An Investigation of Three-Dimensional Void Changes and Top-Down Microcrack Formation of AC-16 in Rutted and Non-Rutted Zones Under Extremely High Temperature and Heavy Load

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Raw Materials

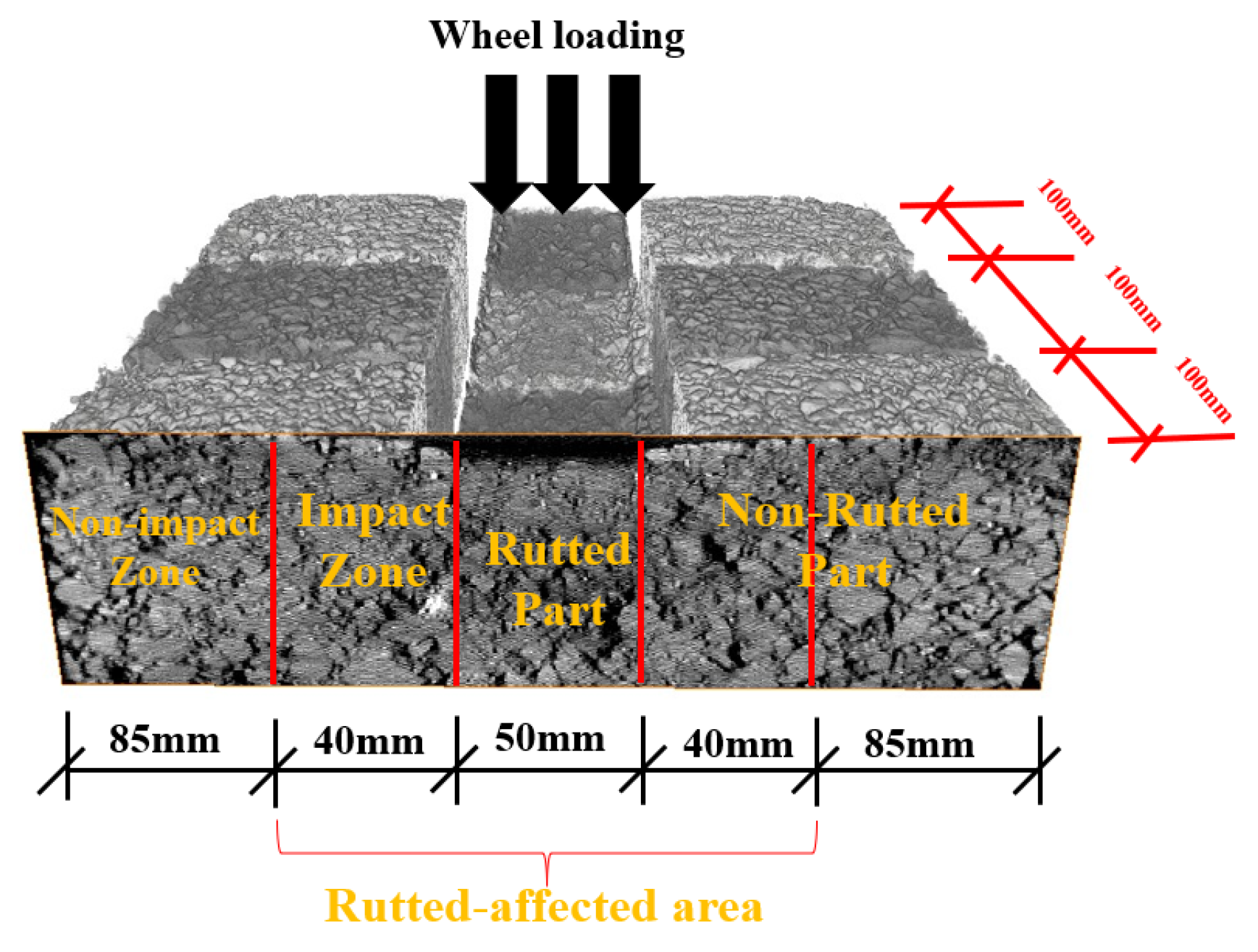

2.1.2. Specimen Fabrication and Rutting Test

2.2. Experiment and Computation Methods

