1. Introduction

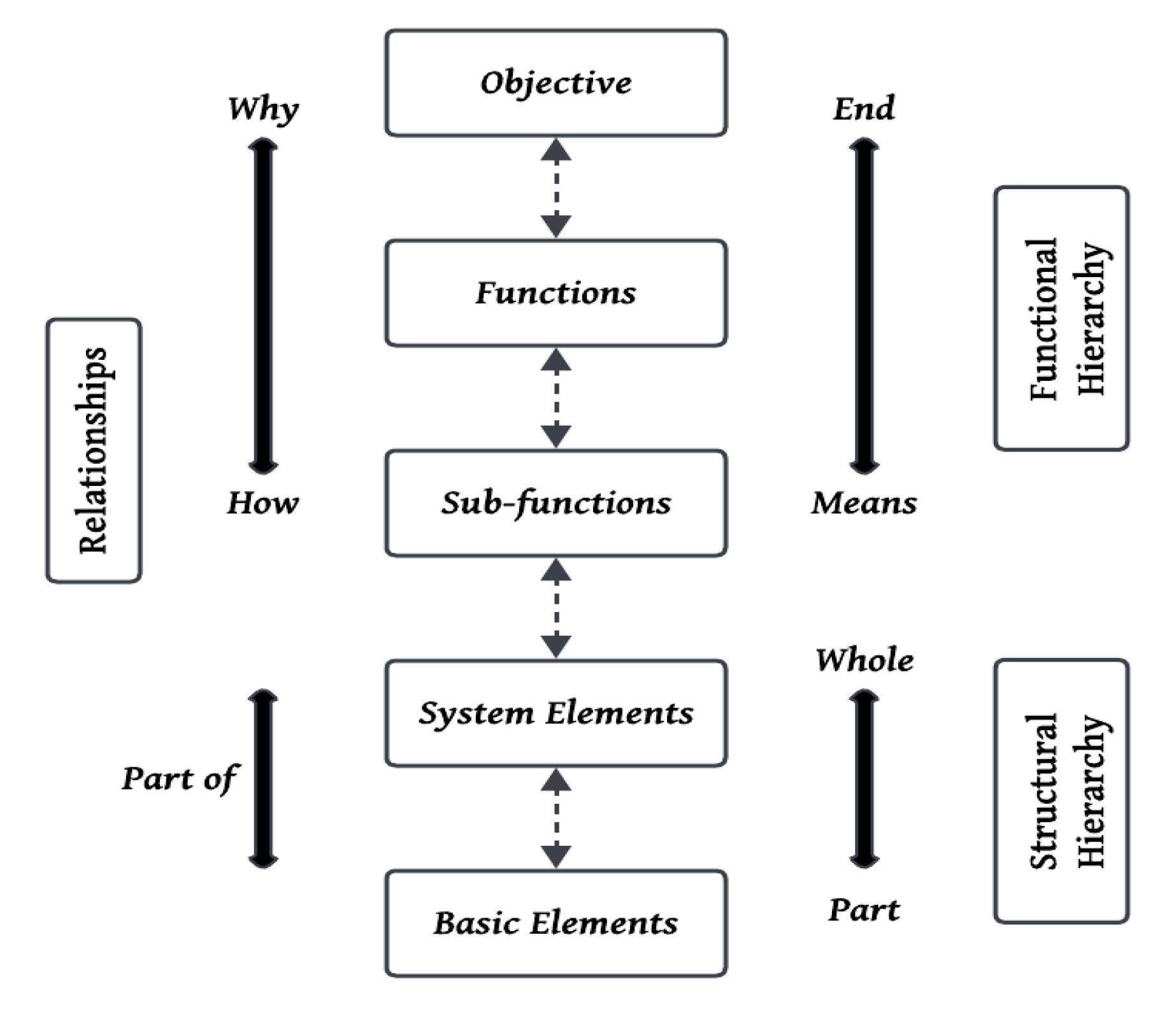

The analysis of complex engineered systems, particularly those in high-reliability and safety-critical industries such as nuclear power plants, requires systematic approaches to assess system integrity, reliability, and performance. Traditional diagnostic tools have predominantly relied on event-based modeling, where the outcomes of specific failure pathways, faults or abnormal initiating events are analyzed. Although effective in some domains, event-based approaches become extremely complex, incomplete and inadequate when applied to complex, interconnected systems with numerous interdependencies. As the scale and complexity of systems increase, functional modeling approaches are considered more suitable, where the emphasis is placed on understanding the roles, dependencies, and contributions of system components toward achieving primary system objectives. Functional modeling involves the development of system models based on the actions and relationships of their constituent parts [

1,

2]. These models are inherently hierarchical, enabling a systematic decomposition of the system into goals, functions, and subfunctions. One important framework within this category is the Dynamic Master Logic (DML) model, introduced by Hu and Modarres [

3], which represents system behavior through a hierarchy linking functional objectives to underlying structures. By organizing systems into functional and structural layers, DML enables critical causal pathways, system interdependencies, and fault propagation mechanisms to be systematically analyzed. This hierarchical framework supports the tracing of failures from system-level objectives down to elemental components, offering a powerful tool for diagnostic analysis.

Although DML models provide a robust framework for system diagnostics, their construction, maintenance, and interpretation require significant manual effort and extensive domain expertise. As system complexity grows, the burden associated with constructing and interacting with large DML models increases accordingly. In response to these challenges, powerful Artificial Intelligence (AI) tools such as Large Language Models (LLMs) [

4] have been recognized as offering opportunities to enhance the development, interaction, and usability of functional models for diagnosis of faults and failures in complex engineering systems. LLMs have demonstrated strong capabilities in natural language understanding, summarization, and reasoning across a wide range of domains. However, certain limitations, such as hallucination and restricted domain-specific reasoning, have been observed [

5,

6]. To address these challenges and improve diagnostic reliability, knowledge representations such as Knowledge Graphs (KGs) [

7] can be used alongside LLMs to enable more consistent and interpretable reasoning by guiding diagnostic logic through external tools rather than unconstrained language generation. More generally, combining LLMs with KGs helps mitigate hallucination and provides a mechanism for introducing verified domain knowledge into the reasoning process [

8,

9]. Detailed examples of such integrations in fault diagnostics, which form the methodological foundation of this work, are discussed in

Section 2.3.

Given the increasing complexity of engineered systems and the need for scalable, interpretable diagnostic tools, there is a strong motivation to explore AI-driven frameworks that combine domain knowledge with language-based reasoning. In this paper, an approach is proposed that leverages LLMs and KGs to support and enhance interaction with DML models, to reduce manual effort, improve transparency, and facilitate more efficient fault analysis in safety-critical applications.

