1. Introduction

The increasing global emphasis on sustainable practices has elevated the role of recycling within the paper industry, with Old Corrugated Containers (OCCs) serving as a primary source of recycled fiber. Recycling OCCs not only reduces environmental impact but also lessens reliance on virgin pulp resources, supporting both ecological and economic [

1,

2]. Within this context, refining is a critical step in the recycling process, as it enhances the mechanical properties and bonding potential of recycled fibers, thereby improving the quality of the final paper product [

3].

Refining involves the mechanical treatment of pulp fibers to modify key characteristics such as flexibility, surface area, and fibrillation. These modifications are essential for strengthening fiber bonding and optimizing paper properties [

4,

5,

6]. Among the various factors influencing refining efficiency, the cutting edge length (CEL) of the refining plates is particularly significant. CEL determines the nature and intensity of fiber treatment, directly impacting energy consumption, fiber modification, and the resulting paper quality [

7,

8,

9,

10,

11].

Shorter CELs generally increase the intensity of fiber treatment, leading to greater fibrillation and improved bonding, albeit with higher energy consumption [

7]. Conversely, longer CELs provide a gentler refining action, which can be advantageous for certain paper grades that prioritize fiber strength and integrity. This trade-off between fiber quality and energy efficiency presents a key challenge in optimizing the refining process for recycled fibers.

Further research has shown that CEL variations also influence fiber morphology, including swelling and flexibility, both of which are critical for achieving desirable paper properties [

1,

5]. Advanced microscopy techniques and fiber quality analyses have revealed how different CELs can alter fiber structure, thus affecting the performance of the final product. However, most existing studies focus on general fiber types, with limited attention to the unique characteristics and challenges presented by OCCs.

OCCs pose specific challenges in the recycling process due to its heterogeneous composition and the presence of contaminants such as adhesives and coatings—commonly known as ‘stickies’—which can cause operational issues and product defects [

4,

12]. Additionally, OCC fibers are typically shorter and more degraded due to multiple recycling cycles, particularly in countries with intensive recycling practices such as South Korea, Japan, Germany, and the Netherlands [

1,

13]. This deterioration results in lower fiber quality and reduced bonding potential, making effective refining even more critical for OCC-based products [

14].

Optimizing refining conditions, especially the CEL of refining plates, is essential for overcoming these challenges. Proper refining can enhance fiber flexibility and surface area, thereby improving bonding strength and the overall quality of recycled paper [

5,

7,

15,

16]. By tailoring refining strategies to the specific needs of OCCs, it is possible to mitigate the negative effects of contaminants and fiber deterioration, leading to more efficient and sustainable recycling operations. While previous studies have primarily examined refining plates with relatively short CELs of 14 and 37 km/rev for American OCCs [

7], our study uniquely focuses on the effects of a significantly higher CEL of 97 km/s. This much greater CEL represents an ultra-fine bar plate design, which provides a distinct refining intensity and fiber interaction mechanism compared to those investigated previously. By exploring this higher CEL, our research aims to uncover its potential for enhanced refining efficiency, improved fiber length retention, and superior paper property optimization, specifically within the context of Korean OCCs, which presents different recycling challenges and fiber characteristics than American OCCs. This novel focuses on high CEL refining plates, filling an important gap in the literature [

7] and providing new empirical data critical for advancing refining technology in recycled fiber processing.

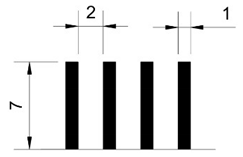

This study aims to address the current knowledge gap by systematically investigating the effects of two distinct CELs—37 km/s and 97 km/s—on the refining efficiency of OCCs. Through a series of controlled pilot-scale refining experiments, the research will compare the impact of CEL variation on key metrics such as fiber morphology, tensile strength, and energy consumption. The findings are expected to provide valuable insights into optimizing refining configurations for OCCs, thereby supporting improved sustainability and cost-effectiveness in recycled paper production.

Ultimately, this research seeks to inform industry practices by offering empirical data on CEL effects in OCC refining, guiding manufacturers in selecting optimal refining parameters to meet specific product requirements. As the demand for recycled paper continues to rise, a deeper understanding of refining processes and their optimization is vital for advancing the environmental and economic sustainability of the paper industry.

3. Results

3.1. Stock Throughput

Figure 1 compares the stock throughput (g/s) as a function of specific refining energy (kWh/t) for KOCCs refined with plates of two different cutting edge lengths (CELs), 37 km/s and 97 km/s. The conventional plate at 37 km/s presents higher initial throughput, reaching up to approximately 25 g/s at about 70 kWh/t, evidencing greater throughput efficiency at lower energy consumption. This increased throughput is largely due to wider grooves that lower resistance to stock flow, facilitating material passage and reducing energy expenditure. Throughput stabilizes near 24 g/s at higher specific energies (~125 kWh/t), indicating consistent performance.

