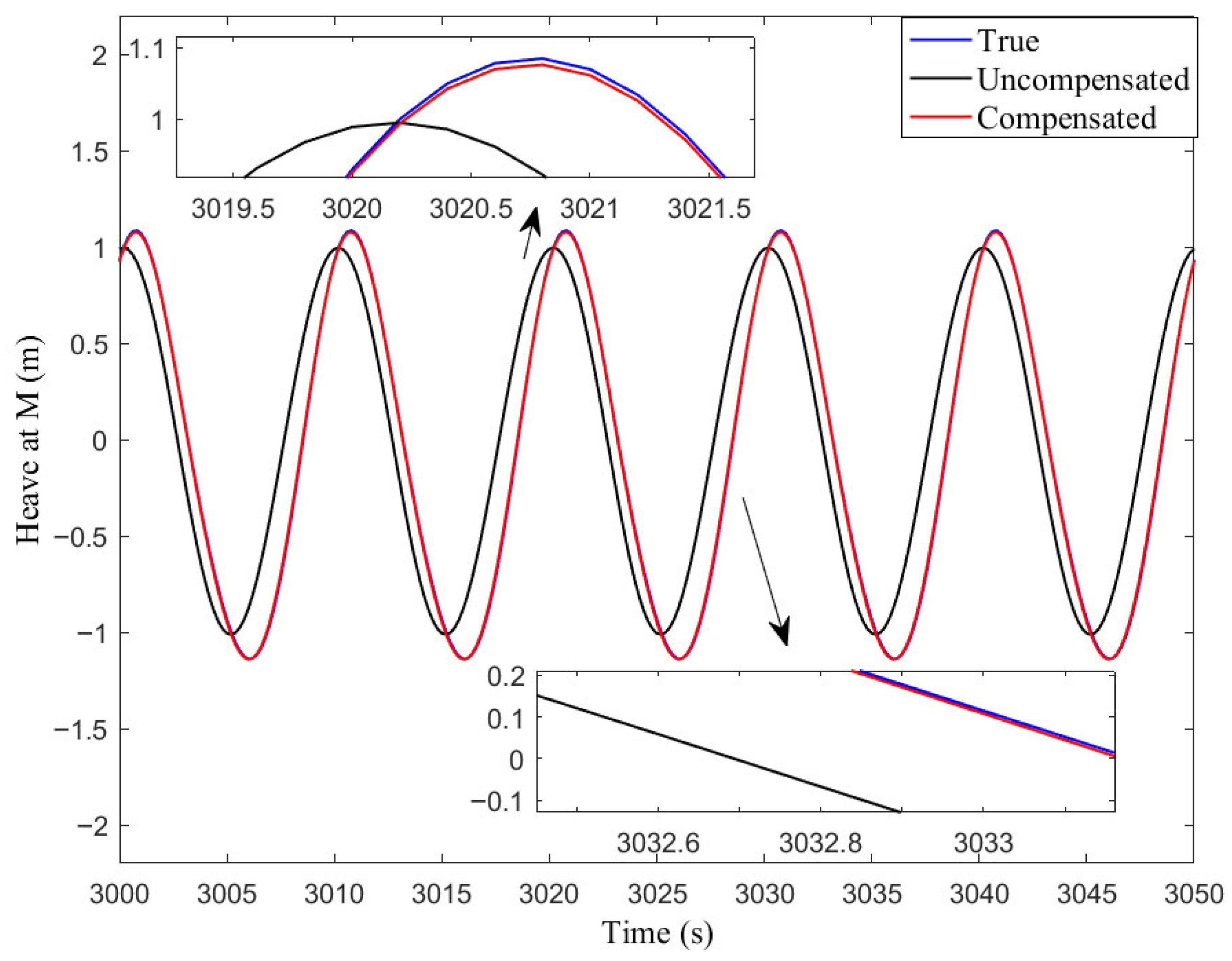

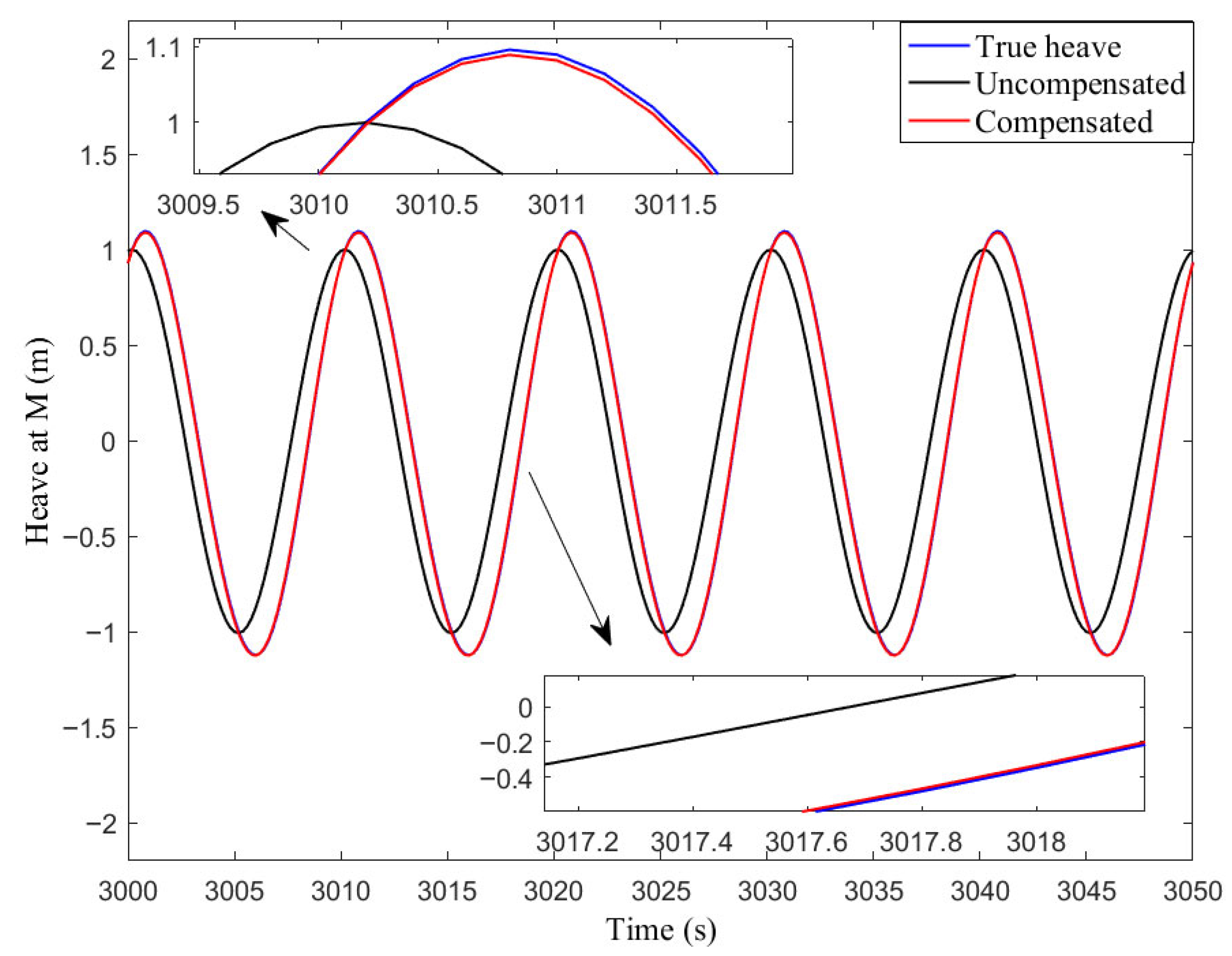

Conventional heave measurement methods are developed under the assumption that the INS is mounted at the vessel’s center of gravity. In other words, the fixed point of INS and the vessel’s center of gravity coincide. Generally, the fixed point of INS does not overlap with the monitoring point. Because the lever arm effect exists, which is caused by the ship’s roll and pitch, the heave motion of the fixed point of INS and the monitoring point is also different. For expressing and using conveniently in this study, let the primary lever arm denote the lever arm from point F to M. And the center of gravity lever arm denotes the lever arm from point F to CG.

The INS detects only a change in the vertical displacement for a certain period of time where it is fixed. Relative to the local geographic frame, due to the influence of the ship’s attitude and the primary lever arm, the heave of point

M can be divided into two parts: translational heave

and induced heave

, which is

where

corresponds to vertical movement due to waves,

due to the lever arm between

F and

M and vessel attitude (roll and pitch).

