1. Introduction

The H2ELIOS project [

1] is an ambitious initiative to develop an innovative hydrogen storage solution for the aviation sector [

2]. The main idea is to reduce emissions and minimize the environmental impact of the aircraft by developing a lightweight [

3] and cost-effective solution for storing liquid hydrogen, utilizing sustainable polymer-based materials for the tank structure [

3].

In the development of composite cryo-tank technology, the Boeing Company has been building cryo-tanks focused on composite material since 2010. Key design features included one-piece wall construction to minimize overall weight (eliminating the need for a bellyband joint), 3-dimensionally (3D) reinforced y-joint material to alleviate stress concentrations at the tank-to-skirt interface, and a purgeable fluted core skirt to carry high axial launch loads [

4].

Gloyer-Taylor Laboratories Inc. (Tullahoma, TN, USA) [

5], an aerospace engineering research and development company, has announced breakthrough results in its ultra-lightweight cryogenic tanks made from graphite fiber composites and other materials. According to GLT, its cryogenic tanks have demonstrated a huge 75 percent mass reduction when compared to “state-of-the-art aerospace cryo-tanks (metal or composite).”

The AIMEN Technology Centre has achieved a milestone in the field of industrial innovation with the 3D manufacture of an innovative cryogenic tank demonstrator, designed for future applications in the storage of liquid hydrogen (LH

2) in aircraft [

6].

LH2 is a key fuel used for space launchers but is also being developed by Airbus and other aircraft OEMs for zero-emission aviation. When transferring LH2 from a delivery or storage tank to vehicle tanks, NASA [

7] and other entities have reported high losses due to boil-off of the cryogenic liquid to vapor and other issues that still need to be addressed.

The EU, indeed, recognizes hydrogen as a clean fuel with the potential to reduce emissions in the aviation sector, but current technologies limit the use of hydrogen-powered aircraft due to challenges in terms of storage safety, weight, and cost-efficiency.

Airworthiness regulation [

8] must be formulated to support the adoption of hydrogen. Although its gravimetric energy density is 2.5 times [

9] greater than that of kerosene, its volumetric energy density is 4 times lower, leading to larger tanks and posing significant limitations for cost-effectiveness on medium to long-range flights.

The new generation of cryo-tank storage systems must comply with specific analysis [

10]. Integral tanks, which are part of the aircraft’s main structure, seem promising, but existing designs show limitations in the integration with the airframe and insulation capabilities. To address these issues, the study in [

11] proposes the analysis of an integral tank concept featuring a double wall architecture with vacuum insulation and outward-facing structural reinforcements connecting to the fuselage skin. Preliminary results point to fuel containment efficiencies consistent with previous designs, with buckling stability identified as the critical design criterion.

For the new generation of cryogenic composite vessels, additional standards and optimized on-board inspection techniques need to be implemented more than ever.

Due to their complex geometry, sometimes characterized by encapsulated shell assemblies and peculiar material properties, internal, and therefore hidden, defects such as flaws, delamination or joint debonding may occur.

As a result, conventional inspections and maintenance procedures can be very expensive and difficult. For many reasons, among the other extreme pressure and temperature levels, the tank system must be verified both prior to flight and throughout its service life.

Currently, tomography is one of the most used techniques for this kind of analysis. It guarantees a complete and detailed survey but is expensive and time consuming [

12]. There is therefore an industrial demand for the implementation of different, integrated and flight-ready systems.

From a safety and maintenance perspective, an integrated monitoring system working during operational life appears to be a useful tool [

13]. In this sense, the standard regulations require sensors able to work in harsh conditions [

14]: ATEX-certified sensors, preventing embrittlement, exhibiting EM immunity, limiting their impact on weight, reducing the thermal bridge and hydrogen darkening effects.

Currently, many areas foresee a significant growth of fiber optic sensor applications, from medical to civil, aerospace, and industrial applications [

15]. This kind of monitoring architecture is highly desirable for non-destructive assessment for many reasons. Among others, one recalls the capability to resist under chemically aggressive environments, the high integrability, and the characteristic of hosting many sensitive elements on a single fiber. Bragg grating arrays (FBGs) and long-period gratings (LPGs) have been developed during the last decades and allow very accurate sensing. For the most demanding applications, a quasi-continuous sensing technology is available based on Rayleigh backscattering, enabling the monitoring of tens of meters with millimeter-resolution. This kind of system is generally used for monitoring large civil infrastructures such as bridges, railways, and so on [

16].

In this paper, different optical monitoring technologies are analyzed, with the perspective of developing a robust and integrated approach for SHM applications on composite cryo-tanks, particularly during acceptance static pressure tests.

Specifically regarding pressurized tank items, some studies in the literature report the implementation of monitoring systems by using fiber optic sensors. Strain sensors are used to monitor distributed strain in composite overwrapped pressure vessels (COPVs) throughout the manufacturing process until qualification testing [

17]. Sensible elements are embedded along circumferential patterns, at various locations along the structural thickness. Filament-wound cylinders are investigated with multiple layers of carbon fiber, integrated with glass fiber composite on the outer surface for extra durability. Each cylinder is filled with water and pressurized to complete the process.

In [

18,

19], cryogenic y-joint tests validated the performance of distributed optical strain sensing at liquid helium temperatures (around 130 °K). SHM experiments are conducted to explore the durability and survivability of the fiber optic sensor system and related surface bonding techniques through multiple liquid helium temperature excursions and mechanical load cycles. The results on a reduced-scale tank showed that internally bonded strain gauges often failed, while the use of fiber optics sensors seemed a viable method to mitigate the evidenced problems, especially in harsh or extreme environmental conditions.

In [

20], the issue is again faced. Indeed, strict process control is required during bonding operations. The latest non-destructive joint inspection techniques cannot quantify the strength of the bond and only indicate the presence of disbonds or delaminations. Expensive and time-consuming proof-load testing of the joints is required to demonstrate structural performance. This work focuses on experimentally evaluating joint-health monitoring with piezoelectric sensors exposed to repeated loadings until failure.

