As global energy costs rise and environmental awareness increases, particularly in the manufacturing sector, there is growing pressure to improve energy efficiency and reduce environmental impact. Machine tools consume a significant amount of energy during operation, especially in the movement of mechanical components. Moreover, with the advancement of high-speed precision machining technologies, the structural stiffness and vibration-damping capabilities of the machine tools have become even more critical for improving machining accuracy and extending service life. Therefore, integrating high stiffness and lightweight characteristics during the structure design phase to meet the demands of high-speed precision machining and low energy consumption has become a crucial challenge for the machine-tool industry. This involves not only the application of new materials but also the development and implementation of innovative structural design methods.

A major challenge in this performance enhancement process is how to reduce weight while maintaining or even promoting the structural stiffness and strength of the machine-tool. Traditionally, machine-tool stiffness improvement has relied on increasing the geometrical size and thickness of the components, such as by reinforcing rib designs. While effective in enhancing structural rigidity, this approach also adds weight to the machine-tool, which contradicts the goal of energy efficiency and structural performance. This limitation has led to the pursuit of novel rib design strategies that aim to enhance machine-tool performance through structural optimization without adding extra weight. In the field of machine-tool design and manufacturing, lightweight technologies have proven to be an effective way to reduce energy consumption and enhance production efficiency. These technologies include advanced methods such as topology optimization, structural bionics, shape or sizing optimization, and system integration design, which aim to reduce the weight of machine-tool components while maintaining their mechanical performance. This not only reduces energy demands during manufacturing but also helps lower operational energy consumption.

The study conducted by Li et al. [

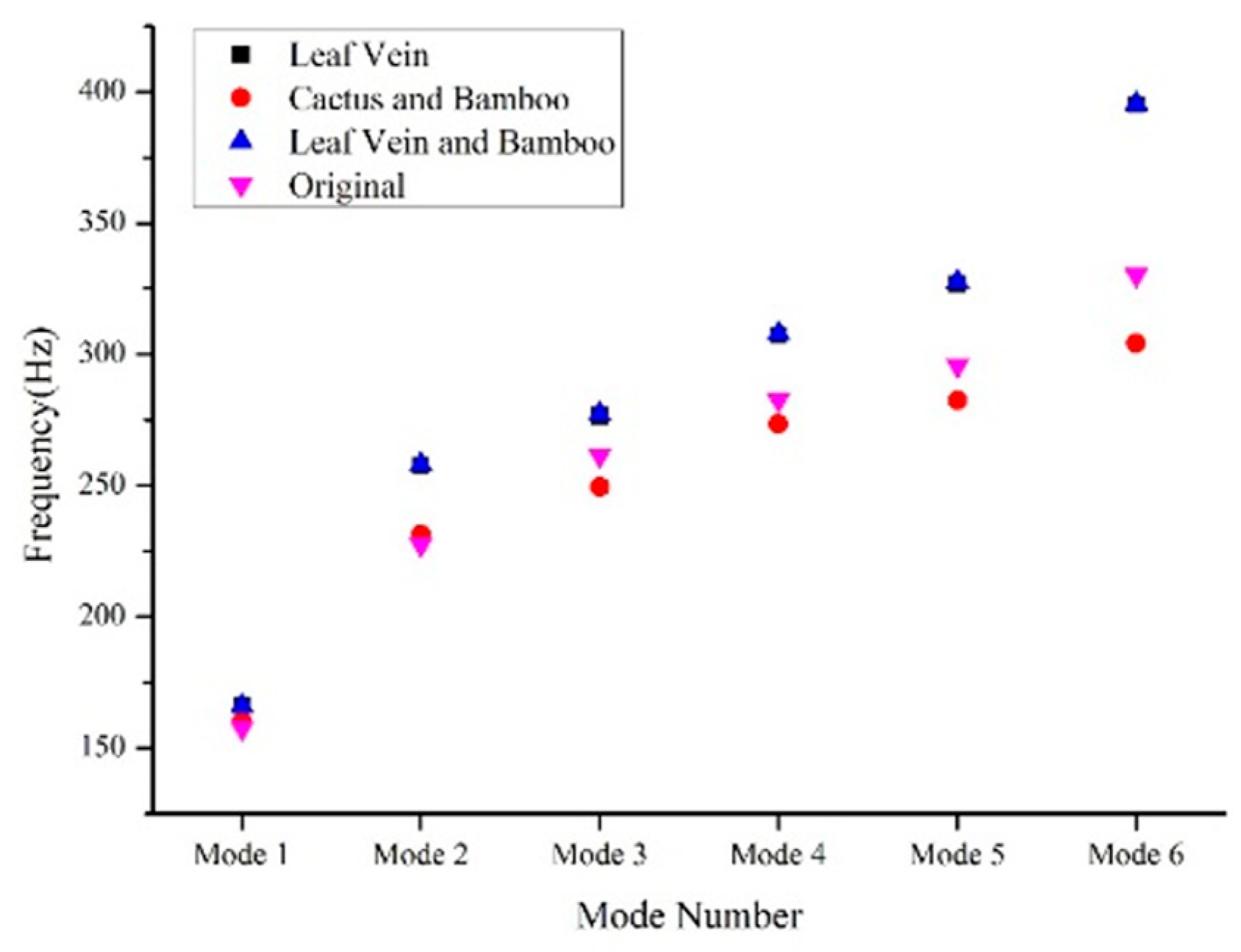

1] proposed a method that applies the self-optimal growth principle of plant branching systems in nature to design the internal stiffener layout of large machine tools. The potential of leaf vein structures as conceptual generators for creating optimal load-bearing topologies in machine-tool structures was validated through numerical investigations. Based on this, an evolutionary algorithm was developed, in which three growth strategies were employed to determine whether candidate stiffeners should grow or atrophy according to the applied loads. It was found that leaf venation is a type of compliance-effective structure with a branching pattern. Its geometric and mechanical characteristics were identified through numerical studies as having significant potential for innovative application in stiffener layout design for machine tools. The stiffness enhancement was verified through both numerical analysis and experimental testing, and therefore, the proposed growth-based method was considered as a suitable choice for the design of eco-efficient machine tools. Gao et al. [

2] developed a new machine-tool stiffness model, based on the analysis of the machining space, to optimize the machine-tool structure design and layout, thereby improving machining quality and predicting machining errors. The approach involved decomposing the machine-tool into multiple components and modeling the stiffness of each component separately. Then, using a synthesis method, these individual stiffness models were combined into an overall machine stiffness model to predict the machining errors of the entire machine-tool. Experimental results showed that the proposed stiffness model could effectively predict the stiffness of the machine-tool at different machining positions and could be used to evaluate and reduce machining errors during the processes. This model improves the efficiency of machine-tool structure and layout design and holds practical application potential for future manufacturing processes. Revanasiddesh et al. [

3] investigated the modal parameters of CNC lathes to investigate the dynamic behavior of the machine-tool and improve its performance. The finite element method was used to simulate the CNC lathe and predict its modal characteristics, including natural frequency, damping, and mode shapes. The CNC lathe was then struck with a hammer, and its response was measured to obtain experimental modal parameters. The results from finite element simulations and experiments were compared. The experimental results showed that the proposed FEM simulation and modal analysis exhibited good consistency with the experimental results. Gao et al. [

