Research on the Mechanism of Reverse Sand Addition in Horizontal Shale Gas Well Fracturing Based on Intergranular Erosion of Proppants in near Wellbore Fractures

Abstract

1. Introduction

2. Experiment and Simulation

2.1. Experimental Materials

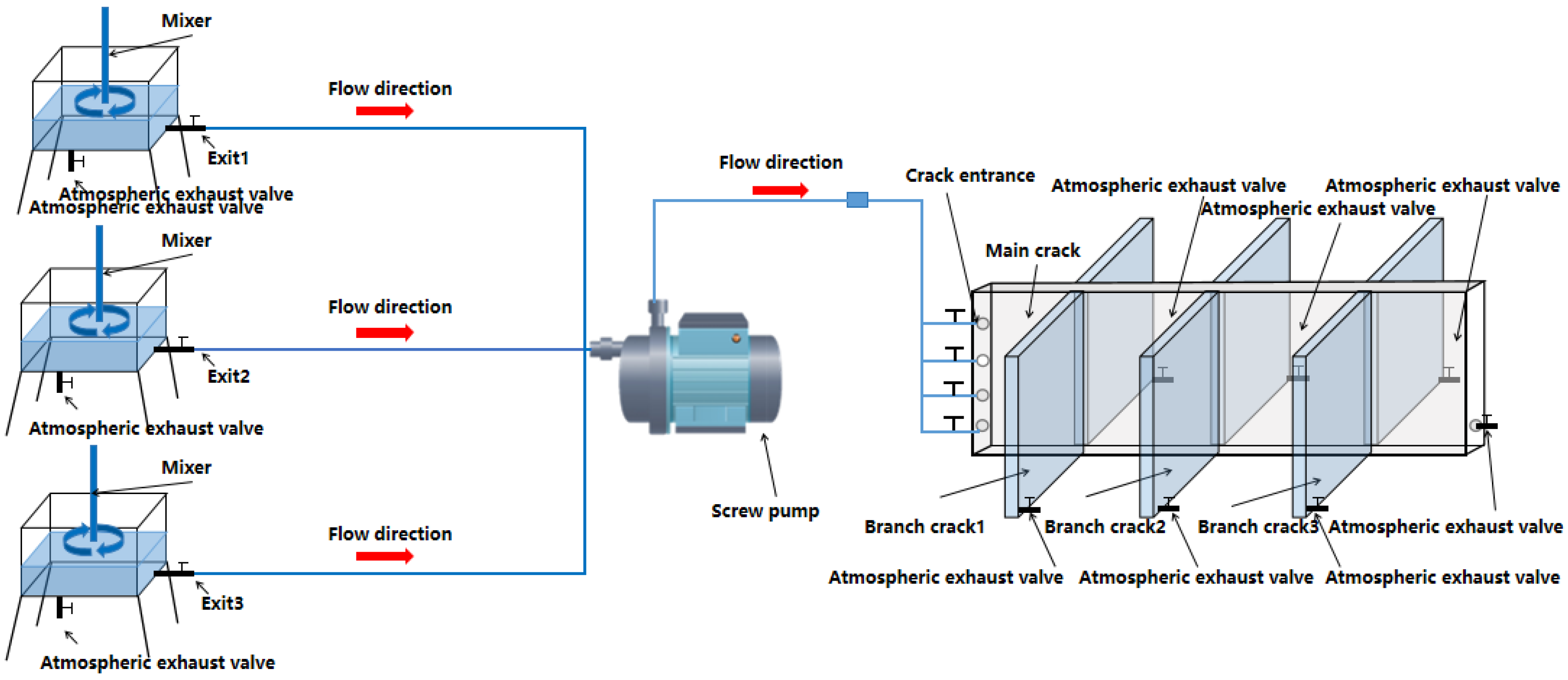

2.2. Study on the Laying Law of Proppant Under Different Sanding Processes

- (1)

- Experimental Principle

- (2)

- Experimental steps

- ①

- Complete the connection work of various components of the experimental equipment, focusing on checking the sealing condition of the interface parts, and carefully cleaning the inside of the cracks to ensure their cleanliness.

- ②

- Use water pipes to circulate clean water in the system in order to test the sealing performance and liquid circulation effect of the equipment. After completing the inspection, promptly drain the clean water.

- ③

- Prepare the required fracturing fluid, proppants, and other materials according to the experimental design requirements. Adjust the camera position, accurately control the distance between it and the flat crack, and capture the wide angle to ensure that the camera can fully record the image of the crack area.

- ④

- According to the established sand ratio, add fracturing fluid and proppant to the sand mixing tank, and then turn on the mixer to ensure that the two are thoroughly and evenly mixed.

- ⑤

- Once the proppant begins to enter the crack, quickly turn on the camera to capture real-time footage of the formation and changes in the sand embankment within the crack.

- ⑥

- When all the proppants have been injected and the floating sand at the inlet has completely disappeared, it is determined that the experiment has reached the termination condition.

- ⑦

- Discharge the fracturing fluid and proppant from the sand mixing tank through the discharge port, and then inject clean water with a large displacement pump to circulate and flush the experimental equipment.

- ⑧

- Continue flushing until there is no residual proppant in the crack, then open the discharge port of the sand mixing tank, thoroughly drain the fracturing fluid and proppant from the tank until all the water in the crack and sand mixing tank is drained, and turn off the screw pump and power switch in sequence.