In order to verify the functionality of fiber optic sensors at cryogenic conditions, several studies have been conducted. In [

21], the authors described the experimental characterization of thermal responses of four commercially available optical fiber samples with different polymeric coatings in the temperature range from 5 K to 300 K: two with acrylate coatings of different thickness, one with a polyimide coating and one with a polyether–ether–ketone (PEEK) coating.

In the present paper, strain acquisition is performed on a representative cylindrical coupon of the target structural system, during bending solicitation up to flaw initiation. The experimental data are processed by specific algorithms, already developed by the authors [

22,

23,

24], considering either quasi-static or dynamic patterns. The aim is to correlate the achieved readouts by means of static and transient features, providing an integral view of the phenomenon driven by the structural defect, and, in the end, to provide a methodology selection with respect to the established target, addressing industrial requirements and issues.

2. Industrial Requirements

The most immediate application of health monitoring would be during flight, and the information provided could also be vital in post-flight analyses to detect anomalies and provide corrections to the design in order to improve reliability, which is the most important parameter, along with cost.

After manufacturing, cryo-tank components are usually required to undergo acceptance pressure tests to simulate the flight environment with appropriate margins and reduce the probability of a structural failure in flight. Such tests usually start with a quasi-static pressurization, and then, if success is involved, large facilities are needed to implement the final functionality test, simulating fully operative conditions.

Thus, monitoring during a test would allow the test engineers to decide to stop the test when an item is revealed to be critical. In the end, no propagation or initiation of defects is allowed during such tests by the relevant standards. To monitor its status, the case is subjected to non-destructive inspections NDIs before and after the test. Such controls are very time-consuming and costly. For this reason, finding signs of defect evolution using the instrumentation involved in the test would have a strong impact on the optimization of the overall production and verification processes. In particular, the LH2 storage concept demonstrator being developed at H2ELIOS [

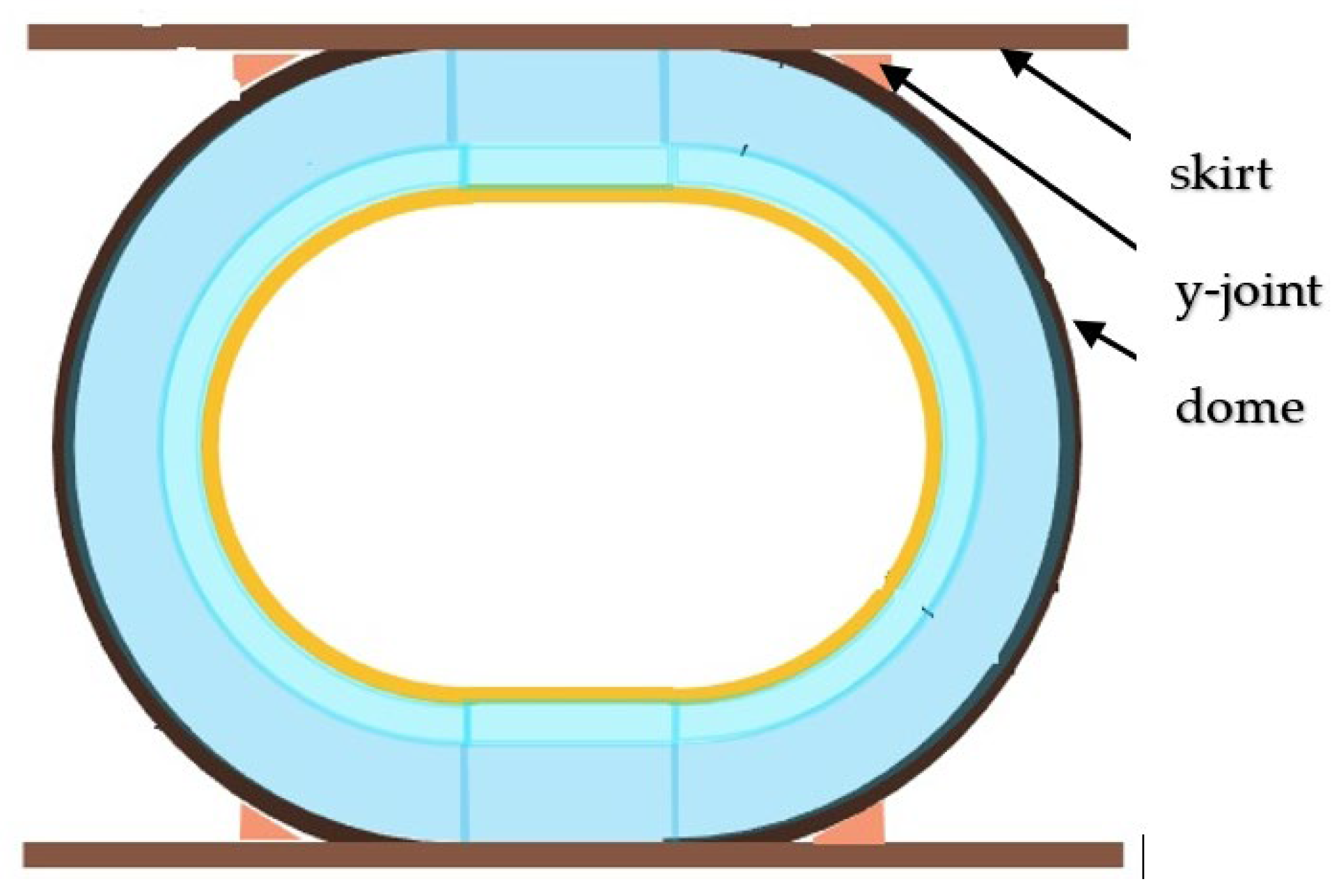

1] (

Figure 1) consists of the following components:

Figure 1.

LH2 storage concept demonstrator being developed at H2ELIOS (patented by ACITURRI) [

1].