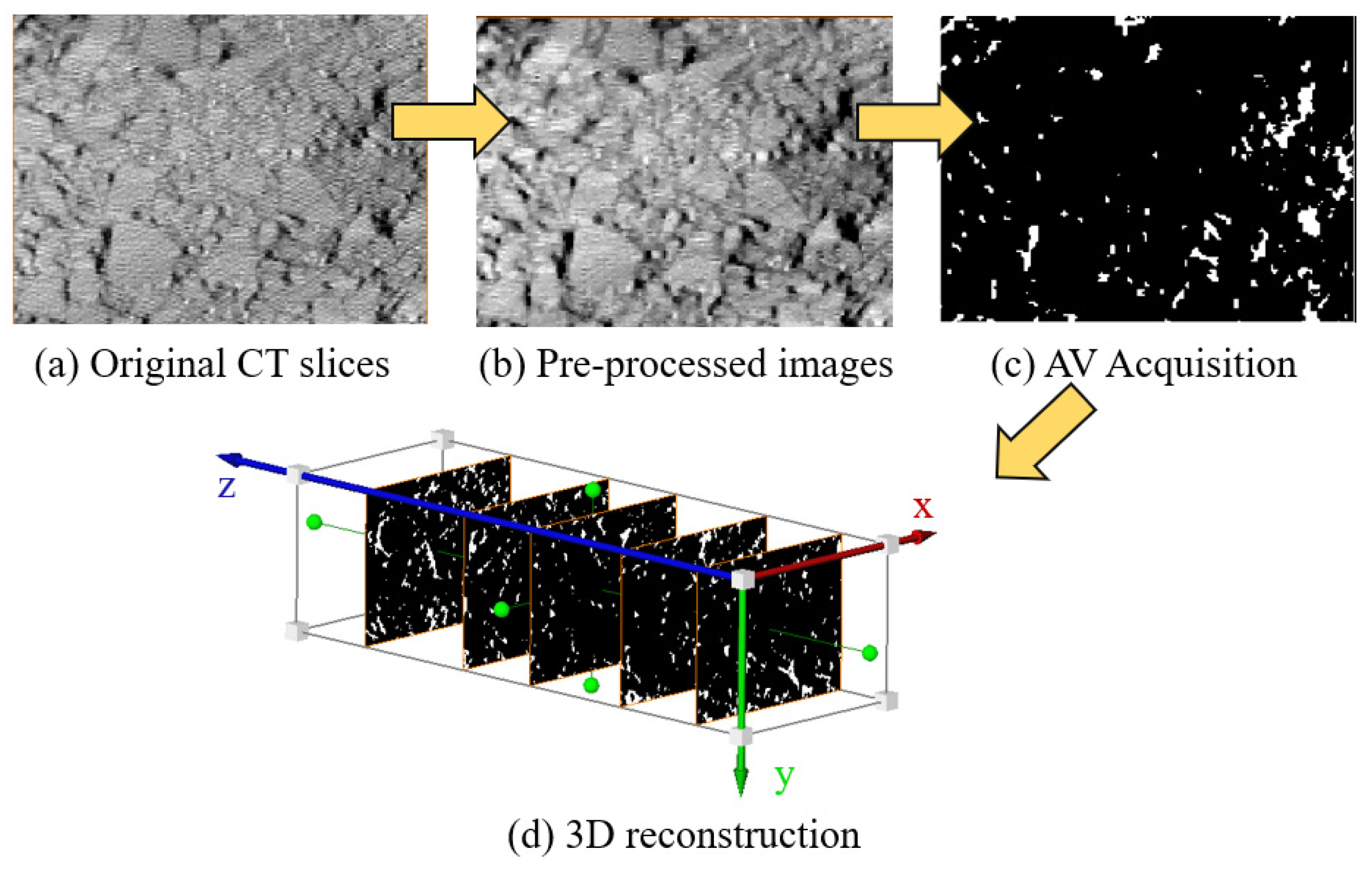

2.2.1. Image Data Acquisition

2.2.2. Digital Image Processing

2.2.3. Three-Dimensional Distribution and Morphological Features of Voids

3. Results and Discussion

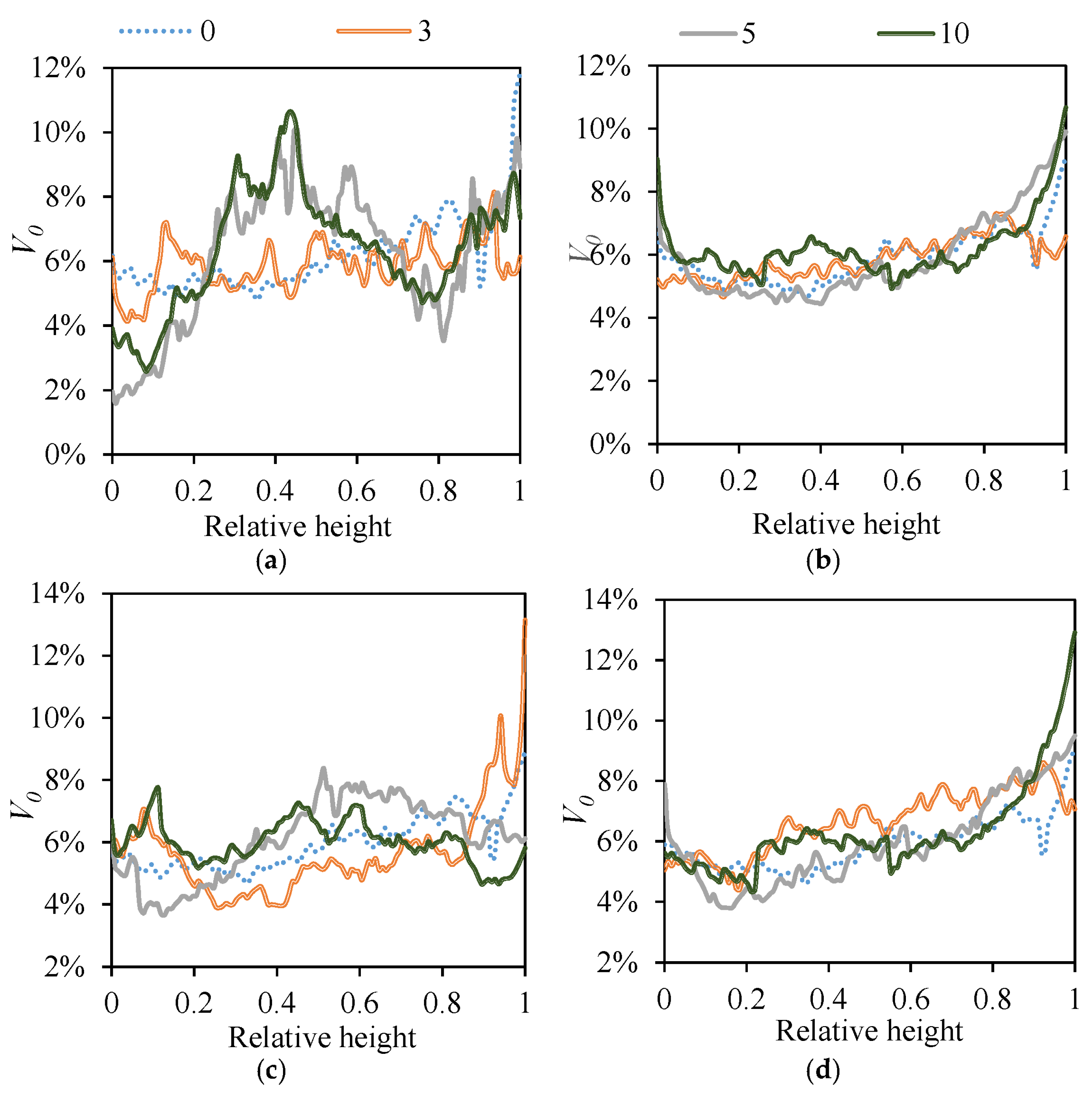

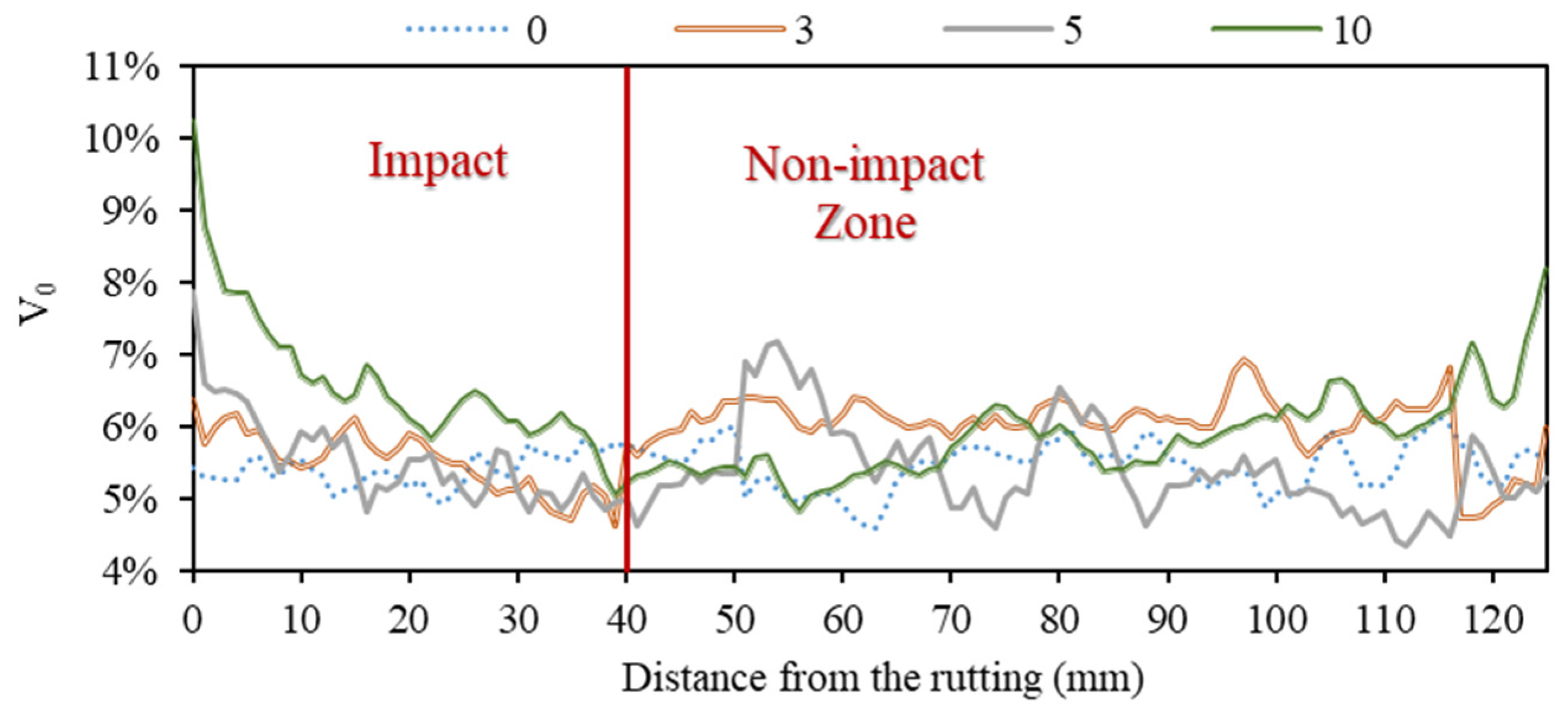

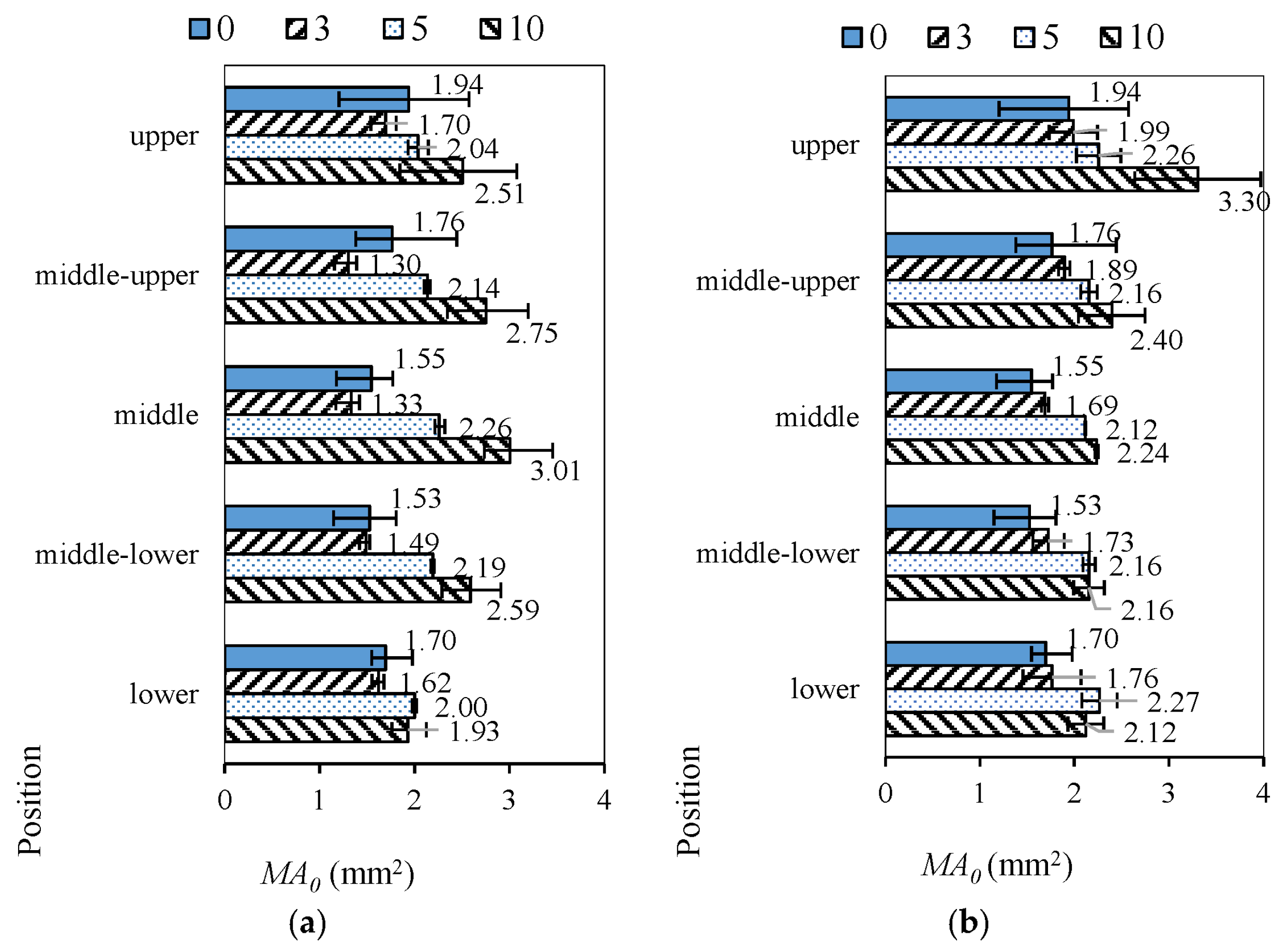

3.1. Void Ratio and Void Area

