Tensile Behavior of a Fiber-Reinforced Stabilized Soil—Cyclic Loading Frequency Study

Abstract

1. Introduction

2. Materials

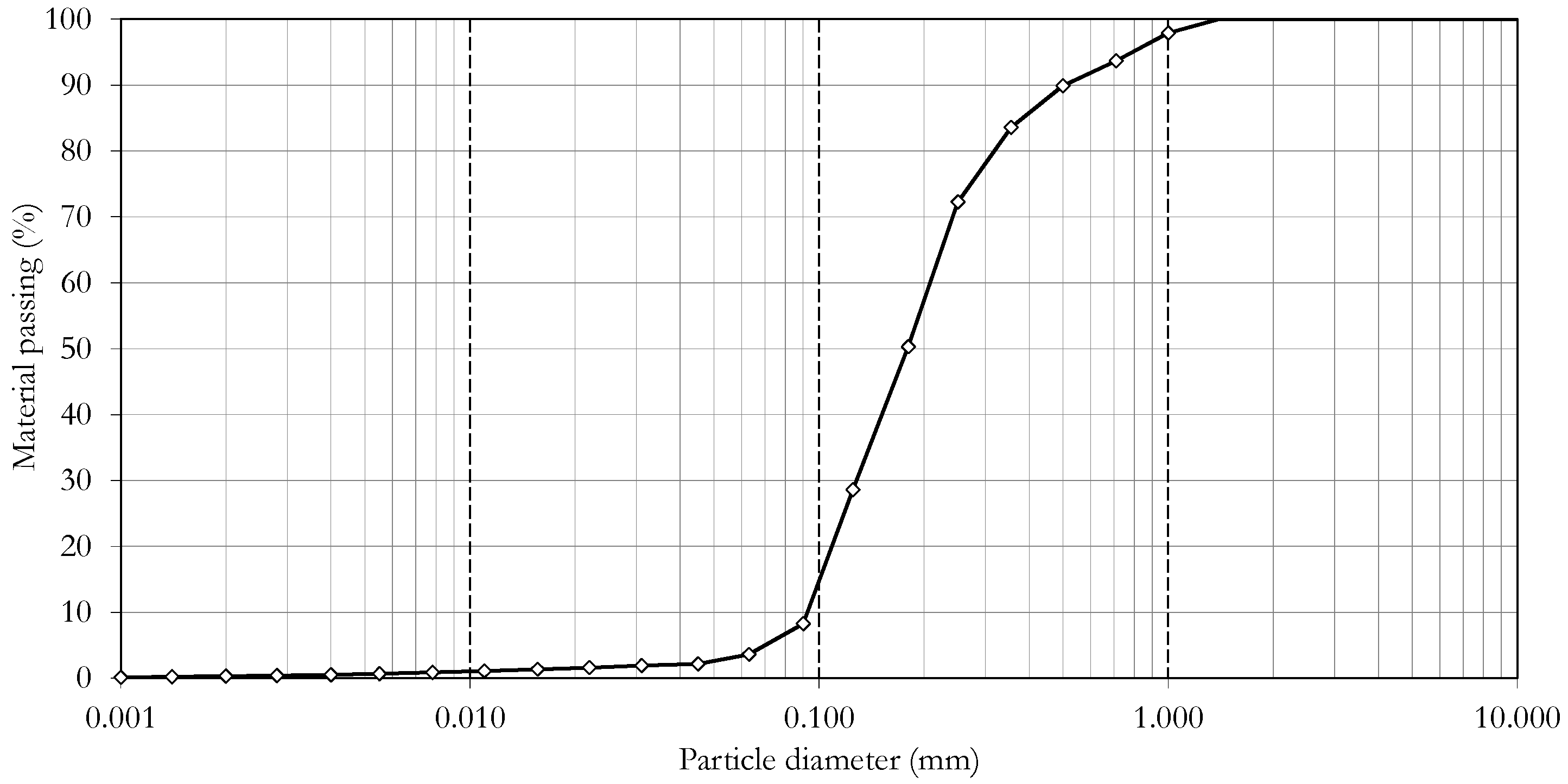

2.1. Characteristics of the Soil

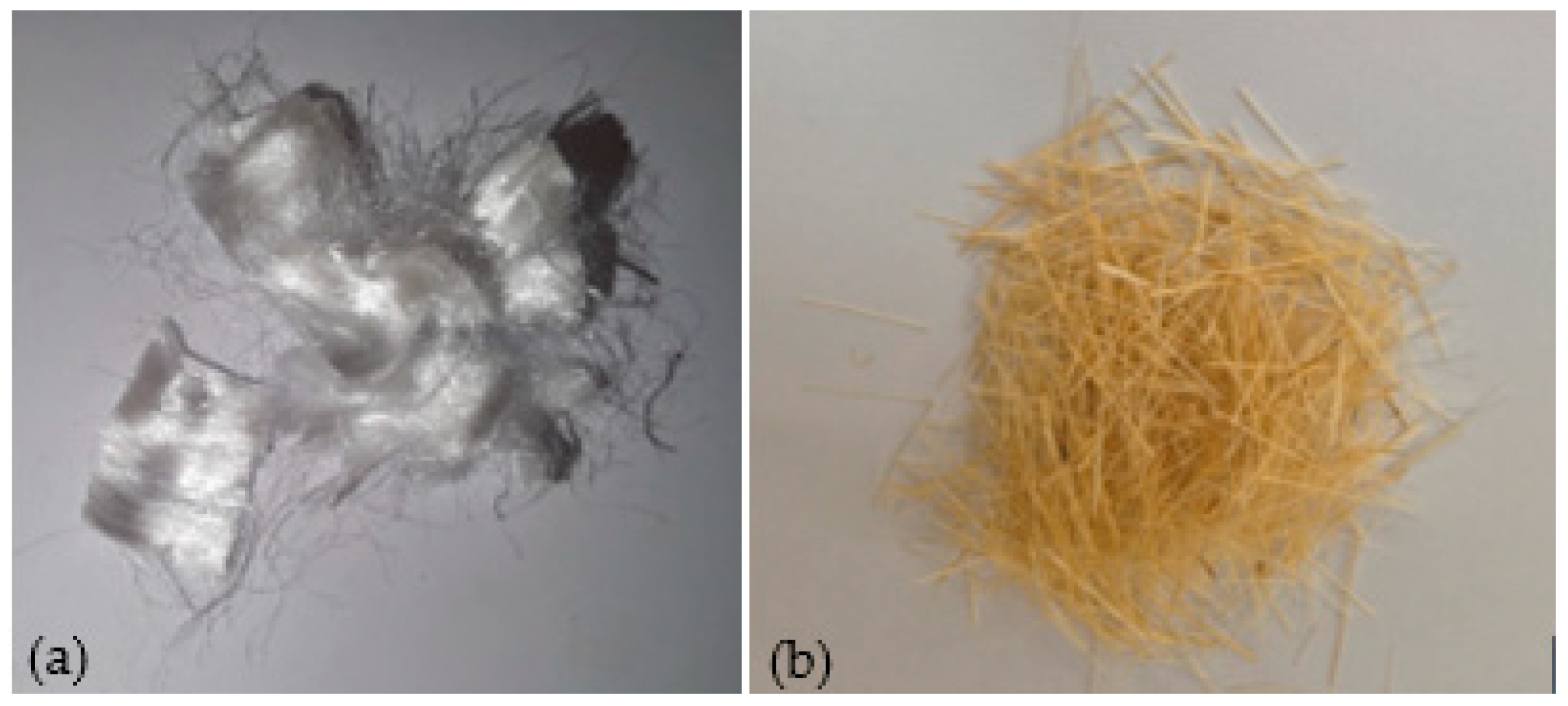

2.2. Characteristics of the Binder and the Fibers

3. Sample Preparation and Testing

- The sandy soil was first homogenized to reduce inherent variability and ensure reproducibility across tests. A dry soil mass corresponding to the maximum dry unit weight of 16.3 kN/m3, as determined by the standard Proctor test, was used.