This research addresses emerging needs in AI-based machinery health monitoring by introducing an LLM-powered agenting workflow for intelligent fault diagnosis in safety-critical systems.

The remainder of this paper is organized as follows.

Section 2 reviews related work on DML modeling, LLMs, and the integration of KGs in diagnostic systems.

Section 3 provides an overview of the research approach.

Section 4 presents the proposed diagnostic framework, detailing both the model construction and interaction phases.

Section 5 describes a case study involving an auxiliary feedwater system in a nuclear power plant, illustrating the application of the framework.

Section 6 reports the evaluation results from both the model construction and interaction components, based on repeated runs using the case study.

Section 7 discusses the results, outlines the limitations of the current work, and proposes directions for future research. Finally,

Section 8 concludes the paper with key findings.

5. Case Study

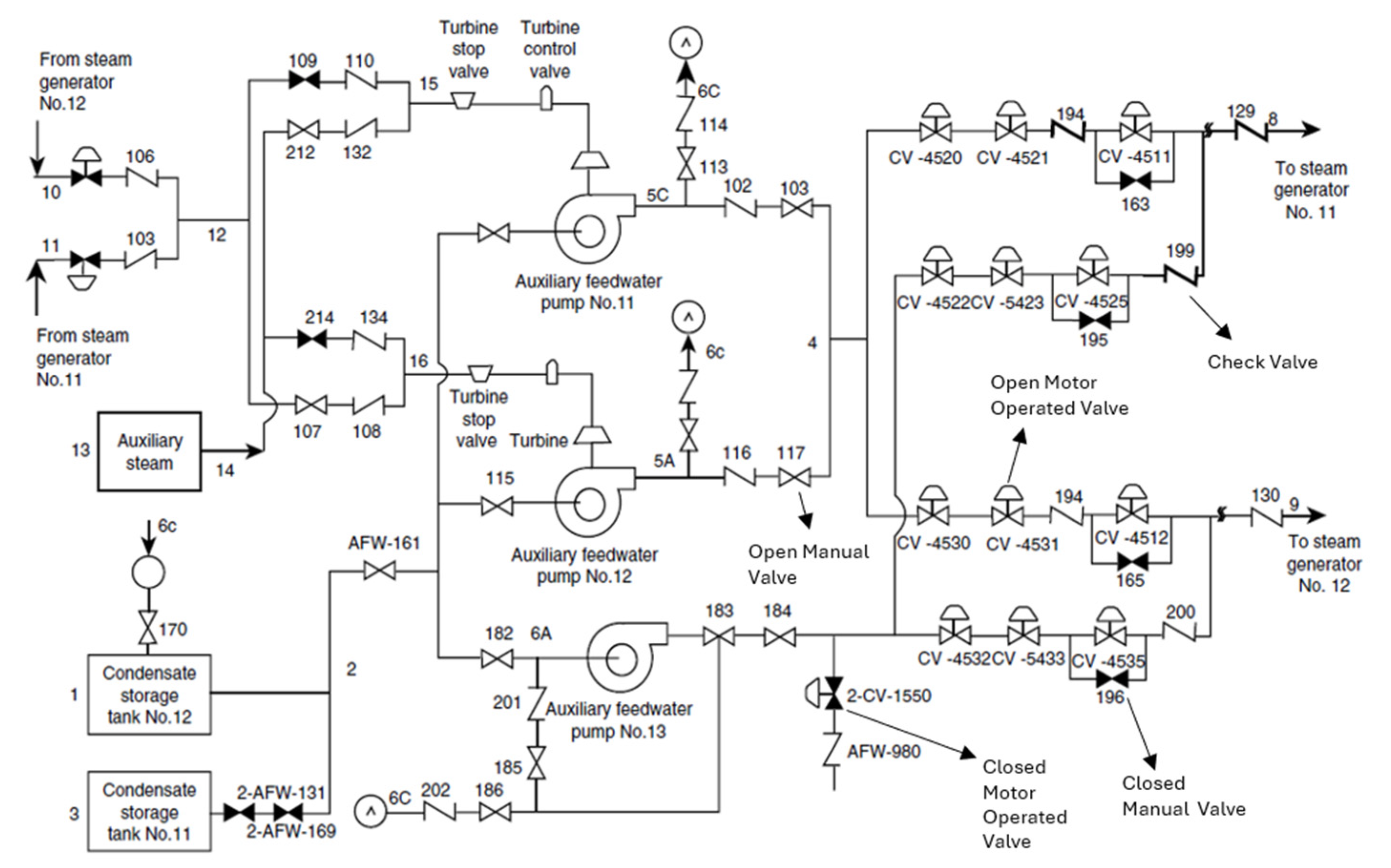

The proposed system, illustrated in the Piping and Instrumentation Diagram (P&ID) in

Figure 3, is used as the case study for implementing the proposed LLM-informed diagnostic framework. This P&ID shows a simplified auxiliary feedwater system used for emergency cooling of steam generators at pressurized light water nuclear power plants. It starts automatically upon a loss of normal feedwater to the steam generators. Its main purpose is to keep the steam generator water levels stable as ultimately protecting the reactor core. The system does this by drawing water from a storage tank and delivering it through motor-driven or turbine-driven pumps, valves, and piping, with flow controlled automatically by instrumentation. The system is structured with the main goal defined as “Ensure safe and effective operation of the auxiliary feedwater system”. This goal is supported by four primary functions: “Supply Feedwater”, “Control Water Flow”, “Manage System Integration and Response”, and “Provide Emergency and Automated Response”.