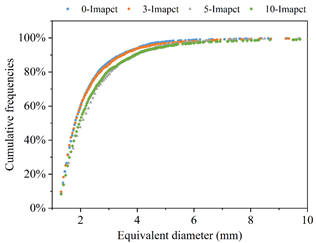

3.2. Equivalent Void Diameter

3.3. Aspect Ratio

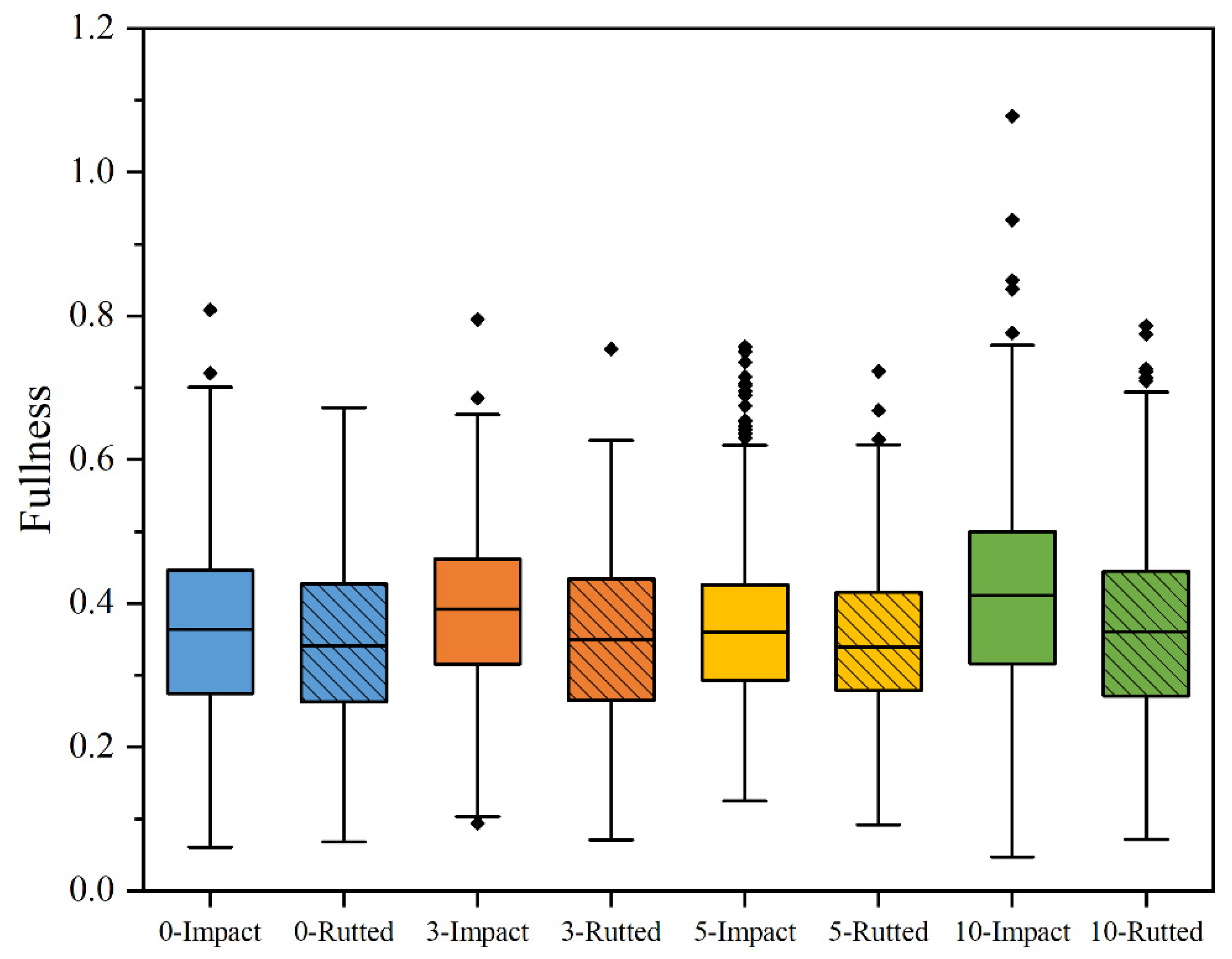

3.4. Sphericity and Fullness

3.5. Influence of Material and Testing Factors

4. Conclusions and Recommendations for Future Work

- The rut-impacted zone exhibits significant differences from both the rutted section