Impact of Calefaction and AdBlue Atomization by Magneto-Strictive and Piezoelectric Phenomena on NOx in SCR Systems for Diesel Engines

Abstract

1. Introduction

2. Materials and Methods

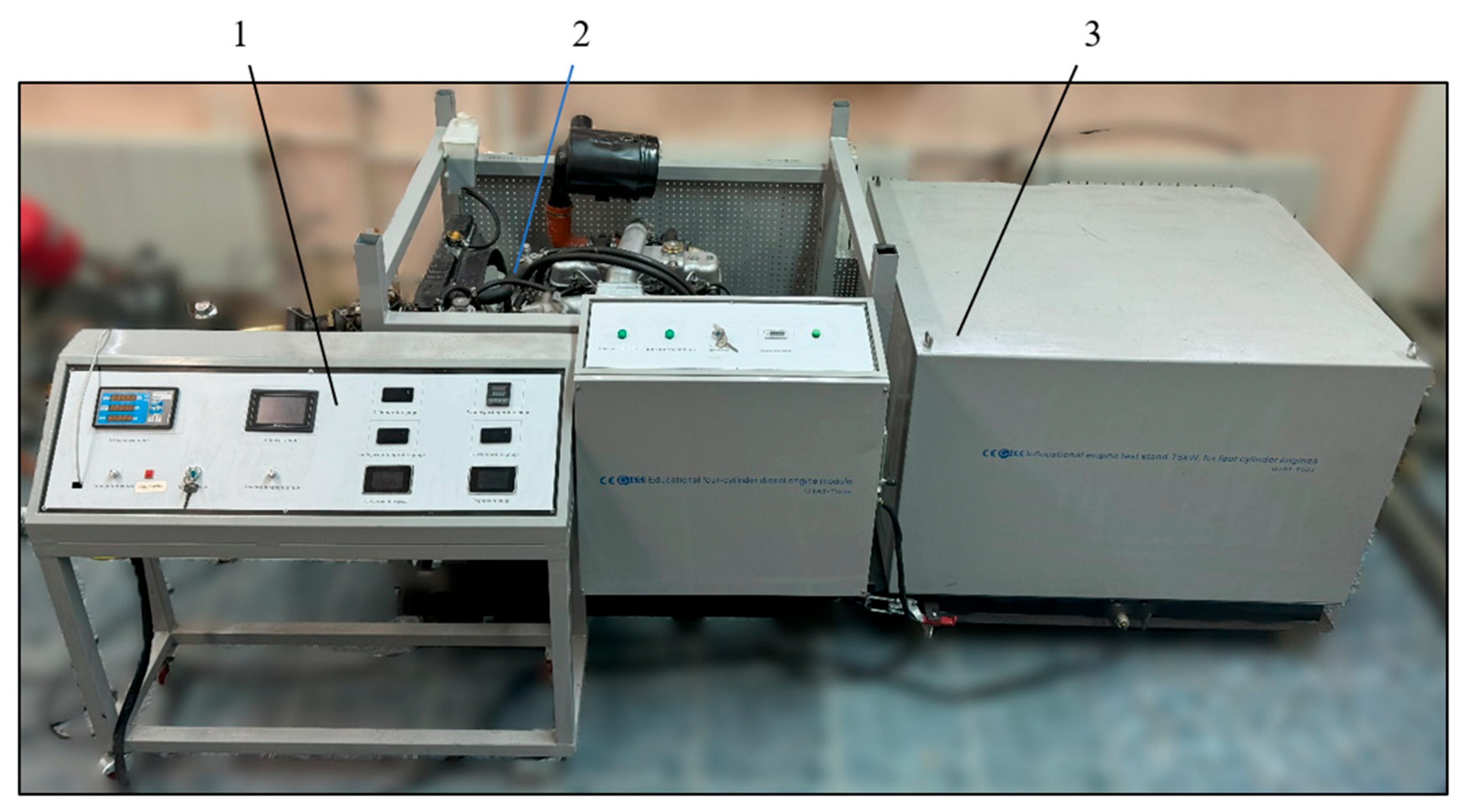

2.1. Experimental Setup

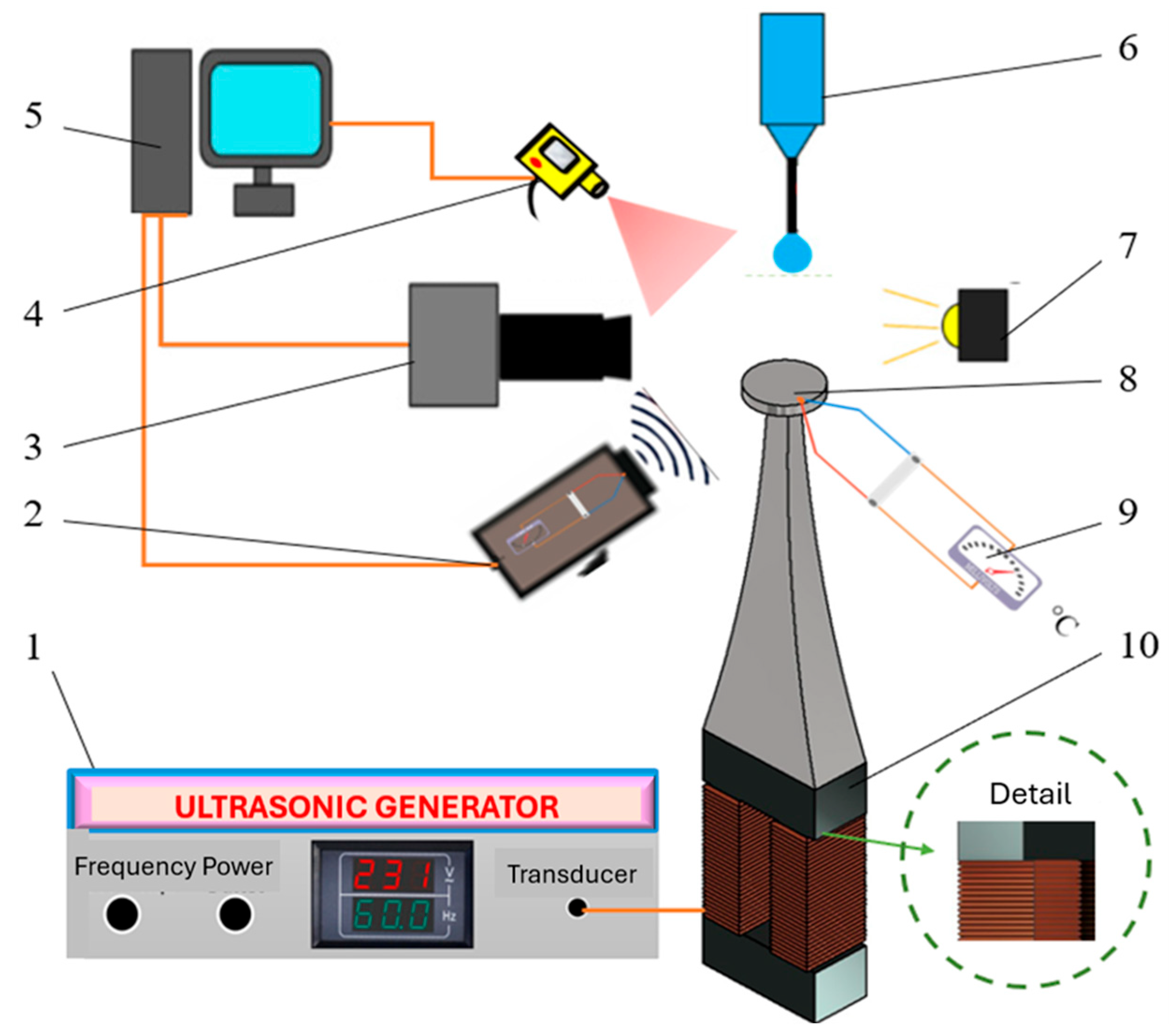

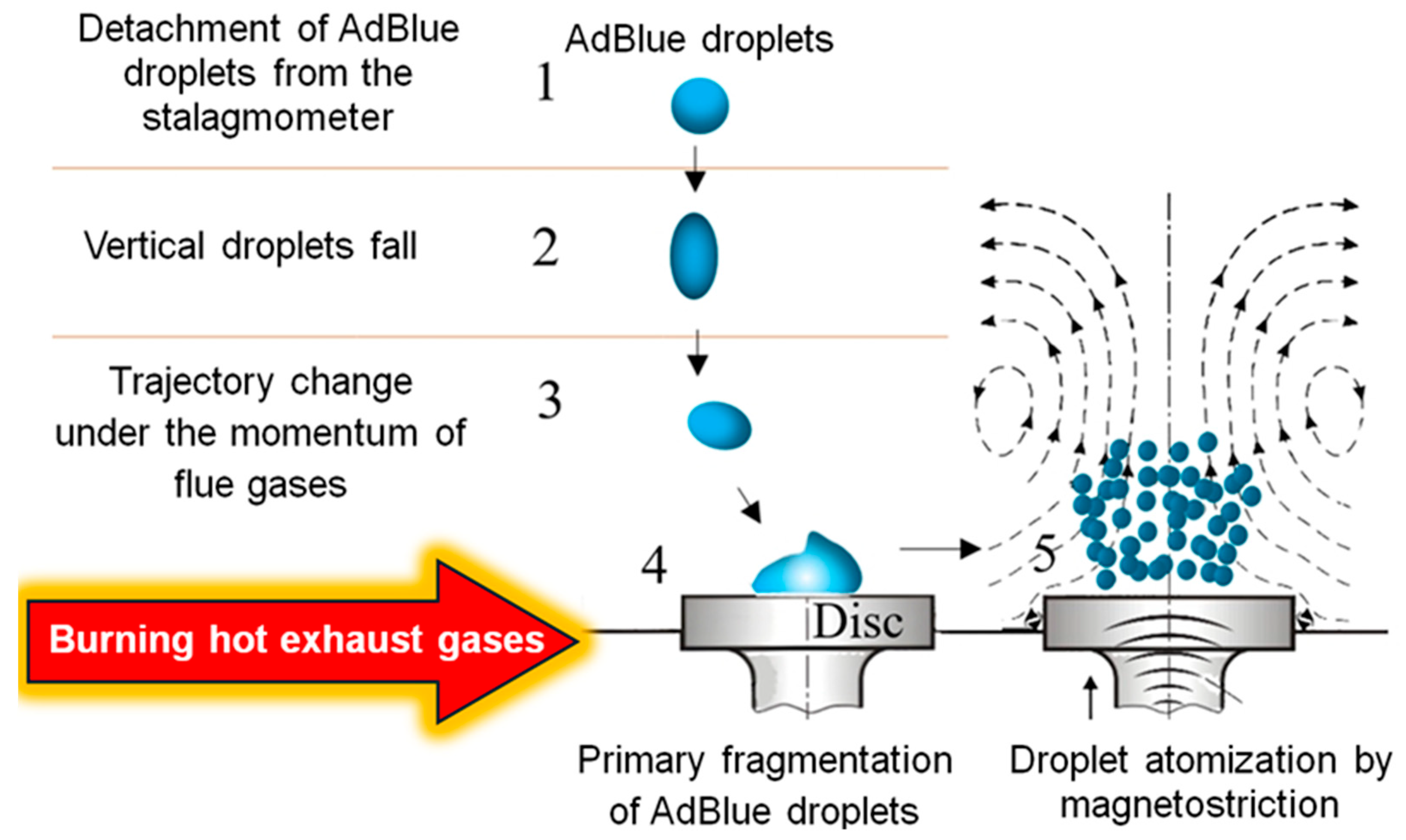

2.2. New AdBlue Solution Atomization Enhancement Techniques Applicable to SCR Systems

2.2.1. Calefaction Using the Magnetostrictive Principle

2.2.2. Implementation of Piezoelectric Cells for the Generation of AdBlue Micro Droplets in SCR Systems

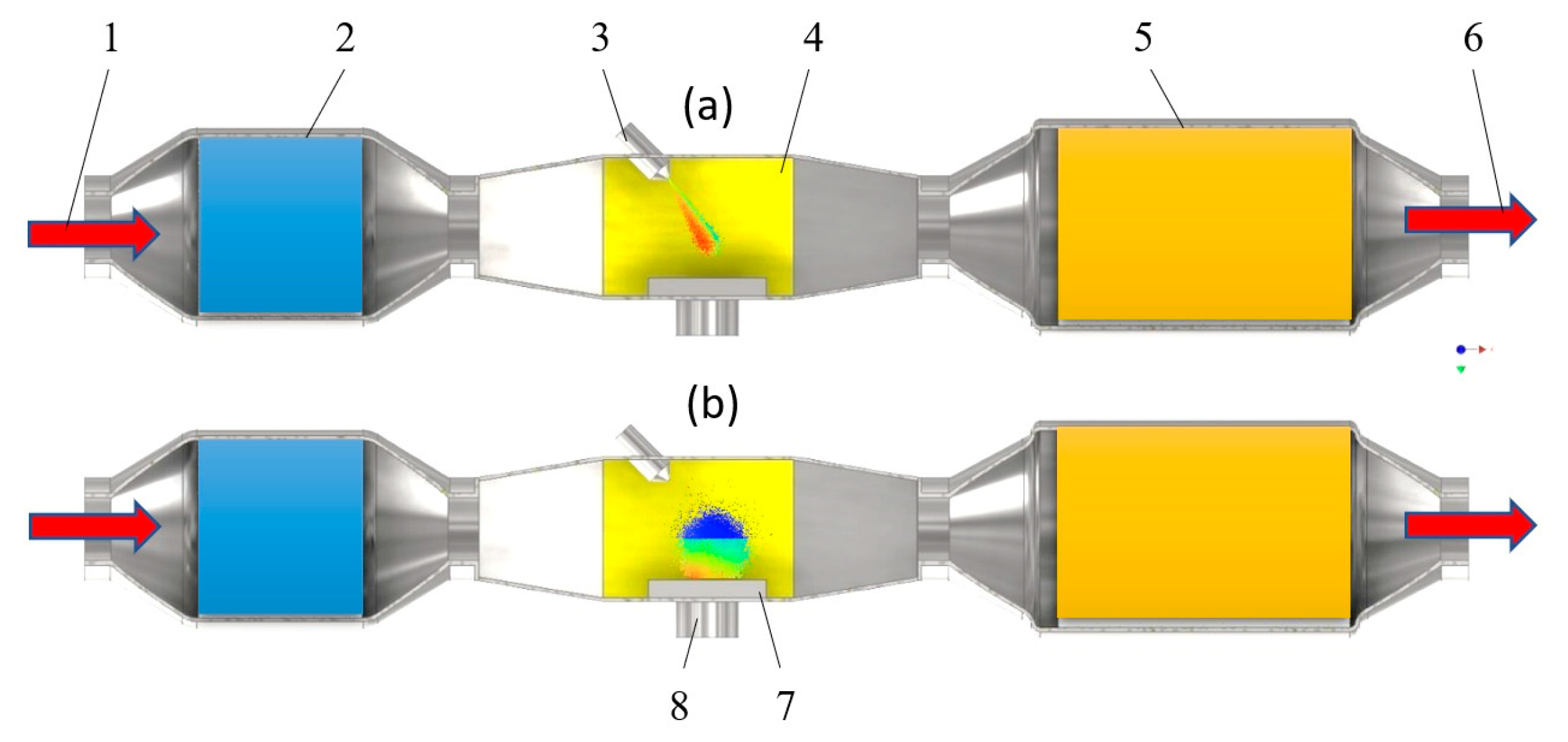

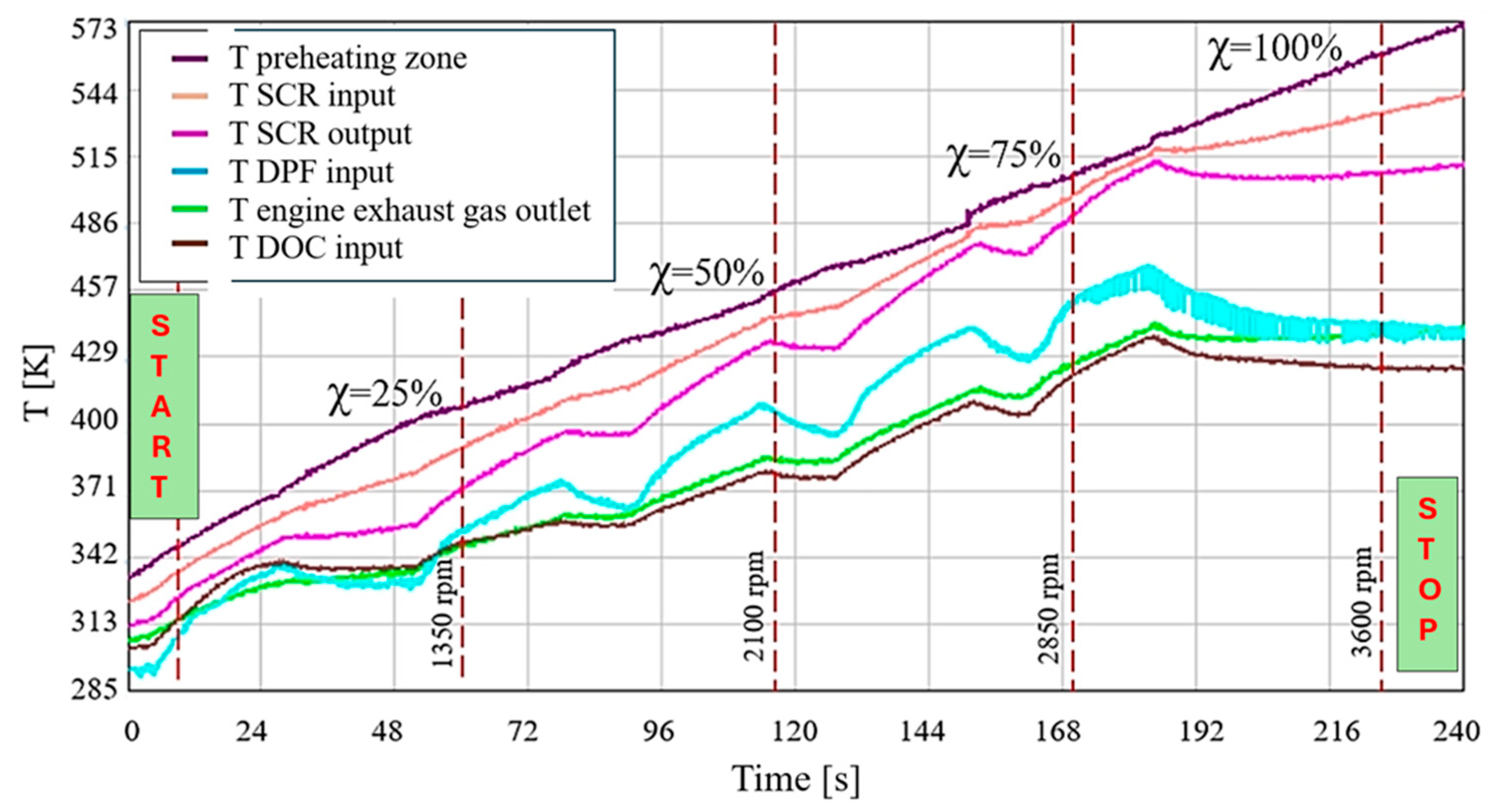

