1. Introduction

In recent years, resin-based 3D printing has evolved beyond being just a tool for rapid prototyping—it is increasingly being used to produce functional components that are expected to perform under real-world loads. Technologies like masked stereolithography (MSLA) have opened up new possibilities thanks to their ability to create highly detailed and smooth parts at a relatively low cost. However, as this technology advances toward industrial and structural applications, questions about the actual load-bearing capacity of printed parts become increasingly pressing. Factors such as the orientation of the print and how the object is filled internally can make a surprising difference in how the part behaves when put to the test. While there is growing interest in optimizing materials and post-curing techniques, less attention has been paid to how these print settings interact to affect mechanical performance. This research provides a closer examination of this issue, offering practical insights into how orientation and infill choices can significantly impact the durability and efficiency of resin-printed parts.

Junk and Bär [

1] developed detailed design guidelines for mSLA technology, highlighting that excessively thin walls, undercuts, and small holes can lead to significant manufacturing defects. It was noted that incorrect orientation and improper post-curing can lead to deformation or delamination, which directly affects the load-bearing capacity of printed parts [

1].

A broader-spectrum study was conducted by Prabhakar et al. [

2], who investigated the impact of 3D printing processes in three main categories: geometric, process parameters, and structural settings. In particular, their work highlights the influence of raster orientation, infill pattern, and layer thickness on mechanical properties and emphasizes the problem of anisotropy, a key issue in resin systems [

2].

Orzeł and Stecuła [

3], comparing MSLA and FDM technologies, found that MSLA generally provides better surface quality, while FDM can result in more accurate geometric edges. Orientation has emerged as a critical factor in both technologies, especially along the Z-axis, which is prone to layer separation. Similar conclusions were reached by Suryatal et al. [

4], who, in an investigation of their own SLA system, noted that excessively long exposure times and inappropriate orientations can lead to increased dimensional deviations in the Z-direction and structural weakening [

3,

4].

Gaikwad et al. [

5] performed comparative measurements on a benchmark using FDM and MSLA technologies. The MSLA method printed finer details but proved to be more sensitive to geometric distortions in certain directions, especially in the Z direction. Their results confirmed that CAD-STL conversion and orientation are critical points for load-bearing stability [

5].

Mechanical and thermal properties were analyzed by Štaffová et al. [

6] using DMA and HDT measurements, which showed that post-curing time significantly increases the glass transition temperature, elastic modulus, and mesh density of resin-based parts. The printing direction also had a crucial influence on the fracture behavior: parts printed in the X direction showed higher strength, while those printed in the Z direction were more prone to delamination [

6].

Another advance was the work of Ozóg et al. [

7], who fabricated porous biosilicate/carbon composites using MSLA technology, demonstrating that tight control of resin composition, porosity, and heat treatment allows the fabrication of load-bearing porous structures, confirming that, with a suitable printing strategy, resin printing can be used not only for prototyping but also for structural purposes [

7].

An example of an industrial application is provided by Aimon et al. [

8], who utilized TR300 resin for the production of extrusion dies using the MSLA process. The printed elements demonstrated stability under thermal stresses of up to 215 °C, confirming that the printing direction and material choice have a direct impact on applicability [

8].

Measurement techniques based on digital image correlation (DIC) play a key role in testing the mechanical and geometric reliability of resin printing. The GOM ARAMIS system enables non-contact, high-resolution deformation measurements, allowing not only the validation of numerical simulations but also the spatial mapping of the effects of the printing strategy.

Trajković et al. [

9] performed fracture mechanics tests on 3D-printed polyamide specimens of PRNT and SENT types, using the GOM ARAMIS system to monitor crack growth and displacement fields. The measured data were used to plot crack growth curves that were independent of geometric configuration—confirming material-dominated fracture behavior [

9].

A similarly detailed picture was provided by the work of Gljušćić et al. [

10], who investigated CFRTP composites with different fiber orientations. Using the ARAMIS system (GOM, Braunschweig, Germany), they were able to identify not only deformation fields but also damage zones resulting from manufacturing defects (e.g., voids) [

10].

Sabik et al. [

11] investigated the effect of raster direction on fracture behavior on PLA specimens fabricated by FDM technology and validated the accuracy of the finite element models by ARAMIS measurements. The shear behavior at a 45° orientation could only be adequately described by a nonlinear model; the necessary parameters were also obtained from DIC data [

11].

Ivaničić et al. [

12] investigated the mechanical behavior of a topologically optimized 3D-printed cantilever load-bearing element made of PET-G and ABS. The deformation of the printed specimens was measured using the ARAMIS system, and the resulting displacements showed good agreement with the FEA simulations, with deviations ranging from 4% to 12%. The study demonstrated the applicability of DIC measurements in validating the mechanical performance of optimized molds [

12].

Overall, the mechanical reliability of resin 3D printing is highly dependent on the printing direction, layer thickness, resin composition, and post-curing conditions. Digital image correlation measurements with the GOM ARAMIS system provide a reliable solution for accurately mapping the effects of these parameters. The resulting spatial deformation data are crucial for predicting structural performance and validating finite element models, thereby playing a vital role in the development of advanced, load-bearing printed components.

2. Literature Review

The authors prepared a detailed literature review encompassing eight different and relevant fields (see

Section 2.1,

Section 2.2,

Section 2.3,

Section 2.4,

Section 2.5,

Section 2.6,

Section 2.7,

Section 2.8 and

Section 2.9, with

Section 2.9 providing a summary of

Section 2.1,

Section 2.2,

Section 2.3,

Section 2.4,

Section 2.5,

Section 2.6,

Section 2.7 and

Section 2.8).

2.1. Material Innovation in Photopolymer Resin Systems

2.1.1. Hybrid and Reinforced Resins

Hybrid and reinforced resin systems significantly enhance the mechanical properties of photopolymers. Among these advancements, ceramic-filled, fiber-reinforced, and nanoparticle-enhanced resins have shown considerable promise in improving the overall performance of printed parts. For instance, the incorporation of fiber and ceramic materials can increase strength, rigidity, and impact resistance [

13,

14]. Cazin et al. [

15] highlighted that bio-based polyester resins synthesized for vat photopolymerization improve suitability for additive manufacturing by demonstrating successful high-performance applications in various structural forms. Similarly, nanocomposite resins have been explored for their mechanical properties. Alshaikh et al. [

14] found that ZrO

2 nanoparticles significantly improve the mechanical and surface properties of denture-base resins, suggesting the efficiency of nanoparticles in enhancing structural integrity.

Research indicates that incorporating fibers or nanoparticles leads to an enhancement in flexural behavior, which is particularly essential for dental and prosthetic applications [

13]. The mechanical augmentation achieved through such composites is attributed to the synergistic effects of dual-phase systems, where the matrix benefits from the reinforcement introduced by secondary materials [

16,

17].

2.1.2. Biocompatible and Biodegradable Resin Formulations

The development of biocompatible and biodegradable resin formulations addresses the growing demand for environmentally friendly materials in medical applications, particularly dentistry and tissue engineering. The significance of biological compatibility has been addressed in multiple studies, where the reported decrease in cytotoxicity and improved biocompatibility have made these resins appealing for human applications [

18,

19]. Recent advancements have detailed protocols for synthesizing bio-based resins through environmentally sustainable procedures, while achieving the requisite mechanical properties [

20,

21].

Kim et al. [

22] present experiments that highlight the bond strength of pediatric dental restorations using 3D-printed resins, emphasizing their suitability for pediatric applications due to the reduced leaching of harmful substances [

22]. Conversely, research by Al-Amiri et al. suggests significant improvements in gloss stability and hardness, thereby enhancing the longevity of dental applications [

8].

