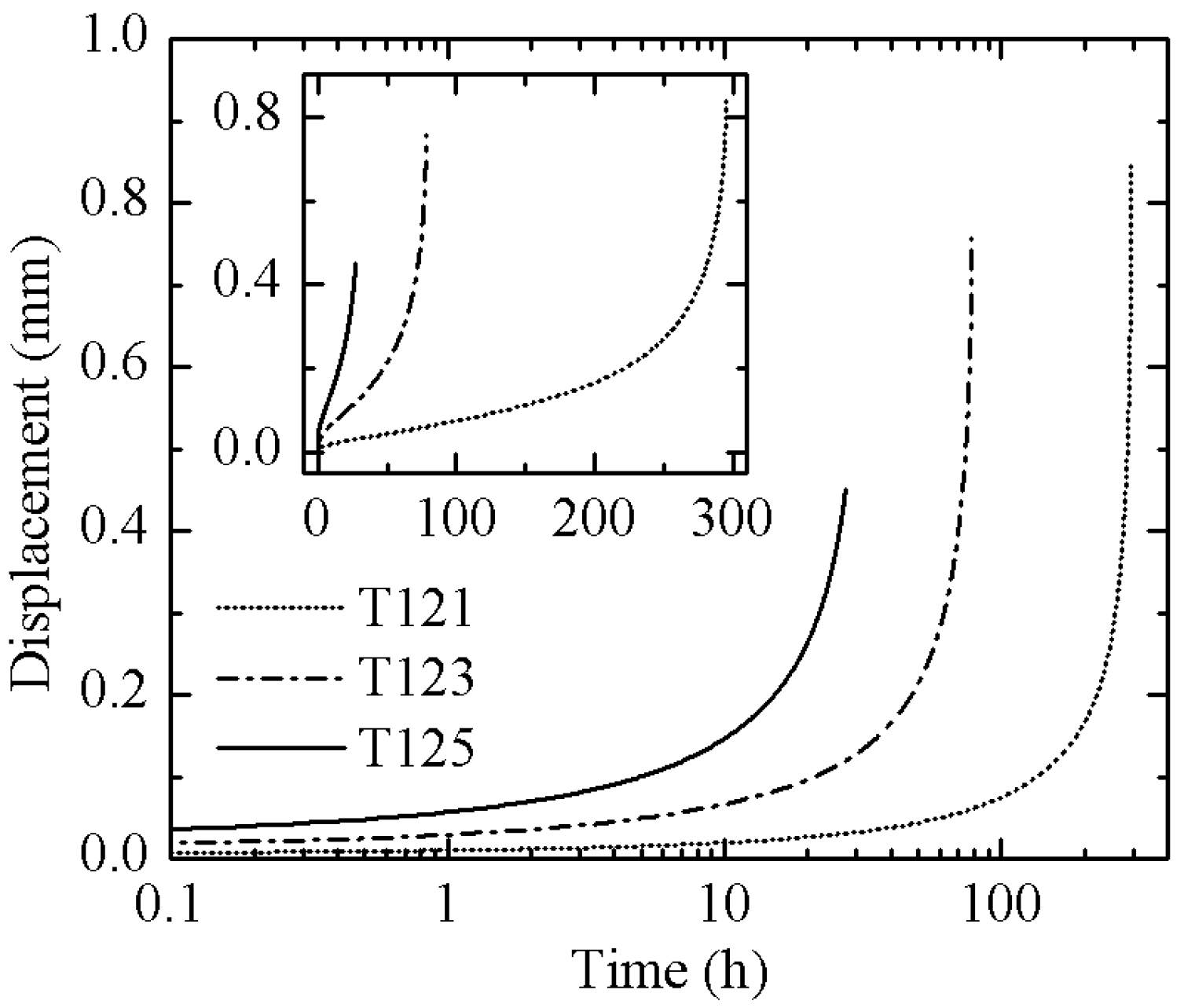

3.1. Creep Buckling of the Cylindrical Shell with Initial Ovality

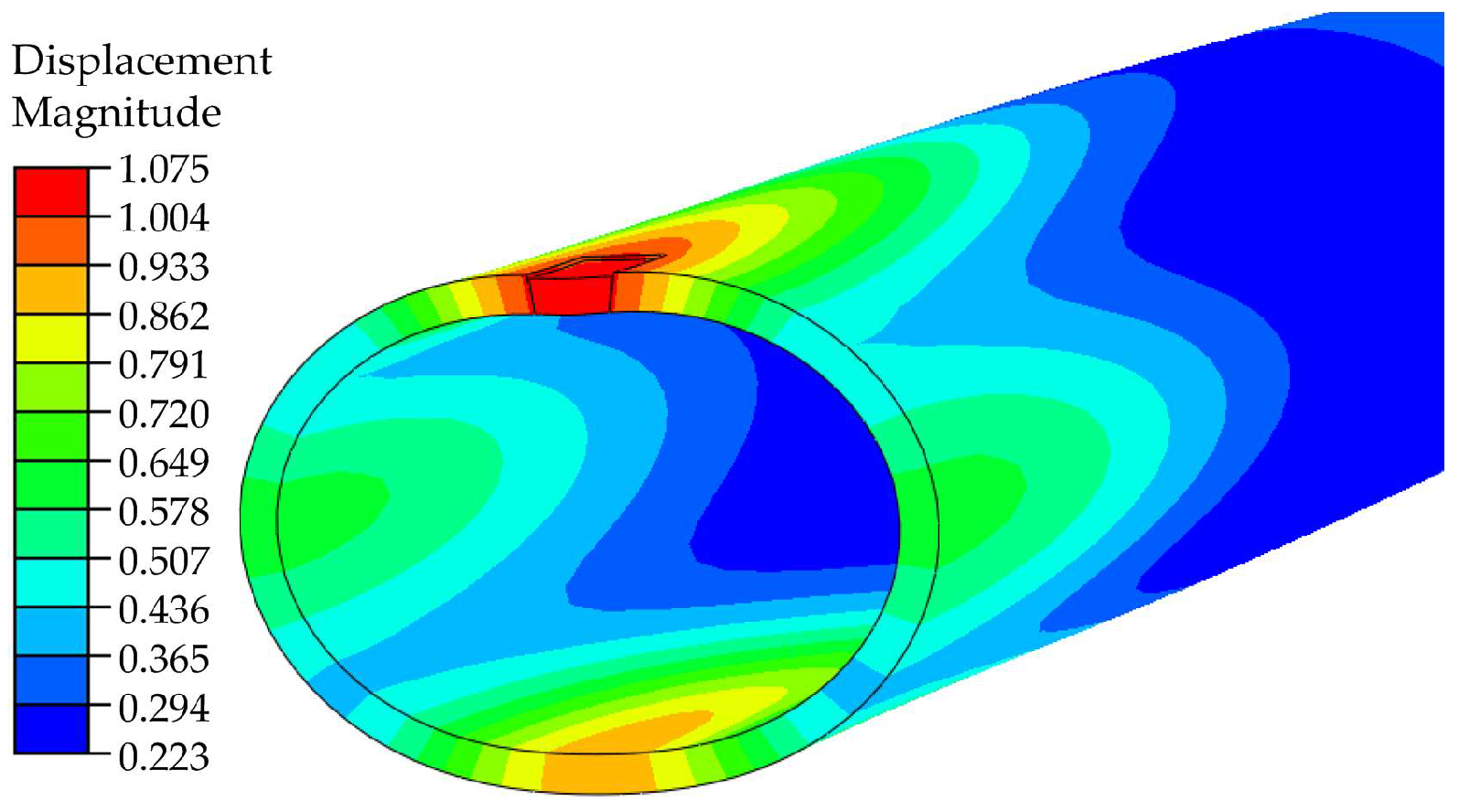

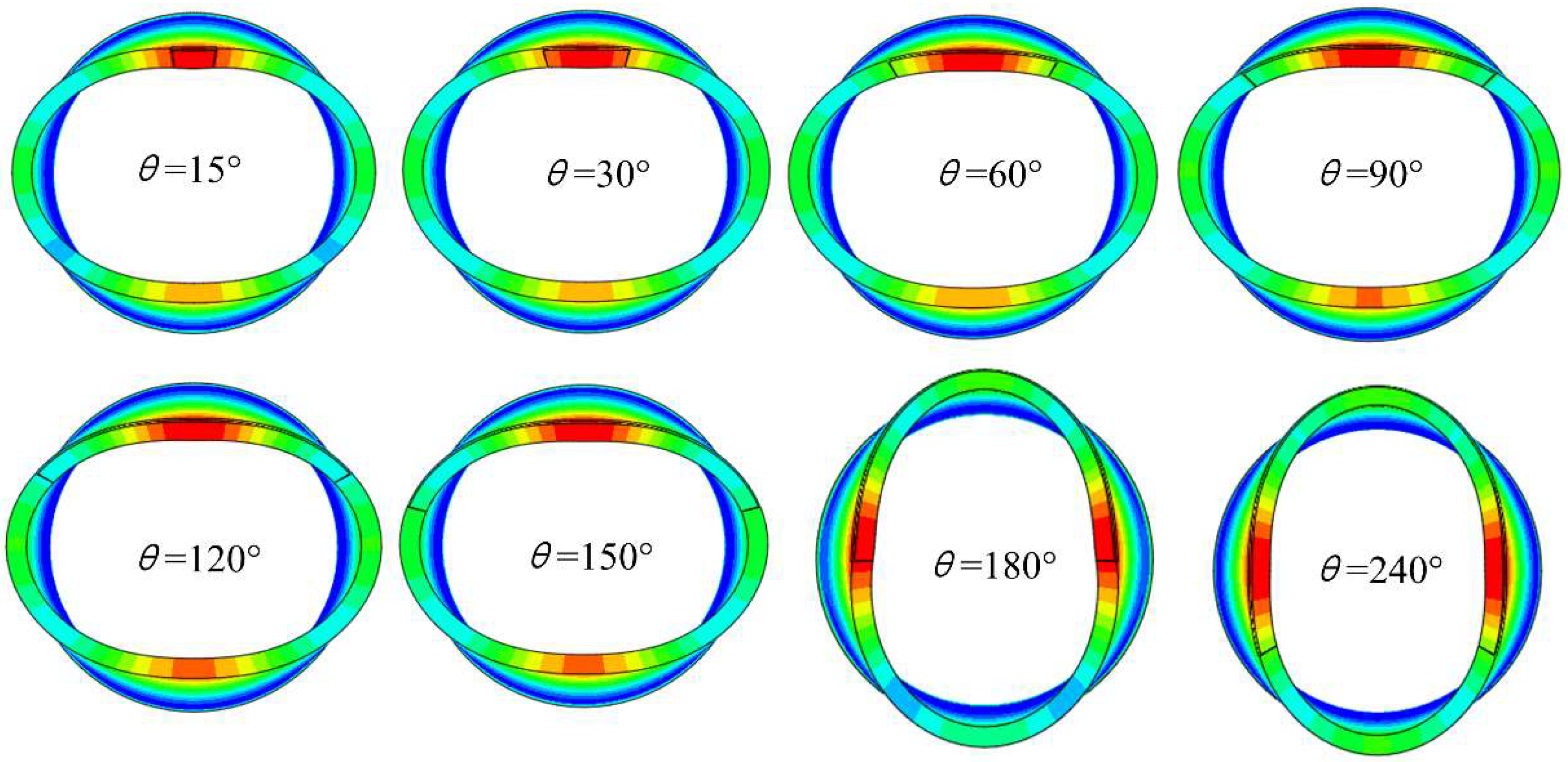

3.2. Creep Buckling of Cylindrical Shell with Local Thinning Defects

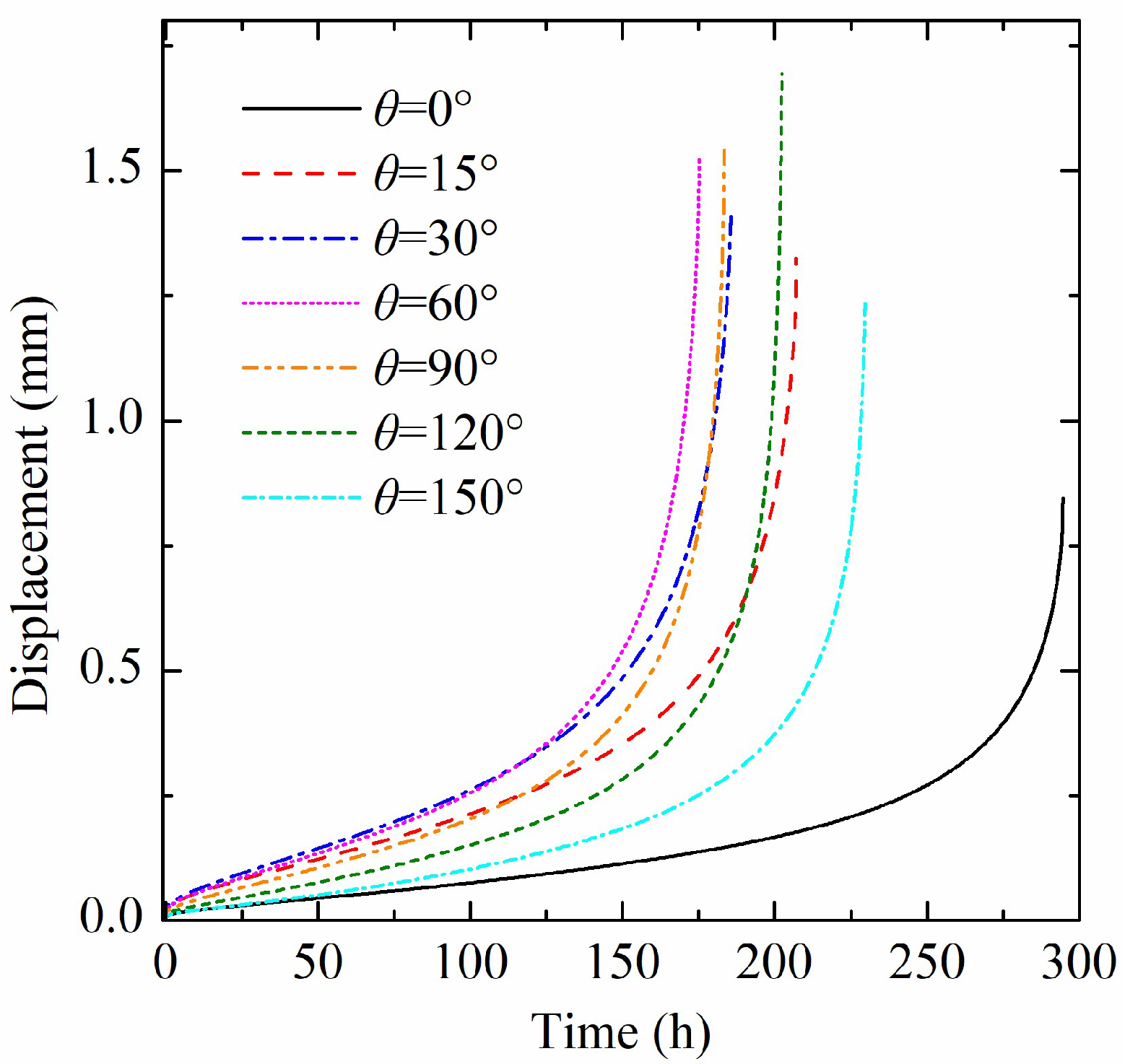

3.3. Creep Buckling of Cylindrical Shell with Initial Ovalities and Local Thinning Defects

4. Conclusions

- (1)

