Development of a Multi-Robot System for Autonomous Inspection of Nuclear Waste Tank Pits

Abstract

Featured Application

Abstract

1. Introduction

- Integration of six primary groups of components into a multi-robot system: This lays the foundation of the Autonomous Pit Exploration System to operate two types of robots to perform autonomous inspection for nuclear waste-storage tank pits.

- Propose the “System on a Truck” concept: Utilize an EV pickup truck to support the system for a full 10 h shift, eliminating risks associated with combustible fuels and enhancing the safety and efficiency of transportation and deployment.

- Digital twinning for autonomous operations: Create a digital twin framework using intermittent signatures captured by robotics system. The development of autonomy for the robotic systems will increase the likelihood of system adoption by the site and will ensure adequate data collection needed for digital twin generation and artificial intelligence (AI) models training.

- Novel actuator designs: The combination of the pipe clamper and the telescopic arm designs is selected for the superior reach, load distribution, stability, making it an ideal solution for accessing and inspecting the tank pits.

2. Related Works

3. Conceptual Design

3.1. Design Overview

3.1.1. Phase 1: Data Collection and Interface Definition

3.1.2. Phase 2: Component Selection and Hardware Design

3.1.3. Phase 3: Integration, Testing, and Demonstration

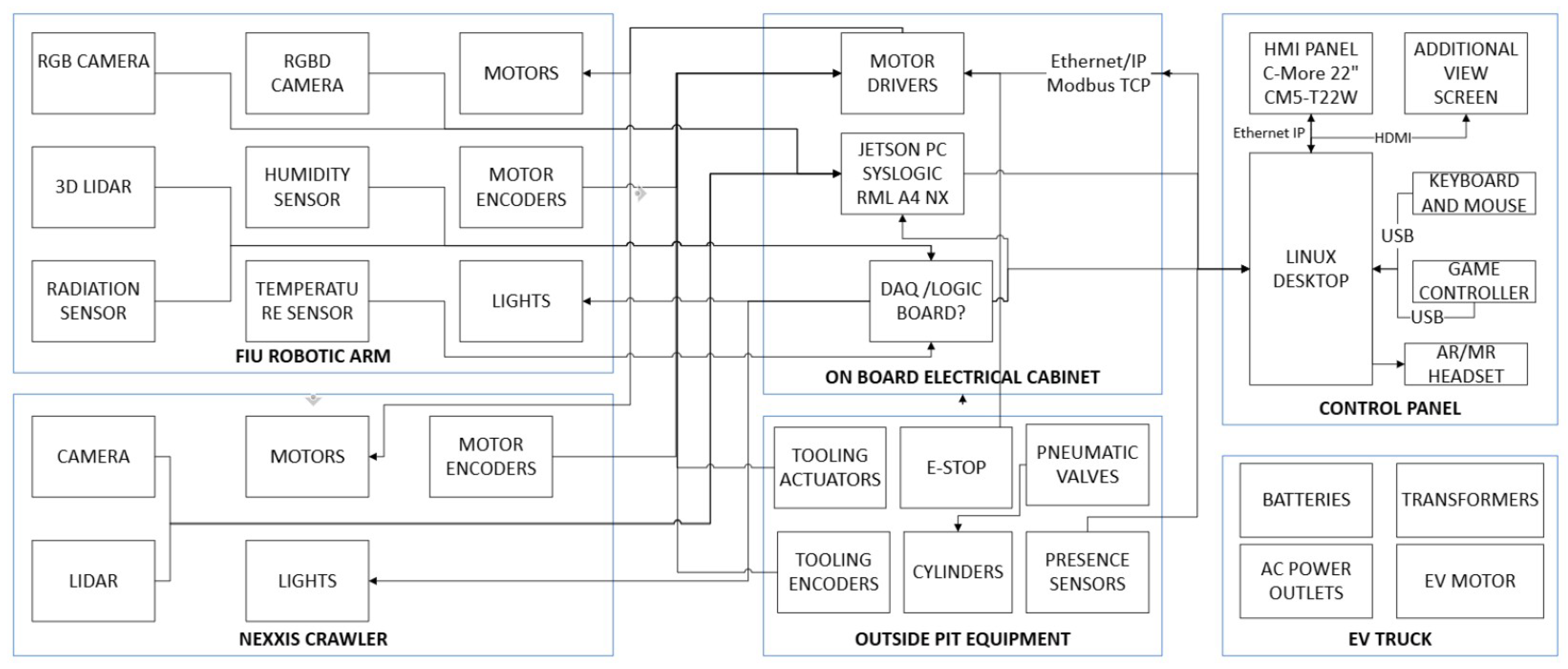

3.2. System Communication Design

- Gateway Devices: Use gateway devices that can bridge different communication protocols (e.g., USB-to-Ethernet, CAN-to-Ethernet) while supporting TSN features. These gateways will ensure that all data, regardless of its original protocol, can be managed under the TSN framework.

- Synchronization of Heterogeneous Networks: Implement synchronization mechanisms to align the timing of USB, Ethernet, and CAN networks. This involves using precise time synchronization protocols (IEEE 802.1AS [22]) to ensure that all devices, regardless of the communication protocol, operate on the same time base.

- Priority Queuing and Scheduling: Assign priority levels to different types of traffic based on their criticality. For example, control signals for the robotic arm and crawler robot should be assigned the highest priority, while less critical data like monitoring and logging information can be assigned lower priorities. Time-Aware Shaper (IEEE 802.1Qbv [23]) can be used to schedule-transmission windows for high-priority traffic, reducing latency and jitter.