Figure 1.

LH2 storage concept demonstrator being developed at H2ELIOS (patented by ACITURRI) [

1].

The test article taken into consideration for the preliminary SHM implementation and functionality verification is representative of the tank’s cylinder material. Typical skirt-cylinder joints are indeed considered as a critical region for flaws onset, and the highest strain variations, during pressurization, are actually expected to solicit the middle section of the cylinder.

The performance requirements for the measurement system specialized for this application are as follows:

Easy and fast application for compliance with industrial applications;

Robustness during process operations and testing;

Negligible losses due to hydrogen darkening;

Atex cables designed for use in hazardous environments where explosive atmospheres may be present;

Distributed measures to detect local variations in strain;

A sample rate that can capture variations in the strain trend;

Handling of a large amount of data, reducing cable routing complexity;

The possibility of embedding the sensor inside the composite material before curing.

The latter requirement is a desirable one: this capability would indeed allow for the monitoring of the tank throughout the production cycle, delivery, and flight. In particular, it would come in handy to intercept anomalies when they occur or to obtain a large amount of direct data from the structure if local failures occur. For this feature to be available, the sensing elements shall not jeopardize the structural performance. Moreover, they shall withstand the very low temperature reached during gaseous H2 filling, and compensation for thermal effects is possible.

3. Test Article Description

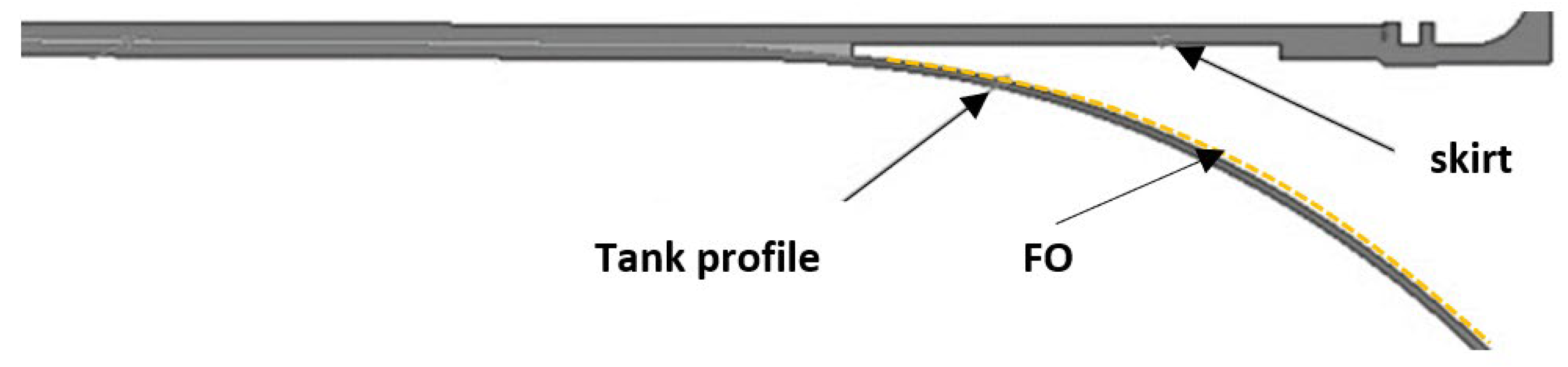

The test articles are representative sections of the cylinder skirt, schematically shown in

Figure 2, in which a typical junction is illustrated, even if this is not a current solution considered in H2ELIOS. The most effective sensor installation method in terms of both time and cost is to bond the fiber on the surface, in the longitudinal direction.

A dedicated test rig,

Figure 3, is designed to apply an incremental bending action to simulate, to some extent, the effects of a pressure solicitation on the cylinder element. In fact, since the external surface is the region of interest of this study, the selected type of load provides an effective means of inducing high-strain levels along the monitored area, where potential flaw emergence and delamination propagation can be observed.

