Predicting the Mechanical Strength of Caliche Using Nanoindentation to Preserve an Archaeological Site

Abstract

1. Introduction

2. Materials and Methods

2.1. Caliche Samples

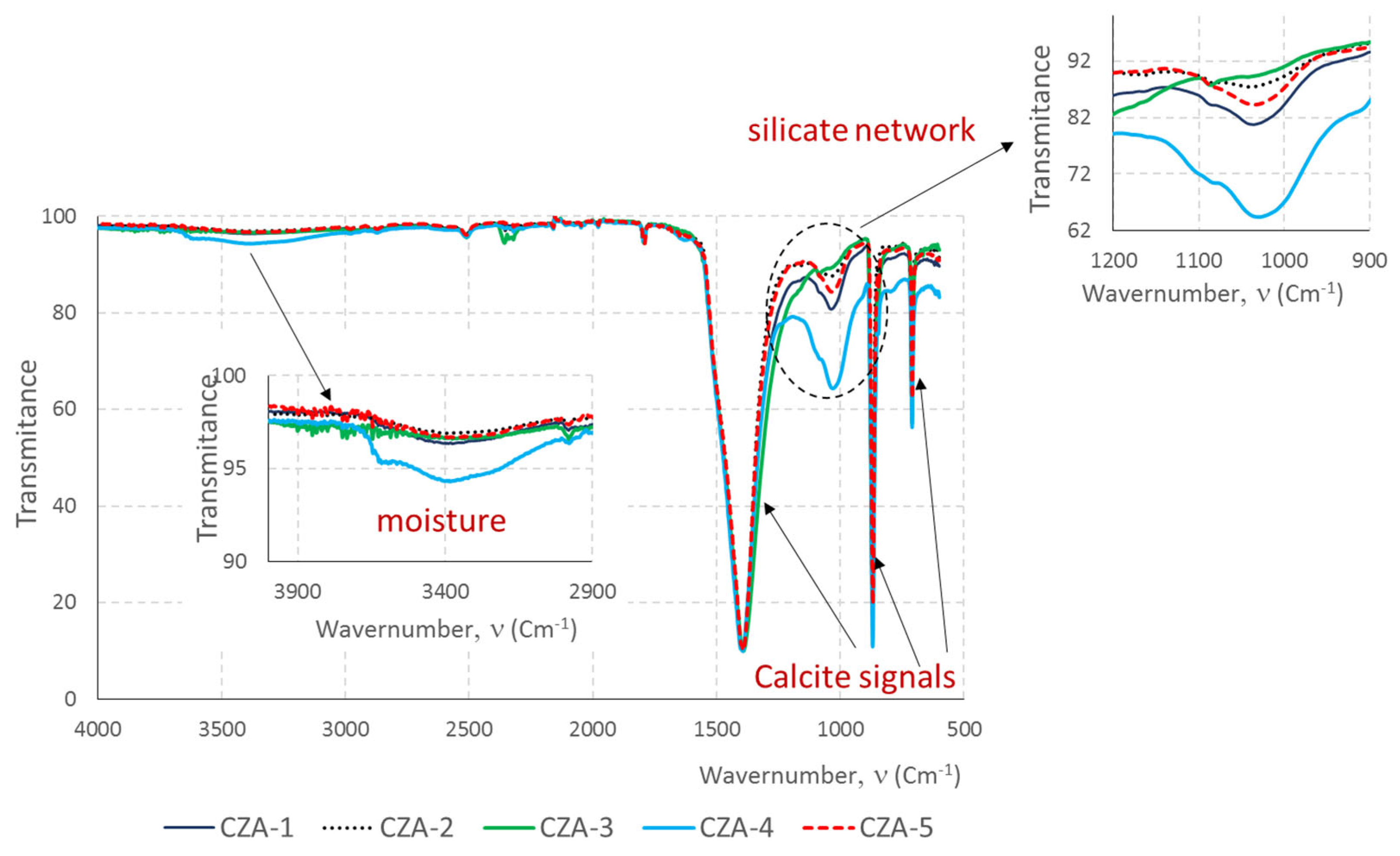

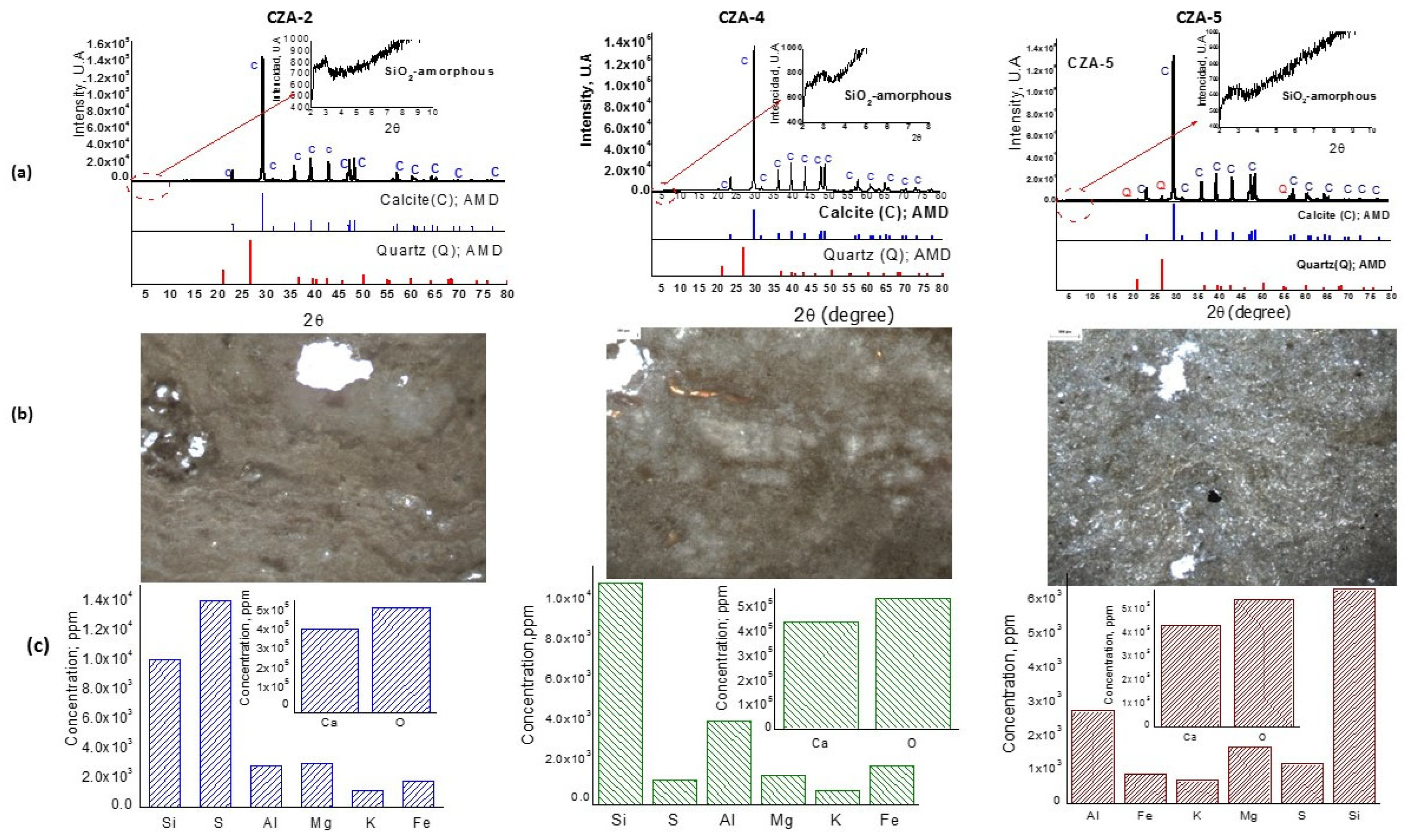

2.2. Chemical Characterization of Caliche

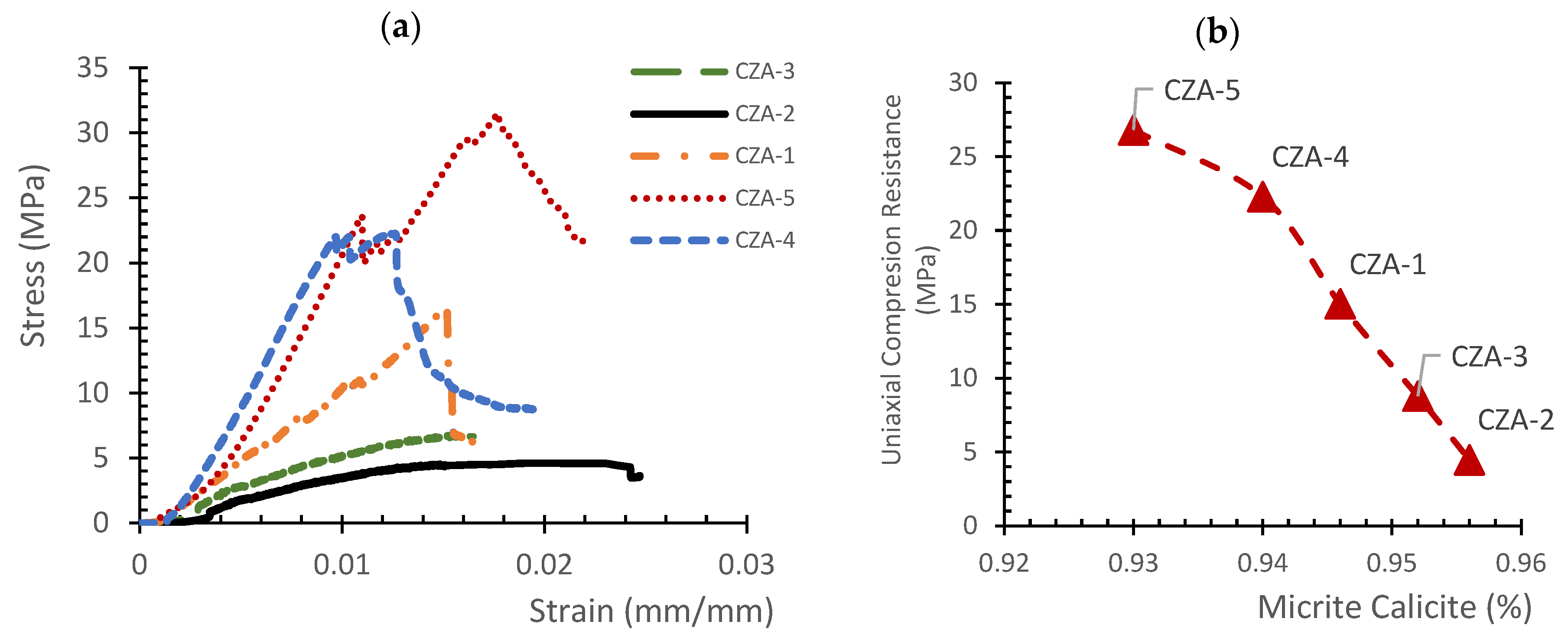

2.3. Mechanical Characterization of Caliche

3. Results

3.1. Caliche from Archaeological Zone: Chemical and Geochemical Characterization