5.1. Model Construction

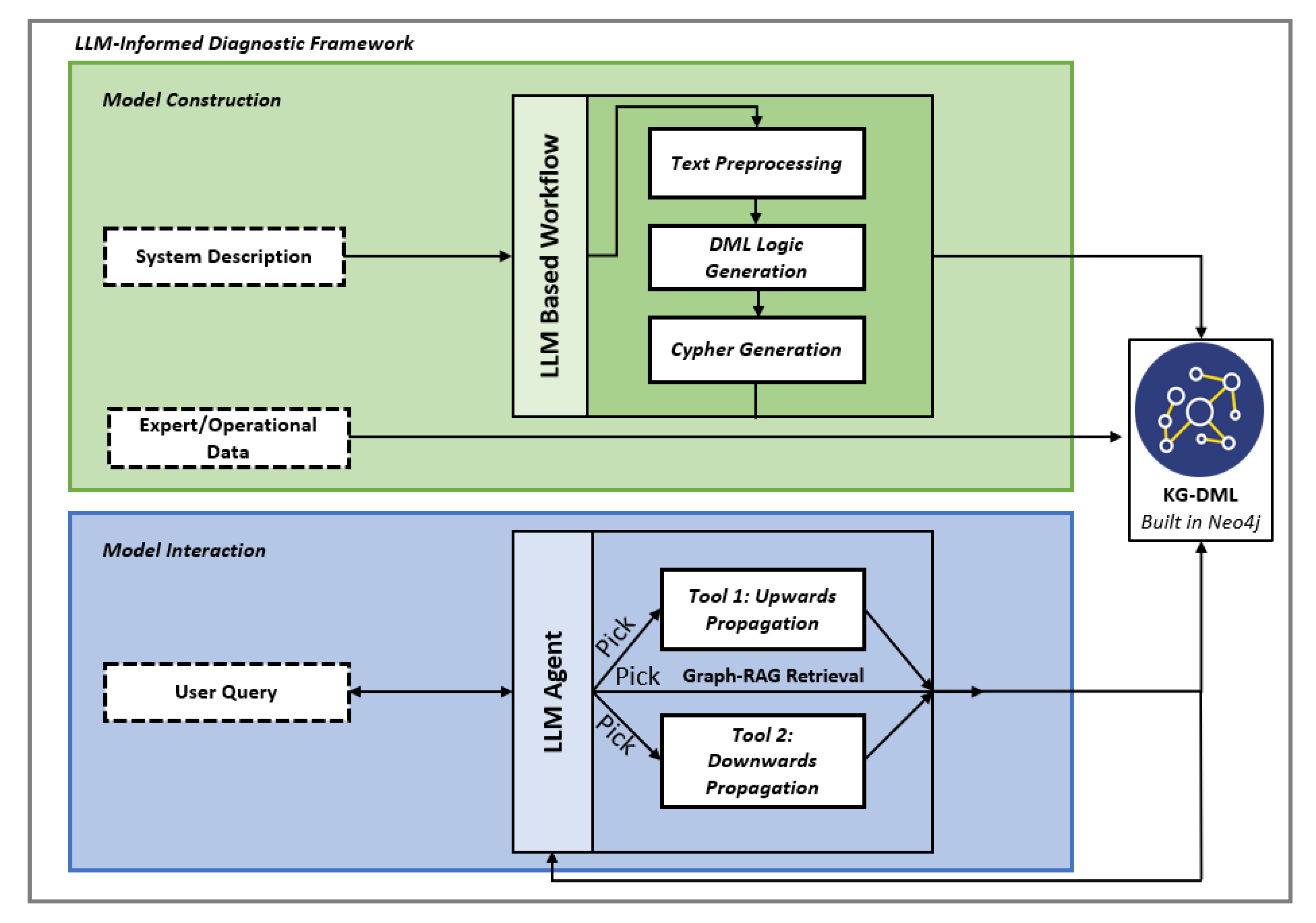

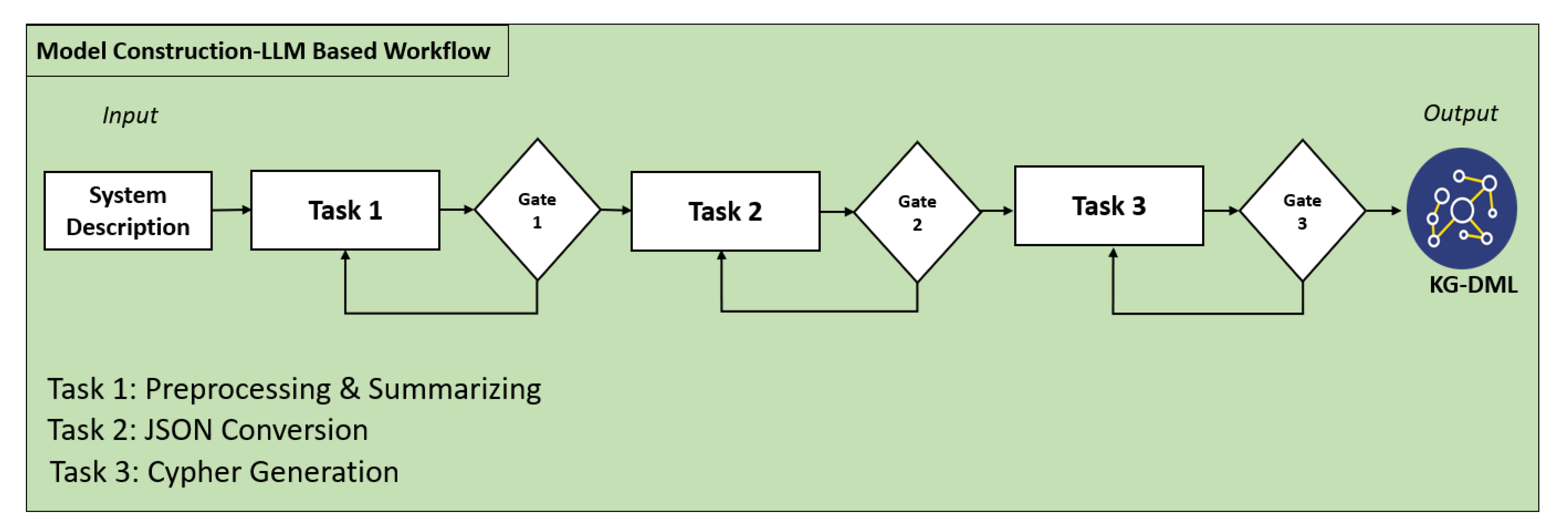

To construct a KG representing DML logic from a system description (which included only major components and functions), a prompt chaining workflow was implemented, with each stage handled by a dedicated LLM call. The hierarchy follows the DML structure, starting with a high-level goal and breaking down into functions, subfunctions, and components, each linked to success conditions. Logical relationships are shown using binary AND or OR logic gates, which define how lower-level elements contribute to achieving higher-level objectives.