2.3. Simulation Section

- (3)

- Fluid flow

- (4)

- Particle gravity

- (5)

- The drag force of fluid on particles

- (6)

- Initial conditions

- (7)

- Boundary conditions

3. Experimental Results and Analysis

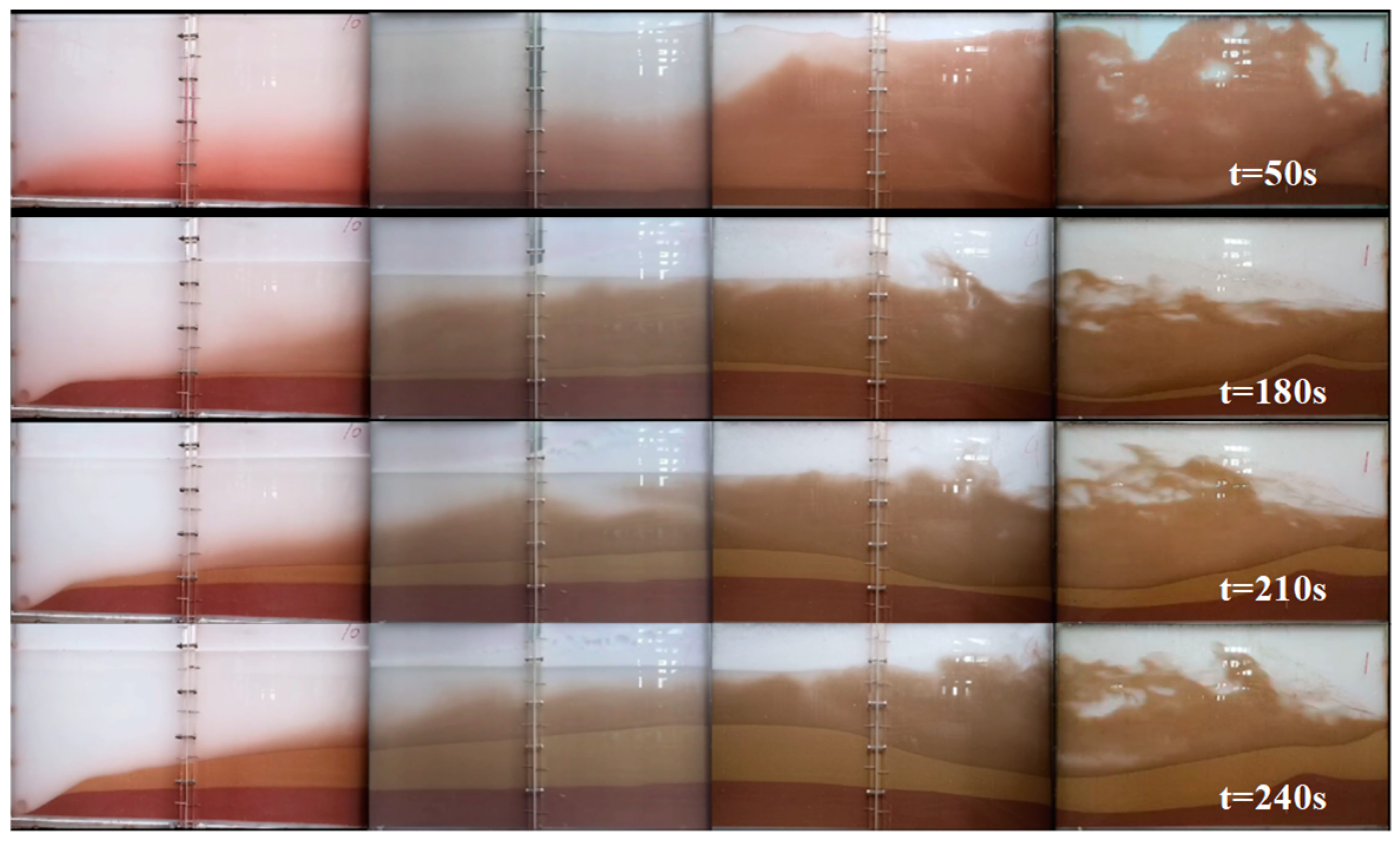

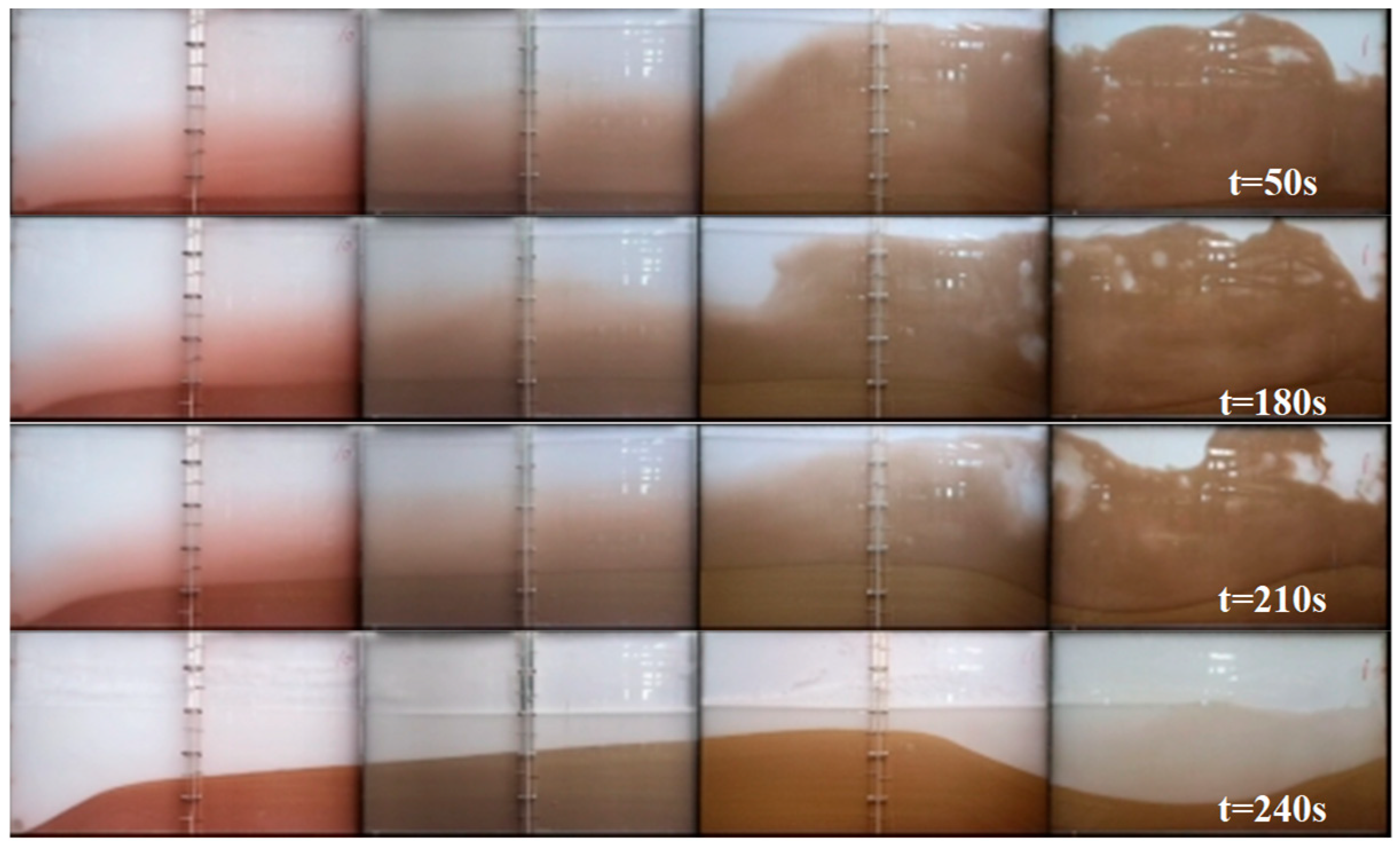

3.1. Transport Characteristics of Proppants in the Near-Wellbore Zone Under Different Sand Addition Processes

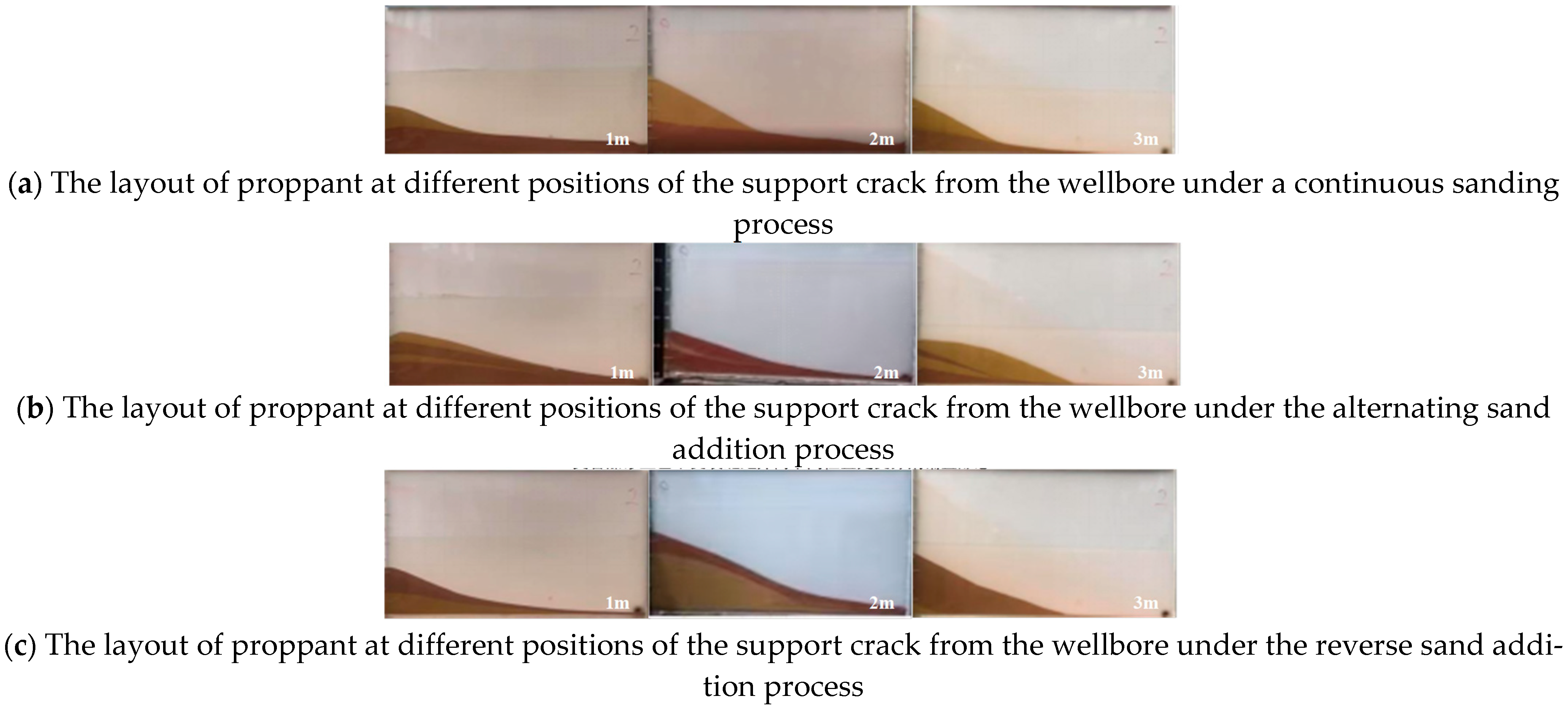

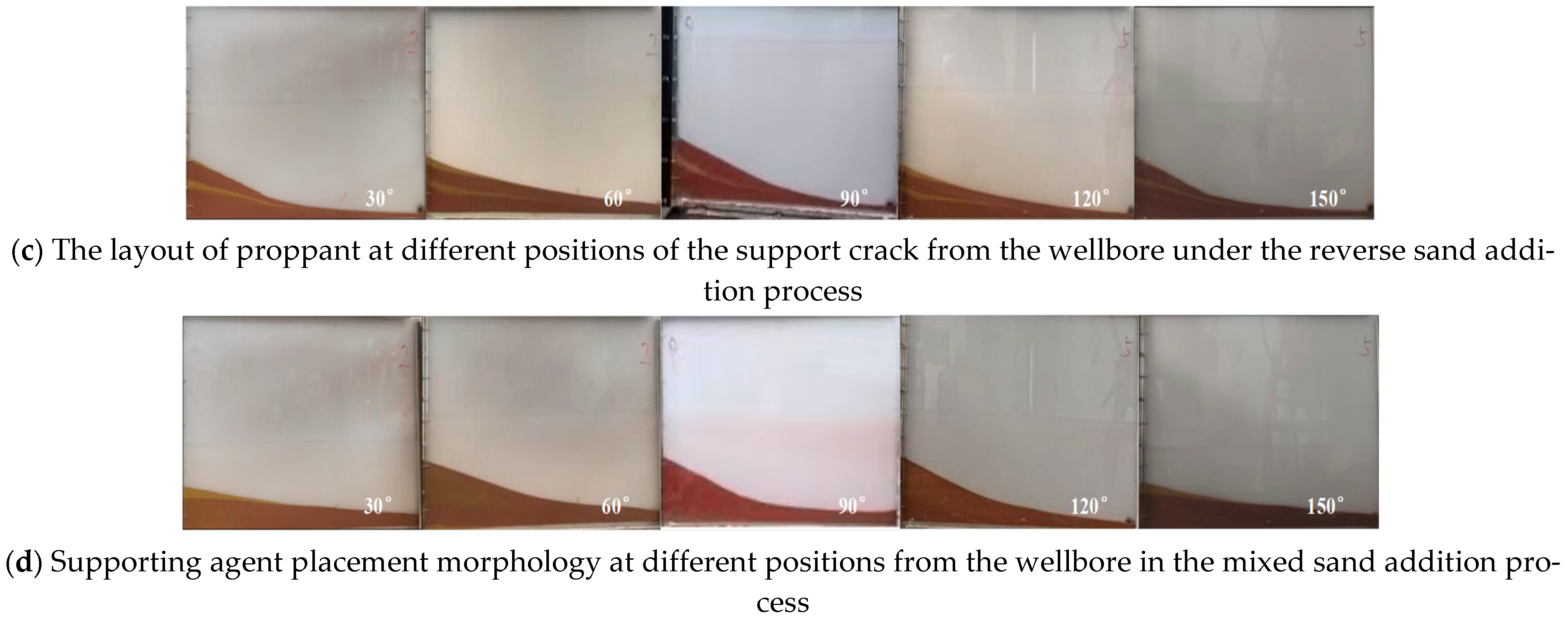

3.2. Study on the Variation Law of Sand Paving Morphology of Branch Cracks Under Different Sanding Processes

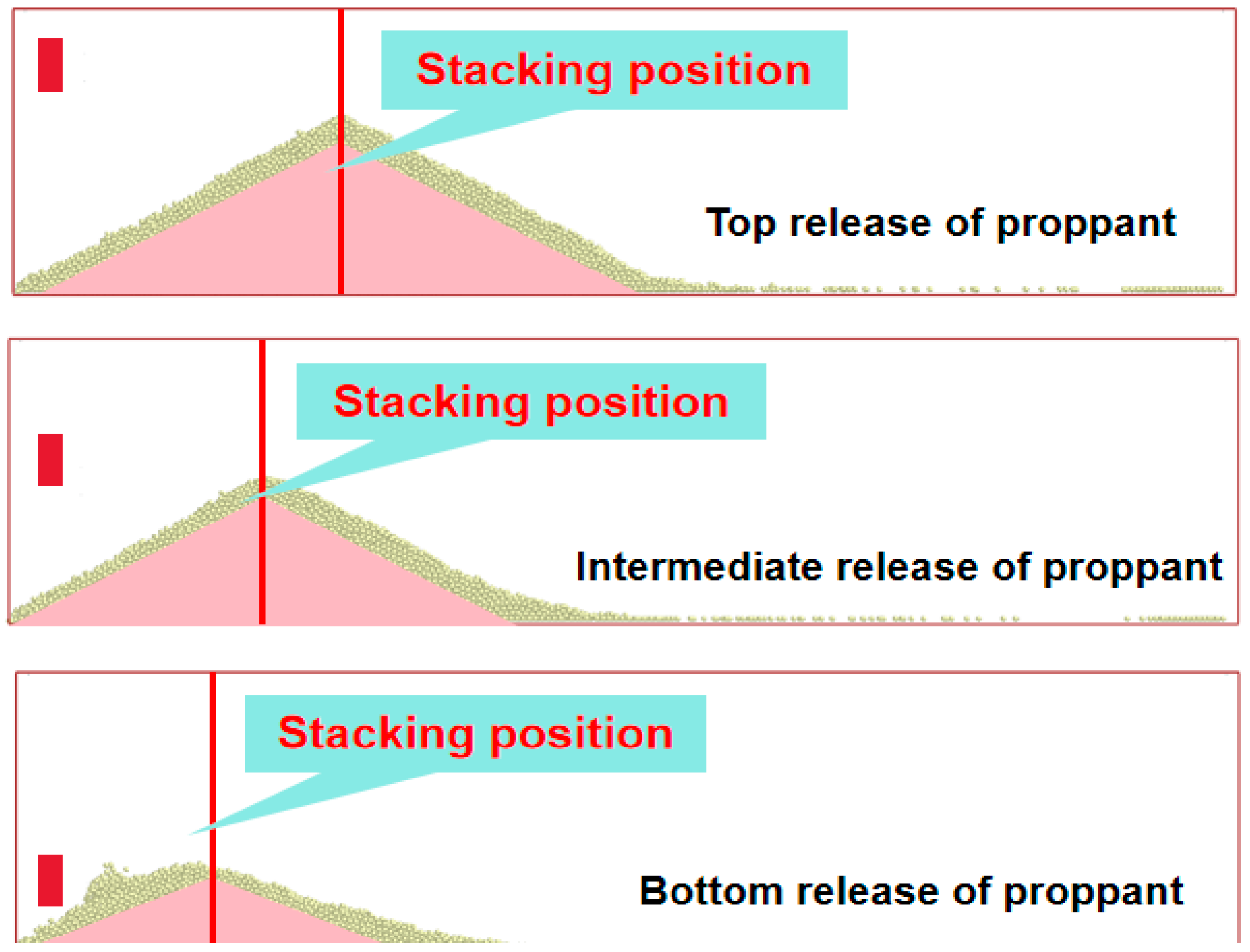

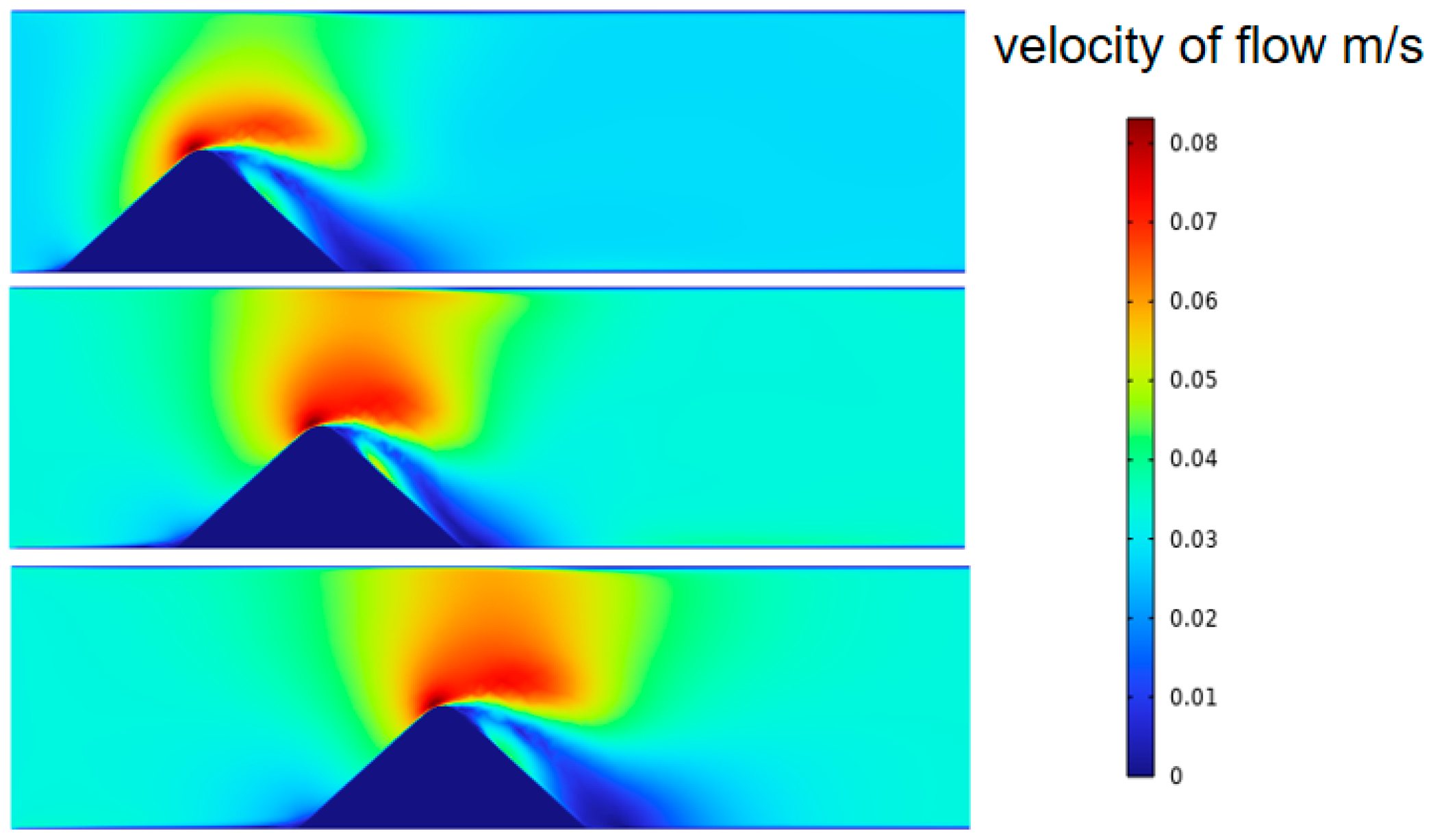

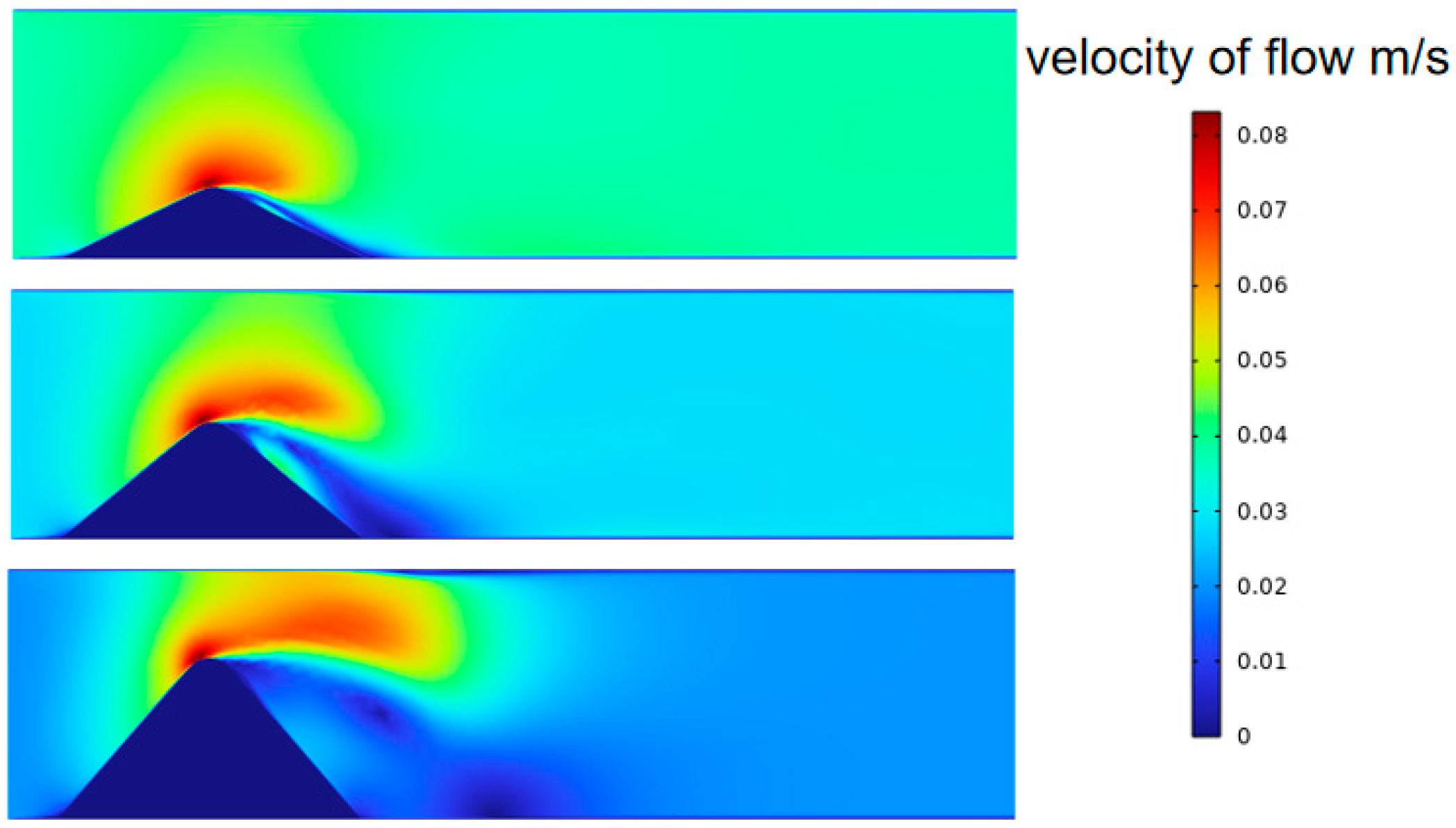

3.3. The Influence of the Accumulation Morphology of Proppant in Cracks Under Reverse Sand Addition on the Subsequent Flow of Fracturing Fluid

4. Conclusions

- (1)

