1. Introduction

Gears are fundamental mechanical elements that play a crucial role in the transmission of power and motion across various technical and industrial systems. They consist of a body and a rim, with the rim comprising a series of precisely shaped and distributed teeth. These teeth are designed to enable efficient and continuous contact between paired gears, ensuring reliable torque transmission.

Gear geometry, as a specialized field of mechanical engineering, deals with analyzing the shape, dimensions, and mutual relationships of gear tooth elements. Depending on the tooth profile, gears are classified as having involute or cycloidal gearing, with involute profiles being the most widely used due to their ease of manufacturing and stable power transmission.

A precisely defined and correctly applied gear geometry is essential for the efficient operation of power transmission systems. Proper tooth profile design directly reduces friction losses, ensures even load distribution, and minimizes wear, resulting in highly reliable machines with extended service life and improved energy efficiency.

Gears can be manufactured using various technological processes, among which conventional methods such as hobbing, turning, shaping, and grinding are most commonly used. Over the past decades, these methods have been extensively researched, with studies analyzing their advantages, limitations, and influence on gear quality.

However, despite significant progress in material processing technologies, the application of modern methods—such as laser cutting—for gear manufacturing remains insufficiently explored. Laser cutting represents a potentially efficient alternative to conventional methods, particularly in the case of small series, complex geometries, and high precision requirements. Still, it is necessary to thoroughly examine how this technology affects the geometric and functional properties of gears.

For that reason, the main objective of this study is to analyze the geometric characteristics of gears produced using laser cutting. Special attention is given to dimensional accuracy, tooth profile shape, and potential deformations resulting from thermal effects during cutting. The obtained results contribute to a better understanding of this method’s potential and its application in modern power transmission systems.

Continuous development of gear manufacturing methodologies involves the refinement of traditional gear production techniques such as gear hobbing, shaping, and shaving [

1]. Additionally, the use of CNC machining and other advanced technologies significantly enhances this process [

2,

3,

4,

5]. Such methods demand a high level of engineering expertise and considerable machining time.

Improving these methods, as well as investigating new manufacturing techniques, may lead to reduced production times and improved gear quality [

6,

7,

8].

Exploring new gear production methodologies requires quality assessment of the resulting gears. This includes surface roughness parameters such as

Ra,

Rz, etc. [

9], as well as the geometric accuracy compared to the gear design. These evaluations are performed using various gear measurement methods [

10,

11], followed by comparison with the prescribed values in ISO 1328-1 [

12].

In recent decades, laser cutting of metals has experienced rapid development and has been adopted in numerous industrial sectors, including the automotive, mechanical, and energy industries. Although typically used for cutting sheets, tubes, and components of simple geometry, the potential of this technology for manufacturing functional mechanical components—such as gears—has only recently started to be explored.

When laser cutting gears, it is essential to consider cutting parameters that directly affect the quality of the finished gear. Laser power, cutting speed, and focus height are among the parameters that need to be controlled during laser processing [

13].

Producing gears by laser cutting results in significant savings in both time and material compared to conventional machining methods [

14]. Another advantage is the high precision achievable, particularly demonstrated in the production of miniature gears with diameters not exceeding 9.04 mm. Several studies have shown that laser cutting can produce miniature gears with high accuracy and smooth surfaces [

15]. These gears have been subjected to various tests, including surface integrity analysis, performance evaluation, and thermo-mechanical testing [

16,

17,

18].

However, most previous studies have been limited to gears with external diameters up to 9.04 mm, made exclusively from stainless steel. In this study, the analysis is expanded to include gears of different sizes, thereby contributing to a broader understanding of laser cutting in gear production.

This research presents a simple and fast gear manufacturing method characterized by high efficiency in terms of time and resources. After the manufacturing process, dimensional and geometric accuracy was assessed using universal precision measuring tools. Gears of various sizes were analyzed, and the results were compared to evaluate the influence of process parameters.