- The buckling modes for the considered model are dominated by the ovality deformation in a large range of defect width, whether the global initial ovality imperfection appears or not. For the case without initial ovality, the minor and major axes of the ovality configuration in buckling modes will switch with increasing the defect width, and a pear-mode also appears if the defect thickness is considerably large.

- (2)

- In comparison to the defect width, the critical buckling time is more sensitive to the defect thickness and decreases significantly with the defect thickness. If the global imperfection occurs, the local thinning defects can reduce the critical buckling time more severely, and a 30% reduction was observed even with a small local defect, which could be a common situation in engineering practice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, C.; Xiong, Y.; Liu, Y.; Xue, J.; Xu, P. Creep buckling of long-term-serving super-heating pipes in boilers subjected to high temperature loading. Int. J. Press. Vessel. Pip. 2022, 200, 104822. [Google Scholar] [CrossRef]

- Aybar, H.S.; Ortego, P. A review of nuclear fuel performance codes. Prog. Nucl. Energy 2005, 46, 127–141. [Google Scholar] [CrossRef]

- Jo, B.; Okamoto, K.; Kasahara, N. Creep buckling of 304 stainless-steel tubes subjected to external pressure for nuclear power plant applications. Metals 2019, 9, 536. [Google Scholar] [CrossRef]

