Temporal and Statistical Insights into Multivariate Time Series Forecasting of Corn Outlet Moisture in Industrial Continuous-Flow Drying Systems

Abstract

1. Introduction

1.1. Background and State of the Art

1.2. Advantages and Limitations of AI in Corn Drying

1.3. Objectives and Contributions

- Comprehensive statistical analysis of process variables using regression and hypothesis testing.

- Comparative evaluation of LSTM, GRU, and TCN models for multivariate time-series forecasting.

- Assessment of temporal robustness through visual inspection of sequential prediction behavior.

2. Materials and Methods

2.1. Experimental Setup

- User-defined settings: Target air temperature and material discharge interval.

- Process parameters: Module temperatures at three positions along the drying path (T3, T5, and T6). These parameters reflect both feedstock conditions and internal thermal states of the dryer.

- Moisture measurements: Inlet and Outlet corn moisture content, which was measured using a Schaller portable moisture meter and cross-validated using an Infratec 1241 grain analyzer. The average measurement deviation between devices was 0.09%, ensuring high reliability [22]. Measurement traceability was verified through periodic calibration against certified standards provided by Bureau Veritas Slovenia [29].

- Weather data: Ambient temperature, relative humidity, precipitation, and solar radiation data were acquired from two nearby meteorological stations (Radenci and Gačnik), operated by the Environmental Agency of the Republic of Slovenia [30]. These were included to account for environmental variability affecting dryer performance.

2.2. Variable Summary and Preprocesing

- Nearest neighbor and average neighbor imputation for temperature sensors using adjacent time points;

- Linear interpolation for continuous series such as target air temperature and inlet moisture;

- Regression imputation for variables with strong inter-feature correlations.

2.3. Statistical Analysis Approach

2.3.1. Regression Analysis and F-Tests

2.3.2. Independent-Sample T-Tests

2.4. Neural Network Modeling Approach

2.4.1. Data Preparation and Normalization

2.4.2. Model Architecture

- An input layer accepting multivariate time sequences with variable window sizes;

- A single layer with recurrent block (LSTM, GRU or TCN) with 64 units, followed by dropout regularization;

- A dense hidden layer with a tunable activation function (e.g., ReLU or Swish);

- A final output layer producing a single regression value (outlet moisture).

2.4.3. Hyperparameter Optimization

2.4.4. Model Training, Evaluation and Visualization

- Mean absolute error (MAE);

- Root mean squared error (RMSE);

- Mean absolute percentage error (MAPE);

- Mean squared error (MSE).