- Centralized Network Management: Use a centralized network-management system to configure and monitor TSN parameters across all devices. This system will handle tasks such as setting up time slots, managing synchronization, and monitoring network performance.

- Traffic Shaping: Implement traffic shaping techniques to control the flow of data and prevent network congestion. This involves configuring the Time-Aware Shaper to allocate specific time slots for high-priority traffic, ensuring that it is transmitted without delay.

- Redundancy and Failover Mechanisms: Incorporate redundancy and failover mechanisms to enhance network reliability. This includes implementing redundant paths and devices that can take over in case of a failure, ensuring continuous operation without interruptions.

3.3. Transportation and Tooling Design

3.3.1. Transportation Approach

3.3.2. Power Management Design

3.3.3. Pipe Tooling Design

3.3.4. Robotic Arm Design

3.4. Radiation Hardness Assurance Design

3.4.1. Radiation Hardness Shielding

- Material Selection: Use high-density materials like lead, tungsten, and specialized radiation-hardened alloys to construct the cabinet and enclosures.

- Layered Shielding: Implement a layered shielding approach, combining different materials to attenuate both neutron and gamma radiation effectively.

- Component Encapsulation: Encapsulate sensitive electronic components within the cabinet using radiation-hardened materials to provide an additional layer of protection.

- Sensor Housing: Design sensor housings using radiation-hardened materials to shield the sensors from direct exposure to radiation.

- Cable Shielding: Use radiation-resistant cables and conduit to protect the communication lines between the sensors, motors, and the onboard electrical cabinet.

- Modular Shielding: Implement modular shielding solutions that can be easily replaced or upgraded as needed to maintain protection levels over time.

3.4.2. Electromagnetic Compatibility Compliance

3.5. Control Logic and Safety Assurance Dseign

3.5.1. Collision-Free Control Logic

3.5.2. Safety Envelope

3.5.3. Augmented Reality/Virtual Reality Interface Enhancements

3.6. Compensations for Poor-Quality Signals

- Local Autonomy: Equip the robotic system with local autonomy capabilities, allowing it to make real-time collision-avoidance decisions independently when communication with the operator is delayed or interrupted.