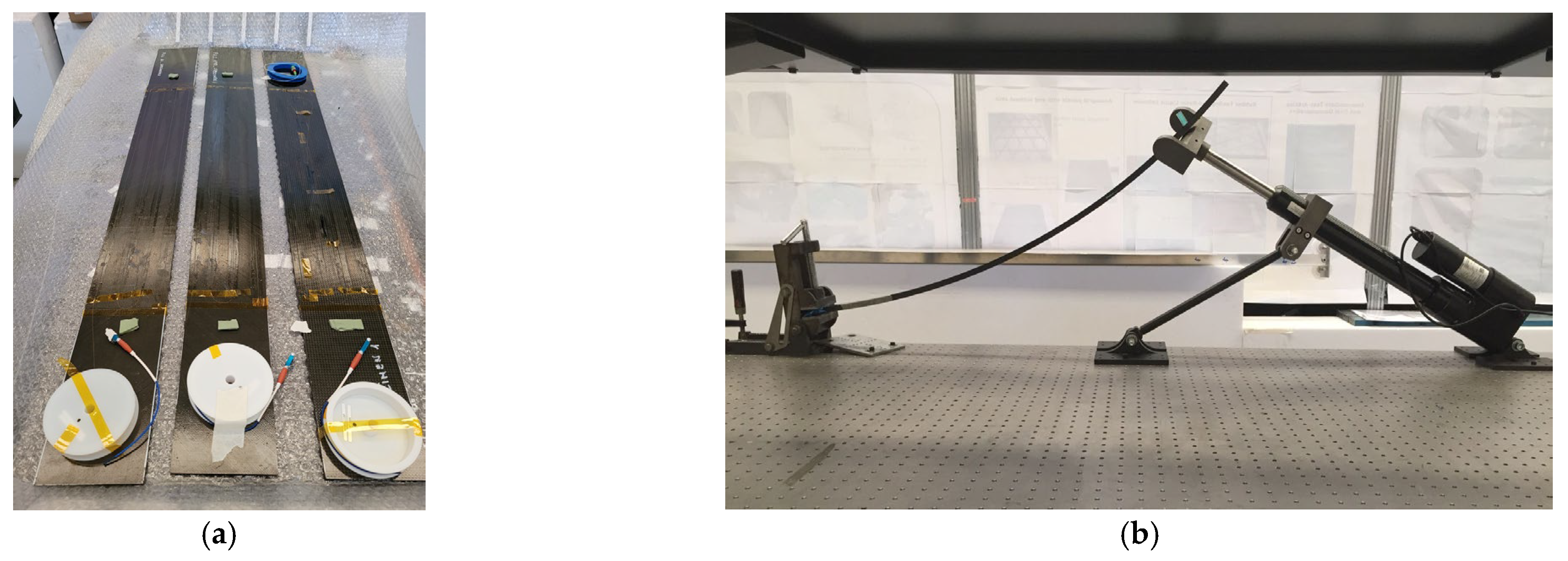

There are three items (

Figure 4a) provided by the manufacturer and sensorized by using fiber optic sensors, both FBGs and distributed, with consistent results. Nevertheless, the damage realized during bending solicitation in two of these items was characterized by negligible energy release to provide a meaningful post-processing analysis. The test article is clamped on one side and driven by a linear actuator at the free edge (HIWIN type LAI2), as shown in

Figure 4b. Strain data are logged at a specific data rate. Specific off-line post-processing techniques are then applied, according to the selected methodology, and the results are evaluated.

3.1. Optical Technologies

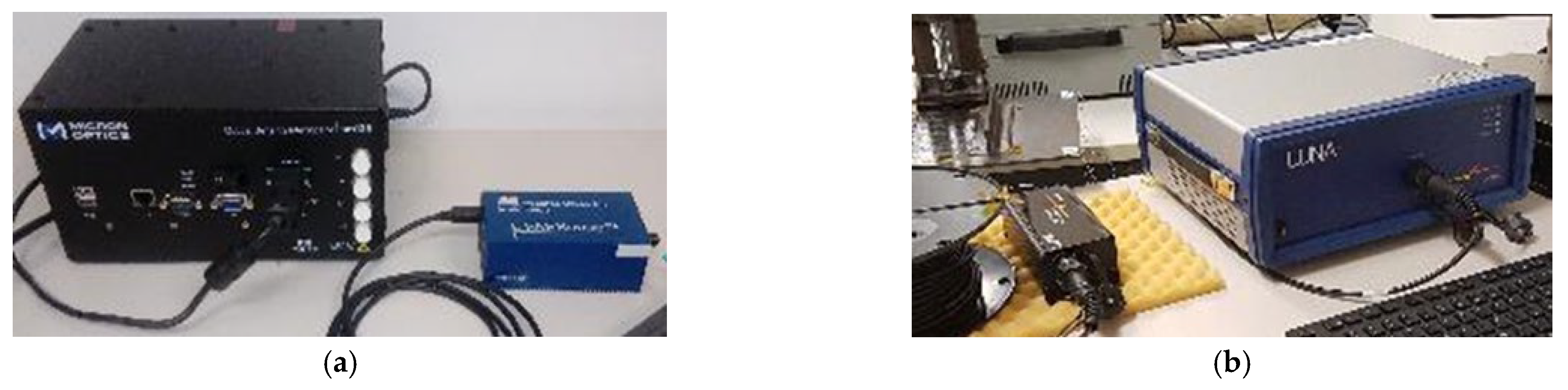

Referring to the experimental setup previously described in

Figure 4b, fiber optic sensors (both FBG and distributed) are used for quasi-static (tens of Hz) and dynamic acquisitions (tens of kHz). The three systems are simultaneously applied during the test in order to achieve signal correlation (

Figure 5a,b).

3.1.1. Fiber Bragg Grating Sensor

The physical principle of the FBG is based on the diffraction occurring from an electromagnetic radiation in accordance with Bragg’s law. It describes the condition for constructive interference from several crystallographic planes of the crystalline lattice separated by a distance d:

where θ is the incident angle,

n is an integer, and λ is the wavelength. The reflected spectrum is centered on the Bragg wavelength and depends on the effective index of refraction and the period (Λ) of the grating, according to the well-known equation:

In the hypothesis of constant temperature, if a local deformation is present, the grating period varies, and the reflected wavelength changes accordingly.

An FBG is bonded close to the clamped edge of the tested curved plate, where the strain achieves the maximum value. Related strain data are logged along the entire test execution by two different sets of instruments. The quasi-static-strain history is saved by an MOI sm-130 interrogator, while time response is monitored by Redondo FAE sense 400 (Redondo Optics, Inc., Corona, CA, USA), characterized by a dynamic bandwidth of tens of kHz. The two data sets are correlated but refer to distinct phenomena: the modification of the structural elastic behavior following an internal crisis, and the structure-borne sound caused by flaws initiation, respectively.

3.1.2. Distributed Fiber Optic Sensor

By contrast, the physical principle at the basis of the distributed sensing is the Rayleigh scattering, which originates from the interaction between the electromagnetic wave propagating in the fiber core and the intrinsic silica impurities. The Rayleigh backscatter profile of a certain optical fiber is correlated with its specific heterogeneous reflective index, distributed randomly along its length (called fiber signature). After an external stimulus (such as strain), the backscatter pattern exhibits a spectral shift that may be used to estimate the occurred deformation field along the fiber itself by a comparison with the reference (original) state. The space resolution of such information (ΔZ) is related to the optical frequency sweep range of the tunable laser source (ΔF) exciting the fiber, as given by Equation (3), where c is the speed of light and n is the fiber refractive index:

In this application, the distributed fiber is again displayed along the main direction of the plate. Strain data are logged during the test execution by the Luna OdisiB interrogator.