- The binder was added in a content of 10.5% (dry binder mass relative to dry soil mass), and mixed with the soil at the optimum moisture content of 14.2%, also established through the standard Proctor test, to create a slurry. For reinforced samples, polypropylene or sisal fibers were incorporated in a content of 0.6% (dry fiber mass relative to dry soil mass).

- The resulting slurry (with or without fibers) was thoroughly blended in a mechanical mixer operating at a rotational speed of 142 rpm for 4 min, producing a homogeneous paste. The fibers were gradually added in small increments during the first minute of the mixing to avoid fiber clumping or uneven dispersion of the fibers within the composite matrix.

- This paste was then placed into cylindrical PVC molds (70 mm in diameter, D, and 140 mm in length, L) in three successive layers (Figure 3a). Each layer was compacted using the same energy defined in the standard Proctor test, and its top surface was lightly scarified to improve adhesion/bonding with the subsequent layer.

- After molding, the specimens were demolded (Figure 3b) and cured under controlled conditions (temperature of 20 ± 2 °C, relative humidity of 95 ± 5%) to minimize suction effects.

- Following a 28-day curing period, the specimens were mounted on a loading frame, capable of both static and cyclic loading tests (Figure 3c). Instrumentation, including the load cell and linear displacement transducer, was properly configured, and data were continuously recorded using an automated acquisition system.