The environmental implications of 3D-printable resins necessitate further inquiry into the degradation and end-of-life options of these materials. More sustainable formulations, as explored by Weng et al. [

23], indicate that engineered photopolymers can decompose into non-toxic components under environmental conditions, potentially reducing their long-term ecological footprint.

2.1.3. Smart/Functional Resins

Smart and functional resins, including self-healing, conductive, and temperature-sensitive materials, are rapidly being integrated into 3D printing technologies, paving the way for the next generation of advanced applications. Notably, self-healing capacity is a compelling development that enables 3D-printed structures to autonomously repair minor damages, significantly enhancing the lifespan and reliability of printed parts [

24,

25].

Research into subject-specific applications for functional resins has led to innovations, such as conductive resins integrated with nanoparticles, which showcase properties suitable for electronic applications [

26]. For example, polyaniline nanofibers and graphene flakes have demonstrated remarkable improvements in conductivity in ABS-like resin composites, enabling emotion-sensitive electronic components [

26].

Additionally, thermal and environmental stimuli-responsive materials have been successfully formulated, offering potential in the realms of adaptive structures and biomedical implants. Studies indicate that such responses to external stimuli can be engineered into resin formulations, ensuring the adaptability of printed structures under varying environmental conditions [

27,

28].

2.2. Process-Induced Defects and Microstructural Characterization

2.2.1. Resin Curing Shrinkage and Microvoid Formation

Curing shrinkage and the subsequent formation of microvoids remain significant challenges in optimizing 3D-printed photopolymer systems. The polymerization process often leads to dimensional inaccuracies, which can be attributed to the volumetric changes that occur when transitioning from a liquid to a solid state [

16,

29]. The introduction of advanced materials, such as modified epoxy–acrylate resins, has shown promise in mitigating the effects of these volumetric changes. Research by Li et al. [

16,

30] substantiates this by demonstrating that modifications can result in decreased curing shrinkage and reduced internal stresses, thus elevating the operational reliability of printed objects.

Furthermore, detailed studies using micro-computed tomography (micro-CT) and scanning electron microscopy (SEM) have been pivotal in characterizing these microstructural defects. These methodologies facilitate an insightful analysis of void distributions and microstructural anomalies, which are critical to understanding the integrity of printed components [

27,

31]. For example, recent advancements in utilizing micro-CT technologies enable non-destructive examinations that reveal internal flaws, informing design and process adjustments in real time [

32,

33].

2.2.2. Internal Stress Development During Polymerization

The development of internal stresses during polymerization is another critical area of inquiry, as these stresses can significantly impact the mechanical properties and durability of 3D-printed parts. The particular kinetics of photopolymerization lead to uneven contraction, which exacerbates the formation of internal stress [

34,

35]. A simulation model developed by Zhao et al. [

29] illustrates how varying energy inputs during light curing can manipulate these stress levels, leading to an optimized polymerization profile.

Further considerations involve the consideration of printing orientations and layer thicknesses, which have direct correlations with the stress distributions within fabricated parts. Research has shown that adaptive approaches to building orientation can help reduce residual stress and improve the mechanical attributes of printed structures [

36,

37]. The comprehensive approach to understanding internal stresses extends to predicting warping behaviors associated with these stress distributions, which can hinder functional applications in critical sectors, such as biomedical device fabrication [

38,

39].

Continual advancements in characterization methodologies, including optical microscopy, further enable detailed assessments of polymerized layers and stress distributions, thus driving improvements in design and process efficiencies [

40,

41].

2.3. Environmental Effects on Resin-Printed Part Performance

2.3.1. Hygroscopic Behavior and Moisture-Induced Swelling

The hygroscopic behavior of photopolymers and its impact on 3D-printed parts is a critical concern, particularly for resin materials utilized in water-exposed environments. Water absorption tends to lead to dimensional changes and compromised mechanical properties, potentially undermining the performance of printed structures. Recent studies have highlighted that 3D-printed resins exhibit higher water sorption rates compared to their traditionally processed counterparts, which consequently affects their integrity and service longevity [

28,

42].

Moisture-induced swelling is often evaluated through experimental methods that focus on dimensional stability and physical properties over time spans under varying humidity conditions. Zhang et al. [

28,

33] report that the water absorption behavior of acrylic-based resins has significant implications for their application in dental restoratives, where reliability under moist conditions is crucial.

Furthermore, attention to moisture impacts results in an increased requirement for hybrid resin formulations that combine traditional and innovative polymers, effectively mitigating swelling through tailored structural reinforcements [

34,

43].

2.3.2. UV Aging and Degradation in Photopolymers

Ultraviolet (UV) degradation significantly affects the longevity and efficacy of photopolymer-based materials. The susceptibility of photopolymers to UV radiation poses challenges in outdoor applications, as UV exposure tends to degrade resin properties, resulting in cracks and discolorations over time [

44,

45]. Warnings regarding the long-term mechanical behavior of photopolymers under UV exposure have been supported by studies demonstrating a decline in flexural strength and mechanical disintegration resulting from repeated UV cycles [

33,

46].

Laboratory studies confirm that UV exposure leads to a decrease in material toughness and elasticity, ultimately impacting their suitability for load-bearing applications. Thus, current research increasingly emphasizes the need to develop UV-stabilized formulations that can overcome such deficiencies and extend the usability of photopolymers in diverse environments [

47,

48].

2.3.3. Long-Term Mechanical Property Decay in Varying Service Environments

The long-term mechanical property decay of resin-printed parts under varying service conditions is a multifaceted challenge. Factors such as thermal cycling, chemical exposure, and prolonged mechanical loading can all lead to the deterioration of printed resins. Studies reveal that post-curing processes are inadequate for completely addressing the mechanical weaknesses that emerge from environmental stressors [

17,

49].

Notably, experimental evaluations have underscored that repeated mechanical loads lead to fatigue failure behaviors in certain photopolymer systems, necessitating a reevaluation of service life expectations for 3D-printed applications. Research into alternative crosslinking agents and fillers is being pursued to enhance resilience against such decay mechanisms, effectively informing the design of more robust and reliable resin formulations [

23,

45].

2.4. Residual Stress and Warping Mechanisms in Resin-Based 3D Printing

2.4.1. Origins and Measurement of Residual Stress During Photopolymerization

Residual stress during photopolymerization has profound implications for the dimensional accuracy and structural integrity of 3D-printed parts. The inherent stresses result from constraints on polymer chain mobility during matrix solidification, leading to warping and discrepancies in the intended geometries [

34,

50]. Advanced measurement techniques, including digital image correlation and thermal imaging, are now being employed to quantify these residual stresses post-printing, thereby enabling a deeper understanding of stress distributions and warp mechanisms [

29,

42].

Moreover, simulation approaches frequently employed in mechanical design can assist in predicting residual stress formation patterns, significantly aiding in fine-tuning build strategies to optimize output quality [

41,

51].

2.4.2. Simulation Models for Curing-Induced Distortions

The use of advanced simulation models to predict curing-induced distortions has become increasingly critical, as they offer predictive capabilities essential for mitigating warping effects. Dynamic models simulate layer-by-layer curing processes, taking into account the heat generated during polymerization and the ensuing volumetric shrinkages. Recent studies highlight how thermal gradients and surface tension dynamics can trigger localized distortions, which can be counteracted through strategic design alterations and optimized printing conditions [

52,

53].