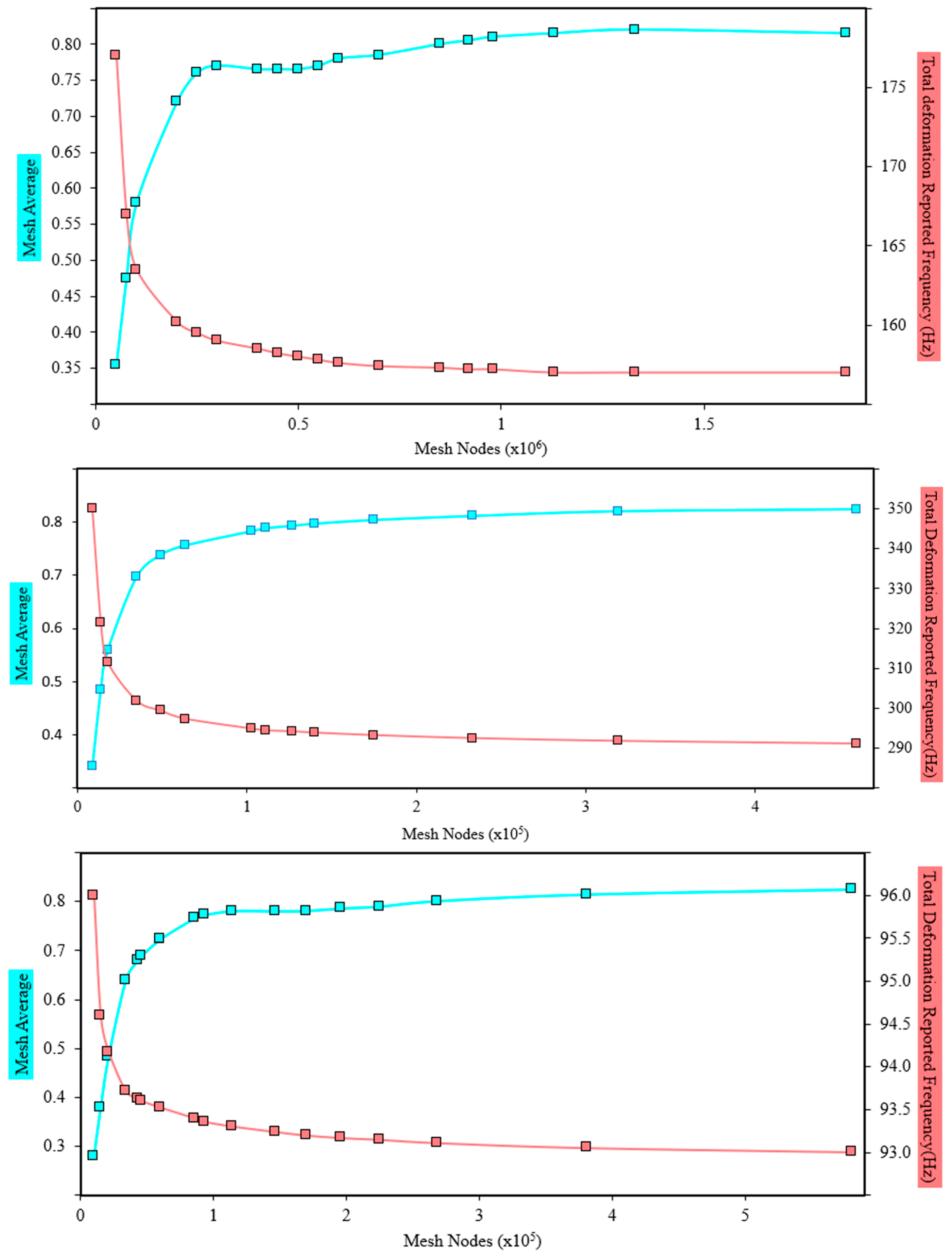

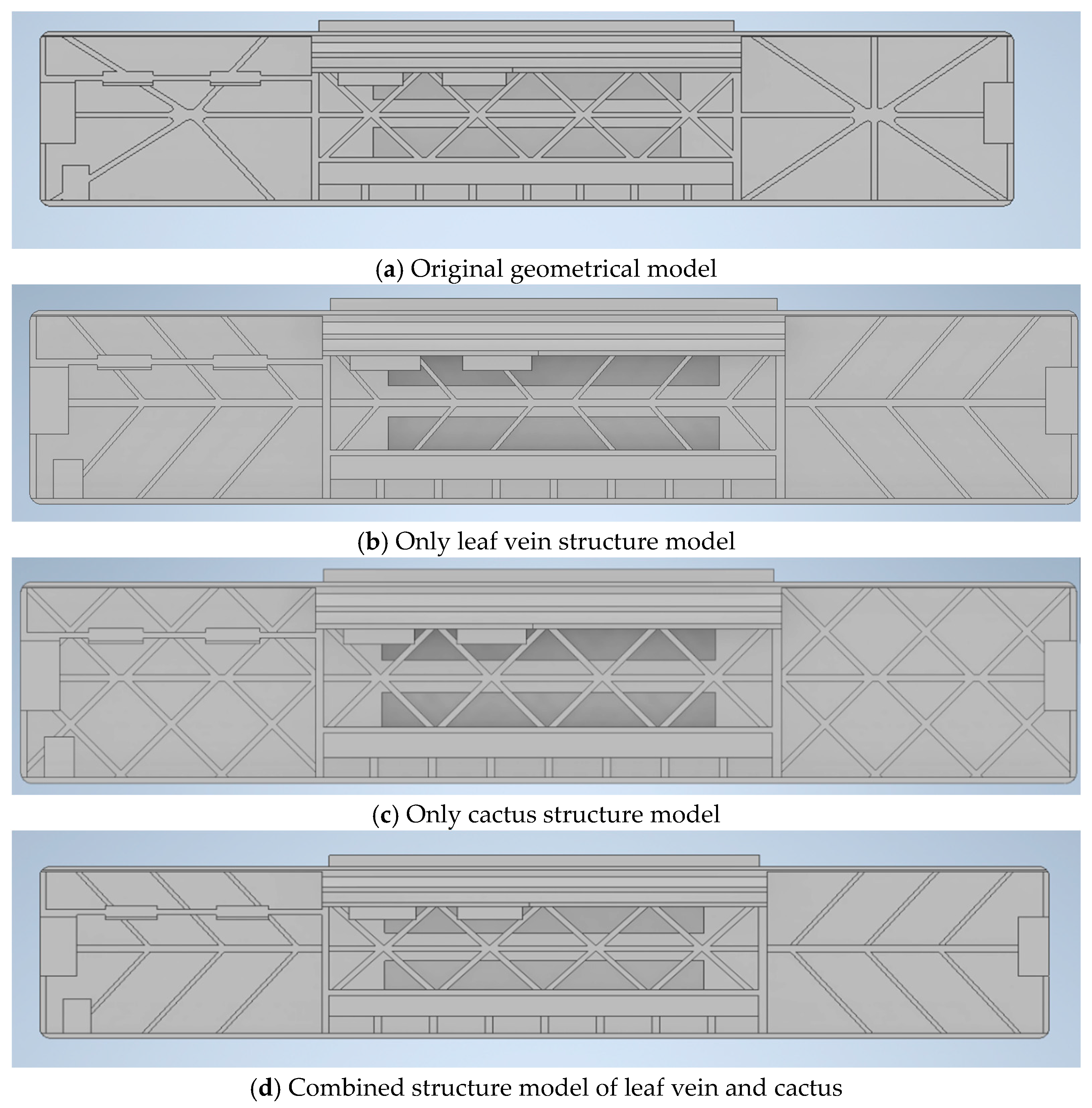

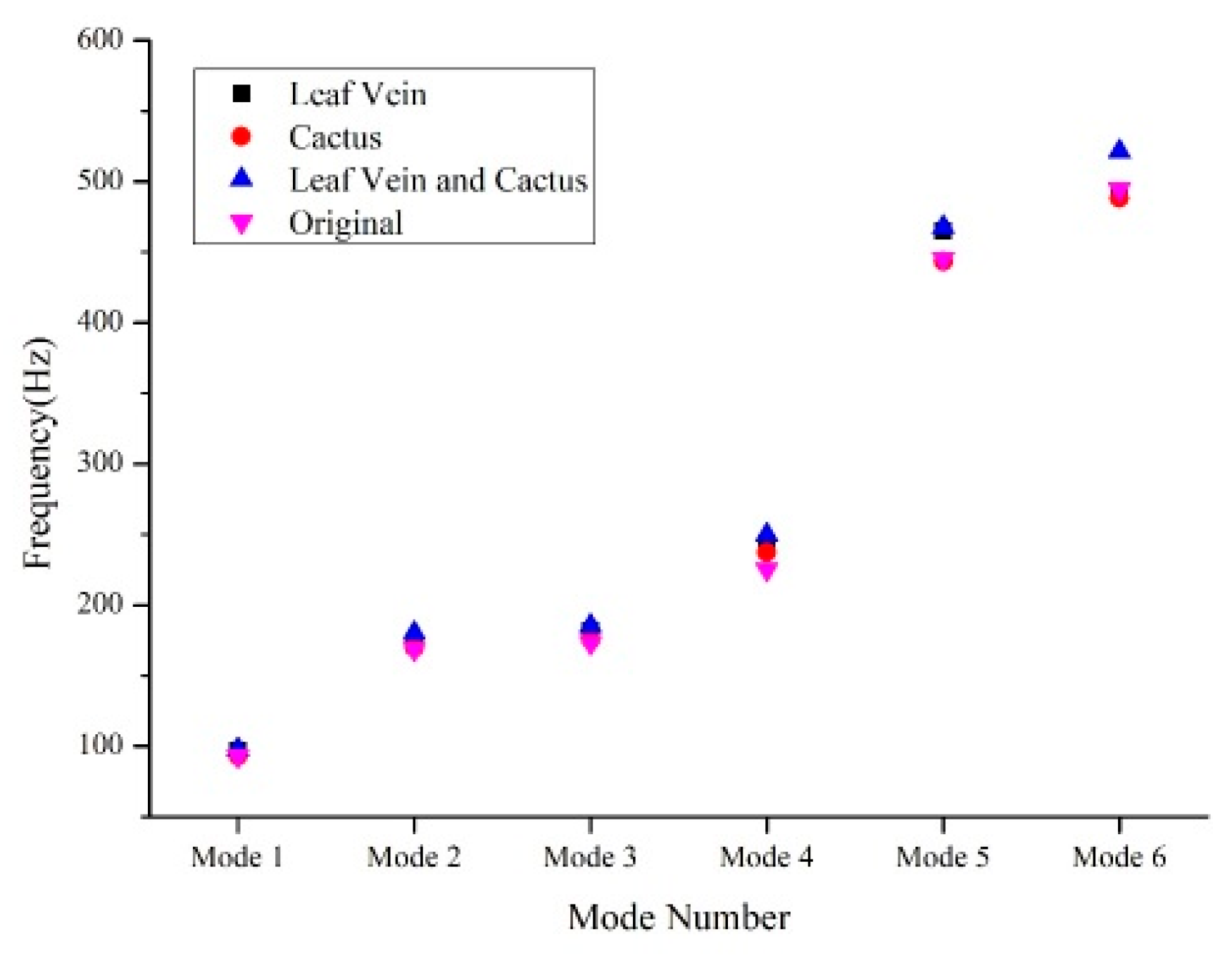

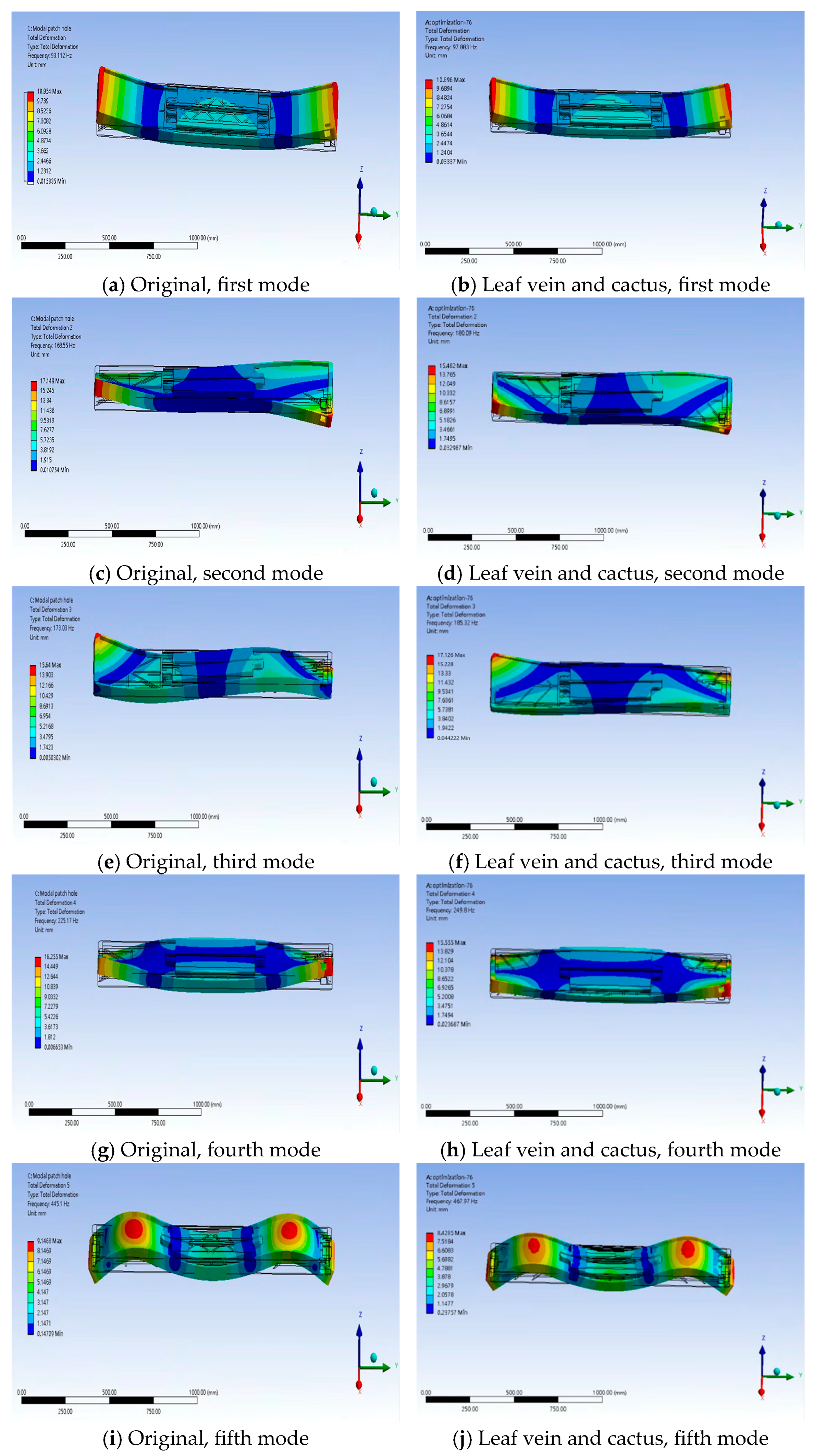

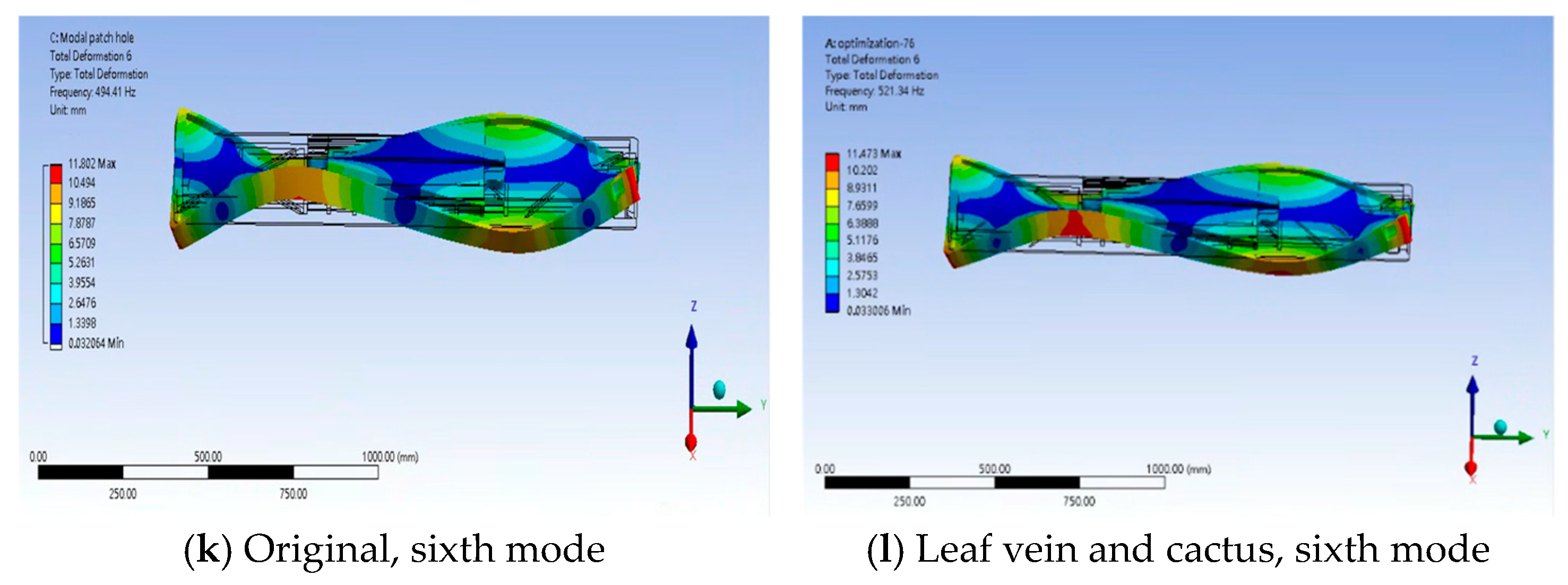

4] used Ansys software to perform static and modal analyses on the worktable, followed by topology optimization. A 3D model of the worktable was created by SolidWorks, and the static and modal analyses were conducted in Ansys Workbench. Then, structural optimization was carried out on the worktable in the topology optimization module of Ansys Workbench to improve its performance. The experimental results showed that the worktable after topology optimization improved its dynamic performance while maintaining the original static performance and reducing its weight. Zhao et al. [