and the non-impacted zone in terms of void depth distribution, volumetric development, and morphological characteristics. Under extreme high-temperature and heavy-load conditions, these differences are reflected in earlier crack initiation, larger voids, and increased instability in the fine-scale structure of the void–asphalt mortar–aggregate system.

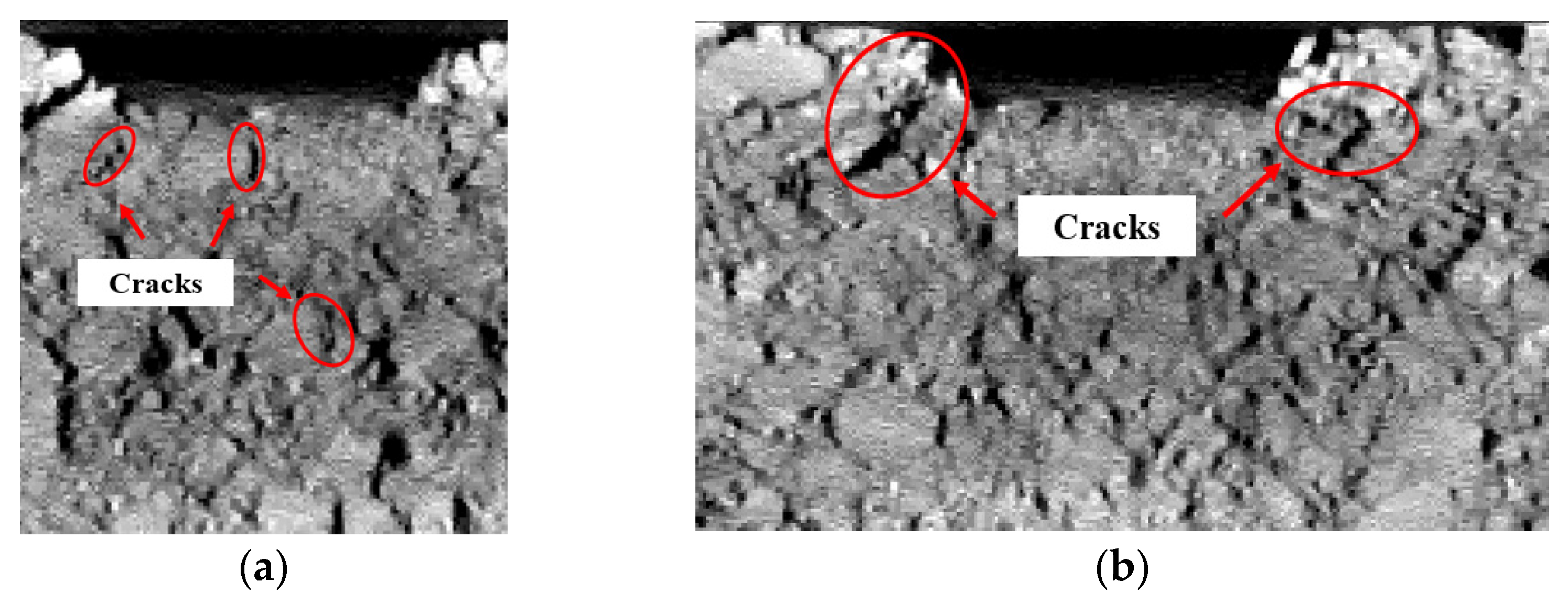

- At a rut depth of 5 mm, several TDCs longer than 6 mm were observed in the rut-impacted zone, whereas only one microcrack was detected in the rutted section of the same specimen. At a rut depth of 10 mm, the number of cracks became similar between the two zones; however, those in the impacted zone remained larger and wider.