Furthermore, researchers have been utilizing finite element analysis tools to investigate how adjustments in print parameters can simultaneously alleviate internal stresses while improving dimensional fidelity across builds [

36,

38].

2.4.3. Influence of Support Strategies and Build Platform Adhesion

Support strategies have a significant influence on residual stress and warping during the resin printing process. Studies show that inappropriate support structures can exacerbate warping by introducing additional stresses at the layer interfaces [

32,

36]. Innovative support designs and strategies, including adaptive support placements and automated generation based on active stress analysis, have been proposed to enhance part fidelity and minimize the need for post-process correction [

54,

55].

Additionally, enhancing the adhesion characteristics of the build platforms through optimized coating applications has been shown to create improved foundation stability, leading to lower instances of layer separation due to warp-induced tensions [

13,

56].

2.5. Topology Optimization and Lattice Design for Resin-Printed Structures

2.5.1. Design Principles for Optimizing Mechanical Efficiency with Minimal Material

Topology optimization forms the backbone of advanced lattice design strategies, facilitating mechanical efficiency while minimizing material use. Utilizing computational tools, designers can create lightweight structures that maintain strength and functionality, inherently promoting sustainable manufacturing practices through material conservation [

36,

57]. Research demonstrates that dynamic and adaptable lattice designs can significantly reduce the weight of components while ensuring that load-bearing capabilities meet or exceed the standards of traditional solid structures [

52,

58].

The incorporation of topology optimization principles enhances both the strength–weight ratio and overall resource efficiency, effectively responding to economic pressures in production [

24,

33].

2.5.2. Use of Lattice and Cellular Structures to Reduce Weight While Maintaining Strength

The implementation of lattice structures in resin printing establishes a mode of construction that aligns strength with flexibility while addressing weight concerns. Structures designed with cellular architectures benefit from distribution patterns that enable stress diffusion and enhance impact resistance [

13,

59]. This methodology has a significant impact on various applications, particularly in aerospace engineering, where weight savings are paramount to energy efficiency [

25,

60].

Research into optimizing cell geometries further emphasizes the connection between lattice structuring and mechanical performance. By varying void ratios and strut dimensions, it is now possible to adjust mechanical outputs tailored to specific application demands, resulting in enhanced performance across various service conditions [

16,

37].

2.5.3. Integration of Optimization Tools into Resin Printing Workflows

Integrating advanced optimization tools into resin printing workflows promises significant deployment efficiencies as production technology continues to evolve. These tools facilitate design for manufacturability (DfM) principles by allowing designers to simulate functional performance under real-world conditions prior to the physical printing phase [

34,

35]. Leveraging generative design techniques empowers engineers to explore non-conventional geometries and establish innovative cross-sections that traditional design approaches might overlook [

30,

35].

Studies have highlighted the successful applications of such integrated systems across multiple sectors, establishing equitable benefits that enhance adaptation across diverse applications and industries [

33,

61].

2.6. Multi-Scale Modeling of Photopolymer-Based Additive Manufacturing

2.6.1. Coupling of Polymerization Kinetics, Thermal Transport, and Mechanical Modeling

The advancement of multi-scale modeling approaches has become a pivotal development in characterizing the complex interactions between polymerization kinetics, thermal transport, and mechanical properties in photopolymer systems. This coupling enables a deeper understanding of how alterations in thermal energy during the curing process can influence mechanical properties and overall performance [

62,

63].

Research into these attributes facilitates optimization strategies to minimize residual stress and warping issues during the manufacturing of complex geometries while ensuring mechanical integrity [

16,

34]. Such modeling frameworks provide insight into predicting long-term performance, enabling more efficient lifecycle management of 3D-printed parts.

2.6.2. Constitutive Models for Anisotropic Resin Parts

Constitutive modeling strategies aim to understand the anisotropic behaviors exhibited by photopolymer structures due to their layer-dependent mechanical properties. These models enable the accurate capture of discrepancies in stiffness and strength in the X, Y, and Z directions, providing a more reliable basis for predicting structural performance during operation [

24,

64].

Engagement with anisotropic models enhances simulation accuracy and informs design decisions about part architecture based on anticipated force distributions and loading scenarios. This predictive capability serves critical applications where precise mechanical performance is a prerequisite, such as in biomedical devices and aerospace components [

54,

65].

2.6.3. Simulation of Layer-by-Layer Accumulation Effects

Simulating layer-by-layer accumulation effects provides insight into cumulative phenomena that contribute to the final product’s integrity and performance characteristics. Considering the impact of each subsequent layer on the underlying structure is crucial to understanding the full scope of interactions that occur throughout the build process, which influences issues such as interlayer adhesion and overall tensile strength [

61,

62].

This approach emphasizes the importance of iterative simulation methodologies in promoting a responsive design ethos, enabling engineers to refine their structures based on predictive insights that account for both manufacturing variables and environmental factors throughout product lifecycle assessments [

64,

66].

2.7. Standardization and Qualification of Resin 3D Printed Parts

2.7.1. Standards Related to Photopolymer Printing

Standardization efforts through organizations such as ASTM, ISO, and DIN aim to establish essential benchmarks for evaluating and certifying the quality and performance of 3D-printed parts. These standards span various measures, including mechanical properties assessments, dimensional accuracy validation, and biocompatibility testing, ensuring that products meet or exceed industry requirements [

29,

32].

Adherence to such stringent standards fosters trust in the reliability of 3D-printed products, particularly in critical sectors such as aerospace and medical manufacturing, where safety and performance are paramount [

34,

67]. Companies that embrace these guidelines demonstrate proactive engagement with quality management processes, ensuring compliance with international regulatory frameworks while leveraging efficient practices [

28,

68].

2.7.2. Mechanical Test Standardization (Tensile, Flexural, Impact)

Mechanical test standardization across tensile, flexural, and impact testing parameters is crucial for generating consistent and reliable data to evaluate photopolymer resins. Research indicates that standard test conditions significantly influence mechanical outcomes, thereby necessitating uniform testing protocols to allow for direct comparability across studies and applications [

28,

65].

The implementation of such standardized testing not only strengthens industry confidence in material applications but also provides a cohesive framework for further research and development efforts targeting enhanced material formulations and restructured manufacturing processes [

29,

67].

2.7.3. Certification Frameworks for Aerospace, Medical, and Tooling Applications

Establishing robust certification frameworks tailored to specific applications, such as aerospace, medical, and tooling sectors, supports the transition of 3D-printed materials from experimental to mainstream utilization. Such frameworks delineate specific performance criteria and operational parameters that ensure that parts meet rigorous safety standards [

14,

28].

Recent studies have detailed certification pathways that involve thorough validation processes encompassing design verification, operational qualification, and performance validation, paving the way for the wide-scale adoption of novel resin technologies across demanding applications [

54,

69].

2.8. Advancements in In Situ Process Monitoring for Resin 3D Printing

2.8.1. Optical and Thermal Imaging During Layer Deposition

In situ process monitoring utilizing optical and thermal imaging technologies has emerged as an essential advancement in enhancing the quality assurance of resin printing processes. The incorporation of real-time imaging enables the immediate detection of defects during layer deposition, allowing corrective measures to be implemented in real time [

63,

70].

Research has demonstrated that employing these technologies significantly reduces the occurrence of print failures while simultaneously improving the overall dimensional fidelity of printed components [

33,

34]. Continuous data stream analyses facilitate dynamic adjustments to printer settings, improving process yield and ultimately enhancing the reliability and robustness of 3D printing workflows [

27,

52].