- IAEA. Quality and Reliability Aspects in Nuclear Power Reactor Fuel Engineering; International Atomic Energy Agency: Vienna, Austria, 2024. [Google Scholar]

- Zhang, M.; Luo, Y.; Lu, Y.; Zhu, Y.; Liu, X.; Li, J.; Miao, X. On the creep collapse of the cladding considering the irradiation growth effect. In Proceedings of the 2023 Water Reactor Fuel Performance Meeting, Singapore, 17–21 July 2024; pp. 16–19. [Google Scholar]

- Musa, A.E.S.; Al-Ainieh, M.M.K.; Al-Osta, M.A. Buckling of circular cylindrical shells under external pressures—A critical review. J. Constr. Steel Res. 2025, 228, 109439. [Google Scholar] [CrossRef]

- Cancemi, S.A.; Lo Frano, R. Preliminary analysis of long-term performance of a piping: Aging and creep effects. Materials 2021, 14, 1703. [Google Scholar] [CrossRef] [PubMed]

- Jawad, M.; Griffin, D. Design limits for buckling in the creep range. J. Press. Vessel. Technol. 2012, 134, 065001. [Google Scholar] [CrossRef]

- Miyazaki, N.; Hagihara, S. Creep buckling of shell structures. Mech. Eng. Rev. 2015, 2, 14-00522. [Google Scholar] [CrossRef]

- Sammari, A.; Jullien, J.F. Creep buckling of cylindrical shells under external lateral pressure. Thin-Walled Struct. 1995, 23, 255–269. [Google Scholar] [CrossRef]

- Combescure, A. Simplified prediction of the creep buckling of cylinders under external pressure. Part 2: Experimental verification. Eur. J. Mech.-A/Solids 1999, 18, 1045–1059. [Google Scholar] [CrossRef]

- Lo Frano, R.; Forasassi, G. Experimental evidence of imperfection influence on the buckling of thin cylindrical shell under uniform external pressure. Nucl. Eng. Des. 2009, 239, 193–200. [Google Scholar] [CrossRef]

- Koundy, V.; Forgeron, T.; Hivroz, J. Creep buckling of ovalized tubes under external pressure. J. Press. Vessel. Technol. 1996, 118, 460–463. [Google Scholar] [CrossRef]

- Combescure, A. Simplified prediction of creep buckling of cylinders under external pressure. Part 1: Finite element validation. Eur. J. Mech.-A/Solids 1998, 17, 1021–1036. [Google Scholar] [CrossRef]

- Combescure, A.; Jullien, J.-F. Creep buckling of cylinders under uniform external pressure: Finite element simulation of buckling tests. Int. J. Solids Struct. 2017, 124, 14–25. [Google Scholar] [CrossRef]

- Schmidt, H. Stability of steel shell structures: General Report. J. Constr. Steel Res. 2000, 55, 159–181. [Google Scholar] [CrossRef]

- Schneider, W.; Brede, A. Consistent equivalent geometric imperfections for the numerical buckling strength verification of cylindrical shells under uniform external pressure. Thin-Walled Struct. 2005, 43, 175–188. [Google Scholar] [CrossRef]

- Rathinam, N.; Prabu, B. Static buckling analysis of thin cylindrical shell with centrally located dent under uniform lateral pressure. Int. J. Steel Struct. 2013, 13, 509–518. [Google Scholar] [CrossRef]

- Rathinam, N.; Prabu, B. Numerical study on influence of dent parameters on critical buckling pressure of thin cylindrical shell subjected to uniform lateral pressure. Thin-Walled Struct. 2015, 88, 1–15. [Google Scholar] [CrossRef]

- Du, X.; Zhang, J.; Liu, Y. Plastic failure analysis of defective pipes with creep damage under multi-loading systems. Int. J. Mech. Sci. 2017, 128–129, 428–444. [Google Scholar] [CrossRef]

- Du, X.; Liu, Y.; Zhang, J. High temperature limit analysis of pressure vessels and piping with local wall-thinning. In Advances in Direct Methods for Materials and Structures; Barrera, O., Cocks, A., Ponter, A., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 199–217. [Google Scholar]

- Rathinam, N. Investigations on the Effect of Geometrical Imperfections on the Buckling of Thin Cylindrical Shells Under Uniform Lateral Pressure. Ph.D. Thesis, Pondicherry University, Puducherry, India, 2016. [Google Scholar]