- Buffering and Smoothing: Implement buffering and data-smoothing techniques to reduce the impact of latency and jitter on the operator’s view. This can involve predictive modeling to fill in gaps in the data stream.

- Redundant Communication Channels: Use redundant communication channels to ensure continuous data flow. If one channel experiences degradation, the system can switch to an alternative channel to maintain connectivity.

- Pre-Defined Safe States: Define pre-programmed safe states or behaviors for the robotic system to assume if signal quality drops below a certain threshold. This ensures the system defaults to a safe and predictable state during communication disruptions.

4. Experimental Results

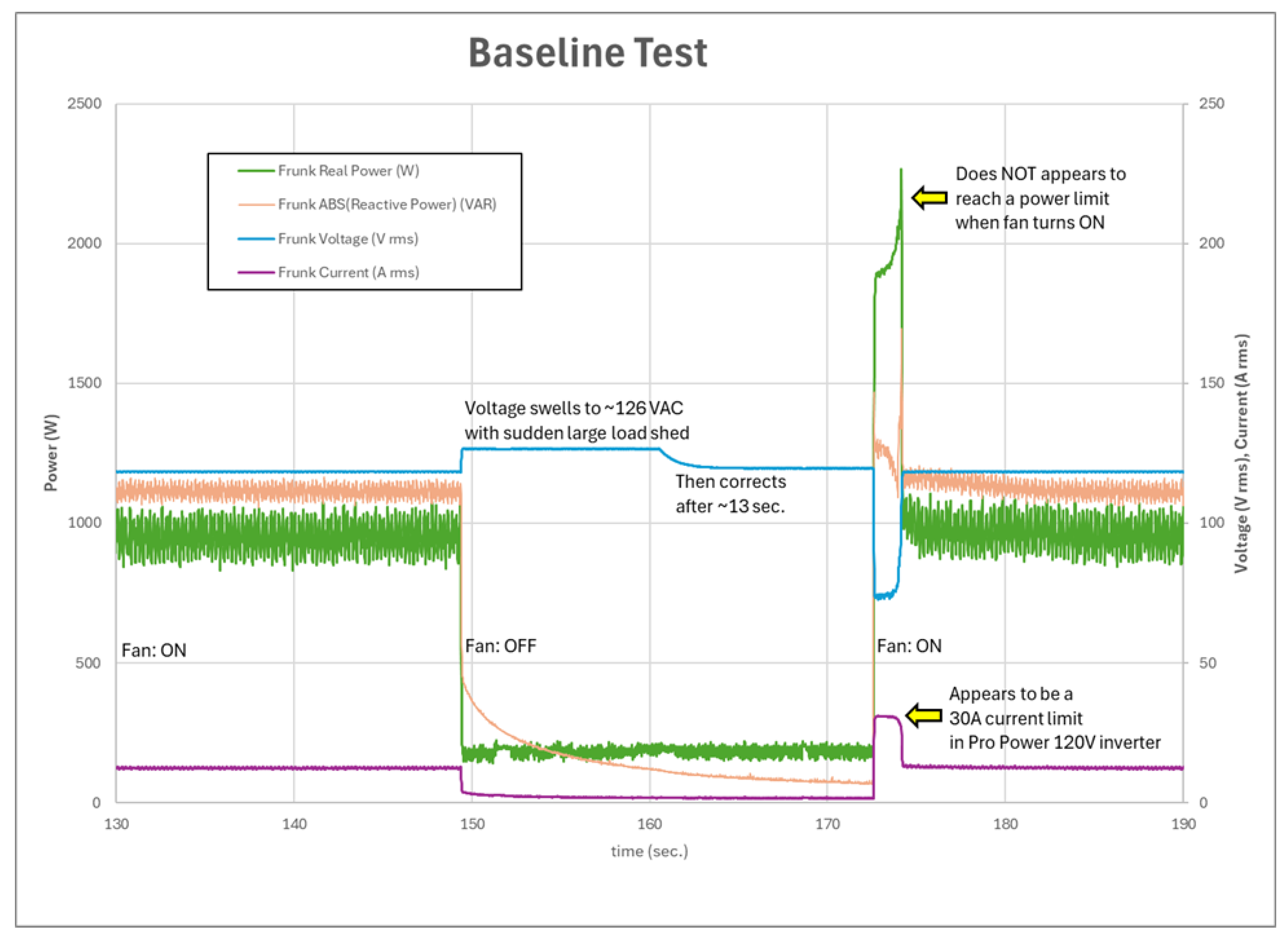

4.1. EV Power Tests

4.2. ROS 2 Communication Tests

4.2.1. Distributed Cloud Computing

4.2.2. Time Synchronization on Distributed Computers

4.2.3. Failover Mechanisms upon Communication Loss

- Local autonomy: By enabling local processing capabilities, edge devices can continue executing critical operations independently when connectivity to the cloud is lost. For instance, in SLAM-based navigation, the edge device can utilize onboard sensors to perform real-time mapping and localization without relying on cloud-based data. This local autonomy allows the system to maintain functionality and complete tasks, even in the absence of a communication link.

- Redundant communication paths: ensure continued operation when communication between the edge and cloud is lost. These mechanisms enable mission-critical operations like SLAM-based navigation and radiation mapping to proceed with minimal disruption.

- Automatic switching to backup nodes: On the edge-side of the system, the corresponding backup nodes could be named e.g., /rgbd_camera_node_backup and /lidar_sensor_node_backup, providing redundancy for the primary sensor nodes. On the cloud-side, backup EKF localization node could be designated as /ekf_localization_node_backup, ensuring that higher-level processing tasks can continue seamlessly in the event of a failure. The mechanism for triggering automatic switching involves continuous