2.8.2. UV Photopolymerization Monitoring Systems

Developing UV photopolymerization monitoring systems enhances operational insights during the curing process by evaluating polymerization rates through spectroscopic techniques. These systems can measure light absorption characteristics, allowing for precise adjustments to exposure times and intensities based on real-time feedback on the curing responses of the resin [

49,

71].

The integration of spectroscopic monitoring systems within production workflows establishes a feedback loop, ultimately ensuring higher-quality outcomes and reducing variability in part processing [

18,

59].

2.8.3. Closed-Loop Control in High-Precision Resin Printing

The adoption of closed-loop control mechanisms for high-precision resin printing allows for automated adjustments based on in situ feedback from monitoring systems. Such systems possess the capacity to correlate real-time conditions with software-controlled operational parameters, leading to adaptive printing strategies that optimize process efficiency and reduce error margins [

70,

72].

Critical findings emphasize that closed-loop systems not only augment the manufacturability of complex geometries but also provide enhanced predictive capabilities for maintaining dimensional tolerances throughout the build process [

58,

73].

2.9. Summary of the Literature Review

The literature review (see

Section 2.1,

Section 2.2,

Section 2.3,

Section 2.4,

Section 2.5,

Section 2.6,

Section 2.7 and

Section 2.8) highlights significant advancements in photopolymer resin systems for 3D printing, focusing on material innovation, process-induced defects, environmental effects, and standardization. Hybrid and reinforced resins, such as ceramic-filled and nanoparticle-enhanced formulations, have demonstrated improved mechanical properties, particularly in dental and structural applications [

13,

14,

15]. Biocompatible and biodegradable resins address both environmental and medical needs, with studies showing reduced cytotoxicity and enhanced durability [

18,

19,

22]. Smart resins, including self-healing and conductive variants, enable advanced applications in electronics and adaptive structures [

24,

25,

26].

Process-related challenges, such as curing shrinkage, microvoid formation, and residual stress, significantly impact part performance. Research by Li et al. [

16,

30] and Zhao et al. [

29] explores mitigation strategies, while micro-CT and SEM analyses provide insights into microstructural defects [

27,

31,

32]. Environmental factors, such as hygroscopic behavior and UV degradation, further impact material longevity, necessitating the development of UV-stabilized and moisture-resistant formulations [

28,

33,

44]. Standardization efforts, as outlined in the ASTM and ISO guidelines, ensure reliability in aerospace and medical applications [

29,

32,

34].

Advancements in in situ monitoring, such as optical imaging and closed-loop control systems, enhance print quality and precision [

63,

70,

72]. Multi-scale modeling and topology optimization enhance mechanical efficiency and lightweight design [

36,

57,

62]. Certification frameworks and mechanical testing protocols further validate resin performance for industrial adoption [

14,

28,

54]. Collectively, these developments underscore the potential of photopolymer resins in additive manufacturing, while addressing key challenges in material science and process engineering.

2.10. Identified Research Gap

While resin-based 3D printing is becoming increasingly common for producing functional parts—not just prototypes—there is still a lot we do not know about how basic print settings, such as orientation and infill density, affect their real-world strength. Most existing research focuses on materials, post-curing, or compares different printing technologies, often overlooking how these everyday settings influence mechanical performance in MSLA printing specifically. Even fewer studies examine how these factors interact or utilize high-precision tools, such as digital image correlation (DIC), to track precisely how parts deform under stress. This study helps fill this gap by examining the impact of changes in print angle and internal structure on the behavior of resin-printed parts under load, providing practical insights for both engineers and hobbyists seeking more reliable results from their printers.

The paper is structured as follows:

Section 3 presents the materials and methods,

Section 4 summarizes the results and discussion, and

Section 5 presents the conclusions derived from the results.

3. Materials and Methods

This section describes the resin materials, 3D printers, measuring instruments, and test methods used in the research.

3.1. Materials

To start the experiments, the first step was to select the printing material. Here, Elegoo Standard Resin Colored 1 kg resin was selected for the printing tasks. This is a basic resin and is relatively common for 3D printing with MSLA technology; it is easily available commercially, which was also an important selection criterion. The choice was therefore guided by the main guideline to fabricate the test specimens with a readily available generic material, as the focus of this research is to investigate the impact of different printing strategies. The residual data are summarized in

Table 1.

3.2. Instruments and Methods

For the application of MSLA 3D printing technology, the Elegoo Mars 5 Ultra printer (Elegoo, Shenzhen, China) is available, with the parameters shown in

Table 2. The printer is also a readily available, general-purpose, residential printer that is often used in industrial applications.

Masked stereolithography apparatus (MSLA) printing is a “bottom-lit” form of vat photopolymerization (where liquid resin is stored in a vat form and then solidified layer by layer using light to build a 3D model), where a light source of UV LEDs is “masked” by a large LCD panel. The panel’s pixels act as gate-openers: where a pixel is off, it allows light to pass through; where it is on, it blocks it. In this way, the entire layer pattern generated by the slicer is bound in the resin in a single flash, rather than point by point, as in classical laser SLA.

MSLA printing technology is characterized by the fact that the finished printed product remains resinous due to the immersion method, which necessitates its removal from the surface. Therefore, at the end of the 3D printing process, the printed test pieces must be washed with isopropyl alcohol. Another technological property is that the finished product only reaches its final strength when it is cured by UV light after printing. A general characteristic of resins is that they reach their final mechanical properties when exposed to UV light. Resin manufacturers do not specify an exact curing time because it depends largely on the size, shape, and transparency of the product. Generally speaking, a curing time of 10–15 min is sufficient for test specimens prepared in the experiments. For this purpose, the Elegoo Mercury V3.0 Wash and Cure apparatus (Shenzhen Elegoo Technology Co., Ltd., Shenzhen, China) was used, the main parameters of which are given in

Table 3.