3. Results and Discussion

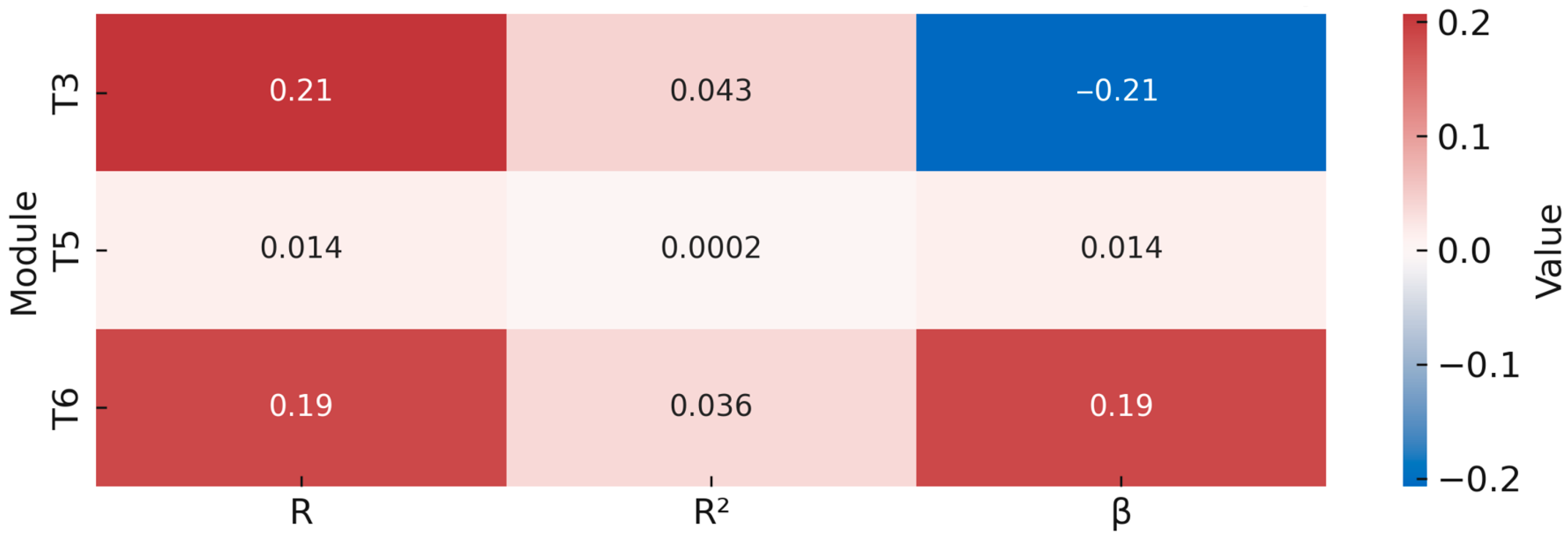

3.1. Statistical Effects of Inlet Corn Moisture (MI) on Process Parameters

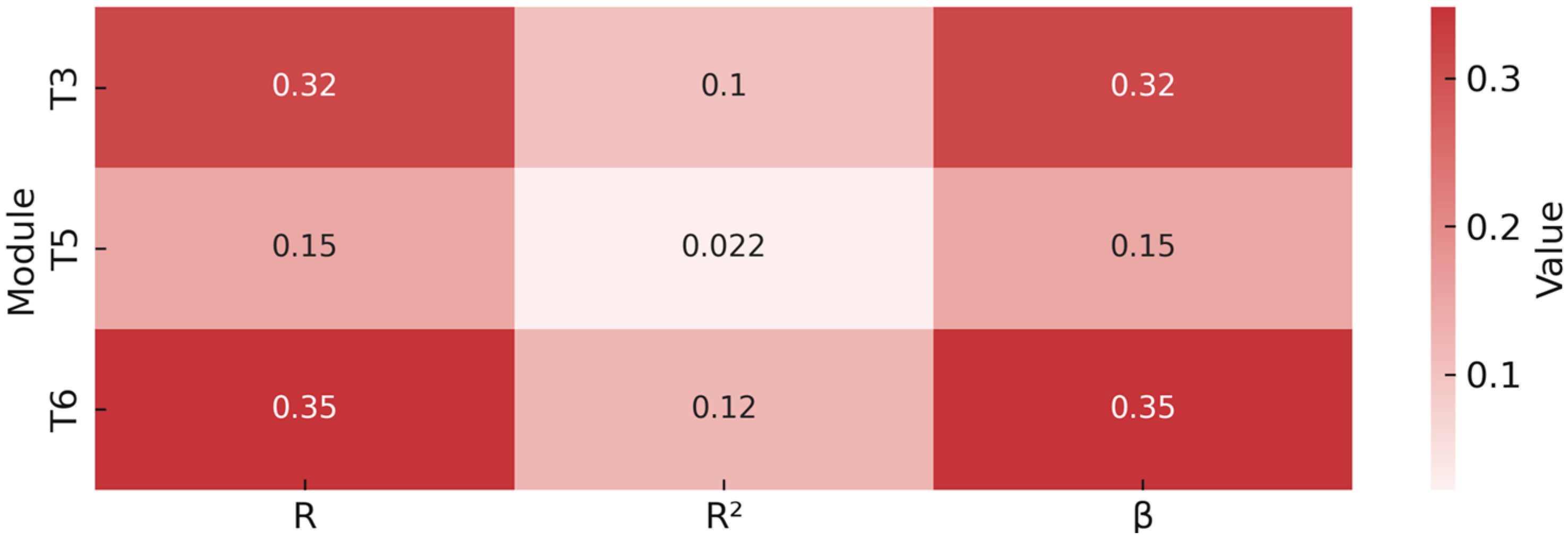

3.2. Statistical Effects of Target Air Temperature (TA) on Process Parameters

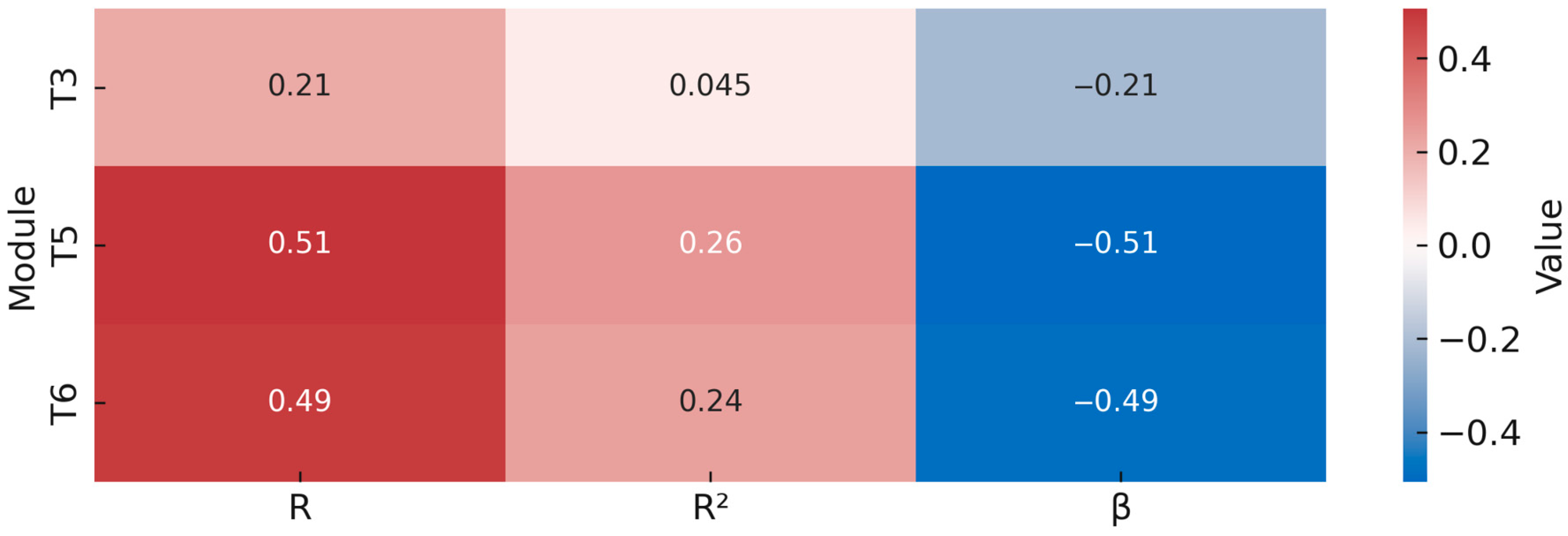

3.3. Statistical Effects of Material Discharge Interval (MD) on Process Parameters

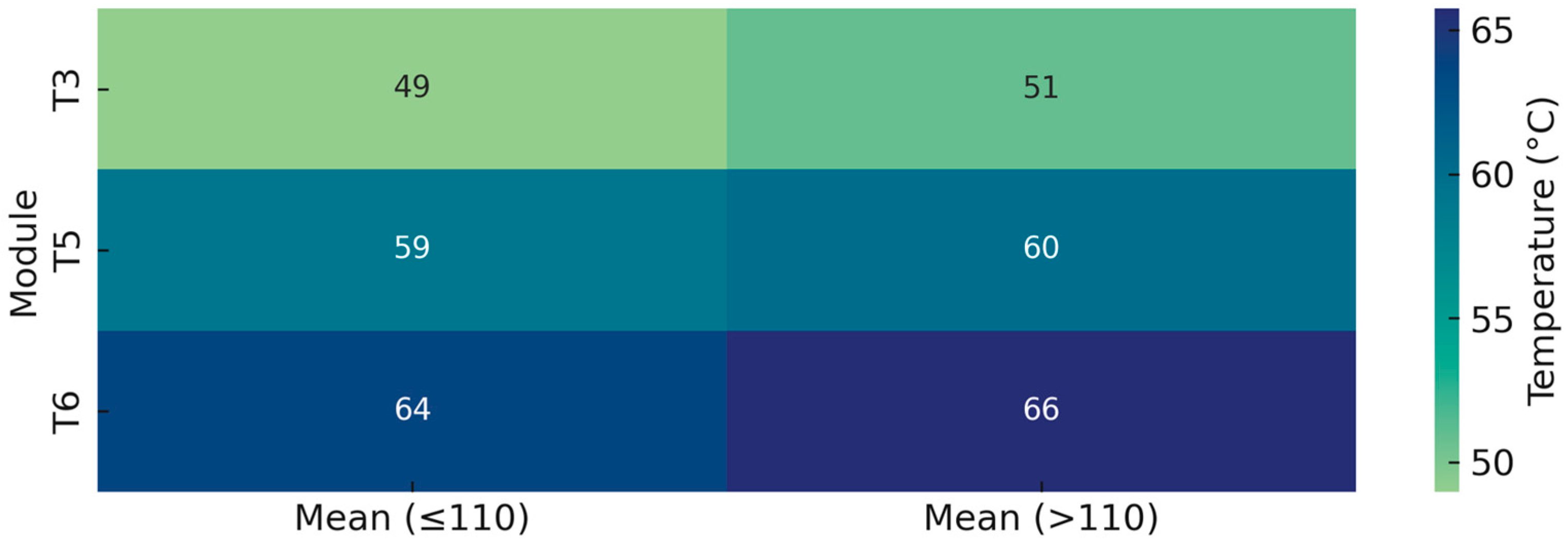

3.4. T-Test: Effects of Target Air Temperature Groups on Module Temperatures

3.5. Practical Interpretation of Statistical Models

3.6. Time Series Modeling of Outlet Corn Moisture

3.7. Predictive Performance of Time Series Models

3.8. Visualization of Timeseries Models

3.8.1. Residual Distribution

