Experimental Investigation of Wetting Materials for Indirect Evaporative Cooling Applications

Abstract

1. Introduction

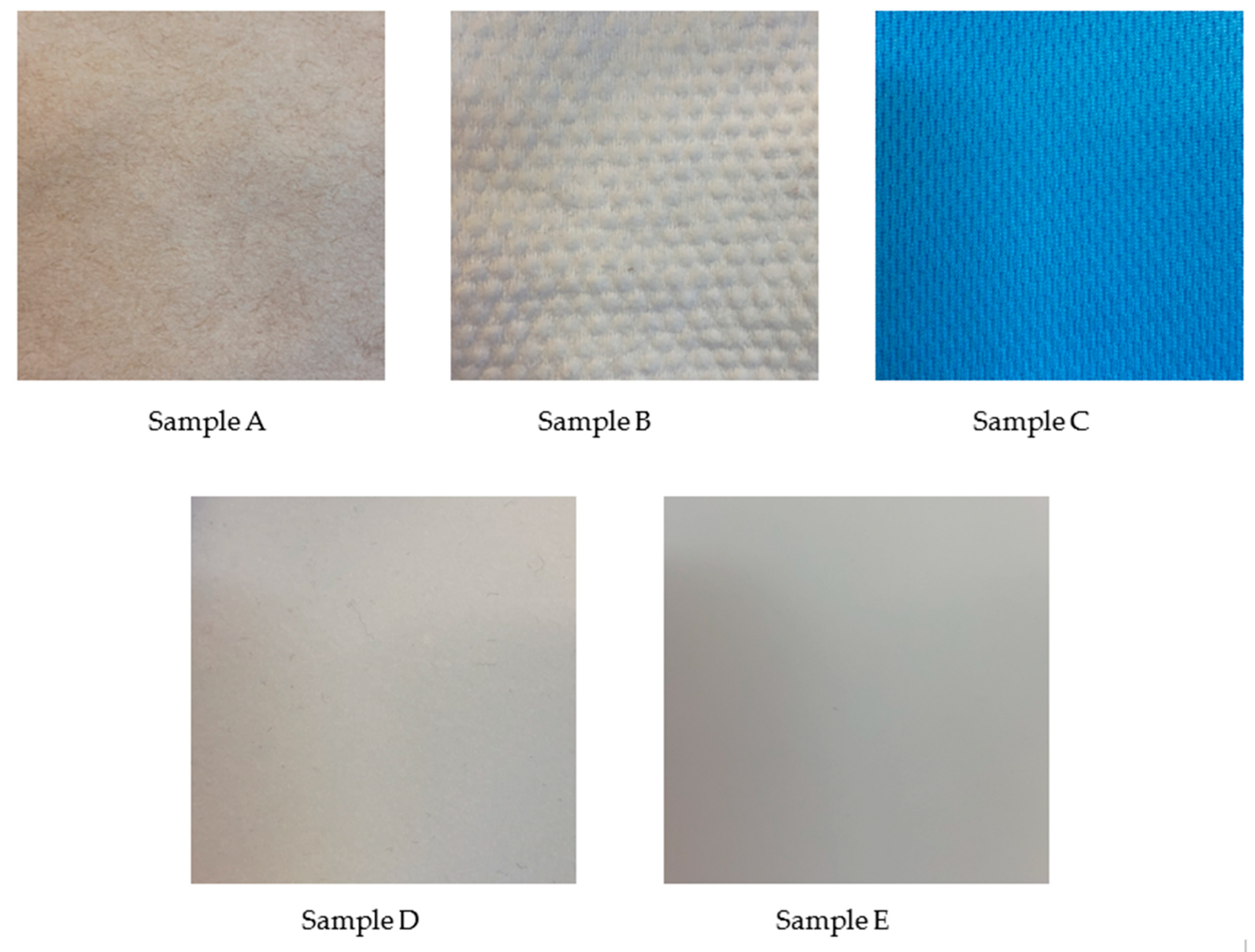

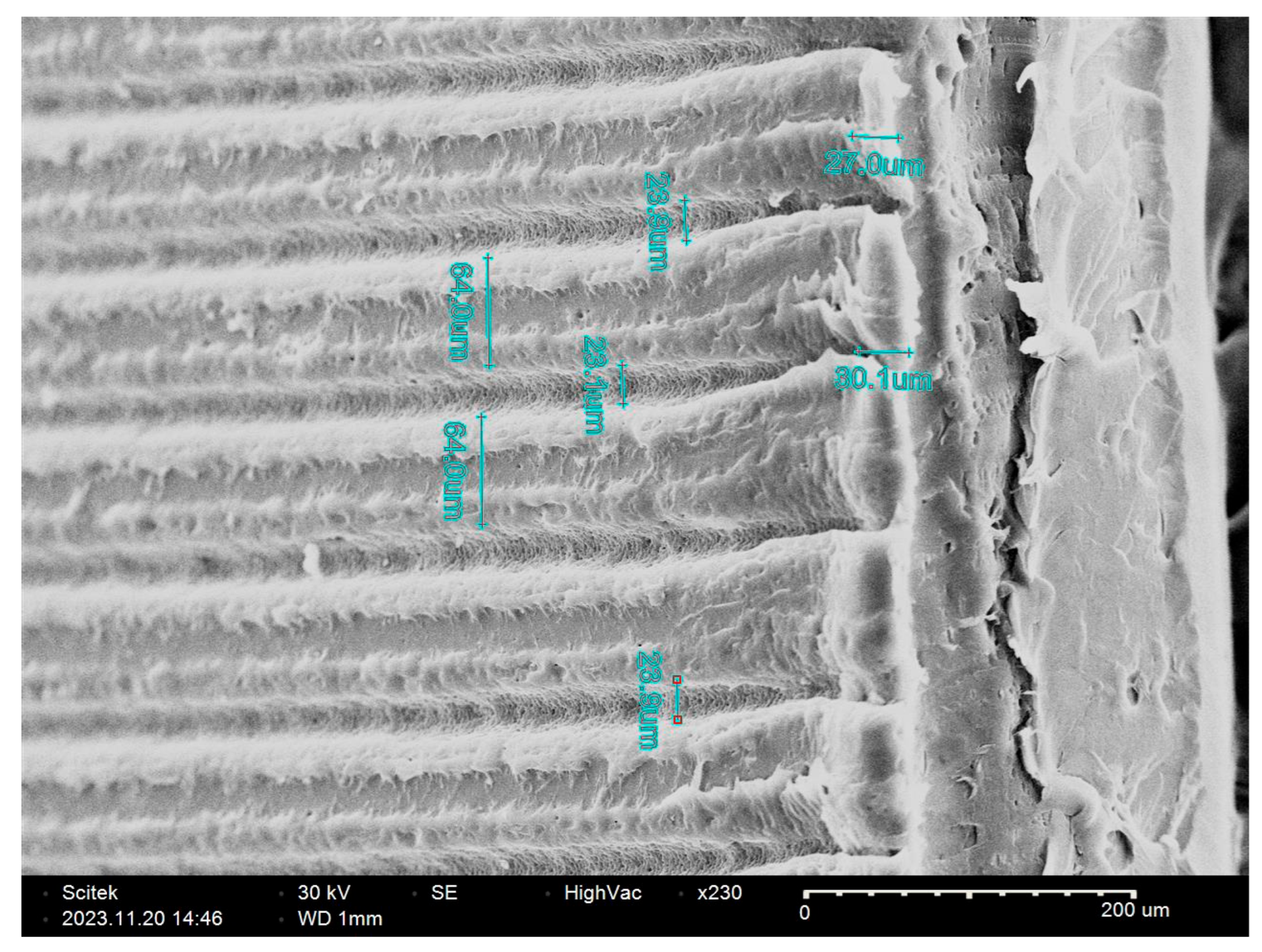

2. Characteristics of the Materials

3. Experimental Methodology

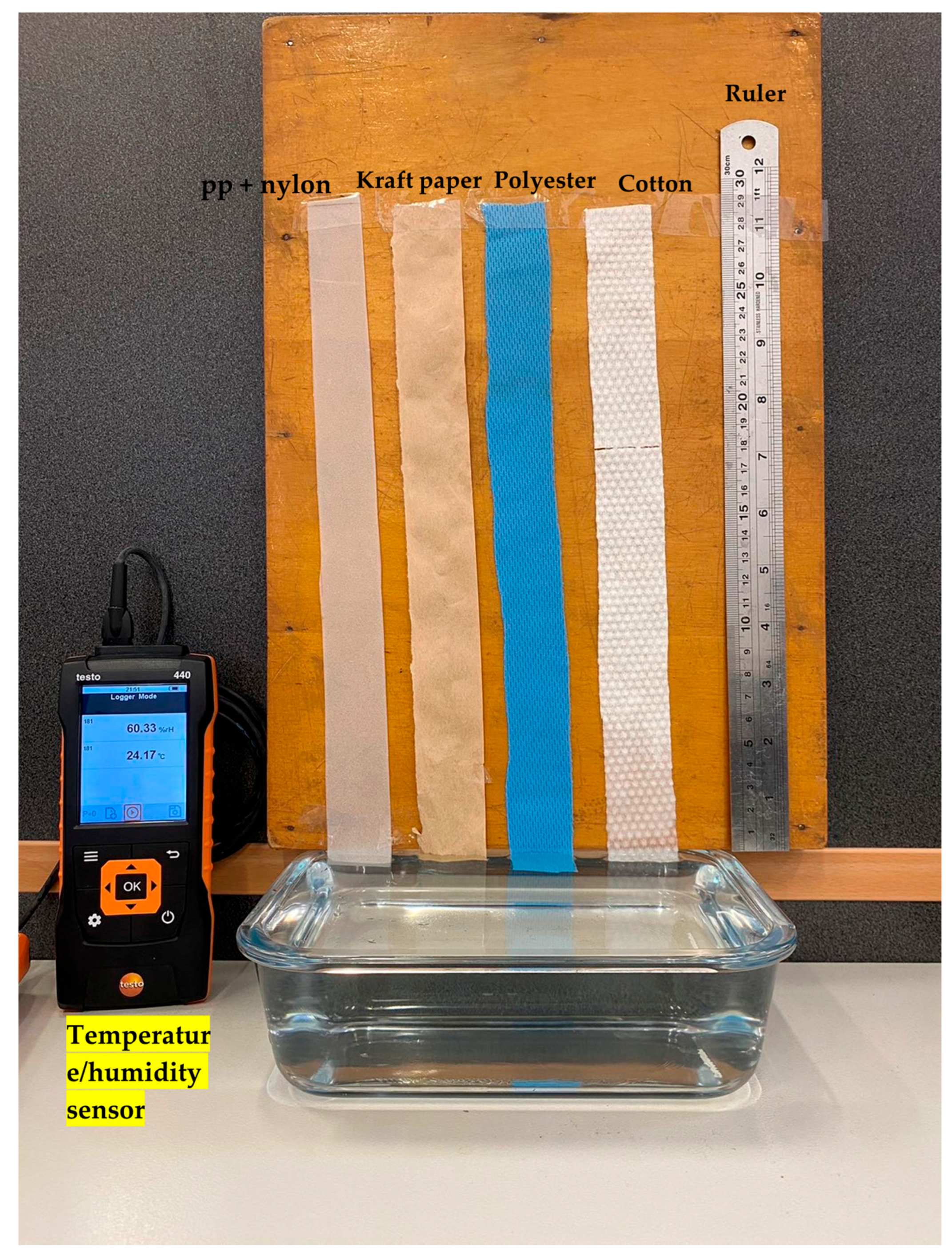

3.1. Wicking Capacity Test

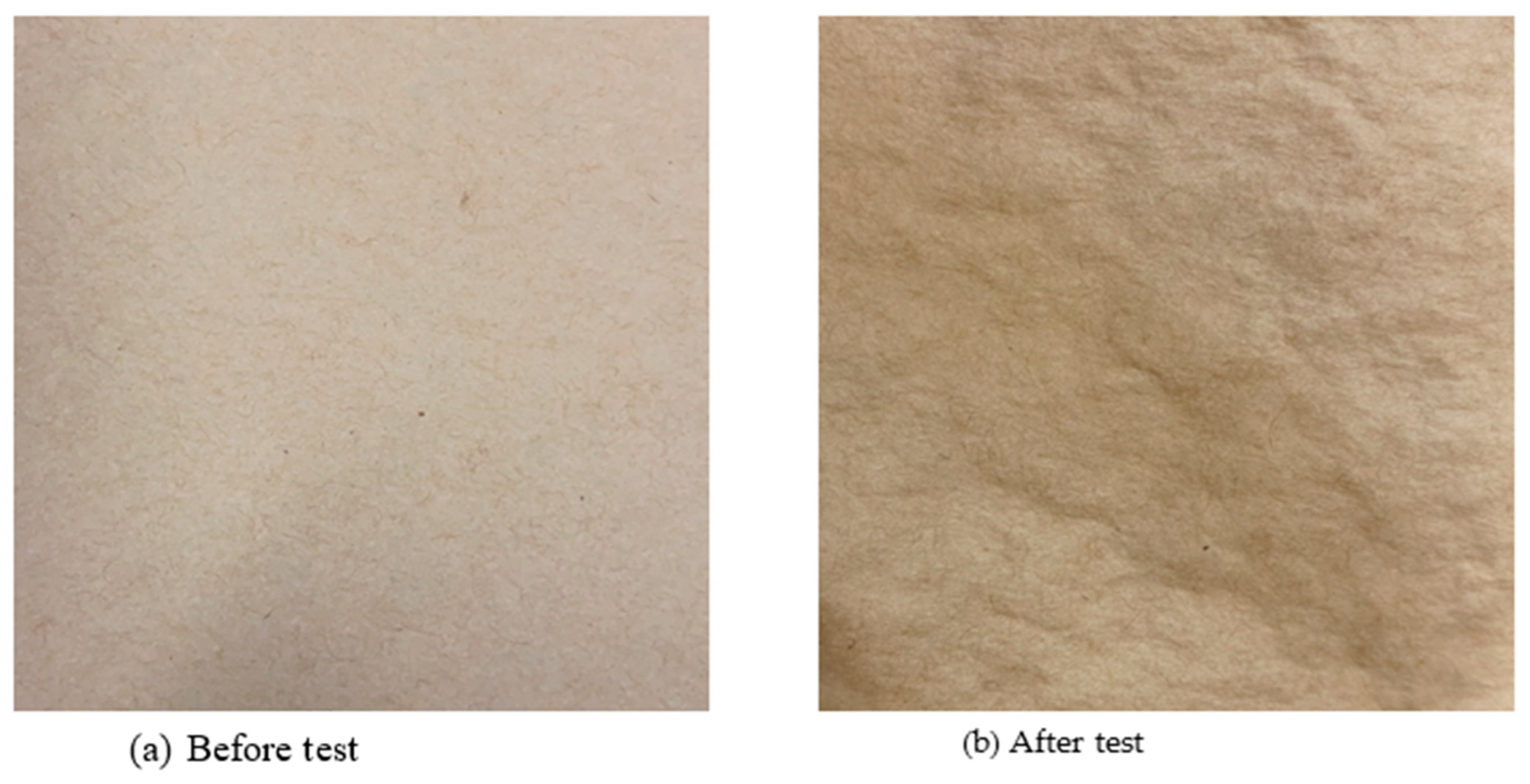

3.2. Water-Holding Capacity

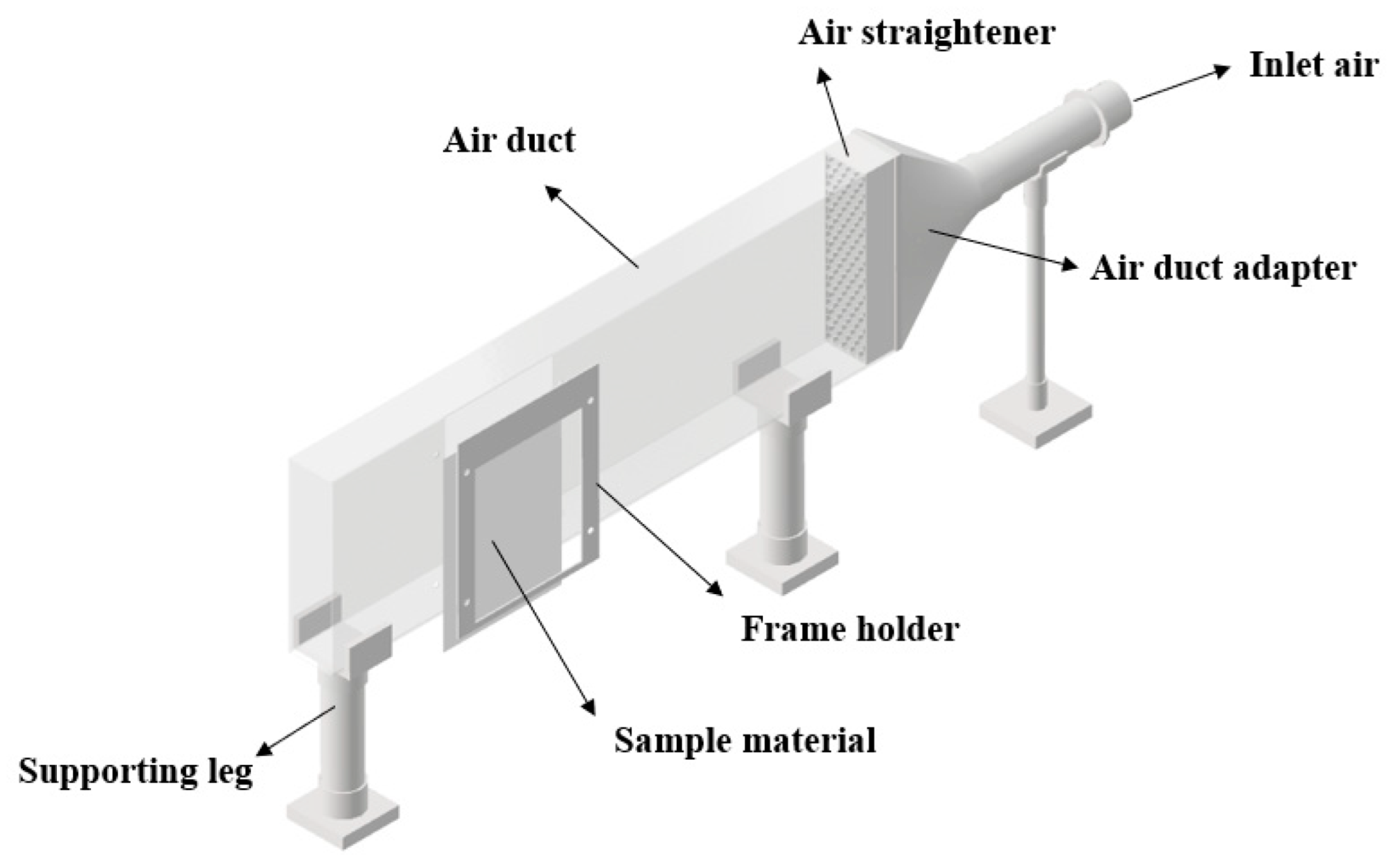

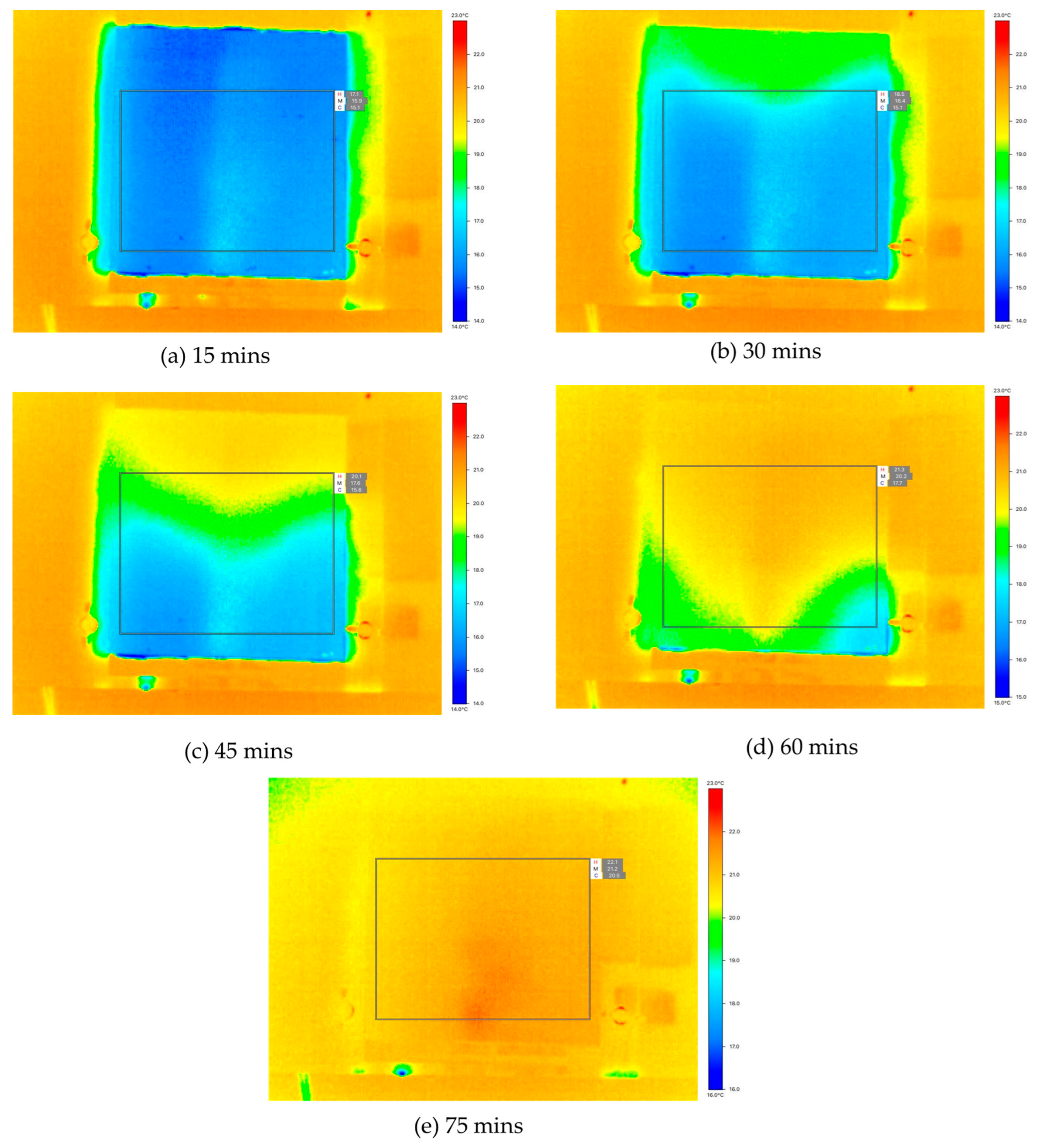

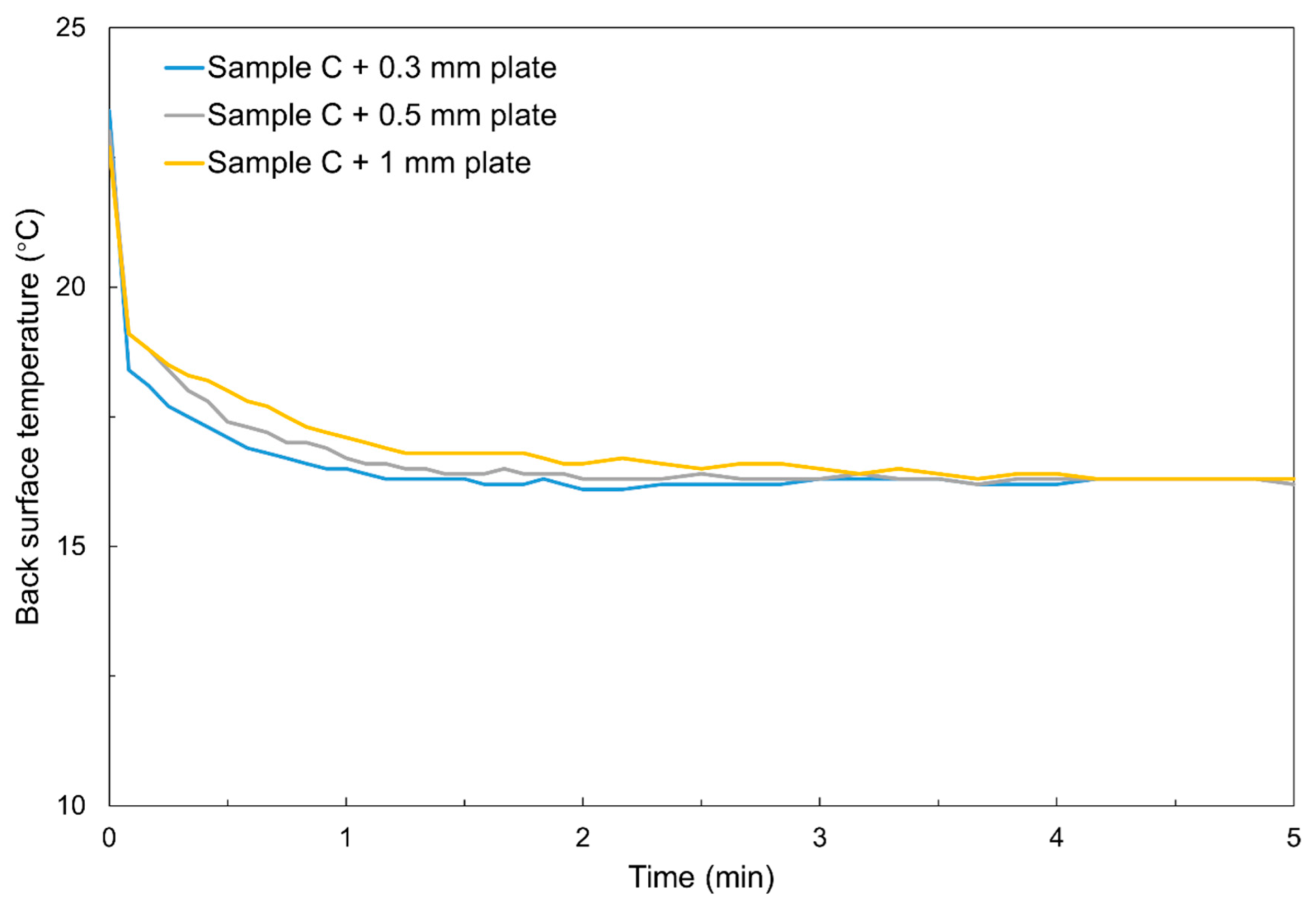

3.3. Thermal Response Analysis

4. Results and Discussion

4.1. Wicking Height

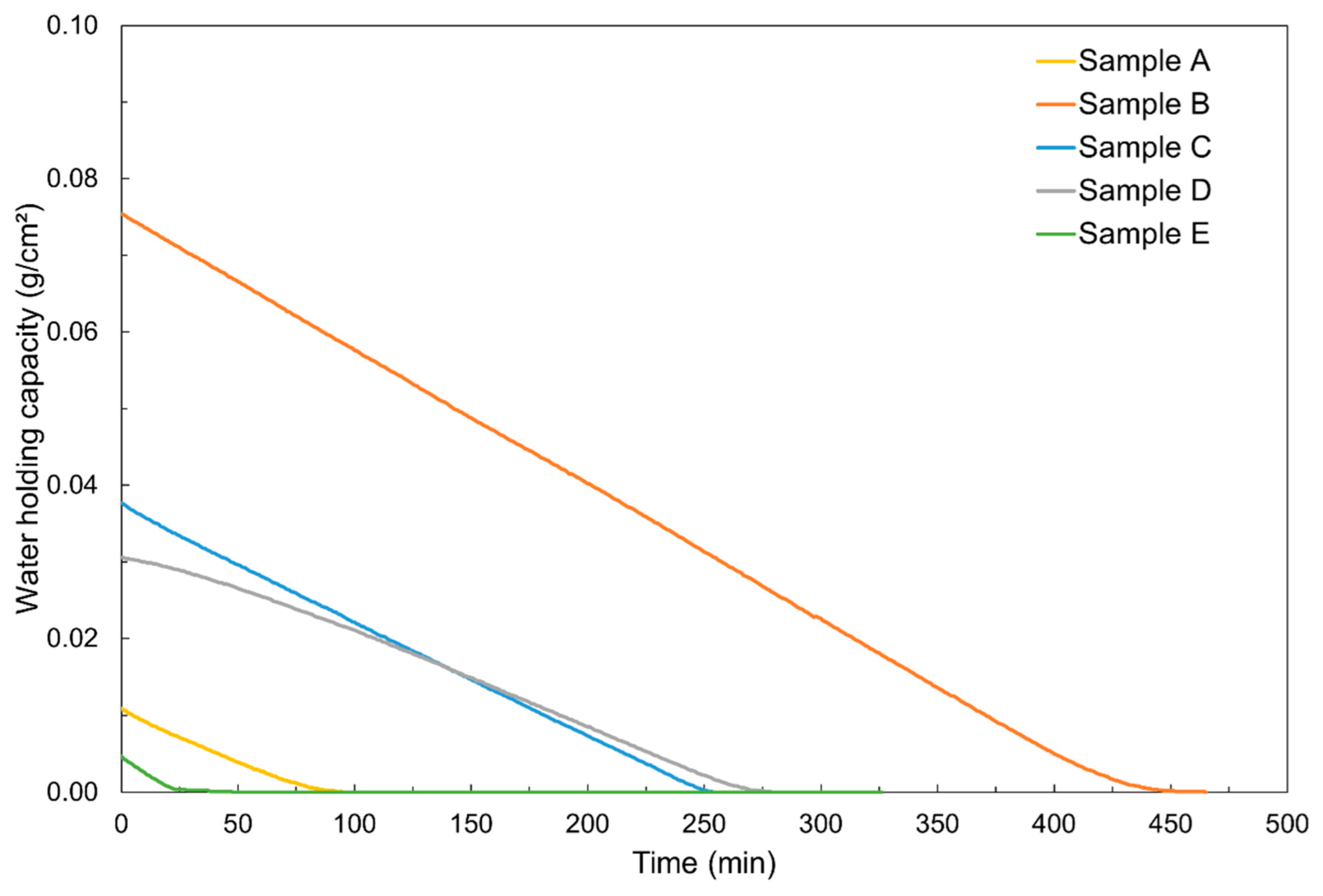

4.2. Water Retention Capacity