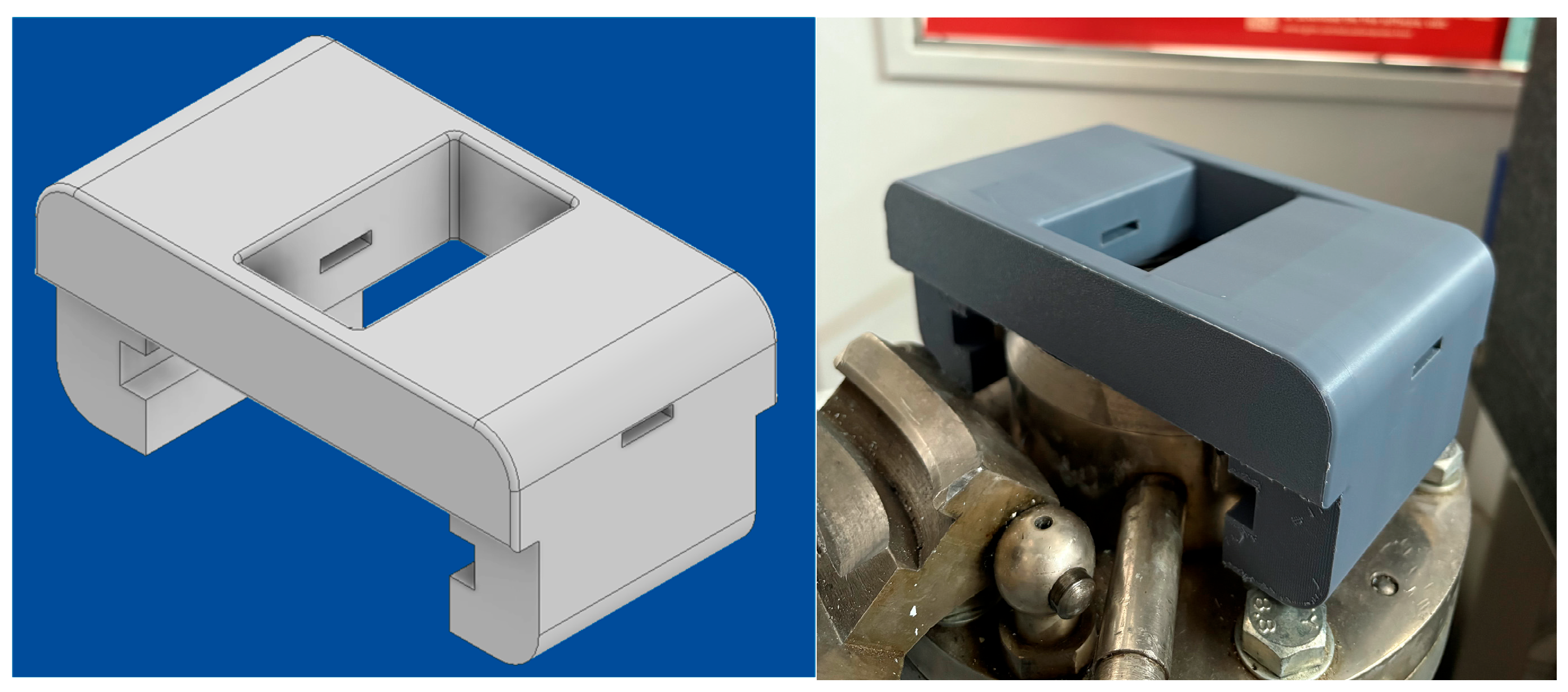

The test specimens were prepared as described above and subjected to mechanical loading. Most literature uses the traditional tensile test or the Charpy impact test. The present research is a more complex application, but it better demonstrates the real stresses that occur in practice. It was inspired by the traditional 3-point bending test and the Erichsen cupping test standard (ISO 20482:2013) [

74]. The Erichsen test is designed for sheet materials and essentially creates biaxial loading, whereas the 3-point bending test creates bending loading. The stresses acting on some products in real-life conditions are also rather complex; therefore, the Erichsen test apparatus has been modified to accommodate the test data. The equipment was modified with a 3D-printed adapter (

Figure 1), and the forming stamp remained the standard 20 mm diameter spherical end tool. This creates biaxial-like stress on the surface due to the spherical tool, which can be interpreted as even more bending stress for small displacements. For simplicity, this test is referred to in this article as the bending test.

For the bending tests, the GOM ARAMIS 5M system was also used to measure the displacements in a non-contact, optical measuring principle. The GOM system is a DIC system, so the specimen surfaces had to be sprayed with a speckle pattern of black paint. For this, United Sealants Matt Black Spray Paint was used. This random speckle pattern becomes measurable using the GOM ARAMIS 5M system, which tracks the displacement and deformation of the speckle pattern during the forming process and calculates the deformation of the specimen based on this data.

3.3. Process

For this research, the first step of 3D printing was to determine the dimensions of the test specimen. Here, the dimensions of the existing equipment were taken into account, and the dimensions of the specimens used in the tensile and bending tests served as a guideline. The dimensions of the specimens were determined to be 120 × 20 × 4 mm. Another important initial step in 3D printing is the selection of the appropriate slicing program. The slicing software Chitubox Basic, a free tool recommended by the manufacturer of the 3D printer and one of the most used in practice (according to all3dp.com), was used here. Frequent use was also important because the main aim of the research was to investigate how software and a strategy that can be set up in an industrial practice would show mechanical behavior.

Besides choosing the slicing software, it is also important to define the experimental matrix. The present research investigates two important settings: the orientation of products on the table and the effect of filling, which is already common in FDM technology but can also be applied in resin printing.

Three test pieces were placed on the printer’s table, with the wider side lying flat. This was the initial condition, and the tilt angles were set relative to this, increasing by 15 degrees up to 90 degrees along the longitudinal side. Importantly, where the software deemed it necessary, an automatic support setting was applied to each orientation angle. This is important because in practice, most users do this, so individual solutions do not significantly affect the experimental results. In preparation for the experiments, a test matrix (

Table 4) was compiled. Therefore, the main focus of the research is to print standard test specimens at different angles relative to the printer table with automatic support settings and then to load these specimens to failure by bending.

Following the first phase of the experiments, the research also examines the effect of changing the orientation of the test pieces. For the different infill tests, the specimens were set up based on the parameters found in Chitubox; the parameters used are shown in

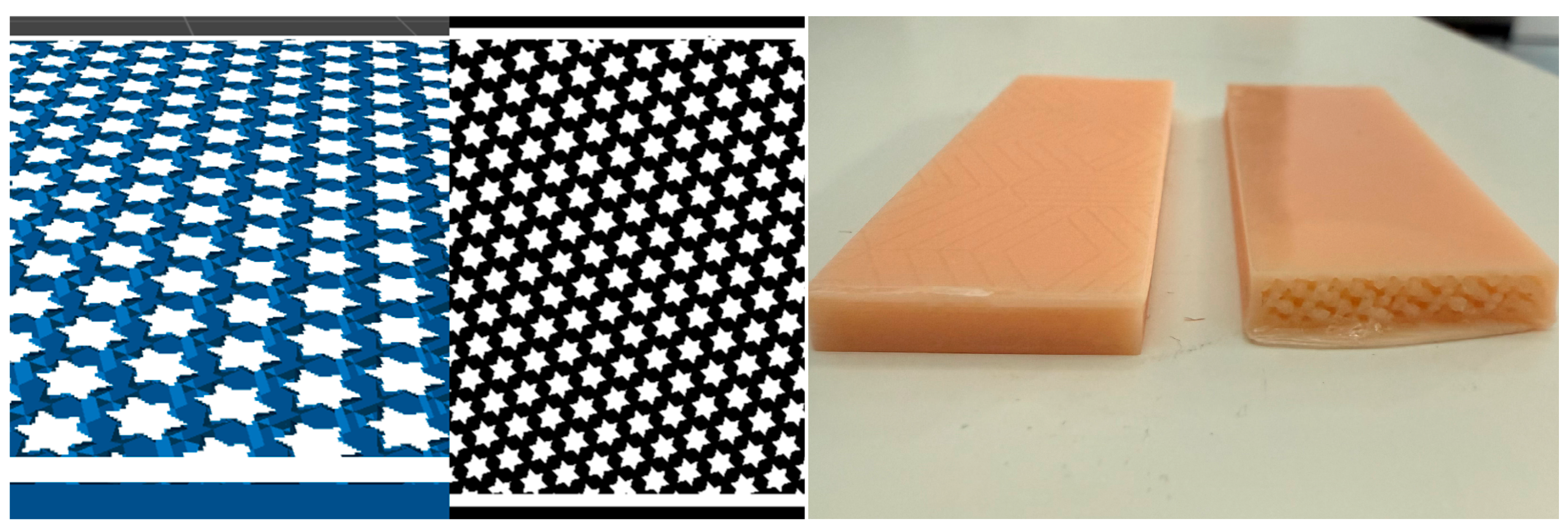

Table 5. The Cross3D infill pattern was used in this research; this pattern is similar to the 3D cross pattern found in FDM technologies. This will result in a material-efficient, slightly flexible in all directions, but stiffer internal grid than the plain “Cross”. An additional advantage of this type is that fewer surfaces need to be cured at a time for each layer, resulting in faster printing. It will provide similar but moderate stiffness in all directions, preventing distortion of the outer walls and resulting in more flexible pieces that are less prone to breakage.