In

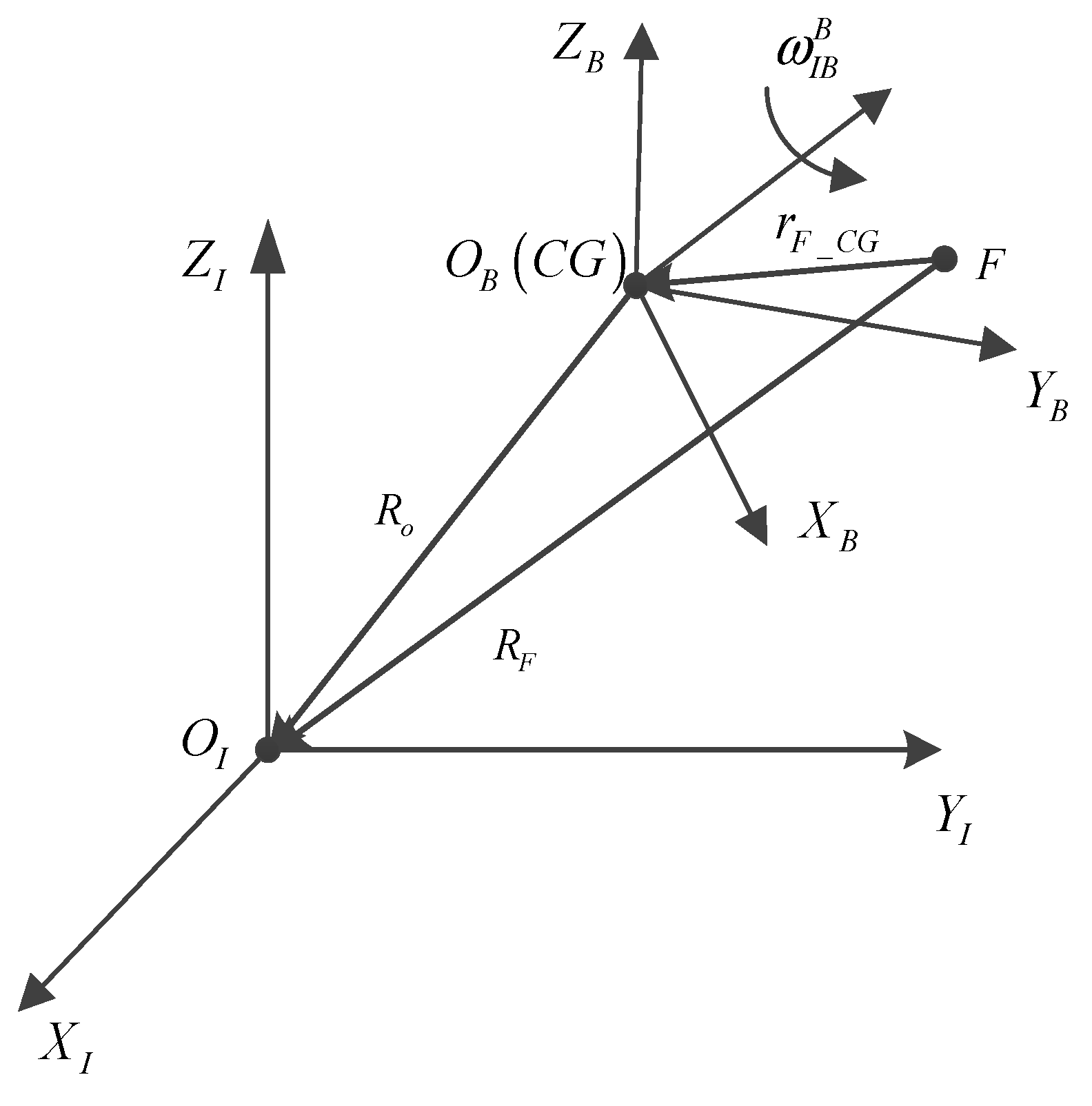

Figure 1, CG denotes the center of gravity of the vessel.

F is the fixed point of INS.