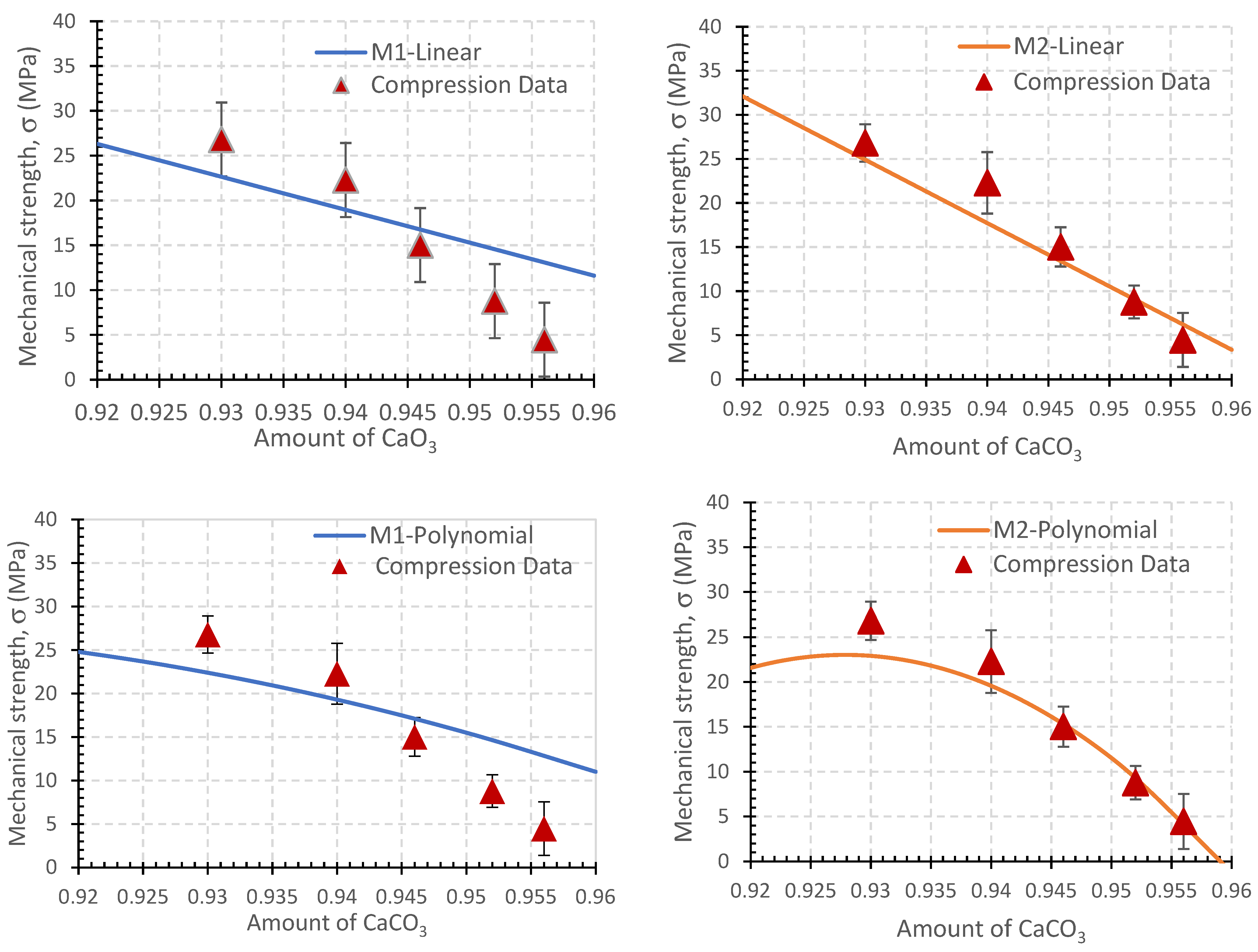

3.2. Caliche NIIT Mechanical Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

Abbreviations

| NIIT | Nanoindentation |

| P-h | Load–displacement graph |

| hc | Maximum displacement |

| H | Hardness |

| S | Stiffness material |

| ε | Indenter constant |

| Eeff | Effective elasticity modulus |

| Ei | Young’s modulus |

| ν | Poisson’s modulus |

| CZA | Caliche samples found in Cerro de los Remedios Guanaguato México Archeological zone |

| XRD | X-ray diffraction |

| XRF | X-ray fluorescence spectroscopy |

| σi | Mechanical strength of mineralogical phase |

| σq | Mechanical strength of SiO2–quartz |

| M1 | Model to predict mechanical resistance considering the contribution of all components |

| M2 | Model of linear function to predict mechanical resistance |

References

- Snethlage, R. Stone Conservation. In Stone in Architecture, 5th ed.; Siegesmund, S., Snethlage, R., Eds.; Springer: Berlin, Germany, 2014; pp. 415–550. [Google Scholar] [CrossRef]

- Acun, S.; Arioglu, N. A Method for the Preservation and Restoration of the Stones Used in Historical Buildings. Archit. Sci. Rev. 2006, 49, 143–148. [Google Scholar] [CrossRef]

- Borgia, G.C.; Camaiti, M.; Cerri, F.; Fantazzini, P.; Piacenti, F. Hydrophobic Treatments for Stone Conservation: Influence of the Application Method on Penetration, Distribution and Efficiency. Stud. Conserv. 2003, 48, 217–226. [Google Scholar] [CrossRef]