Traditional gear manufacturing techniques—such as milling, turning, and grinding—remain the industry standard due to their ability to deliver high precision, reliability, and repeatability in serial production. However, these methods require specialized equipment, specific tooling, and significant machining time, which may pose limitations, especially in the early stages of product development. On the other hand, laser cutting is increasingly recognized as a modern and flexible alternative, particularly suitable for rapid prototyping and small-batch production. This technology enables high cutting precision without additional tooling and reduces both production time and cost. Despite these advantages, a key question remains: can laser-cut gears fully meet the stringent geometric and functional requirements defined by current technical standards? Answering this question requires a detailed assessment of the manufacturing quality, tooth profile accuracy, and overall mechanical reliability of such gears.

The aim of this paper is to provide an answer through experimental testing of spur gears made from S355 steel using laser cutting. The research focuses on the geometric analysis of tooth profiles and the evaluation of gear quality in relation to the transmission ratio. Based on the obtained results, the paper discusses the potential industrial applicability of such gears.

In addition to technical performance, it is important to emphasize the economic and time-saving advantages of laser cutting in gear manufacturing. This technology allows for significant reductions in production time and costs, particularly in the context of small series or prototype production, making it highly beneficial in product development, as well as in educational and research environments. The aim of this study is to provide deeper insight into the practicality and cost-effectiveness of this method compared to traditional manufacturing techniques.

2. Materials and Methods

The research began with the development of three-dimensional CAD models of gears and the generation of DXF files required for gear fabrication. Autodesk Inventor 2019 was used to create the 3D models, and the “Export Tooth Shape” function was applied to ensure accurate involute tooth profiles. Following the modeling process, DXF files were generated based on the models, providing the contour paths for the laser cutting process.

Using this approach, 3D CAD models of six gear pairs—twelve individual gears—were created. All six gear pairs were designed with the same center distance of 80 mm. This identical center distance was chosen to facilitate future experimental testing, specifically to determine transmission efficiency, which was later performed using the GUNT (Barsbüttel, Germany) AT200 apparatus [

19].

Despite having the same center distance, the gears were designed with varying dimensions, numbers of teeth, and modules using profile corrections in Autodesk Inventor. This ensured diversity in geometric parameters and transmission ratios, enabling a more comprehensive analysis of the influence of laser cutting on gear quality and manufacturing accuracy—particularly relevant given the limited number of studies addressing this topic in the available literature.

To achieve the same center distance for all pairs, this was chosen in order to enable the use of a single experimental setup for testing a larger number of different gear pairs and transmission ratios. In this way, a foundation was established for future standardization and systematization of results. To ensure a consistent center distance the previous theoretical center distance was calculated by Equation (1).

where

d1 and

d2 are the pitch circle diameters of the driving and driven gears, respectively. This relation represents the fundamental geometrical condition for establishing proper meshing in a gear pair and ensures the prescribed center distance, which is necessary to limit the range of parameters chosen for the experiment.

In order to ensure consistency between the theoretical and practical calculations, it was assumed in the subsequent analysis that the calculated center distance corresponds to the actual center distance. In this way, the theoretical model of the gear pair accurately reflects the actual design conditions. This approach eliminates the possibility of deviations in determining the operating pressure angle, which could otherwise affect the distribution of contact forces and the accuracy of the subsequent experimental efficiency evaluation. The practical center distance is calculated by Equation (2).

From Equation (2) the pressure angle,

αw, is obtained. The pressure angle represents a fundamental parameter of involute gearing and defines the direction of load transmission between gears. Its value directly influences the distribution of contact forces, transmission efficiency, and tooth wear resistance. An increase in the pressure angle reduces sliding within the contact but simultaneously generates higher radial forces, which is significant for evaluating the reliability and durability of the gear pair. After determining the pressure angle, the sum of profile shift coefficients can be obtained by using Equation (3).

