Study on Influencing Factors and Spectrum Characteristics of Tire/Road Noise of RIOHTrack Full-Scale Test Road Based on CPXT Method

Abstract

1. Introduction

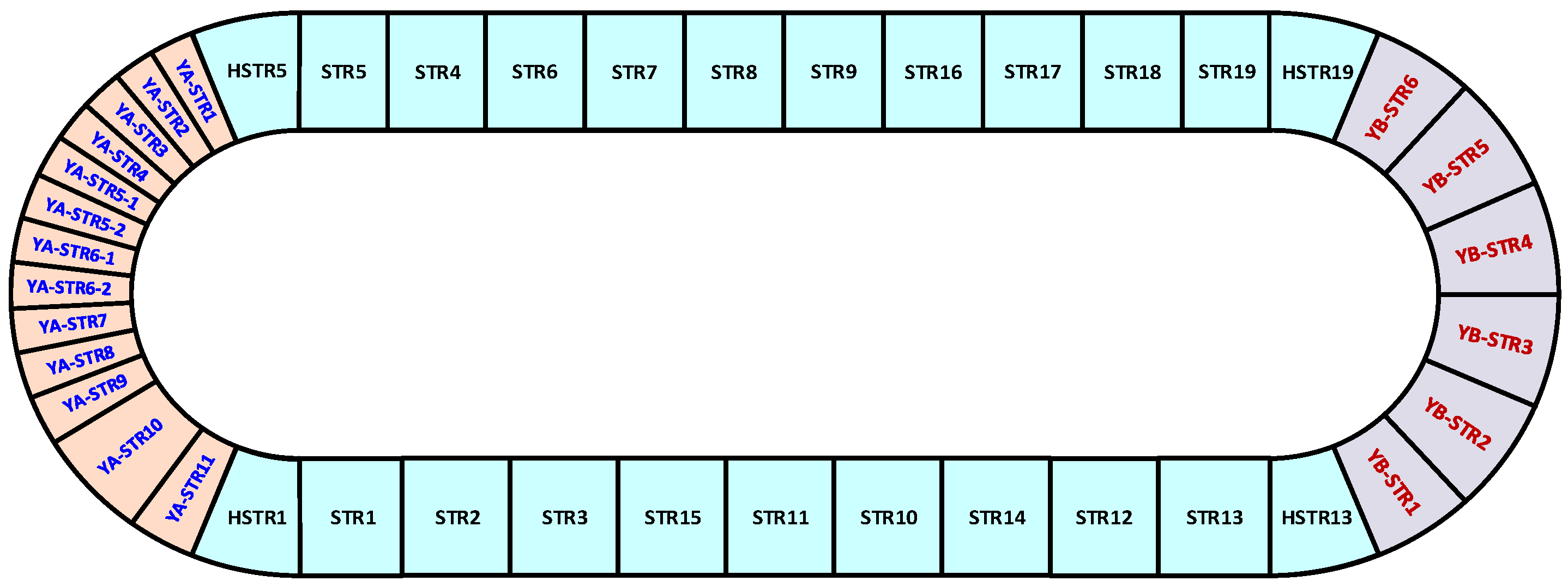

2. Overview of Test

2.1. Pavement Structure Type

2.2. Methods

2.2.1. Speed

2.2.2. Tire Texture