- Alternating sand addition exhibits the best performance in main fractures: compared to conventional continuous sand addition, it increases sand-laying efficiency by 10 percentage points, reduces sand embankment void area by 18.3%, and enhances proppant entry into secondary cracks by 23.8%. Its sand embankment balances uniformity and retention—gentler than reverse sand addition and taller than continuous sand addition, avoiding local blockage and insufficient support.

- (2)

- Branch crack geometry significantly affects proppant placement: at Position 2, alternating sand addition achieves an equilibrium height of 210 mm, which is 48.4% lower than continuous sand addition but 15.3% higher than reverse sand addition; the optimal branch crack angle is 90°, at which alternating sand addition’s paving rate is 11.7% higher than mixed sand addition. Quartz sand has a filling rate 2.5 times higher than ceramic particles in branch cracks, consistent with classic particle transport theory and providing a basis for proppant selection.

- (3)

- The proposed optimal parameter combination (alternating injection of 70/140 mesh quartz sand and 40/70 mesh ceramic particles, displacement 0.0018 m3/s, fluid viscosity 8.91 mPa·s) improves fracture network support efficiency by 21.5% vs. conventional continuous sand addition. This scheme is verified by both experiments and simulations, ensuring reliability for field application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, Z.; Bai, L.; Hu, Q.; Yang, Z.; Jiang, Z.; Wang, Z.; Xin, H.; Zhang, L.; Yang, A.; Jia, L.; et al. Shale oil migration across multiple scales: A review of characterization methods and different patterns. Earth-Sci. Rev. 2024, 254, 104819. [Google Scholar] [CrossRef]

- Wang, H.Y. Hydraulic fracture propagation in naturally fractured reservoirs: Complex fracture or fracture networks. J. Nat. Gas Sci. Eng. 2019, 68, 102911. [Google Scholar] [CrossRef]