In cases where both the center distance and the transmission ratio are fixed, as it is in this research, an asymmetric distribution of the profile shift coefficients must be applied to satisfy specific design requirements. While the sum of the coefficients must fulfill the condition

x1 +

x2 =∑

x, their individual values can be adjusted to prevent undercutting of the driving gear, to improve the overlap ratio, or to optimize the tooth shape for load distribution. Increasing the coefficient of the driving gear (

x1 >

x2) reduces the risk of undercutting at low tooth numbers but may increase sliding losses. Conversely, assigning a higher value to the driven gear (

x2 >

x1) improves contact conditions and increases the operating pressure angle, but at the cost of higher radial forces. Therefore, the asymmetric allocation of profile shifts under these constraints enables the designer to balance geometric limitations with strength, efficiency, and durability requirements of the gear pair. After the shift coefficients are calculated, other important parameters, which are crucial for spur gears operation, can be obtained by Equations (4) and (5).

In addition, each gear pair was designed with a different transmission ratio, gradually increasing from 1, in increments of approximately 0.2, up to a maximum value of 2. This progression allowed for consistent monitoring of transmission ratio variations in relation to gear geometry and supported the evaluation of how different transmission ratios affect manufacturing quality and dimensional deviations.

Table 1 presents the basic parameters of each individual gear. Gear pair 1–1′ has a transmission ratio of 1.04. Each subsequent gear pair exhibits a higher transmission ratio, with the final pair, 6–6′, reaching a value of 1.96. This systematic progression in gear ratios provided a clear framework for analyzing the effect of transmission ratio on dimensional accuracy and manufacturing deviations.

The parameters in

Table 1 include: module

m, mm; tooth number

z, pitch diameter

d, mm; outside diameter

da, mm; root diameter

df, mm; profile shift coefficient; and gear ratio u.

All gears were manufactured from low-alloy structural steel grade S355, known for its good machinability and strength. S355 steel was chosen due to the following characteristics:

Availability—S355 is a structural steel widely used in industry thanks to its easy availability and cost-effectiveness, making it a suitable choice both for prototyping and experimental applications, as well as for mass production.

Suitability for various processing methods—This material exhibits good machinability, which ensures stability during laser cutting and allows for the creation of precise contours with minimal deformation.

Strength—With a yield strength of 355 MPa, as specified by EN 10025-2:2019 [

20], S355 meets the strength requirements for gears intended for laboratory testing.

The cutting process was carried out using a BODOR (Shandong, China) C6 fiber laser cutter [

21], with parameters optimized for minimal deformation and high-quality cut surfaces. The CNC (Computer Numerical Control) BODOR C6 laser cutting machine operates at a total power of 12 kW.

The machine is equipped with a high-precision fiber laser source and an automatic focusing system, enabling stable and accurate cutting of miniature and complex contours. Due to these characteristics, the BODOR C6 is an excellent choice for manufacturing gears that require high precision, repeatability, and minimal deviations.

The process of gear production using laser cutting consists of several interconnected stages.

In

Figure 1 is given the schematic process of laser gear processing as follows: in the initial stage (a), a three-dimensional model of the gear is created in Autodesk Inventor software. After the model is created, in the second stage (b), a file in DXF (Drawing Exchange Format) is obtained, containing the gear tooth contour that serves as the basis for the laser cutting process, since it defines the exact coordinates of lines and curves along which the cutting beam will move. In the next stage (c), material preparation is performed, in this case a plate of structural steel grade S355, selected due to its favorable mechanical properties and suitability for laser processing.

The cutting phase (d) was carried out with a BODOR C6 laser, which provides high accuracy, good reproducibility, and high-quality edges after processing. The final product (e) is a gear manufactured by laser cutting. As shown in

Figure 1, the schematic of gear production using laser cutting is presented.

The parameters used during the laser cutting process were selected considering the following factors: material thickness, material type, material properties, contour complexity, piercing points, gas pressure, gas type, etc. The parameters applied for cutting 10 mm thick gears are presented in

Table 2.