2.2.3. Trailer Axle Weight

3. Results

3.1. Comparison of Sound Pressure Level (SPL)

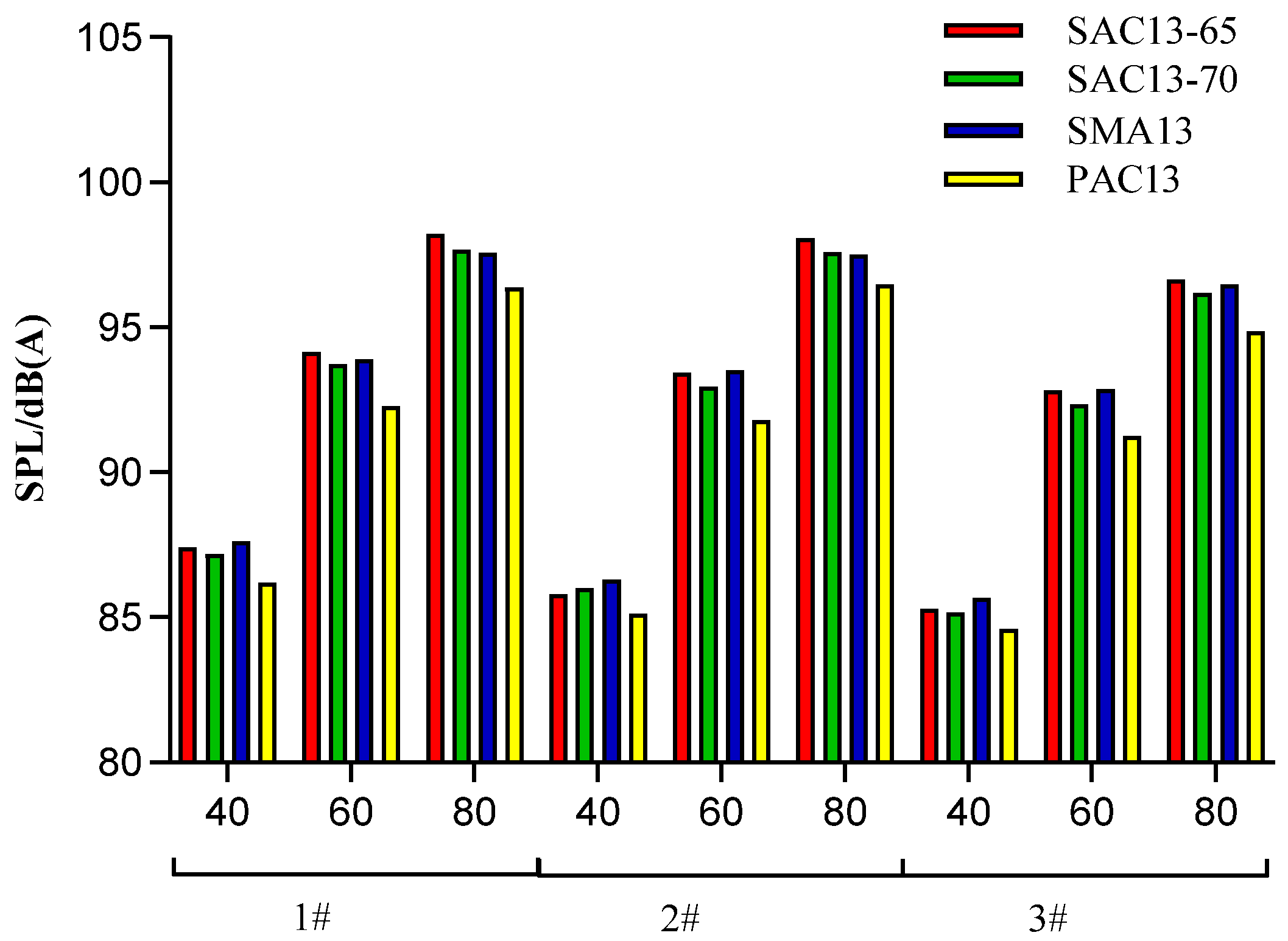

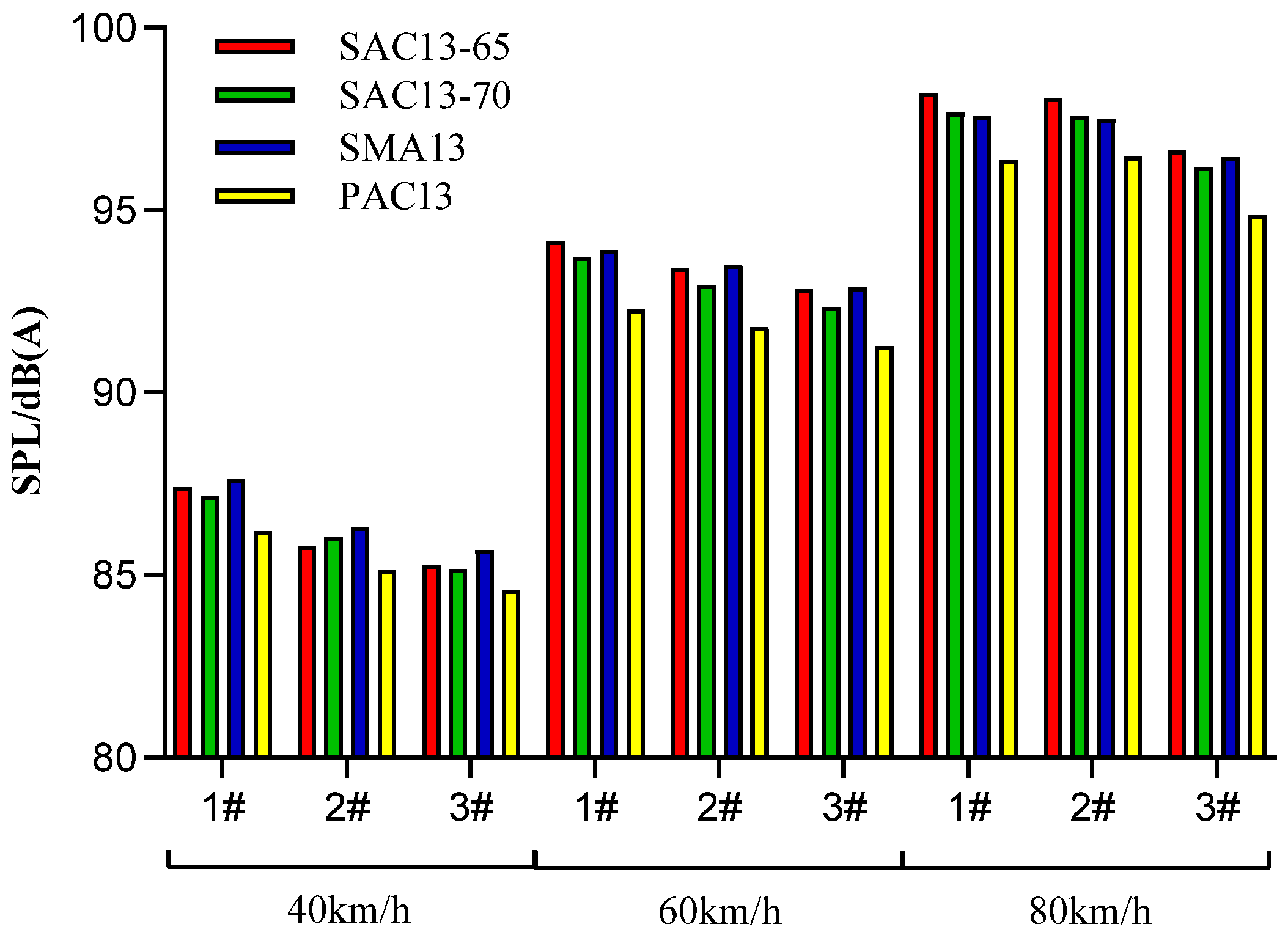

3.1.1. Effect of Vehicle Speed

3.1.2. Effect of Tire Texture

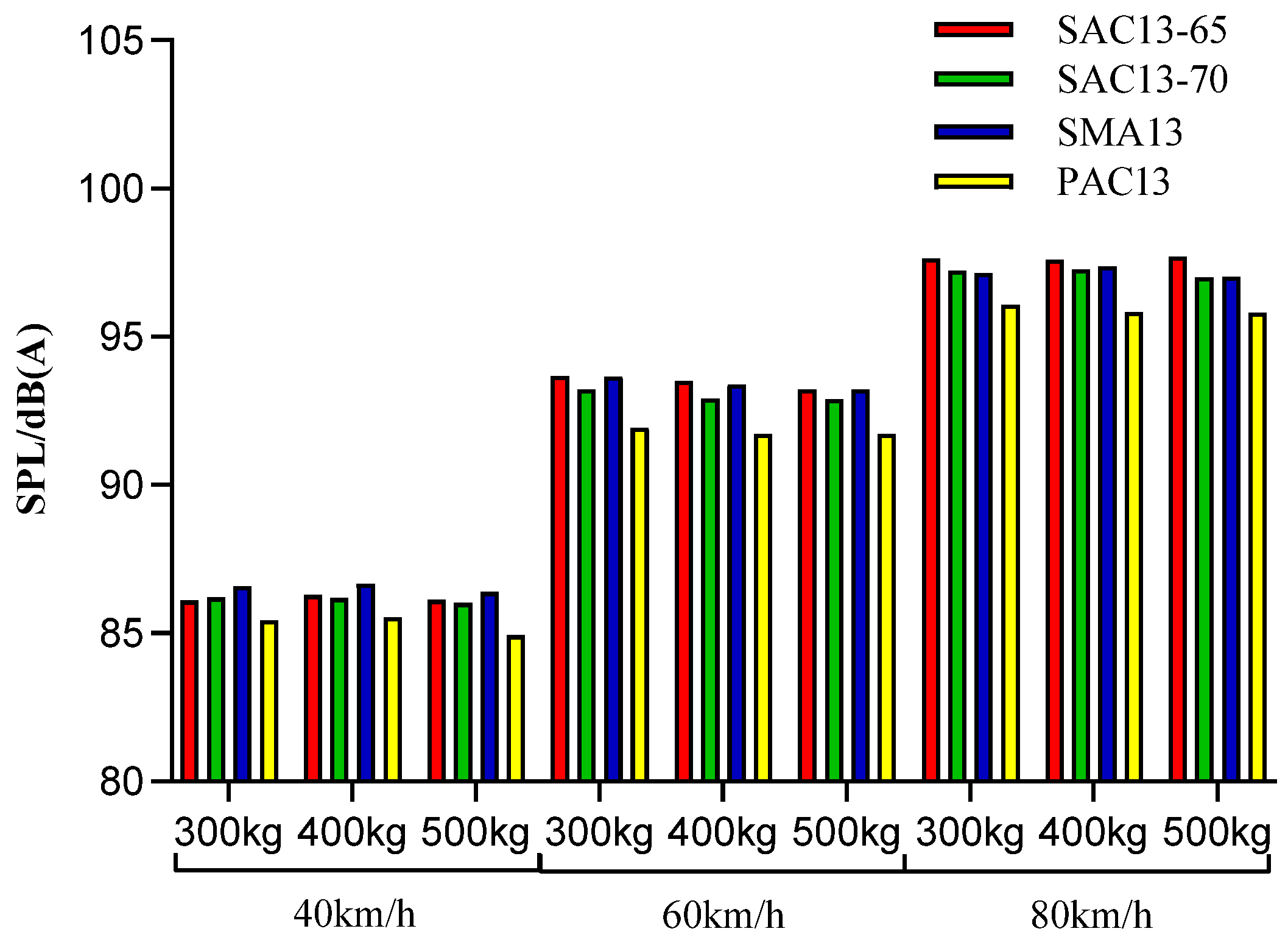

3.1.3. Effect of Trailer Axle Weight