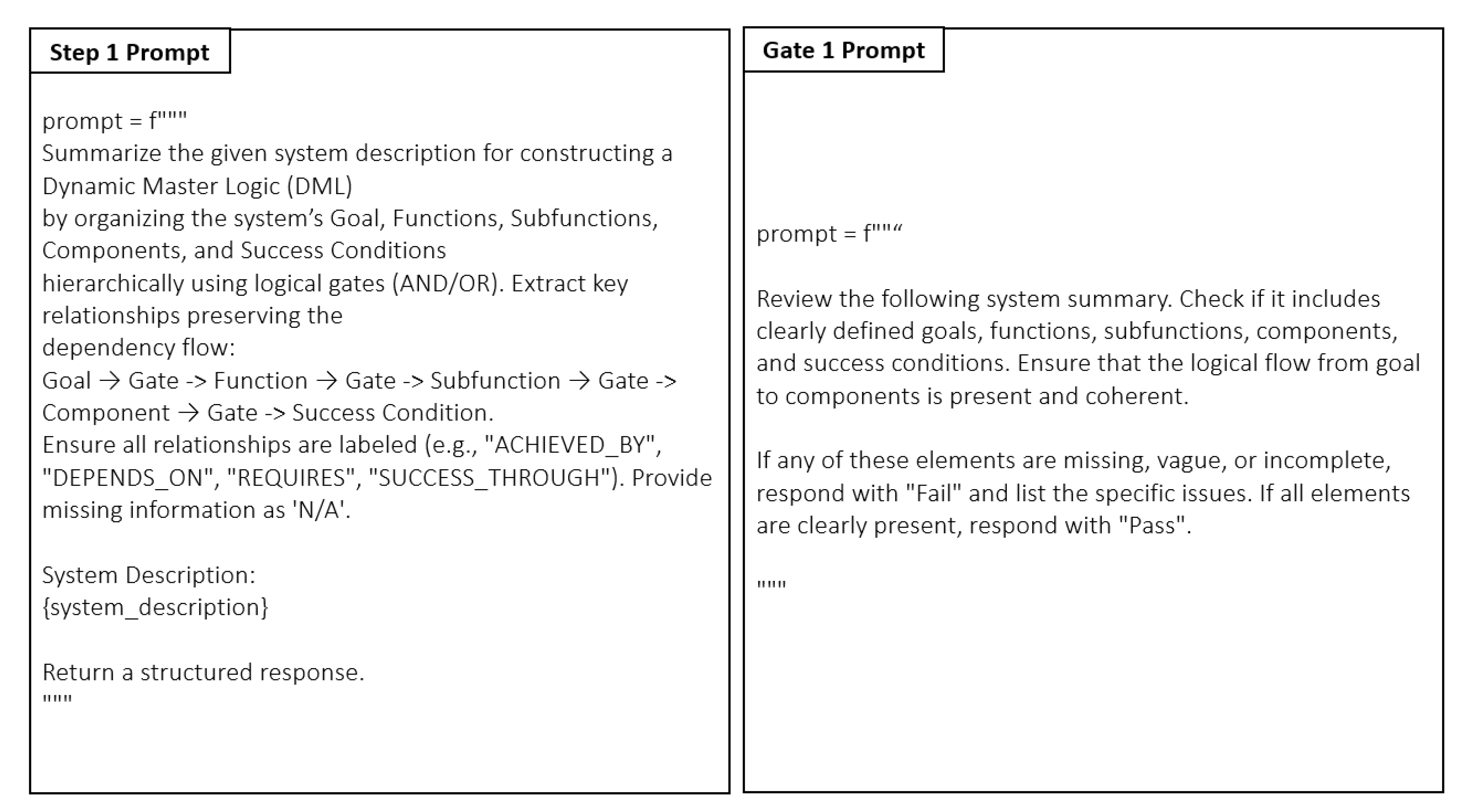

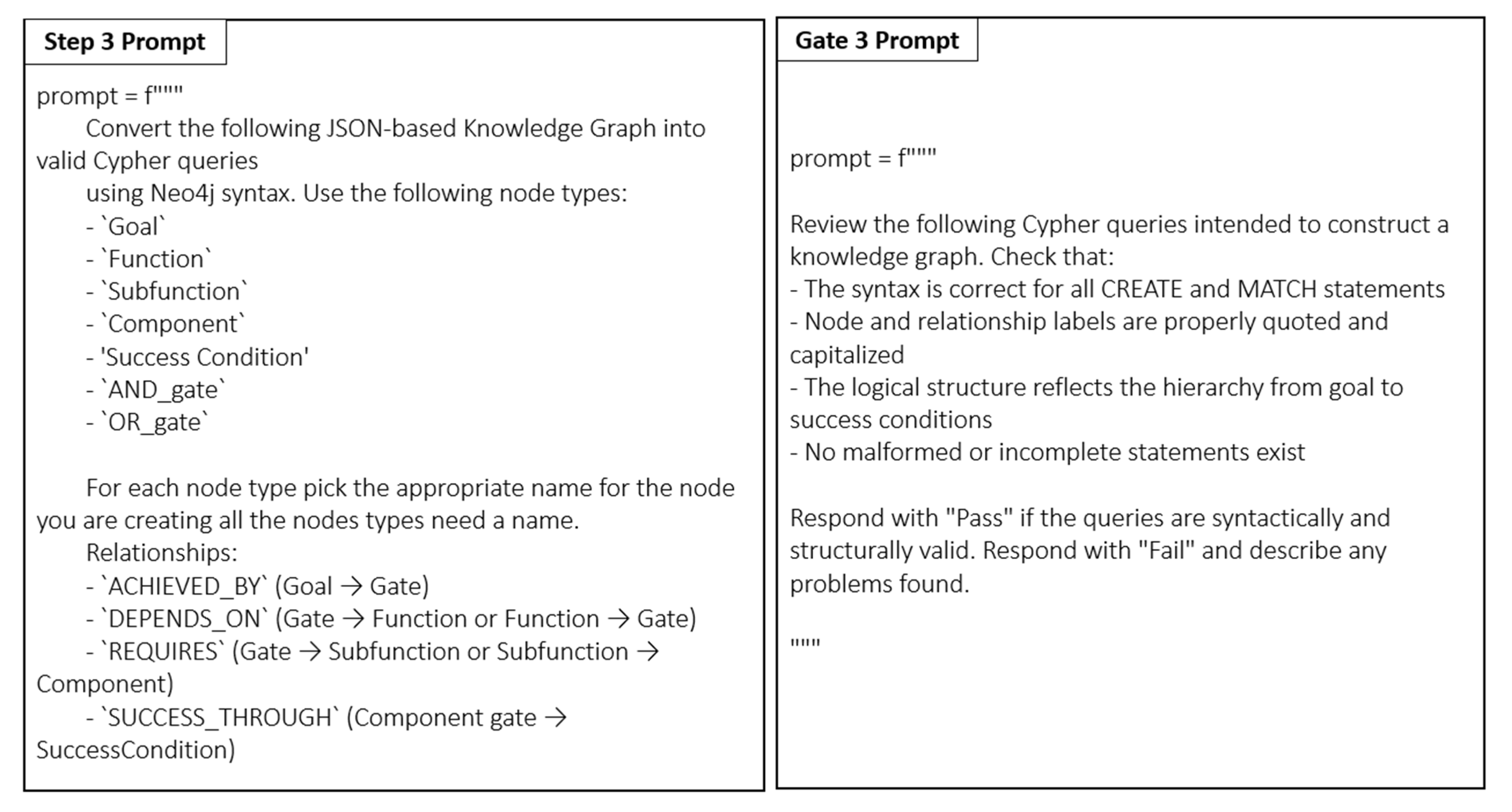

The workflow begins with an initial LLM call that summarizes the system description and extracts goals, functions, subfunctions, components, and success conditions. The result is passed to a second LLM that converts this information into a JavaScript Object Notation (JSON) format aligned with the DML hierarchy. A third LLM then transforms the JSON into Cypher queries for KG construction. Each LLM call is followed by a gate, implemented as another LLM, that validates the output before the next stage proceeds. If validation fails, the workflow routes the input back to the relevant LLM for revision. The first gate checks for missing or incomplete information in the summary, including vague goals, incomplete function chains, or missing success criteria. The second gate validates the JSON structure by checking key formatting, nesting, and logical gate consistency. The third gate examines the generated Cypher queries to ensure they are syntactically correct.

This gated prompt chaining design improves consistency, filters out errors early, and manages variability in LLM outputs. It is especially effective when task steps are clearly defined and expected outputs are explicitly structured.