3.8.2. Time Series Prediction Performance

3.9. Performance Comparison with Related Studies

4. Conclusions

4.1. Summary of Findings

4.2. Practical Implications

4.3. Limitations and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fountas, S.; Espejo-García, B.; Kasimati, A.; Gemtou, M.; Panoutsopoulos, H.; Anastasiou, E. Agriculture 5.0: Cutting-Edge Technologies, Trends, and Challenges. IT Prof. 2024, 26, 40–47. [Google Scholar] [CrossRef]

- Bissadu, K.D.; Sonko, S.; Hossain, G. Society 5.0 Enabled Agriculture: Drivers, Enabling Technologies, Architectures, Opportunities, and Challenges. Inf. Process. Agric. 2025, 12, 112–124. [Google Scholar] [CrossRef]

- Saiz-Rubio, V.; Rovira-Más, F. From Smart Farming towards Agriculture 5.0: A Review on Crop Data Management. Agronomy 2020, 10, 207. [Google Scholar] [CrossRef]

- Shiferaw, B.; Prasanna, B.M.; Hellin, J.; Bänziger, M. Crops That Feed the World 6. Past Successes and Future Challenges to the Role Played by Maize in Global Food Security. Food Sec. 2011, 3, 307–327. [Google Scholar] [CrossRef]

- Ziegler, V.; Paraginski, R.T.; Ferreira, C.D. Grain Storage Systems and Effects of Moisture, Temperature and Time on Grain Quality—A Review. J. Stored Prod. Res. 2021, 91, 101770. [Google Scholar] [CrossRef]

- Kechkin, I.A.; Ermolaev, V.A.; Ivanov, M.V.; Romanenko, A.I.; Gurkovskaya, E.A. Dependence of Fat Acidity Value on Wheat Grain Storage Conditions. BIO Web Conf. 2020, 17, 00107. [Google Scholar] [CrossRef]