- Sahai, R.; Moghanloo, R.G. Proppant transport in complex fracture networks—A review. J. Pet. Sci. Eng. 2019, 182, 106199. [Google Scholar] [CrossRef]

- Roostaei, M.; Nouri, A.; Fattahpour, V.; Chan, D. Numerical simulation of proppant transport in hydraulic fractures. J. Pet. Sci. Eng. 2018, 163, 119–138. [Google Scholar] [CrossRef]

- Ngameni, K.L.; Miskimins, J.L.; Abass, H.H.; Cherrian, B. Experimental Study of Proppant Transport in Horizontal Wellbore Using Fresh Water. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Woodlands, TX, USA, 24–26 January 2017. [Google Scholar]

- Alotaibi, M.A.; Miskimins, J.L. Slickwater Proppant Transport in Complex Fractures: New Experimental Findings & Scalable Correlation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28 September 2015. [Google Scholar]

- Yang, S.; Cheng, W.; Hu, Q.; Lei, G. Sensitivity analysis of proppant transportation and settling in a hydraulic fracture. Phys. Fluids 2025, 37, 013360. [Google Scholar] [CrossRef]

- Budiman, O.; Alajmei, S.; Bahri, A.; Aljawad, M.S.; Miskimins, J. A Review of Proppant Transport and Distribution in Slickwater Fracturing. Arab. J. Sci. Eng. 2025, 50, 5303–5322. [Google Scholar] [CrossRef]

- Guowen, Z.; Xiaojun, W.; Jinyou, Z.; Zhao, L.; Yunfeng, B.; Ying, Z.; Xiuli, F.; Huasen, Z. Enrichment conditions and favorable zones for exploration and development of continental shale oil in Songliao Basin. Acta Pet. Sin. 2023, 44, 110. [Google Scholar]

- Liu, H.; Huang, Y.; Cai, M.; Meng, S.; Tao, J. Practice and development suggestions of hydraulic fracturing technology in the Gulong shale oil reservoirs of Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 688–698. [Google Scholar] [CrossRef]

- Haberman, W.L.; Sayre, R.M. David Taylor Model Basin Report; Department of the Navy: Washington, DC, USA, 1958.