- TDC damage caused by high-temperature rutting primarily occurs in the mid-to-upper region of the slab. Therefore, fine-scale data from the bottom region should be interpreted with caution.

- Combining morphological indicators with volumetric parameters can effectively track the initiation and propagation of microcracks. However, it should be noted that equivalent void diameter is not a sensitive indicator for distinguishing the degree of compaction or deformation in the same type of mixture. Furthermore, the fullness parameter should be applied in conjunction with aggregate characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Slurry Surfacing Association. Recommended Performance Guideline for Microsurfacing; ISSA A143; ISSA: Annapolis, MD, USA, 2010. [Google Scholar]

- Jiang, Y.J. Pavement Performance Measures and Forecasting and the Effects of Maintenance and Rehabilitation Strategy on Treatment Effectiveness; FHWA-HRT-17-095; Office of Infrastructure Research and Development: Washington, DC, USA, 2016.

- JTG/T 5148-01-2021; Technical Specifications for Preventive Maintenance of Highway Asphalt Pavement. Key Laboratory of Highway Engineering of Ministry of Education: Xi’an, China, 2021. (In Chinese)

- Shackil, G.; Ali, A.; Mehta, Y.; Papuc, D. Evaluating the laboratory cracking performance of pavement preservation materials using the Texas overlay tester. Constr. Build. Mater. 2020, 262, 120802. [Google Scholar] [CrossRef]

- Canestrari, F.; Ingrassia, L.P. A review of top-down cracking in asphalt pavements: Causes, models, experimental tools and future challenges. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 541–572. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Key Laboratory of Highway Engineering of Ministry of Education: Xi’an China, 2011. (In Chinese)

- Rieksts, K.; Pettinari, M.; Haritonovs, V. The influence of filler type and gradation on the rheological performance of mastics. Road Mater. Pavement Des. 2018, 20, 964–978. [Google Scholar] [CrossRef]

- Du, Y.; Chen, J.; Han, Z.; Liu, W. A review on solutions for improving rutting resistance of asphalt pavement and test methods. Constr. Build. Mater. 2018, 168, 893–905. [Google Scholar] [CrossRef]

- Simms, R.; Hernando, D.; Roque, R. A new paradigm to explain the development of instability rutting in asphalt pavements. Road Mater. Pavement Des. 2020, 21, 1815–1828. [Google Scholar] [CrossRef]

- Radhakrishnan, V.; Ramya Sri, M.; Reddy, K.S. Sensitivity of rutting and moisture resistance of asphalt mixes to gradation and design air void content. Int. J. Pavement Eng. 2020, 21, 1035–1043. [Google Scholar] [CrossRef]

- Norouzi, A.; Kim, D.; Richard Kim, Y. Numerical evaluation of pavement design parameters for the fatigue cracking and rutting performance of asphalt pavements. Mater. Struct. 2016, 49, 3619–3634. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, W.; Bahia, H.U.; Tang, N.; Zhu, T. Three-Stage Damage Evolution of Asphalt Mixture in the Wet Hamburg Wheel Tracking Device Test Using X-Ray Computed Tomography. J. Mater. Civ. Eng. 2018, 30, 04018138. [Google Scholar] [CrossRef]

- Ma, X.; Zhou, P.; Wang, L.; Jiang, J.; Wang, J. Internal structure change of porous asphalt concrete under coupled conditions of load, moisture and temperature. Constr. Build. Mater. 2022, 314, 125603. [Google Scholar] [CrossRef]

- Ren, J.; Xue, B.; Zhang, L.; Liu, W.; Li, D.; Xu, Y. Characterization and prediction of rutting resistance of rock asphalt mixture under the coupling effect of water and high-temperature. Constr. Build. Mater. 2020, 254, 119316. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, H.; Yu, T.; Shi, Y.; Liu, Y. Microscopic void characteristics of OGFC in Sponge City and its effect on noise reduction performance using X-ray CT. Constr. Build. Mater. 2023, 408, 133729. [Google Scholar] [CrossRef]

- Deng, Y.; Lu, T.; Ma, J.; Sun, D. Analysis on Factor Dependence of Rutting Depth in Composite Pavement Considering Tunnel Conditions. Int. J. Pavement Res. Technol. 2023, 16, 1501–1521. [Google Scholar] [CrossRef]

- Alamnie, M.M.; Taddesse, E.; Hoff, I. Advances in Permanent Deformation Modeling of Asphalt Concrete—A Review. Materials 2022, 15, 3480. [Google Scholar] [CrossRef]

- Alae, M.; Zarei, S.; Ouyang, J.; Xiao, F. Prediction of top-down crack resistance in semi-flexible pavements under coupling effect of rutted surface and temperature gradient. Int. J. Pavement Eng. 2023, 24, 2152024. [Google Scholar] [CrossRef]