- Martinez-Feria, R.A.; Licht, M.A.; Ordóñez, R.A.; Hatfield, J.L.; Coulter, J.A.; Archontoulis, S.V. Evaluating Maize and Soybean Grain Dry-down in the Field with Predictive Algorithms and Genotype-by-Environment Analysis. Sci. Rep. 2019, 9, 7167. [Google Scholar] [CrossRef]

- Odjo, S.D.P.; Malumba, P.K.; Beckers, Y.; Béra, F. Impact of Drying and Heat Treatment on the Feeding Value of Corn. A Review. Biotechnol. Agron. Soc. Environ. 2015, 19, 301–312. [Google Scholar]

- Jimoh, K.A.; Hashim, N.; Shamsudin, R.; Man, H.C.; Jahari, M.; Onwude, D.I. Recent Advances in the Drying Process of Grains. Food Eng. Rev 2023, 15, 548–576. [Google Scholar] [CrossRef]

- Grelier, A.; Zadravec, M.; Remmelgas, J.; Forgber, T.; Colacino, F.; Pilcer, G.; Stauffer, F.; Hörmann-Kincses, T. Model-Guided Development of a Semi-Continuous Drying Process. Pharm. Res. 2022, 39, 2005–2016. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, S.; Fan, H.; Zhang, M.; Hu, N.; Yang, H. Modeling and Experimental Study on Drying Characteristics of Corn Particles with Hot Air in Downward Moving Bed. Fluids 2023, 8, 63. [Google Scholar] [CrossRef]

- Peart, M.; Foster, G.H. Matllematical Simulation of Corn Drying A New Model. Trans. ASAE 1968, 11, 582–586. [Google Scholar]

- Gautam, S.; Gautam, A.; Mahant, B. A Statistical Optimization of Convective Drying of Corn Kernels in a Fluidized Bed Dryer. J. Eng. Res. 2021, 11, 30–40. [Google Scholar] [CrossRef]

- Raimundini Aranha, A.C.; Lopes Ferrari, A.; Paschoal, S.M.; Sgorlon, J.G.; Sérgi Gomes, M.C.; De Matos Jorge, L.M.; Tonin, L.T.D.; Oliveira Defendi, R. Heat Consumption and Modeling of Corn Seeds Intermittent Drying. JSFA Rep. 2023, 3, 588–596. [Google Scholar] [CrossRef]

- Valencia Ceballos, L.A.; López-Vidaña, E.C.; Romero-Perez, C.K.; Escobedo-Bretado, J.; García-Valladares, O.; Martín Domínguez, I.R. Techno-Economic and Environmental Assessment of a Photovoltaic-Thermal (PV-T) Solar Dryer for Habanero Chili (Capsicum chinense): 4E (Energy, Economic, Embodied and Environmental) Analysis. Renew. Energy 2025, 245, 122758. [Google Scholar] [CrossRef]

- Shi, R.; Conrad, S.A. Correlation and Regression Analysis. Ann. Allergy Asthma Immunol. 2009, 103, S35–S41. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Li, C.; Huang, J.; Li, C. Application of Artificial Neural Network for Prediction of Key Indexes of Corn Industrial Drying by Considering the Ambient Conditions. Appl. Sci. 2020, 10, 5659. [Google Scholar] [CrossRef]

- Xing, S.; Lin, Z.; Gao, X.; Wang, D.; Liu, G.; Cao, Y.; Liu, Y. Research on Outgoing Moisture Content Prediction Models of Corn Drying Process Based on Sensitive Variables. Appl. Sci. 2024, 14, 5680. [Google Scholar] [CrossRef]

- Zhang, Y.; Fang, Z.; Li, C.; Li, C. Deep-Learning-Based Model Predictive Control of an Industrial-Scale Multistate Counter-Flow Paddy Drying Process. Foods 2023, 13, 43. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, Y.; Han, F.; Zhang, Y.; Wang, G.; Wu, Z.; Wu, W. Control Method for Continuous Grain Drying Based on Equivalent Accumulated Temperature Mechanism and Artificial Intelligence. Foods 2022, 11, 834. [Google Scholar] [CrossRef]