The infill percentages were set as shown in the following experimental matrix (

Table 6), maintaining the 0° orientation (i.e., laid on the plane of the table). This was necessary because this phase of the experiments was intended only to investigate the effect of filling, not the effect of orientation.

The Cross 3D infill is shown in

Figure 2, with a 50% infill density and a wall thickness of 0.5 mm. Here again, it is easy to see how the layers are formed. The grid pattern breaks up the large, continuous surfaces, allowing less air to be trapped during the peel process, thereby reducing the vacuum effect—a common source of failure in resin printing. The vacuum effect, or the peel or suction force resulting from negative pressure, can hold the fresh layer back from the FEP film during Z-axis (table) lifting, potentially leading to damage or even cracking of the FEP film. The FEP film is an important element that separates the liquid resin from the UV display of the printer.

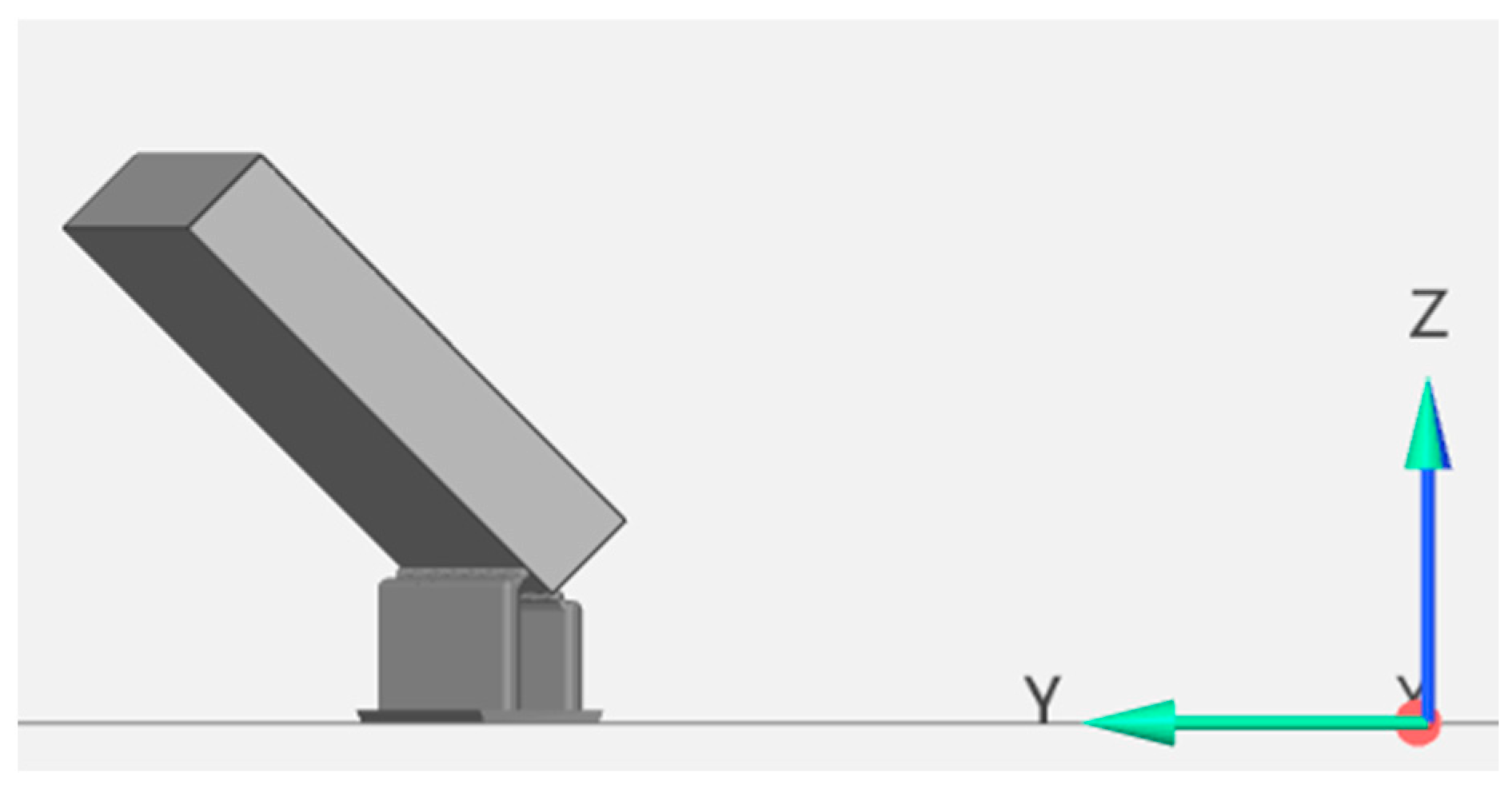

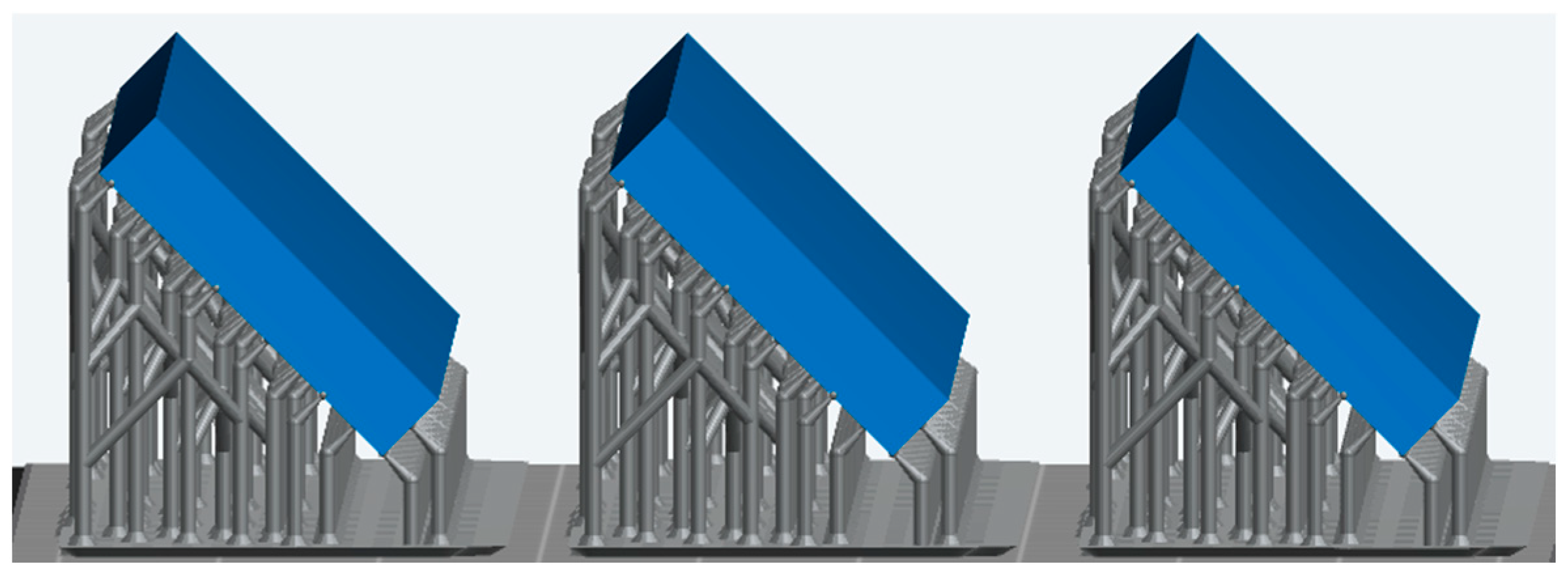

To verify the choice of slicing software, the research also examined other software options. This was important because, among other things, support settings and filling patterns can vary from one software to another, so it is essential to investigate what other solutions exist. Therefore, the support generation was also run using Elegoo’s SatelLite software v1.0.1.11 (see

Figure 3). Test prints were also made in this way, but their print structure did not prove to be flawless in terms of layer stacking; they would come off during printing or result in a highly deformed piece. Therefore, the settings from the Chitubox slicing software were retained (see

Figure 4).