3.2. Sensors Performance

Fiber optic sensors are selected as they have well-established advantages. Nevertheless, in this application, the extremely “on the edge” operating conditions of a cryo-tank storing liquid hydrogen during flight would expose to the monitoring system to an extremely harsh environment, potentially explosive, characterized by a temperature window ranging from cryogenic to high temperatures.

For this reason, among the requirements for the selection of specialized sensors, it is mandatory to install devices without affecting the overall gravimetric index, while ensuring safety in a harsh environment and minimizing hydrogen darkening effects, which in turn would produce power losses and signal absence. In [

25], the influence of hydrogen gas on fiber Bragg grating (FBG)-based optical fiber sensors has been validated experimentally. The paper demonstrates that the refractive index changes due to the presence of hydrogen in the micro-holes and its penetration into the fiberglass.

To preliminarily evaluate the sensor’s performance and functionality, the first step is to test the Bragg grating in the presence of gaseous hydrogen. The sensors are put inside a pressurized tank under a hydrogen atmosphere at a pressure of 4 bar. After the filling–emptying cycle, the tank is filled with hydrogen, which is kept inside the tank for approximately 2 days. After this time, the hydrogen is removed from the tank using nitrogen, following the same procedure explained before (filling–emptying cycles).

Absorption may occur at specific wavelengths and is observed as an increase in attenuation. In this case, a pure silica core single-mode fiber with carbon-polyimide coating is specifically designed for hydrogen-rich environments. The silica core prevents photodarkening effects, which are normally associated with germanium-doped fibers [

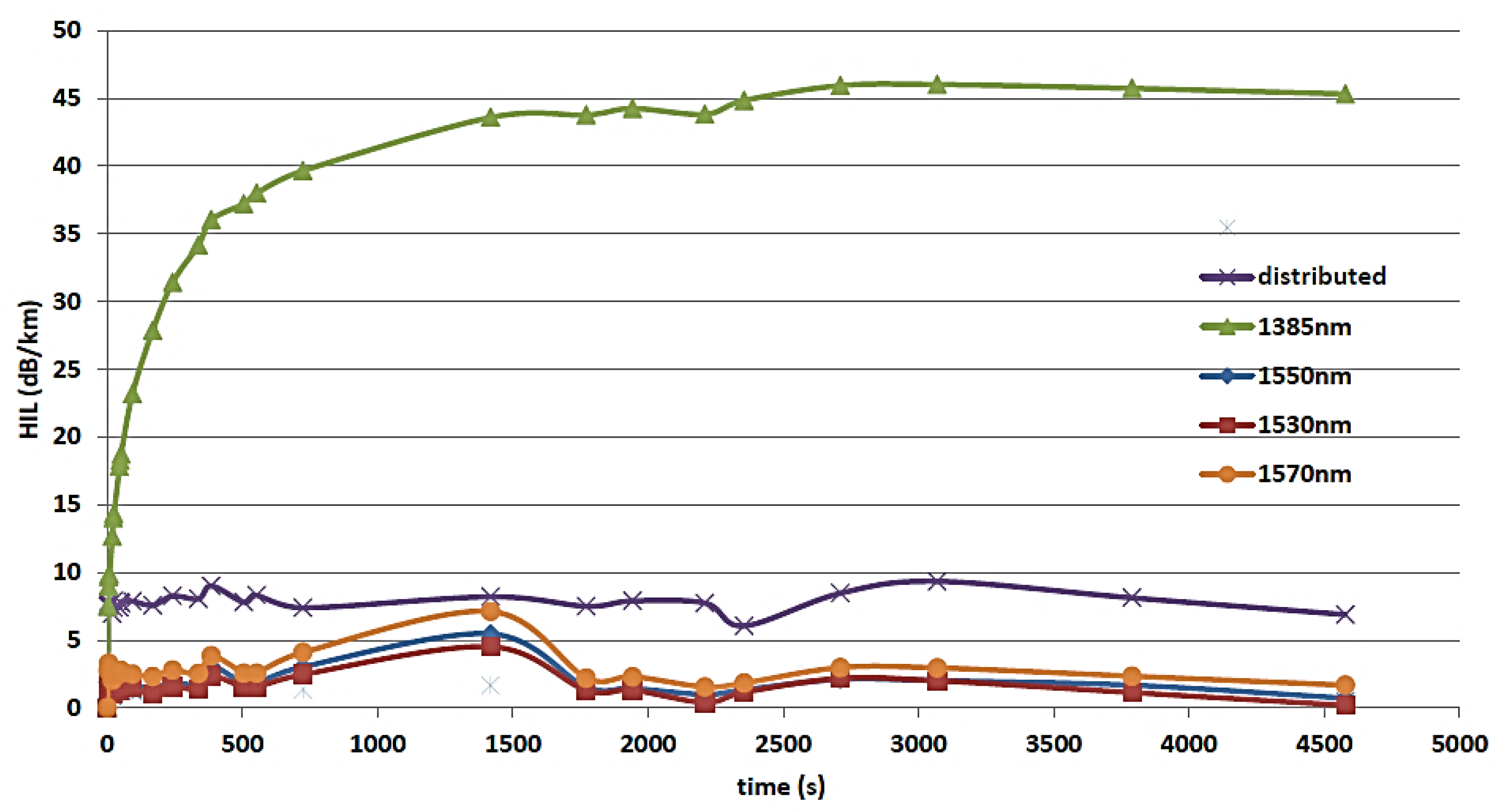

26]. As shown in

Figure 6, the central wavelengths exhibiting lower hydrogen absorption are 1530 nm 1550 nm and 1570 nm for the FBGs, while in the case of distributed fiber, the internal laser module emitted wavelengths swept from 1510 to 1570 nm which is in line with the observation.

The functionality test campaign is then conducted in order to verify the sensing response at specific thermo-mechanical loading conditions, after hydrogen exposure.