In contrast, the ultra-fine bar plate at 97 km/s exhibits a gradual throughput increase, peaking at around 22 g/s near 80 kWh/t, beyond which a plateau is observed. This plateau likely arises from the plate’s narrow grooves, which, while enhancing fiber fibrillation and bonding effectiveness, impose higher flow resistance and restrict stock flow at elevated energy levels [

5,

7]. Despite this limitation, the ultra-fine bar plate achieves superior fiber quality metrics, such as tensile and tear strength improvements and increased water retention, reflecting a favorable energy-to-quality trade-off.

Thus, the selection between conventional and ultra-fine bar plates depends on balancing throughput priorities with desired fiber modifications. The conventional plate maximizes material throughput and energy economy, while the ultra-fine bar plate excels in refining quality, particularly beneficial for recycled fiber enhancement.

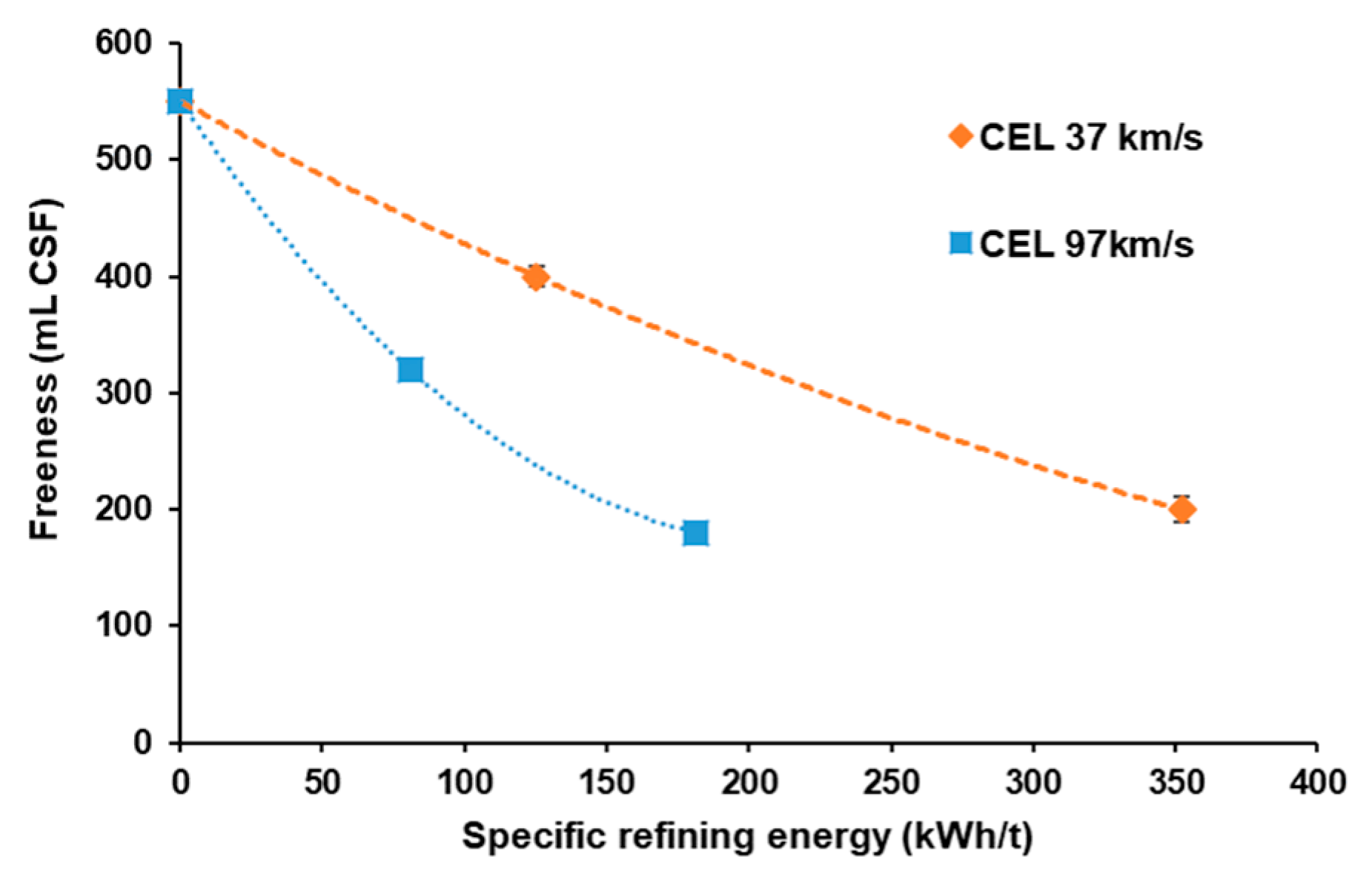

3.2. Freeness

Figure 2 presents a comparative analysis of stock throughput (g/s) versus specific refining energy (kWh/t) for KOCCs using two different cutting edge lengths (CELs): 37 km/s and 97 km/s. The plate at CEL 37 km/s initially exhibits a higher throughput, reaching approximately 25 g/s at 70 kWh/t, demonstrating a higher throughput at a lower energy input. This is largely attributable to its wider grooves, which reduce flow resistance and facilitate greater stock passage. The throughput stabilizes at around 24 g/s at 125 kWh/t, showcasing its efficiency in achieving high throughput with reduced energy.