health monitoring of the primary nodes, where each node periodically checks the status of its counterpart. If a primary node fails to respond within a predefined timeout period or if it detects a critical error, the system will automatically switch to the backup node. This can be implemented through a combination of watchdog timers and heartbeat signals, which ensure that the backup nodes are activated without significant delay. Additionally, the edge and cloud nodes can communicate their operational status through ROS 2 topics, allowing the system to maintain awareness of which nodes are active. This proactive approach to node management not only minimizes downtime but also enhances the overall reliability of the system, ensuring that critical operations like SLAM-based navigation and radiation mapping can continue without interruption.

- Health monitoring and diagnostics: This enables the system to detect communication issues proactively. The edge devices can continuously monitor the status of the communication link and the performance of critical subsystems. If a fault is detected, the system can trigger predefined failover procedures, such as switching to local autonomy or engaging backup systems. This proactive approach ensures that the system can respond to emerging issues before they escalate into significant failures.

4.2.4. Cybersecurity and Quality of Service Enforcement

4.2.5. Dynamic Bandwidth Allocation

4.3. Mapping Tests

5. Discussion

5.1. Overall Design Considerations

5.2. SLAM Performance Evaluations

5.3. Issues with Mapping Software Deployment

5.4. Challenges and Strategies for Developing Digital Twins

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Colburn, H.A.; Peterson, R.A. A history of Hanford tank waste, implications for waste treatment, and disposal. Environ. Prog. Sustain. Energy 2021, 40, e13567. [Google Scholar] [CrossRef]

- Office of Management, U.S.; Department of Energy. Hanford Tank Farm Workers Begin Tank Waste Retrieval Ahead of Schedule. Available online: https://www.energy.gov/management/articles/hanford-tank-farm-workers-begin-tank-waste-retrieval-ahead-schedule (accessed on 30 May 2025).