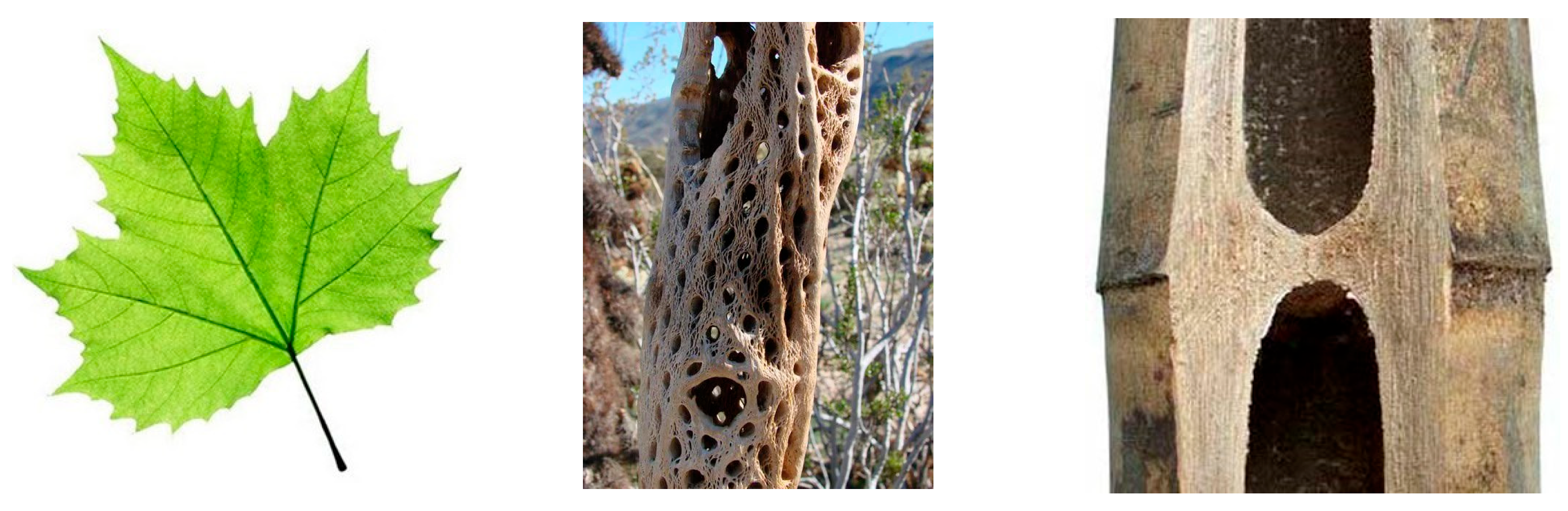

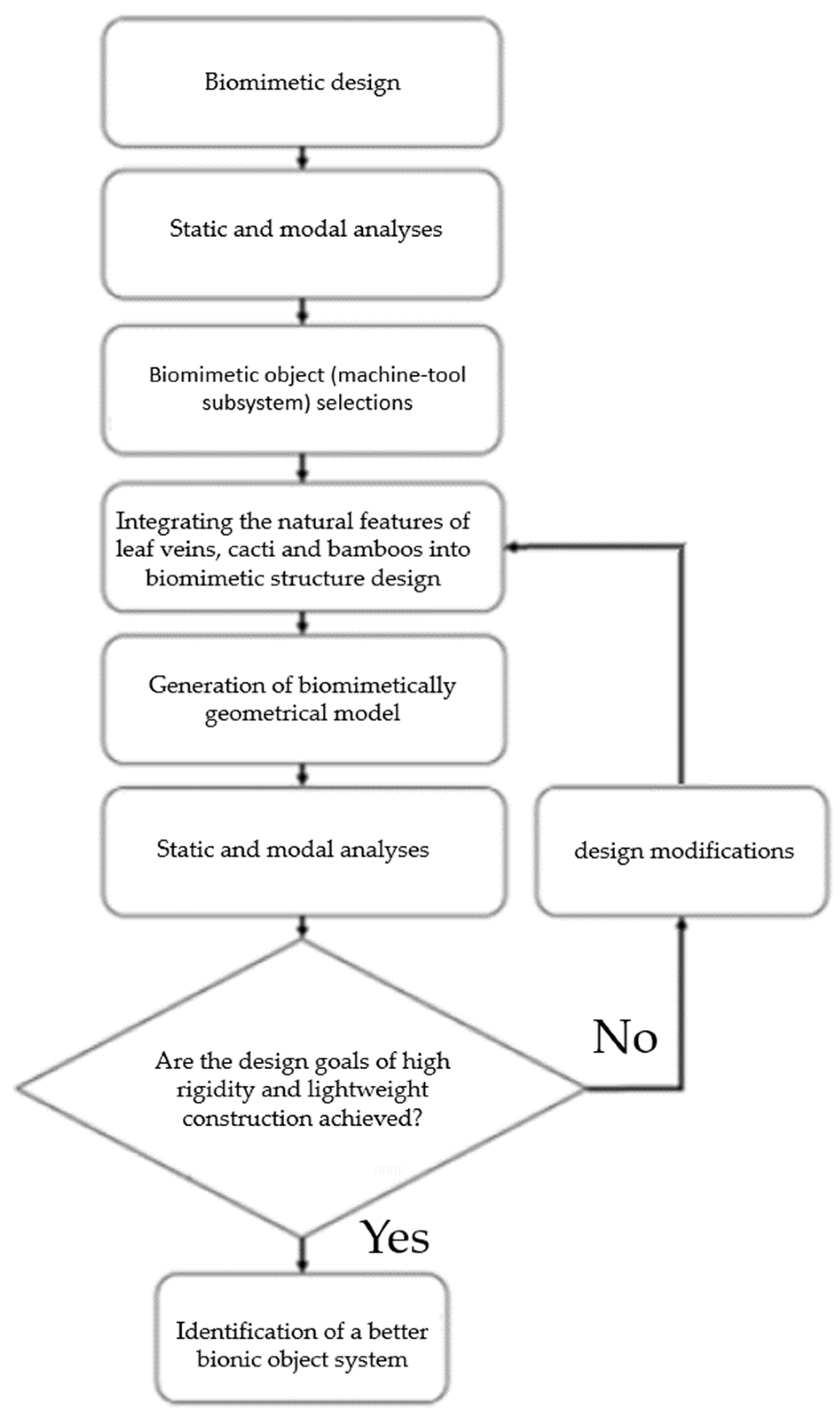

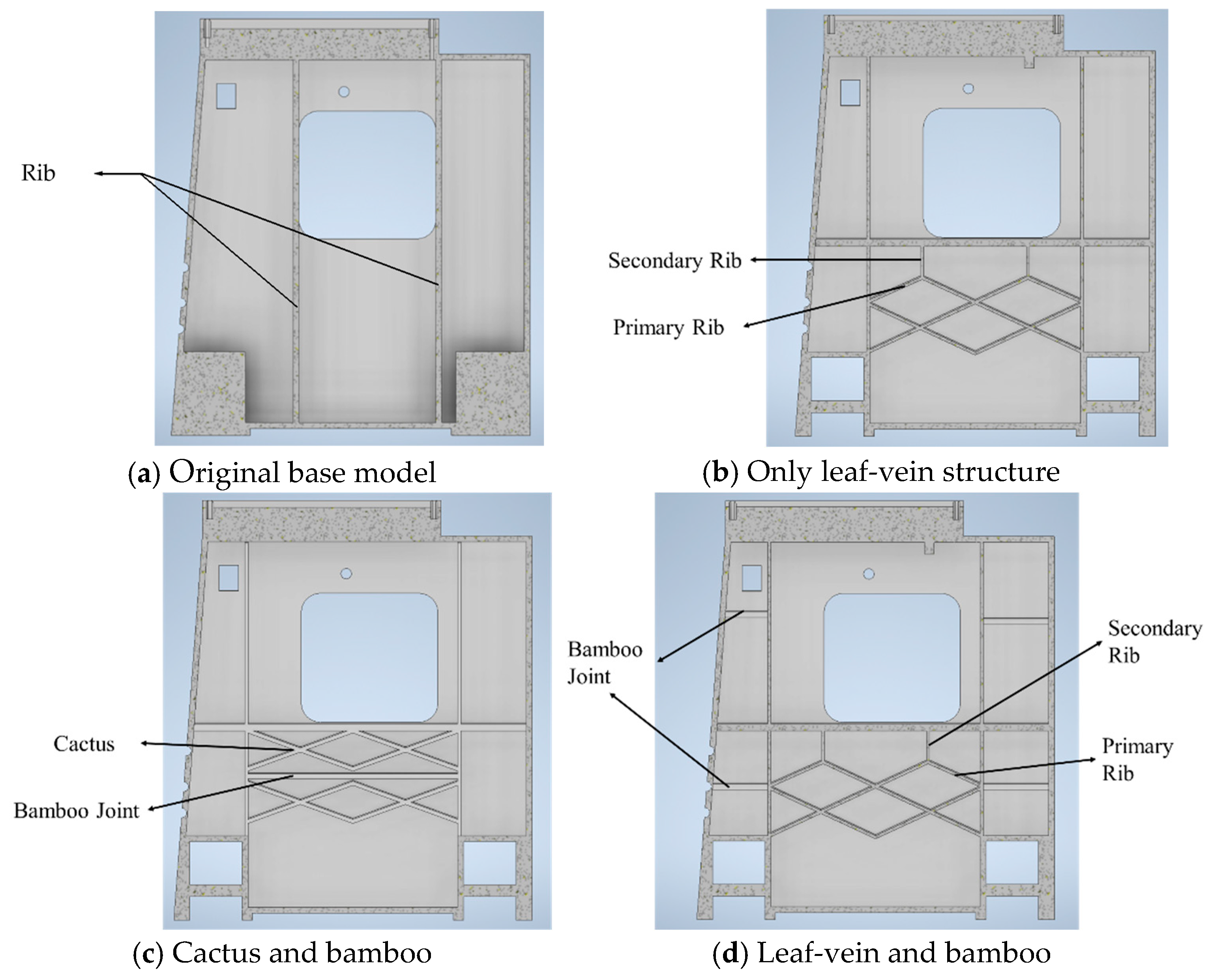

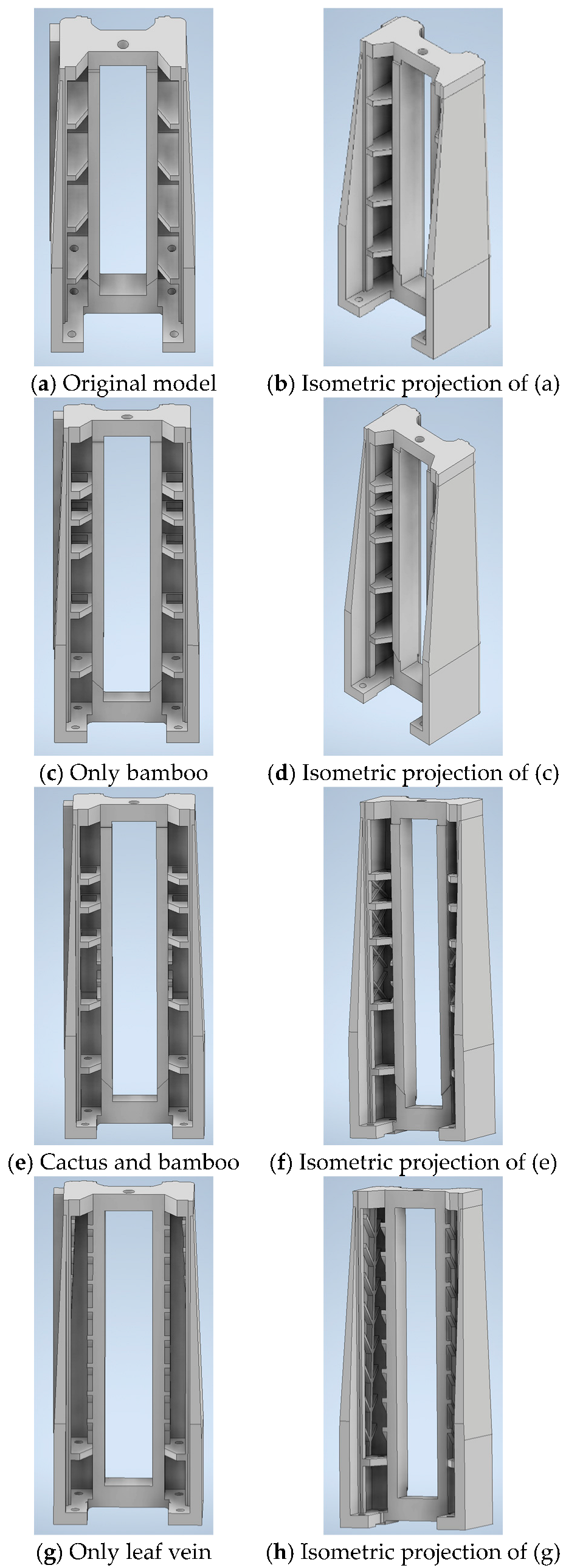

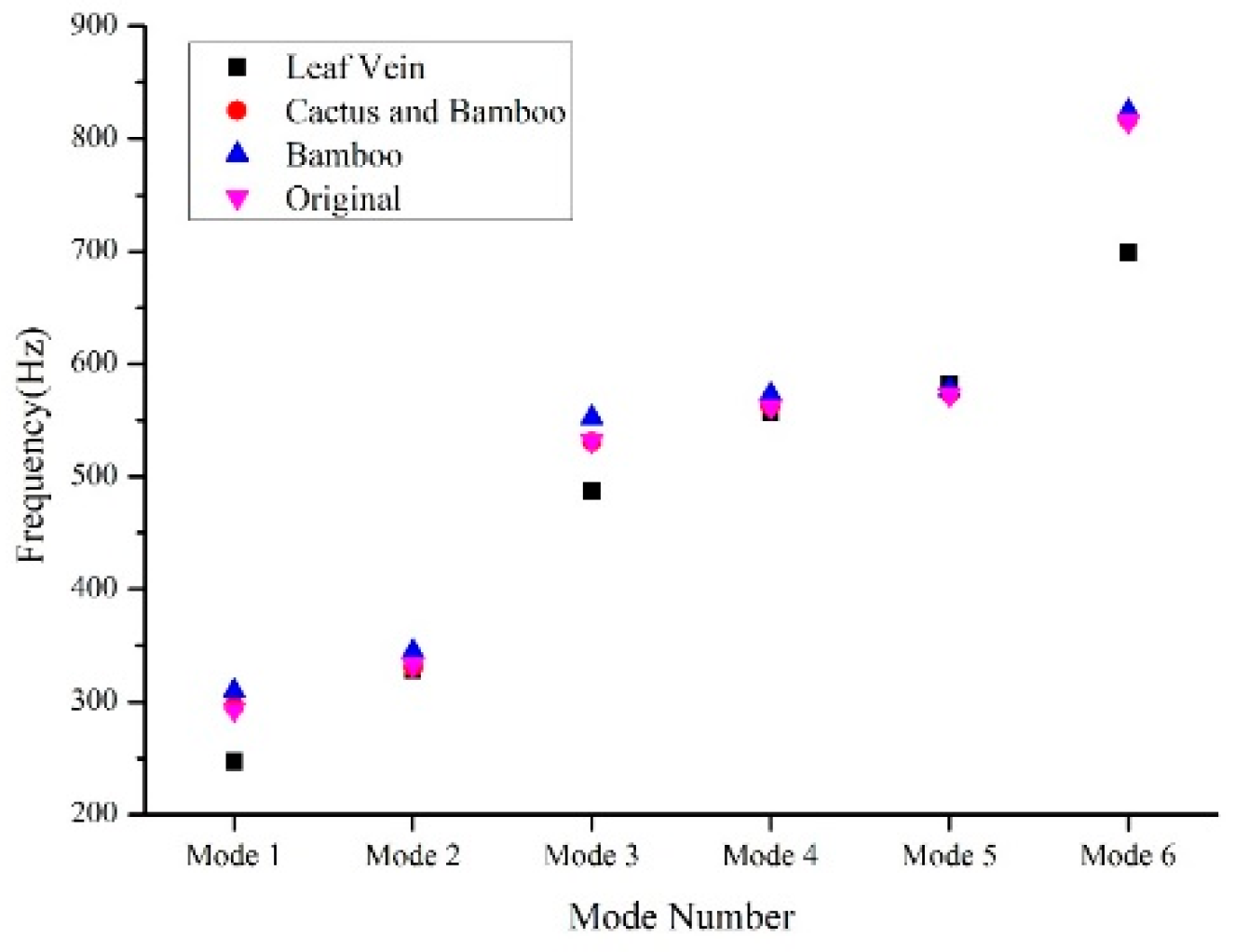

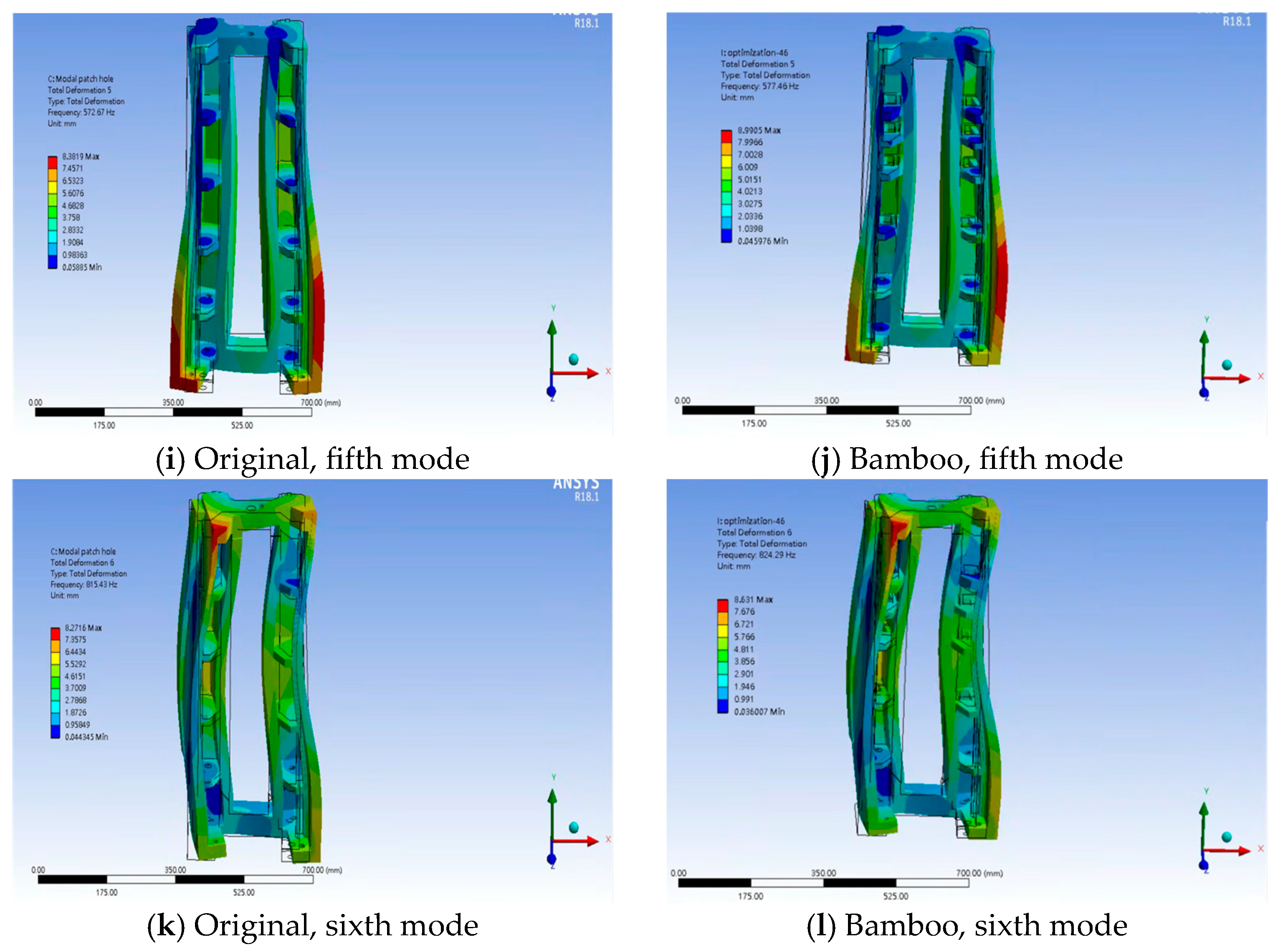

5] studied the use of structural biomimetics, based on the structural principles of biological skeletons and sandwich stems, to design a machine-tool column with internal reinforcing ribs. FEM simulations were conducted using Ansys software to compare the differences between the original and biomimetic designs in terms of static displacement and dynamic performance. The experimental part involved manufacturing a scaled model using selective laser sintering (SLS) technology, followed by static and dynamic testing. The experimental results showed that the bionic column reduced the maximum static displacement, decreased its mass, and improved the first two natural frequencies, indicating that the biomimetic design was effective in improving the static and dynamic structural performances of the high-speed machine tools. Xing et al. [