Conversely, the ultra-fine bar plate at CEL 97 km/s shows a steady increase in throughput up to 22 g/s at approximately 80 kWh/t, after which throughput plateaus. This plateau is likely caused by the design’s narrower grooves that, while promoting superior fiber fibrillation and bonding, increase flow resistance and limit stock flow at higher energies—a phenomenon reported in previous studies. Despite the lower throughput, the ultra-fine bar plate is more energy-efficient in achieving desired fiber quality improvements, such as tensile strength and tear strength, reflecting a trade-off between throughput and fiber modification effectiveness.

Therefore, while conventional plates excel in throughput and energy input efficiency, ultra-fine bar plates provide enhanced fiber quality improvements at a moderate trade-off in throughput. Selecting the appropriate refining plate design is essential for optimizing recycled KOCC refining to balance manufacturing efficiency and paper performance.

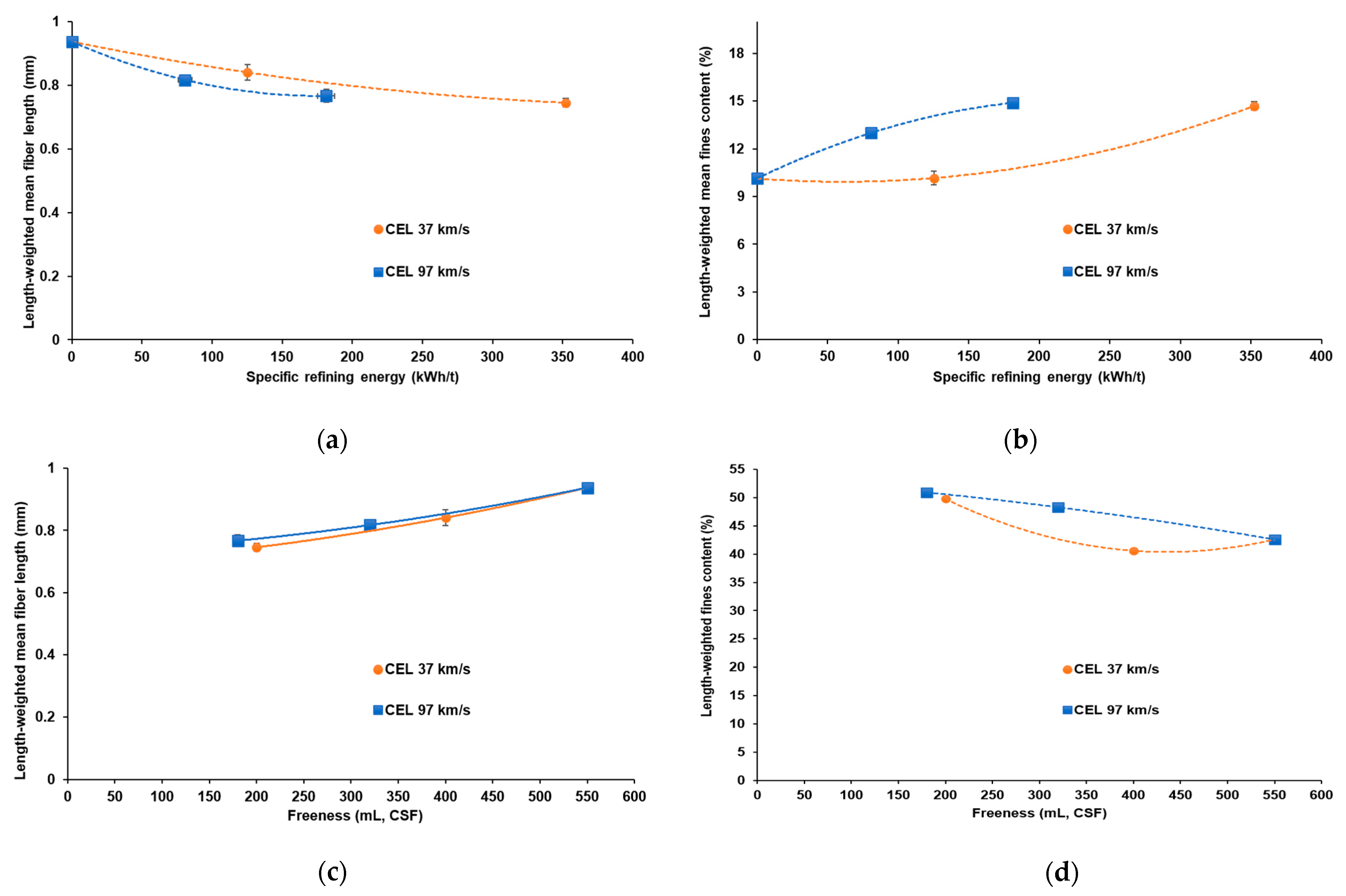

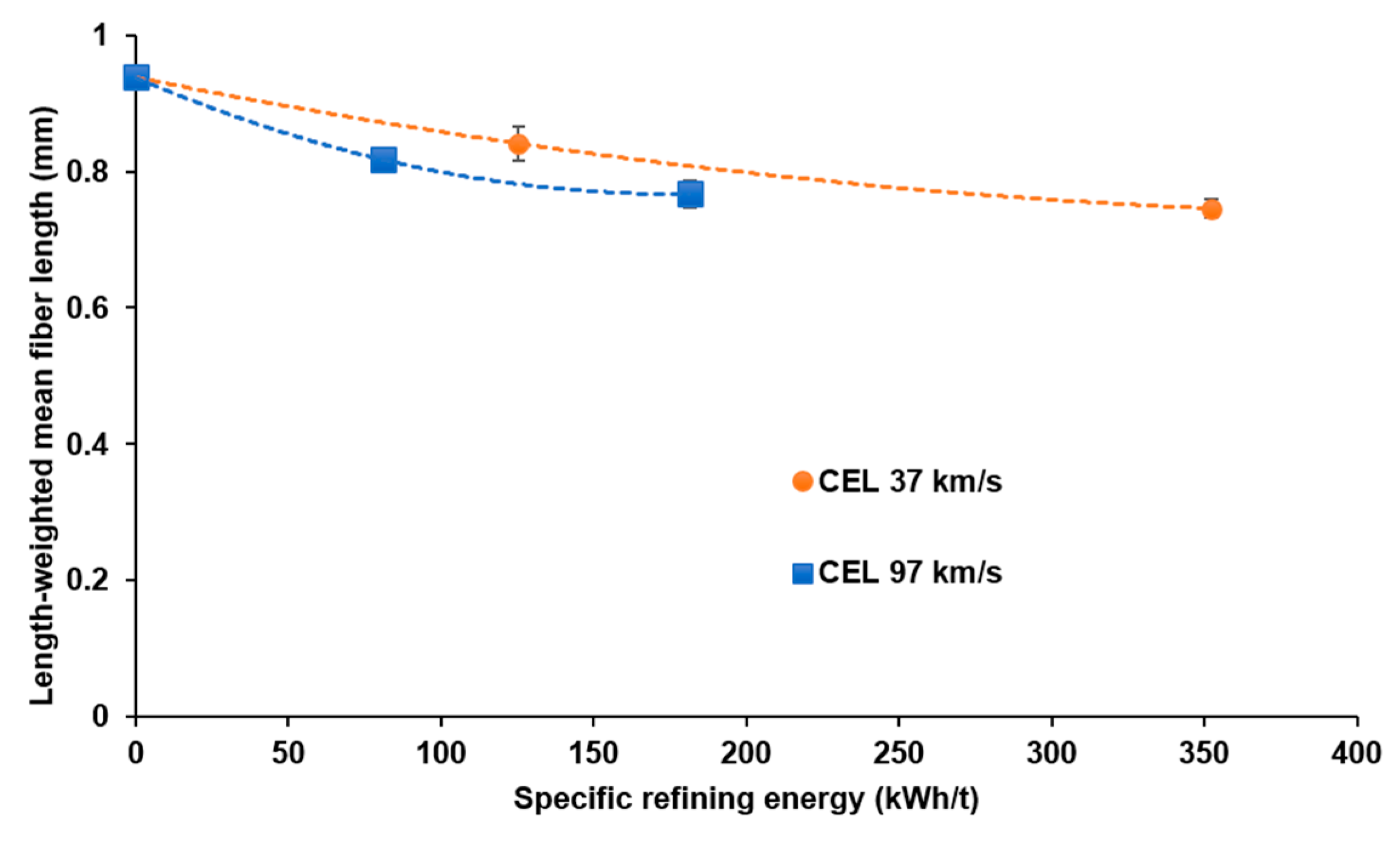

3.3. Fiber Length and Fines

Figure 3 illustrates the effects of refining energy on mean fiber length and fines content for KOCCs, comparing refiner plates with cutting edge lengths (CELs) of 37 km/s and 97 km/s. As shown in

Figure 3a,b, increasing refining energy leads to a decrease in mean fiber length and an increase in fines content for both plate types. Notably, the ultra-fine bar plate with a CEL of 97 km/s causes a more rapid drop in fiber length and a quicker rise in fines content at lower refining energies compared to the conventional plate. This trend is consistent with the findings of previous research, which reported that plates with sharper bar edges and higher CELs result in more aggressive fiber cutting, especially in the early refining stages [

7]. Similar results highlight the amplifying effects of refining intensity and plate design on fiber shortening and fines production in recycled fibers [

24].