3.2. Construction of Noise Level Model

3.3. Noise Spectrum Analysis

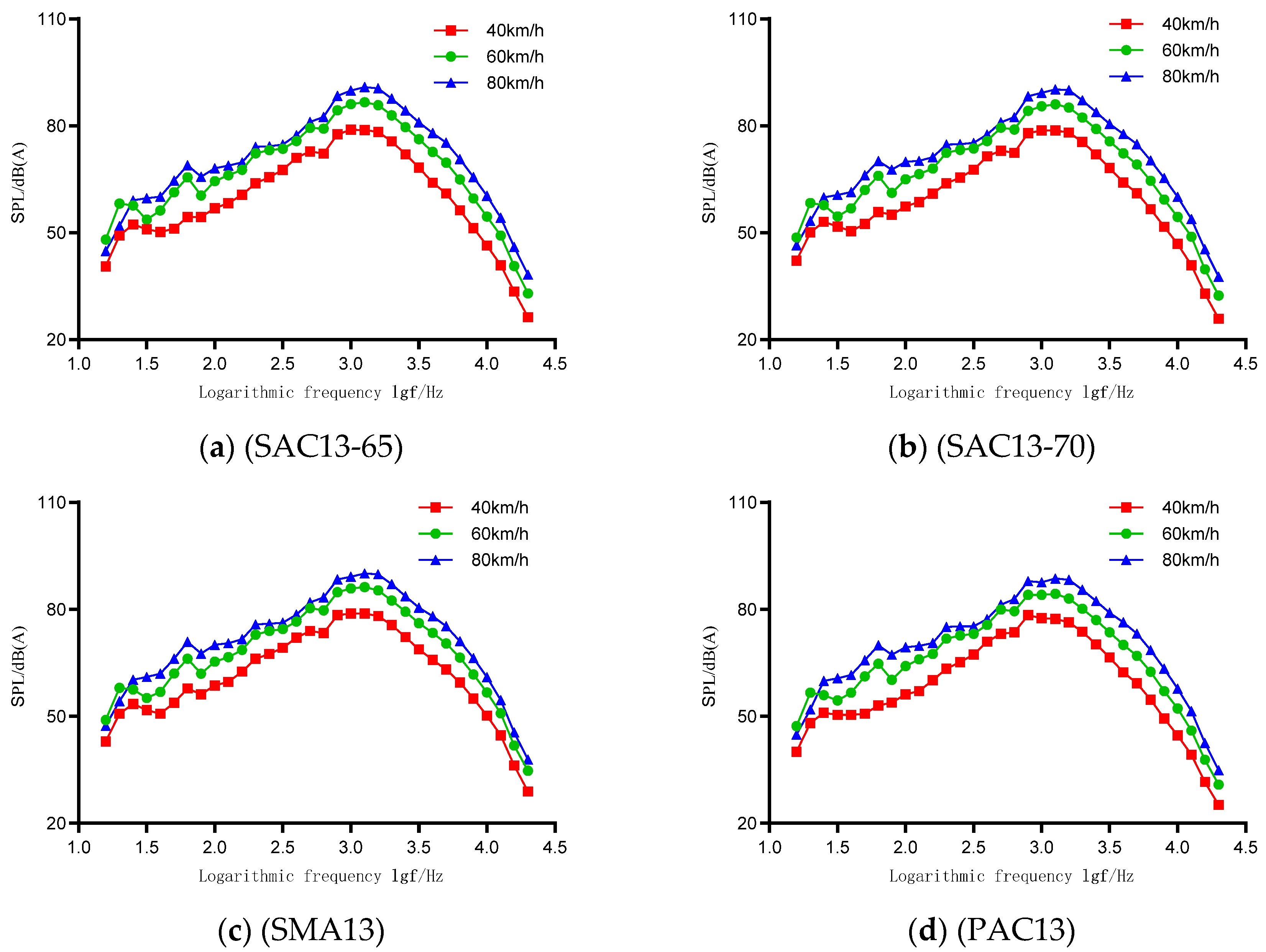

3.3.1. Spectrum Analysis at Different Vehicle Speeds

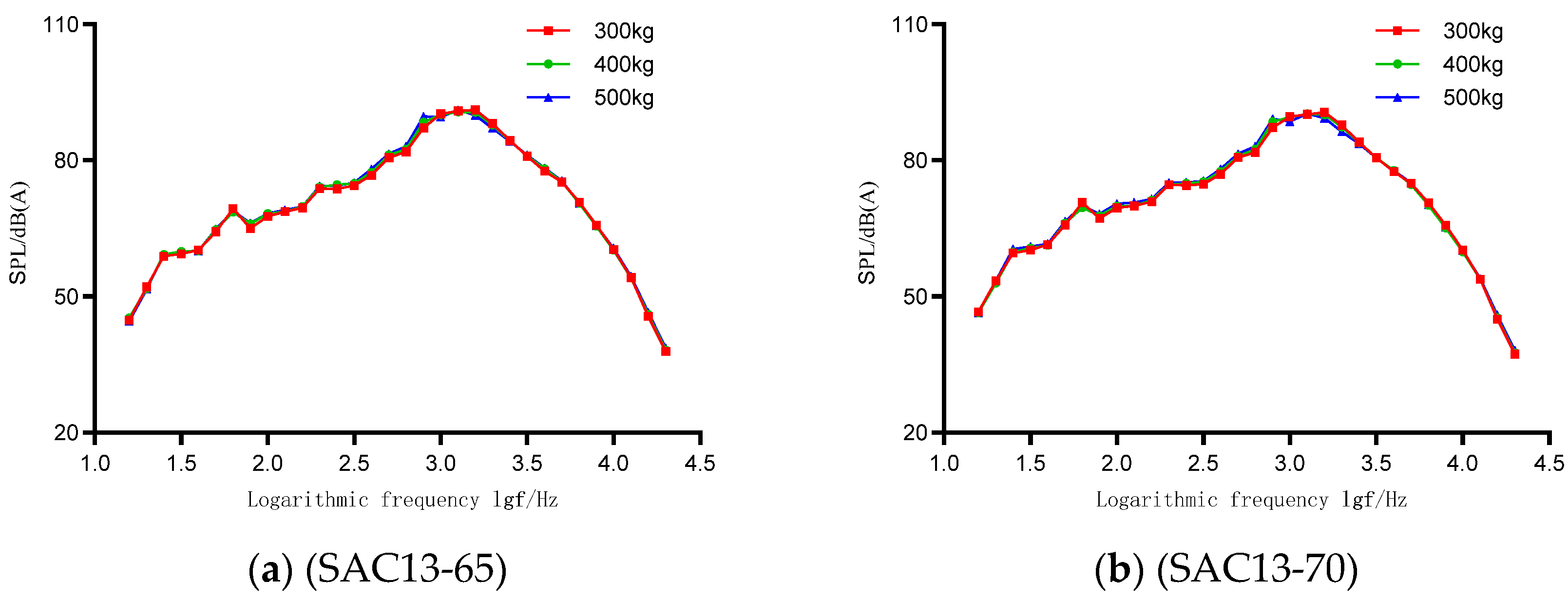

3.3.2. Spectrum Analysis with Different Tires

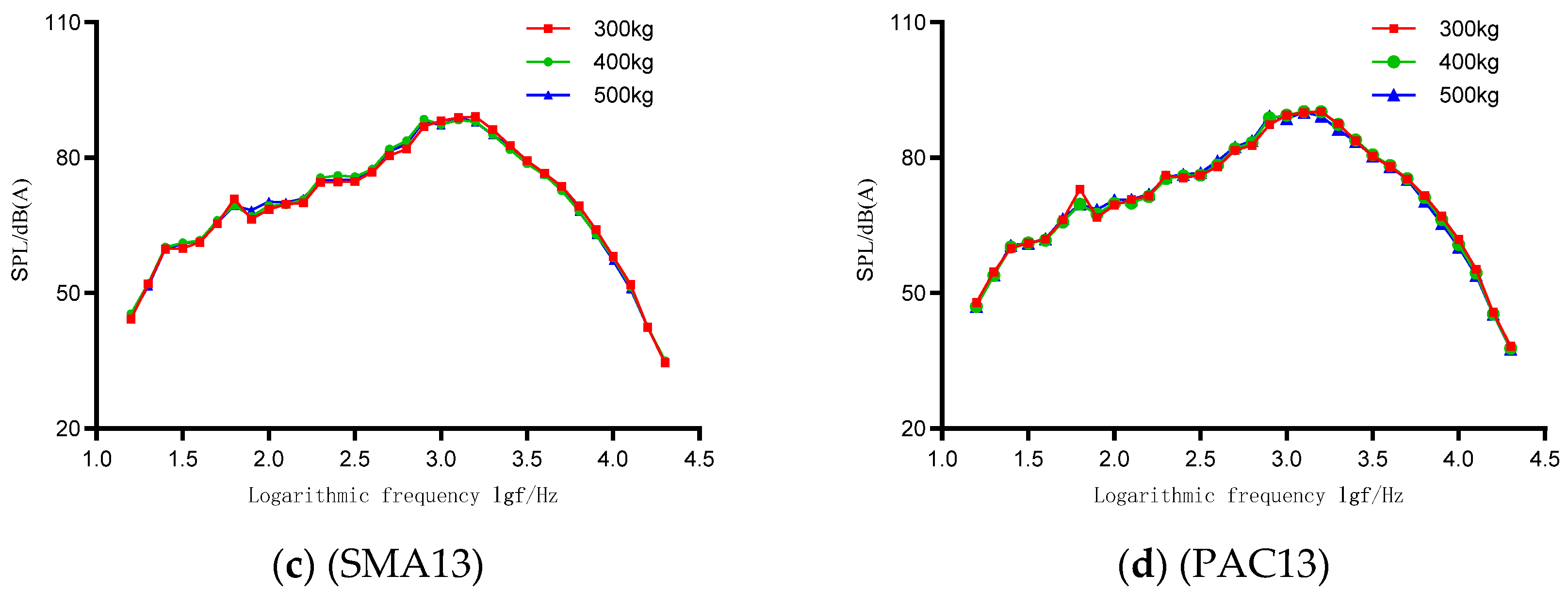

3.3.3. Spectrum Analysis for Different Trailer Axle Weights

