Multi-Scale Electromechanical Impedance-Based Bolt Loosening Identification Using Attention-Enhanced Parallel CNN

Abstract

1. Introduction

2. Materials and Methods

2.1. Theoretical Background of EMI-Based Technique

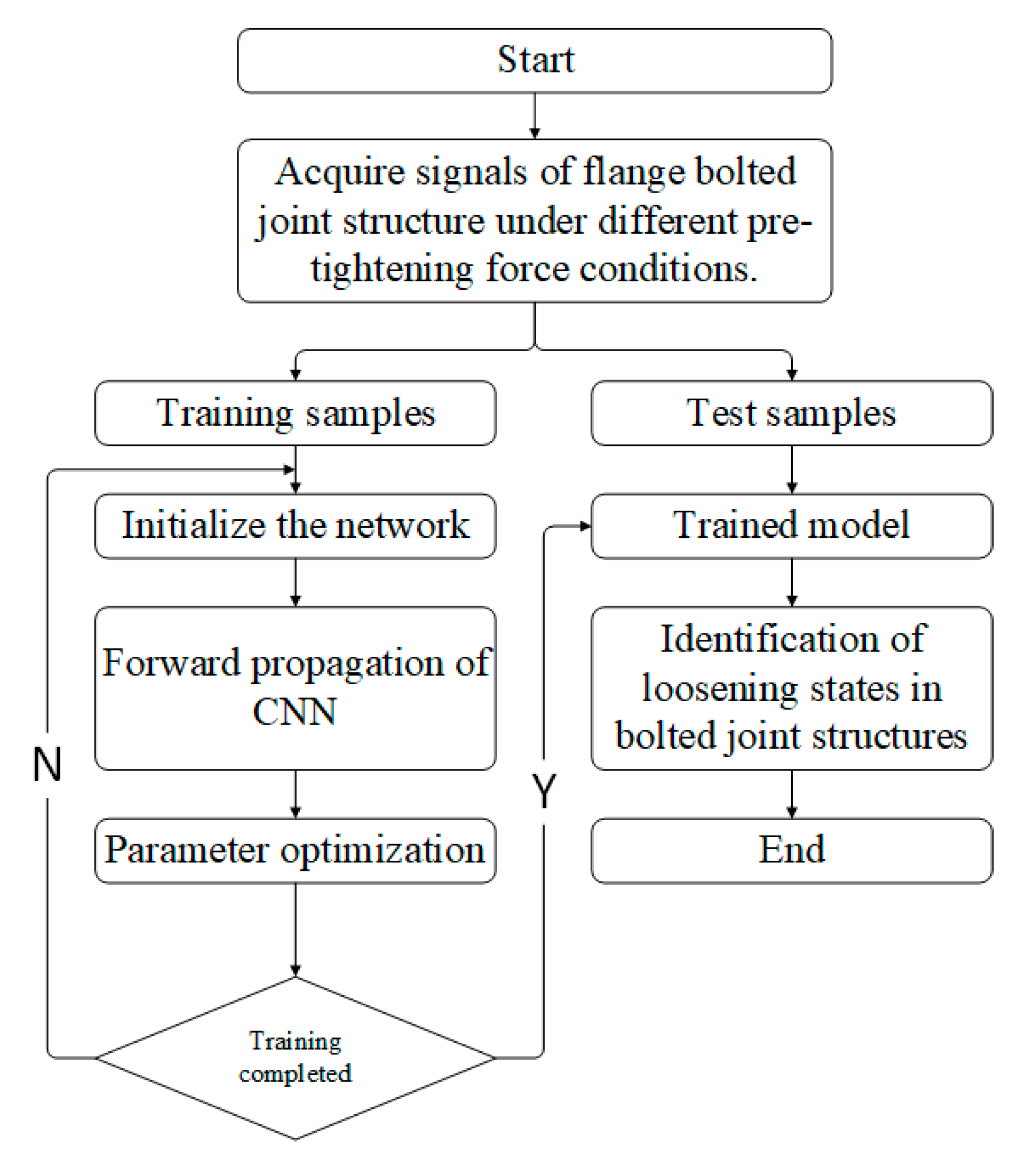

2.2. Proposed Bolt Loosening Identification Method Using EMI Data

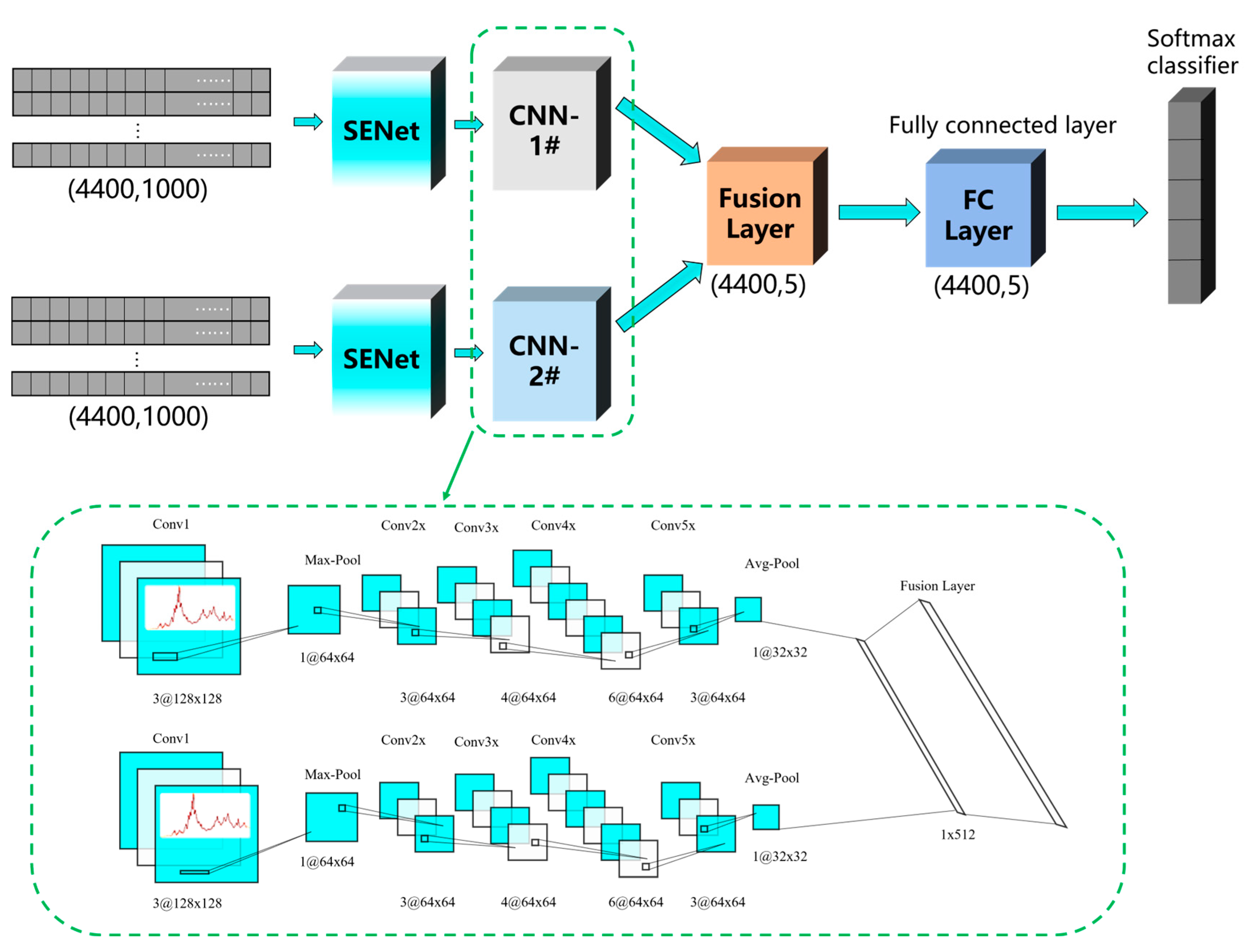

2.2.1. Architecture of the Proposed Dual Parallel Channels Convolutional Neural Network

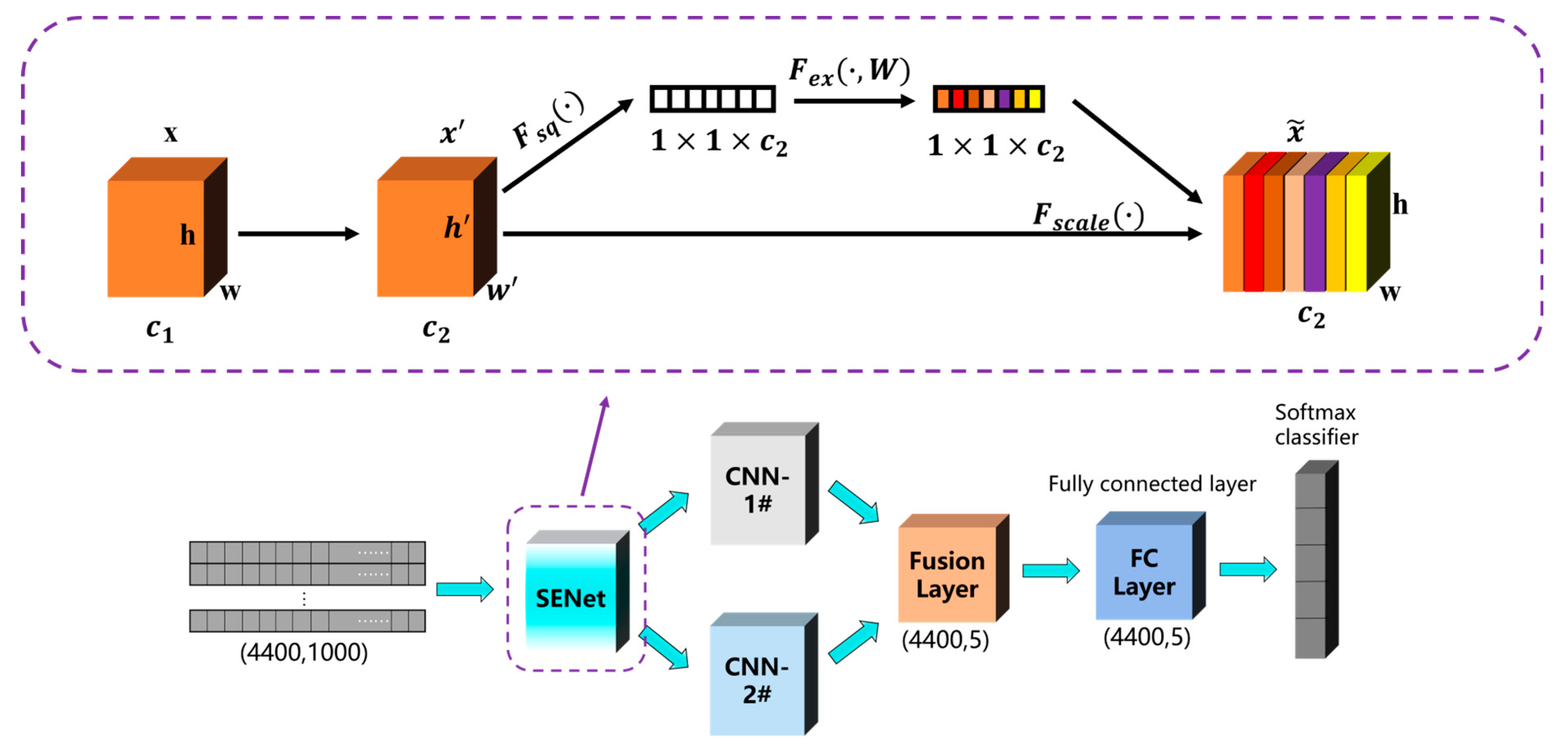

2.2.2. Channel Attention Module (SENet)

2.2.3. Hyperparameter Determination of the P-CNN Model

- (1)