Figure 4 illustrates the prompt chaining workflow described above, showing the sequential LLM tasks and validation gates leading from the system description to the final KG-DML output. Each task is followed by an LLM-based gate, which ensures the correctness of the output before advancing to the next stage. Feedback loops are included to allow correction and regeneration when validation fails. The specific prompts used for each LLM call in this workflow are provided in the

Appendix A to this paper.

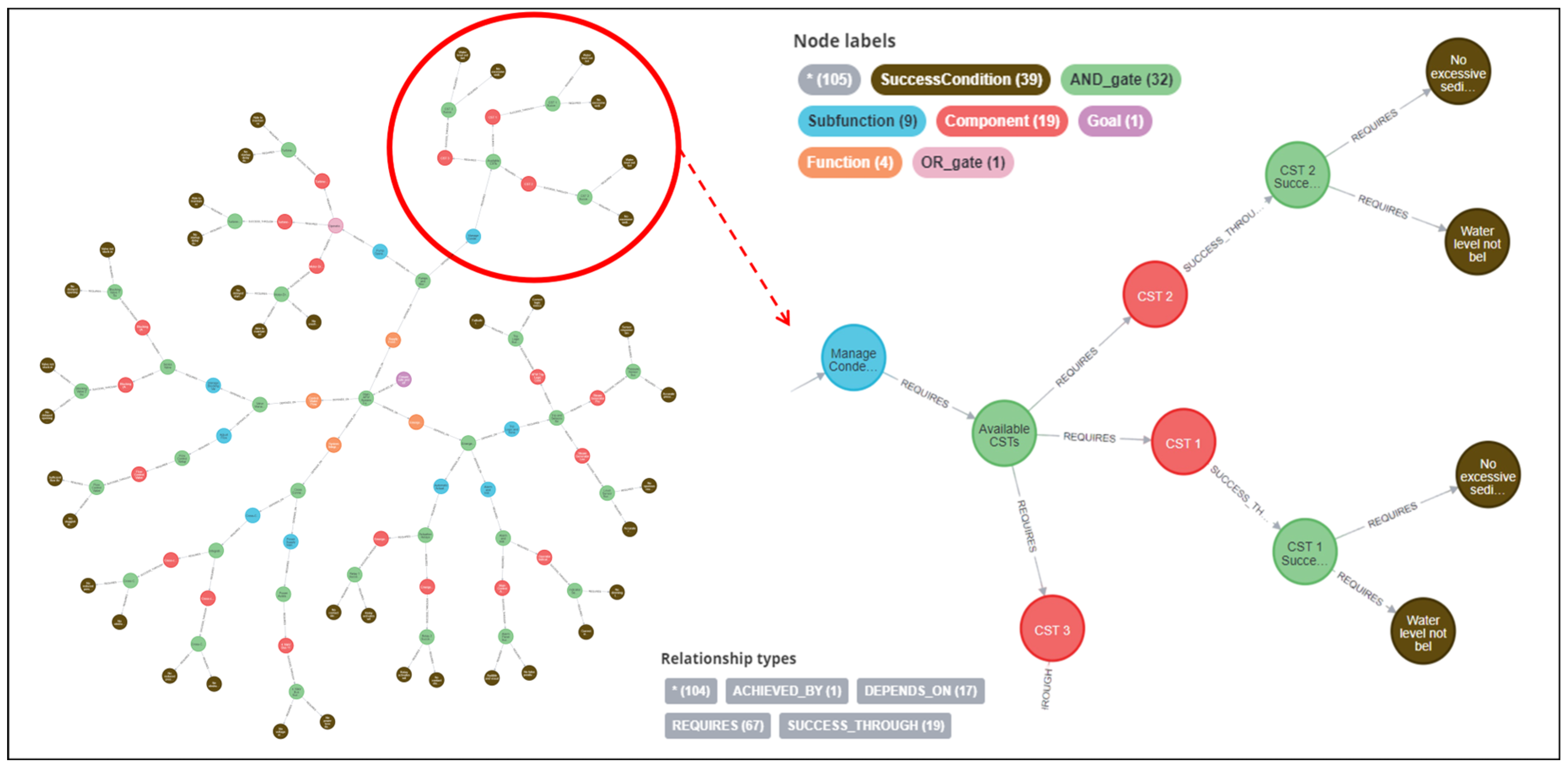

The KG representing the DML logic is structured hierarchically, starting from a high-level goal and descending through functions, subfunctions, components, and finally success conditions. Logical gates, such as AND or OR, define how each level contributes to achieving the level above. A goal may be achieved by multiple functions, each of which depends on one or more subfunctions that require specific components to operate successfully. At the lowest level of the hierarchy, components are connected to success conditions through additional gates. Success conditions reflect observable or measurable outcomes that confirm whether a component is performing as intended. Attributes are stored within the nodes themselves and may include expert knowledge or information derived from ML or DL models based on operational data or manual inspections.