6] studied the optimization of the structural design of a high-speed machine-tool worktable by applying the distribution principles of leaf veins, aiming to reduce the weight of the worktable while enhancing its rigidity. Statistical and FEA were used to explore the mechanical effects and structural benefits of leaf veins, which were then applied to the design of the worktable. FEA and experimental verification were performed to assess the effectiveness of the design. The experimental results showed that the biomimetic design of the worktable reduced the average displacement, and the average displacement in experiments was also decreased, proving the effectiveness of the biomimetic design. Zhao et al. [

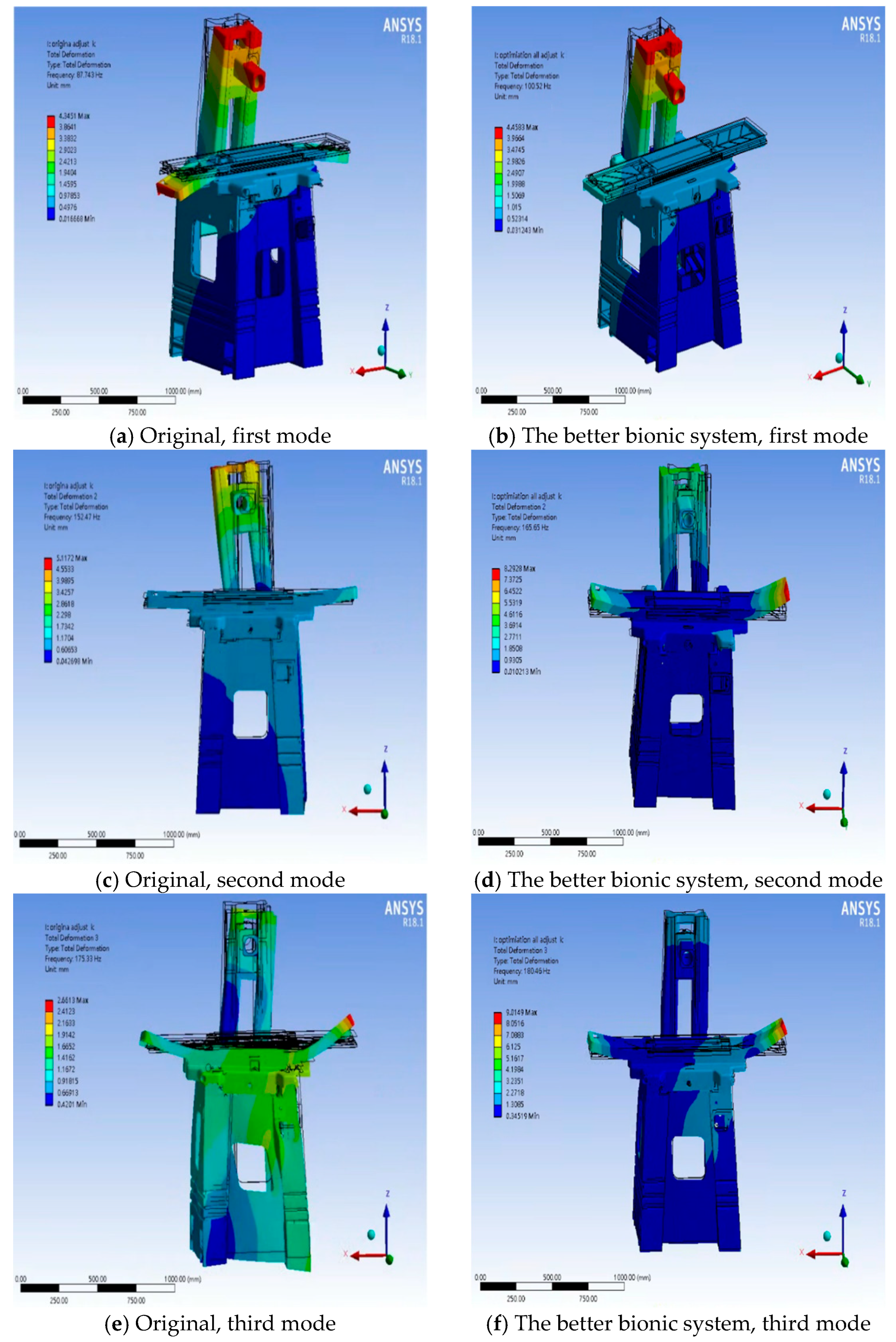

7] aimed to find innovative solutions for lightweight mechanical design through the application of structural biomimetics, particularly exploring the structural features of giant waterlily leaf ribs and cactus stems, and applying them to the design of the gantry machining center. By mimicking similar network structures found in nature, a bionic model was created, which showed better load-carrying capacity compared to the original distribution. Reinforced ribs in parallel or vertical configurations were adjusted to reduce weight while maintaining or enhancing structural rigidity. The results showed that the specific stiffness of the bionic model was increased, the maximum static deformation was decreased, the weight was reduced, and the first four natural frequencies significantly improved, demonstrating the effectiveness of the structural biomimetic design. Gao et al. [