- Batch Size

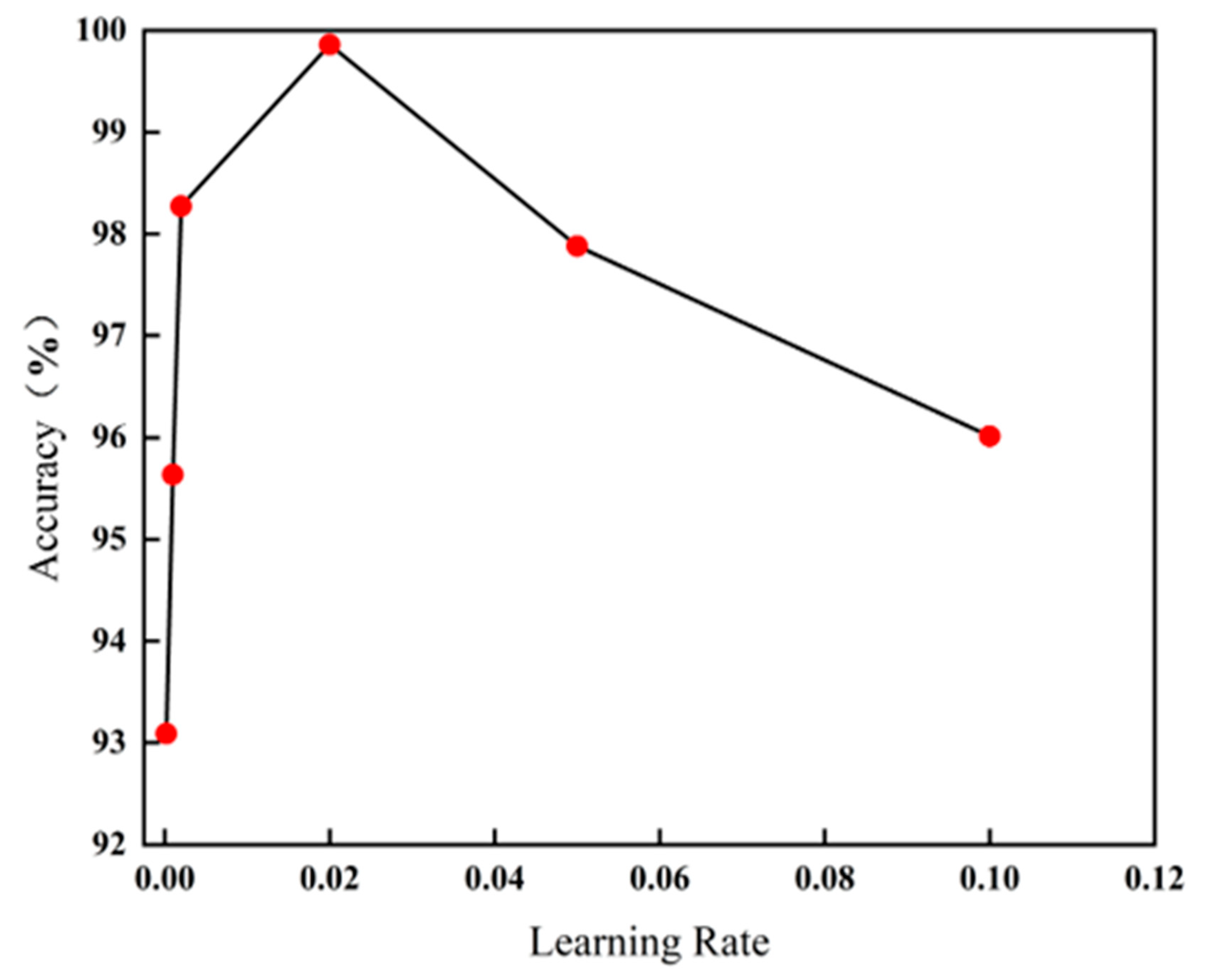

- (2)