After laser cutting, local material buildup was observed at the tooth tips of the fabricated gears due to melting and resolidification (so-called material deposition).

This phenomenon is typical of thermal cutting processes and may affect the accuracy of geometric measurements. To remove these irregularities and prepare the gears for further analysis, the deposits were eliminated by belt grinding (grain size P80, linear velocity 15 m/s) of the lateral sides of the gear rims using an abrasive belt.

Figure 2a shows two gears, one immediately after the cutting process, and the other after preparation for measurement by sanding the lateral surface of the gear rim.

Figure 2b presents a gear pair produced by laser cutting.

Preparation of the gears for measurement involved sanding the lateral sides of the gear rims for each manufactured gear. After that, each side of the gear was scanned using a high-resolution scanner (1200 DPI), resulting in a digital image of the tooth profile suitable for preliminary profile analysis.

This step is important as it serves as a visual inspection of the gears. Using this method, it was determined that the gears were ready for further measurement on a coordinate measuring machine and with detailed analysis.

Figure 3 shows a gear from the side view, with the tooth shapes clearly visible. The edges are straight and sharply defined, while the cut surface exhibits the characteristic appearance resulting from the laser cutting process.

Figure 4 shows two gears, one with a ground side and the other in its state immediately after laser cutting, without additional processing. The grinding was performed to remove the edge burr formed during the laser cutting process.