4. Analysis of the Results

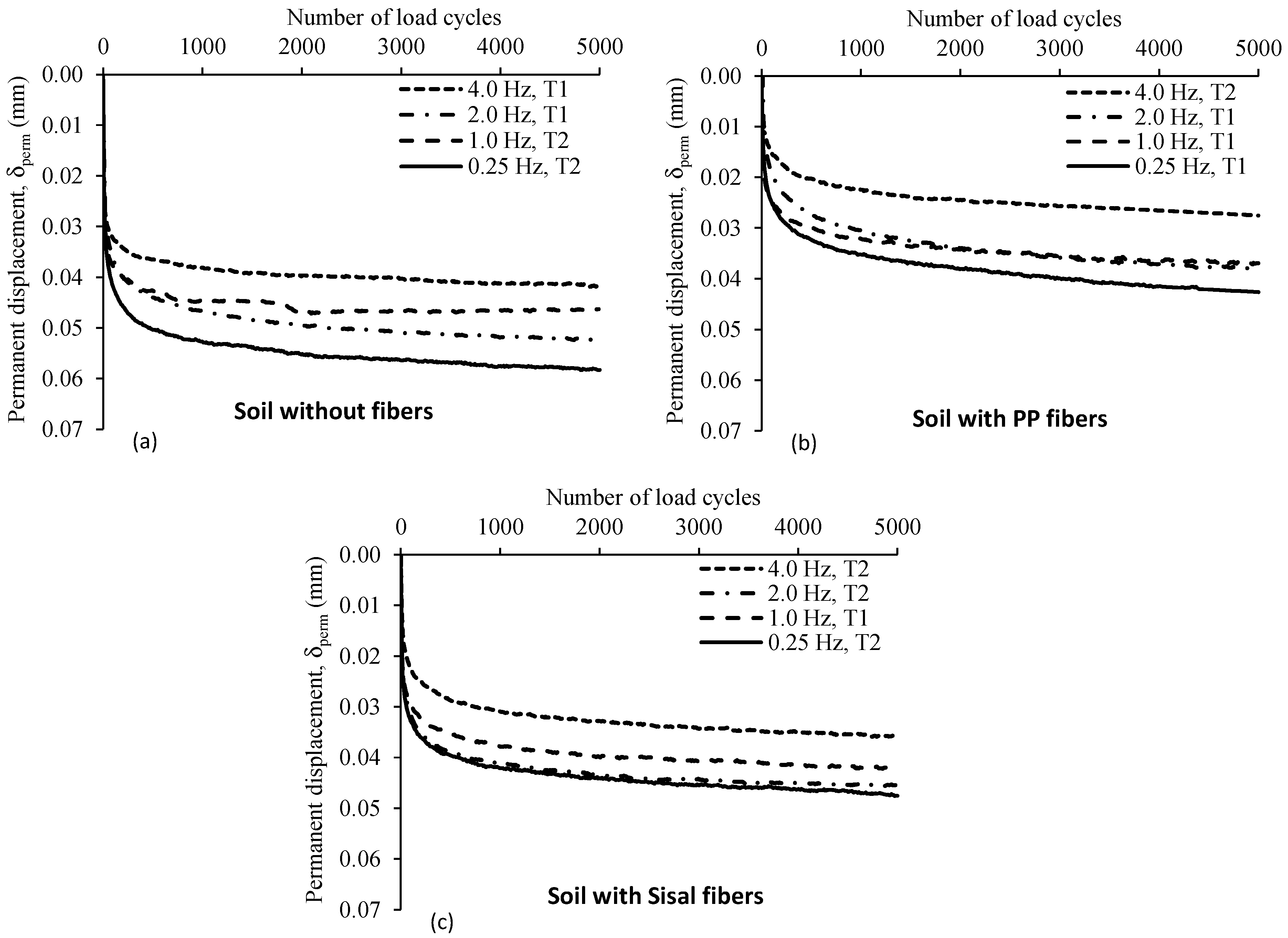

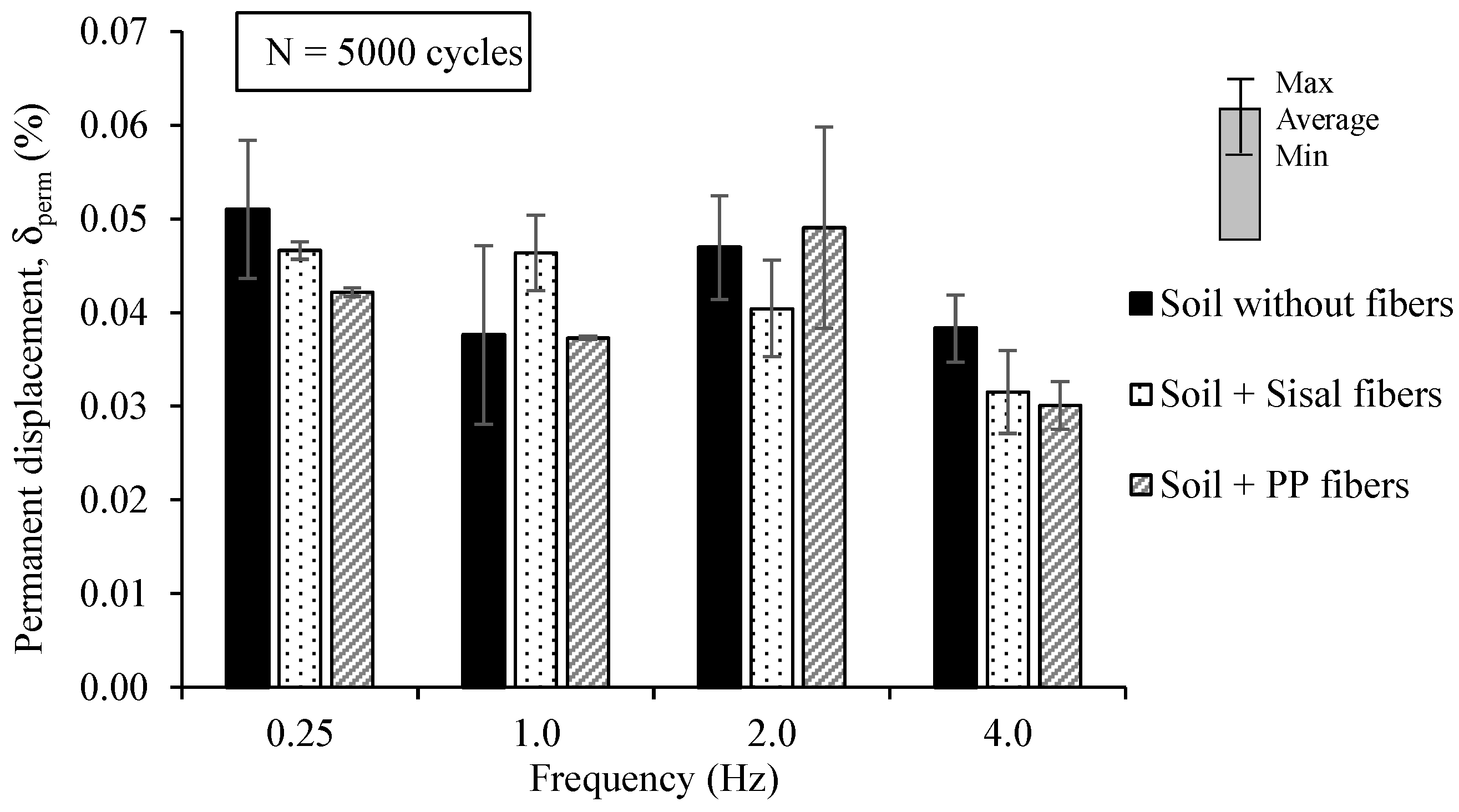

4.1. Cyclic Stage

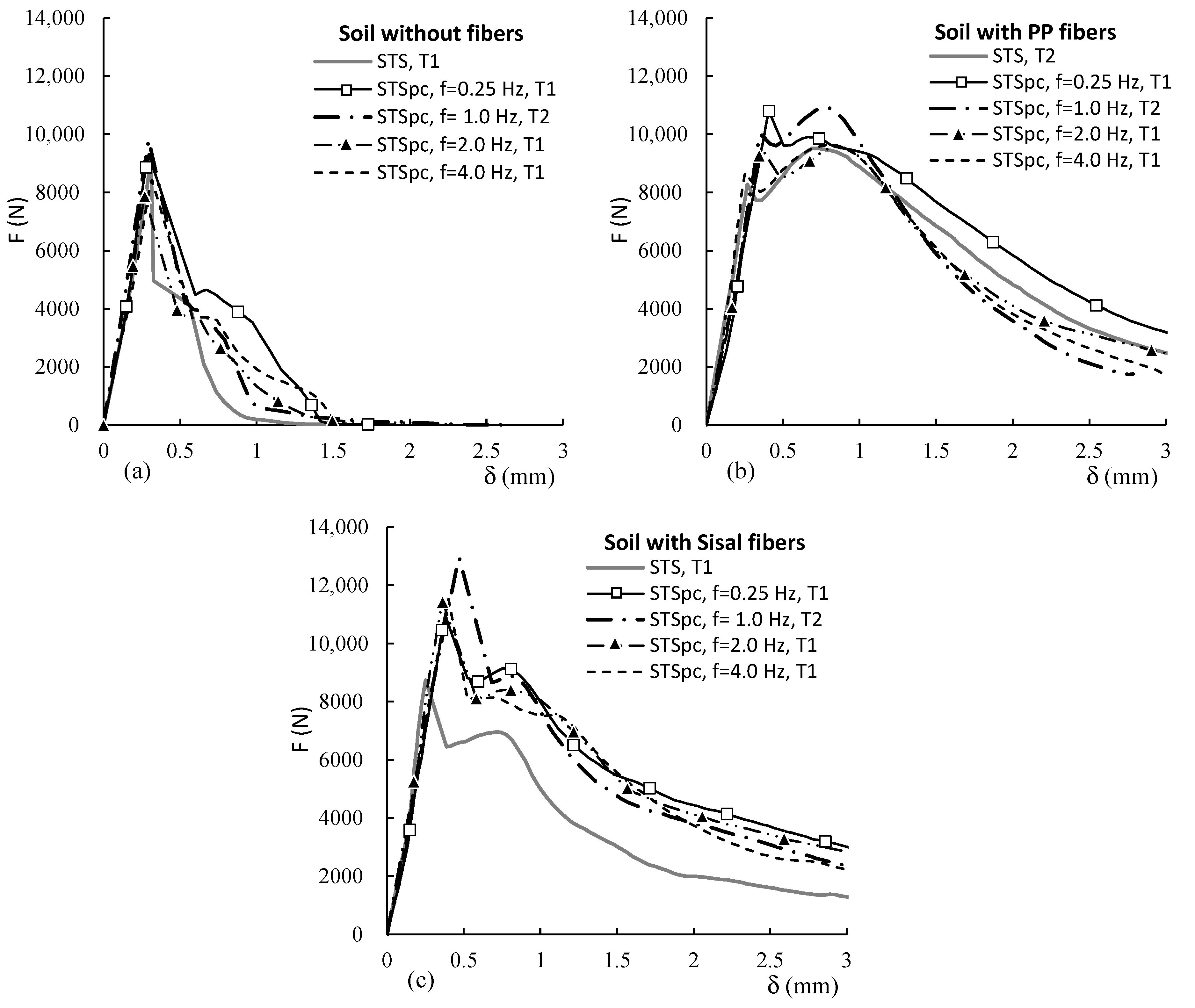

4.2. Load-Displacement Curves

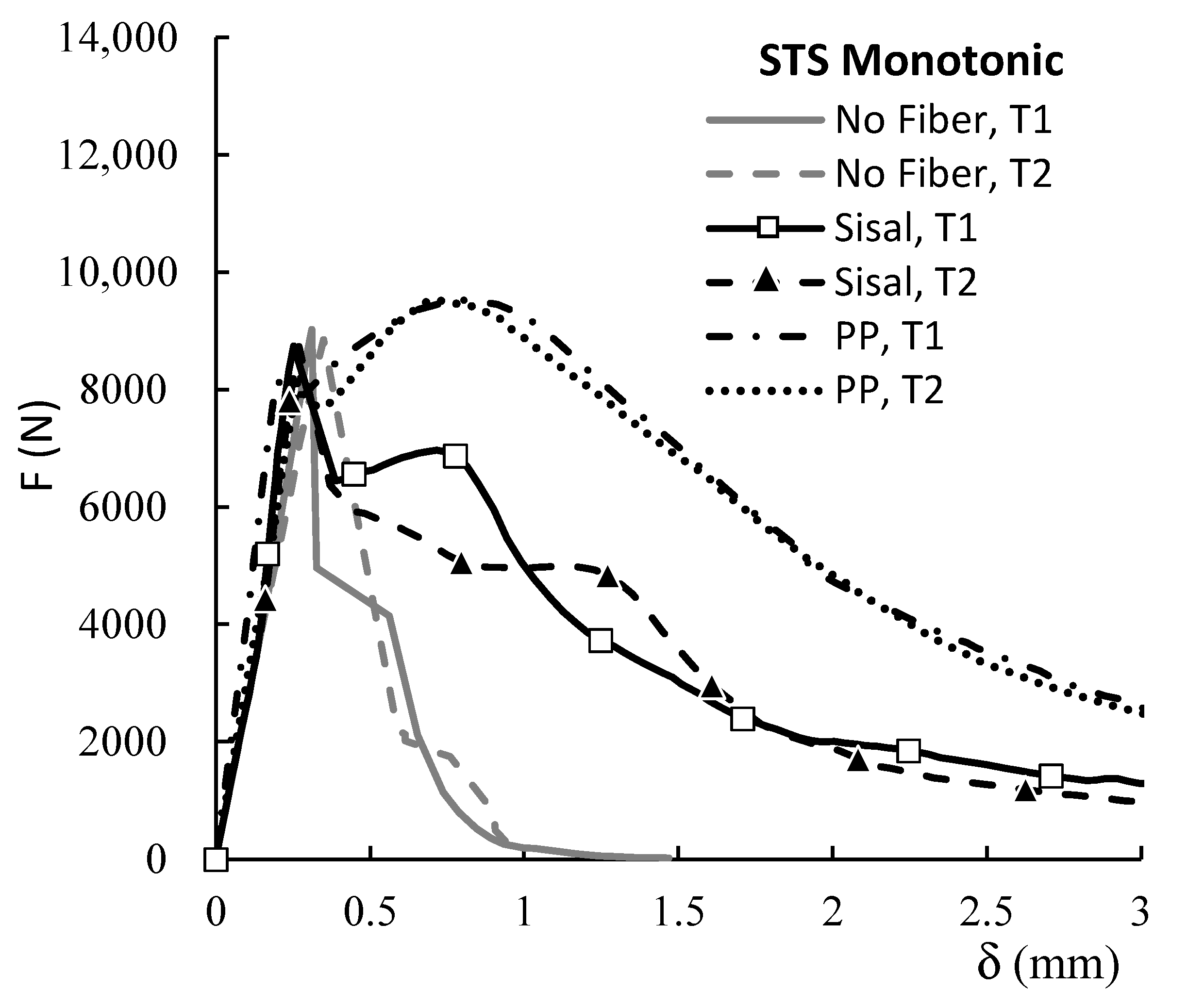

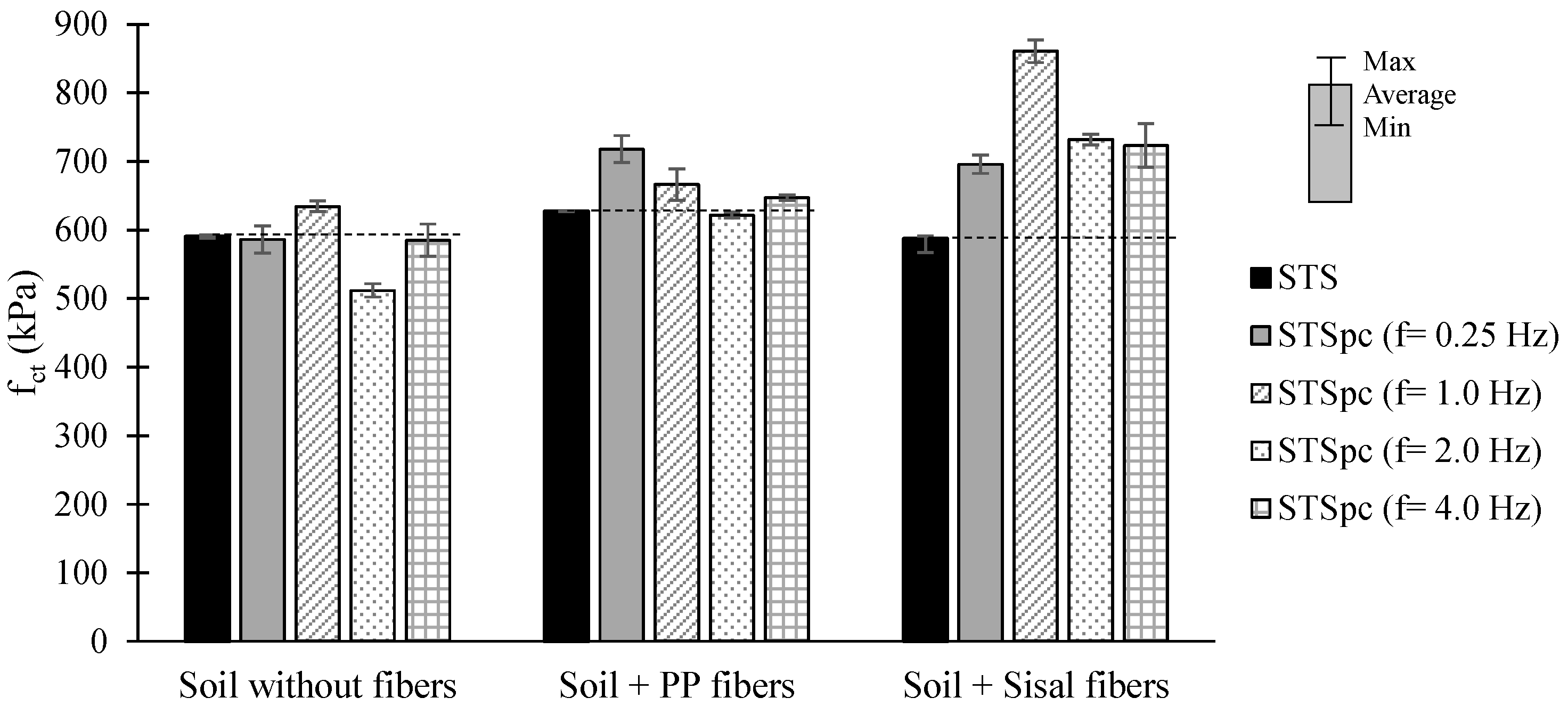

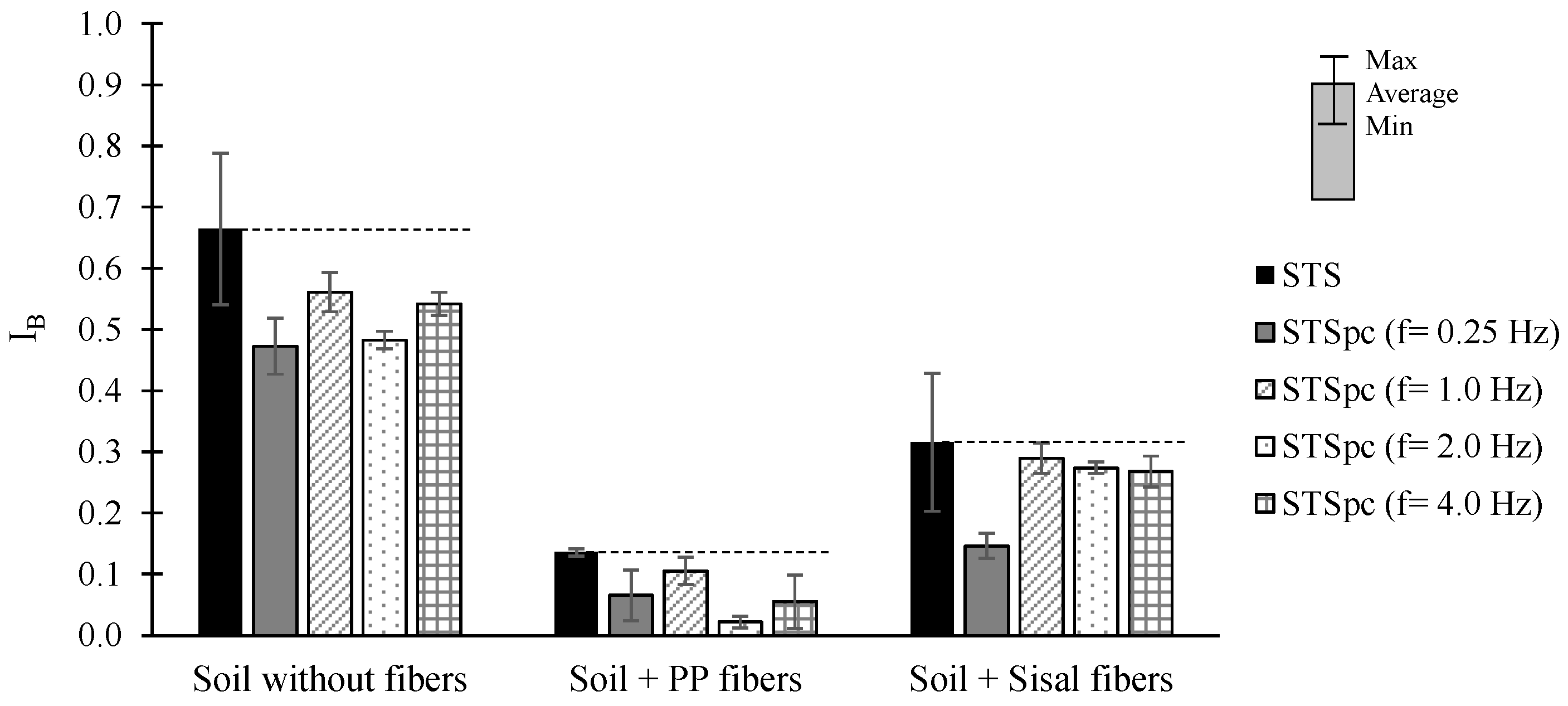

4.3. Tensile Mechanical Behavior

5. Conclusions

- Incorporating fibers into the stabilized sandy soil confers a ductile tensile behavior, which is characterized by a double-peak tensile strength and a noticeable residual tensile strength. This behavior results from a progressive mobilization of fibers crossing the vertical failure surface imposed by the splitting tensile strength tests.

- A higher number of fibers inside the stabilized matrix (associated with PP fibers) results in a higher probability of the fibers crossing the vertical failure plane. This induces a decrease in the stresses applied to the fibers and a better stress redistribution inside the composite matrix, which allows a more pronounced ductile tensile behavior.

- During the cyclic stage, the incorporation of fibers and the increase in loading frequency led to a reduction in accumulated plastic axial displacement. On average, the accumulated plastic axial displacement decreased by 28% for polypropylene fibers and 14% for sisal fibers. The frequency dependent behavior is explained by the fact that, for higher frequency levels (4.0 Hz), there is a larger portion of elastic deformation due to the limited displacement mobility and a higher degree of reversibility in deformation due to a decrease in the shear/breakage of cementation bonds (i.e., lower deterioration of the cemented matrix).

