Logistics Companies’ Efficiency Analysis and Ranking by the DEA-Fuzzy AHP Approach

Abstract

1. Introduction

2. Literature Review

2.1. The Development of the Logistics Service Industry

2.2. DEA and Its Application in the Logistics Service Industry

2.3. FAHP and Its Application in the Logistics Service Industry

2.4. Summary

3. Materials and Methods

3.1. DEA Method

- It is possible to increase any of its outputs without increasing any of its inputs and without decreasing any of its other outputs.

- It is possible to decrease any of its inputs without decreasing any of its outputs and without increasing any of its inputs.

CCR Model

3.2. AHP Method in Fuzzy Environment

4. Model Application

4.1. Overview of Used Criteria and Data

4.2. DEA Method Application

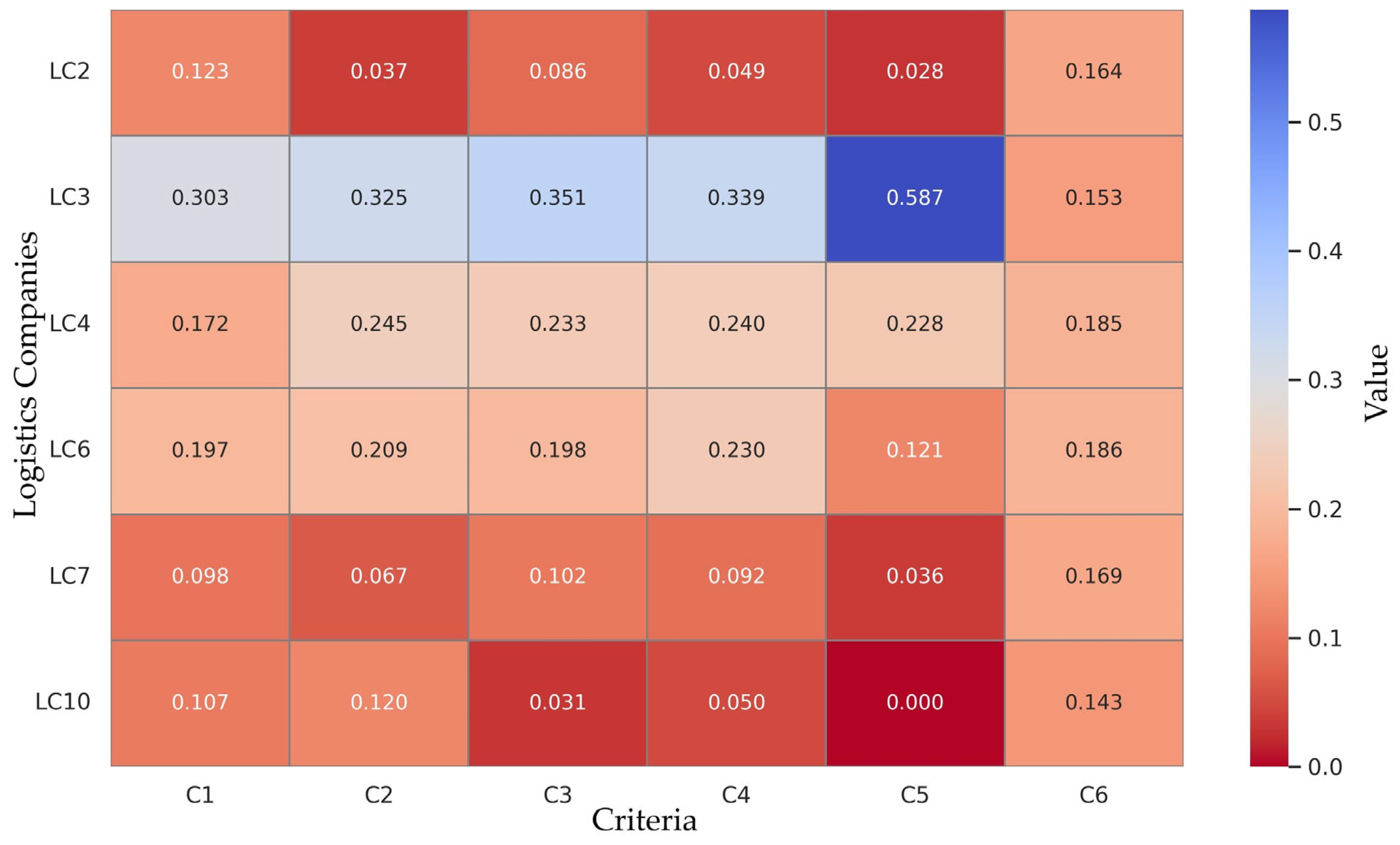

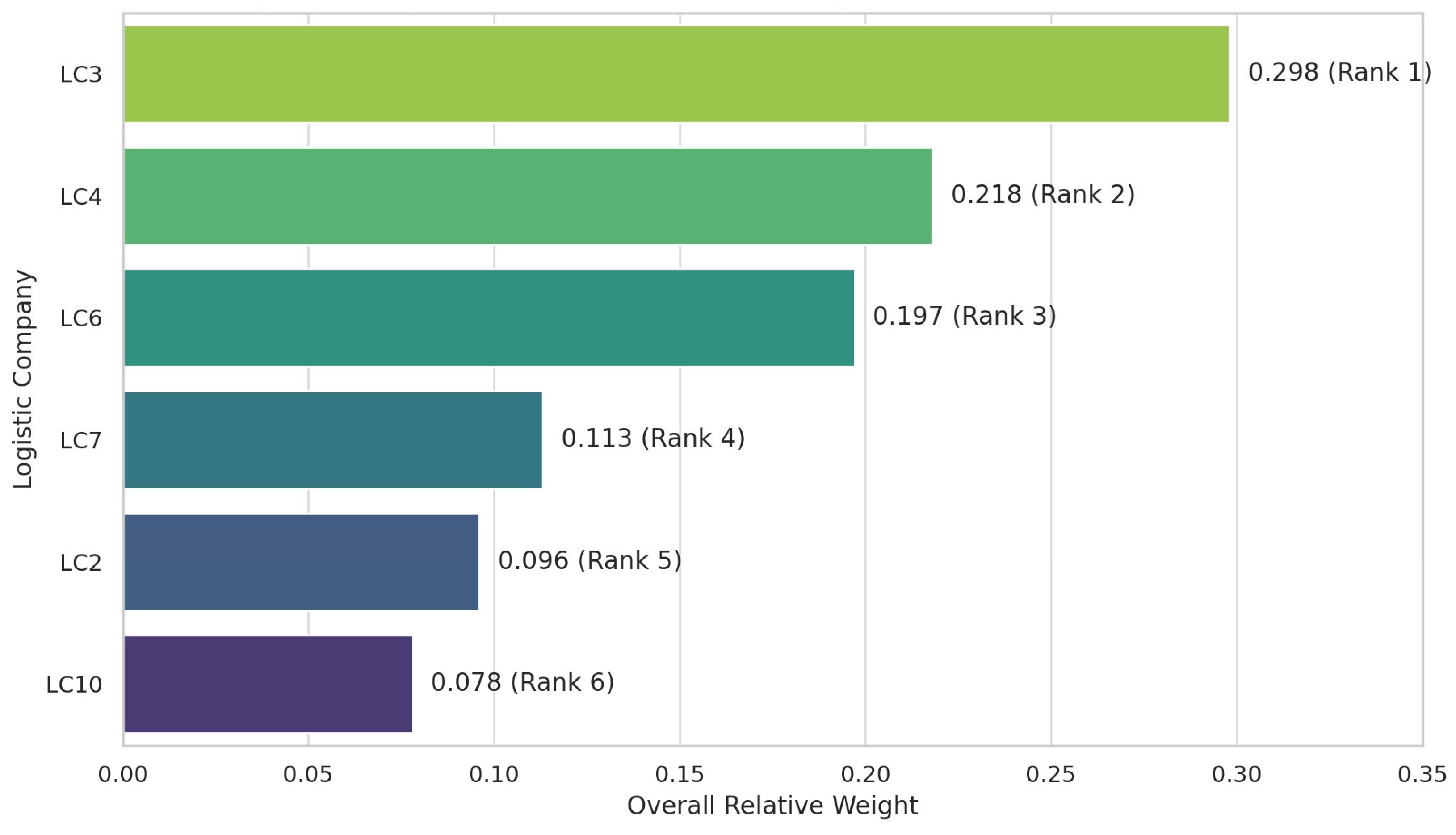

4.3. Fuzzy-AHP Method Application

5. Sensitivity Analysis Approach

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Initial Input Given by the Logistics Experts

| Rank | Logistics Experts | |||||

|---|---|---|---|---|---|---|

| LE1 | LE2 | LE3 | LE4 | LE5 | LE6 | |

| 1 | C6 | C6 | C3 | C3 | C3 | C3 |

| 2 | C3 | C3 | C6 | C6 | C6 | C6 |

| 3 | C4 | C4 | C4 | C4 | C4 | C4 |

| 4 | C5 | C2 | C2 | C2 | C2 | C2 |

| 5 | C2 | C5 | C5 | C5 | C1 | C1 |

| 6 | C1 | C1 | C1 | C1 | C5 | C5 |

| No. | Criteria | LE1 | LE2 | LE3 | LE4 | LE5 | LE6 |

|---|---|---|---|---|---|---|---|

| C1 | Number of vehicles | 6 | 6 | 6 | 6 | 5 | 5 |

| C2 | Fuel costs | 5 | 4 | 4 | 4 | 4 | 4 |

| C3 | Vehicle engagement time | 2 | 2 | 1 | 1 | 1 | 1 |

| C4 | Distance traveled | 3 | 3 | 3 | 3 | 3 | 3 |

| C5 | Transported quantity | 4 | 5 | 5 | 5 | 6 | 6 |

| C6 | Vehicle utilization | 1 | 1 | 2 | 2 | 2 | 2 |

Appendix B. Calculation in Excel Program—Tables and Matrices

| C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 0.33 | 0.20 | 0.25 | 0.50 | 0.17 |

| C2 | 3.00 | 1.00 | 0.33 | 0.33 | 3.00 | 0.17 |

| C3 | 5.00 | 3.00 | 1.00 | 2.00 | 6.00 | 2.00 |