- Asmussen, R.M. 14 Tank Waste Disposal. In Remediation of Legacy Hazardous and Nuclear Industrial Sites: Perspectives from Hanford; CRC Press: Boca Raton, FL, USA, 2024; p. 236. [Google Scholar]

- Katayama, K.; Nishikawa, M. Safety confinement system. Tritium: Fuel of Fusion Reactors; Springer: Tokyo, Japan, 2017; pp. 297–329. [Google Scholar]

- Baniqued, P.D.E.; Bremner, P.; Sandison, M.; Harper, S.; Agrawal, S.; Bolarinwa, J.; Blanche, J.; Jiang, Z.; Johnson, T.; Mitchell, D.; et al. Multimodal immersive digital twin platform for cyber–physical robot fleets in nuclear environments. J. Field Robot. 2024, 41, 1521–1540. [Google Scholar] [CrossRef]

- Mitchell, D.; Baniqued, P.D.E.; Lennox, B.; Watson, S.; West, A.; Groves, K.; Lopez, E.; Flynn, D.; Francis, D.J.; Pulgarin, E.J.L.; et al. Lessons learned: Symbiotic autonomous robot ecosystem for nuclear environments. IET Cyber-Syst. Robot. 2023, 5, e12103. [Google Scholar] [CrossRef]

- Daniyan, I.; Balogun, V.; Ererughurie, O.K.; Daniyan, L.; Oladapo, B.I. Development of an inline inspection robot for the detection of pipeline defects. J. Facil. Manag. 2022, 20, 193–217. [Google Scholar] [CrossRef]

- Schoor, W.; Förster, M.; Radetzky, A. Realistic training simulations of explosive ordnance disposal & improvised explosive device disposal robots. In Proceedings of the IEEE 10th International Conference on Industrial Informatics, Beijing, China, 25–27 July 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 875–880. [Google Scholar]

- Cao, P.; Bewley, T.; Kuester, F. Cluster-based Dynamic Object Filtering via Egocentric Motion Detection for Building Static 3D Point Cloud Maps. In Proceedings of the 2023 Seventh IEEE International Conference on Robotic Computing (IRC), Laguna Hills, CA, USA, 11–13 December 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 368–372. [Google Scholar]

- DiBono, M.; Abrahao, A.; McDaniel, D.; Tan, Y.T. Development and testing of robotic inspection tools for the hanford high-level waste double shell tanks. In Proceedings of the Waste Management Symposia 2017, Phoenix, AZ, USA, 5–9 March 2017. [Google Scholar]

- Hirose, S. Snake-like locomotors and manipulators. In Biologically Inspired Robots; Oxford University Press: Oxford, UK, 1993. [Google Scholar]

- Matsuno, F. Snake Robots and Their Applications in Harsh Environments—A Review. In Proceedings of the 2025 IEEE International Conference on Mechatronics (ICM), Wollongong, Australia, 28 February–2 March 2025; IEEE: Piscataway, NJ, USA, 2025; pp. 1–6. [Google Scholar]

- Cho, H.S.; Woo, T.H. Project strategy for clean-up of sedimentary radioactive material in Fukushima bay areas using snake-like robotics. Nucl. Technol. Radiat. Prot. 2015, 30, 318–323. [Google Scholar] [CrossRef]

- Petänen, P.; Salo, M. Exploring Digital Innovation Hub ecosystems in robotics for inspection and maintenance. In Proceedings of the 25th International Academic Mindtrek Conference, Tampere, Finland, 16–18 November 2022; pp. 364–367. [Google Scholar]

- Sareh, S.; Badia, O.; Skilton, R.; Kovac, M.; Hauert, S.; Phillips, A.; Cole, E.; Richardson, R.; Montano, G.N. Interoperable Robotics Proving Grounds: Investing in Future-Ready Testing Infrastructures; EPSRC UK-RAS Network: London, UK, 2023. [Google Scholar]

- Mineo, C. Advancements in integrated robotic sensing: A European perspective. Open Res. Eur. 2024, 4, 39. [Google Scholar] [CrossRef] [PubMed]