- In terms of maximum tensile strength, the cyclic loading makes sisal fibers a more effective reinforcement than PP fibers due to the greater mechanical characteristics of sisal fibers (higher tensile strength, stiffness, and roughness). The plastic axial displacements induced during the cyclic stage are sufficient to define small vertical cracks. This makes it possible to mobilize the tensile strength of sisal fibers (high stiffness and roughness) from the beginning of the post-cyclic STS test, thus leading to a greater tensile strength. Indeed, it was observed that the post-cyclic tensile strength of sisal fibers increased by 23% to 51%, compared to an increase of 1% to 16% for PP fibers.

- The frequency level of the cyclic loading does not have a clear tendency regarding the post-cyclic tensile strength behavior, which seems to be related to the materials’ mechanical properties (cemented matrix and fibers).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Cyc | cyclic stage |

| D0 | sample’s initial diameter |

| F | load (N) |

| fct | maximum tensile strength (Pa) |

| IB | brittleness index |

| PP | polypropylene fiber |

| STS | splitting tensile strength test |

| STSpc | post-cyclic splitting tensile strength test |

| Δδcyc-perm | variation in the axial or vertical displacement of the sample during the cyclic stage |

| δf | displacement at failure (%) |

| δperm | cumulative plastic displacement or permanent displacement (%) |

References