- Francis, A.W. Wall effect in falling ball method for viscosity. J. Appl. Phys. 1933, 4, 403–406. [Google Scholar] [CrossRef]

- Clift, R.; Grace, J.R.; Weber, M.E. Bubbles, Drops and Particles; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Iwaoka, M.; Ishii, T. Experimental wall correction factors of single solid spheres in circular cylinders. J. Chem. Eng. Japan. 1979, 12, 239–242. [Google Scholar] [CrossRef]

- Fidleris, V.; Whitmore, R.L. Experimental determination of the wall effect for spheres falling axially in cylindrical vessels. Br. J. Appl. Phys. 1961, 12, 490–494. [Google Scholar] [CrossRef]

- Schols, R.S.; Visser, W. Proppant bank Buildup in a vertical fracture without fluid loss. In Proceedings of the SPE European Spring Meeting, Amsterdam, The Netherlands, 29 May 1974. [Google Scholar]

- Kirkby, L.L.; Rockefeller, H.A. Proppant settling velocities in non-flowing slurries. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference/Low-Permeability Reservoirs Symposium, Denver, CO, USA, 19–22 May 1985; SPE 13906. pp. 567–576. [Google Scholar]

- Sievert, J.A.; Wahl, H.A.; Clark, P.E.; Harkin, M.W. Prop transport in a large vertical model. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference/Low-Permeability Reservoirs Symposium, Denver, CO, USA, 27–29 May 1981; SPE 9865. pp. 335–341. [Google Scholar]

- Kern, L.R.; Perkins, T.K.; Wyant, R.E. The Mechanics of Sand Movement in Fracturing. In Proceedings of the 33rd Annual Fall Meeting of SPE, Houston, TX, USA, 5–8 October 1958. SPE 2037. [Google Scholar]

- Liu, Y. Settling and Hydrodynamic Retardation of Proppants in Hydraulic Fractures; University of Texas at Austin: Austin, TX, USA, 2006. [Google Scholar]

- Chhabra, R.; Tiu, C.; Uhlherr, P. A study of wall effects on the motion of a sphere in viscoelastic fluids. Can. J. Chem. Eng. 1981, 59, 771–775. [Google Scholar] [CrossRef]

- Sugeng, F.; Tanner, R. The drag on spheres in viscoelastic fluids with significant wall effects. J. Non-Newton. Fluid Mech. 1986, 20, 281–292. [Google Scholar] [CrossRef]

- Malhotra, S.; Sharma, M.M. Settling of spherical particles in unbounded and confined surfactant-based shear thinning viscoelastic fluids: An experimental study. Chem. Eng. Sci. 2012, 84, 646–655. [Google Scholar] [CrossRef]

- Di Felice, R. The voidage function for fluid-particle interaction systems. Int. J. Multiph. Flow 1994, 20, 153–159. [Google Scholar] [CrossRef]

- Di Felice, R. The particle-in-a-tube analogy for a multiparticle suspension. Int. J. Multiph. Flow 1996, 22, 515–525. [Google Scholar] [CrossRef]

- Brannon, H.D.; Wood, W.D.; Wheeler, R.S. Large Scale Laboratory Investigation of the Effects of Proppant and Fracturing Fluid Properties on Transport. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 18–20 February 2006; p. 13. [Google Scholar]

- Anschutz, D.A.; Lowrey, T.A.; Stribling, M.; Wildt, P.J. An In-Depth Study of Proppant Transport and Placement with Various Fracturing Fluids. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019; p. 27. [Google Scholar]

- Fernández, M.E.; Sánchez, M.; Pugnaloni, L.A. Proppant transport in a scaled vertical planar fracture: Vorticity and dune placement. J. Pet. Sci. Eng. 2019, 173, 1382–1389. [Google Scholar] [CrossRef]

- Tong, S.; Singh, R.; Mohanty, K.K. A visualization study of proppant transport in foam fracturing fluids. J. Nat. Gas Sci. Eng. 2018, 52, 235–247. [Google Scholar] [CrossRef]

- Tong, S.; Gu, M.; Singh, R.; Mohanty, K.K. Proppant transport in foam fracturing fluid during hydraulic fracturing. J. Petrol. Sci Eng. 2019, 182, 106–112. [Google Scholar] [CrossRef]

- Hou, L.; Sun, B.; Geng, X.; Jiang, T.; Wang, Z. Study of the slippage of particle/supercritical CO2 two-phase flow. J. Supercrit. Fluids 2017, 120, 173–180. [Google Scholar] [CrossRef]

- Huang, H.; Babadagli, T.; Li, H.A.; Develi, K.; Wei, G. Effect of injection parameters on proppant transport in rough vertical fractures: An experimental analysis on visual models. J. Petrol. Sci. Eng. 2019, 180, 380–395. [Google Scholar] [CrossRef]

- Wen, Q.; Wang, S.; Duan, X.; Li, Y.; Wang, F.; Jin, X. Experimental investigation of proppant settling in complex hydraulic-natural fracture system in shale reservoirs. J. Nat. Gas Sci. Eng. 2016, 33, 70–80. [Google Scholar] [CrossRef]

- Chun, T.; Zhu, D.; Zhang, Z.; Mao, S.; Wu, K. Experimental study of proppant transport in complex fractures with horizontal bedding planes for slickwater fracturing. SPE Prod. Oper. 2021, 36, 83–96. [Google Scholar] [CrossRef]