- Learning Rate

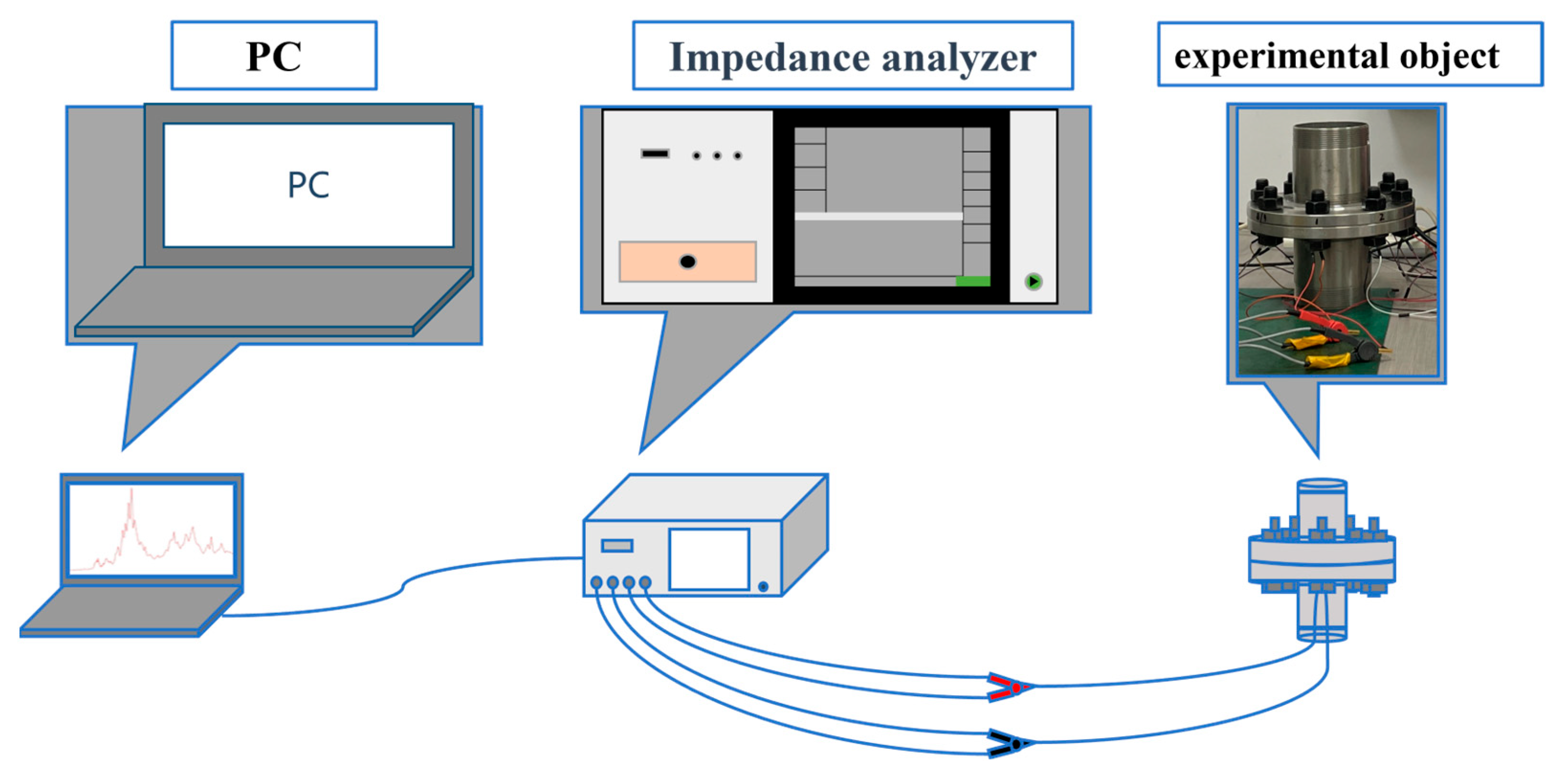

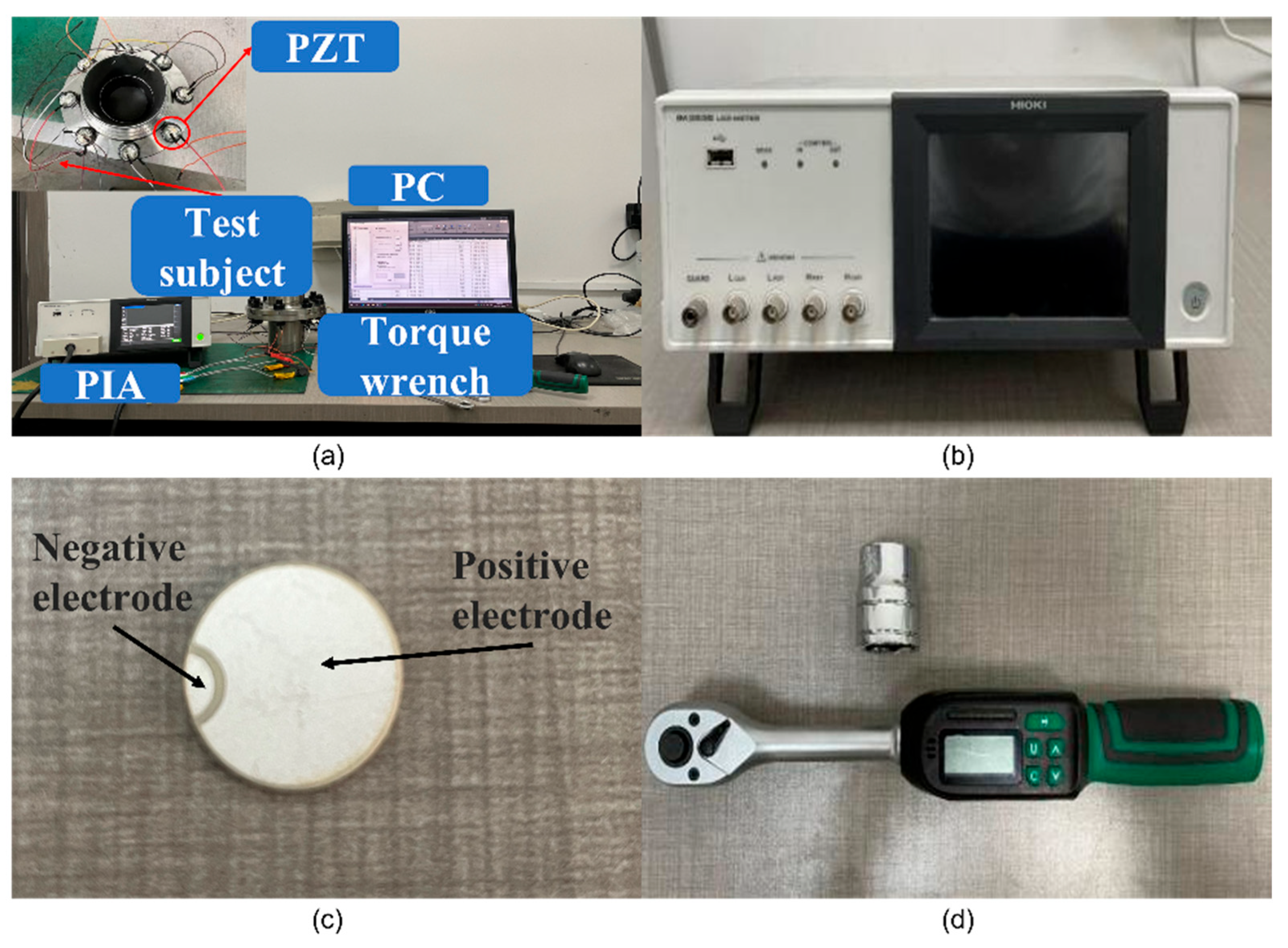

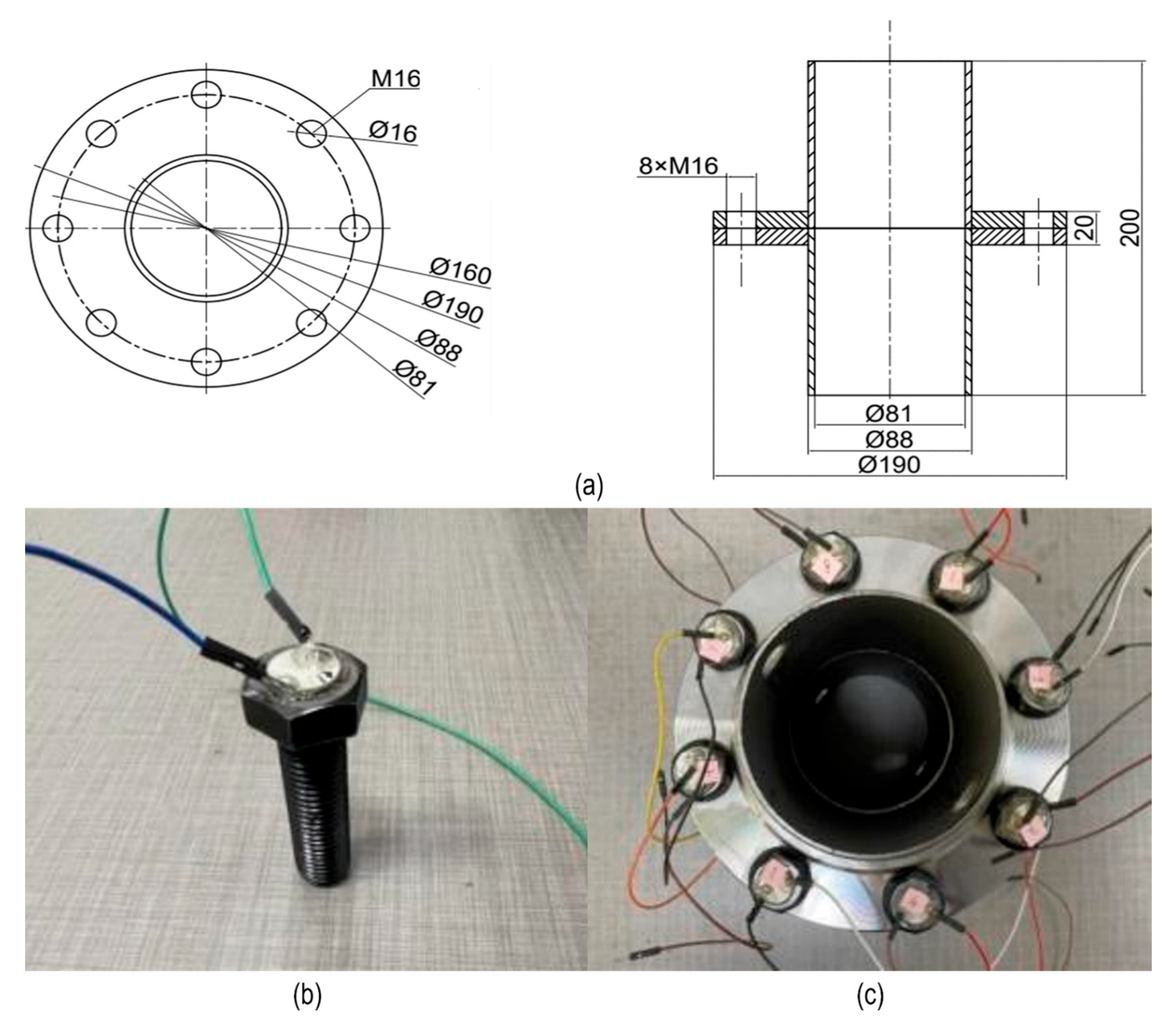

2.2.4. Experimental Configuration

- (1).

- Initial Configuration: All bolts were uniformly torqued to 50 N·m and rested for 5 min to stabilize.

- (2).

- Preload Variation on Bolt #1: Bolt #1 was fully loosened and re-tightened to 50 N·m for baseline testing. Then, its preload was reduced stepwise to 10 N·m in 10 N·m increments. After each adjustment, a 5 min rest period was applied, followed by impedance data acquisition.

- (3).

- Sequential Testing: Step 2 was repeated for bolts #2 through #8 to ensure full coverage.

- (4).

- Repeatability Check: After all bolts were unloaded, the entire test process was repeated the following day to verify data repeatability.

- (5).

- Data Management: All acquired admittance signals were saved and analyzed to ensure signal consistency and experimental reproducibility.