- Tranzatto, M.; Miki, T.; Dharmadhikari, M.; Bernreiter, L.; Kulkarni, M.; Mascarich, F.; Andersson, O.; Khattak, S.; Hutter, M.; Siegwart, R.; et al. Cerberus in the darpa subterranean challenge. Sci. Robot. 2022, 7, eabp9742. [Google Scholar] [CrossRef]

- Rouček, T.; Pecka, M.; Čížek, P.; Petříček, T.; Bayer, J.; Šalanskỳ, V.; Heřt, D.; Petrlík, M.; Báča, T.; Spurnỳ, V.; et al. Darpa subterranean challenge: Multi-robotic exploration of underground environments. In Proceedings of the International Conference on Modelling and Simulation for Autonomous Systems, Palermo, Italy, 29–31 October 2019; Springer: Cham, Switzerland, 2019; pp. 274–290. [Google Scholar]

- Orekhov, V.L.; Chung, T.H. The DARPA subterranean challenge: A synopsis of the circuits stage. Field Robot. 2022, 2, 735–747. [Google Scholar] [CrossRef]

- Aitken, J.M.; Veres, S.M.; Shaukat, A.; Gao, Y.; Cucco, E.; Dennis, L.A.; Fisher, M.; Kuo, J.A.; Robinson, T.; Mort, P.E. Autonomous nuclear waste management. IEEE Intell. Syst. 2018, 33, 47–55. [Google Scholar] [CrossRef]

- Mizuno, N.; Tazaki, Y.; Hashimoto, T.; Yokokohji, Y. A comparative study of manipulator teleoperation methods for debris retrieval phase in nuclear power plant decommissioning. Adv. Robot. 2023, 37, 541–559. [Google Scholar] [CrossRef]

- IEEE P802.1AS/D2.0; IEEE Draft Standard for Local and Metropolitan Area Networks–Timing and Synchronization for Time-Sensitive Applications; IEEE: Piscataway, NJ, USA, 2025.

- Institute of Electrical and Electronics Engineers, Inc. (IEEE) 802.1 Qbv—Enhancements for Scheduled Traffic. 2016. IEEE: Piscataway, NJ, USA, 2016; draft 3.1. Available online: http://www.ieee802.org/1/pages/802.1bv.html (accessed on 13 August 2025).

- Cao, P.; D’Andrea, A.; Houck, K.; Bonebright, P.; Carlson, B.; Xia, Y. Power Quality and Load Capacity Evaluations of an Electric Vehicle for Multi-Robot System Applications. In Proceedings of the 2025 IEEE Conference on Technologies for Sustainability (SusTech), Los Angeles, CA, USA, 20–23 April 2025; IEEE: Piscataway, NJ, USA, 2025; pp. 1–6. [Google Scholar]

- Gomez, V.; Hernando, M.; Aguado, E.; Bajo, D.; Rossi, C. Design and kinematic modeling of a soft continuum telescopic arm for the self-assembly mechanism of a modular robot. Soft Robot. 2024, 11, 347–360. [Google Scholar] [CrossRef] [PubMed]

- Reed, F.K.; Ezell, N.; Ericson, M.N.; Britton, C.L., Jr. Radiation Hardened Electronics for Reactor Environments; Technical Report; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2020. [Google Scholar]

- Morgan, D. A Handbook for EMC Testing and Measurement; IET: Singapore, 1994; Volume 8. [Google Scholar]

- Mazzola, S. MIL-STD-461: The basic military EMC specification and it’s evolution over the years. In Proceedings of the 2009 IEEE Long Island Systems, Applications and Technology Conference, Farmingdale, NY, USA, 1 May 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–5. [Google Scholar]

- Sakthivel, K.; Das, S.K.; Kini, K. Importance of quality AC power distribution and understanding of EMC standards IEC 61000-3-2, IEC 61000-3-3 and IEC 61000-3-11. In Proceedings of the 8th International Conference on Electromagnetic Interference and Compatibility, Chennai, India, 18–19 December 2003; IEEE: Piscataway, NJ, USA, 2003; pp. 423–430. [Google Scholar]