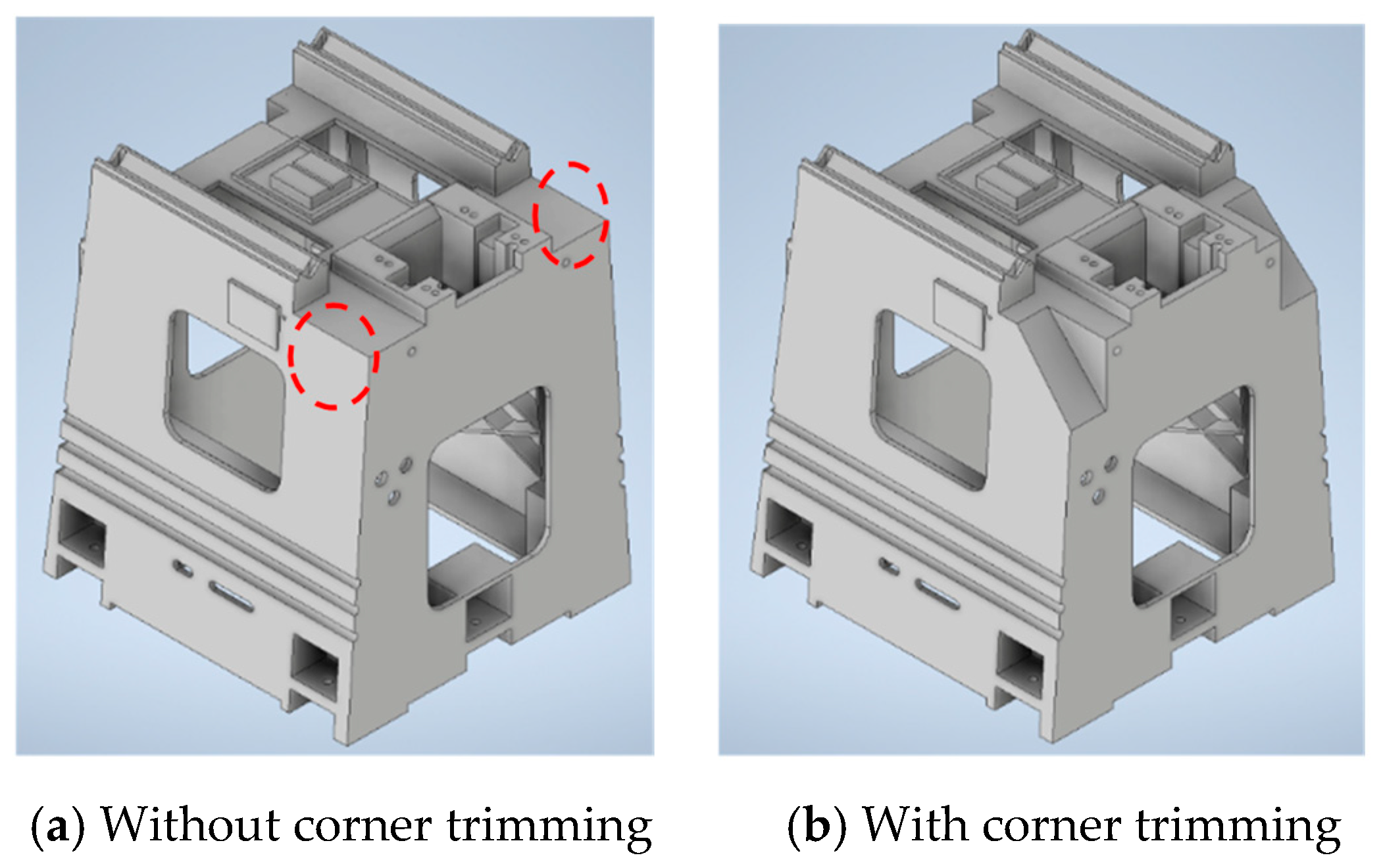

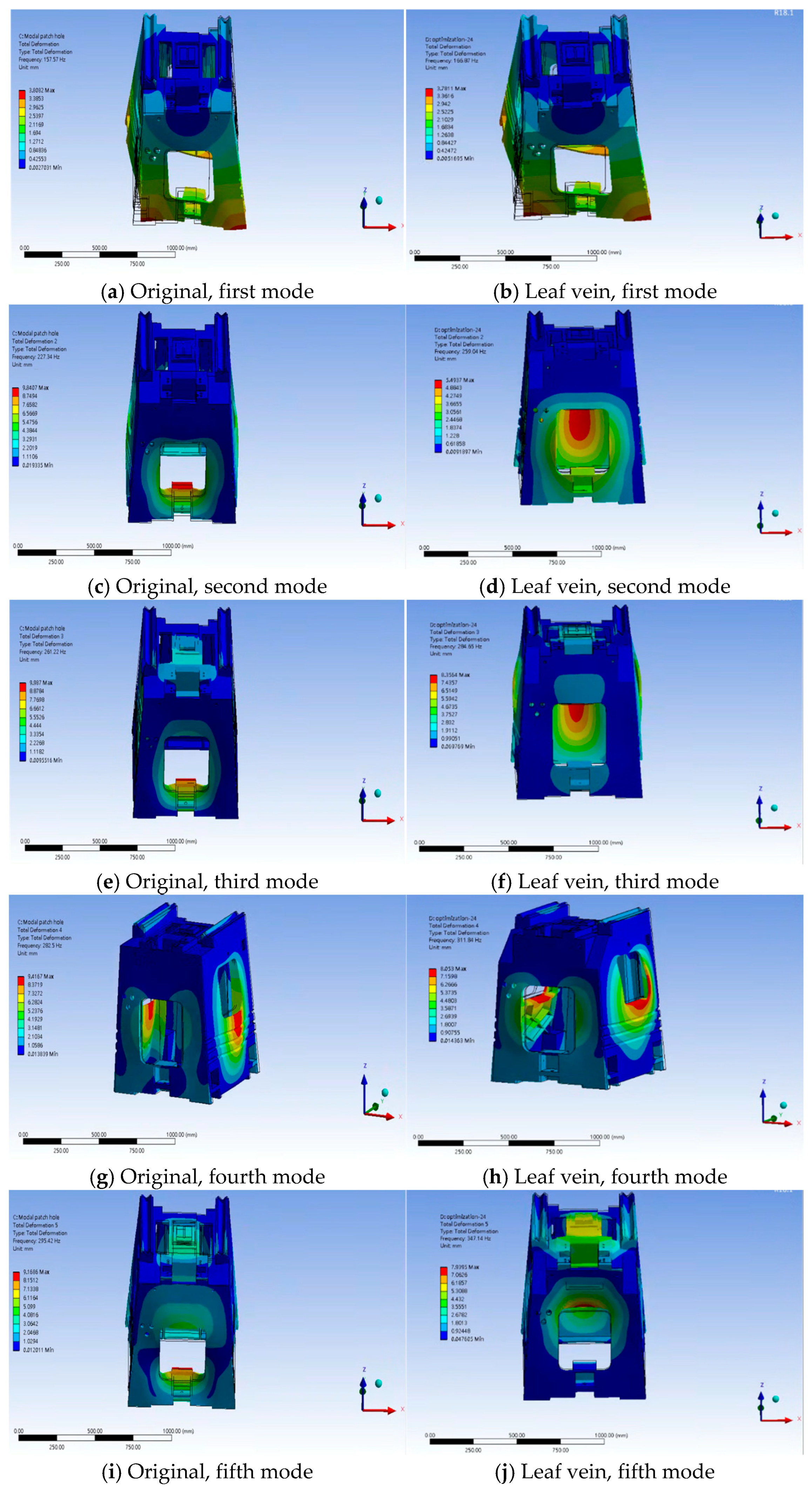

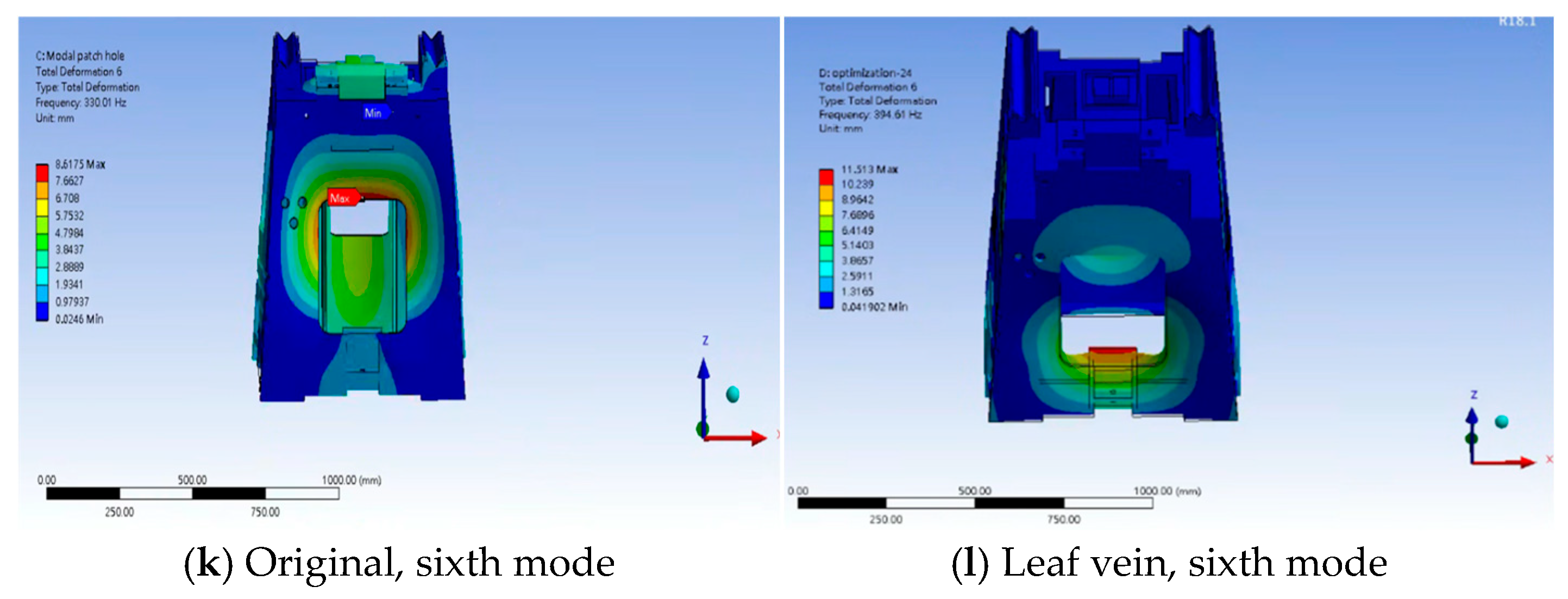

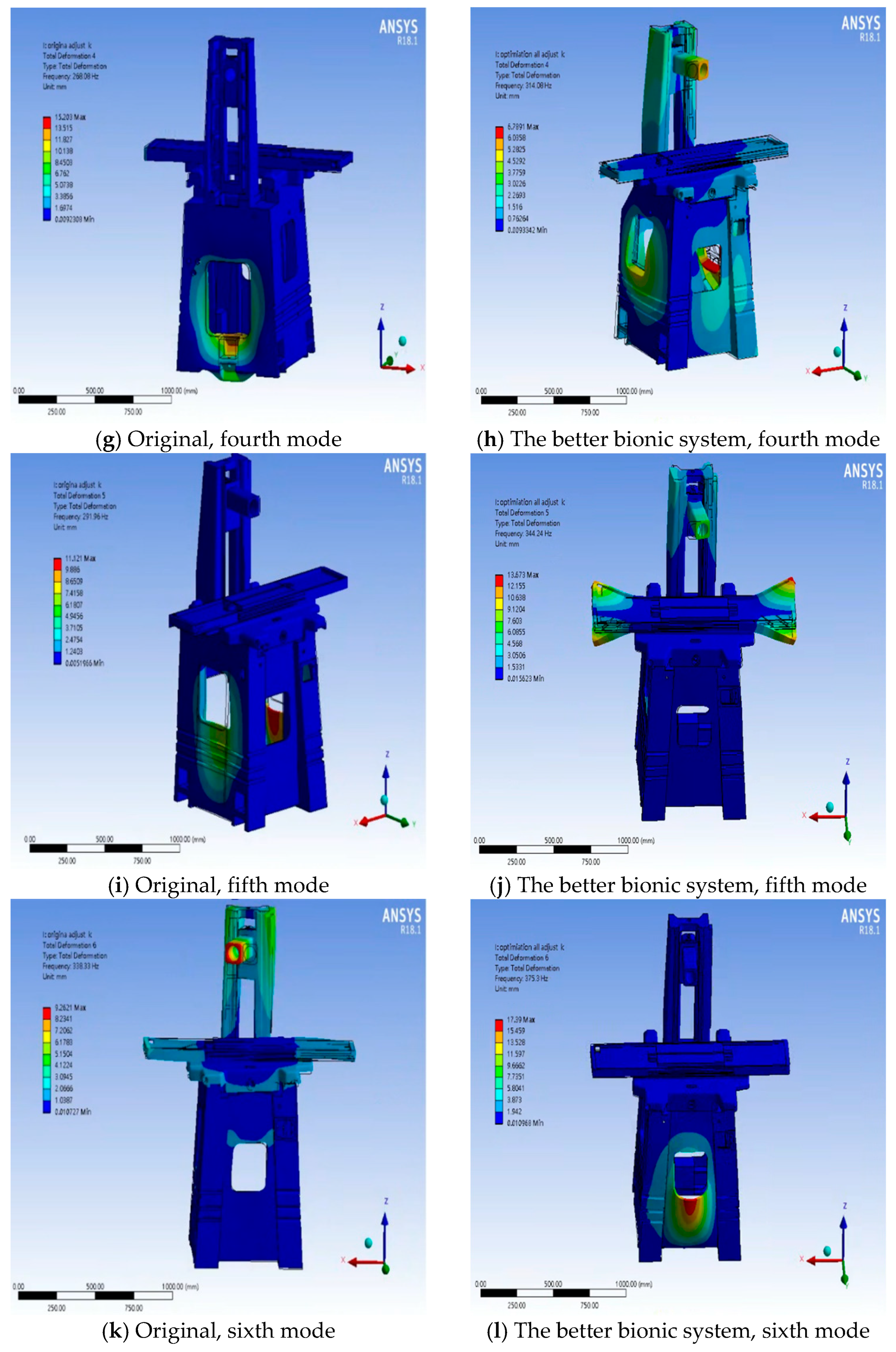

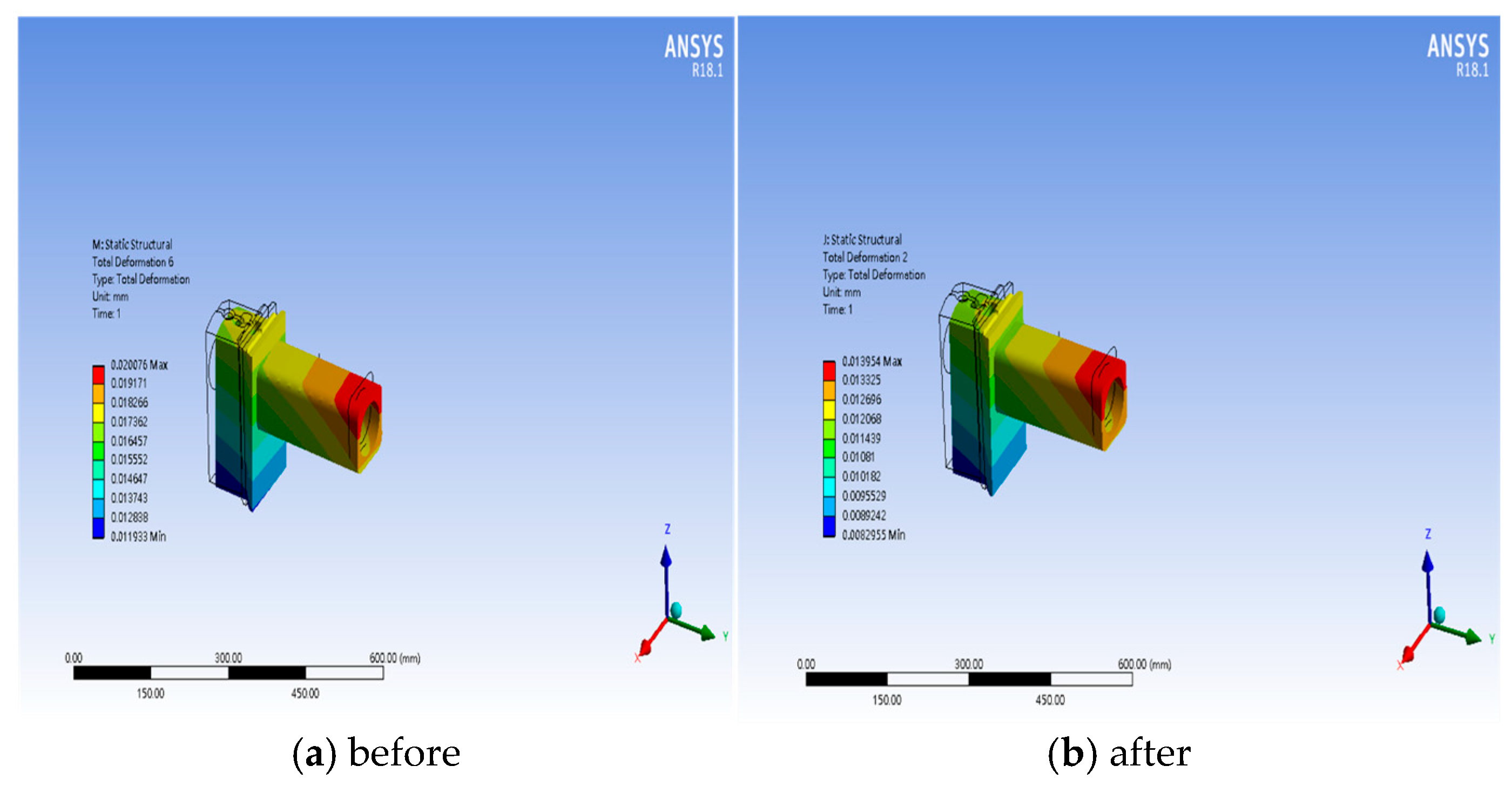

8] conducted a structural biomimetic design for the machine-tool columns, aiming to improve the performance of mechanical components, especially in terms of enhancing static and dynamic performance, by mimicking the distribution features of the leaf veins. Based on the features of leaf vein structures, the internal configuration of the stiffening ribs in the column was adjusted to improve the overall structural load-bearing efficiency and reduce weight, while ensuring manufacturability. The results showed that, compared to the original column, the bionic column reduced the maximum deformation, and the natural frequencies of the six modes were increased to different extents. Liu et al. [