M is the monitoring point.

is the geographic frame. This frame has its origin at the current geographic location and is fixed to the Earth’s surface. The frame is chosen with the following successive axes directions:

geographic north,

geographic east, and

up.

is the body frame. This frame is fixed to the vehicle or ship with its origin in the ship’s center of gravity. The definition of the axes directions is as follows:

the bow direction of a ship,

the starboard direction of a ship, and

the down in the direction of gravity.

is roll angle. A rotation about

is defined as positive when the starboard side of the ship moves down.

2.1. Translational Heave

The acceleration signal

of point

F contains not only the measurement acceleration

of point

F but also several error sources. In the following,

can be described by the acceleration model [

18]

where

is the transform matrix from

frame to

frame, and

and

are the bias and high-frequency noise, respectively.

is represented by components

. Because sensor bias and high-frequency noise exist, the estimated heave calculated by integrating the measured

z-axis acceleration

twice would drift off rapidly. Therefore, a heave filter is usually applied to the measured

z-axis acceleration

to reduce the impact of sensor bias and high-frequency noise.

A heave filter is composed of the double integration and a high-pass filter. The double integration is used to remove the high-frequency noise and obtain heave information via acceleration . The high-pass filter is employed to remove the gravitational constant and the slowly time-varying bias.

A heave filter, which includes double integration

and a high-pass filter

, is given by [

19]

where integration

meets the requests

and the high-pass filter as

where

is the Laplace variable,

is the damping coefficient,

is normally taken

, and

is the cutoff frequency of the high-pass filter.

The high-pass filter changes the amplitude and phase characteristics of the desired signals. Therefore, the choice of the cutoff frequency

directly affects the results of the heave measurement. Leaving the phase shift out of account, the amplitude error induced by the high-pass filter is

where

is the calculated heave displacement, and

is the true heave displacement.

Since the true heave displacement is the double integration of the heave acceleration, we have

The calculated heave displacement is the double integration and high-pass filtering of the heave acceleration

Compared (7) with (8), we get

Using (9), the amplitude response error is expressed by

With the aid of

and (4), (10) is rewritten as

where

is the dominant frequency of wave motion, obtained by the fast Fourier transform (FFT) of the measured

z-axis acceleration.

The applied cutoff frequency is determined by satisfying performance specifications. The performance specification of 2% peak-to-peak error is reached when

If the dominant frequency of wave motion is 0.1 Hz, it is necessary that the cutoff frequency . In this paper, the equation is used to obtain the cutoff frequency.

The transfer function can only be used in a continuous system, and the measured signals from INS and the designed compensation system are discrete. Thus, the bilinear transformation is adopted to perform the conversion between an analog filter

and a digital filter

, of which the basic relationship is [

20]

where

is the update period.

Translational heave is calculated by

In practice, there is a need for a real-time estimate of heave to compensate for the wave motion. The real-time heave error for filter (4) is given by