For example, a component such as a turbine-driven pump may contain attributes indicating the probability of being in various states, such as operational, degraded, or failed. Attributes may also be present in higher-level nodes, such as functions or goals. Their role and interpretation will be discussed in the model interaction (next section). This hierarchical structure supports reasoning, traceability, and consistency throughout the KG-DML representation.

Figure 5 illustrates how the DML model is represented within the KG. For example, the subfunction “Manage Condensation Tanks” is fulfilled only if all three Condensation Storage Tanks (CSTs) operate successfully, as defined by an AND gate. Each tank must meet two success conditions: maintaining an appropriate water level and ensuring the absence of excessive sediment. This same hierarchical logic applies when tracing the model upward through functions and system-level goals.

5.2. Model Interaction

As shown in

Figure 2, model interaction begins when a user submits a natural language query to the system. The LLM agent interprets the query and selects from a set of predefined diagnostic functions available to it as tools. These tools perform specialized tasks such as upward fault tracing and the generation of success path sets. Each tool is implemented as an external code module that analyzes the KG based on the logical structure derived from the model. The LLM uses these tools to carry out reasoning over the graph and generate diagnostic insights. To enable accurate selection, the agent was fine-tuned on a dataset consisting of diverse user queries paired with their corresponding tool calls. This included both diagnostic queries requiring tool invocation and interpretive queries requiring Cypher query generation for KG retrieval. This dataset was manually constructed to include multiple phrasings, semantic variations, and tones in which users might pose the same diagnostic intent. These examples were then used to guide the fine-tuning process so that the model learns to map a wide range of natural language inputs to the appropriate tool.

In the implemented tool for upward propagation, the success probability for each success condition

associated with a component is first evaluated. This is done using Equation (1), which computes the probability as a weighted sum over the component’s possible operational states. Each term combines the likelihood of the component being in state

with the probability that it fulfills the success condition

in that state. A state refers to a possible condition of a component, such as operational, degraded, or failed. Each state influences the component’s ability to fulfill its associated success conditions. For example, consider a CST in the auxiliary feedwater system. One possible state of the CST is “failed”, which may be inferred from sensor data. The success condition for the CST could be defined as “maintains sufficient water level for feedwater supply.” If operational data indicates a high probability that the CST is in a failed state, the likelihood of satisfying this success condition would be correspondingly low. This affects the overall success probability of the subfunction “Manage Condensation Tanks,” which depends on all CSTs through an AND gate. Thus, the failure of even one CST can reduce the success probability of the higher-level function and system goal.

N: Total number of operational states for a component.

The probability of success for the success condition . This reflects how likely the component will fulfill the success condition

under state .

: The probability of the component being in state

given the data which can be evidence of events or numerical information.

After evaluating for all success conditions associated with each component in the system, the results are aggregated using logical gates to compute a single success probability for each component. Success probability represents how well the component is fulfilling its intended function. It is based on the combined satisfaction of all defined success conditions. Each condition reflects a specific performance indicator. The aggregation of these conditions provides a quantitative measure of the component’s overall operational effectiveness. The KG stores each element of Equation (1) as attributes within component nodes, including both the conditional success probabilities and the state likelihoods derived from data. In the context of engineering diagnostics, this data may include sensor readings (e.g., temperature, pressure, vibration), event logs, failure reports, and maintenance histories. These attributes serve as the basis for upward propagation and are retained in the KG to support traceability and diagnostic reporting. Once a single success probability is determined for each component, these values are propagated upward through the DML hierarchy using additional logical gates. The gates define how component-level probabilities combine to determine the success of associated subfunctions, functions, and ultimately system-level goals. If the success probability of an upper-level node falls below a predefined threshold, the tool considers that node to be impacted. The corresponding logic that performs the probabilistic propagation is captured in the pseudocode shown in Algorithm 1.

To estimate

, various strategies can be applied depending on data availability and system characteristics. In the absence of real-time sensor data, these probabilities can be derived from expert judgment or reliability reports, which provide baseline estimates of failure or degradation likelihoods. These priors can be refined as new operational data become available. When numerical indicators such as temperature, pressure, or vibration readings are accessible, ML or DL models trained on historical labeled data can be used to estimate state probabilities more dynamically. In systems requiring continuous monitoring and probabilistic inference under uncertainty, particle filtering techniques may be used. Particle filters apply a sequential Monte Carlo approach to approximate probability distributions using a set of weighted samples, enabling real-time Bayesian inference even in nonlinear or non-Gaussian conditions [

39,

40].

| Algorithm 1. Upwards Propagation Pseudocode. |

procedure PROPAGATESUCCESSPROBABILITIES

for each Component C do

for each Success Condition j of component C do

Compute:

end for

Combine success conditions using gate type (e.g., AND, OR)

(C) in KG

end for

for each Subfunction SF do

Retrieve linked Components and gate type

if gateType = AND then

Compute:

else

Compute:

end if

in KG

end for

for each Function F do

Retrieve linked Subfunctions and gate type

if gateType = AND then

Compute:

else

Compute:

end if

in KG

end for

for each Goal G do

Retrieve linked Functions and gate type

if gateType = AND then

Compute:

else

Compute:

end if

) in KG

end for

< threshold

return impacted nodes and probabilities

end procedure |

For downward propagation, given an upper-level node, the tool traces the KG downward to determine the required paths for achieving that node’s success. Using the defined gates, it identifies the necessary dependencies at each level. The path-set generation method determines the minimal components required for system functionality by recursively traversing the KG. Starting from a specified node, the process follows dependencies downward until reaching the Component and Success Condition levels. At each step, the method evaluates the logical dependencies based on the gate type. If an AND gate is present, all dependencies must be met simultaneously, requiring a Cartesian product of the success path-sets from the child nodes to generate valid paths. In contrast, for an OR gate, only one dependency needs to succeed, so the success path sets from the child nodes are aggregated without combination, representing alternative paths to success. This approach ensures that the generated success path-sets accurately reflect the minimal elements necessary to maintain system operability. The approach of downward propagation is formalized by the pseudocode in Algorithm 2. The implementation code for both the tool definitions and the LLM agent workflow is provided in the

Supplementary Materials.