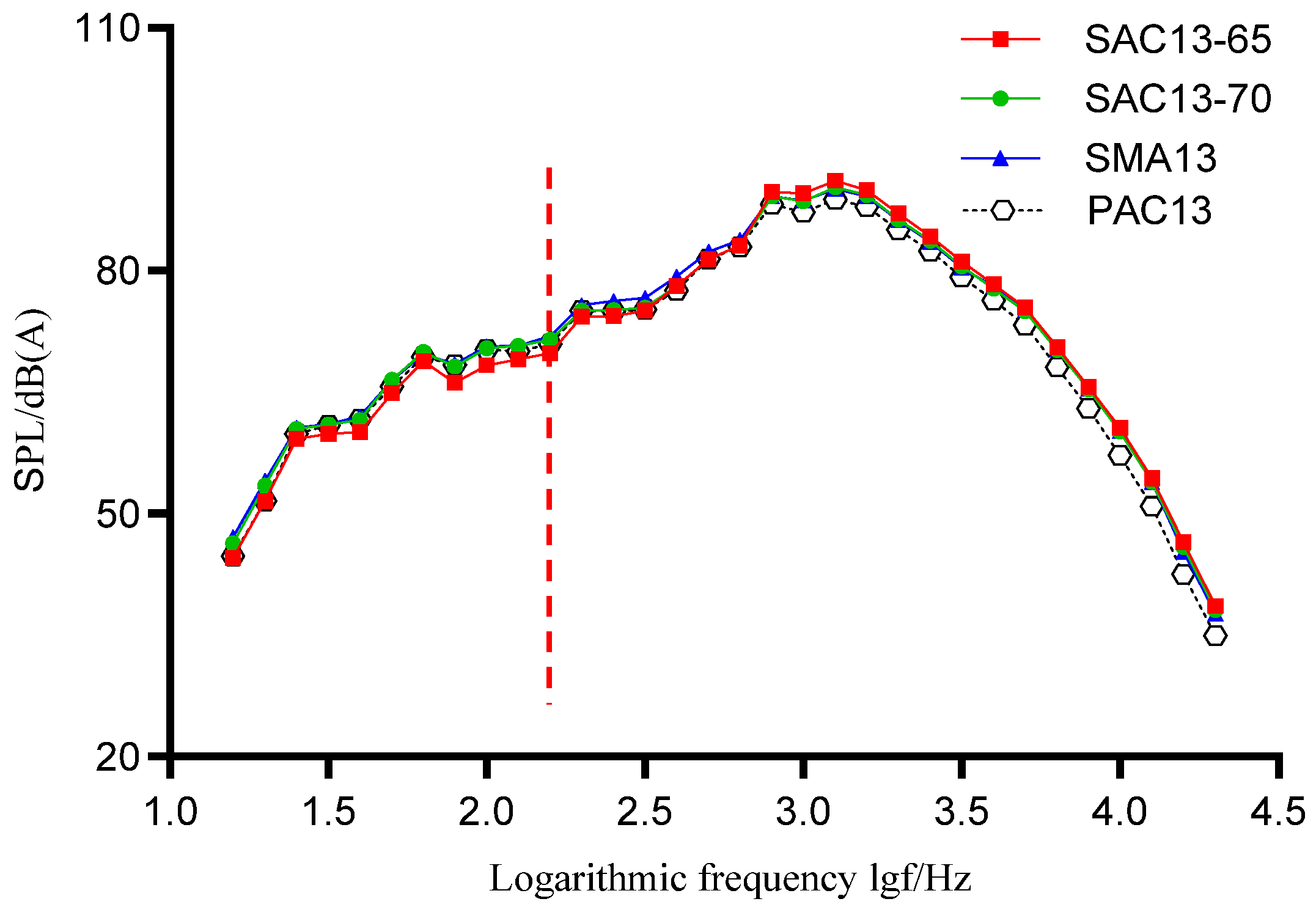

3.3.4. Spectrum Analysis for Different Surface Materials

4. Conclusions

- (1)

- From the perspective of noise level, vehicle speed is the most important factor affecting tire/road noise; the noise levels of different tire textures also vary to a certain extent, and the tire/road noise level can be reduced by changing the tire texture; different axle weights have little effect on noise.

- (2)

- Through test analysis of experimental variables of noise detection, characteristics of surface materials, and basic information of road surface tested by road condition inspection vehicle, noise prediction models for three different tire textures were constructed based on the RIOHTrack full-scale test road using FWD center deflection (D0), standard mean structural depth (SMTD), international roughness index (IRI), surface material air void (VV), and vehicle speed (v).