However, a closer analysis using

Figure 3c,d, which relate fiber length and fines content to freeness, reveals a key nuance: at comparable freeness (i.e., when the drainage resistance of the pulp is matched), the mean fiber length and fines content are very similar for both plates. In other words, while the ultra-fine bar plate accelerates fiber modification—achieving target freeness with less total energy input and in fewer refining passes—it does not lead to increased fiber cutting or fines content at a given final freeness compared to the conventional plate. This observation aligns with the work of previous research, which found that optimized plate designs can achieve rapid freeness reduction without compromising final fiber length retention [

5], as well as with other studies reporting comparable trends in both hardwood and recycled fiber systems [

1,

2]. Similarly, at a key production target (e.g., 200 mL CSF), both plates produce similar fiber and fines profiles, indicating no disadvantage in fiber preservation for the ultra-fine bar plate at matched drainage levels [

25,

26].

Therefore, although the ultra-fine bar plate induces faster fiber shortening at higher refining energies, it preserves fiber length relative to the freeness target, offering the advantage of process efficiency without sacrificing final fiber integrity. This underscores the importance of selecting refining plates that optimize the trade-off between process speed, energy input, and product quality, particularly for recycled KOCC fibers that are sensitive to mechanical treatment [

27,

28].

3.4. Water Retention Value

Figure 4 illustrates how the water retention value (WRV) of Korean Old Corrugated Containers (KOCCs) fibers evolves when refined with two different refiner plates, featuring cutting edge lengths (CELs) of 37 km/s and 97 km/s. The results show that as specific refining energy increases, WRV also slightly increases for both refiner plates. This trend supports the well-established understanding that higher refining energy enhances the water retention capacity of fibers, which is beneficial for improving fiber bonding and the mechanical strength of paper [

28,

29].

The ultra-fine bar plate at CEL 97 km/s is particularly effective at promoting both external and internal fibrillation, resulting in slightly higher WRV at equivalent refining energy levels compared to the cast plate at CEL 37 km/s. This finding is consistent with previous research, which reported that refiner plates with sharper bar edges and narrower grooves induce more effective fibrillation, thereby increasing the fiber surface area and water retention [

5,

7]. Enhanced fibrillation not only improves water retention value (WRV) by increasing the fiber’s surface area and swelling capacity but also strengthens the bonding potential of recycled fibers through the formation of more fibrillar bonds, which is especially important for KOCCs that have undergone multiple recycling cycles [

27,

30].

WRV is a critical parameter for assessing the effects of refining on fiber properties. Higher WRVs indicate improved water-holding capacity, which is essential for enhancing fiber bonding and the mechanical properties of the final paper product [

24,

29]. WRV is influenced by both external and internal fibrillation, as well as the content of fines [

26]. For recycled fibers such as KOCCs, optimizing WRV through refining is crucial for significantly improving paper quality and performance [

31].

The observed increase in WRV with higher specific refining energy for both refiner plates underscores the importance of refining energy in enhancing KOCC fiber water retention. However, the ultra-fine bar plate at CEL 97 km/s demonstrates a more pronounced improvement in WRV, attributable to its superior capacity for inducing fibrillation [

5,

7]. This makes the ultra-fine bar plate particularly suitable for ultra-low intensity refining of recycled fibers like KOCCs.

The ultra-fine bar plate’s design, with narrower grooves and sharper bars, intensifies fibrillation by applying more focused shear and compression forces to the fibers. This enhanced fibrillation increases fiber swelling and creates more fibrillar surfaces, which improves WRV—a key factor for stronger fiber bonding and paper strength. Although the narrower grooves can reduce stock throughput due to higher flow resistance, the plate optimizes fiber-bar contact to modify fibers efficiently with minimal excessive cutting. As a result, the ultra-fine bar plate achieves superior WRV improvement and fiber quality while maintaining or reducing energy consumption compared to conventional plates with wider grooves.

In conclusion, the ultra-fine bar plate at CEL 97 km/s is optimal for improving the properties of KOCCs in papermaking, providing enhanced water retention and fiber bonding through effective fibrillation. Balancing refining energy and the choice of refiner plate is essential for optimizing the refining process and achieving superior paper quality, as reflected in improved mechanical strength (tensile, burst, and tear strength), fiber length retention, and sheet uniformity [

5,

27,

28].

3.5. Physical Properties

3.5.1. Bulk

A comparison of the bulk properties of paper made from KOCCs refined with 37 km/s and 97 km/s CEL plates is provided in

Figure 5. Paper bulk, which reflects the volume occupied by a given mass of paper, is a key property influencing texture, porosity, and end-use performance [

29,

32].