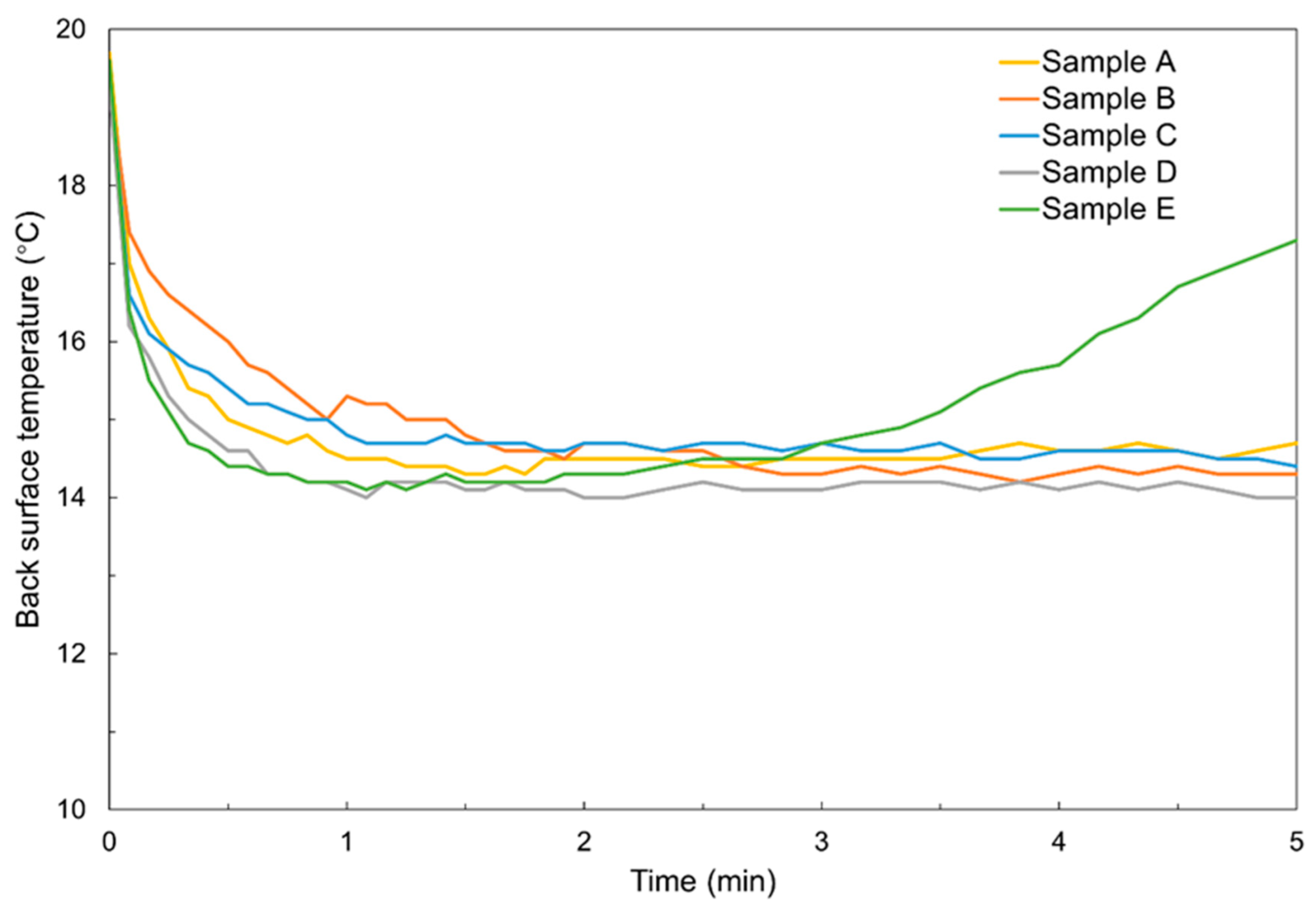

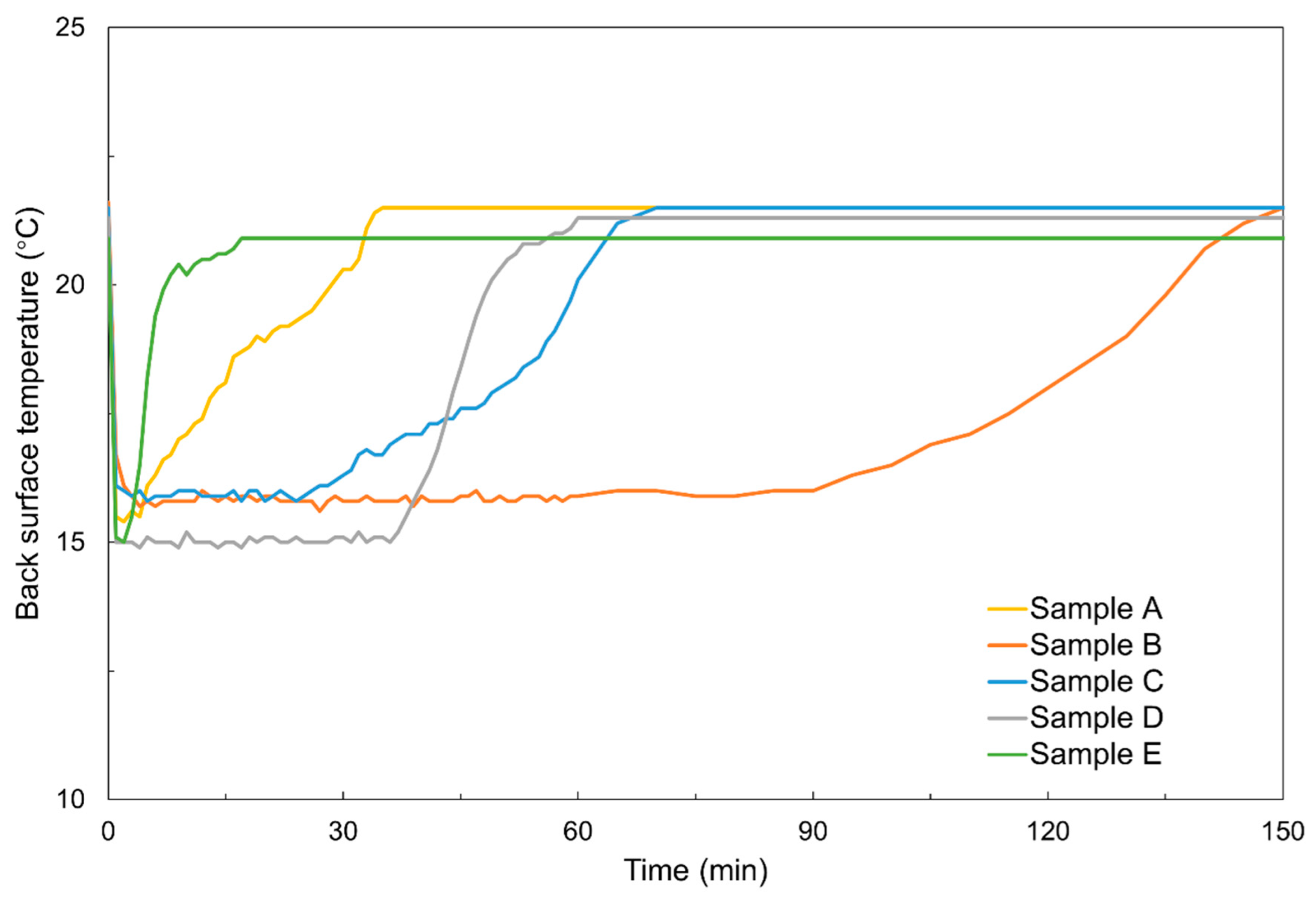

4.3. Thermal Response Performance Results

4.4. Overall Comparison of the Five Materials

5. Conclusions and Future Works

- (1)

- Fabric materials (Samples B and C) showed outstanding vertical wicking ability (>16 cm) and long-term cooling stability (up to 90 min), making them highly suitable for IEC designs favouring intermittent spray strategies and extended operational periods. Sample D offered a balanced performance, combining moderate wicking with a fast and durable thermal response without the need for mechanical support plates, which makes it promising for compact or simplified IEC configurations.