2.3. Use of Exhaust Gas Preheating Before the Selective Catalytic Reduction Stage

2.4. Design of Experiments Used for the Determination of NOx on the IZUZU 4JB1 Engine Using or Not an SCR System

3. Results and Discussion

- -

- an ultrasonic magnetostrictive concentrator;

- -

- piezoelectric AdBlue vapor generation cells;

- -

- an ejector to transport and mix the droplets with exhaust gases; and

- -

- an inductive preheating system with a metal honeycomb located upstream of the SCR catalyst;

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol/Abbreviation | Definition |

| AdBlue | Aqueous urea solution (32.5% urea, 67.5% deionized water) used in SCR systems |

| DOC | Diesel Oxidation Catalyst |

| DPF | Diesel Particulate Filter |

| SCR | Selective catalytic Reduction |

| NOx | Nitrogen oxides (NO + NO2) |

| SMD | Sauter Mean Diameter (characteristic droplet size of droplets) |

| μm | Micrometer (10−6 m) |

| ppm | Parts per million |

| rpm | Revolutions per minute |

| χ | Engine load coefficient (%) |

| K | Kelvin (absolute temperature) |

| s | Second |

| ISUZU 4JB1 | Experimental diesel engine model used in tests |

| DSC | Differential Scanning Calorimeter |

| SEM | Scanning Electron Microscope |

| CWM | Confocal White Light Microscope |

| IR | Infrared (camera) |

| Calefaction | Phenomenon in which a liquid droplet forms a vapor layer when contacting a surface significantly hotter than its boiling point (Leidenfrost effect), preventing direct contact and enhancing vaporization |

References

- McCarthy, J.E.; Copeland, C.; Parker, L.; Schierow, L. Clean Air Act: A Summary of the Act and its Major Requirements; CRS Report RL30853; Congressional Research Service: Washington, DC, USA, 2007. [Google Scholar]

- Kristie, R.; James, F.C.; Thomas, F. The impact of the Clean Air Act. J. Pediatr. 2012, 161, 781–786. [Google Scholar] [CrossRef] [PubMed]

- U.S. Environmental Protection Agency. Basic Concepts in Environmental Sciences; Air Knowledge Training Institute: Moreton Bay, Australia, 2024. Available online: https://airknowledge.gov/BASC-SI.html (accessed on 1 November 2024).