- Duffey, C.K.; Stratford, R.P. Update of harmonic standard IEEE-519: IEEE recommended practices and requirements for harmonic control in electric power systems. IEEE Trans. Ind. Appl. 2002, 25, 1025–1034. [Google Scholar] [CrossRef]

- Blooming, T.M.; Carnovale, D.J. Application of IEEE Std 519-1992 harmonic limits. In Proceedings of the Conference Record of 2006 Annual Pulp and Paper Industry Technical Conference, Appleton, WI, USA, 18–23 June 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 1–9. [Google Scholar]

- Labbé, M.; Michaud, F. RTAB-Map as an open-source lidar and visual simultaneous localization and mapping library for large-scale and long-term online operation. J. Field Robot. 2019, 36, 416–446. [Google Scholar] [CrossRef]

- 10.RTAB 3D Mapping and Navigation,Version 4.0.5; Yahboom Technology: Shenzhen, China, 2025. Available online: https://drive.google.com/file/d/1b-x8kRcrsH7NeT4DmyXZlkCyPyBX2IdF/view?usp=drive_link (accessed on 20 August 2025).

- Dumiak, M. Ford, Volkswagen, and GM Explore EV-Powered Houses. IEEE Spectr. 2022, 59, 12–13. [Google Scholar]

- Nguyen, H.G.; Pezeshkian, N.; Gupta, A.; Farrington, N. Maintaining communication link for a robot operating in a hazardous environment. In Proceedings of the ANS 10th International Conference on Robotics and Remote Systems for Hazardous Environments, Gainesville, FL, USA, 28–31 March 2004; pp. 28–31. [Google Scholar]

- Kennel-Maushart, F.; Coros, S. Payload-aware trajectory optimisation for non-holonomic mobile multi-robot manipulation with tip-over avoidance. IEEE Robot. Autom. Lett. 2024, 9, 7669–7676. [Google Scholar] [CrossRef]

- Park, J.; Delgado, R.; Choi, B.W. Real-time characteristics of ROS 2.0 in multiagent robot systems: An empirical study. IEEE Access 2020, 8, 154637–154651. [Google Scholar] [CrossRef]

- Ginting, M.F.; Otsu, K.; Edlund, J.A.; Gao, J.; Agha-Mohammadi, A.A. CHORD: Distributed Data-Sharing via Hybrid ROS 1 and 2 for Multi-Robot Exploration of Large-Scale Complex Environments. IEEE Robot. Autom. Lett. 2021, 6, 5064–5071. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, P.; Houck, E.K.; D'Andrea, A.; Kinoshita, R.; Egan, K.B.; Zohner, P.J.; Xia, Y. Development of a Multi-Robot System for Autonomous Inspection of Nuclear Waste Tank Pits. Appl. Sci. 2025, 15, 9307. https://doi.org/10.3390/app15179307

Cao P, Houck EK, D'Andrea A, Kinoshita R, Egan KB, Zohner PJ, Xia Y. Development of a Multi-Robot System for Autonomous Inspection of Nuclear Waste Tank Pits. Applied Sciences. 2025; 15(17):9307. https://doi.org/10.3390/app15179307

Chicago/Turabian StyleCao, Pengcheng, Edward Kaleb Houck, Anthony D'Andrea, Robert Kinoshita, Kristan B. Egan, Porter J. Zohner, and Yidong Xia. 2025. "Development of a Multi-Robot System for Autonomous Inspection of Nuclear Waste Tank Pits" Applied Sciences 15, no. 17: 9307. https://doi.org/10.3390/app15179307

APA StyleCao, P., Houck, E. K., D'Andrea, A., Kinoshita, R., Egan, K. B., Zohner, P. J., & Xia, Y. (2025). Development of a Multi-Robot System for Autonomous Inspection of Nuclear Waste Tank Pits. Applied Sciences, 15(17), 9307. https://doi.org/10.3390/app15179307