9] aimed to improve the design of the column in a gantry machining center by using a biomimetic design method to enhance its static and dynamic performance, by designing the stiffener plates of the column based on the structural configuration of the ginkgo root system. The distribution principles of the ginkgo root system were applied to design the stiffener plates, with the goal of achieving structural lightweightness and enhancing anti-vibration performance. These designs were modeled in CAD software and simulated using Ansys software for FEA. Experimental results showed that the bionic column design reduced its weight while increasing the first five natural frequencies. The experimental results confirmed the correctness of the biomimetic design method and verified the improvements in the structural design. Li et al. [

10] investigated how to use the macroscopic and microscopic features of bamboo for the biomimetic design of the CNC boring and milling machine-tool columns, aiming to improve the structural efficiency of the column and reduce material redundancy. The initial design of the column was cylindrical, and optimization was carried out based on the relationship between the number of transverse ribs and the whole bending deformation. Further optimization was achieved by designing and adjusting the transverse rib configuration based on inspiration from the bamboo joint node structure. The outer profile of the A-type column is an octagonal cross-section with a circular hollow structure inside, while the B-type column features a chamfered rectangular hollow structure with similar inner and outer profiles. The results showed that the specific stiffness of the B-type column increased, and its overall performance outperformed the A-type column. The final choice was the B-type as the final bionic structure. FEA results showed that the maximum displacement of the B-type column was decreased, and its specific stiffness was increased. Gao et al. [

11] investigated the design of an aluminum alloy honeycomb structure for the worktable of a high-speed machine-tool, aiming to reduce the weight of the worktable and thus minimize the inertial forces generated by rapid movements to improve machining accuracy. Ansys Workbench was used for static and modal analyses to compare the performance of the new structural worktable with the original worktable. This study focused on structural improvement by incorporating lightweight aluminum alloy honeycomb structures inside the worktable to reduce the overall weight and inertial forces, thus enhancing structural performance. The results showed that the weight of the honeycomb structure worktable was reduced as compared to the original structure, with smaller static deformation, indicating better static characteristics. Modal analysis results showed that the natural frequencies of the improved worktable were higher, indicating better dynamic characteristics. Jiao et al. [

12] explored the lightweight design of a low radar cross-section (RCS) pylon based on structural biomimetics. The aim of this study was to improve the specific structural efficiency (SSE) of the pylon, thereby reducing its weight and enhancing its properties. FEA was conducted, along with static, dynamic, and electromagnetic tests to analyze the properties of both the original and bionic pylons. The characteristics of the bionic pylon were verified by comparing the displacement, stress, and weight of the original beam and the bionic beam based on plant structural features. The design process included requirements identification, analysis, and experimental validation. The experimental results showed that the bionic pylon improved the specific strength efficiency and specific stiffness efficiency, and significantly reduced the RCS. These results demonstrate the effectiveness and potential of structural biomimetics in designing low-RCS pylons. The biomimetic design not only significantly reduced the weight but also improved the overall structural characteristics. Zhang et al. [

13] conducted a study on the bending characteristics analysis and lightweight design of a bionic bamboo structure beam. The structure was inspired by the natural features of bamboo, particularly its light weight and high strength. A bending model of the bionic bamboo beam was developed and validated using FEM. For the lightweight design, the response surface method was used for structural optimization. Experimental results showed that the optimized bionic bamboo beam was lighter than the hollow beam and also lighter than the solid beam, with excellent bending resistance. The bending resistance was 234% of the hollow beam and 271% of the solid beam. The bionic structure also outperformed the original structure in energy absorption characteristics, and the 12-hole structure performed better than the 13-hole structure. This study offers a new approach to improving artificial structures based on natural structures and has significant implications for the development of lightweight and high-strength energy-absorbing devices. Xing et al. [

14] used structural bionics to perform a lightweight design for an aircraft reinforcing frame. First, the structural features of peltate venation and root architecture were analyzed, and then these features were used to develop a frame design model. FEA was conducted to assess the properties of different design options, and the optimized design was selected to achieve lightweight goals. Experimental results showed that the bionic method designed frame reduced the total weight by approximately 6.0% while maintaining stiffness and strength. Additionally, this study found that the bionic frame exhibited lower maximum displacement and stress under shear and bending conditions as compared to the conventional frames. Yan et al. [

15] studied how to improve the rigidity and lightweight properties of machine-tool structures through biomimetic design, particularly by mimicking adaptive growth phenomena in nature to optimize the layout of reinforcement ribs. A mathematical model was first established theoretically to support the adaptive growth of reinforcing plates under applied loads, followed by the development of algorithms to generate the reinforcement rib layout. Experimental results showed that the new reinforcement rib layout through biomimetic design significantly enhanced the rigidity of the machine-tool bed, demonstrating the applicability and effectiveness of this method. Liu et al. [

16] conducted a study on the structural biomimetic design of a machine-tool table, employing four types of bionic structures: namely, bamboo cross-section bionic structure table, spider web bionic structure table, honeycomb bionic structure table, and prairie rushes bionic structure table. Finite element simulations were used to perform static and modal analyses. Furthermore, the entropy-weight TOPSIS method was applied to evaluate the four bionic structures, and based on these results, a multi-objective optimization design was carried out. The results indicated that the prairie rushes bionic structure was identified as the optimal design. As compared to the original table, the bionic structure reduced mass, increased the first natural frequency, reduced maximum displacement, and significantly lowered the maximum equivalent stress. Wu et al. [

17] investigated a novel bionic energy absorber based on a tree-like fractal approach. These structures are inspired by the branch distribution in nature, and fractal design is used to optimize the energy absorption efficiency of the structure. First, based on the tree-liked fractal method, tree-like structures with fractal geometric features were designed. Then, FEM and experimental tests were used to evaluate the performance of these structures, and structures were optimized to achieve better energy absorption efficiency. The experimental results showed that this study offers a new design concept that effectively develops lightweight and high-efficiency energy absorbers. In particular, by adjusting the fractal order and wall thickness distribution, the energy absorption and impact stability of the structure can be significantly improved. Furthermore, comparative studies show that the third-order fractal structure outperforms the original structure in terms of energy absorption and structural stability. Zhang et al. [

18] aimed to optimize the distribution of internal stiffeners in a machine-tool base structure by mimicking the growth mechanism of biological branching systems in nature to improve overall structural stiffness and lightweight design. The study used the adaptive growth method, a biomimetic topology optimization technique, to optimize the distribution of stiffeners in a box structure. The experiment mainly focused on the topological optimization of the internal stiffener distribution, including rib growth, branching, and degradation, to seek the optimal structural layout under given loading and support conditions. Furthermore, based on the optimal stiffener distribution design, structural dimension optimization was performed to achieve the lightweight design goal. The experimental results showed that the optimized structure improved both dynamic and static characteristics, significantly reduced the weight as compared to the initial structure, and enhanced the rigidity of the machine bed structure, with a more reasonable rib layout. Cai et al. [

19] proposed a new topology optimization method designed specifically for materials subjected only to tensile or compressive forces, based on bone remodeling theory to find the optimal topology for structures. The method uses reference interval and material replacement methods, simplifying the optimization processes through FEM. This method first replaces the original material subjected to only tensile or compressive forces with an equivalent isotropic material, then calculates the effective strain energy density to update design variables. The results showed that this new method can significantly reduce the computational cost of structural analysis while maintaining the accuracy of the analysis. Ji et al. [

20] investigated how to optimize the internal stiffener layout in three-dimensional box structures based on the natural branching phenomenon, with the aim of enhancing the overall stiffness and durability of the structure. First, a basic model of the three-dimensional box structure is established, including both solid and shell elements. The thickness and position of the reinforcements are then updated through iterative formulas, based on minimizing the structural stress or strain energy. The results show the effectiveness of this method through several typical design examples, including designs under both single and multiple loading conditions. The application of the natural branching growth approach can significantly improve the mechanical properties of the structure. Zhao et al. [

21] investigated the application of structural bionic methodology in the lightweight design of mechanical structures. The primary objective was to develop a standard methodology for dead-load reduction and performance improvement in bionic mechanical structures. By transferring structural principles from nature into technical construction, the goal was to achieve maximum structural efficiency from minimal resources. The research process included extracting structural principles from natural models, performing simulation tests using the FEM, and constructing and testing models using various fabrication techniques. The results showed that the bionic models were lighter but stiffer than the original ones. This demonstrated that structural biomimetic design can effectively update traditional design concepts, achieve maximum structural efficiency, and verify that structural bionics can serve as a systematic theory and standard methodology in mechanical structure design. Li et al. [

22] developed a new topology optimization solution based on the morphology of plant ramifications, aiming to provide designers with feasible stiffener layout options for the interior of large-scale garbage truck containers. An evolutionary algorithm is used to simulate the growth process of the stiffening rib layout. This process does not require a dense ground structure, nor does it require modifications to existing FE software, making it fast, easy to apply, and virtually unconstrained. Experimental results show that the method effectively provides a stiffening rib layout with a uniform stress distribution.