- Stępień, Z. Ammonia as an alternative fuel to internal combustion engines. Combust. Engines (2300-9896) 2025, 200, 117–127. [Google Scholar] [CrossRef]

- Nadimi, E.; Przybyła, G.; Lewandowski, M.T.; Adamczyk, W. Effects of ammonia on combustion, emissions, and performance of the ammonia/diesel dual-fuel compression ignition engine. J. Energy Inst. 2023, 107, 101158. [Google Scholar] [CrossRef]

- Moltner, L. Model-based analysis of ammonia generation in SCR systems. Univ. J. Control Autom. 2015, 3, 39–46. [Google Scholar] [CrossRef][Green Version]

- Majewski, W.A. Selective Catalytic Reduction. In DieselNet Technology Guide—Diesel Catalysts; DieselNet: Mississauga, ON, Canada, 2023; Available online: https://dieselnet.com/tech/cat_scr.php (accessed on 22 January 2024).

- Gabrielsson, L.T.P. Urea-SCR in automotive applications. Top. Catal. 2004, 28, 177–184. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Q.; Liu, H.; Wang, T. Recent Advances in SCR Systems of Heavy-Duty Diesel Vehicles—Low-Temperature NOx Reduction Technology and Combination of SCR with Remote OBD. Atmosphere 2024, 15, 997. [Google Scholar] [CrossRef]

- Elkaeea, S.; Phule, A.D.; Yang, J.H. Advancements in (SCR) technologies for NOx reduction: A comprehensive review of reducing agents. Process Saf. Environ. Prot. 2024, 184, 854–880. [Google Scholar] [CrossRef]

- Naseri, M.; Aydin, C.; Mulla, S.; Conway, R.; Chatterjee, S. Development of Emission Control Systems to Enable High NOx Conversion on Heavy Duty Diesel Engines. SAE Int. J. Engines 2015, 8, 1144–1151. [Google Scholar] [CrossRef]

- Di Blasio, G.; Vassallo, A.; Pesce, F.C.; Beatrice, C.; Belgiorno, G.; Avolio, G. The Key Role of Advanced, Flexible Fuel Injection Systems to Match the Future CO2 Targets in an Ultra-Light Mid-Size Diesel Engine. SAE Int. J. Engines 2019, 12, 129–144. [Google Scholar] [CrossRef]

- Sermet-Gaudelus, I.; Le Cocguic, Y.; Ferroni, A.; Clairicia, M.; Barthe, J.; Delaunay, J.P.; Brousse, V.; Lenoir, G. Nebulized antibiotics in cystic fibrosis. Pediatr. Drugs 2002, 4, 455–467. [Google Scholar] [CrossRef]

- Kentish, S.; Feng, H. Applications of power ultrasound in food processing. Annu. Rev. Food Sci. Technol. 2014, 5, 263–284. [Google Scholar] [CrossRef]

- Yao, Y.; Pan, Y.; Liu, S. Power ultrasound and its applications: A state-of-the-art review. Ultrason. Sonochem. 2020, 62, 104722. [Google Scholar] [CrossRef]

- Wang, X.; Tsuchiya, K. Frequency specificity of liquid-fountain swinging with mist generation: Effects of ultrasonic irradiation angle. Fluids 2022, 7, 306. [Google Scholar] [CrossRef]

- Avvaru, B.; Patil, M.N.; Gogate, P.R.; Pandit, A.B. Ultrasonic atomization: Effect of liquid phase properties. Ultrasonics 2006, 44, 146–158. [Google Scholar] [CrossRef]

- Niwa, A.; Sakatani, S.; Matsumura, E.; Kitamura, T. Prediction of spray behavior by urea SCR injector and reaction products. SAE Int. J. Fuels Lubr. 2017, 10, 877–888. [Google Scholar] [CrossRef]

- Miao, Y.; Chen, L.-D.; He, Y.; Tang, K.T.-W. Study of SCR cold-start by energy method. Chem. Eng. J. 2009, 155, 260–265. [Google Scholar] [CrossRef]

- Culbertson, D.; Khair, M.; Zhang, S.; Tan, J.; Spooler, J. The study of exhaust heating to improve SCR cold start performance. SAE Int. J. Engines 2015, 8, 1187–1195. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, W.; Wang, Y. Experimental Study on Improving Cold Start Performance of Diesel Engines at Extremely Low Ambient Temperatures with Diethyl Ether. Energy 2023, 283, 129122. [Google Scholar] [CrossRef]

- Al-Juboori, R.A.; Yusaf, T.; Aravinthan, V.; Bowtell, L.L. Insights into the Scalability of Magnetostrictive Ultrasound Technology for Water Treatment Applications. Ultrason. Sonochem. 2016, 28, 357–366. [Google Scholar] [CrossRef]