- (3)

- Analyzing noise spectra, the spectrum curves of different vehicle speeds are basically parallel, and the spectrum lines gradually move upward as the vehicle speed increases; the differences in different tire textures mainly exist in the spectrum peak range (630 Hz~2000 Hz), which in turn affects the noise level; and the spectra of different trailer axle weights basically overlap, which explains why the noise levels of different axle weights are roughly the same.

- (4)

- In the full frequency range greater than 800 Hz, the noise spectrum curve of porous asphalt concrete PAC13 is significantly lower than that of the other three asphalt concretes, which fully demonstrates its significant noise reduction effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, X.-D.; Li, M.-J. Low-Noise Asphalt Pavement; China Communications Press: Beijing, China, 2008. [Google Scholar]

- Campillo-Davo, N.; Peral-Orts, R.; Campello-Vicente, H.; Velasco-Sanchez, E. An alternative close-proximity test to evaluate sound power level emitted by a rolling tyre. Appl. Acoust. 2019, 143, 7–18. [Google Scholar] [CrossRef]

- Donavan, P.; Rymer, B. Assessment of highway pavements for tire-road noise generation. In Proceedings of the Society of Automotive Engineers Noise and Vibration, Grand Traverse, MI, USA, 3 May 2003. [Google Scholar]

- Sandberg, U.; Ejsmont, J.A. Tyre/Road Noise Reference Book; INFORMEX: Kisa, Sweden, 2002. [Google Scholar]

- Wang, X.-D. Research of the Low-noise Asphalt Pavement Design. J. Highw. Transp. Res. Dev. 2003, 1, 33–37. [Google Scholar]

- Freitas, E.; Tinoco, J.; Soares, F.; Costa, J.; Cortez, P.; Pereira, P. Modelling tyre-road noise with data mining techniques. Arch. Acoust. 2015, 40, 547–560. [Google Scholar] [CrossRef]

- Freitas, E.F.; Martins, F.F.; Oliveira, A.; Segundo, I.R.; Torres, H. Traffic noise and pavement distresses: Modelling and assessment of input parameters influence through data mining techniques. Appl. Acoust. 2018, 138, 147–155. [Google Scholar] [CrossRef]

- Chen, D.; Ling, C.; Wang, T.; Su, Q.; Ye, A. Prediction of tire-pavement noise of porous asphalt mixture based on mixture surface texture level and distributions. Constr. Build. Mater. 2018, 173, 801–810. [Google Scholar] [CrossRef]

- Cho, D.S.; Mun, S. Study to analyze the effects of vehicles and pavement surface types on noise. Appl. Acoust. 2008, 69, 833–843. [Google Scholar] [CrossRef]

- Wang, X.-D. Design of Pavement Structure and Material for Full-scale Test Track. J. Highw. Transp. Res. Dev. 2017, 34, 30–37. [Google Scholar]

- Sha, A.-M.; Jiang, W. Design Philosophy and Architecture of Eco-friendly Porous Pavement Materials. China J. Highw. Transp. 2018, 31, 1–6. [Google Scholar]

- Cesbron, J.; Klein, P. Correlation between tyre/road noise levels measured by the Coast-By and the Close-Proximity methods. Appl. Acoust. 2017, 126, 36–46. [Google Scholar] [CrossRef]

- Soares, F.; Freitas, E.; Cunha, C.; Silva, C.; Lamas, J.; Mouta, S.; Santos, J. Traffic noise: Annoyance assessment of real and virtual sounds based on close proximity measurements. Transp. Res. Part D Transp. Environ. 2017, 52, 399–407. [Google Scholar] [CrossRef]

- Mioduszewski, P.; Gardziejczyk, W. Inhomogeneity of low-noise wearing courses evaluated by tire/road noise measurements using the close-proximity method. Appl. Acoust. 2016, 111, 58–66. [Google Scholar] [CrossRef]

- Guo, C.-Y.; Shen, G.-H.; Wang, X.-Y.; Li, L.-M. Analysis of Asphalt-rubber Pavement Noise Spectrum with Close-proximity Trailer Method. China J. Highw. Transp. 2012, 25, 22–28. [Google Scholar]

- National Center for Asphalt Technology (NCAT). Tire-Pavement Noise Study for the Michigan Department of Transportation; Michigan Department of Transportation: Lansing, MI, USA, 2003. [Google Scholar]

- Li, T. Influencing parameters on tire–pavement interaction noise: Review, experiments, and design considerations. Designs 2018, 2, 38. [Google Scholar] [CrossRef]

- Sirin, O. State-of-the-art review on sustainable design and construction of quieter pavements—Part 2: Factors affecting tire-pavement noise and prediction models. Sustainability 2016, 8, 692. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Piao, Z.; Kakar, M.R.; Bueno, M.; Athari, S.; Pieren, R.; Heutschi, K.; Poulikakos, L. Low-Noise pavement technologies and evaluation techniques: A literature review. Int. J. Pavement Eng. 2022, 23, 1911–1934. [Google Scholar] [CrossRef]