3. Results

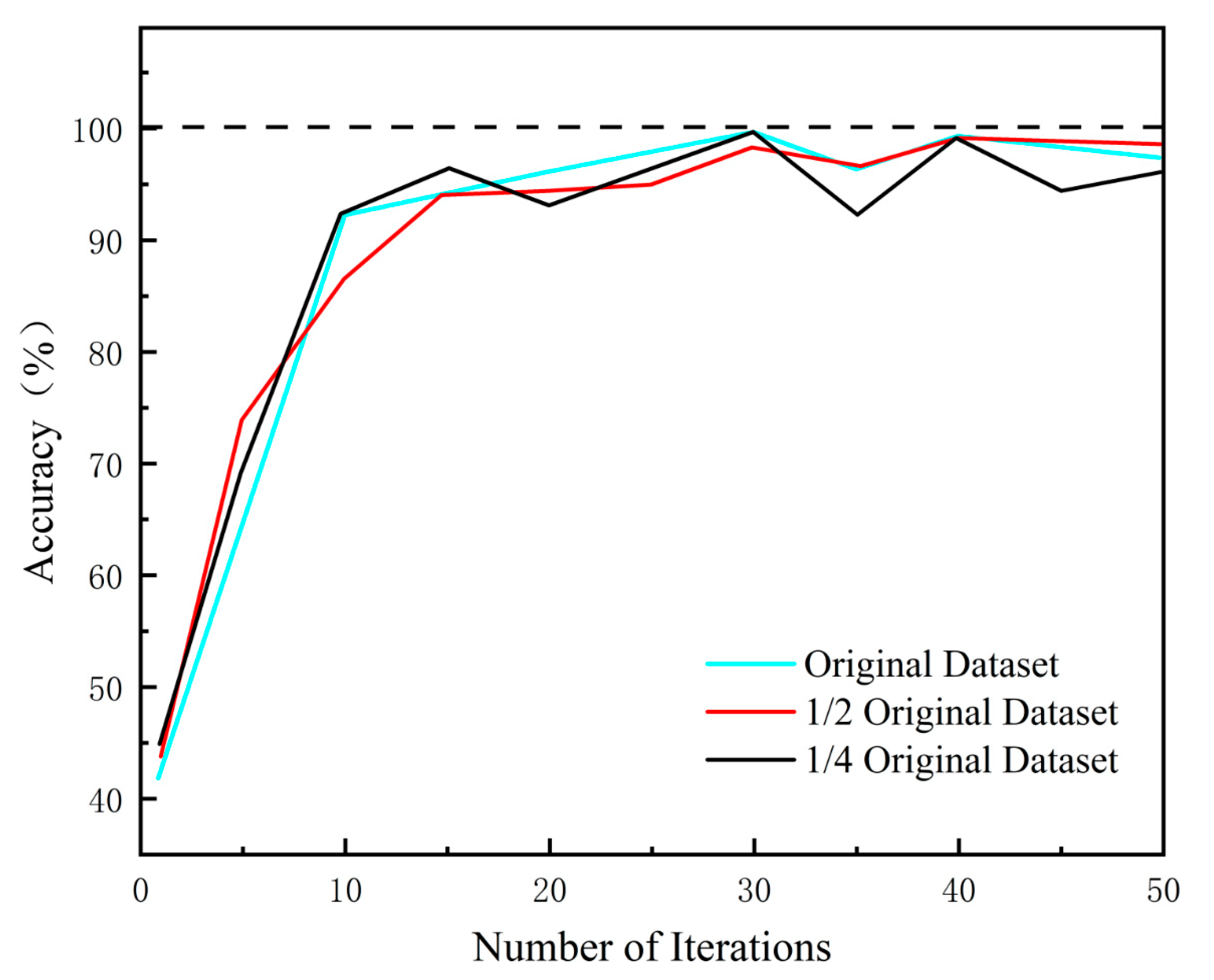

3.1. Hyperparameter Optimization Results

- (1)

- Batch size

- (2)