- (2)

- The laser-resurfaced polymer (Sample E) demonstrated a fast thermal response and mechanical robustness due to its direct hydrophilic surface, eliminating reliance on supporting plates. However, its limited water retention curtailed the cooling duration, highlighting the need for further groove-structure optimisation to balance thermal efficiency and moisture storage.

- (3)

- From an engineering perspective, these results provide practical design recommendations. Continuous spraying is appropriate for low-retention materials (Samples A and E), while intermittent spraying is more effective for high-capacity materials (Samples B, C, and D). The observed gravitational influence on vertical moisture distribution suggests that alternative orientations (horizontal configuration) may enhance the moisture utilisation and cooling performance of IEC systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Romero-Lara, M.J.; Comino, F.; de Adana, M.R. Seasonal energy efficiency ratio of regenerative indirect evaporative coolers—Simplified calculation method. Appl. Therm. Eng. 2023, 220, 119710. [Google Scholar] [CrossRef]

- Yan, M.; He, S.; Li, N.; Huang, X.; Gao, M.; Xu, M.; Miao, J.; Lu, Y.; Hooman, K.; Che, J.; et al. Experimental investigation on a novel arrangement of wet medium for evaporative cooling of air. Int. J. Refrig. 2021, 124, 64–74. [Google Scholar] [CrossRef]