- Aji, G.K.; Bachtiar, W.F.; Yuliando, H.; Suwondo, E. Dynamic Modeling of the Drying Process of Corn Grains Using Neural Networks. Agritech 2019, 39, 251. [Google Scholar] [CrossRef]

- Simonič, M.; Ficko, M.; Klančnik, S. Predicting Corn Moisture Content in Continuous Drying Systems Using LSTM Neural Networks. Foods 2025, 14, 1051. [Google Scholar] [CrossRef]

- Ahmadi, A.; Daccache, A.; Sadegh, M.; Snyder, R.L. Statistical and Deep Learning Models for Reference Evapotranspiration Time Series Forecasting: A Comparison of Accuracy, Complexity, and Data Efficiency. Comput. Electron. Agric. 2023, 215, 108424. [Google Scholar] [CrossRef]

- DiPietro, R.; Hager, G.D. Deep Learning: RNNs and LSTM. In Handbook of Medical Image Computing and Computer Assisted Intervention; Elsevier: Amsterdam, The Netherlands, 2020; pp. 503–519. ISBN 978-0-12-816176-0. [Google Scholar]

- Hewage, P.; Behera, A.; Trovati, M.; Pereira, E.; Ghahremani, M.; Palmieri, F.; Liu, Y. Temporal Convolutional Neural (TCN) Network for an Effective Weather Forecasting Using Time-Series Data from the Local Weather Station. Soft Comput. 2020, 24, 16453–16482. [Google Scholar] [CrossRef]

- Shiri, F.M.; Perumal, T.; Mustapha, N.; Mohamed, R. A Comprehensive Overview and Comparative Analysis on Deep Learning Models: CNN, RNN, LSTM, GRU. arXiv 2023, arXiv:2305.17473. [Google Scholar] [CrossRef]

- Hoque, A. Artificial Intelligence in Post-Harvest Drying Technologies: A Comprehensive Review on Optimization, Quality Enhancement, and Energy Efficiency. Int. J. Sci. Res. 2024, 13, 493–502. [Google Scholar] [CrossRef]

- Simtro Energija d.o.o.|Spletna Stran. Available online: https://www.simtro.si/ (accessed on 19 May 2025).

- Home|Bureau Veritas Slovenia. Available online: https://www.bureauveritas.si/ (accessed on 16 May 2025).

- ARSO Vreme. Available online: https://vreme.arso.gov.si/napoved (accessed on 16 May 2025).

- IBM—United States. Available online: https://www.ibm.com/us-en (accessed on 16 May 2025).

- MinMaxScaler. Available online: https://scikit-learn.org/stable/modules/generated/sklearn.preprocessing.MinMaxScaler.html (accessed on 16 May 2025).

- GridSearchCV. Available online: https://scikit-learn.org/stable/modules/generated/sklearn.model_selection.GridSearchCV.html (accessed on 16 May 2025).

- Scikeras.Wrappers.KerasRegressor—SciKeras 0.13.0 Documentation. Available online: https://adriangb.com/scikeras/stable/generated/scikeras.wrappers.KerasRegressor.html (accessed on 16 May 2025).

- Liashchynskyi, P.; Liashchynskyi, P. Grid Search, Random Search, Genetic Algorithm: A Big Comparison for NAS. arXiv 2019, arXiv:1912.06059. [Google Scholar] [CrossRef]

- ReLU—PyTorch 2.7 Documentation. Available online: https://docs.pytorch.org/docs/stable/generated/torch.nn.ReLU.html (accessed on 16 May 2025).

- Sigmoid—PyTorch 2.7 Documentation. Available online: https://docs.pytorch.org/docs/stable/generated/torch.nn.Sigmoid.html (accessed on 16 May 2025).