- Panão, M.R.O.; Gonçalves, J.; Oliveira, A.V.M. Ultrasonic Atomization: New Spray Characterization Approaches. Fluids 2022, 7, 29. [Google Scholar] [CrossRef]

- Bransky, A.; Korin, N.; Khoury, M.; Levenberg, S. A Microfluidic Droplet Generator Based on a Piezoelectric Actuator. Lab Chip 2009, 9, 516–520. [Google Scholar] [CrossRef] [PubMed]

- Venkatachalam, P.; Shiva, S.; Govindarajan, V.; Soni, P.; Patidar, S. Novel UWS Injection Technique for SCR Performance Improvement; SAE Technical Paper 2024-28-0133; SAE Internation: Warrendale, PA, USA, 2024. [Google Scholar] [CrossRef]

- Kaźmierski, B.; Kapusta, Ł.J. The Importance of Individual Spray Properties in Performance Improvement of a Urea-SCR System Employing Flash-Boiling Injection. Appl. Energy 2023, 329, 120217. [Google Scholar] [CrossRef]

- Majewski, W.A. Urea Dosing and Injection Systems. In DieselNet Technology Guide; Revision 2025.07; DieselNet: Mississauga, ON, Canada, 2025; Available online: https://dieselnet.com/tech/cat_scr_diesel_urea_dosing.php (accessed on 20 August 2025).

- Masoudi, M.; Poliakov, N.; Noorfeshan, S. A Multi-Function, Heated Mixer for Rapid Heat-up, Low-Temperature Ammonia Demand, Deposit Prevention and to Meet Ultra-Low NOx Regulations; SAE Technical Paper 2023-01-0356; SAE Internation: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Shan, T.-Y.; Wu, X.-S.; Hu, Y.-W.; Lin, X.-D.; Sun, D.-F. Injection of Viscous Micro-Droplet via Nozzle-Driven Piezoelectric Micro-Jet and Its Performance Control Method. Micromachines 2023, 14, 1267. [Google Scholar] [CrossRef] [PubMed]

- Culbertson, D.; Khair, M.; Zha, Y.; Diestelmeier, J. Exhaust Heating System Performance for Boosting SCR Low Temperature Efficiency; SAE Technical Paper 2018-01-1428; SAE Internation: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Moon, S.; Park, S.; Son, J.; Oh, K.; Jang, S. Simplified Modeling and Analysis of Surface Temperature Distribution in Electrically Heated Catalyst for Diesel Urea-SCR Systems. Energies 2022, 15, 6406. [Google Scholar] [CrossRef]

- Garimella, S.; Patil, R.; Hornby, A.; Smytka, J.; Ferreira, E. Pre-Heating the Aftertreatment System with a Burner. In SAE Technical Paper; SAE Press: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

| Diesel Engine Configuration ISUZU 4JB1—With/Without Preheating | ||||||||

|---|---|---|---|---|---|---|---|---|

| No SCR, No AdBlue Injection | With SCR, AdBlue Injection with Magnetostrictive System With SCR, AdBlue Ejection, with Piezo Cells | |||||||

| Diesel Engine Speed | Diesel Engine Load | Diesel Engine Torque | Diesel Engine Power | Diesel Engine Speed | Diesel Engine Load | Diesel Engine Torque | Diesel Engine Power | |

| No. | [rpm] | [%] | [Nm] | [kW] | [rpm] | [%] | [Nm] | [kW] |

| 1 | 750 | 0% | 0 | 0 | 750 | 0% | 0 | 0 |

| 2 | 2300 | 25% | 56 | 13.487 | 2300 | 25% | 56 | 13.487 |

| 3 | 50% | 111 | 26.734 | 50% | 111 | 26.734 | ||

| 4 | 75% | 167 | 40.233 | 75% | 167 | 40.233 | ||

| 5 | 100% | 245 | 53.645 | 100% | 245 | 53.645 | ||

| Test Cases, Where χ—The Diesel Engine Load | r.p.m. | Cold Diesel Engine T < 343 K | Hot Diesel Engine T > 343 K | ||

|---|---|---|---|---|---|

| Max Value | Stabilized Value | Max Value | Stabilized Value | ||

| NOx [ppm] | NOx [ppm] | NOx [ppm] | NOx [ppm] | ||

| χ = 0%, without SCR | 1000 | 129 | 125 | 132 | 98 |

| χ = 0%, with SCR magnetostrictive system | 1000 | 91 | 81 | 110 | 62 |

| χ = 0%, with SCR, magnetostrictive system—with preheating | 1000 | 88 | 81 | 93 | 79 |