- Luo, L. Experimental Study of Proppant Settling in a Narrow Fracture Analyzed with Particle Image Velocimetry. Ph.D. Thesis, University of California, San Diego, CA, USA, 2016. [Google Scholar]

| proppant | 70/140 mesh quartz sand | density 2650 kg/m3, sphere |

| 40/70 mesh ceramic particles | density 2000 kg/m3, sphere | |

| fracturing fluid | viscosity (25 °C) | 1–5 mpa s |

| crosslinking time | 8–10 min | |

| demulsification rate | ≥95% | |

| compatibility | no flocculation phenomenon and no precipitation generated |

| Field Data | Experimental Data | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Equivalent Hydraulic Diameter (m) | Displacement (m3/s) | Linear Velocity (m/s) | Fracturing Fluid Viscosity (10−6 mPa·s) | Reynolds Number | Equivalent Hydraulic Diameter (m) | Maximum Displacement (m3/s) | Maximum Linear Velocity (m/s) | Fracturing Fluid Viscosity (10−6 mPa·s) | Reynolds Number |

| 0.0119928 | 0.0167 | 0.278 | 2.97 | 1132.8 | 0.0157894 | 0.0015 | 0.312 | 4.46 | 1118.5 |

| 0.019 | 0.324 | 2.97 | 1321.6 | 0.0018 | 0.375 | 4.46 | 1342.2 | ||

| 0.022 | 0.370 | 2.97 | 1510.4 | 0.0021 | 0.437 | 4.46 | 1565.9 | ||

| 0.025 | 0.417 | 2.97 | 1699.1 | 0.0024 | 0.500 | 4.46 | 1789.6 | ||

| 0.017 | 0.278 | 8.91 | 377.6 | 0.0015 | 0.312 | 1.34 | 372.8 | ||

| 0.019 | 0.324 | 8.91 | 440.5 | 0.0018 | 0.375 | 1.3 | 447.4 | ||

| 0.022 | 0.370 | 8.91 | 503.5 | 0.0021 | 0.437 | 1.345 | 521.9 | ||

| 0.025 | 0.417 | 8.91 | 566.3 | 0.0024 | 0.5 | 1.34 | 596.5 | ||

| Crack length | 4 m | Fracturing fluid density | 1000 kg/m3 |

| Crack height | 1 m | Proppant size | 70 eyes |

| Crack width | 20 mm | Proppant density | 2200 kg/m3 |

| Fracturing fluid viscosity | 10 mPa·s | Injection rate | 12 m3/min |

| Accumulation height of proppant | 0.3–0.7 m | Accumulation length of proppant | 1 m |

| Sand Addition Method | Slope of the Leading Edge of the Sand Embankment/° | Gap Distance/cm | Gap Area/cm2 | Balance Height/cm | Sand Laying Efficiency/% |

|---|---|---|---|---|---|

| Continuous sand addition | 20 | 100 | 1714 | 30 | 42% |

| Alternating sand addition | 25 | 75 | 1400 | 42 | 52% |

| Add sand in reverse order | 42 | 80 | 1350 | 32 | 45% |

| Mix and sand | 30 | 60 | 1500 | 35 | 40% |

| Sand Addition Process | Equilibrium Height (mm)–Position 1/2/3 | Laying Efficiency (%)–Position 1/2/3 |

|---|---|---|

| Continuous sand addition | 192.9/407.1/231.4 | 12.3/24.4/8.2 |

| Alternating sand addition | 175.7/210.0/173.6 | 9.7/13.1/11.9 |

| Add sand in reverse order | 231.4/336.4/225.0 | 11.1/21.8/10.3 |

| Mix and add sand | 222.9/182.1/167.1 | 30.5/12.2/8 |

| Sand Addition Process | Equilibrium Height (mm)—30°/60°/90°/120°/150° | Laying Efficiency (%)—30°/60°/90°/120°/150° |

|---|---|---|

| Continuous sand addition | 348.0/389.0/407.1/391.0/353.0 | 19.1/21.3/24.4/21.9/19.9 |

| Alternating sand addition | 193.0/204.0/210.0/205.0/190.0 | 16.5/17.3/18.1/17.5/16.9 |

| Add sand in reverse order | 210.0/270.0/336.4/271.0/209.0 | 9.7/15.3/21.8/15.7/10.3 |

| Mix and add sand | 145.0/168.0/182.1/169.0/144.0 | 8.7/11.1/12.2/11.5/9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Yi, F.; Guo, S.; Zhu, M.; Bai, Y. Research on the Mechanism of Reverse Sand Addition in Horizontal Shale Gas Well Fracturing Based on Intergranular Erosion of Proppants in near Wellbore Fractures. Appl. Sci. 2025, 15, 9589. https://doi.org/10.3390/app15179589

Liu X, Yi F, Guo S, Zhu M, Bai Y. Research on the Mechanism of Reverse Sand Addition in Horizontal Shale Gas Well Fracturing Based on Intergranular Erosion of Proppants in near Wellbore Fractures. Applied Sciences. 2025; 15(17):9589. https://doi.org/10.3390/app15179589

Chicago/Turabian StyleLiu, Xuanyu, Faxin Yi, Song Guo, Meijia Zhu, and Yujie Bai. 2025. "Research on the Mechanism of Reverse Sand Addition in Horizontal Shale Gas Well Fracturing Based on Intergranular Erosion of Proppants in near Wellbore Fractures" Applied Sciences 15, no. 17: 9589. https://doi.org/10.3390/app15179589

APA StyleLiu, X., Yi, F., Guo, S., Zhu, M., & Bai, Y. (2025). Research on the Mechanism of Reverse Sand Addition in Horizontal Shale Gas Well Fracturing Based on Intergranular Erosion of Proppants in near Wellbore Fractures. Applied Sciences, 15(17), 9589. https://doi.org/10.3390/app15179589