| C4 | 4.00 | 3.00 | 0.50 | 1.00 | 5.00 | 0.33 |

| C5 | 2.00 | 0.33 | 0.17 | 0.20 | 1.00 | 0.33 |

| C6 | 6.00 | 6.00 | 0.50 | 3.00 | 3.00 | 1.00 |

| The sum of the columns | 21 | 13.66667 | 2.7 | 6.783333 | 18.5 | 4 |

| C1 | C2 | C3 | C4 | C5 | C6 | The Sum of the Rows | Average | |

|---|---|---|---|---|---|---|---|---|

| C1 | 0.048 | 0.024 | 0.074 | 0.037 | 0.027 | 0.042 | 0.252 | 0.042 |

| C2 | 0.143 | 0.073 | 0.123 | 0.049 | 0.162 | 0.042 | 0.592 | 0.099 |

| C3 | 0.238 | 0.220 | 0.370 | 0.295 | 0.324 | 0.500 | 1.947 | 0.325 |

| C4 | 0.190 | 0.220 | 0.185 | 0.147 | 0.270 | 0.083 | 1.096 | 0.183 |

| C5 | 0.095 | 0.024 | 0.062 | 0.029 | 0.054 | 0.083 | 0.348 | 0.058 |

| C6 | 0.286 | 0.439 | 0.185 | 0.442 | 0.162 | 0.250 | 1.764 | 0.294 |

| b | b/w | λmax | CR | CI |

|---|---|---|---|---|

| 0.263461 | 6.2820533 | 6.4653294 | 0.0930659 | 0.075053134 |

| 0.616756 | 6.2461245 | |||

| 2.132187 | 6.5702025 | |||

| 1.197152 | 6.5525737 | |||

| 0.363476 | 6.2627204 | |||

| 2.022618 | 6.8783021 |

| L | M | R | Fuzzification | |

|---|---|---|---|---|

| very small VM | 0 | 0 | 0.20 | 0.066667 |

| small M | 0.10 | 0.25 | 0.40 | 0.25 |

| medium S | 0.30 | 0.50 | 0.70 | 0.50 |

| large L | 0.55 | 0.75 | 0.95 | 0.75 |

| very large VL | 0.80 | 1 | 1 | 0.933333 |

| b1 | b2 | b3 | b4 | b5 | b6 | β Is Not Equal to 1 | ||

|---|---|---|---|---|---|---|---|---|

| b1 | 1.000 | 0.933 | 0.750 | 0.750 | 0.750 | 0.933 | 0.85 | 0.846336047 |

| b2 | 0.933 | 1.000 | 0.750 | 0.933 | 0.933 | 0.250 | 0.80 | 0.730889724 |

| b3 | 0.750 | 0.750 | 1.000 | 0.067 | 0.933 | 0.500 | 0.67 | 0.509534206 |

| b4 | 0.750 | 0.933 | 0.067 | 1.000 | 0.500 | 0.933 | 0.70 | 0.52844838 |

| b5 | 0.750 | 0.933 | 0.933 | 0.500 | 1.000 | 0.933 | 0.84 | 0.820395977 |

| b6 | 0.933 | 0.250 | 0.500 | 0.933 | 0.933 | 1.000 | 0.76 | 0.683129929 |

| C1 | C2 | C3 | C4 | C5 | C6 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | M | R | L | M | R | L | M | R | L | M | R | L | M | R | L | M | R | |