- Learning rate

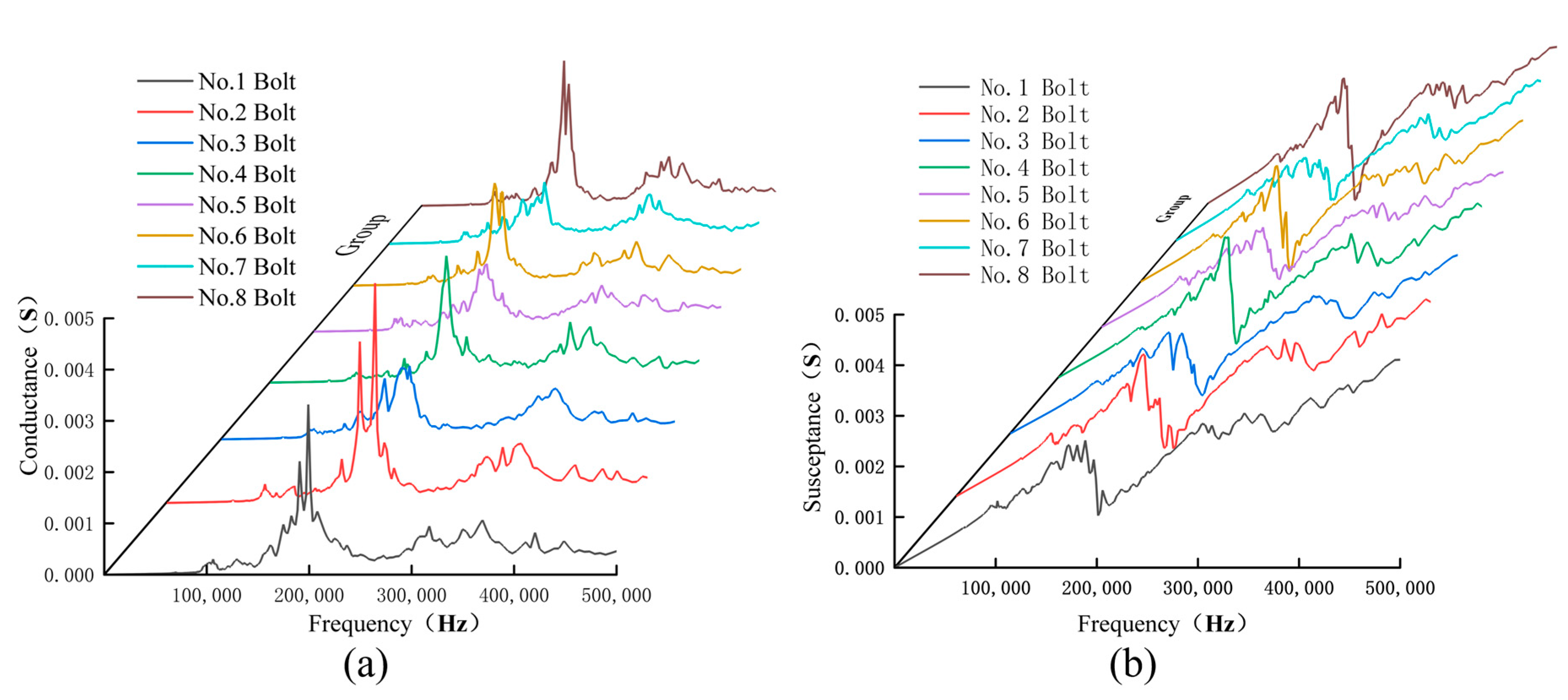

3.2. Experiment Results

3.3. Comparative Analysis with Conventional CNN

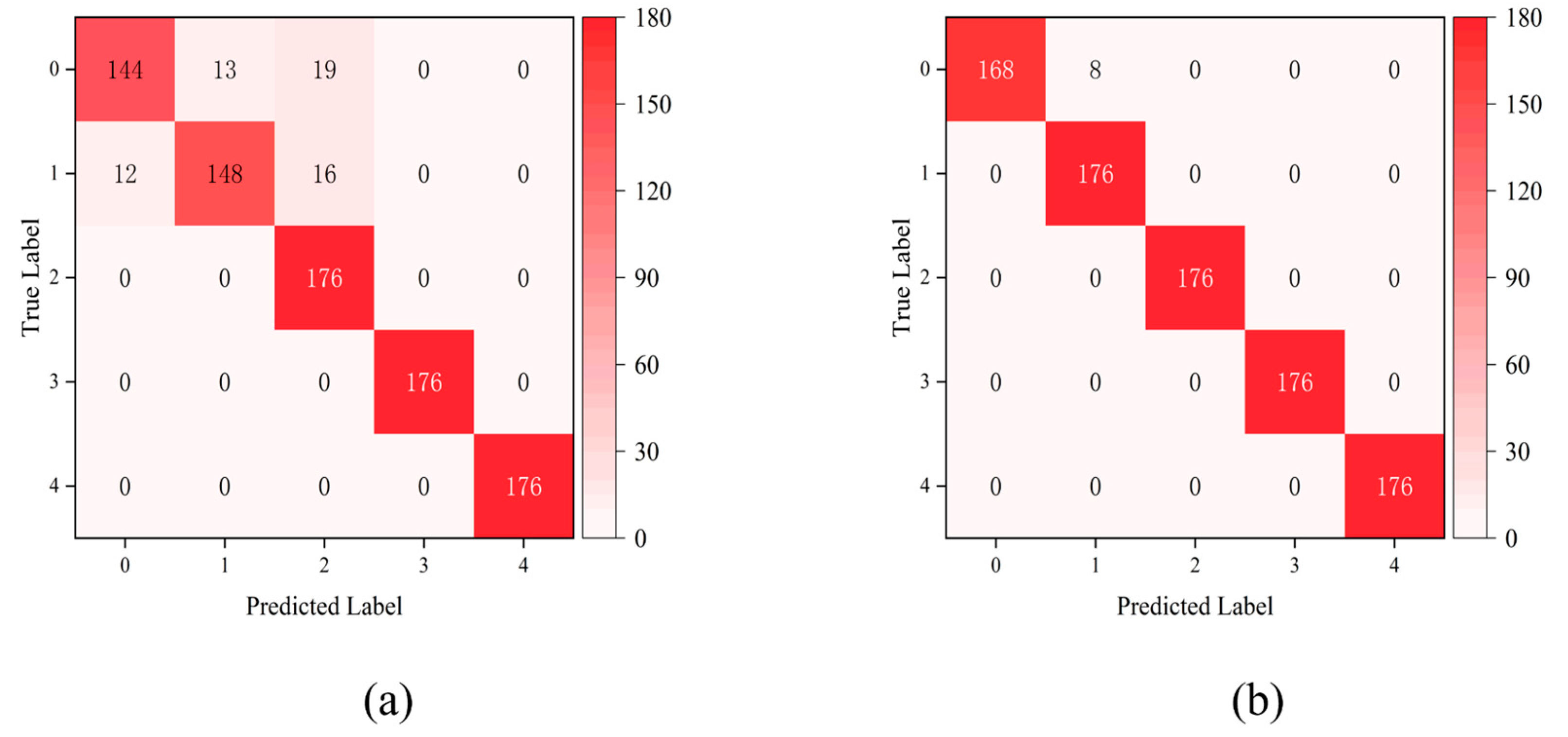

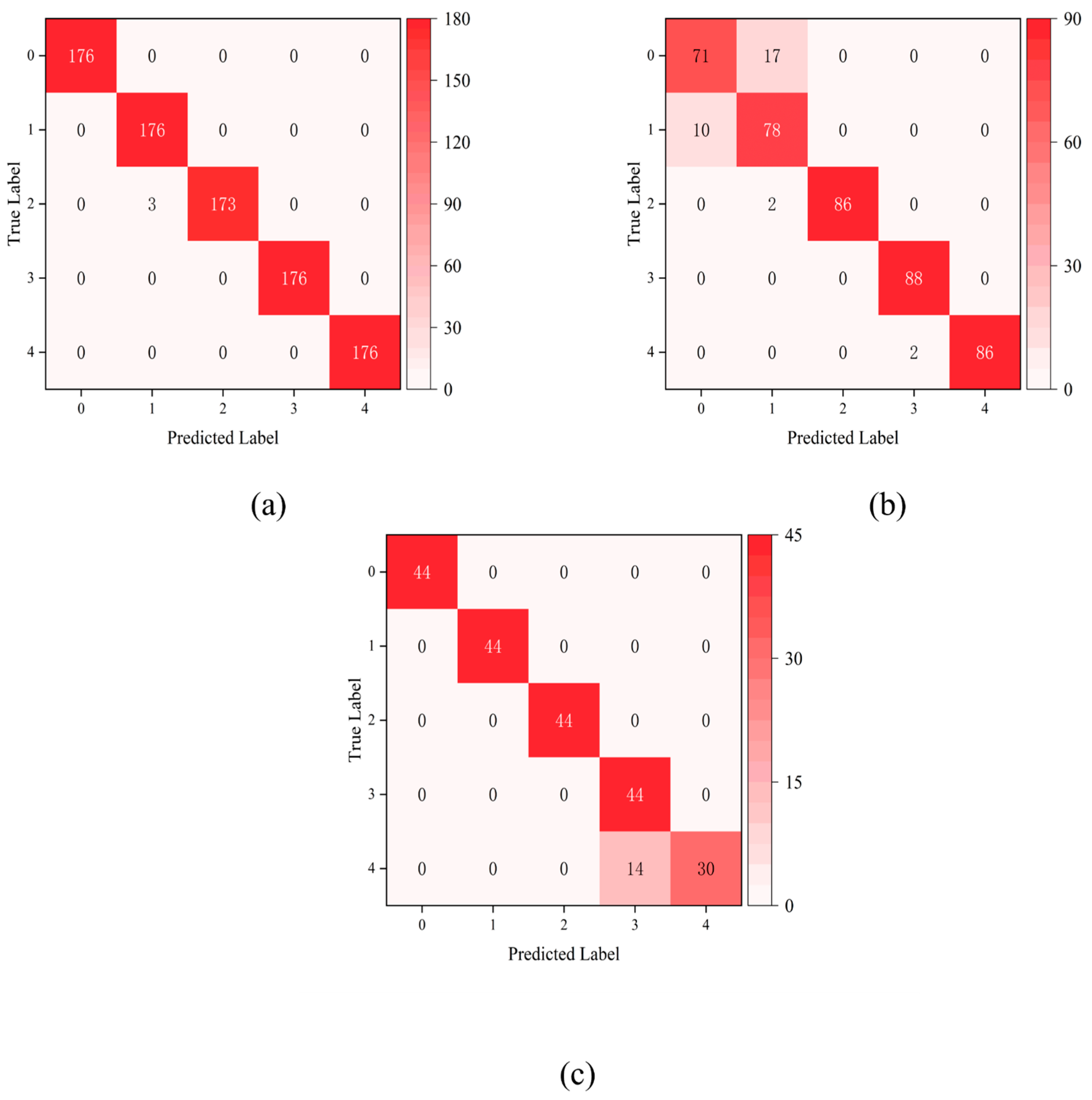

3.4. Confusion Matrix Analysis

4. Discussion

5. Conclusions

- The method combines multi-scale convolutional feature extraction and channel attention mechanisms to monitor changes in bolt preload by analyzing the changes in the electrical admittance spectra of surface-mounted piezoelectric sensors. A wide excitation frequency range of 10–400 KHz is selected to capture key signal changes related to bolt loosening, such as resonance peak shifts and amplitude attenuations.

- The method innovatively employs a dual-branch multi-scale convolutional strategy. It uses convolutional kernels of sizes 1 × 3 and 1 × 7 to extract local and global frequency–domain features, respectively. Dilated convolutions are applied to enhance the long-range receptive field. Moreover, a channel attention module based on SENet is embedded to adaptively recalibrate the importance of the learned frequency bands. This approach helps to mitigate the limitations of traditional CNNs in capturing weak damage signals.

- Under laboratory-scale bolted flange connections, the P-CNN achieved a classification accuracy of 99.86% across different preload levels (50–10 N m), which is 11.65% higher than that of traditional CNN models. Even with only 25% of the original training data, the model still maintained an accuracy of 95.4%, demonstrating strong robustness and generalization ability under data-scarce conditions. By combining electromagnetic impedance techniques with data-driven learning, this method effectively decouples multi-scale signal features related to connection stiffness degradation, providing a highly sensitive and scalable solution for bolt health monitoring. It also represents a significant advancement in the practical deployment of electromagnetic impedance-based methods in complex engineering environments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EMI | Electro-mechanical impedance |

| PZT | Lead zirconate titanate |

| SHM | Structural health monitoring |

| NDT | Non-destructive testing |

| CNN | Convolutional neural network |

| P-CNN | Multi-scale dual-core parallel convolutional neural network |

| SENet | Squeeze-and-Excitation Network |

References

- Wang, Y.-Q.; Wu, J.-K.; Liu, H.-B.; Kuang, K.; Cui, X.-W.; Han, L.-S. Analysis of elastic interaction stiffness and its effect on bolt preloading. Int. J. Mech. Sci. 2017, 130, 307–314. [Google Scholar] [CrossRef]

- Na, W.S.; Baek, J. A review of the piezoelectric electromechanical impedance based structural health monitoring technique for engineering structures. Sensors 2018, 18, 1307. [Google Scholar] [CrossRef]

- Huda, F.; Kajiwara, I.; Hosoya, N.; Kawamura, S. Bolt loosening analysis and diagnosis by non-contact laser excitation vibration tests. Mech. Syst. Signal Process. 2013, 40, 589–604. [Google Scholar] [CrossRef]