Using (7), the real-time heave error is expressed by

With the aid of

and (4), (16) is rewritten by

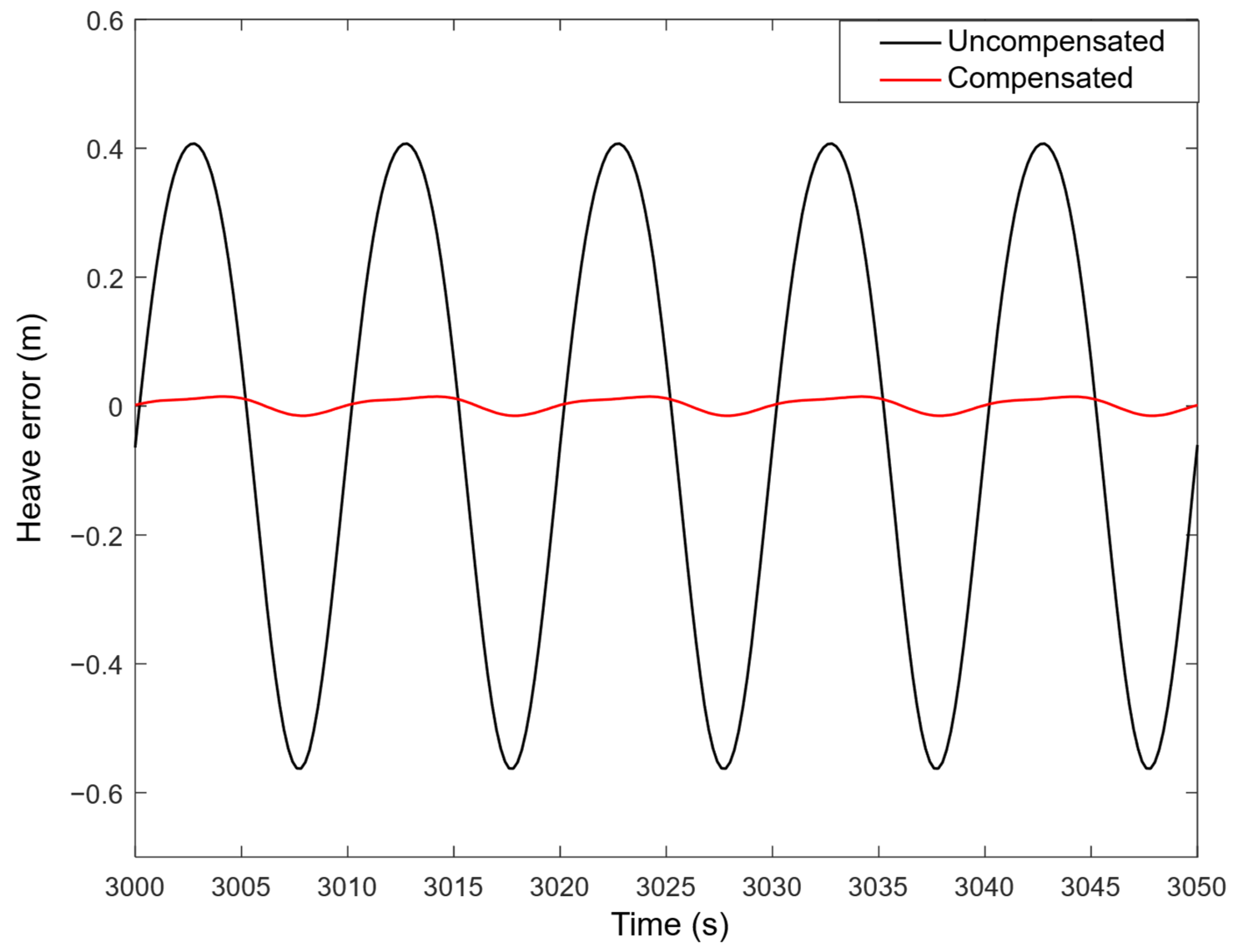

In comparison of (11) and (17), the real-time heave error is much greater than the amplitude response error . Most of is due to the positive phase. This means that the measurement is sometimes ahead of the actual wave.

The phase error is large and would significantly influence the accuracy of heave estimation. In order to improve the accuracy of heave measurement, many researchers share the same spirit of trying to find the real-time phase compensation methods.

For example, Ning et al. introduced a low-pass filter that cascaded after the heave filter to avoid phase correction [

15].

where

The phase response of

and

with

are written as

The low-pass cutoff frequency

is determined by

Another attempt is by Hu et al., who employed an all-pass filter

to balance the phase lead [

16].

where

The phase response of the all-pass filter is

The coefficient

is determined by

However, the real-time performance of those phase compensation methods was not enough.

2.2. Induced Heave

induced the heave of (1) due to the primary lever arms and vessel attitude (roll and pitch). It corresponds to the projection difference between the with and without pitch and roll of the primary lever arms

on the vertical axis of the geographic frame [

17].

where

is the projection with pitch and roll of the primary lever arms on the vertical axis of the geographic frame.

is the projection without pitch and roll of the primary lever arms on the vertical axis of the geographic frame.

The relationship between

and

is:

where

The projection

is

The relationship between

and

is:

where

The projection

is

Therefore, the induced heave

can be expressed as [

13]

Finally, the heave information of M is calculated by (14) and (29)

Generally speaking, it is often not possible to mount the INS at precisely the CG. There is the center of gravity lever arm. During turns, when roll and pitch change, the measured acceleration of the INS includes an acceleration error . This acceleration error will act like an impulse response to the heave filter and make the estimate oscillate temporarily.

For example, the filter impulse response is obtained by the inverse Laplace transform of the heave filter

Substituting (5) into (10) yields

The heave error caused by the impulse response of the heave filter and heave acceleration error

is given by [

14]

Based on the above analysis, the center of gravity lever arm effect should be taken into account.