| C1 | 1.00 | 1.00 | 1.00 | 0.31 | 0.33 | 0.36 | 0.16 | 0.20 | 0.27 | 0.20 | 0.25 | 0.33 | 0.40 | 0.50 | 0.67 | 0.16 | 0.17 | 0.18 |

| C2 | 2.80 | 3.00 | 3.20 | 1.00 | 1.00 | 1.00 | 0.27 | 0.33 | 0.44 | 0.31 | 0.33 | 0.36 | 2.80 | 3.00 | 3.20 | 0.10 | 0.17 | 0.67 |

| C3 | 3.75 | 5.00 | 6.25 | 2.25 | 3.00 | 3.75 | 1.00 | 1.00 | 1.00 | 1.00 | 2.00 | 3.87 | 5.60 | 6.00 | 6.40 | 1.00 | 2.00 | 3.00 |

| C4 | 3.00 | 4.00 | 5.00 | 2.80 | 3.00 | 3.20 | 0.26 | 0.50 | 1.00 | 1.00 | 1.00 | 1.00 | 2.50 | 5.00 | 7.50 | 0.31 | 0.33 | 0.36 |

| C5 | 1.50 | 2.00 | 2.50 | 0.31 | 0.33 | 0.36 | 0.16 | 0.17 | 0.18 | 0.13 | 0.20 | 0.40 | 1.00 | 1.00 | 1.00 | 0.31 | 0.33 | 0.36 |

| C6 | 5.60 | 6.00 | 6.40 | 1.50 | 6.00 | 10.50 | 0.33 | 0.50 | 1.00 | 2.80 | 3.00 | 3.20 | 2.80 | 3.00 | 3.20 | 1.00 | 1.00 | 1.00 |

| C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 0.31 | 0.16 | 0.20 | 0.40 | 0.16 |

| C2 | 2.80 | 1.00 | 0.27 | 0.31 | 2.80 | 0.10 |

| C3 | 3.75 | 2.25 | 1.00 | 1.00 | 5.60 | 1.00 |

| C4 | 3.00 | 2.80 | 0.26 | 1.00 | 2.50 | 0.31 |

| C5 | 1.50 | 0.31 | 0.16 | 0.13 | 1.00 | 0.31 |

| C6 | 5.60 | 1.50 | 0.33 | 2.80 | 2.80 | 1.00 |

| The sum of the columns | 17.6500 | 8.1750 | 2.1749 | 5.4458 | 15.1000 | 2.8765 |

| C1 | C2 | C3 | C4 | C5 | C6 | The Sum of the Rows | Average | |

|---|---|---|---|---|---|---|---|---|

| C1 | 0.041 | 0.016 | 0.041 | 0.022 | 0.018 | 0.028 | 0.167 | 0.028 |

| C2 | 0.115 | 0.052 | 0.069 | 0.034 | 0.127 | 0.017 | 0.414 | 0.069 |

| C3 | 0.154 | 0.117 | 0.257 | 0.109 | 0.255 | 0.180 | 1.073 | 0.179 |

| C4 | 0.123 | 0.146 | 0.066 | 0.109 | 0.114 | 0.056 | 0.615 | 0.103 |

| C5 | 0.062 | 0.016 | 0.040 | 0.015 | 0.046 | 0.056 | 0.234 | 0.039 |

| C6 | 0.230 | 0.078 | 0.086 | 0.306 | 0.127 | 0.180 | 1.007 | 0.168 |

| C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|

| C1 | 1.00 | 0.36 | 0.27 | 0.33 | 0.67 | 0.18 |

| C2 | 3.20 | 1.00 | 0.44 | 0.36 | 3.20 | 0.67 |

| C3 | 6.25 | 3.75 | 1.00 | 3.87 | 6.40 | 3.00 |

| C4 | 5.00 | 3.20 | 1.00 | 1.00 | 7.50 | 0.36 |

| C5 | 2.50 | 0.36 | 0.18 | 0.40 | 1.00 | 0.36 |

| C6 | 6.40 | 10.50 | 1.00 | 3.20 | 3.20 | 1.00 |

| The sum of the columns | 24.35 | 19.1642 | 3.88968 | 9.15714 | 21.9666 | 5.55952 |

| C1 | C2 | C3 | C4 | C5 | C6 | The Sum of the Rows | Average | |

|---|---|---|---|---|---|---|---|---|

| C1 | 0.057 | 0.044 | 0.123 | 0.061 | 0.044 | 0.062 | 0.390 | 0.065 |

| C2 | 0.181 | 0.122 | 0.204 | 0.066 | 0.212 | 0.232 | 1.017 | 0.170 |

| C3 | 0.354 | 0.459 | 0.460 | 0.710 | 0.424 | 1.043 | 3.449 | 0.575 |

| C4 | 0.283 | 0.391 | 0.460 | 0.184 | 0.497 | 0.124 | 1.939 | 0.323 |

| C5 | 0.142 | 0.044 | 0.082 | 0.073 | 0.066 | 0.124 | 0.531 | 0.089 |

| C6 | 0.363 | 1.284 | 0.460 | 0.588 | 0.212 | 0.348 | 3.254 | 0.542 |

| Criteria | L | M | R | Defuzzification | Rank | Normalized Values Final |

|---|---|---|---|---|---|---|

| C1 | 0.028 | 0.042 | 0.065 | 0.045 | 6 | 0.0403 |

| C2 | 0.069 | 0.099 | 0.170 | 0.112 | 4 | 0.1007 |

| C3 | 0.179 | 0.325 | 0.575 | 0.359 | 1 | 0.3220 |

| C4 | 0.103 | 0.183 | 0.323 | 0.203 | 3 | 0.1817 |

| C5 | 0.039 | 0.058 | 0.089 | 0.062 | 5 | 0.0554 |

| C6 | 0.168 | 0.294 | 0.542 | 0.335 | 2 | 0.2999 |

| Sum | 0.585 | 1.000 | 1.764 | 1.116 |

References

- Chen, P. Analysis on the operational efficiency of port logistics listed companies based on DEA. J. Innov. Dev. 2022, 1, 1–4. [Google Scholar] [CrossRef]

- Kautsar, M.A.; Slamet, A.S.; Mulyati, H. Performance of Cow’s Milk Inbound Logistics at PT XYZ Subang. Eduvest-J. Univers. Stud. 2025, 5, 893–902. [Google Scholar] [CrossRef]

- Xu, J. Research on the Strategies and Methods for Improving the Efficiency of Logistics Supply Chain. Adv. Econ. Manag. Political Sci. 2025, 147, 123–128. [Google Scholar] [CrossRef]