- Miao, R.; Shen, R.; Zhang, S.; Xue, S. A review of bolt tightening force measurement and loosening detection. Sensors 2020, 20, 3165. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Song, G.; Wang, Z.; Li, Y. Proof-of-concept study of monitoring bolt connection status using a piezoelectric based active sensing method. Smart Mater. Struct. 2013, 22, 087001. [Google Scholar] [CrossRef]

- Wang, F.; Chen, Z.; Song, G. Monitoring of multi-bolt connection looseness using entropy-based active sensing and genetic algorithm-based least square support vector machine. Mech. Syst. Signal Process. 2020, 136, 106507. [Google Scholar] [CrossRef]

- Li, D.; Nie, J.-H.; Wang, H.; Ren, W.-X. Loading condition monitoring of high-strength bolt connections based on physics-guided deep learning of acoustic emission data. Mech. Syst. Signal Process. 2024, 206, 110908. [Google Scholar] [CrossRef]

- Kaye, A. Undertaking bolted joint integrity management: Getting to zero leaks quickly and effectively. In Proceedings of the Pressure Vessels and Piping Conference, Vancouver, BC, Canada, 17–21 July 2016; American Society of Mechanical Engineers: Two Park Avenue, NY, USA, 2016; Volume 50398, p. V003T03A010. [Google Scholar]

- Deka, A.; Rao, A.N.; Kamath, S.R.; Anmol, G.; Gangadharan, K.V. Bolted lap joint structure: Structural health monitoring using damping ratio as indicator. In Proceedings of the 2nd Mechanical Engineering Graduate Research Symposium, Mumbai, India, 21 March 2015; IIT Mumbai: Mumbai, India, 2015. [Google Scholar]

- Liu, H.; Sun, W.; Du, D.; Liu, X. Modeling and free vibration analysis for bolted composite plate under inconsistent pre-tightening condition. Compos. Struct. 2022, 292, 115634. [Google Scholar] [CrossRef]

- Wang, F.; Ho, S.C.M.; Huo, L.; Song, G. A novel fractal contact-electromechanical impedance model for quantitative monitoring of bolted joint looseness. IEEE Access 2018, 6, 40212–40220. [Google Scholar] [CrossRef]

- Parvasi, S.M.; Ho, S.C.M.; Kong, Q.; Mousavi, R.; Song, G. Real time bolt preload monitoring using piezoceramic transducers and time reversal technique—A numerical study with experimental verification. Smart Mater. Struct. 2016, 25, 085015. [Google Scholar] [CrossRef]

- Yin, H.; Wang, T.; Yang, D.; Liu, S.; Shao, J.; Li, Y. A smart washer for bolt looseness monitoring based on piezoelectric active sensing method. Appl. Sci. 2016, 6, 320. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, H.; Liao, Y.; Su, Z.; Xiao, Y. Vibro-acoustic modulation (VAM)-inspired structural integrity monitoring and its applications to bolted composite joints. Compos. Struct. 2017, 176, 505–515. [Google Scholar] [CrossRef]

- Kong, Q.; Zhu, J.; Ho, S.C.M.; Song, G. Tapping and listening: A new approach to bolt looseness monitoring. Smart Mater. Struct. 2018, 27, 07LT02. [Google Scholar] [CrossRef]

- Wang, F.; Song, G. Bolt-looseness detection by a new percussion-based method using multifractal analysis and gradient boosting decision tree. Struct. Health Monit. 2020, 19, 2023–2032. [Google Scholar] [CrossRef]

- Tenreiro, A.F.G.; Lopes, A.M.; da Silva, L.F.M. A review of structural health monitoring of bonded structures using electromechanical impedance spectroscopy. Struct. Health Monit. 2022, 21, 228–249. [Google Scholar] [CrossRef]