- Cruces Cervantes, O. Cerro de los Remedios, emplazamiento en el Laja Bajío. In Relaciones Interregionales en el Centro Norte de Mesoamérica; Castañeda, C., Ed.; Ediciones La Rana, Conaculta/INAH/Instituto Estatal de la Cultura: Guanajuato, Mexico, 2015; pp. 37–49. [Google Scholar]

- Ahedo-Díaz, A.; Luna-Muñoz, M.A.; Miranda-Avilés, R.; Salazar-Hernández, M.; Cervantes, J.; Cruces-Cervantes, O.; Salazar-Hernández, C.; Puy-Alquiza, J.M. Caliche from Archaeological Zone of Guanajuato Mexico and Nearby Deposits: Geochemical and Mechanical Characterizations. J. Am. Inst. Conserv. 2024, 63, 74–88. [Google Scholar] [CrossRef]

- Shuman, D.; Costa, A.L.; Andrade, M.S. Calculating the elastic modulus from nanoindentation and microindentation reload curves. Mater. Charact. 2007, 58, 380–389. [Google Scholar] [CrossRef]

- Pharr, G.M.; Oliver, W.C. Measurement of Thin Film Mechanical Properties Using Nanoindentation. MRS Bull. 1992, 17, 28–33. [Google Scholar] [CrossRef]

- Oyen, M.L.; Cook, R.F. A practical guide for analysis of nanoindentation data. J. Mech. Behav. Biomed. Mater. 2009, 2, 396–407. [Google Scholar] [CrossRef]

- Kurma Sharma, H.; Kurma Sharma, R.; Saxena, R.S.; Prasad, R. A review of nanoindentation and related cathodoluminescence studies on semiconductor materials. J. Mater. Sci. Mater. Electron. 2022, 33, 21223–21245. [Google Scholar] [CrossRef]

- Guillonneau, G.; Kermouche, G.; Bec, S.; Loubet, J.L. Determination of mechanical properties by nanoindentation independently of indentation depth measurement. J. Mater. Res. 2012, 27, 2551–2560. [Google Scholar] [CrossRef]

- Pharr, G.M.; Bolshakov, A. Understanding nanoindentation unloading curves. J. Mater. Res. 2002, 17, 2660–2671. [Google Scholar] [CrossRef]

- Pshyk, O.; Nakonechna, O.; Coy, E. Current view of nanoindentation: Recent developments and application in material characterization. ACS Appl. Mater. Interfaces 2025, 17, 36275–36300. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Gamage, R.P.; Zhang, C. Application of nanoindentation technology in rocks: A review. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 60. [Google Scholar] [CrossRef]

- Deng, T.; Zhao, J.; Yin, H.; Xie, Q.; Gou, L. Mechanical characterization of main minerals in carbonate rock at the micro scale based on nanoindentation. Processes 2024, 12, 2727. [Google Scholar] [CrossRef]

- Chattaraj, S.; Pant, P.; Nanavati, H. Inter-relationships between mechanical properties of glassy polymers from nanoidentation and uniaxial compression. Polymer 2018, 144, 128–141. [Google Scholar] [CrossRef]

- Grunenwald, A.; Keyser, C.; Sautereau, A.M.; Crubézy, E.; Ludes, B.; Drouet, C. Revisiting carbonate quantification in apatite (bio)minerals: A validated FTIR methodology. J. Archaeol. Sci. 2014, 49, 134–141. [Google Scholar] [CrossRef]

- Monnier, G.; Frahm, E.; Luo, B.; Missal, K. Developing FTIR microspectroscopy for analysis of plant residues on stone tools. J. Archaeol. Sci. 2017, 78, 158–178. [Google Scholar] [CrossRef]

- Kilic, A.; Teymen, A. Determination of mechanical properties of rock using simple methods. Bull. Eng. Geol. Environ. 2008, 67, 237–244. [Google Scholar] [CrossRef]

- Zorlu, K.; Kasapoglu, K.E. Determination of geomechanical properties and collapse potential of a caliche by in situ and laboratory tests. Environ. Geol. 2009, 56, 1449–1459. [Google Scholar] [CrossRef]