- Gong, Z.; Miao, Y.; Lantieri, C. Review of research on tire–pavement contact behavior. Coatings 2024, 14, 157. [Google Scholar] [CrossRef]

- Ling, S.; Yu, F.; Sun, D.; Sun, G.; Xu, L. A comprehensive review of tire-pavement noise: Generation mechanism, measurement methods, and quiet asphalt pavement. J. Clean. Prod. 2021, 287, 125056. [Google Scholar] [CrossRef]

- Adrian, X.; Kim, B.-S.; Lee, T.-K.; Cha, H.-D. A Study on the Prediction of Tire/Road Noise. J. Korean Soc. Mech. Technol. 2011, 13, 77–84. [Google Scholar] [CrossRef]

- Rapino, L.; Liu, L.; Dinosio, A.; Ripamonti, F.; Corradi, R.; Baro, S. Processing of tyre data for rolling noise prediction through a statistical modelling approach. Mech. Syst. Signal Process. 2023, 188, 110042. [Google Scholar] [CrossRef]

- Cao, P.; Yan, X.; Xiao, W.; Chen, L. A prediction model to coupling noise of tire tread patterns and road texture. In Logistics: The Emerging Frontiers of Transportation and Development in China; ASCE: New York, NY, USA, 2009; pp. 2332–2338. [Google Scholar]

- Liang, C.; Hao, M.; Shen, Y.; Li, H.; Fan, J. Tire noise prediction based on transfer learning and multi-modal fusion. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2024, 239, 1959–1969. [Google Scholar] [CrossRef]

- Liao, G.; Zha, J.; Lu, X.; Wu, W.; Zhang, W.; Wang, H.; Zhang, Z.; Liu, X. Spectral noise reduction of double-layer porous asphalt: From laboratory to field. Constr. Build. Mater. 2024, 445, 138025. [Google Scholar] [CrossRef]

- Del Pizzo, A.; Teti, L.; Moro, A.; Bianco, F.; Fredianelli, L.; Licitra, G. Influence of texture on tyre road noise spectra in rubberized pavements. Appl. Acoust. 2020, 159, 107080. [Google Scholar] [CrossRef]

- Peng, B.; Han, S.; Han, X.; Zhang, H. Laboratory and field evaluation of noise characteristics of porous asphalt pavement. Int. J. Pavement Eng. 2022, 23, 3357–3370. [Google Scholar] [CrossRef]

- Ganji, M.R.; Ghelmani, A.; Golroo, A.; Sheikhzadeh, H. A brief review on the application of sound in pavement monitoring and comparison of tire/road noise processing methods for pavement macrotexture assessment. Arch. Comput. Methods Eng. 2021, 28, 2977–3000. [Google Scholar] [CrossRef]

| Mix Type | Structure Number (STR) | Coarse Aggregate Content (>4.75 mm, %) | Binder Type | Air Void(%) |

|---|---|---|---|---|

| SAC13-65 | 1, 2, 3, 10, 11, 12, 13, 14, 15 | 65 | SBS I-D | 4.6 |

| SAC13-70 | 4, 5, 6, 7, 8 | 70 | SBS I-D | 5.1 |

| SMA13 | 16, 17, 18, 19 | 75 | SBS I-D | 4.5 |

| PAC13 | 9 | 80 | SBS HV4 | 18.3 |

| Test Variables | Parameters |

|---|---|

| Speed | 40 km/h, 60 km/h, 80 km/h |

| Tire texture | 1#, 2#, 3# |

| Trailer weight | 300 kg, 400 kg, 500 kg |

| Tire No. | Multiple-Linear-Regression Model | R2 |

|---|---|---|

| 1# | 0.982 | |

| 2# | 0.975 | |

| 3# | 0.984 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, G.; Wang, X.; Chen, L.; Dong, Z. Study on Influencing Factors and Spectrum Characteristics of Tire/Road Noise of RIOHTrack Full-Scale Test Road Based on CPXT Method. Appl. Sci. 2025, 15, 9741. https://doi.org/10.3390/app15179741

Yang G, Wang X, Chen L, Dong Z. Study on Influencing Factors and Spectrum Characteristics of Tire/Road Noise of RIOHTrack Full-Scale Test Road Based on CPXT Method. Applied Sciences. 2025; 15(17):9741. https://doi.org/10.3390/app15179741

Chicago/Turabian StyleYang, Guang, Xudong Wang, Liuxiao Chen, and Zejiao Dong. 2025. "Study on Influencing Factors and Spectrum Characteristics of Tire/Road Noise of RIOHTrack Full-Scale Test Road Based on CPXT Method" Applied Sciences 15, no. 17: 9741. https://doi.org/10.3390/app15179741

APA StyleYang, G., Wang, X., Chen, L., & Dong, Z. (2025). Study on Influencing Factors and Spectrum Characteristics of Tire/Road Noise of RIOHTrack Full-Scale Test Road Based on CPXT Method. Applied Sciences, 15(17), 9741. https://doi.org/10.3390/app15179741