| χ = 0%, with SCR piezo cells | 1000 | 61 | 62 | 79 | 56 |

| χ = 0%, with SCR piezo cells—with preheating | 1000 | 71 | 49 | 61 | 49 |

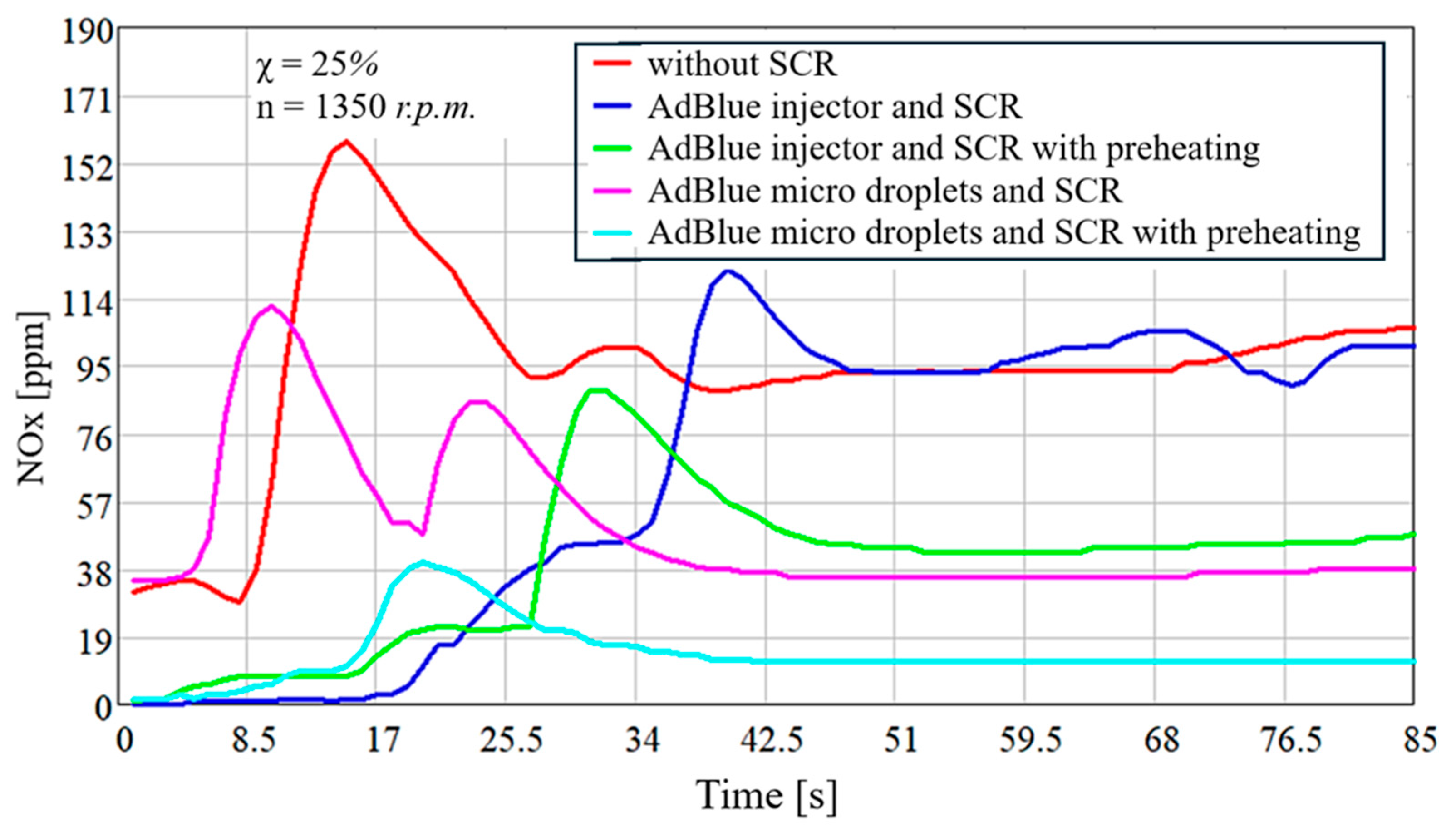

| χ = 25%, without SCR | 1350 | 158 | 99 | 160 | 90 |

| χ = 50%, without SCR | 2100 | 175 | 137 | 170 | 91 |

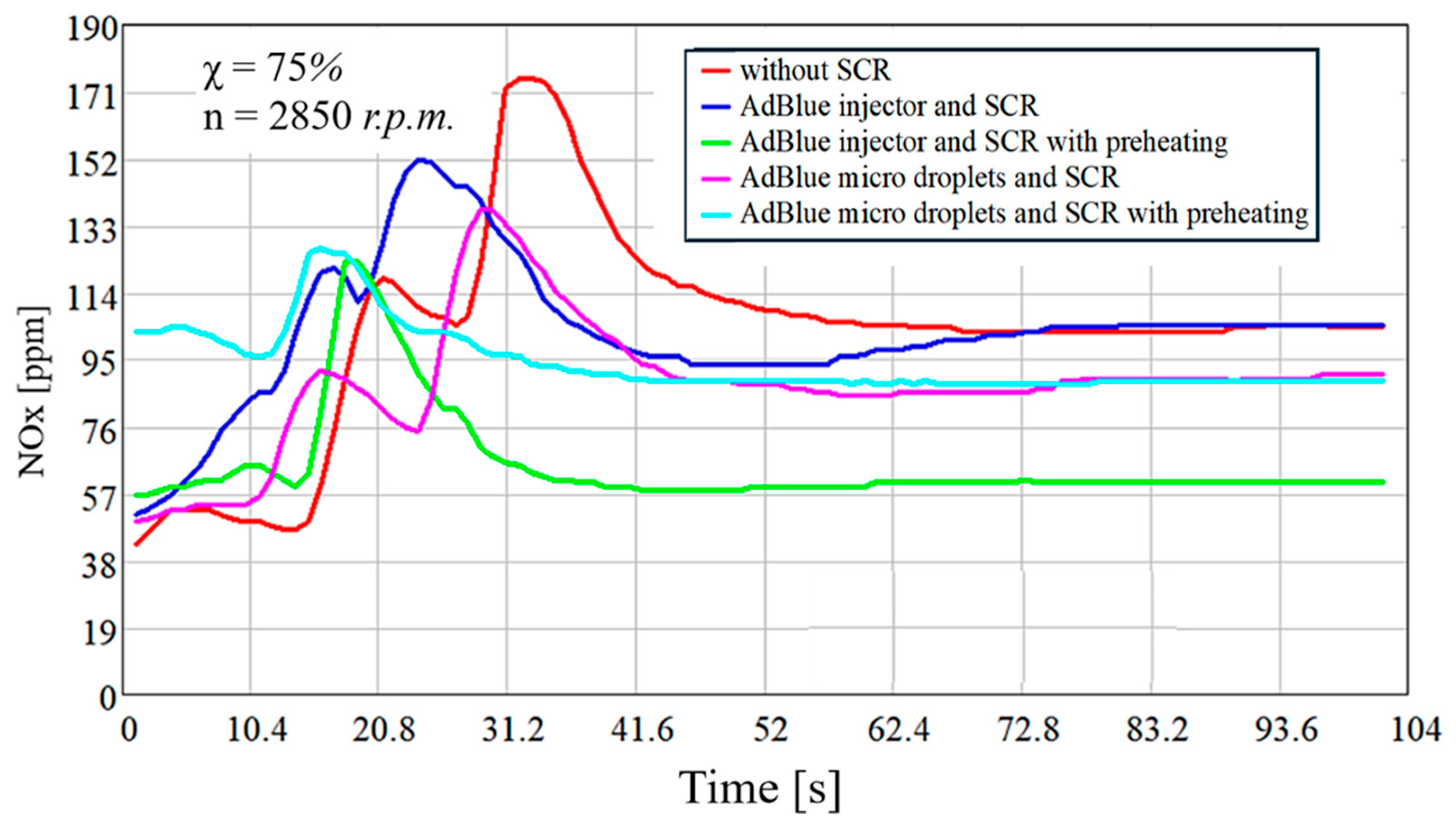

| χ = 75%, without SCR | 2850 | 175 | 104 | 173 | 110 |

| χ = 100%, without SCR | 3600 | 224 | 138 | 185 | 120 |

| χ = 25%, with SCR, magnetostrictive system | 1350 | 120 | 99 | 130 | 80 |

| χ = 50%, with SCR, magnetostrictive system | 2100 | 139 | 100 | 160 | 110 |

| χ = 75%, with SCR, magnetostrictive system | 2850 | 152 | 105 | 162 | 100 |

| χ = 100%, with SCR, magnetostrictive system | 3600 | 168 | 113 | 172 | 111 |

| χ = 25%, with SCR, piezo cells | 1350 | 88 | 48 | 90 | 36 |

| χ = 50%, with SCR, piezo cells | 2100 | 94 | 54 | 144 | 42 |

| χ = 75%, with SCR, piezo cells | 2850 | 123 | 61 | 158 | 93 |

| χ = 100%, with SCR, piezo cells | 3600 | 192 | 20 | 169 | 12 |

| χ = 25%, with SCR, piezo cells—with preheating | 1350 | 40 | 12 | 40 | 10 |

| χ = 50%, with SCR, piezo cells—with preheating | 2100 | 89 | 47 | 83 | 50 |

| χ = 75%, with SCR, piezo cells—with preheating | 2850 | 127 | 89 | 86 | 50 |

| χ = 100%, with SCR, piezo cells—with preheating | 3600 | 151 | 17 | 91 | 43 |

| χ = 25%, with SCR, magnetostrictive system—with preheating | 1350 | 112 | 38 | 92 | 27 |