- Park, K.; Jun, S.; Kim, D. Effect of Strength Enhancement of Soil Treated with Environment-Friendly Calcium Carbonate Powder. Sci. World J. 2014, 1, 526491. [Google Scholar] [CrossRef]

- Merkel, C.; Deuschle, J.; Griesshaber, E.; Enders, S.; Steinhauser, E.; Hochleitner, R.; Brand, U.; Schmahl, W.W. Mechanical properties of modern calcite- (Mergerlia truncata) and phosphate-shelled brachiopods (Discradisca stella and Lingula anatina) determined by nanoindentation. J. Struct. Biol. 2009, 168, 396–408. [Google Scholar] [CrossRef] [PubMed]

| Minerals | Weight % | ||

|---|---|---|---|

| CZA-2 | CZA-4 | CZA-5 | |

| Micritic calcite (CaCO3) | 95.6 | 94 | 93.0 |

| Alkqali feldspar; Plagioclase ((NaCa)SiAl3O8 and biotite (K(Mg,Fe)3AlSi3O10(OHF)2) | 2.51 | 0.42 | 0.42 |

| High-calcium aluminosilicates | 1.89 | 3.19 | 3.14 |

| Quartz/SiO2—amorphous | –– | 2.39 | 3.43 |

| Maximum Displacement, hmax (nm) | Displacement After Unloading, hf (nm) | % Elastic Recovery | ||

|---|---|---|---|---|

| CZA-2 | Group 1 | 1813.59 ± 356.58 | 1588.58 ± 331.71 | 12.44 ± 3.72 |

| Group 2 | 3145.23 ± 461.46 | 2826.07 ± 413.15 | 10.09 ± 2.59 | |

| Group 3 | 6272.32 ± 250 | 6049.11 ± 174.11 | 3.52 ± 1.07 | |

| CZA-4 | Group 1 | 943.39 ± 206.57 | 761.71 ± 212.55 | 20.16 ± 4.6 |

| Group 2 | 1841.44 ± 145.55 | 1605.59 ± 154.39 | 12.88 ± 2.98 | |

| Group 3 | 2732.36 ± 409.21 | 2331.06 ± 368.36 | 14.74 ± 2.84 | |

| CZA-5 | Group 1 | 1155.77 ± 415.96 | 989.58 ± 410.025 | 16.01 ± 6.45 |

| Group 2 | 1533.32 ± 210.53 | 1145.23 ± 153.29 | 24.906 ± 8.42 | |

| Group 3 | 3232.24 ± 4.25 | 2784.48 ± 9.34 | 13.96 ± 0.401 | |

| Maximum Resistance O&P *, σ (MPa) | Young’s Modulus, E (GPa) | Vickers Hardness (HV) | Associated Material | ||

|---|---|---|---|---|---|

| CZA-2 | Group 1 | 148.47 ± 57.52 | 8.28 ± 1.52 | 13.75 ± 5.33 | Aluminosilicates |

| Group 2 | 48.93 ± 6.88 | 3.76 ± 0.94 | 4.53 ± 1.04 | Feldspars | |

| Group 3 | 9.80 ± 0.30 | 1.40 ± 0.06 | 0.908 ± 0.03 | Calcite; Micrite | |

| CZA-4 | Group 1 | 312.30 ± 117 | 20.30 ± 3.6 | 28.9 ± 10.8 | Quartz/Silica |

| Group 2 | 125.56 ± 21.18 | 10.41 ± 1.93 | 11.63 ± 1.96 | Aluminosilicates | |

| Group 3 | 325.07± | 1.07 ± 7.41 | 34.08 ± 1.26 | Quartz/Silica | |

| CZA-5 | Group 1 | 368 ± 13.61 | 17.38 ± 5.6 | 30.10 ± 6.97 | Quartz/Silica |

| Group 2 | 209.97 ± 6.24 | 12.14 ± 0.39 | 19.45 ± 0.58 | Quartz/Silica | |

| Group 3 | 122.57 ± 15.47 | 36.22 ± 2.92 | 113.51 ± 14.24 | Aluminosilicates | |