The results show that as specific refining energy increases, paper bulk decreases for both refiner plates. This trend is consistent with established findings that higher refining energy compacts the fiber network, leading to denser and less bulky paper [

28,

33]. Notably, the ultra-fine bar plate with a CEL of 97 km/s produces paper with slightly lower bulk compared to the plate with a CEL of 37 km/s at equivalent energy levels. This outcome suggests that the ultra-fine bar plate, which promotes more extensive external and internal fibrillation, results in a tighter, more compact fiber structure [

5,

7]

Paper bulk is a crucial parameter in determining the suitability of paper for various end-use applications. Higher bulk is generally associated with increased thickness and porosity, which contribute to a softer tactile feel and greater liquid absorbency—properties particularly desirable in tissue papers and the middle ply of cartonboard used for cushioning and insulation [

30]. In contrast, lower bulk results in denser, smoother sheets with enhanced mechanical strength, making them better suited for printing and writing papers where surface uniformity and durability are essential [

33,

34].

The observed decrease in bulk with increasing refining energy underscores the importance of refining conditions in tailoring paper properties from KOCCs. The ultra-fine bar plate at 97 km/s is particularly suitable for applications requiring a lower bulk and a higher density, as it increases fiber bonding and network densification. Conversely, for products where a higher bulk is beneficial—such as tissue, copy paper, or certain packaging layers—the conventional plate at CEL 37 km/s may be more appropriate, as it allows for greater paper bulk and the associated functional advantages [

5,

28].

In summary, optimizing the choice of refiner plate and refining energy enables the production of KOCC-based papers with properties tailored to specific end-use requirements.

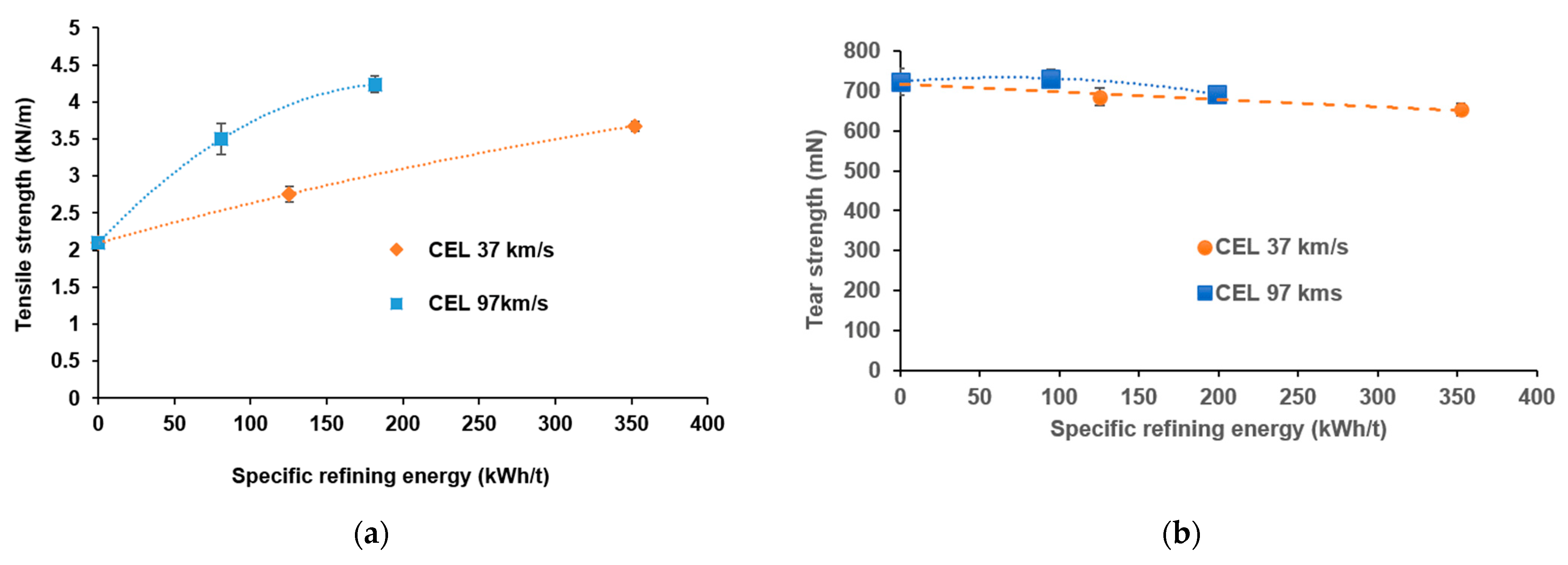

3.5.2. Tensile and Tear Strength

The tensile strength results for KOCCs refined using two different CEL refiner plates are shown in

Figure 6a. For both plates, tensile strength increases as specific refining energy rises, demonstrating a positive correlation between refining energy and fiber bonding. The ultra-fine bar plate (CEL 97 km/s) consistently achieves higher tensile strength than the conventional plate (CEL 37 km/s) at equivalent energy levels, and the rate of increase is steeper. This indicates that the ultra-fine bar plate is more efficient in enhancing fiber bonding and tensile strength with lower energy input. These results are supported by previous research, which found that refining plate geometry and bar parameters significantly influence fiber modification and strength development during low-consistency refining [

34]. Enhanced fibrillation increases the surface area for hydrogen bonding between fibers, a primary mechanism for tensile strength improvement in recycled pulps [

5,

7].