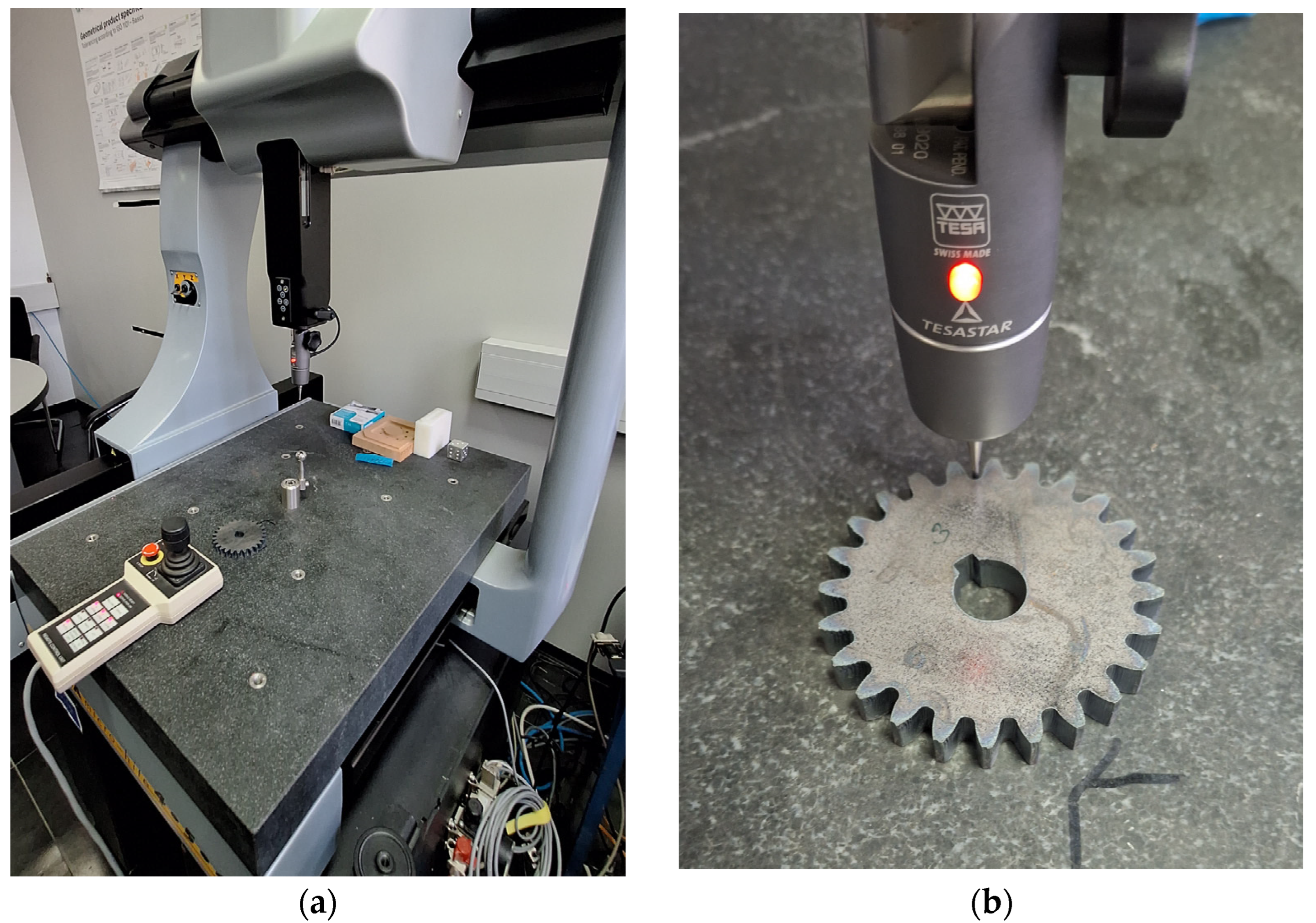

Comprehensive three-dimensional measurements were performed using a TESA (Renens, Switzerland) Micro-Hite coordinate measuring machine [

22], shown in

Figure 5a along with PC-DMIS GEAR 2.5 software [

23], which allows comparison with ideal theoretical profiles in accordance with ISO 1328-1 [

12]. The TESA Micro-Hite machine is equipped with a TESA-Star probe that uses a tactile stylus to locate points on the gear surface, enabling high accuracy in gear measurements. All measurements were conducted in laboratory conditions under controlled environmental influences: temperature maintained at 20 °C, a prepared and clean work surface, and the absence of noise and vibrations. These conditions ensured the precision of measurements for each individual gear.

Figure 5b illustrates the measurement procedure on one of the gears. The image shows the measurement stylus making precise contact with the tooth flank, while the software automatically records the measured value.

For the purposes of this study, the PS-DMIS GEAR 2.5 software package developed by Hexagon Manufacturing Intelligence was used. This software is specialized for the measurement of gear geometric parameters and features a high degree of automation, making it suitable for evaluating various gear characteristics such as pitch deviations, tooth profile deviations, gear tooth thickness, and more.

Once the machine and software are started, the gear measurement process consists of several steps:

Input of gear parameters—“The Define Gear” command is used to enter all necessary gear parameters, including the module, number of teeth, various gear diameters, and standard according to which the measurement will be conducted. This step is essential for the software to recognize the gear’s shape and dimensions and to enable automated and accurate gear measurement (

Figure 6).

Gear positioning—The “Align Gear” command enables precise positioning of the gear within the coordinate system of the measuring machine. The process begins with the measurement of a plane—typically the lateral face of the gear—at three distinct points. This establishes the first reference plane for orienting the machine in space. Next, the circular surface is measured, followed by the identification of the zero tooth.

In

Figure 7 is shown the dialog box which is opened after starting the command Align Gear.

Gear measurement is initiated using the “Measure Gear” command. This command opens a dialog box in which the gear parameters must be confirmed. Once confirmed, the software automatically activates the measuring machine and begins the measurement process.

Gear measurements were performed in accordance with the ISO 1328-1 standard [

12]. The pitch deviation parameters measured include the following:

fpt (µm)—Individual pitch deviation;

fu (µm)—Adjacent pitch deviation;

Fp (µm)—Cumulative pitch deviation;

Fpk (µm)—Cumulative k teeth pitch deviation;

Fr (µm)—Radial runout.