| Algorithm 2. Downward Propagation Pseudocode |

procedure GENERATESUCCESSPATHSETS(nodeType, nodeName)

if nodeType = Component then

Retrieve success conditions and gate type for nodeName

if no success conditions exist then

return {{nodeName}}

end if

if gateType = AND then

return {successConditions}

else

return {{cond} for each cond in successConditions}

end if

end if

Retrieve dependencies and gate type for nodeName

if no dependencies exist then

return {{nodeName}}

end if

Initialize childPathsets ← empty list

for each dependency depName in dependencies do

childPaths ← GENERATESUCCESSPATHSETS(depType, depName)

Append childPaths to childPathsets

end for

if gateType = AND then

Initialize combinedPaths ← empty list

for each combination in Cartesian product of childPathsets do

Append concatenated combination to combinedPaths

end for

return combinedPaths

else

return Flattened list of all childPathsets

end if

end procedure |

5.3. Interaction Interface

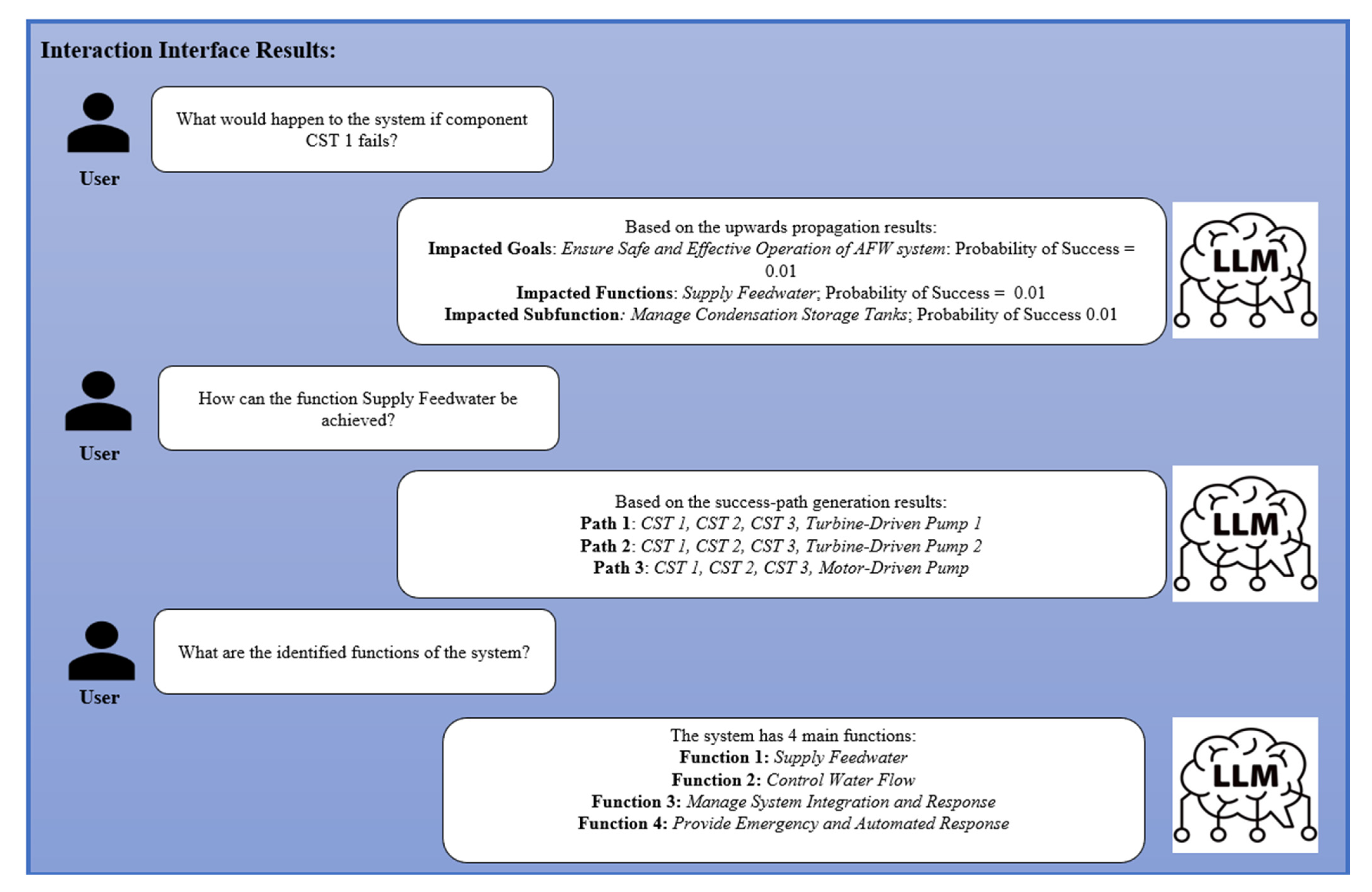

The diagnostic interface enables natural language interaction between the user and the system, allowing users to explore system behavior and fault scenarios. As illustrated in

Figure 6, users can ask questions such as the impact of a specific component failure or how a given function can succeed. When queried about the impact of the failure of a CST, the LLM agent invokes the upward propagation tool to trace the impact across the system hierarchy. Because the CSTs are connected through an AND gate, the success of higher-level nodes depends on the simultaneous functionality of all CSTs. Therefore, the failure of even a single CST significantly reduces the probability of success for the related subfunctions, functions, and overall system goals. Conversely, when asked about the success conditions for a function like “

Supply Feedwater”, the agent employs downward tracing to identify all minimal success paths. Results are returned in a human-readable format, supporting transparent and intuitive diagnostic analysis without requiring technical familiarity with the underlying model.

7. Discussion

The proposed LLM–KG-based diagnostic framework offers major improvements in development speed while maintaining high accuracy compared to traditional functional modeling methods. In typical practice, building a DML model for a complex system can take several months. Domain experts must manually extract goals, functions, and component relationships from technical documentation and assemble them into a structured model. The described framework reduces this tedious process for a complex system to just a few days by using LLMs to automatically extract DML elements from unstructured text and store them in a KG for reasoning and analysis.

Results from testing indicate high structural accuracy for the KG elements, with extraction accuracies exceeding 90% for all categories, and consistent element identification in every case. The LLM agent demonstrates consistent performance across all query types. Averaged over five independent runs of a 60-query test set, the agent achieved high classification accuracy, correctly identifying the intended reasoning or retrieval task in nearly all cases. For upward reasoning, the agent correctly classified an average of 19.8 out of 20 queries per run and generated valid tools or Cypher queries for 19.2 of them, yielding a total accuracy of 96.0%. For downward reasoning, both classification and valid tool or Cypher generation averaged 19.6 per run, corresponding to a total accuracy of 98.0%. For explanatory queries, all 20 queries were classified correctly on average, with valid Cypher queries generated for 19.2, resulting in a total accuracy of 96.0%. These results demonstrate the agent’s reliability in distinguishing between diagnostic and interpretive tasks and its effectiveness in performing structured reasoning and knowledge retrieval based on the system model.