Figure 6b examines the tear strength of KOCCs refined using the same plates. For CEL at 37 km/s, tear strength shows a slight decline as refining energy increases, starting at 724 mN and dropping marginally at higher energy levels. In contrast, tear strength for CEL at 97 km/s remains stable, ranging from 724 to 743 mN across the energy spectrum, and is generally higher than that achieved with the conventional plate. This stability suggests that the ultra-fine bar plate is more effective at preserving fiber length during refining, which is critical for maintaining tear resistance [

7,

27,

35]. The relationship between refining, fiber length, and tear strength is well documented in previous studies: excessive refining or aggressive plate patterns can significantly reduce fiber length and consequently tear strength, whereas optimized refining conditions can effectively balance fiber bonding and fiber length retention to maintain or enhance tear resistance [

28,

32]. The ability of the ultra-fine bar plate to maintain or slightly improve tear strength, despite promoting faster fiber shortening (as seen in

Figure 3a), is explained by its impact on overall fiber network structure. While the ultra-fine plate increases fines content and fiber cutting, it also greatly enhances external fibrillation due to the concentrated mechanical action of its narrower grooves and sharper bars. This results in a more extensive fibrillar surface area, which substantially strengthens inter-fiber bonding. As a result, the network integrity and sheet toughness are maintained or even improved, compensating for the reduction in mean fiber length. The improved fiber-fiber bonding, supported by higher WRV and a denser fiber network, offsets the negative effects generally associated with shorter fibers and higher fines content. This synergy aligns with previous findings [

5,

7,

28], confirming that enhanced fibrillation and bonding quality can play a decisive role in sustaining tear strength in recycled KOCC papers, even as average fiber length declines.

Balancing tensile strength and bulk is essential, depending on the end-use requirements of the paperboard. Higher tensile strength improves durability and resistance to tearing, making it suitable for packaging applications requiring enhanced mechanical performance, such as shipping containers and industrial cartons. In contrast, higher bulk contributes to stiffness and a softer feel, which are desirable qualities for paperboard used in consumer packaging and folding cartons. If high tensile and tear strength are prioritized, the ultra-fine bar plate (CEL 97 km/s) at lower refining energy is recommended, as it efficiently enhances fiber bonding and preserves fiber length. However, for paperboard products where greater bulk or a softer feel is required, the conventional plate (CEL 37 km/s) may be more appropriate.

3.5.3. Fiber Morphology Analysis

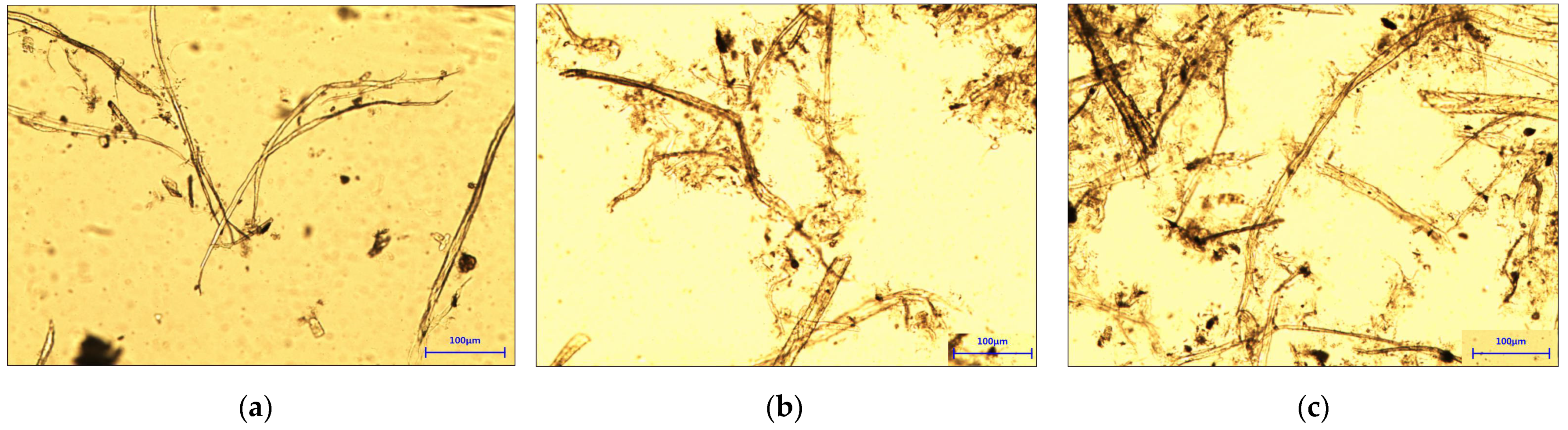

Figure 7 and

Figure 8 present a comparative analysis of KOCC fiber and sheet morphologies before and after refining, as observed through optical and scanning electron microscopy (SEM), respectively. All samples were refined to a consistent Canadian Standard Freeness (CSF) of 200 mL to ensure valid comparisons across different refining conditions.