The settings for automatic support generation in Chitubox Basic are as follows. Since the weight of the specimens is not significant for support generation, the Light support setting was used. For this, the software sets the support angle to 43°, the pillar diameter to 1.00 mm, and the connection shape to Cone to 0.91 mm. To ensure the appropriate adhesion of the table, a raft is generated under the pillars. The raft thickness is 0.5 mm, and its shape is a cross-grid.

The specimens prepared from the different matrices required the time and material consumption shown in

Table 7. Each variation is for 3 test specimens, as this is the number of specimens that could be printed on the table. As the specimens with 0° and those with 100% infill have the same parameters, their time and material consumption are listed only once in the table below.

Based on the methods and experimental matrix described in this chapter, the test specimens were printed, cleaned, and finally measured. The results are presented in

Section 4.

4. Results and Discussion

The primary focus of this research was to determine whether print orientation and filling have an impact on the load behavior of printed products in resin 3D printing. This is also an important question because, in addition to the mechanical properties, the material and time consumption of the different alignments vary. The reference value for all evaluations was the test specimen with a 0° orientation and 100% filling, and the results were compared with this value for all the analyses.

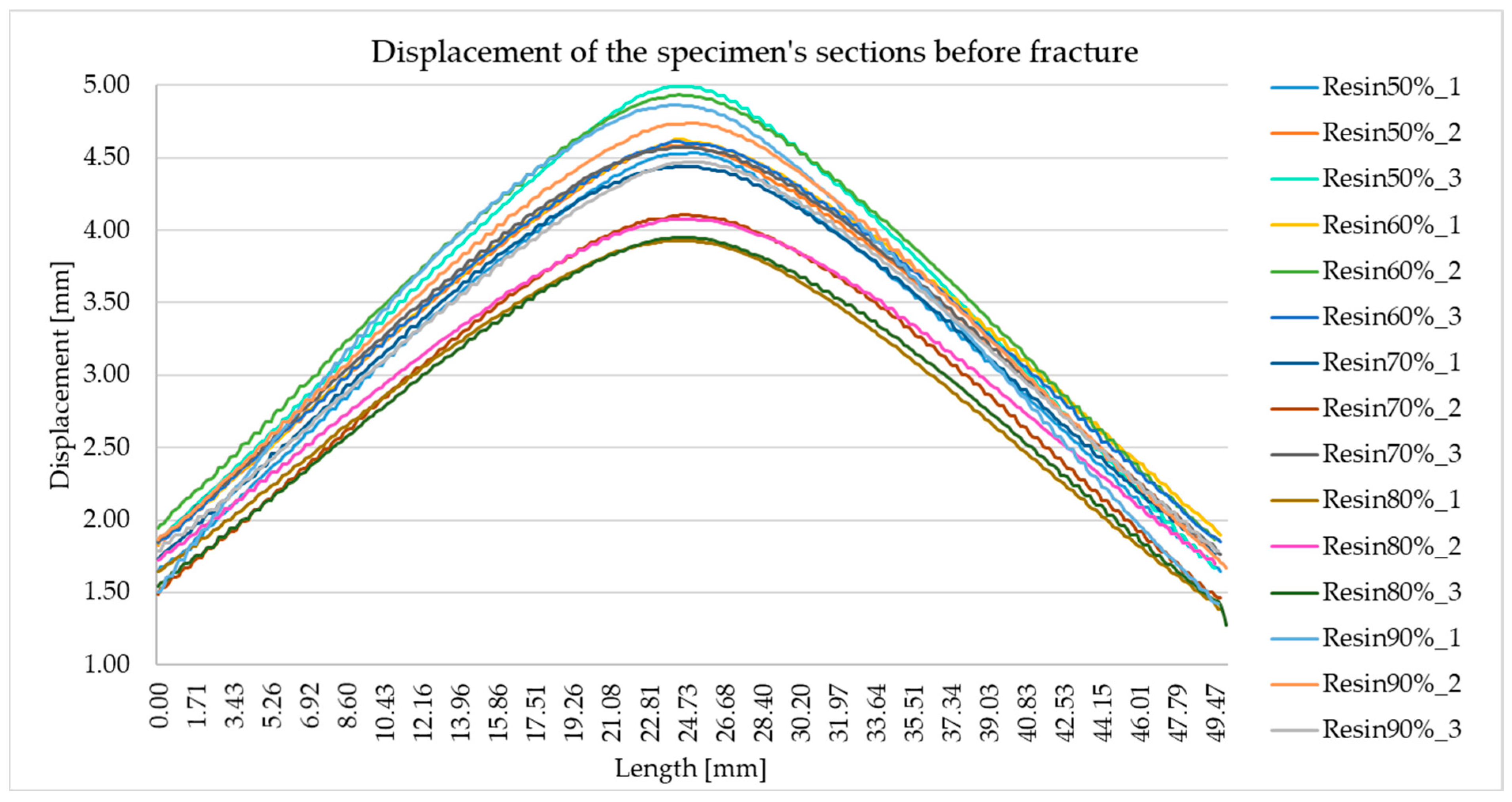

Figure 5 shows the deformation measurement results for the test specimens printed in different orientations, as specified in the experimental matrix. During the tests, the displacement (deformation) produced by the forming action of the punch was recorded because these data reveal the possible differences between the specimens more clearly; this evaluation approach is customary in DIC analyses.

The measurement results are clearly visible, and pronounced differences can be identified between the specimens printed in different orientations. It can be seen that as the inclination angle increases, the attainable deformation rises steadily. At a 60° tilt, however, the deformation is 7% lower than the reference value. This is linked to the observation that, around 60°, the slicing software first changes its automatic support-generation settings. At still higher tilts, the deformation grew by 19.11% and 9.32%, respectively.

These findings clearly demonstrate that the choice of build orientation has a significant impact on the deformation that can be achieved. The data also show that a 75° orientation is optimal, yielding up to a 20% increase compared with the reference.