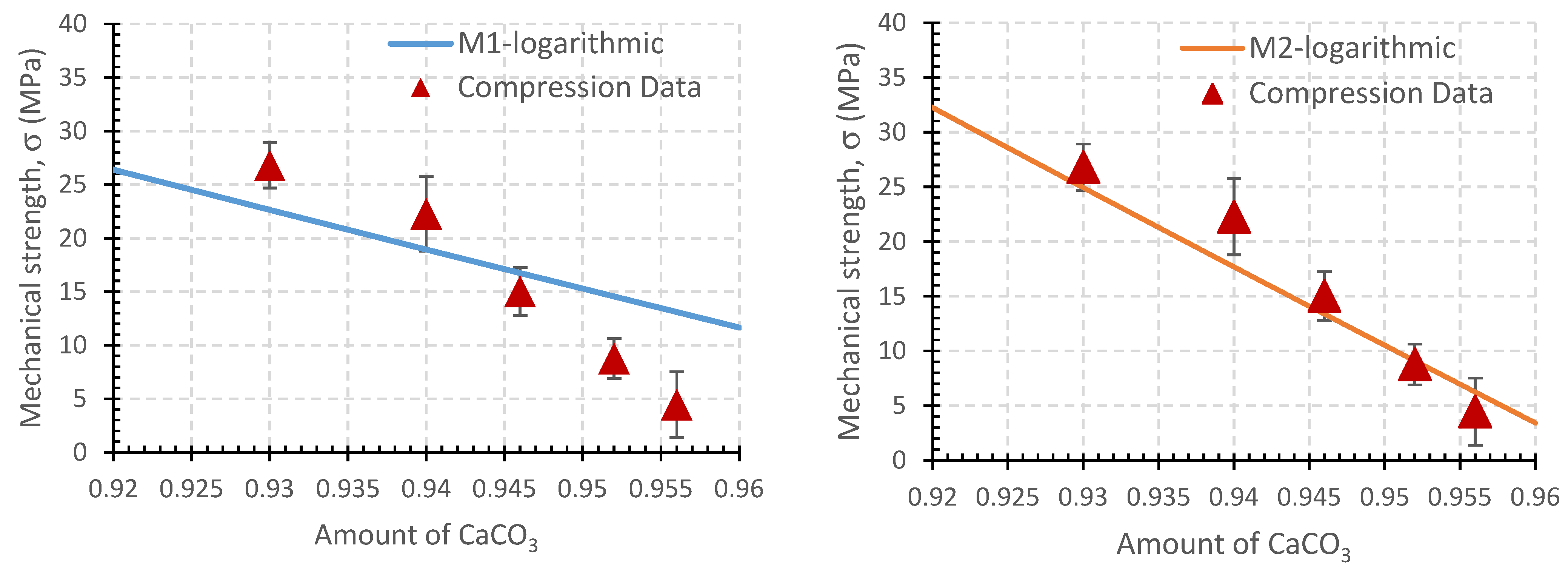

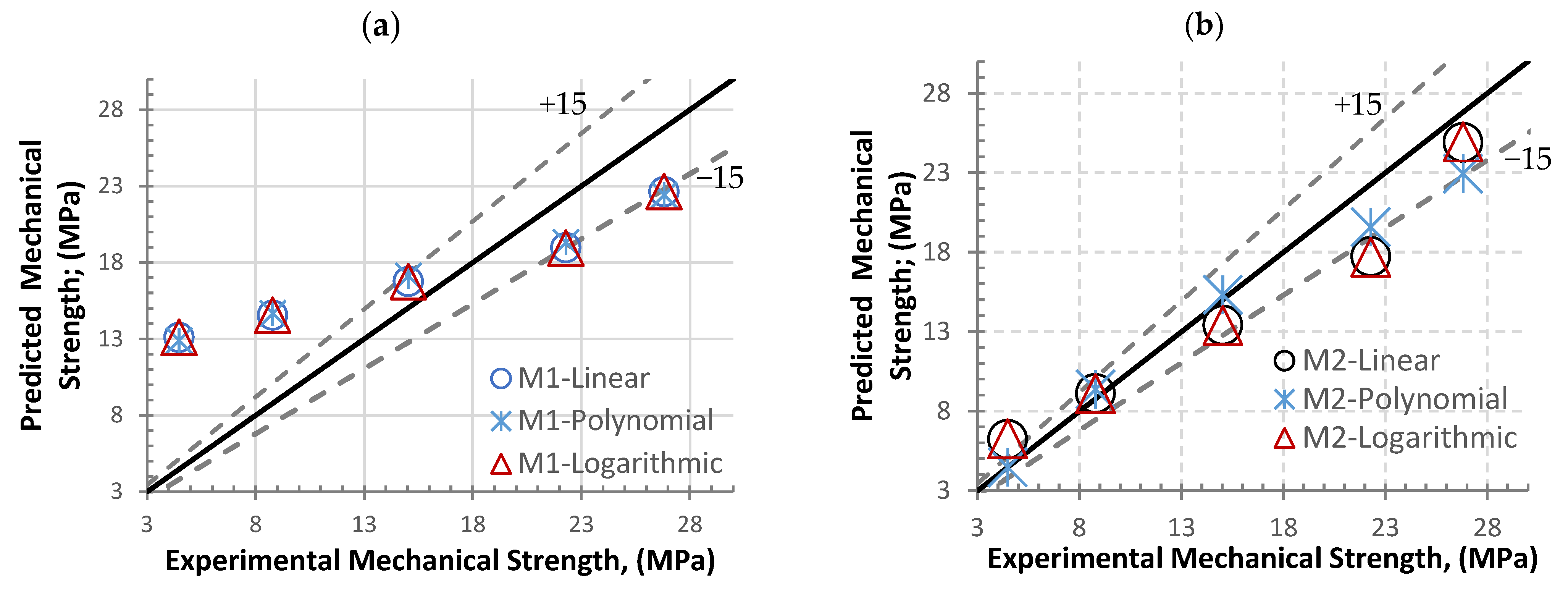

| Equation | R2 | |

|---|---|---|

| M1–linear | y = −367.33x + 364.26 | 0.996 |

| M1–polynomial | y = −3504.1x2 + 6242.7x − 2752.6 | 1 |

| M1–logarithmic | y = −346.3 ln(x) − 2.477 | 0.995 |

| M2–linear | y = −718.61x + 693.22 | 0.952 |

| M2–polynomial | y = −23,447x2 + 43,511x − 20,163 | 1 |

| M2–logarithmic | y = −677.2lnx − 24.216 | 0.951 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salazar-Hernández, C.; Cervantes, J.; Salazar-Hernández, M.; Mendoza-Miranda, J.M.; Guerra-Contreras, A.; Cruces-Cervantes, O.; Puy-Alquiza, M.J. Predicting the Mechanical Strength of Caliche Using Nanoindentation to Preserve an Archaeological Site. Appl. Sci. 2025, 15, 9355. https://doi.org/10.3390/app15179355