- Hu, H.; Tang, G. Research on the Dynamic Evolution Model of the Influence of Foreign Trade on Economic Resilience Level Based on Triangular Fuzzy Entropy. Teh. Vjesn. 2025, 32, 1151–1161. [Google Scholar] [CrossRef]

- Radović, D.; Stević, Ž.; Pamučar, D.; Zavadskas, E.K.; Badi, I.; Antuchevičiene, J.; Turskis, Z. Measuring Performance in Transportation Companies in Developing Countries: A Novel Rough ARAS Model. Symmetry 2018, 10, 434. [Google Scholar] [CrossRef]

- Pankaj, K.; Sanjay, G.; Pavan, K.M. DEA Approach to Assess the Efficiency Assessment of Major Wholesale Markets in Case City of Jaipur, North India. Transp. Res. Procedia 2025, 82, 1313–1324. [Google Scholar] [CrossRef]

- Sanusi, S.A.; Ramli, N.A.; Shariff, S.R.; Masudin, I. Evaluating the Efficiency Measurement of Malaysian Logistics Company. Semarak Int. J. Transp. Logist. 2025, 2, 1–14. [Google Scholar] [CrossRef]

- Karakoç, Ö.; Memiş, S.; Sennaroglu, B. A Review of Sustainable Supplier Selection with Decision-Making Methods from 2018 to 2022. Sustainability 2024, 16, 125. [Google Scholar] [CrossRef]

- Özçağ, M.; Akkaya, O. Sustainability, climate change and energy efficiency. In Reference Module in Social Sciences; Elsevier: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Krejnus, M.; Stofkova, J.; Stofkova, K.R.; Binasova, V. The Use of the DEA Method for Measuring the Efficiency of Electronic Public Administration as Part of the Digitization of the Economy and Society. Appl. Sci. 2023, 13, 3672. [Google Scholar] [CrossRef]

- Sternad, M.; Grofelnik, I. Comparison of railway performance in the European Union based on DEA analysis during COVID crisis. Transp. Probl. 2023, 18, 210. [Google Scholar] [CrossRef]

- Kamber, E.; Baskak, M. Green logistics park location selection with circular intuitionistic fuzzy CODAS method: The case of Istanbul. J. Intell. Fuzzy Syst. 2023, 46, 4173–4189. [Google Scholar] [CrossRef]

- Zare, Z.; Ashrafzadeh, M.; Karatas, M. A Hybrid Fuzzy AHP and Fuzzy TOPSIS Approach for Warehouse Location Selection. Comput. Decis. Mak. Int. J. 2025, 2, 613–632. [Google Scholar] [CrossRef]

- Joseph, J.; Kadadevaramath, R.S.; Shankar, B.L.; Chen, S.-Y.; Kadadevaramath, A. Performance evaluation of green suppliers using the integrated Fuzzy DEMATEL-AHP-VIKOR multi-criteria decision making techniques. Metall. Mater. Eng. 2025, 31, 740–750. [Google Scholar] [CrossRef]

- Petrović, N.; Jovanović, V.; Marković, S.; Marinković, D.; Nikolić, B. Multi-criteria Decision-Making Approach for choising e-Bus for Urban Public Transport in the City of Niš. Acta Tech. Jaurinensis 2025, 18, 1–8. [Google Scholar] [CrossRef]

- Petrović, N.; Mihajlović, J.; Jovanović, V.; Ćirić, D.; Živojinović, T. Evaluating Annual Operation Performance of Serbian Railway System by using Multiple Criteria Decision-Making Technique. Acta Polytech. Hung. 2023, 20, 157–168. [Google Scholar] [CrossRef]

- Tomić, V.; Marinković, D.; Marković, D. The selection of logistic centers location using multi-criteria comparison: Case study of the Balkan Peninsula. Acta Polytech. Hung. 2014, 11, 97–113. [Google Scholar] [CrossRef]

- Stević, Ž.; Baydaş, M.; Kavacık, M.; Ayhan, E.; Marinković, D. Selection of data conversion technique via sensitivity-performance matching: Ranking of small e-vans with PROBID method. Facta Univ. Ser. Mech. Eng. 2024, 22, 643–671. [Google Scholar] [CrossRef]

- Tadić, D.; Komatina, N. A Hybrid Interval Type-2 Fuzzy DEMATEL-MABAC Approach for Strategic Failure Management in Automotive Manufacturing. J. Eng. Manag. Syst. Eng. 2025, 4, 21–38. [Google Scholar] [CrossRef]

- Krstić, M.; Tadić, S.; Čvorović, A.; Veljović, M. Optimization of Last-Mile Delivery Alternatives Using the Fuzzy FARE and ADAM Multi-Criteria Decision-Making Methods. J. Eng. Manag. Syst. Eng. 2025, 4, 98–108. [Google Scholar] [CrossRef]

- Božanić, D.; Epler, I.; Puška, A.; Biswas, S.; Marinković, D.; Koprivica, S. Application of the DIBR II—ROUGH MABAC Decision-making model for ranking methods and techniques of Lean organization systems management in the process of technical maintenance. Facta Univ. Ser. Mech. Eng. 2024, 22, 101–123. [Google Scholar] [CrossRef]

- Jin, G.; Meng, Q.; Feng, W. Optimization of Logistics System with Fuzzy FMEA-AHP Methodology. Processes 2022, 10, 1973. [Google Scholar] [CrossRef]

- Deepika, S.; Anandakumar, S.; Bhuvanesh, K.M.; Baskar, C. Performance appraisement of supplier selection in Construction Company with Fuzzy AHP, Fuzzy TOPSIS, and DEA: A case study based approach. J. Intell. Fuzzy Syst. 2023, 45, 10515–10528. [Google Scholar] [CrossRef]

- Saleem, H.; Ahmad, S.; Shafeeque, U.B.; Khan, N.A. Fuzzy TOPSIS Method for Sustainable Supplier Assortment in Green Supply Chain Management. EAI Endorsed Trans. Scalable Inf. Syst. 2025, 12. [Google Scholar] [CrossRef]

- Le, M.-T. Strategic Prioritization for Sustainable Development in the Logistics Industry: A FAHP-NFAD Approach. Appl. Sci. 2025, 15, 4364. [Google Scholar] [CrossRef]

- Kilibarda, M.; Andrejic, M.; Pajic, V. Supply Chain RFID Solution Evaluation Applying AHP and FAHP Methods: A Case Study of the Serbian Market. Teh. Vjesn. 2022, 29, 1811–1818. [Google Scholar] [CrossRef]