- Cao, P.; Zhang, S.; Wang, Z.; Zhou, K. Damage identification using piezoelectric electromechanical impedance: A brief review from a numerical framework perspective. Structures 2023, 50, 1906–1921. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, S.X.; Ni, Y.Q.; Choy, A.W.H. EMI-GCN: A hybrid model for real-time monitoring of multiple bolt looseness using electromechanical impedance and graph convolutional networks. Smart Mater. Struct. 2021, 30, 035032. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Bhalla, S.; Soh, C.K. Structural identification and damage diagnosis using self-sensing piezo-impedancetransducers. Smart Mater. Struct. 2006, 15, 987. [Google Scholar] [CrossRef]

- Ai, D.; Luo, H.; Wang, C.; Zhu, H. Monitoring of the load-induced RC beam structural tension/compression stress and damage using piezoelectric transducers. Eng. Struct. 2018, 154, 38–51. [Google Scholar] [CrossRef]

- Bois, C.; Hochard, C. Monitoring of laminated composites delamination based on electro-mechanical impedance measurement. J. Intell. Mater. Syst. Struct. 2004, 15, 59–67. [Google Scholar] [CrossRef]

- Ai, D.; Zhang, R. Deep learning of electromechanical admittance data augmented by generative adversarial networks for flexural performance evaluation of RC beam structure. Eng. Struct. 2023, 296, 116891. [Google Scholar] [CrossRef]

- Martowicz, A.; Sendecki, A.; Salamon, M.; Rosiek, M.; Uhl, T. Application of electromechanical impedance-based SHM for damage detection in bolted pipeline connection. Nondestruct. Test. Eval. 2016, 31, 17–44. [Google Scholar] [CrossRef]

- Wang, L.; Yuan, B.; Xu, Z.; Sun, Q. Synchronous detection of bolts looseness position and degree based on fusing electro-mechanical impedance. Mech. Syst. Signal Process. 2022, 174, 109068. [Google Scholar] [CrossRef]

- Huo, L.; Chen, D.; Liang, Y.; Li, H.; Feng, X.; Song, G. Impedance based bolt pre-load monitoring using piezoceramic smart washer. Smart Mater. Struct. 2017, 26, 057004. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Ta, Q.B.; Ho, D.D.; Kim, J.T.; Huynh, T.C. A method for automated bolt-loosening monitoring and assessment using impedance technique and deep learning. Dev. Built Environ. 2023, 14, 100122. [Google Scholar] [CrossRef]

- Luo, W.; Liu, T.; Li, W.; Luo, M. Pitting corrosion prediction based on electromechanical impedance and convolutional neural networks. Struct. Health Monit. 2023, 22, 1647–1664. [Google Scholar] [CrossRef]

- Li, G.; Luo, M.; Huang, J.; Li, W. Early-age concrete strength monitoring using smart aggregate based on electromechanical impedance and machine learning. Mech. Syst. Signal Process. 2023, 186, 109865. [Google Scholar] [CrossRef]

- de Rezende, S.W.F.; Moura, J.d.R.V.d.; Neto, R.M.F.; Gallo, C.A.; Steffen, V. Convolutional neural network and impedance-based SHM applied to damage detection. Eng. Res. Express 2020, 2, 035031. [Google Scholar] [CrossRef]

- Du, F.; Wu, S.; Xu, C.; Yang, Z.; Su, Z. Electromechanical impedance temperature compensation and bolt loosening monitoring based on modified Unet and multitask learning. IEEE Sens. J. 2021, 23, 4556–4567. [Google Scholar] [CrossRef]

- Ai, D.; Cheng, J. A deep learning approach for electromechanical impedance based concrete structural damage quantification using two-dimensional convolutional neural network. Mech. Syst. Signal Process. 2023, 183, 109634. [Google Scholar] [CrossRef]

- Ghaderiaram, A.; Schlangen, E.; Fotouhi, M. Structural Fatigue Life Monitoring with Piezoelectric-Based Sensors: Fundamentals, Current Advances, and Future Directions. Sensors 2025, 25, 334. [Google Scholar] [CrossRef]

- Zu, K.; Zhu, J.; Haardt, M. Uplink Multi—User MIMO Detection via Parallel Access. In Proceedings of the ICASSP 2019 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Brighton, UK, 12–17 May 2019; pp. 4365–4369. [Google Scholar]

- Guo, H.; Zhong, J.; Feng, B.; Chen, Y.; Zhong, S. Detection Method for Bolt Loosening Based on Summation Coefficient of Absolute Spectrum Ratio. Sensors 2025, 25, 246. [Google Scholar] [CrossRef]

- Liang, C.; Sun, F.P.; Rogers, C.A. An impedance method for dynamic analysis of active material systems. J. Vib. Acoust. 1994, 116, 120–128. [Google Scholar] [CrossRef]

- Ju, M.; Dou, Z.; Li, J.-W.; Qiu, X.; Shen, B.; Zhang, D.; Yao, F.-Z.; Gong, W.; Wang, K. Piezoelectric materials and sensors for structural health monitoring: Fundamental aspects, current status, and future perspectives. Sensors 2023, 23, 543. [Google Scholar] [CrossRef]

- Park, G.; Inman, D.J. Impedance-Based Structural Health Monitoring. In Damage Prognosis: For Aerospace, Civil and Mechanical Systems; Wiley: Hoboken, NJ, USA, 2005; pp. 275–292. [Google Scholar]

| Evaluation Criteria | Traditional CNN | D-CNN | P-CNN |

|---|---|---|---|

| Epoch (times) | 50 | 50 | 50 |

| Iteration time (s) | 40.8 | 88.2 | 76.9 |

| Accuracy (%) | 88.21 | 94.66 | 99.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, X.; Kong, J.; Wang, H.; Huang, K.; Zhao, T.; Li, L. Multi-Scale Electromechanical Impedance-Based Bolt Loosening Identification Using Attention-Enhanced Parallel CNN. Appl. Sci. 2025, 15, 9715. https://doi.org/10.3390/app15179715

Fan X, Kong J, Wang H, Huang K, Zhao T, Li L. Multi-Scale Electromechanical Impedance-Based Bolt Loosening Identification Using Attention-Enhanced Parallel CNN. Applied Sciences. 2025; 15(17):9715. https://doi.org/10.3390/app15179715

Chicago/Turabian StyleFan, Xingyu, Jiaming Kong, Haoyang Wang, Kexin Huang, Tong Zhao, and Lu Li. 2025. "Multi-Scale Electromechanical Impedance-Based Bolt Loosening Identification Using Attention-Enhanced Parallel CNN" Applied Sciences 15, no. 17: 9715. https://doi.org/10.3390/app15179715

APA StyleFan, X., Kong, J., Wang, H., Huang, K., Zhao, T., & Li, L. (2025). Multi-Scale Electromechanical Impedance-Based Bolt Loosening Identification Using Attention-Enhanced Parallel CNN. Applied Sciences, 15(17), 9715. https://doi.org/10.3390/app15179715