- Liu, J.; Bu, F.; Bai, Y.; Chen, Z.; Kanungo, D.P.; Song, Z.; Wang, Y.; Qi, C.; Chen, J. Study on engineering properties of sand strengthened by mixed fibers and polyurethane organic polymer. Bull. Eng. Geol. Environ. 2020, 79, 3049–3062. [Google Scholar] [CrossRef]

- Jiang, H.; Cai, Y.; Liu, J. Engineering Properties of Soils Reinforced by Short Discrete Polypropylene Fiber. J. Mater. Civ. Eng. 2010, 22, 1315–1322. [Google Scholar] [CrossRef]

- Li, H.; Senetakis, K.; Khoshghalb, A. On the small-strain stiffness of polypropylene fibre-sand mixtures. Geosynth. Int. 2019, 26, 66–80. [Google Scholar] [CrossRef]

- Liu, C.Y.; Lv, Y.; Yu, X.; Wu, X. Effects of freeze-thaw cycles on the unconfined compressive strength of straw fiber-reinforced soil. Geotext. Geomembr. 2020, 48, 581–590. [Google Scholar] [CrossRef]

- Yixian, W.; Panpan, G.; Shengbiao, S.; Haiping, Y.; Binxiang, Y. Study on Strength Influence Mechanism of Fiber-Reinforced Expansive Soil Using Jute. Geotech. Geol. Eng. 2016, 34, 1079–1088. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Pradhan, P.K.; Kar, R.K.; Naik, A. Effect of Random Inclusion of Polypropylene Fibers on Strength Characteristics of Cohesive Soil. Geotech. Geol. Eng. 2012, 30, 15–25. [Google Scholar] [CrossRef]

- Lirer, S.; Flora, A.; Consoli, N.C. On the Strength of Fibre-Reinforced Soils. Soils Found. 2011, 51, 601–609. [Google Scholar] [CrossRef]

- Silva dos Santos, A.P.; Consoli, N.C.; Baudet, B.A. The mechanics of fibre-reinforced sand. Géotechnique 2010, 60, 791–799. [Google Scholar] [CrossRef]

- Consoli, N.C.; Casagrande, M.D.; Coop, M.R. Effect of Fiber Reinforcement on the Isotropic Compression Behavior of a Sand. J. Geotech. Geoenviron. Eng. 2005, 131, 1434–1436. [Google Scholar] [CrossRef]