- Luo, Y. Research on the Operational Efficiency Evaluation of Listed Logistics Enterprises in China Based on the DEA-Malmquist Index. Adv. Econ. Manag. Political Sci. 2025, 154, 179–189. [Google Scholar] [CrossRef]

- Chakraborty, S.; Saha, A. Selection of forklift unit for transport handling using integrated MCDM under neutrosophic environment. Facta Univ. Ser. Mech. Eng. 2024, 235–256. [Google Scholar] [CrossRef]

- Popović, V.; Pamučar, D.; Stević, Ž.; Lukovac, V.; Jovković, S. Multicriteria Optimization of Logistics Processes Using a Grey FUCOM-SWOT Model. Symmetry 2022, 14, 794. [Google Scholar] [CrossRef]

- Qiu, Y. Competitiveness evaluation of listed logis tics companies based on factor analysis method. Econ. Bus. Manag. 2025, 1, 97–106. [Google Scholar] [CrossRef]

- Selamzade, F.; Ersoy, Y.; Tehci, A. CO2 Emission Efficiency Measurement: Green Logistics Perspective. Veriml. Derg. (Product. Logist.) 2025, 139–148. [Google Scholar] [CrossRef]

- Petrović, N.; Bojović, N.; Marinković, D.; Jovanović, V.; Milanović, S. A Two-Phase Model for the Evaluation of Urbanization Impacts on Carbon Dioxide Emissions from Transport in the European Union. Teh. Vjesn. 2023, 30, 514–520. [Google Scholar] [CrossRef]

- Kozoderović, J.; Pajić, V.; Andrejić, M. A Multi-Criteria Analysis for E-commerce Warehouse Location Selection Using SWARA and ARAS Methods. J. Eng. Manag. Syst. Eng. 2025, 4, 122–132. [Google Scholar] [CrossRef]

- Petrović, N.; Jovanović, V.; Marinković, D.; Marković, S.; Nikolić, B. Measuring the Efficiency of Rail Freight Transport—A Case Study. Acta Polytech. Hung. 2025, 22, 123–136. [Google Scholar] [CrossRef]

- Čiković, K.F.; Keček, D.; Lozić, J. A PRISMA-Compliant Review of DEA Applications in Multimedia. Teh. Vjesn. 2023, 30, 655–659. [Google Scholar] [CrossRef]

- Li, R. A TOPSIS and DEA Based Approach to Evaluate the Operational Efficiency of Sponge City. Teh. Vjesn. 2023, 30, 8–16. [Google Scholar] [CrossRef]

- Štreimikienė, D.; Bathaei, A.; Streimikis, J. MCDM Approaches for Supplier Selection in Sustainable Supply Chain Management. Sustainability 2024, 16, 10446. [Google Scholar] [CrossRef]

- Farrell, M.J. The measurement of productive efficiency. J. R. Stat. Soc. Ser. A (Gen.) 1957, 120, 253–281. [Google Scholar] [CrossRef]

- Gleason, J.M.; Barnum, D.T. Toward valid measures of public sector productivity: Performance measures in urban transit. Manag. Sci. 1982, 28, 379–386. [Google Scholar] [CrossRef]

- Min, H.; Jong Joo, S. Benchmarking the operational efficiency of third party logistics providers using data envelopment analysis. Supply Chain Manag. Int. J. 2006, 11, 259–265. [Google Scholar] [CrossRef]

- Götz, L.N.; Staudt, H.F.; Borba, G.L.J.; Bouzon, M. A framework for logistics performance indicators selection and targets definition: A civil construction enterprise case. Production 2023, 33, e20220075. [Google Scholar] [CrossRef]

- Peixoto, M.G.M.; Mendonça, M.C.A.; Carvalho de Castro, C.; Gonzaga de Castro Júnior, L.; Alves de Melo, G.; Batalha, O.M. Evaluation of the operational efficiency of southeast intermodal terminals in the grain logistics chain using data envelopment analysis. Manag. Decis. Econ. 2022, 43, 3044–3058. [Google Scholar] [CrossRef]

- Lee, P.F.; Lam, W.S.; Lam, W.H. Performance Evaluation of the Efficiency of Logistics Companies with Data Envelopment Analysis Model. Mathematics 2023, 11, 718. [Google Scholar] [CrossRef]

- Ertok Onurlu, M.; Aliyev, E. The Evaluation of Financial Performances of Logistics Companies in Turkey: A Data Envelopment Analysis Approach. Yönetim Bilim. Derg. 2021, 19, 773–798. [Google Scholar] [CrossRef]

- Abdel-Halim, A.; Al Khars, M.; Alnasser, A. Evaluating the technical efficiency of Saudi Arabian telecommunications companies using window DEA and AHP techniques. Int. J. Islam. Middle East. Financ. Manag. 2023, 16, 1306–1325. [Google Scholar] [CrossRef]

- Alfina, K.N.; Ratnayake, R.M.C.; Wibisono, D.; Basri, H.M.; Nur Budi Mulyono, B.N. Prioritizing Performance Indicators for the Circular Economy Transition in Healthcare Supply Chains. Circ. Econ. Sustain. 2025, 5, 231–276. [Google Scholar] [CrossRef]

- Alves de Araújo, F.; Mendes dos Reis, J.G.; Terra da Silva, M.; Aktas, E. A Fuzzy Analytic Hierarchy Process Model to Evaluate Logistics Service Expectations and Delivery Methods in Last-Mile Delivery in Brazil. Sustainability 2022, 14, 5753. [Google Scholar] [CrossRef]

- Lu, Z.-P.; Lu, C.-Y. Logistics Performance Evaluation of Logistics Enterprise Integrated with KPIs and FAHP Model. In Proceedings of the 2011 International Conference on Computer and Management (CAMAN), Wuhan, China, 19–21 May 2011; pp. 1–4. [Google Scholar] [CrossRef]

- Kaewfak, K.; Huynh, V.-N.; Ammarapala, V.; Ratisoontorn, N. A Risk Analysis Based on a Two-Stage Model of Fuzzy AHP-DEA for Multimodal Freight Transportation Systems. IEEE Access 2020, 8, 153756–153773. [Google Scholar] [CrossRef]

- Sheikhalishahi, M.; Hakimi, A.; Hakimi, M. An integrated fuzzy AHP- fuzzy DEA approach for location optimization of renewable energy plants. J. Ind. Syst. Eng. 2022, 14, 11–18. Available online: https://www.jise.ir/article_143884_c3439c46bb5aa6d7f011f29c6f995f7d.pdf (accessed on 8 May 2025).