Salazar-Hernández C, Cervantes J, Salazar-Hernández M, Mendoza-Miranda JM, Guerra-Contreras A, Cruces-Cervantes O, Puy-Alquiza MJ. Predicting the Mechanical Strength of Caliche Using Nanoindentation to Preserve an Archaeological Site. Applied Sciences. 2025; 15(17):9355. https://doi.org/10.3390/app15179355

Chicago/Turabian StyleSalazar-Hernández, Carmen, Jorge Cervantes, Mercedes Salazar-Hernández, Juan Manuel Mendoza-Miranda, Antonio Guerra-Contreras, Omar Cruces-Cervantes, and María Jesús Puy-Alquiza. 2025. "Predicting the Mechanical Strength of Caliche Using Nanoindentation to Preserve an Archaeological Site" Applied Sciences 15, no. 17: 9355. https://doi.org/10.3390/app15179355

APA StyleSalazar-Hernández, C., Cervantes, J., Salazar-Hernández, M., Mendoza-Miranda, J. M., Guerra-Contreras, A., Cruces-Cervantes, O., & Puy-Alquiza, M. J. (2025). Predicting the Mechanical Strength of Caliche Using Nanoindentation to Preserve an Archaeological Site. Applied Sciences, 15(17), 9355. https://doi.org/10.3390/app15179355