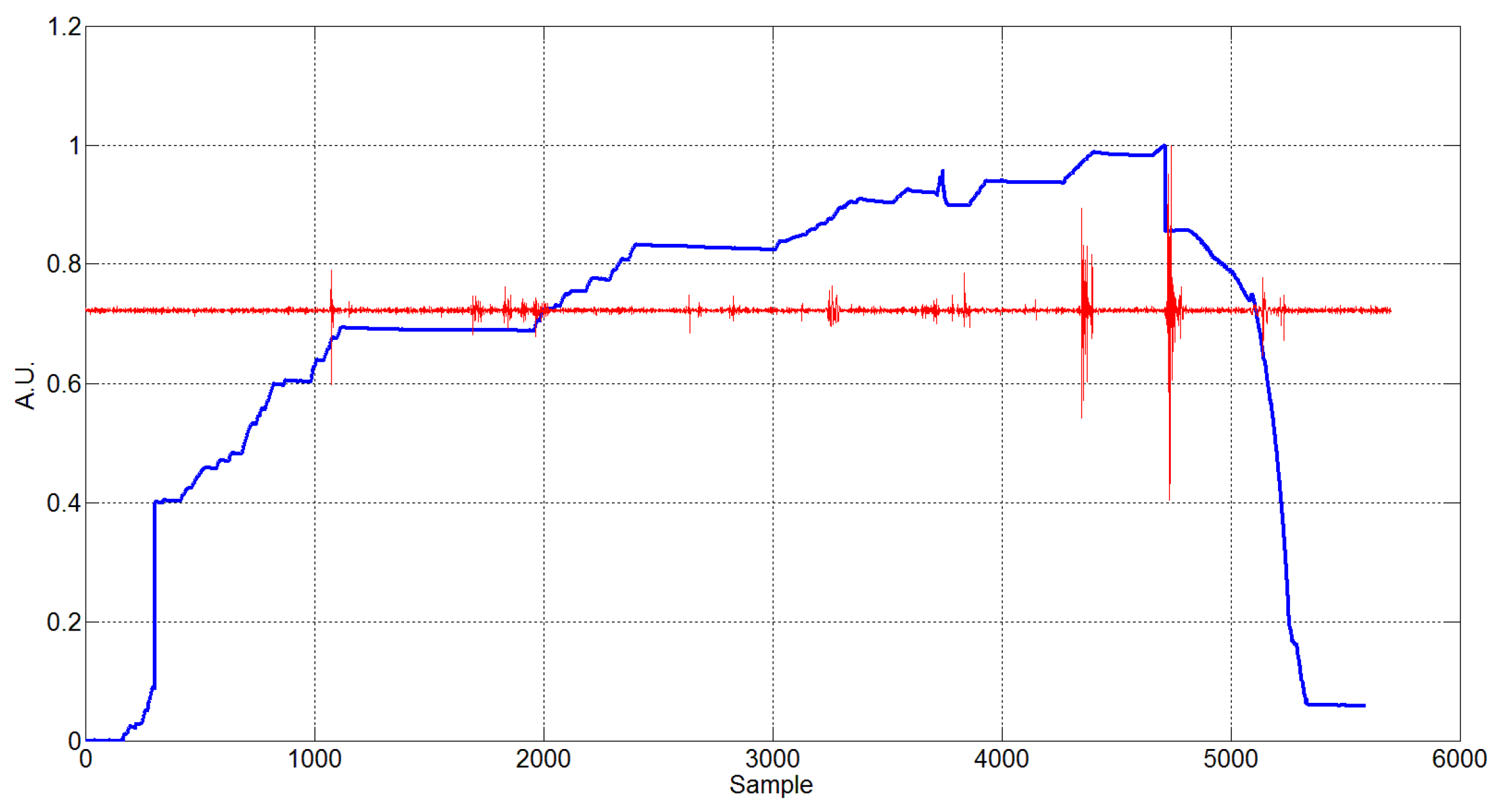

The sensors are tested in a controlled chamber in two steps. First −70 Celsius (

Figure 7a) is targeted. A thermocouple is used as a reference sensor to calibrate the FO output. The fiber optic is left unstrained in the chamber to experience only thermo-optic deformations driven by its CTE (thermal expansion coefficient and refractive index variations). The gauge factor used to convert wavelength to temperature is 10.021 pm/°C, providing a linear response and consistent temperature values concerning the reference. In the second step, the temperature is cooled down to cryogenic conditions to verify the optical signal stability at −160 Celsius again (

Figure 7b) and to simulate the operating working scenario.

At this point, to assess possible measurement deviations or uncertainty recorded before and after these exposures, a simple tension solicitation is applied to the sensors, comparing strain signals before and after both hydrogen conditioning and the cryogenic bath. The strain signal comparison is reported for the FBG (

Figure 8a) and for the distributed fiber (

Figure 8b), showing very good consistency.

5. Conclusions

Damage detection is a complex and crucial operation enhancing the level of safety through the early identification of critical flaws before failure or, alternatively, reducing the design penalty factors in composite structures, required by safety and maintenance regulations. Unfortunately, there is a wide range of damage, each exhibiting specific characteristics. Therefore, techniques that can be suitable for one, often are not, or poorly, applicable to others. Even for a single type of defect, different attributes should be considered, and this cannot be achieved with a single technology. With a focus on fiber optic technologies, different systems, despite their specific limitations, can be highlighted for their ability to access some of the traits, distinguishing features to be correlated and merged, in view of an integrated multi-scenario approach. Experiments are conducted on a representative coupon thermoplastic material from the cylinder element, but the reported concepts may be scaled to full-scale systems.

From this perspective, the non-destructive methods are not taken into consideration, as they cannot be installed on board or operate during the system’s service life, being intended to be used on the ground during scheduled inspections. The SHM system is instead conceived to provide a tool to aid in the real-time detection of structural faults.