- Hussain, H.; Gao, X.; Shi, A. A finite element study on compressive resistance degradation of square and circular steel braces under axial cyclic loading. Appl. Sci. 2021, 11, 6094. [Google Scholar] [CrossRef]

- Gong, S.; Zhou, L.; Wang, X.; Yuan, L.; Liu, C. On the collapse of thick-walled pipes with corrosion defects under external pressure. Mar. Struct. 2021, 76, 102925. [Google Scholar] [CrossRef]

- Musa, A.E.S.; Al-Shugaa, M.A.; Al-Gahtani, H.J. The buckling strength of axially compressed thin circular cylindrical shells subjected to dent imperfection. Arab. J. Sci. Eng. 2023, 48, 5481–5492. [Google Scholar] [CrossRef]

- Zhou, S.; Zhao, Z.; Lao, Z.; Gao, H. Buckling capacity of spherical shells with local thickness reduction under radial ring load. Int. J. Press. Vessel. Pip. 2025, 214, 105441. [Google Scholar] [CrossRef]

- Fatt, M.S.H. Elastic-plastic collapse of non-uniform cylindrical shells subjected to uniform external pressure. Thin-Walled Struct. 1999, 35, 117–137. [Google Scholar] [CrossRef]

- Netto, T.A.; Ferraz, U.S.; Botto, A. On the effect of corrosion defects on the collapse pressure of pipelines. Int. J. Solids Struct. 2007, 44, 7597–7614. [Google Scholar] [CrossRef]

- Sakakibara, N.; Kyriakides, S.; Corona, E. Collapse of partially corroded or worn pipe under external pressure. Int. J. Mech. Sci. 2008, 50, 1586–1597. [Google Scholar] [CrossRef]

- Netto, T.A. On the effect of narrow and long corrosion defects on the collapse pressure of pipelines. Appl. Ocean. Res. 2009, 31, 75–81. [Google Scholar] [CrossRef]

- Moreira Junior, N.M.; Carrasquila, A.A.; Figueiredo, A.; da Fonseca, C.E. Worn pipes collapse strength: Experimental and numerical study. J. Pet. Sci. Eng. 2015, 133, 328–334. [Google Scholar] [CrossRef]

- Yan, S.-T.; Shen, X.-L.; Jin, Z.-J.; Ye, H. On elastic-plastic collapse of subsea pipelines under external hydrostatic pressure and denting force. Appl. Ocean. Res. 2016, 58, 305–321. [Google Scholar] [CrossRef]

- Fan, Z.; Yu, J.; Sun, Z.; Wang, H. Effect of axial length parameters of ovality on the collapse pressure of offshore pipelines. Thin-Walled Struct. 2017, 116, 19–25. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, H.; Li, X.; Feng, X. A semi-analytical approach to elastic–plastic buckling analysis of pipes with asymmetric local wall thinning. Thin-Walled Struct. 2021, 162, 107615. [Google Scholar] [CrossRef]

- Chen, Y.; Dong, S.; Zang, Z.; Gao, M.; Zhang, H.; Ao, C.; Liu, H.; Ma, S.; Liu, H. Collapse failure and capacity of subsea pipelines with complex corrosion defects. Eng. Fail. Anal. 2021, 123, 105266. [Google Scholar] [CrossRef]

- Chen, B.-Q.; Zhang, X.; Guedes Soares, C. The effect of general and localized corrosions on the collapse pressure of subsea pipelines. Ocean. Eng. 2022, 247, 110719. [Google Scholar] [CrossRef]

- Zhou, L.; Lin, Y.; Gong, S. On the collapse of thick-walled steel pipes under coupling initial geometric imperfection and corrosion defect. Ships Offshore Struct. 2023, 18, 325–337. [Google Scholar] [CrossRef]

- Tian, H.; Guan, F.; Wan, F.; Yang, Y.; Liu, W. The effect of corrosion defects on the collapse pressure of submarine pipelines. Ocean. Eng. 2024, 310, 118647. [Google Scholar] [CrossRef]

- Zhou, L.; Gong, S.; Yuan, L.; Wang, X.; Huang, J. Theoretical analysis of the collapse behaviour of subsea pipelines with corrosion defects under external pressure. Ocean. Eng. 2024, 307, 118069. [Google Scholar] [CrossRef]