- Lai, L.; Wang, X.; Kefayati, G.; Hu, E. Performance evaluation of a solar powered solid desiccant evaporative cooling system with different recirculation air ratios. Energy Build. 2022, 270, 112273. [Google Scholar] [CrossRef]

- Sajjad, U.; Abbas, N.; Hamid, K.; Abbas, S.; Hussain, I.; Ammar, S.M.; Sultan, M.; Ali, H.M.; Hussain, M.; Tauseef ur, R.; et al. A review of recent advances in indirect evaporative cooling technology. Int. Commun. Heat Mass Transf. 2021, 122, 105140. [Google Scholar] [CrossRef]

- Lai, L.; Wang, X.; Kefayati, G.; Hu, E. Evaporative Cooling Integrated with Solid Desiccant Systems: A Review. Energies 2021, 14, 5982. [Google Scholar] [CrossRef]

- Sun, T.; Huang, X.; Qu, Y.; Wang, F.; Chen, Y. Theoretical and experimental study on heat and mass transfer of a porous ceramic tube type indirect evaporative cooler. Appl. Therm. Eng. 2020, 173, 115211. [Google Scholar] [CrossRef]

- Liu, Y.; Akhlaghi, Y.G.; Zhao, X.; Li, J. Experimental and numerical investigation of a high-efficiency dew-point evaporative cooler. Energy Build. 2019, 197, 120–130. [Google Scholar] [CrossRef]

- Kashyap, S.; Sarkar, J.; Kumar, A. Effect of surface modifications and using hybrid nanofluids on energy-exergy performance of regenerative evaporative cooler. Build. Environ. 2021, 189, 107507. [Google Scholar] [CrossRef]

- Alharbi, A.; Almaneea, A.; Boukhanouf, R. Integrated hollow porous ceramic cuboids-finned heat pipes evaporative cooling system: Numerical modelling and experimental validation. Energy Build. 2019, 196, 61–70. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Lin, J.; Xu, B.B.; Dala, L.; Chen, Q.; Burhan, M.; Sultan, M.; Worek, W.; Ng, K.C. A spatiotemporal indirect evaporative cooler enabled by transiently interceding water mist. Energy 2021, 217, 119352. [Google Scholar] [CrossRef]

- Gao, F.; Thu, K.; Wang, S.; Zhao, F.; Lin, J.; Wu, K. Numerical investigation of a novel tubular dew-point evaporative cooler. Appl. Therm. Eng. 2023, 223, 120064. [Google Scholar] [CrossRef]