Figure 7 provides optical microscopy images of KOCC fibers prior to and following the application of two different refiner plate types: a conventional cast plate (CEL 37 km/s) and an ultra-fine bar plate (CEL 97 km/s). The disintegrated fibers before refining in

Figure 7a appear as elongated, uncut fibers with minimal fines or debris. Most fibers remain bundled, indicating that only limited morphological change has occurred due to initial disintegration.

Refining with the conventional cast plate, shown in

Figure 7b, results in evident morphological alterations. The fibers exhibit substantial external fibrillation and increased formation of short fiber fragments and fines. Many fibers are noticeably shortened or cut, and the fiber network appears heterogeneous with a greater presence of debris among the fibers. Such modifications are indicative of an aggressive refining action that enhances fiber separation and increases the surface area for bonding but may also introduce an excess of fines.

In contrast, the use of the ultra-fine bar plate in

Figure 7c yields a different fiber morphology. The resulting fibers largely retain their original length and structure, with fewer short fibers and fines produced. Fibrillation is present but more uniform and less pronounced. The overall structure is coherent with fewer visible debris particles, reflecting the more controlled action of the ultra-fine bar plate. These differences highlight the important role of plate selection in controlling fiber breakdown, fines generation, and network uniformity [

5,

10,

11].

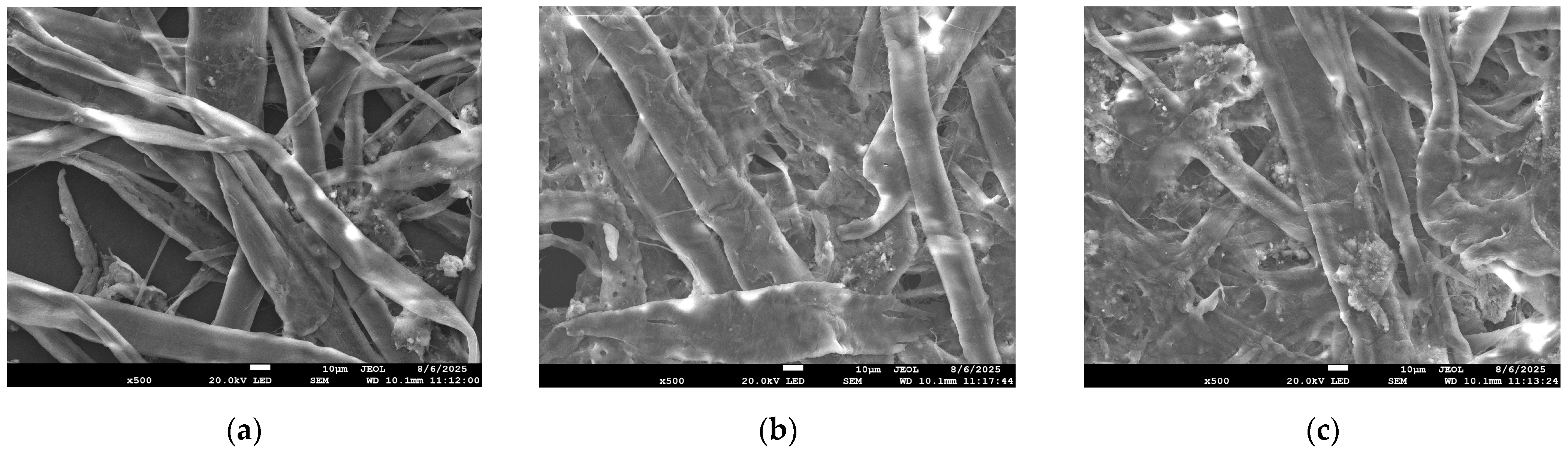

Figure 8 shows the corresponding differences in sheet structure as observed by SEM. Sheets formed from disintegrated fibers (

Figure 8a) reveal loosely bound networks with smooth fiber surfaces and limited bonding. When fibers refined at CEL 37 km/s are used (

Figure 8b), the resulting sheet displays a denser and more compact network, characterized by abundant fines that fill void spaces and improved interfiber bonding, though often at the expense of drainage and formation due to the excessive presence of fines. Sheets derived from fibers refined at CEL 97 km/s (

Figure 8c) show a well-developed network structure with strong bonding and relatively fewer fines. The sheet retains an open yet interconnected architecture, consistent with the more moderate morphological changes induced under these conditions.

Together, the optical and SEM analyses suggest that the severity and type of refining have a direct influence on both fiber and sheet morphologies. Refining with a conventional plate promotes fragmentation and fines production, while refining with an ultra-fine bar plate better preserves fiber length and integrity, resulting in improved fiber network formation. These morphological distinctions are important in the context of optimizing pulp quality and papermaking performance.