- Park, J.-Y.; Choi, B.-K.; Yoo, S.J.; Jeong, Y.H. Corrosion behavior and oxide properties of Zr–1.1wt% Nb–0.05wt% Cu alloy. J. Nucl. Mater. 2006, 359, 59–68. [Google Scholar] [CrossRef]

- Kim, H.-K.; Lee, Y.-H.; Lee, K.-H. On the geometry of the fuel rod supports concerning a fretting wear failure. Nucl. Eng. Des. 2008, 238, 3321–3330. [Google Scholar] [CrossRef]

- Kim, K.-T.; Suh, J.-M. Impact of nuclear fuel assembly design on grid-to-rod fretting wear. J. Nucl. Sci. Technol. 2009, 46, 149–157. [Google Scholar] [CrossRef]

- Khattak, M.; Omran, A.A.B.; Kazi, S.; Khan, M.; Ali, H.M.; Tariq, S.L.; Akram, M.A. A review of failure modes of nuclear fuel cladding. J. Eng. Sci. Technol. 2019, 14, 1520–1541. [Google Scholar]

| Geometric Parameter | Value |

|---|---|

| 0, 0.0075, 0.11 | |

| 0.1, 0.2, 0.4 | |

| 15°, 30°, 60°, 90°, 120°, 150°, 180°, 240° |

| Cylinder | ξ | Critical Buckling Time (h) | ||

|---|---|---|---|---|

| Experiment | FEM | |||

| T121 | 0.0075 | 0.258 | 220 | 294.6 |

| T123 | 0.05 | 0.258 | 48 | 78.0 |

| T125 | 0.11 | 0.258 | 20 | 31.0 |

| d/t | Critical Time (h) | |||||||

|---|---|---|---|---|---|---|---|---|

| θ = 15° | θ = 30° | θ = 60° | θ = 90° | θ = 120° | θ = 150° | θ = 180° | θ = 240° | |

| 0.1 | 1046.5 | 848.42 | 681.92 | 675.39 | 758.23 | 912.26 | 1154.37 | 626.05 |

| 0.2 | 691.91 | 552.79 | 461.20 | 466.49 | 540.24 | 766.79 | 642.23 | 379.52 |

| 0.4 | 360.87 | 295.27 | 267.41 | 297.78 | 420.45 | 424.31 | 225.10 | 170.50 |

| Cylinder | Critical Buckling Time (h) | ||||||

|---|---|---|---|---|---|---|---|

| θ = 0° | θ = 15° | θ = 30° | θ = 60° | θ = 90° | θ = 120° | θ = 150° | |

| T121 | 294.55 | 207.11 | 185.58 | 175.18 | 183.31 | 202.24 | 229.72 |

| T125 | 30.96 | 25.64 | 24.71 | 23.95 | 23.92 | 23.06 | 20.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Wu, H.; Pan, Y.; Zhao, C.; He, L.; Zhang, J. Finite Element Modeling and Analysis for Creep Buckling of a Cylindrical Shell Subjected External Lateral Pressure with Local Wall Thinning. Appl. Sci. 2025, 15, 10005. https://doi.org/10.3390/app151810005

Chen Z, Wu H, Pan Y, Zhao C, He L, Zhang J. Finite Element Modeling and Analysis for Creep Buckling of a Cylindrical Shell Subjected External Lateral Pressure with Local Wall Thinning. Applied Sciences. 2025; 15(18):10005. https://doi.org/10.3390/app151810005

Chicago/Turabian StyleChen, Zekai, Hongbo Wu, Yuanbiao Pan, Chen Zhao, Linghui He, and Jie Zhang. 2025. "Finite Element Modeling and Analysis for Creep Buckling of a Cylindrical Shell Subjected External Lateral Pressure with Local Wall Thinning" Applied Sciences 15, no. 18: 10005. https://doi.org/10.3390/app151810005

APA StyleChen, Z., Wu, H., Pan, Y., Zhao, C., He, L., & Zhang, J. (2025). Finite Element Modeling and Analysis for Creep Buckling of a Cylindrical Shell Subjected External Lateral Pressure with Local Wall Thinning. Applied Sciences, 15(18), 10005. https://doi.org/10.3390/app151810005