- Ramachandran, P.; Zoph, B.; Le, Q.V. Searching for Activation Functions. arXiv 2017, arXiv:1710.05941. [Google Scholar] [CrossRef]

- Zou, F.; Shen, L.; Jie, Z.; Zhang, W.; Liu, W. A Sufficient Condition for Convergences of Adam and RMSProp. In Proceedings of the 2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Long Beach, CA, USA, 15–20 June 2019; IEEE: Long Beach, CA, USA, 2019; pp. 11119–11127. [Google Scholar]

- Zhang, Q.; Zhang, Y.; Shao, Y.; Liu, M.; Li, J.; Yuan, J.; Wang, R. Boosting Adversarial Attacks with Nadam Optimizer. Electronics 2023, 12, 1464. [Google Scholar] [CrossRef]

- TimeSeriesSplit. Available online: https://scikit-learn.org/stable/modules/generated/sklearn.model_selection.TimeSeriesSplit.html (accessed on 16 May 2025).

| Code | Variable | Description | Unit | Source/Note | Type |

|---|---|---|---|---|---|

| TA | Target air temperature | Drying air setpoint | °C | Operator-defined | Independent |

| MD | Discharge interval | Gate opening interval | s | Operator-defined | Independent |

| T3 | Temperature | Corn temperature in drying module 3 | °C | Internal sensor | Dependent |

| T5 | Temperature | Corn temperature in drying module 5 | °C | Internal sensor | Dependent |

| T6 | Temperature | Corn temperature in drying module 6 | °C | Internal sensor | Dependent |

| MI | Inlet Moisture | Corn moisture content before drying | % | Measured | Independent |

| MO | Outlet Moisture | Moisture content after drying | % | Measured | Dependent |

| AT | Ambient Temperature | Outside air temperature | °C | Weatherstations | Independent |

| RH | Relative Humidity | Ambient relative humidity | % | Weatherstations | Independent |

| SR | Solar Radiation | Incoming solar radiation | W/m2 | Weatherstations | Independent |

| PR | Precipitation | Rainfall | mm | Weatherstations | Independent |

| Parameter | Values Tested |

|---|---|

| Learning rate | 0.1, 0.01, 0.001, 0.0001 |

| Dropout rate | 0.0, 0.2, 0.4 |

| Input window size | 1, 2, 3, 4 |

| Optimizer | nadam, rmsprop, adam |

| Activation function | relu, swish, sigmoid |

| Epochs | 10, 20, 50 |

| Batch size | 16, 32, 64 |

| Model | MAE | RMSE | MSE | MAPE (%) |

|---|---|---|---|---|

| LSTM | 0.368 | 0.539 | 0.291 | 2.430 |

| GRU | 0.304 | 0.551 | 0.304 | 2.904 |

| TCN | 0.397 | 0.561 | 0.315 | 2.962 |

| Model | Learning Rate | Dropout Rate | Window Size | Optimizer | Activation | Epochs | Batch Size |

|---|---|---|---|---|---|---|---|

| LSTM | 0.001 | 0 | 4 | Adam | Swish | 50 | 16 |

| GRU | 0.01 | 0 | 2 | nadam | relu | 20 | 32 |

| TCN | 0.0001 | 0 | 4 | nadam | swish | 50 | 64 |

| Model | Duration (s) |

|---|---|

| LSTM | 5212.23 |

| GRU | 6193.23 |

| TCN | 7679.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simonič, M.; Klančnik, S. Temporal and Statistical Insights into Multivariate Time Series Forecasting of Corn Outlet Moisture in Industrial Continuous-Flow Drying Systems. Appl. Sci. 2025, 15, 9187. https://doi.org/10.3390/app15169187

Simonič M, Klančnik S. Temporal and Statistical Insights into Multivariate Time Series Forecasting of Corn Outlet Moisture in Industrial Continuous-Flow Drying Systems. Applied Sciences. 2025; 15(16):9187. https://doi.org/10.3390/app15169187

Chicago/Turabian StyleSimonič, Marko, and Simon Klančnik. 2025. "Temporal and Statistical Insights into Multivariate Time Series Forecasting of Corn Outlet Moisture in Industrial Continuous-Flow Drying Systems" Applied Sciences 15, no. 16: 9187. https://doi.org/10.3390/app15169187

APA StyleSimonič, M., & Klančnik, S. (2025). Temporal and Statistical Insights into Multivariate Time Series Forecasting of Corn Outlet Moisture in Industrial Continuous-Flow Drying Systems. Applied Sciences, 15(16), 9187. https://doi.org/10.3390/app15169187