In addition, tooth profile deviations were measured, including the following parameters:

fHα—Profile form deviation;

Fα—Profile angle deviation;

Ffα—Total profile deviation.

3. Results

The measurement results are presented both in tabular and graphical form for all gear pairs, comparing key metric values with the reference values.

Starting from the zero tooth, each gear was measured individually on both the left and right flanks of every tooth. During gear measurement, it is essential that the tooth profile does not exceed the maximum deviations specified by the standard, as such deviations may lead to improper gear operation or, in the worst case, result in classification as defective components that will be rejected from further processing.

Pitch deviations provide insight into the manufacturing accuracy of the teeth and significantly affect whether the gear will ensure stable power and motion transmission without interruptions or vibrations.

Table 3 presents the measured pitch deviation values for each gear. Maximum and minimum deviations on both the left and right flanks of each tooth are provided.

Profile form and angle deviations were also measured for each individual gear. These profile deviations were measured on four randomly selected teeth. This sampling method helps to reduce or eliminate the influence of potential local defects. Additionally, limiting the number of measurements avoids overloading the measurement process while still ensuring reliability.

After the measurements are completed, the software records the measured values and automatically assigns them to the corresponding tolerance class. If a measured value exceeds the allowable deviation, it is specifically marked (/). The measurements were again performed on both the left and right flanks of each tooth, and the results are presented in

Table 4,

Table 5 and

Table 6.

Table 4 presents the maximum values of profile form deviation (

ffα), along with the following notations:

Profile form deviation does not account for profile shift but only for the deviation of the actual tooth profile from the ideal involute profile. In addition to profile form deviation, total deviation values were also measured, representing the difference between the largest and smallest deviations of the actual profile relative to the theoretical one.

Table 4 shows that most of the gears fall within the allowable tolerance range. However, the table also indicates slight asymmetry in the profile processing, as evidenced by the fact that a greater number of profile form deviations were within tolerance limits on the left flanks of the teeth compared to those of the right flanks.

Table 5 was created using the same procedure. This table contains the maximum values of profile angle deviation for four randomly selected gear teeth. Measurements were taken on both the left and right flanks of each tooth, and the corresponding quality levels were determined. Profile angle deviation is an important criterion in gear analysis, as it indicates the difference between the actual profile inclination angle and the ideal angle.

Table 5 indicates the presence of unacceptable profile angle deviations in a number of gears that otherwise exhibit acceptable profile form. This result suggests that there was displacement of the S355 material sheet during the cutting process, likely due to insufficient clamping.

Table 6 presents the maximum values of total profile deviation (

Fα) measured on the left and right flanks of four randomly selected teeth for each individual gear. The results in

Table 6 also point to asymmetry, as a greater number of deviations beyond the allowed tolerance limits were recorded on the right flanks compared to the left flanks of the teeth.

The following section of the paper presents diagrams that provide a clearer insight into the obtained results. In addition to tabular data, graphical representations of the deviations measured on the gears were also generated.

Figure 8 displays a diagram illustrating the maximum pitch deviations for each manufactured gear. The x-axis shows the labels of the gears from all produced gear pairs, while the y-axis indicates deviation values expressed in micrometers.

Blue bars represent the measured deviations on the left flank of each tooth, while orange bars represent the deviations on the right flank. The red horizontal line at y (

fpt) = 80 µm marks the maximum allowable deviation for a gear to meet the Q12 quality level according to the applied standard [

12].

The diagram in

Figure 8 shows that the gears labeled 1, 1′, 3, 4′, and 5 exhibit maximum pitch deviations ranging from 40 to 80 μm, which is one of the criteria for further consideration of their classification into appropriate quality grades according to the relevant standard.

The total cumulative pitch deviation (Fp) represents the difference between the maximum and minimum values of individual pitch deviations (fpt) along the entire pitch circle of the gear.