- Xu, P.; Ma, X.; Zhao, X.; Fancey, K.S. Experimental investigation on performance of fabrics for indirect evaporative cooling applications. Build. Environ. 2016, 110, 104–114. [Google Scholar] [CrossRef]

- Khalid, O.; Butt, Z.; Tanveer, W.; Rao, H.I. Design and experimental analysis of counter-flow heat and mass exchanger incorporating (M-cycle) for evaporative cooling. Heat Mass Transf. 2016, 53, 1391–1403. [Google Scholar] [CrossRef]

- Lv, J.; Xu, H.; Xu, T.; Liu, H.; Qin, J. Study on the performance of a unit dew-point evaporative cooler with fibrous membrane and its application in typical regions. Case Stud. Therm. Eng. 2021, 24, 100881. [Google Scholar] [CrossRef]

- Abada, D.; Maalouf, C.; Sotehi, O.; Rouag-Saffidine, D.; Polidori, G.; Boudjabi, A.F.; Derghout, Z. Performance evaluation of fabrics for evaporative cooling applications. Energy Build. 2022, 266, 112120. [Google Scholar] [CrossRef]

- Riangvilaikul, B.; Kumar, S. An experimental study of a novel dew point evaporative cooling system. Energy Build. 2010, 42, 637–644. [Google Scholar] [CrossRef]

- Xu, P.; Ma, X.; Zhao, X.; Fancey, K. Experimental investigation of a super performance dew point air cooler. Appl. Energy 2017, 203, 761–777. [Google Scholar] [CrossRef]

- Chen, Y.; Yan, H.; Min, Y. Visualized study of wetting enhancement and thermal performance of fiber-coated indirect evaporative cooler. Appl. Therm. Eng. 2023, 221, 119904. [Google Scholar] [CrossRef]

- Lv, J.; Xu, H.; Zhu, M.; Dai, Y.; Liu, H.; Li, Z. The performance and model of porous materials in the indirect evaporative cooling system: A review. J. Build. Eng. 2021, 41, 102741. [Google Scholar] [CrossRef]

- Yang, H.; Shi, W.; Chen, Y.; Min, Y. Research development of indirect evaporative cooling technology: An updated review. Renew. Sustain. Energy Rev. 2021, 145, 111082. [Google Scholar] [CrossRef]

- Jia, L.; Liu, J.; Wang, C.; Cao, X.; Zhang, Z. Study of the thermal performance of a novel dew point evaporative cooler. Appl. Therm. Eng. 2019, 160, 114069. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, X.; Sun, T.; Chu, J. Experimental study of plant fiber-polymer composite for indirect evaporative cooler application. Appl. Therm. Eng. 2021, 199, 117543. [Google Scholar] [CrossRef]

- Fang, R.; Zhu, H.; Li, Z.; Yan, W.; Zhang, X.; Zhu, X.; Maisotsenko, V.S.; Vorobyev, A.Y. Capillary Nylon 6 polymer material produced by femtosecond laser processing. Opt. Express 2019, 27, 36066–36074. [Google Scholar] [CrossRef] [PubMed]

| Sample | Material Name | Material Type | Thickness (mm) | Weight (g/m2) | Require Support Plates (Y/N) |

|---|---|---|---|---|---|

| A | Kraft paper | Natural fibre | 0.05 | 50 | Y |

| B | Cotton fibre | Natural fibre | 0.30 | 90 | Y |

| C | Polyester fibre | Synthetic fibre | 0.46 | 125 | Y |

| D | Polypropylene + nylon fibre | Composite fibre | 0.40 | 302 | N |

| E | Laser-resurfaced polymer sheet | Resurfaced material | 0.50 | 550 | N |

| Measured Parameter | Instrument | Range | Accuracy |

|---|---|---|---|

| Wicking height | Steel ruler | 0 to 30 cm | ±1 mm |

| Thickness | Calliper | 0 to 15 cm | ±0.01 mm |

| Ambient temperature and relative humidity | Temperature and humidity sensor (Testo 440) | −20 to 70 °C 0 to 100% | ±0.3 °C ±0.6% |

| Air velocity | Hot-wire anemometer (DT-8880) | 0.1 to 25 m/s | ±0.1 m/s |

| Weight | High-precision scale (FZ-3000i) | 0 to 3200 g | ±0.01 g |

| Surface temperature | Thermal imager (Testo 883) | −30 to 650 °C | Thermal sensitivity < 0.04 °C |

| Sample | Performance Evaluation | |||||

|---|---|---|---|---|---|---|

| Wicking Rate | Water-Holding | Mechanical Strength | Thermal Response | Cooling Duration | Water-Spray Strategy Recommendation | |

| A | Poor | Poor | Poor | Good | Poor | Continuous spray |

| B | Excellent | Excellent | Poor | Good | Excellent | Intermittent spray/auto-wicking |

| C | Good | Good | Poor | Good | Good | Intermittent spray |

| D | Poor | Good | Excellent * | Excellent | Good | Intermittent spray |

| E | Poor | Poor | Excellent * | Excellent | Poor | Continuous spray |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, L.; Wang, X.; Kefayati, G.; Hu, E.; Ng, K.C. Experimental Investigation of Wetting Materials for Indirect Evaporative Cooling Applications. Appl. Sci. 2025, 15, 9818. https://doi.org/10.3390/app15179818

Lai L, Wang X, Kefayati G, Hu E, Ng KC. Experimental Investigation of Wetting Materials for Indirect Evaporative Cooling Applications. Applied Sciences. 2025; 15(17):9818. https://doi.org/10.3390/app15179818

Chicago/Turabian StyleLai, Lanbo, Xiaolin Wang, Gholamreza Kefayati, Eric Hu, and Kim Choon Ng. 2025. "Experimental Investigation of Wetting Materials for Indirect Evaporative Cooling Applications" Applied Sciences 15, no. 17: 9818. https://doi.org/10.3390/app15179818

APA StyleLai, L., Wang, X., Kefayati, G., Hu, E., & Ng, K. C. (2025). Experimental Investigation of Wetting Materials for Indirect Evaporative Cooling Applications. Applied Sciences, 15(17), 9818. https://doi.org/10.3390/app15179818