- Yang, J.; Yang, C.; Wang, X.; Cheng, M.; Shang, J. Efficiency Measurement and Factor Analysis of China’s Solar Photovoltaic Power Generation Considering Regional Differences Based on a FAHP–DEA Model. Energies 2020, 13, 1936. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Derbel, A.; Boujelbene, Y. Performance classification of Tunisian public transport operators. Public Transp. 2023, 15, 535–574. [Google Scholar] [CrossRef]

- Stević, Ž.; Miškić, S.; Vojinović, D.; Huskanović, E.; Stanković, M.; Pamučar, D. Development of a Model for Evaluating the Efficiency of Transport Companies: PCA–DEA–MCDM Model. Axioms 2022, 11, 140. [Google Scholar] [CrossRef]

- Johnson, A. Methods in Productivity and Efficiency Analysis with Applications to Warehousing. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2006. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=7eb71a0f1c17027f6eb82c20e00960b94db43063 (accessed on 9 May 2025).

- Yurtay, Y.; Yurtay, N.; Demirci, H.; Zaimoglu, E.A.; Göksu, A. Improvement and Implementation of Sustainable Key Performance Indicators in Supply Chain Management: The Case of a Furniture Firm. IEEE Access 2023, 11, 41913–41927. [Google Scholar] [CrossRef]

- Jeremić, V. Statistical Efficiency Model Based on the Ivanovic Distance. Ph.D. Thesis, Faculty of Organizational Sciences, University of Belgrade, Beograd, Serbia, 2012. Available online: https://nardus.mpn.gov.rs/handle/123456789/3046 (accessed on 9 May 2025).

- Staudt, F.H.; Piran, F.A.S.; Alpan, G. Exploratory Analysis of CCR-DEA application for Logistics performance management. In Proceedings of the 10th International Conference on Control, Decision and Information Technologies (CoDIT), Vallette, Malta, 1–4 July 2024; pp. 2313–2318. [Google Scholar] [CrossRef]

- Chenrrim, P.; Relvas, S. A data envelopment analysis approach for evaluating high-speed freight transportation efficiency. Transp. Res. Interdiscip. Perspect. 2025, 29, 101338. [Google Scholar] [CrossRef]

- Cook, W.D.; Seiford, L.M. Data envelopment analysis (DEA)–Thirty years on. Eur. J. Oper. Res. 2009, 192, 1–17. [Google Scholar] [CrossRef]

- Kharaghania, M.S.R.; Madadkhania, A. Evaluating ESG efficiency using DEA an analysis of Dow Jones Industrial average companies. Accounting 2025, 11, 197–208. [Google Scholar] [CrossRef]

- Saaty, T.L. The analytic hierarchy process (AHP). J. Oper. Res. Soc. 1980, 41, 1073–1076. [Google Scholar]

- Saaty, T.L. Decision-making with the AHP: Why is the principal eigenvector necessary? Eur. J. Oper. Res. 2003, 145, 85–91. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy and Analytic Network Processes for the Measurement of Intangible Criteria and for Decision-Making. In International Series in Operations Research & Management Science; Springer: Berlin/Heidelberg, Germany, 2016; pp. 363–419. [Google Scholar]

- Pivac, J.; Štimac, I.; Bartulović, D.; Vidović, A. Determining the Optimal Level of Service of the Airport Passenger Terminal for Low-Cost Carriers Using the Analytical Hierarchy Process. Appl. Sci. 2025, 15, 1734. [Google Scholar] [CrossRef]

- Erdem, M.; Özdemir, A.; Kosunalp, S.; Iliev, T. Assessment of Sustainability and Risk Indicators in an Urban Logistics Network Analysis Considering a Business Continuity Plan. Appl. Sci. 2025, 15, 5145. [Google Scholar] [CrossRef]

- Hussain, A.; Ullah, K. An Intelligent Decision Support System for Spherical Fuzzy Sugeno-Weber Aggregation Operators and Real-Life Applications. Spectr. Mech. Eng. Oper. Res. 2024, 1, 177–188. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P. Evaluating and Prioritizing Blockchain Networks using Intuitionistic Fuzzy Multi-Criteria Decision-Making Method. Spectr. Mech. Eng. Oper. Res. 2025, 2, 78–92. [Google Scholar] [CrossRef]

- Liou, T.S.; Wang, M.J.J. Ranking fuzzy numbers with integral value. Fuzzy Sets Syst. 1992, 50, 247–255. [Google Scholar] [CrossRef]

- Samhouri, M.; Abualeenein, M.; Al-Atrash, F. Enhancing Supply Chain Resilience Through a Fuzzy AHP and TOPSIS to Mitigate Transportation Disruption. Sustainability 2025, 17, 7375. [Google Scholar] [CrossRef]

- Aguarón, J.; Escobar, M.T.; Moreno-Jiménez, J.M. Reducing inconsistency measured by the geometric consistency index in the analytic hierarchy process. Eur. J. Oper. Res. 2021, 288, 576–583. [Google Scholar] [CrossRef]

- Balusa, B.C.; Gorai, A.G. Sensitivity analysis of fuzzy-analytic hierarchical process (FAHP) decision-making model in selection of underground metal mining method. J. Sustain. Min. 2019, 18, 8–17. [Google Scholar] [CrossRef]

- Vinogradova-Zinkevič, I. Comparative Sensitivity Analysis of Some Fuzzy AHP Methods. Mathematics 2023, 11, 4984. [Google Scholar] [CrossRef]

- Triantaphyllou, E.; Sánchez, A. A Sensitivity Analysis Approach for Some Deterministic Multi-Criteria Decision-Making Methods. Decis. Sci. 1997, 28, 151–194. [Google Scholar] [CrossRef]

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | … |

| RI | 0.00 | 0.00 | 0.52 | 0.89 | 1.11 | 1.25 | 1.35 | 1.40 | 1.45 | 1.49 | … |

| No. | Criteria | Explanation of Criteria | Unit | Character |

|---|---|---|---|---|

| C1 | Number of vehicles | Vehicles used in the company | [number] | Min |

| C2 | Fuel costs | Cost of fuel consumed during transportation during one year | [euro] | Min |

| C3 | Vehicle engagement time | The time the vehicle was hired outside the company’s fleet | [h] | Min |

| C4 | Distance traveled | Distance traveled by all vehicles in one year | [km] | Max |

| C5 | Transported quantity | Transported cargo quantities by vehicles during one year | [t] | Max |

| C6 | Vehicle utilization | Vehicle load capacity utilization during transport | [%] | Max |

| DMU Decision Making Unit | LC Logistics Companies | C1 Number of Vehicles | C2 Fuel Costs | C3 Vehicle Engagement Time | C4 Distance Traveled | C5 Transported Quantity | C6 Vehicle Utilization |