To comply with ISO 1328-1 and classify the gears within a specific quality grade, the maximum cumulative pitch deviation must not exceed 214 µm.

Figure 9 presents a diagram of the total cumulative pitch deviation, with the red horizontal line indicating the maximum allowable deviation.

Figure 10,

Figure 11 and

Figure 12 present diagrams of gear profile deviations, specifically profile form deviation, profile angle deviation, and total profile deviation, respectively. The values shown were measured for the left flanks of the teeth (a) and the right flanks of the teeth (b) for each manufactured gear.

4. Results Discussion

The results of geometric measurements of gears produced by laser cutting indicate the potential to achieve acceptable accuracy levels in accordance with ISO 1328-1 [

12], particularly within quality grade Q12. However, variations in the results among individual gears and between the left and right flanks of the teeth reveal certain challenges in both the manufacturing and measurement processes.

Individual pitch deviations (fpt) are a key indicator of the manufacturing precision of individual teeth. According to the results, approximately 50% of the measured values fall within the tolerance limits for quality grade Q12, while the remainder exhibit localized exceedances. Possible causes include the following:

Micro-variations in the laser feed rate along the contour;

Inadequate material fixation during cutting;

Accumulated molten material at the tooth tip, which disrupts the defined contour (typically from the underside during cutting).

A slight tendency was observed for deviations to be more pronounced on the right tooth flanks, possibly indicating a systematic error in laser head positioning or asymmetric cutting forces during the process.

Cumulative pitch deviation (Fp), as a summative metric that reflects error over the entire gear circumference, remained within allowable limits in 17 out of 24 measurements. Values exceeding the 214 µm threshold may be attributed to the following:

Errors in the initial DXF contour positioning;

Inadequate control of laser pulse parameters (e.g., power, focus, cutting speed);

Vibrations in the worktable supporting the material.

Overall, the high repeatability observed across most samples suggests that the method may be suitable for low-complexity systems or educational applications where Q12 accuracy is sufficient for project requirements.

The analysis of tooth profile form and angle deviations provides insight into the geometric quality of the achieved involute profile. Profile form deviations (ffα) were within tolerance for most gears; however, certain samples (e.g., 5′ and 6′) showed significant exceedances, particularly on the right tooth flank. This may be due to the following:

Uneven heat distribution;

Local variations in material thickness;

Possible internal flaws in the material (the plate was not ultrasonically inspected before cutting).

Regarding profile angle deviations (fHα), numerous out-of-tolerance values were recorded, with negative deviations particularly prominent. This asymmetry may be the result of an undefined or poorly controlled reference point during laser head positioning.

Total profile deviation (Fα) indicates complex deformations that include displacement of the involute line. The results show that most gears do not meet Q12 criteria for this parameter, suggesting that additional finishing operations (e.g., flank grinding) would be required for use in industrial drive applications. As can be observed from the diagrams, the deviations that exceed the Q12 limit appear mainly as isolated points and do not represent severe errors. Under operating conditions, such irregularities are expected to diminish during the running-in period.

Although dimensional and geometrical accuracy were the focus of this study, no detailed surface characterization (roughness, hardness, microstructure) was performed. This represents a clear limitation of the current work and will be addressed in subsequent investigations. It should be emphasized that the analyzed gears are prototypes, produced to demonstrate the feasibility of laser cutting as a manufacturing approach. Consequently, the results should be regarded as a preliminary assessment rather than definitive statistical proof.

It was observed that profile deviations tend to be higher in gears with larger transmission ratios, which is consistent with the increased number of teeth, reduced tooth width, and more complex contour shapes.

An analysis of deviations relative to the transmission ratio shows that gears with intermediate values (e.g., u = 1.23 and u = 1.42) demonstrated slightly better geometric quality compared to pairs with minimum or maximum ratios. This may be due to a more balanced ratio between the driving and driven gear, which enables more stable laser movement and reduces error accumulation along the contour.