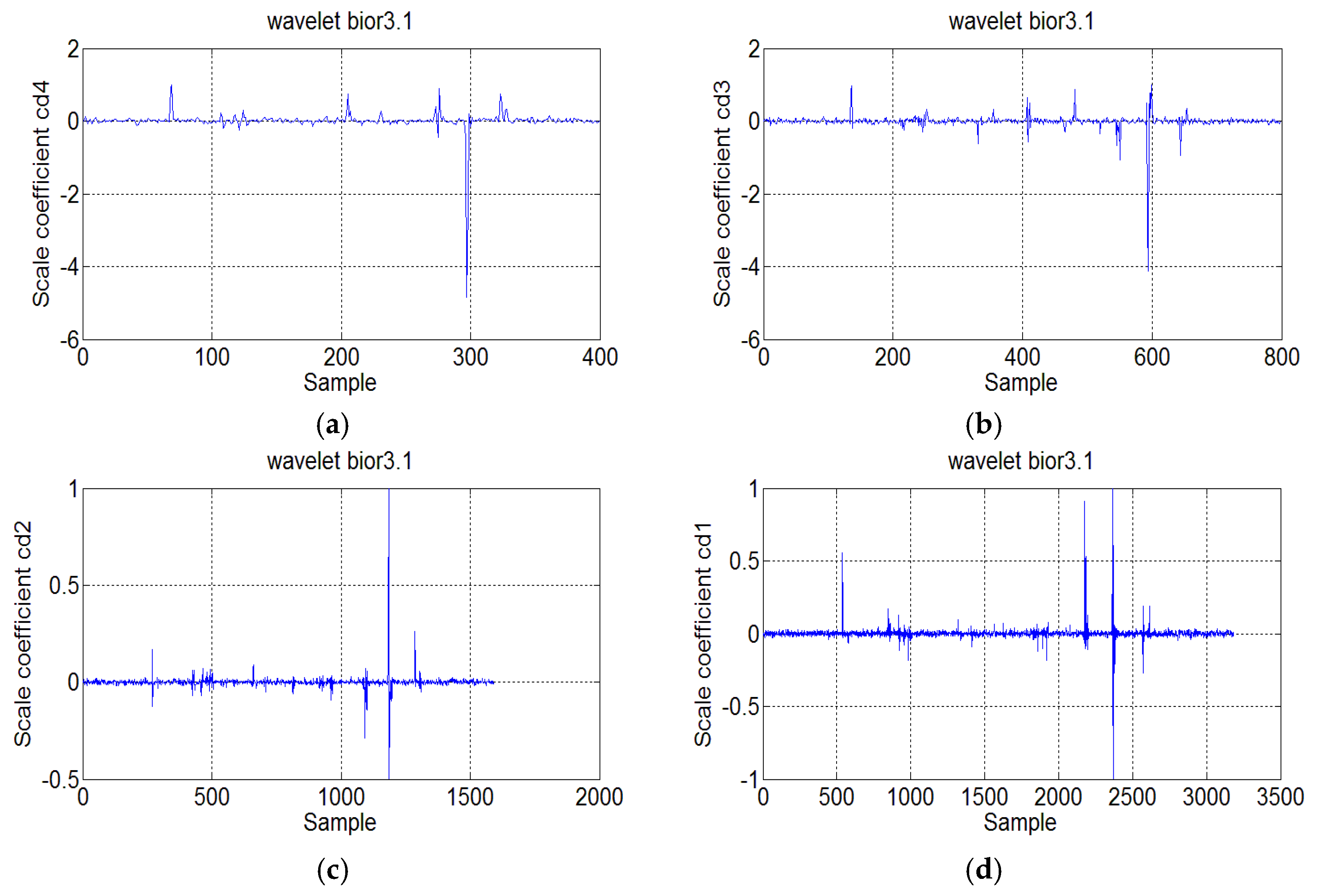

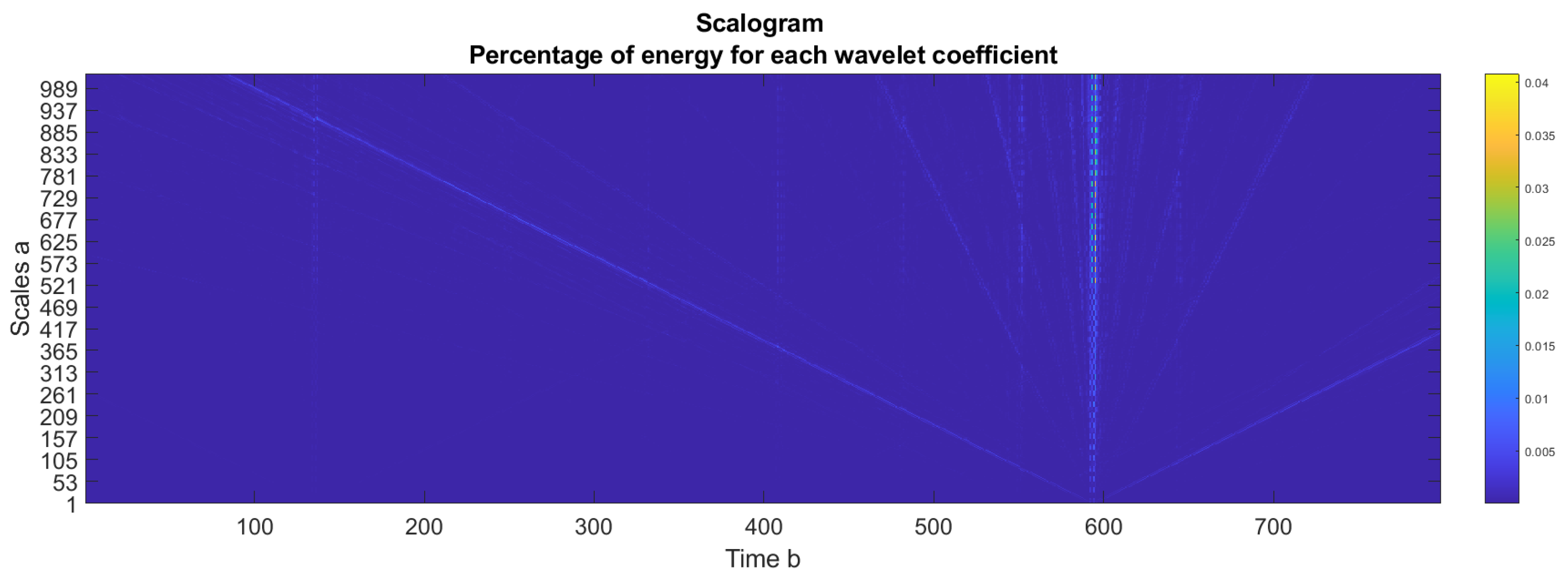

Three different methodologies are investigated in this work: FBG-based sensing, in both static and dynamic configurations, and distributed sensing for static configurations. The distributed sensing technique provides, at different extents, useful information of the strain map, allowing for a structural overview of the region of interest in both the time and space domains. A visual inspection of the tested coupon confirmed the flaw emergence at 34 cm from the clamped edge (located at 3 cm from the origin), as shown in

Figure 15. By comparing the visual inspection with the results of the SHM algorithm (

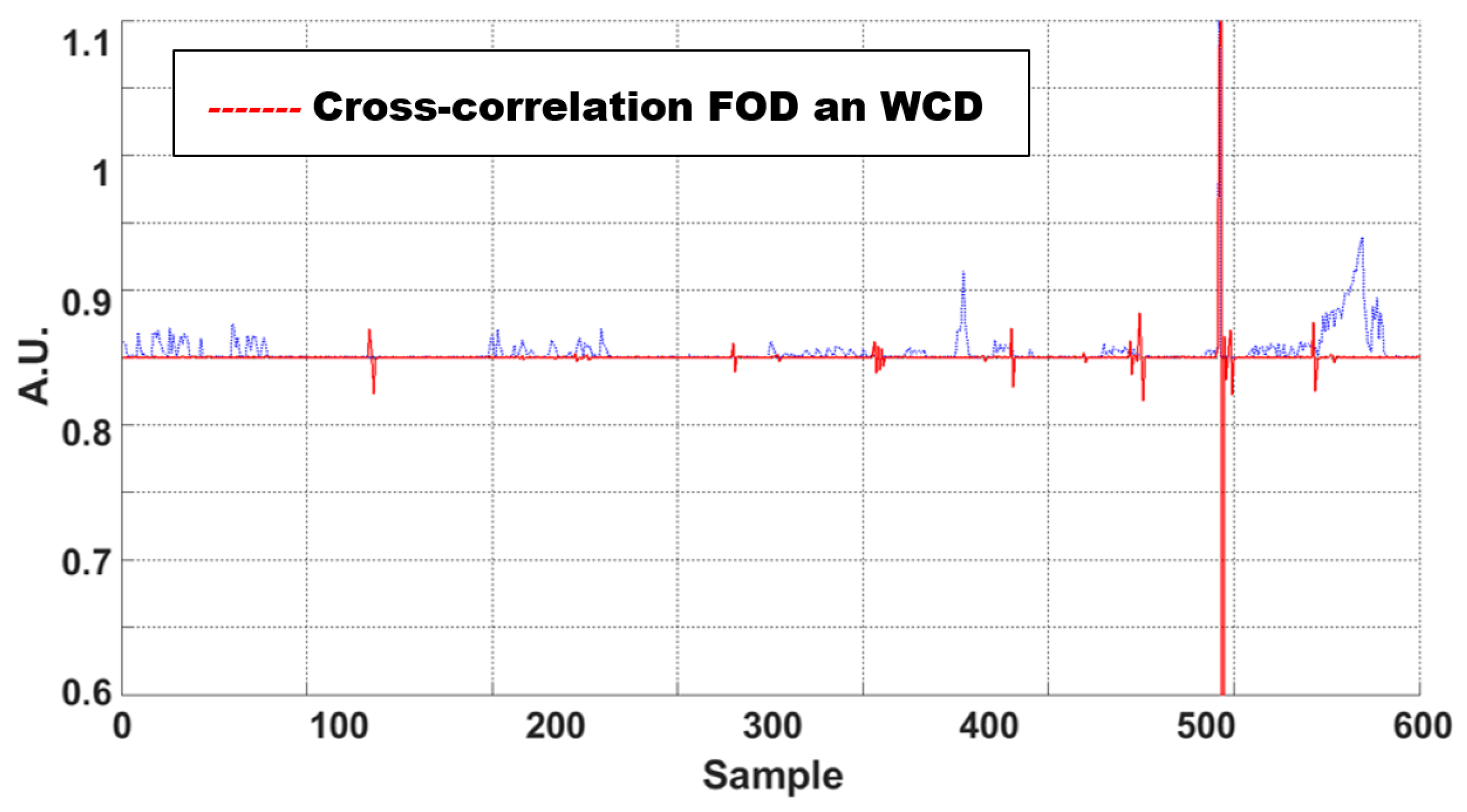

Figure 14), the damage onset is estimated at 1872 mm relative to an origin located at 1544 mm. In addition, the flaw extension can be estimated at 32 mm by fixing its termination at 1904 mm. On the other hand, the FBGs, whether in static or high-dynamic-range configurations, can detect the damage and provide information about its location and evolution in the time domain. Again, the cross-correlation between the two signals allowed the identification of events characterized by a non-negligible energy release, as shown in

Figure 16. In the picture, an anomaly in the processed data makes it possible to understand the instant when the carbon fiber enters the fracture process and the propagation begins.

Table 1 provides a short summary of the different methodologies under the above assumptions, highlighting their main characteristics. In this way, it is believed to offer a preliminary, yet effective tool for better addressing the issue of damage detection. These considerations are not affected by the herein chosen architectures, since this approach can be easily extended to different methodologies, integrating further capabilities.

The current activity is part of an ongoing research project that will end with the full-scale functionality test next year. Mapping damage severity or identifying critical region severity is the focus of the final activity.