|---|---|---|---|---|---|---|---|

| DMU1 | LC1 | 29 | 2370.5 | 6500 | 114,122 | 5,994,686 | 86 |

| DMU2 | LC2 | 15 | 590.2 | 2647 | 32,795 | 917,034 | 87 |

| DMU3 | LC3 | 37 | 5149.9 | 10,771 | 226,242 | 19,279,019 | 81 |

| DMU4 | LC4 | 21 | 3837.3 | 7142 | 159,893 | 7,474,618 | 98 |

| DMU5 | LC5 | 18 | 1098.2 | 3776 | 53,641 | 1,326,588 | 98 |

| DMU6 | LC6 | 24 | 3308.4 | 6079 | 153,413 | 3,988,841 | 99 |

| DMU7 | LC7 | 12 | 1057.7 | 3133 | 61,369 | 1,192,797 | 90 |

| DMU8 | LC8 | 22 | 3492.5 | 2462 | 54,769 | 3423 | 98 |

| DMU9 | LC9 | 16 | 2320.6 | 1525 | 38,813 | 1721 | 86 |

| DMU10 | LC10 | 13 | 1904.9 | 939 | 33,334 | 1334 | 76 |

| DMU | DEA-Input | DEA-Output | DEA-Final |

|---|---|---|---|

| DMU1 | 1.037 | 0.963 | 0.928 |

| DMU2 | 1.000 | 1.000 | 1.000 |

| DMU3 | 1.000 | 1.000 | 1.000 |

| DMU4 | 1.000 | 1.000 | 1.000 |

| DMU5 | 1.155 | 0.865 | 0.748 |

| DMU6 | 1.000 | 1.000 | 1.000 |

| DMU7 | 1.000 | 1.000 | 1.000 |

| DMU8 | 1.307 | 0.764 | 0.584 |

| DMU9 | 1.125 | 0.888 | 0.789 |

| DMU10 | 1.000 | 1.000 | 1.000 |

| DMU Decision Making Unit | LC Logistics Companies | C1 Number of Vehicles | C2 Fuel Costs | C3 Vehicle Engagement Time | C4 Distance Traveled | C5 Transported Quantity | C6 Vehicle Utilization |

|---|---|---|---|---|---|---|---|

| DMU1 | LC1 | 7.467004 | 0 | 635.1409 | 0 | 0 | 17.71902 |

| DMU2 | LC2 | 0 | 0 | 0 | 0 | 0 | 0 |

| DMU3 | LC3 | 0 | 0 | 0 | 0 | 0 | 0 |

| DMU4 | LC4 | 0 | 0 | 0 | 0 | 0 | 0 |

| DMU5 | LC5 | 0.402932 | 0 | 0 | 0 | 0 | 0 |

| DMU6 | LC6 | 0 | 0 | 0 | 0 | 0 | 0 |

| DMU7 | LC7 | 0 | 0 | 0 | 0 | 0 | 0 |

| DMU8 | LC8 | 0 | 323.0135 | 0 | 0 | 482,844.0 | 0 |

| DMU9 | LC9 | 0 | 80.23866 | 0 | 2077.830 | 172,291.4 | 0 |

| DMU10 | LC10 | 0 | 0 | 0 | 0 | 0 | 0 |

| LC Logistics Companies | C1 Number of Vehicles | C2 Fuel Costs | C3 Vehicle Engagement Time | C4 Distance Traveled | C5 Transported Quantity | C6 Vehicle Utilization |

|---|---|---|---|---|---|---|

| LC2 | 15 | 590.2 | 2647 | 32,795 | 917,034 | 87 |

| LC3 | 37 | 5149.9 | 10,771 | 226,242 | 19,279,019 | 81 |

| LC4 | 21 | 3837.3 | 7142 | 159,893 | 7,474,618 | 98 |

| LC6 | 24 | 3308.4 | 6079 | 153,413 | 3,988,841 | 99 |

| LC7 | 12 | 1057.7 | 3133 | 61,369 | 1,192,797 | 90 |

| LC10 | 13 | 1904.9 | 939 | 33,334 | 1334 | 76 |

| b1 | b2 | b3 | b4 | b5 | b6 | |

|---|---|---|---|---|---|---|

| b1 | 1.00 | 0.33 | 0.20 | 0.25 | 0.50 | 0.17 |

| b2 | 3.00 | 1.00 | 0.33 | 0.33 | 3.00 | 0.17 |

| b3 | 5.00 | 3.00 | 1.00 | 2.00 | 6.00 | 2.00 |

| b4 | 4.00 | 3.00 | 0.50 | 1.00 | 5.00 | 0.33 |

| b5 | 2.00 | 0.33 | 0.17 | 0.20 | 1.00 | 0.33 |

| b6 | 6.00 | 6.00 | 0.50 | 3.00 | 3.00 | 1.00 |

| L | M | R | Fuzzification | |

|---|---|---|---|---|

| very small VM | 0 | 0 | 0.20 | 0.066667 |

| small M | 0.10 | 0.25 | 0.40 | 0.25 |

| medium S | 0.30 | 0.50 | 0.70 | 0.50 |

| large L | 0.55 | 0.75 | 0.95 | 0.75 |

| very large VL | 0.80 | 1 | 1 | 0.933333 |

| C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|

| C1 | 1.000 | 0.933 | 0.750 | 0.750 | 0.750 | 0.933 |

| C2 | 0.933 | 1.000 | 0.750 | 0.933 | 0.933 | 0.250 |

| C3 | 0.750 | 0.750 | 1.000 | 0.067 | 0.933 | 0.500 |

| C4 | 0.750 | 0.933 | 0.067 | 1.000 | 0.500 | 0.933 |

| C5 | 0.750 | 0.933 | 0.933 | 0.500 | 1.000 | 0.933 |

| C6 | 0.933 | 0.250 | 0.500 | 0.933 | 0.933 | 1.000 |

| Left | Median | Right | |

|---|---|---|---|

| C1 | 0.028 | 0.042 | 0.065 |

| C2 | 0.069 | 0.099 | 0.170 |

| C3 | 0.179 | 0.325 | 0.575 |

| C4 | 0.103 | 0.183 | 0.323 |

| C5 | 0.039 | 0.058 | 0.089 |

| C6 | 0.168 | 0.294 | 0.542 |

| Criteria | C1 Number of Vehicles | C2 Fuel Costs | C3 Vehicle Engagement Time | C4 Distance Traveled | C5 Transported Quantity | C6 Vehicle Utilization |

|---|---|---|---|---|---|---|

| Weights of the criteria | 0.0403 | 0.1007 | 0.3220 | 0.1817 | 0.0554 | 0.2999 |

| Rank | 6 | 4 | 1 | 3 | 5 | 2 |

| Logistic Companies | Criteria | C1 | C2 | C3 | C4 | C5 | C6 | Preference Pi | Rank |