| χ = 50%, with SCR, magnetostrictive system—with preheating | 2100 | 113 | 72 | 124 | 65 |

| χ = 75%, with SCR, magnetostrictive system—with preheating | 2850 | 138 | 91 | 134 | 90 |

| χ = 100%, with SCR, magnetostrictive system—with preheating | 3600 | 149 | 90 | 157 | 104 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mihai, I.; Picus, C.M.; Suciu, C. Impact of Calefaction and AdBlue Atomization by Magneto-Strictive and Piezoelectric Phenomena on NOx in SCR Systems for Diesel Engines. Appl. Sci. 2025, 15, 9648. https://doi.org/10.3390/app15179648

Mihai I, Picus CM, Suciu C. Impact of Calefaction and AdBlue Atomization by Magneto-Strictive and Piezoelectric Phenomena on NOx in SCR Systems for Diesel Engines. Applied Sciences. 2025; 15(17):9648. https://doi.org/10.3390/app15179648

Chicago/Turabian StyleMihai, Ioan, Claudiu Marian Picus, and Cornel Suciu. 2025. "Impact of Calefaction and AdBlue Atomization by Magneto-Strictive and Piezoelectric Phenomena on NOx in SCR Systems for Diesel Engines" Applied Sciences 15, no. 17: 9648. https://doi.org/10.3390/app15179648

APA StyleMihai, I., Picus, C. M., & Suciu, C. (2025). Impact of Calefaction and AdBlue Atomization by Magneto-Strictive and Piezoelectric Phenomena on NOx in SCR Systems for Diesel Engines. Applied Sciences, 15(17), 9648. https://doi.org/10.3390/app15179648