- Wang, G.; Roque, R.; Morian, D. Effects of Surface Rutting on Near-Surface Pavement Responses Based on a Two-Dimensional Axle-Tire-Pavement Interaction Finite-Element Model. J. Mater. Civ. Eng. 2012, 24, 1388–1395. [Google Scholar] [CrossRef]

- Gu, F.; Luo, X.; West, R.C.; Taylor, A.J.; Moore, N.D. Energy-based crack initiation model for load-related top-down cracking in asphalt pavement. Constr. Build. Mater. 2018, 159, 587–597. [Google Scholar] [CrossRef]

- Sun, L.; Wang, G.; Zhang, H.; Liu, L. Initiation and Propagation of Top-Down Cracking in Asphalt Pavement. Appl. Sci. 2018, 8, 774. [Google Scholar] [CrossRef]

- Ling, M.; Luo, X.; Chen, Y.; Hu, S.; Lytton, R.L. A calibrated mechanics-based model for top-down cracking of asphalt pavements. Constr. Build. Mater. 2019, 208, 102–112. [Google Scholar] [CrossRef]

- Gao, L.; Kong, H.; Deng, X.; Wang, Z. Multi-scale finite element simulation of asphalt mixture anti-cracking performance. Theor. Appl. Fract. Mech. 2022, 121, 103490. [Google Scholar] [CrossRef]

- Dai, W.; Qian, G.; Zhu, X.; Yu, H.; Shi, C.; Zhang, C.; Ge, J.; Xie, T. Research on void characteristics during compaction of asphalt mixtures. Constr. Build. Mater. 2024, 416, 135069. [Google Scholar] [CrossRef]

- Jiang, S.; Weng, Z.; Wu, D.; Du, Y.; Liu, C.; Lin, Y. Pavement compactness estimation based on 3D pavement texture features. Case Stud. Constr. Mater. 2024, 21, e03768. [Google Scholar] [CrossRef]

- Teng, X.; Zhang, D.; Zhang, F. Study on Damage of the OGFC Mixture Based on Characteristics of Void Distribution. Adv. Mater. Sci. Eng. 2022, 2022, 1844556. [Google Scholar] [CrossRef]

- Yu, D.; Jing, H.; Liu, J. Effects of Freeze–Thaw Cycles on the Internal Voids Structure of Asphalt Mixtures. Materials 2022, 15, 3560. [Google Scholar] [CrossRef]

- Li, Y.; Hao, P.; Zhao, C.; Ling, J.; Wu, T.; Li, D.; Liu, J.; Sun, B. Anti-rutting performance evaluation of modified asphalt binders: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2021, 8, 339–355. [Google Scholar] [CrossRef]

- Wang, X.; Gu, X.; Hu, X.; Zhang, Q.; Dong, Q. Three-Stage Evolution of Air Voids and Deformation of Porous-Asphalt Mixtures in High-Temperature Permanent Deformation. J. Mater. Civ. Eng. 2020, 32, 04020233. [Google Scholar] [CrossRef]

- Li, Q.; Yang, H.; Ma, X.; Ni, F. Evaluation of microstructure and damage evolution for asphalt pavements in an advanced repeated load permanent deformation test using X-ray computed tomography. Road Mater. Pavement Des. 2017, 18, 1135–1158. [Google Scholar] [CrossRef]

- Li, J.; Han, X.; Li, X.; Diao, H.; He, Z. Investigation of aggregate gradation on air voids distribution in porous asphalt concrete using X-ray CT scanning images. Case Stud. Constr. Mater. 2024, 21, e03710. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, H.; Xie, K.; Jiang, L.; Ren, T.; Sun, Y. Meso-structural evolution characteristics of porous asphalt mixtures with stress-induced and their effects on environmental functions. Constr. Build. Mater. 2024, 432, 136687. [Google Scholar] [CrossRef]

- Zhao, K.; Yang, H.; Wang, W.; Wang, L. Characterization of Rutting Damage by the Change of Air-Void Characteristics in the Asphalt Mixture Based on Two-Dimensional Image Analysis. Materials 2022, 15, 7190. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Wu, Y. Performance Evaluation of Asphalt Pavement with Semi-Rigid Base and Fine-Sand Subgrade by Indoor Large-Scale Accelerated Pavement Testing; Accelerated Pavement Testing to Transport Infrastructure Innovation; Springer: Cham, Switzerland, 2020; pp. 80–89. [Google Scholar] [CrossRef]

- Kuang, X.; Yang, F.; Fu, J.; Liu, F. Analysis of early rutting disease at urban road intersection. Highlights Sci. Eng. Technol. 2022, 18, 38–41. [Google Scholar] [CrossRef]

- Li, J.; Guo, W.; Meng, A.; Han, M.; Tan, Y. Investigation on the Micro Deformation Mechanism of Asphalt Mixtures under High Temperatures Based on a Self-Developed Laboratory Test. Materials 2020, 13, 1791. [Google Scholar] [CrossRef] [PubMed]

- Saeed, F.; Rahman, M.; Chamberlain, D.; Collins, P. Asphalt surface damage due to combined action of water and dynamic loading. Constr. Build. Mater. 2019, 196, 530–538. [Google Scholar] [CrossRef]

- Shi, L.; Wang, Y.; Li, H.; Liang, H.; Lin, B.; Wang, D. Recycled asphalt mixture’s discrete element model-based composite structure and mesoscale-mechanical properties. Case Stud. Constr. Mater. 2023, 18, e01987. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, J. Experimental and Numerical Investigation of Dilation Behavior of Asphalt Mixture. Int. J. Geomech. 2017, 17, 04016062. [Google Scholar] [CrossRef]