- Kanchi, G.M.; Neeraja, V.S.; Babu, G.L.S. Effect of Anisotropy of Fibers on the Stress-Strain Response of Fiber-Reinforced Soil. Int. J. Geomech. 2015, 15, 06014016. [Google Scholar] [CrossRef]

- Tang, C.S.; Wang, D.Y.; Cui, Y.J.; Shi, B.; Li, J. Tensile strength of fiber-reinforced soil. J. Mater. Civ. Eng. 2016, 28, 04016031. [Google Scholar] [CrossRef]

- Li, H.; Senetakis, K. Dynamic properties of polypropylene fibre-reinforced silica quarry sand. Soil Dyn. Earthq. Eng. 2017, 100, 224–232. [Google Scholar] [CrossRef]

- Orakoglu, M.E.; Liu, J.; Niu, F. Dynamic behavior of fiber-reinforced soil under freeze-thaw cycles. Soil Dyn. Earthq. Eng. 2017, 101, 269–284. [Google Scholar] [CrossRef]

- Festugato, L.; Consoli, N.C.; Fourie, A. Cyclic shear behaviour of fibre-reinforced mine tailings. Geosynth. Int. 2015, 22, 196–206. [Google Scholar] [CrossRef]

- Güllü, H.; Khudir, A. Effect of freeze–thaw cycles on unconfined compressive strength of fine-grained soil treated with jute fiber, steel fiber and lime. Cold Reg. Sci. Technol. 2014, 106, 55–65. [Google Scholar] [CrossRef]

- Hasanzadeh, A.; Shooshpasha, I. Influences of silica fume particles and polyethylene terephthalate fibers on the mechanical characteristics of cement-treated sandy soil using ultrasonic pulse velocity. Bull. Eng. Geol. Environ. 2021, 81, 14. [Google Scholar] [CrossRef]

- Ghadakpour, M.; Fakhrabadi, A.; Janalizadeh Choobbasti, A.; Soleimani Kutanaei, S.; Vafaei, A.; Taslimi Paein Afrakoti, M.; Eisazadeh, N. Effect of post-construction moisture condition on mechanical behaviour of Fiber-reinforced-cemented-sand (FRCS). Geomech. Geoengin. 2022, 17, 1852–1864. [Google Scholar] [CrossRef]

- Haghighatjoo, S.M.; Zolfegharifar, S.Y. Effects of fibre type and content on unconfined compressive strength of fibre-reinforced lime or cement-stabilised soils. Geomech. Geoengin. 2022, 17, 1962–1972. [Google Scholar] [CrossRef]

- Olgun, M. Effects of polypropylene fiber inclusion on the strength and volume change characteristics of cement-fly ash stabilized clay soil. Geosynth. Int. 2013, 20, 263–275. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Jamsawang, P. Use of steel and polypropylene fibers to improve flexural performance of deep soil–cement column. Constr. Build. Mater. 2012, 29, 201–205. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Venda Oliveira, P.J.; Custódio, D.G. Effect of polypropylene fibres on the compressive and tensile strength of a soft soil, artificially stabilised with binders. Geotext. Geomembr. 2015, 43, 97–106. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Correia, A.A.S.; Teles, J.M.N.P.C.; Custódio, D.G. Effect of fibre type on the compressive and tensile strength of a soft soil chemically stabilised. Geosynth. Int. 2016, 23, 171–182. [Google Scholar] [CrossRef]

- Consoli, N.C.; Moraes, R.R.; Festugato, L. Split tensile strength of monofilament polypropylene fiber-reinforced cemented sandy soils. Geosynth. Int. 2011, 18, 57–62. [Google Scholar] [CrossRef]

- Consoli, N.C.; Moraes, R.R.; Festugato, L. Parameters Controlling Tensile and Compressive Strength of Fiber-Reinforced Cemented Soil. J. Mater. Civ. Eng. 2013, 25, 1568–1573. [Google Scholar] [CrossRef]

- Consoli, N.C.; Moraes, R.R.; Festugato, L. Variables controlling strength of fibre-reinforced cemented soils. Proc. Inst. Civ. Eng.—Ground Improv. 2013, 166, 221–232. [Google Scholar] [CrossRef]

- Consoli, N.C.; Vendruscolo, M.A.; Fonini, A.; Rosa, F.D. Fiber reinforcement effects on sand considering a wide cementation range. Geotext. Geomembr. 2009, 27, 196–203. [Google Scholar] [CrossRef]

- Park, S.S. Unconfined compressive strength and ductility of fiber-reinforced cemented sand. Constr. Build. Mater. 2011, 25, 1134–1138. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, D. Behavior of cement-stabilized fiber-reinforced pond ash, rice husk ash–soil mixtures. Geotext. Geomembr. 2016, 44, 466–474. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Venda Oliveira, P.J.; Teles, J.M.N.P.C.; Pedro, A.M.G. Strength of a stabilised soil reinforced with steel fibres. Proc. Inst. Civ. Eng.—Geotech. Eng. 2017, 170, 312–321. [Google Scholar] [CrossRef]

- Akbari, H.R.; Sharafi, H.; Goodarzi, A.R. Effect of polypropylene fiber inclusion in kaolin clay stabilized with lime and nano-zeolite considering temperatures of 20 and 40 °C. Bull. Eng. Geol. Environ. 2021, 80, 1841–1855. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Correia, A.A.S.; Teles, J.M.N.P.C.; Pedro, A.M.G. Effect of cyclic loading on the behaviour of a chemically stabilised soft soil reinforced with steel fibres. Soil Dyn. Earthq. Eng. 2017, 92, 122–125. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Correia, A.A.S.; Cajada, J.C.A. Effect of the type of soil on the cyclic behaviour of chemically stabilised soils unreinforced and reinforced with polypropylene fibres. Soil Dyn. Earthq. Eng. 2018, 115, 336–343. [Google Scholar] [CrossRef]

- Chauhan, M.S.; Mittal, S.; Mohanty, B. Performance evaluation of silty sand subgrade reinforced with fly ash and fibre. Geotext. Geomembr. 2008, 26, 429–435. [Google Scholar] [CrossRef]

- Yang, C.; Cui, Y.J.; Pereira, J.M.; Huang, M.S. A constitutive model for unsaturated cemented soils under cyclic loading. Comput. Geotech. 2008, 35, 853–859. [Google Scholar] [CrossRef]

- Viana da Fonseca, A.; Rios, S.; Amaral, M.F.; Panico, F. Fatigue Cyclic Tests on Artificially Cemented Soil. Geotech. Test. J. 2013, 36, 1–9. [Google Scholar] [CrossRef]

- Subramaniam, P.; Banerjee, S. Factors affecting shear modulus degradation of cement treated clay. Soil Dyn. Earthq. Eng. 2014, 65, 181–188. [Google Scholar] [CrossRef]

- Sharma, S.S.; Fahey, M. Degradation of Stiffness of Cemented Calcareous Soil in Cyclic Triaxial Tests. J. Geotech. Geoenviron. Eng. 2003, 129, 619–629. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Anunciação, G.R.; Correia, A.A.S. Effect of Cyclic Loading Frequency on the Behavior of a Stabilized Sand Reinforced with Polypropylene and Sisal Fibers. J. Mater. Civ. Eng. 2022, 34, 06021008. [Google Scholar] [CrossRef]