The evaluation also revealed that some metrics exhibited relatively larger standard deviations. This is primarily due to the discrete nature of the counts, where correct classifications are always whole numbers. Small differences between runs, such as 3 versus 4 correct, yield proportionally larger variability. This effect is a statistical artifact and does not necessarily indicate instability in performance. A small number of misclassifications and extraction errors were observed. These were mainly due to hallucination, where the LLM produced elements that are not present in the system documentation or KG, or misrepresented relationships such as logical gates and dependencies. Contributing factors include incomplete context, prompt limitations, and gaps in domain-specific knowledge. Careful prompt design and the use of validation gates reduced the frequency of such issues. However, they could not be eliminated. This highlights the need for a human-in-the-loop process, where domain experts review and revise the automatically generated DML models to ensure logical consistency and accuracy.

Alternative integration strategies for combining system knowledge with LLMs include prompt-engineered pipelines, rule-based reasoning engines, or providing the entire system model as unstructured text context for each query. While these methods can be effective in limited domains, they have drawbacks for complex, safety-critical systems. For example, passing the system or functional model as raw text makes it difficult to enforce consistent reasoning paths, increases the risk of hallucination due to unstructured context, and is constrained by token limits that restrict the size and complexity of the model that can be processed. Longer inputs also make it more difficult for the LLM to perform multi-step diagnostic tasks effectively. While symptom-based fault diagnostics methods using LLMs and KGs, which store fault symptoms in the KG, can be highly effective, they require a large library of known faults, extensive historical data, and well-defined symptom–fault mappings. These approaches can struggle with diagnosing novel or rare failure modes, making them less adaptable to rapidly evolving or data-sparse systems.

A KG was selected in this work because it constrains reasoning to validated information, supports multi-step fault tracing, and enables verification of results. It can also be incrementally updated as new system information becomes available, allowing the diagnostic capability to remain current without full redevelopment of the reasoning process. This combination of speed, accuracy, and interpretability positions the framework as a strong candidate for deployment in mission-critical sectors such as nuclear power, aerospace, and advanced manufacturing.

7.1. Limitations

Although the proposed architecture reduces manual effort, expert oversight remains essential. Furthermore, while the evaluation reports high element-level extraction accuracy, it does not capture the semantic impact of missing critical nodes. In DML models, elements such as gates, subfunctions, or success conditions are often essential to maintaining the integrity of fault propagation paths. The omission of even a single high-impact node can break logical chains and lead to incomplete or misleading diagnostics. This limitation suggests a need for broader evaluation strategies that assess whether generated models preserve full diagnostic reasoning capabilities.

The current validation also relies on a curated query set based on typical expert interactions, which, while practical, may not reflect edge cases, ambiguous phrasing, or linguistic variation. More comprehensive testing involving adversarial queries, paraphrased inputs, and real-user feedback will be necessary to improve the robustness and generalizability of the system.

The framework also assumes access to well-structured documentation and operational or historical data, which may not always be available in practice. Performance can decline in environments where information is incomplete, outdated, or inconsistent. Adapting the framework to domains beyond nuclear diagnostics may require customized prompts and tool modifications, which could limit its immediate applicability elsewhere. Finally, the approach has only been tested on a moderately scoped system, and its scalability and performance in very large systems with deeply nested hierarchies remain untested.

7.2. Future Work

Future work will focus on improving both the accuracy and the range of applications for the framework. One area will be enhanced evaluation and validation methods. This will include introducing semantic validation techniques that go beyond element-level accuracy, benchmarking generated cut-sets and path-sets against expert-engineered baselines to assess logical soundness and coverage, and applying graph-level metrics such as connectivity fidelity, dependency correctness, and fault propagation traceability. Evaluation will also extend to the robustness of LLM behavior under varied prompt conditions and alternative phrasings. Future Work will also explore iterative model refinement, using autonomous LLM agents to continuously improve the model by incorporating expert feedback, reducing hallucinations, correcting errors, and increasing precision over time.

Additional diagnostic capabilities will be developed, such as probabilistic assessments of component criticality in situations where partial functionality can be tolerated, and recommendations for optimal maintenance or mitigation strategies under uncertainty. Real-time data integration is another planned enhancement, where the KG will be updated with operational data using data fusion techniques that combine sensor readings, maintenance records, and expert observations. Modeling dynamic behavior will also be improved through time-dependent gating mechanisms that better represent evolving system states.

Information extraction will be strengthened by incorporating advanced NER techniques for greater precision and detail in processing technical documents. For long documents that exceed a single LLM context window, better chunking and summarization methods will be implemented, alongside models with larger token capacities to handle extended inputs without losing critical information. Evaluating the framework’s performance on large-scale systems with deeply nested hierarchies, including determining computational limits, optimizing query execution, and ensuring responsiveness in real-time diagnostics, is another planned focus.

8. Conclusions

The integration of LLMs and KGs into diagnostic modeling marks a significant advancement in automating complex system analysis. This research introduces a scale-independent, AI-driven framework that streamlines the generation of diagnostic models and enhances predictive accuracy and fault reasoning through natural language interaction. By reducing reliance on manual modeling and enabling explainable diagnostics, the approach adapts effectively to evolving system configurations. Depending on the query type, system knowledge from the KG is either processed through diagnostic tools or embedded into the LLM prompt, enabling responses that are both context-aware and grounded in system logic.

The framework facilitates human–AI collaboration by allowing users to interact with system behavior through natural language queries, lowering the technical barrier to advanced diagnostics, and extending the utility of functional modeling techniques such as DML, which have traditionally required extensive domain expertise and manual effort.

Comprehensive evaluations of both KG construction and LLM-based query interpretation validate the framework’s ability to generate interpretable, graph-based diagnostics directly from unstructured documentation, achieving high extraction accuracy for critical logic structures and reliable performance across diagnostic and explanatory queries.

Overall, this work contributes to the emerging area of LLM-integrated health monitoring by demonstrating how LLM workflows and agents can bridge human queries with graph-based models for fault diagnostics, enabling fault detection, success path-set generation, and probabilistic propagation through transparent, natural language interactions. This aligns with the broader goals of AI-driven predictive maintenance and intelligent fault analysis for complex systems.