- Liu, J.; Chen, S.; Liu, Q.; Wang, Y.; Yu, B. Influence of steel slag incorporation on internal skeletal contact characteristics within asphalt mixture. Constr. Build. Mater. 2022, 352, 129073. [Google Scholar] [CrossRef]

- Xu, H.; Shi, H.; Tan, Y. Investigation and Characterization of 3DVoid Meso-structures in Asphalt Mixtures. China J. Highw. Transp. 2020, 33, 210–220. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, T.; Ding, X.; Chen, T.; Huang, X.; Xu, G. Impacts of air-void structures on the rutting tests of asphalt concrete based on discretized emulation. Constr. Build. Mater. 2018, 166, 334–344. [Google Scholar] [CrossRef]

- Mahmud, M.Z.H.; Hassan, N.A.; Hainin, M.R.; Ismail, C.R. Microstructural investigation on air void properties of porous asphalt using virtual cut section. Constr. Build. Mater. 2017, 155, 485–494. [Google Scholar] [CrossRef]

- Jennings, B.R.; Parslow, K. Particle Size Measurement: The Equivalent Spherical Diameter. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1988, 419, 137–149. [Google Scholar] [CrossRef]

- Kuo, C.; Frost, J.D.; Lai, J.S.; Wang, L.B. Three-Dimensional Image Analysis of Aggregate Particles from Orthogonal Projections. Transp. Res. Rec. 1996, 1526, 98–103. [Google Scholar] [CrossRef]

- Valsangkar, A.J. Principles, Methods and Applications of Particle Size Analysis; Cambridge University Press: Cambridge, UK, 1992; Volume 29, p. 1006. [Google Scholar] [CrossRef]

- Wadell, H. Sphericity and Roundness of Rock Particles. J. Geol. 1933, 41, 310–331. [Google Scholar] [CrossRef]

- Gao, L.; Ni, F.; Luo, H.; Charmot, S. Characterization of air voids in cold in-place recycling mixtures using X-ray computed tomography. Constr. Build. Mater. 2015, 84, 429–436. [Google Scholar] [CrossRef]

- Xia, X.; Han, D.; Zhao, Y.; Xie, Y.; Zhou, Z.; Wang, J. Investigation of asphalt pavement crack propagation based on micromechanical finite element: A case study. Case Stud. Constr. Mater. 2023, 19, e02247. [Google Scholar] [CrossRef]

| Test Metrics | Value | Test Methods | |

|---|---|---|---|

| Penetration (25 °C, 5 s, 100 g) (0.1 mm) | 69 | T0604-2011 | |

| Penetration index | −0.53 | T0604-2011 | |

| Ductility (5 °C) (cm) | 42 | T0605-2011 | |

| Soft point (°C) | 51.6 | T0606-2011 | |

| Rotating thin film oven test (RTFOT) | Mass loss (%) | 0.5 | T0610-2011 |

| Penetration ratio (%) | 60.2 | T0610-2011 | |

| Ductility (10 °C) (cm) | 27.1 | T0605-2011 | |

| Sieve Size (mm) | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

| Passing rate (%) | 100 | 96.6 | 83.5 | 70.3 | 44 | 30.3 | 22.1 | 15.8 | 10.6 | 7.7 | 5.2 |

| Parts | RD (mm) | a | b | R2 | Fit Curves |

|---|---|---|---|---|---|

| Rutted | 0 | 1.97 | 2.04 | 0.9500 |  |

| 3 | 2.01 | 2.75 | 0.9738 | ||

| 5 | 2.18 | 1.75 | 0.9620 | ||

| 10 | 1.99 | 2.08 | 0.9275 | ||

| Impact Zone | 0 | 1.95 | 2.03 | 0.9389 |  |

| 3 | 2.12 | 2.19 | 0.9720 | ||

| 5 | 2.25 | 1.85 | 0.9646 | ||

| 10 | 2.13 | 1.85 | 0.9460 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Fan, W.; Wang, H. An Investigation of Three-Dimensional Void Changes and Top-Down Microcrack Formation of AC-16 in Rutted and Non-Rutted Zones Under Extremely High Temperature and Heavy Load. Appl. Sci. 2025, 15, 9464. https://doi.org/10.3390/app15179464

Xu Z, Fan W, Wang H. An Investigation of Three-Dimensional Void Changes and Top-Down Microcrack Formation of AC-16 in Rutted and Non-Rutted Zones Under Extremely High Temperature and Heavy Load. Applied Sciences. 2025; 15(17):9464. https://doi.org/10.3390/app15179464

Chicago/Turabian StyleXu, Zhoucong, Wenruo Fan, and Hui Wang. 2025. "An Investigation of Three-Dimensional Void Changes and Top-Down Microcrack Formation of AC-16 in Rutted and Non-Rutted Zones Under Extremely High Temperature and Heavy Load" Applied Sciences 15, no. 17: 9464. https://doi.org/10.3390/app15179464

APA StyleXu, Z., Fan, W., & Wang, H. (2025). An Investigation of Three-Dimensional Void Changes and Top-Down Microcrack Formation of AC-16 in Rutted and Non-Rutted Zones Under Extremely High Temperature and Heavy Load. Applied Sciences, 15(17), 9464. https://doi.org/10.3390/app15179464