- Festugato, L.; Fourie, A.; Consoli, N.C. Cyclic shear response of fibre-reinforced cemented paste backfill. Géotechnique Lett. 2013, 3, 5–12. [Google Scholar] [CrossRef]

- Dall’Aqua, G.P.; Ghataora, G.; Ling, U. Behaviour of fibre-reinforced and stabilized clayey soils subjected to cyclic loading. Stud. Geotech. Et Mech. 2010, 32, 3–16. [Google Scholar]

- Khattak, M.J.; Alrashidi, M. Durability and mechanistic characteristics of fiber reinforced soil–cement mixtures. Int. J. Pavement Eng. 2006, 7, 53–62. [Google Scholar] [CrossRef]

- Maher, M.H.; Ho, Y.C. Behavior of Fiber-Reinforced Cemented Sand Under Static and Cyclic Loads. Geotech. Test. J. 1993, 16, 330–338. [Google Scholar] [CrossRef]

- Ahmed, A.; Naggar, M.H. Effect of cyclic loading on the compressive strength of soil stabilized with bassanite–tire mixture. J. Mater. Cycles Waste Manag. 2018, 20, 525–532. [Google Scholar] [CrossRef]

- Yasuhara, K.; Yamanouchi, T.; Hirao, K. Cyclic Strength and Deformation of Normally Consolidated Clay. Soils Found. 1982, 22, 77–91. [Google Scholar] [CrossRef]

- Zhou, J.; Gong, X. Strain degradation of saturated clay under cyclic loading. Can. Geotech. J. 2001, 38, 208–212. [Google Scholar] [CrossRef]

- Moses, G.G.; Rao, S.N.; Rao, P.N. Undrained strength behaviour of a cemented marine clay under monotonic and cyclic loading. Ocean Eng. 2003, 30, 1765–1789. [Google Scholar] [CrossRef]

- Nguyen, L.D.; Fatahi, B.; Khabbaz, H. A constitutive model for cemented clays capturing cementation degradation. Int. J. Plast. 2014, 56, 1–18. [Google Scholar] [CrossRef]

- Wang, K.; Zhuang, Y. Characterizing the permanent deformation Response-Behavior of subgrade material under cyclic loading based on the shakedown theory. Constr. Build. Mater. 2021, 311, 125325. [Google Scholar] [CrossRef]

- Yang, D.; Zhuang, X.; Tao, G.; Li, X.; Fang, J. Cumulative plastic strain and shakedown analysis in loess subgrades under intermittent loads. Soil Dyn. Earthq. Eng. 2025, 190, 109224. [Google Scholar] [CrossRef]

- Abdullah, H.H.; Shahin, M.A.; Walske, M.L.; Karrech, A. Cyclic behaviour of clay stabilised with fly-ash based geo-polymer incorporating ground granulated slag. Transp. Geotech. 2021, 26, 100430. [Google Scholar] [CrossRef]

- ASTM-D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 1998.[Green Version]

- EN-197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization: Brussels, Belgium, 2000.[Green Version]

- Taylor, H. Cement Chemistry; Thomas Telford: London, UK, 1997. [Google Scholar][Green Version]

- Goulart, D.S. Influence of the Fiber Type in the Mechanical Behavior of a Cemented Sandy Soil Under Static and Dynamic Actions. Master’s Thesis, Univ. of Coimbra, Coimbra, Portugal, 2020. [Google Scholar][Green Version]

- Carvalho, R.; Fangueiro, R.; Neves, J. Durability of Natural Fibers for Geotechnical Engineering. Key Eng. Mater. 2014, 634, 447–454. [Google Scholar] [CrossRef]

- Xie, Q.; Li, F.; Li, J.; Wang, L.; Li, Y.; Zhang, C.; Xu, J.; Chen, S. A new biodegradable sisal fiber–starch packing composite with nest structure. Carbohydr. Polym. 2018, 189, 56–64. [Google Scholar] [CrossRef]

- Chand, N.; Hashmi, S.A.R. Mechanical properties of sisal fibre at elevated temperatures. J. Mater. Sci. 1993, 28, 6724–6728. [Google Scholar] [CrossRef]

- Agboola, O.; Sadiku, E.R.; Popoola, P.; Fayomi, O.S.I.; Ayeni, A.O.; Dick, D.T.; Adegbola, A.T.; Moropeng, L.; Ramakhokhovhu, M. Surface roughness of ternary blends: Polypropylene/chitosan/sisal fiber membranes. Mater. Today Proc. 2021, 38, 2342–2346. [Google Scholar] [CrossRef]

- Silveira, M.V.; Casagrande, M.D.T. Effects of Degradation of Vegetal Fibers on the Mechanical Behavior of Reinforced Sand. Geotech. Geol. Eng. 2021, 39, 3875–3887. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Studies on the durability of natural fibres and the effect of corroded fibres on the strength of mortar. Cem. Concr. Compos. 2005, 27, 575–582. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, k. Durability of alkali-sensitive sisal and coconut fibres in ce-ment mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Zhao, L.; Zhu, S.; Wu, H.; Liang, H.; Liu, C.; Liu, W.; Zhou, W.; Song, Y. The improved resistance against the degradation of sisal fibers under the environment of cement hydration by surface coating of graphene oxide (GO) based membranes. Con-Struction Build. Mater. 2021, 205, 124694. [Google Scholar] [CrossRef]

- Wei, J.; Ma, S.; Thomas, D.G. Correlation between hydration of cement and durability of natural fiber-reinforced cement composites. Corros. Sci. 2016, 106, 1–15. [Google Scholar] [CrossRef]

- Klerk, M.D.; Kayondo, M.; Moelich, G.M.; Villiers, W.I.; Combrinck, R.; Boshoff, W.P. Durability of chemically modified sisal fibre in cement-based composites. Constr. Build. Mater. 2020, 241, 117835. [Google Scholar] [CrossRef]

- EuroSoilStab. Development of design and construction methods to stabilise soft organic soils: Design guide soft soil stabilisation. In Industrial and Materials Technologies Programme (Brite-EuRam III); European Commission: Brussels, Belgium, 2001; p. 94. [Google Scholar][Green Version]

- Correia, A.A.S. Applicability of Deep Mixing Technique to the Soft Soil of Baixo Mondego. PhD Thesis, Univ. of Coimbra, Coimbra, Portugal, 2011. [Google Scholar][Green Version]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key Parameters for Strength Control of Artificially Cemented Soils. J. Geotech. Geoenviron. Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- EN-13286-42; Unbound and Hydraulically Bound Mixtures. Test Method for the Determination of the Indirect Tensile Strength of Hydraulically Bound Mixtures 2011. European Committee for Standardization: Brussels, Belgium, 2011.[Green Version]

- NBR-7222; Concrete and Mortar—Determination of the Tension Strength by Diametrical Compression of Cylindrical Test Specimens. ABNT—Brazilian Association of Technical Standards: Rio de Janeiro-RJ, Brazil, 2011.[Green Version]

- EN-12390-6; Testing Hardened Concrete. Tensile Splitting Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2011.[Green Version]

- Wang, T.; Ye, J.; Zhu, C. Effect of Bi-modulus characteristic on the Brazilian disc test: Insights from numerical study. Int. J. Rock Mech. Min. Sci. 2023, 169, 105447. [Google Scholar] [CrossRef]