|---|---|---|---|---|---|---|---|---|---|

| wi | 0.0403 | 0.1007 | 0.3220 | 0.1817 | 0.0554 | 0.2999 | |||

| LC2 | 0.0049 | 0.0038 | 0.0278 | 0.0089 | 0.0015 | 0.0491 | 0.0961 | 5 | |

| LC3 | 0.0122 | 0.0327 | 0.1129 | 0.0616 | 0.0325 | 0.0457 | 0.2978 | 1 | |

| LC4 | 0.0069 | 0.0247 | 0.0749 | 0.0435 | 0.0126 | 0.0553 | 0.2180 | 2 | |

| LC6 | 0.0079 | 0.0210 | 0.0637 | 0.0418 | 0.0067 | 0.0559 | 0.1971 | 3 | |

| LC7 | 0.0040 | 0.0067 | 0.0328 | 0.0167 | 0.0020 | 0.0508 | 0.1131 | 4 | |

| LC10 | 0.0043 | 0.0121 | 0.0098 | 0.0091 | 0.0000 | 0.0429 | 0.0782 | 6 | |

| Pair of Alternatives | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|

| 0.0403 | 0.1007 | 0.3220 | 0.1817 | 0.0554 | 0.2999 | |

| LC2–LC3 | N/F | 0.0231 | 0.0496 | 0.0292 | 0.0096 | 0.2166 |

| LC2–LC4 | N/F | 0.0185 | 0.0452 | 0.0250 | 0.0150 | 0.1082 |

| LC2–LC6 | N/F | 0.0180 | 0.0440 | 0.0216 | 0.0232 | 0.0888 |

| LC2–LC7 | 0.0213 | 0.0095 | 0.0144 | 0.0091 | 0.0131 | 0.0165 |

| LC2–LC10 | −0.0206 | −0.0055 | −0.0502 | −0.0175 | −12.2504 | −0.0204 |

| LC3–LC4 | −0.1405 | −0.1058 | −0.1203 | −0.1129 | −0.2057 | −0.0659 |

| LC3–LC6 | −0.1552 | −0.1567 | −0.1784 | −0.1484 | −0.4865 | −0.0824 |

| LC3–LC7 | −0.5694 | −0.8992 | −0.6349 | −0.6809 | −2.9850 | −0.1662 |

| LC3–LC10 | −0.6248 | −0.5935 | −2.5181 | −1.4899 | −3172.5720 | −0.2340 |

| LC4–LC6 | −0.0183 | −0.0245 | −0.0245 | −0.0218 | −0.0391 | −0.0207 |

| LC4–LC7 | −0.1836 | −0.3851 | −0.2392 | −0.2733 | −0.6574 | −0.1142 |

| LC4–LC10 | −0.2258 | −0.2849 | −1.0630 | −0.6704 | −783.0627 | −0.1802 |

| LC6–LC7 | −0.1680 | −0.2628 | −0.1630 | −0.2100 | −0.2810 | −0.0924 |

| LC6–LC10 | −0.2194 | −0.2064 | −0.7695 | −0.5471 | −355.4211 | −0.1548 |

| LC7–LC10 | −0.0322 | −0.0193 | −0.1162 | −0.0641 | −31.1525 | −0.0413 |

| Pair of Alternatives | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|

| 0.0403 | 0.1007 | 0.3220 | 0.1817 | 0.0554 | 0.2999 | |

| LC2–LC3 | N/F | 22.9446 | 15.3950 | 16.0931 | 17.3057 | 72.2393 |

| LC2–LC4 | N/F | 18.3966 | 14.0354 | 13.7655 | 26.9831 | 36.0944 |

| LC2–LC6 | N/F | 17.8920 | 13.6647 | 11.8891 | 41.9009 | 29.6087 |

| LC2–LC7 | 52.8554 | 9.4266 | 4.4659 | 5.0061 | 23.6018 | 5.4860 |

| LC2–LC10 | −51.0853 | −5.4804 | −15.6019 | −9.6501 | −22,096.5767 | −6.8022 |

| LC3–LC4 | −349.1817 | −105.0162 | −37.3634 | −62.1266 | −371.1183 | −21.9850 |

| LC3–LC6 | −385.5430 | −155.5260 | −55.3920 | −81.7068 | −877.5421 | −27.4619 |

| LC3–LC7 | −1414.7395 | −892.5494 | −197.1935 | −374.7528 | −5384.2077 | −55.4239 |

| LC3–LC10 | −1552.2715 | −589.0822 | −782.0610 | −820.0868 | −5,722,500.2422 | −78.0152 |

| LC4–LC6 | −45.4105 | −24.3345 | −7.6221 | −11.9834 | −70.6054 | −6.8951 |

| LC4–LC7 | −456.1379 | −382.2848 | −74.2777 | −150.4538 | −1185.8451 | −38.0925 |

| LC4–LC10 | −560.8752 | −282.7546 | −330.1303 | −368.9751 | −1,412,442.8587 | −60.0899 |

| LC6–LC7 | −417.5050 | −260.8718 | −50.6342 | −115.6138 | −506.8265 | −30.8193 |

| LC6–LC10 | −545.1891 | −204.9109 | −238.9938 | −301.1055 | −641,087.8686 | −51.6297 |

| LC7–LC10 | −79.8999 | −19.2017 | −36.1031 | −35.3049 | −56,190.9771 | −13.7574 |

| Criticality degrees Dk | 45.4105 | 5.4804 | 4.4659 | 5.0061 | 17.3057 | 5.4860 |

| Sensitivity coefficient sens (Ck) | 0.0220 | 0.1825 | 0.2239 | 0.1998 | 0.0578 | 0.1823 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrović, N.; Jovanović, V.; Marinković, D.; Nikolić, B.; Marković, S. Logistics Companies’ Efficiency Analysis and Ranking by the DEA-Fuzzy AHP Approach. Appl. Sci. 2025, 15, 9549. https://doi.org/10.3390/app15179549

Petrović N, Jovanović V, Marinković D, Nikolić B, Marković S. Logistics Companies’ Efficiency Analysis and Ranking by the DEA-Fuzzy AHP Approach. Applied Sciences. 2025; 15(17):9549. https://doi.org/10.3390/app15179549

Chicago/Turabian StylePetrović, Nikola, Vesna Jovanović, Dragan Marinković, Boban Nikolić, and Saša Marković. 2025. "Logistics Companies’ Efficiency Analysis and Ranking by the DEA-Fuzzy AHP Approach" Applied Sciences 15, no. 17: 9549. https://doi.org/10.3390/app15179549

APA StylePetrović, N., Jovanović, V., Marinković, D., Nikolić, B., & Marković, S. (2025). Logistics Companies’ Efficiency Analysis and Ranking by the DEA-Fuzzy AHP Approach. Applied Sciences, 15(17), 9549. https://doi.org/10.3390/app15179549