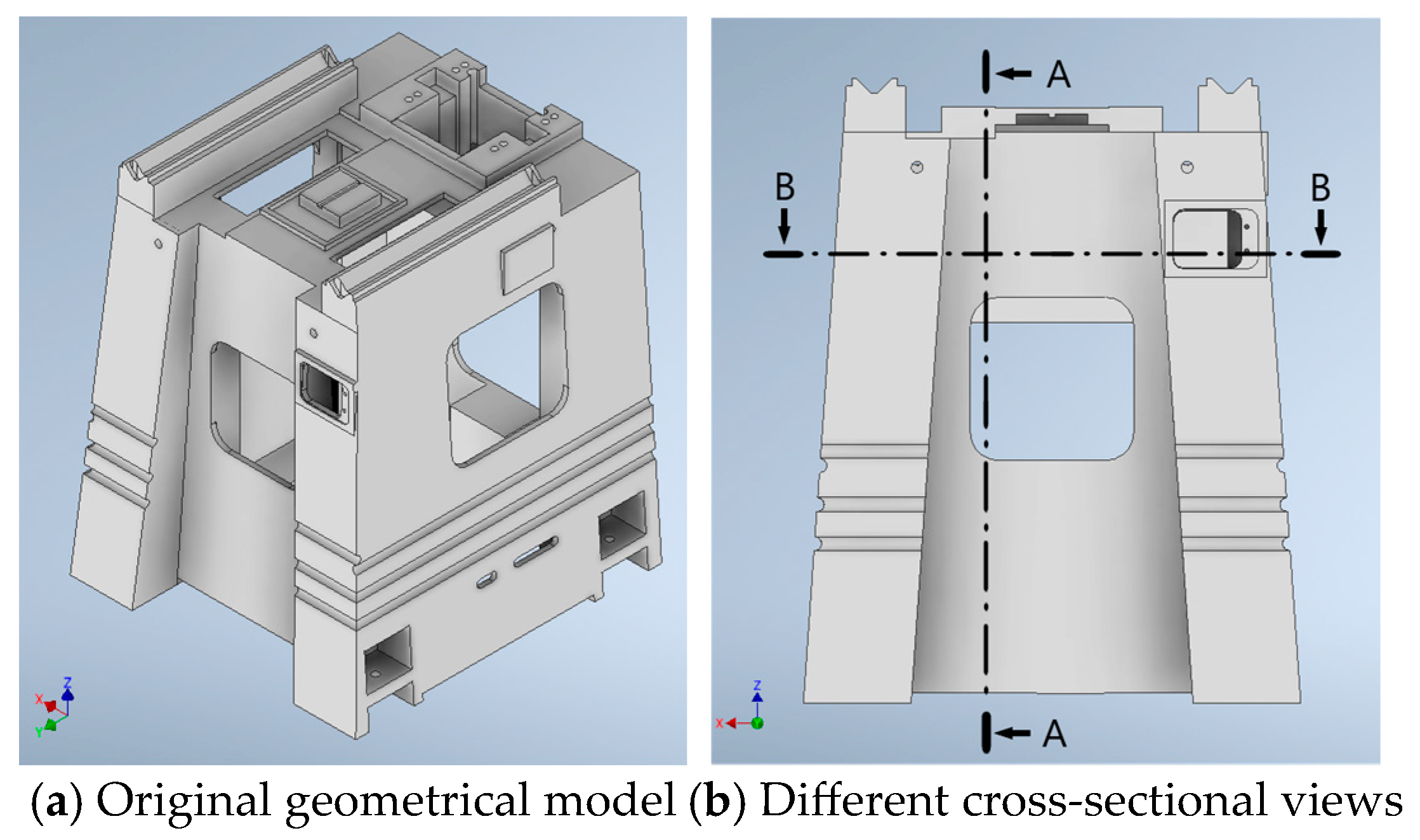

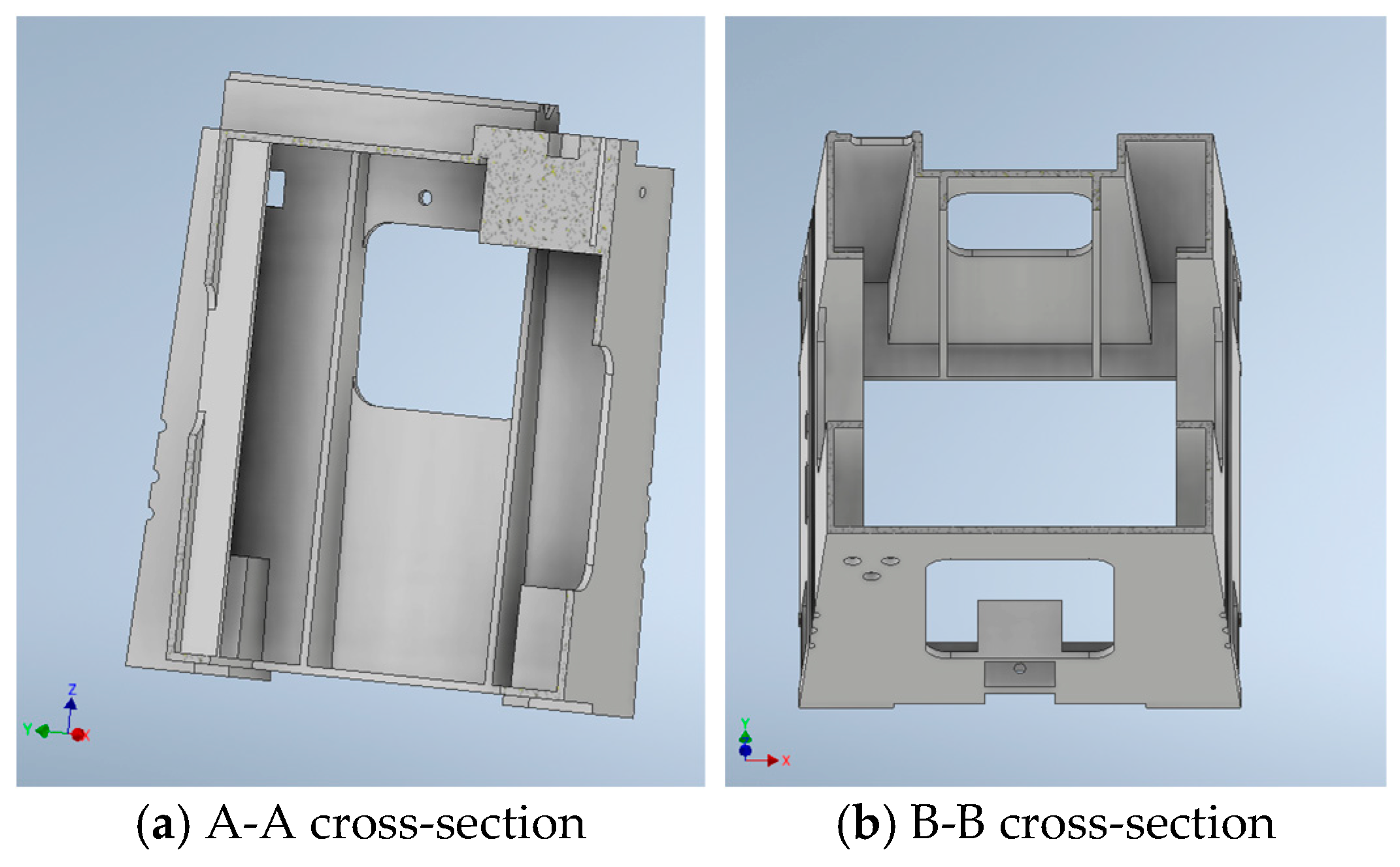

In the field of engineering design, biomimetic design methods have been proven to improve the dynamic characteristics of the machine tools and enhance structural rigidity and durability without adding extra weight. Current research is mainly focused on applying a single biological structure to optimize machine tool components, such as using leaf vein structures to design high-rigidity worktables, strengthening the gantry machining center’s beams using the features of cacti and giant water lily structures, and enhancing the compressive properties of columns using bamboo joint structures. However, research that integrates two or more different biological structural features into a single part structure design simultaneously is still under development, and its potential for industrial applications, such as machine-tool, has not yet been fully realized. Therefore, this study proposes a comprehensive biomimetic design method that combines the structural features of the leaf veins, cacti, and bamboos to fill this research gap. The goal is to provide significant advantages in improving structural rigidity and lightweight design, offering a more comprehensive and efficient solution for machine-tool design. This study not only demonstrates the potential application of biomimetic design in machine-tool components but also lays the foundation for further integration and application in the future.

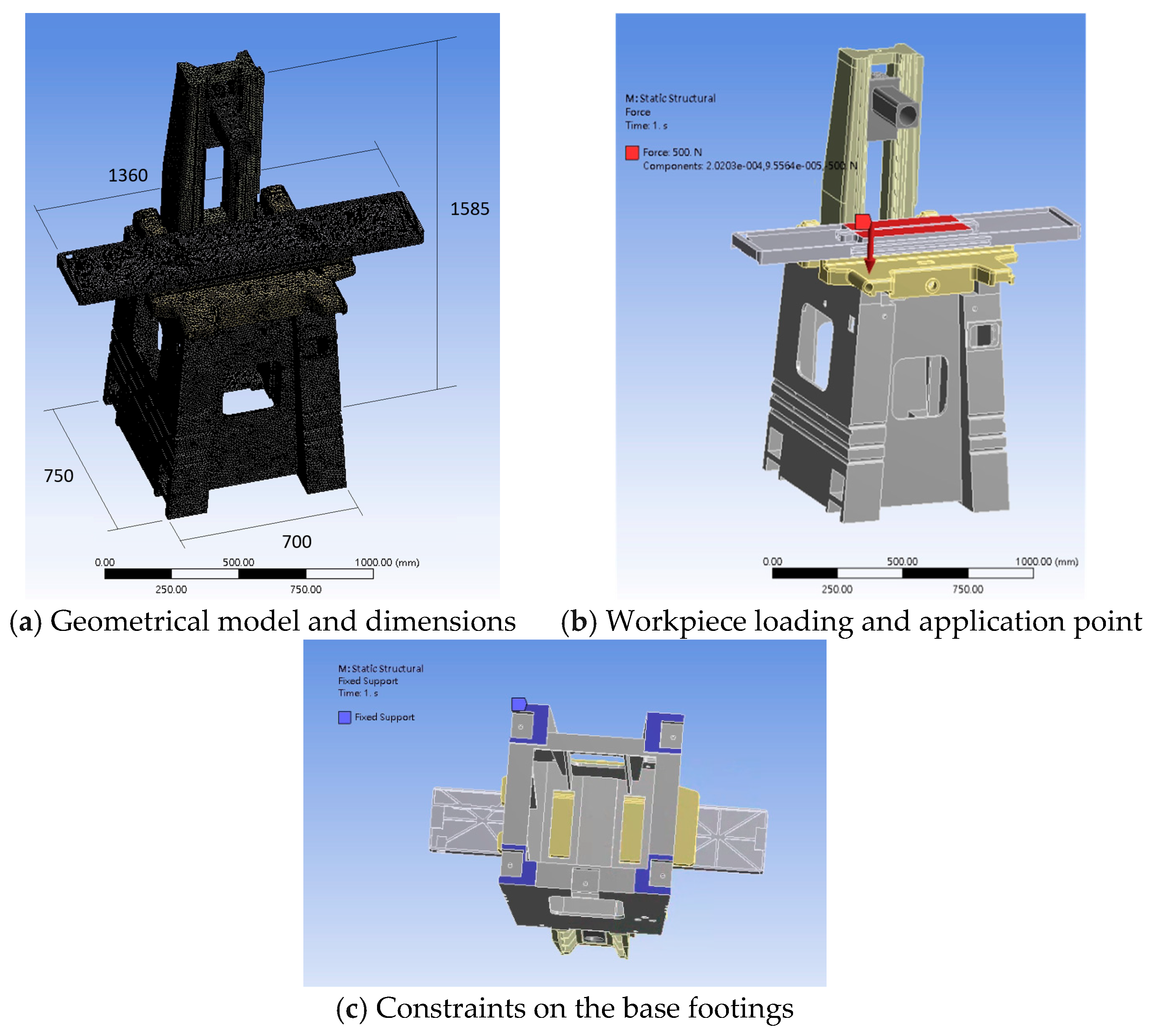

In order to meet the dual goals of high stiffness and lightweightness at the same time, this study aims to develop an innovative rib structure design method that seeks to achieve an optimal balance between high rigidity and lightweight construction. These designs aim not only to reduce unnecessary material usage-thereby lowering the overall weight and energy consumption of the machine-tool, but also to enhance the machining accuracy and speed. Specific strategies include employing various forms and configurations of reinforcement ribs to meet the specific mechanical and dynamic requirements of high-speed precision machining.