- Ye, J.; Wu, F.Q.; Sun, J.Z. Estimation of the tensile elastic modulus using Brazilian disc by applying diametrically op-posed concentrated loads. Int. J. Rock Mech. Min. Sci. 2009, 46, 568–576. [Google Scholar]

- Ye, J.H.; Wu, F.Q.; Zhang, Y.; Ji, H.G. Estimation of the bi-modulus of materials through deformation measurement in a Brazilian disk test. Int. J. Rock Mech. Min. Sci. 2012, 52, 122–131. [Google Scholar] [CrossRef]

- Milliken, W.F.; Milliken, D.L. Race Car Vehicle Dynamics; SAE international: Warrendale, PA, USA, 1995; Volume 400. [Google Scholar][Green Version]

- EN-13286-7; Unbound and Hydraulically Bound Mixtures—Part 7: Cyclic Load Triaxial Test for Unbound Mixtures. European Committee for Standardization: Brussels, Belgium, 2004.[Green Version]

- EN-206-1; Concrete—Part 1: Specification, Performance, Production and Conformity. European Committee for Standardization: Brussels, Belgium, 2007.[Green Version]

- Duong, N.T.; Satomi, T.; Takahashi, H. Potential of corn husk fiber for reinforcing cemented soil with high water content. Constr. Build. Mater. 2021, 271, 121848. [Google Scholar] [CrossRef]

- Consoli, N.C.; Arcari Bassani, M.A.; Festugato, L. Effect of fiber-reinforcement on the strength of cemented soils. Geotext. Geomembr. 2010, 28, 344–351. [Google Scholar] [CrossRef]

- Huang, K.; Ma, Q.; Ma, D. Effect of Basalt Fiber on Static and Dynamic Mechanical Properties of Metakaolin-Based Cement Clay. Adv. Civ. Eng. 2020, 1359163. [Google Scholar] [CrossRef]

- Hernández-Olivares, F.; Barluenga, G.; Bollati, M.; Witoszek, B. Static and dynamic behaviour of recycled tyre rubber-filled concrete. Cem. Concr. Res. 2002, 32, 1587–1596. [Google Scholar] [CrossRef]

- Shao, S.; Khonsari, M.M.; Wang, J.; Shamsaei, N.; Li, N. Frequency dependent deformation reversibility during cyclic loading. Mater. Res. Lett. 2018, 6, 390–397. [Google Scholar] [CrossRef]

- Yao, X.; Huang, G.; Wang, M.; Dong, X.Q. Mechanical Properties and Microstructure of PVA Fiber Reinforced Cemented Soil. KSCE J. Civ. Eng. 2021, 25, 482–491. [Google Scholar] [CrossRef]

| Type of Fibers | Type of Test | Monotonic Stage | Cyclic Stage—Frequency (Hz) | |||

|---|---|---|---|---|---|---|

| 0.25 | 1.0 | 2.0 | 4.0 | |||

| Unreinforced | STS | 2 | -- | -- | -- | -- |

| Cyc | -- | 2 | 2 | 2 | 2 | |

| STSpc | -- | 2 | 2 | 2 | 2 | |

| Polypropylene fibers (10 kg/m3) | STS | 2 | -- | -- | -- | -- |

| Cyc | -- | 2 | 2 | 2 | 2 | |

| STSpc | -- | 2 | 2 | 2 | 2 | |

| Sisal fibers (10 kg/m3) | STS | 2 | -- | -- | -- | -- |

| Cyc | -- | 2 | 2 | 2 | 2 | |

| STSpc | -- | 2 | 2 | 2 | 2 | |

| Portland Cement Type I 42.5 R * | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO (%) | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | SO2 (%) | MgO (%) | K2O (%) | Na2O (%) | ||

| 62.88 | 19 | 5.15 | 3.19 | 3.14 | 2.16 | 1.29 | 0.1 | ||

| Fibers | |||||||||

| L (mm) | D (mm) | L/D (-) | fct (MPa) | E (GPa) | Surface Texture Roughness & | Biodegradability | ρ (g/cm3) | ||

| Polypropylene * | 12 | 32 | 375 | 250 | 3.5–3.9 | Lower | Not biodegradable | 0.905 | |

| Sisal # | 12 | 140 | 86 | 558 | 26 | Higher | Biodegradable | ≈1.4 | |

| Test | Tensile Load, F (N) | ||||

|---|---|---|---|---|---|

| T1 | T2 | Average | Drel * (%) | ||

| Soil without fibers | STS (Monotonic) | 9028.1 | 8855.2 | 8941.7 | 0.97% |

| STSpc (f = 0.25 Hz) | 9310.7 | 8495.9 | 8903.3 | 4.58% | |

| STSpc (f = 1.0 Hz) | 9135.1 | 9804.5 | 9469.8 | 3.53% | |

| STSpc (f = 2.0 Hz) | 7870.4 | 7640.0 | 7755.2 | 1.49% | |

| STSpc (f = 4.0 Hz) | 8438.3 | 9140.6 | 8789.4 | 4.00% | |

| Soil + PP fibers | STS (Monotonic) | 9521.9 | 9519.2 | 9520.5 | 0.01% |

| STSpc (f = 0.25 Hz) | 10,805.8 | 11,370.8 | 11,088.3 | 2.55% | |

| STSpc (f = 1.0 Hz) | 9414.9 | 10,918.3 | 10,166.6 | 7.39% | |

| STSpc (f = 2.0 Hz) | 9568.5 | 9741.4 | 9655.0 | 0.90% | |

| STSpc (f = 4.0 Hz) | 9631.6 | 9639.8 | 9635.7 | 0.04% | |

| Soil + Sisal fibers | STS (Monotonic) | 8737.3 | 8734.5 | 8735.9 | 0.02% |

| STSpc (f = 0.25 Hz) | 10,970.3 | 10,487.5 | 10,728.9 | 2.25% | |

| STSpc (f = 1.0 Hz) | 13,428.2 | 12,937.2 | 13,182.7 | 1.86% | |

| STSpc (f = 2.0 Hz) | 11,431.1 | 11,096.5 | 11,263.8 | 1.49% | |

| STSpc (f = 4.0 Hz) | 11,532.7 | 10,479.3 | 11,006.0 | 4.79% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Correia, A.A.S.; Goulart, D.S.; Venda Oliveira, P.J. Tensile Behavior of a Fiber-Reinforced Stabilized Soil—Cyclic Loading Frequency Study. Appl. Sci. 2025, 15, 8825. https://doi.org/10.3390/app15168825

Correia AAS, Goulart DS, Venda Oliveira PJ. Tensile Behavior of a Fiber-Reinforced Stabilized Soil—Cyclic Loading Frequency Study. Applied Sciences. 2025; 15(16):8825. https://doi.org/10.3390/app15168825

Chicago/Turabian StyleCorreia, António A. S., Daniel S. Goulart, and Paulo J. Venda Oliveira. 2025. "Tensile Behavior of a Fiber-Reinforced Stabilized Soil—Cyclic Loading Frequency Study" Applied Sciences 15, no. 16: 8825. https://doi.org/10.3390/app15168825

APA StyleCorreia, A. A. S., Goulart, D. S., & Venda Oliveira, P. J. (2025). Tensile Behavior of a Fiber-Reinforced Stabilized Soil—Cyclic Loading Frequency Study. Applied Sciences, 15(16), 8825. https://doi.org/10.3390/app15168825