Nevertheless, the precise relationship between the transmission ratio and gear quality requires further statistical investigation, including repeated measurements and testing a larger sample set.

The findings suggest that laser-cut gears made from S355 structural steel can meet the basic geometric criteria for Q12 quality according to ISO 1328-1 [

12], making them suitable for prototyping, educational purposes, and low-complexity mechanical assemblies. However, significant variations in profile deviations and the need for post-processing (e.g., sanding after cutting) indicate that, without additional finishing, these gears are not yet ready for precision industrial applications such as automotive transmissions or high-precision gear reducers. The application of laser-produced gears is limited up to 20 mm of thickness because of laser cut technology imperfections. Even above thicknesses of 10 mm, coning during cutting can occur. One of the goals of further author investigation is to determine laser-produced gears’ geometric boundaries.

Compared to commercially machined steel spur gears (e.g., hobbed or milled), which typically cost EUR 31–75 per piece from suppliers such as KHK or HUCO [

24,

25], laser-cut gears produced from S355 steel can be fabricated for approximately EUR 2.5–3.5 per unit in prototype or small-batch scenarios. This represents a price reduction of roughly 92–95%, making laser cutting highly economical for one-off or low-volume production. Furthermore, whereas conventionally machined gears often require several hours per gear due to tool setup and finishing operations, a laser-cut gear of 78 mm diameter and 10 mm thickness can be manufactured in just a few minutes (for the used example in the 1st row from

Table 1, the cutting time is 1.5 min), enabling much faster turnaround during early design iterations and experimental testing.

The method of laser cutting spur gears is particularly suitable for single pieces or small batches (1–50 units), where the universality and speed of laser cutting offer a major advantage over conventional methods. For medium-sized batches (100–1000 units), laser cutting can still be efficient, whereas for large series (>1000 units), conventional methods (such as forming) become more cost-effective per unit. Laser cutting does not require special tooling, additional equipment, or complex machine setup, which makes it ideal for urgent or experimental cases, as well as for prototypes and small series.

5. Conclusions

The conducted research demonstrates that laser cutting is a fast, flexible, and potentially cost-effective method for manufacturing spur cylindrical gears, particularly in the context of prototype development, small-batch production, and educational applications. By using a fiber laser with carefully selected cutting parameters, acceptable dimensional and geometric accuracy was achieved without the need for extensive post-processing—except for the minimal preparation of contact surfaces.

The measurement results show that most of the analyzed gears fall within quality grade Q12 according to ISO 1328-1 [

12], confirming their potential for industrial use in less demanding assemblies (involving lower torques and speeds). However, local deviations in profile form and profile angle—especially on the right flank—suggest the need for further process optimization, including improved material clamping during cutting and enhanced control of the laser head trajectory. This preliminary research demonstrates that laser cutting in gear production has significant potential, as confirmed by numerous studies in this field.

In addition to the presented results, the study confirms significant advantages of this method in terms of production time, waste reduction, and processing costs. For these reasons, laser-cut gears show strong potential as an attractive solution for rapid gear production during the early stages of a product’s life cycle.

A limitation of this study is the small number of tested samples and the absence of detailed surface quality analysis. These constraints were primarily due to resource limitations, but they clearly define the scope of this work as a proof-of-concept investigation. Future studies with larger sample sizes and comprehensive surface characterization (of roughness, hardness, and microstructural properties) are planned in order to provide stronger statistical validity and to assess the industrial applicability of laser cutting for gear production in greater detail.

Future research will focus on evaluating the functional characteristics of the fabricated gears, including efficiency, noise, and vibration during operation, and durability under both constant and variable loads. Additional investigations are also planned to assess the effects of post-processing treatments (e.g., heat treatment, sandblasting, fine grinding) on improving tooth quality. These efforts aim to develop a comprehensive model for evaluating the suitability of laser cutting as a manufacturing process for spur cylindrical gears.