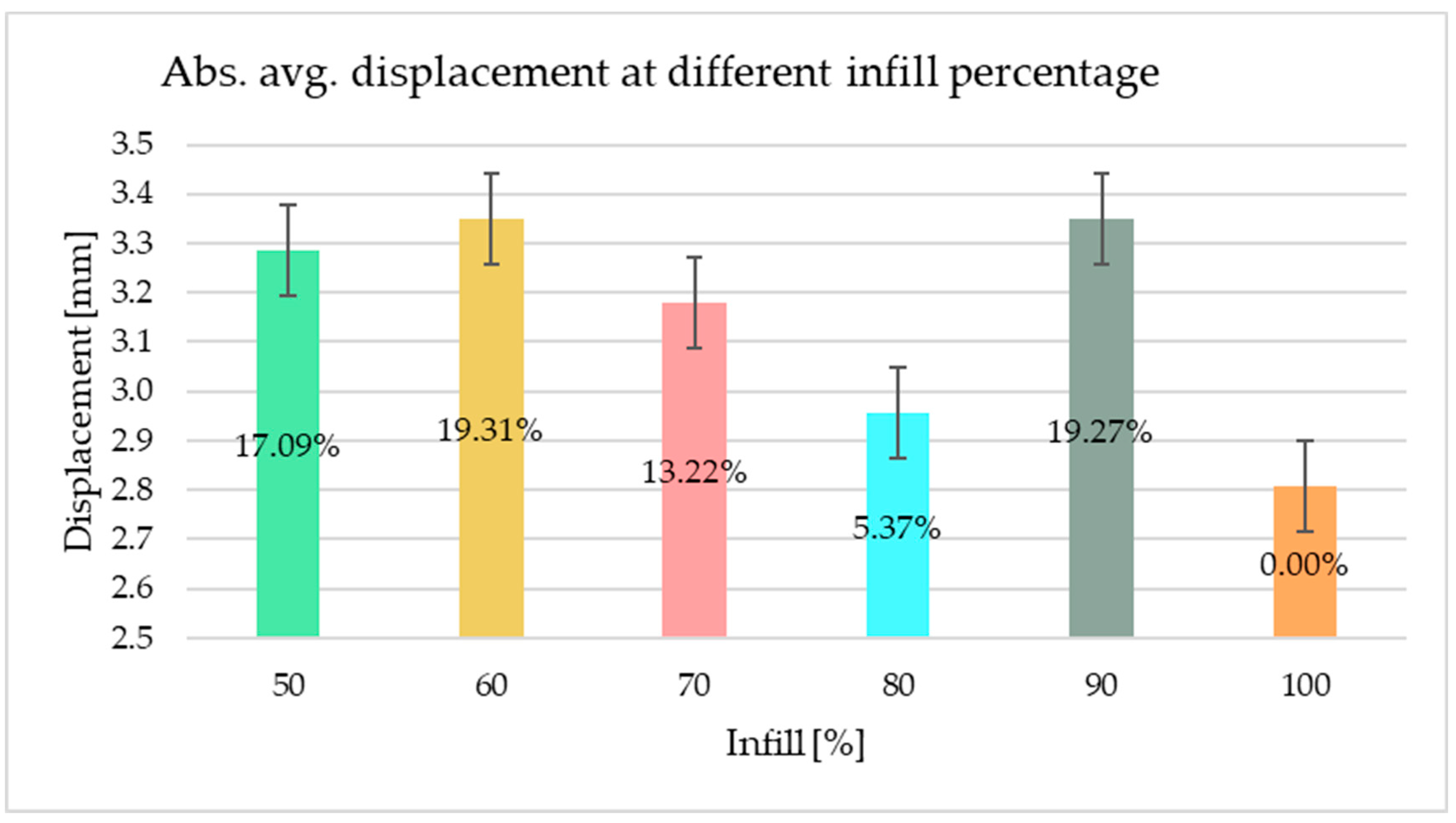

Figure 6 presents the measurement results obtained for the test specimens produced with different infill configurations.

The trends observed here differ from the earlier series. In every case, increasing the infill percentage enhanced the material’s deformation capacity. Interestingly, 90% infill delivered results as good as those for 60% and even 50% infill. Once again, it is clear that the choice of infill can either improve or impair the material’s ability to deform. All values given in the tables and charts are averaged results. Overall, the data indicate that selecting an appropriate infill percentage enables substantial material and weight savings.

The next set of figures (

Figure 7 and

Figure 8) displays the DIC evaluation results for two selected specimens (Resin60%_1 and Resin90%_3). In both cases, the image on the left shows the moment just before fracture, while the image on the right captures the instant of fracture.

The results confirm the conclusion—also reported in the literature (a citation is needed here)—that Cross3D infill reduces the brittleness of printed parts. The figure clearly shows that the denser, almost solid infill “snapped out” of the frame, whereas the sparser infill sheared off more gradually. Although the displacement—i.e., the strain attainable before failure—was nearly the same in both cases, the propensity for brittle fracture decreased. Consequently, whenever a failing component must not shatter into fragments, adjusting the infill percentage is advisable.

The final chart (

Figure 9) displays displacement evaluation data from a cross-section taken along the longer side of the specimens. Here, too, no substantial differences are observed; the curves follow a similar course. Specimens with higher infill generally rise more gently, while those with 50–60% infill climb more steeply, corroborating the trends seen in attainable strain.

5. Conclusions

This research aimed to investigate the impact of two practical print settings—orientation and infill density—on the mechanical performance of resin-printed parts. Based on the experimental results, several key takeaways emerged:

The angle at which a part is printed matters: Printing parts at a 75° tilt turned out to be the most effective, allowing them to stretch and deform the most before breaking. This orientation outperformed the standard flat (0°) setup by almost 20%.

Support settings play a behind-the-scenes role: Around the 60° mark, the slicing software started applying different automatic support settings, which had a noticeable impact on the results. This suggests that not only the angle but also how the software interprets it is important.

Filling the part completely is not always better: Infill densities between 60% and 90% provided just as much, if not better, deformation performance than completely solid parts.

Interestingly, lower infill levels also made the parts less brittle, breaking more slowly and predictably, rather than snapping abruptly.

Someone can save time and material without sacrificing strength: Lighter parts with less infill take less time and use less resin to print, yet still hold up impressively well under load—an ideal balance for many real-world applications.

The DIC system proved to be a powerful tool: Using the GOM ARAMIS system allowed us to track exactly how and where the parts deformed, giving us detailed insight without physically touching or altering them.

In short, with just a few thoughtful adjustments to print orientation and internal structure, it is possible to make resin-printed parts that are stronger, more flexible, and more resource-efficient. These findings can help makers, engineers, and designers get more out of their resin printers—whether they are creating prototypes or real, working parts.

Although this study provides valuable insights into how print orientation and infill density impact the strength and flexibility of resin-printed parts, several limitations are worth noting. The authors worked with only one type of resin, printer, and slicing software, which means the results may not be applicable to other setups or materials. The mechanical testing focused on a modified bending test, so we did not explore how these parts behave under other loads, such as tension or repeated stress over time. Environmental factors—such as heat, moisture, or UV exposure—were also not included, even though they could affect how these parts perform in real-world conditions. Lastly, while we used advanced tools like the GOM ARAMIS system to measure deformation, we did not use simulation or predictive models to extend our findings beyond the tested cases.

Looking ahead, there are several exciting directions that this research could take. For example, integrating artificial intelligence or machine learning [

75,

76,

77] could help predict part performance based on different print settings or material types, saving time and resources during the design phase. Tools like fuzzy logic [

78,

79] can also help navigate the trade-offs between print speed, material usage, and mechanical strength, especially in cases where inputs and priorities are not always clear-cut. On a broader level, future studies could investigate how these print strategies impact the environmental footprint of resin printing by examining factors such as energy consumption, waste generation, and recyclability. By combining smart technology with sustainability goals [

80,

81,

82,

83,

84,

85,

86], someone can move closer to making resin-based 3D printing not just more reliable, but also more responsible.

Future research could also build on current findings by exploring how intelligent design and production frameworks—such as those outlined by Gola [

87], Bocewicz et al. [

88], and Pizoń and Gola [

89]—can be integrated with resin-based 3D printing to support more personalized, flexible manufacturing systems in line with Industry 4.0 and 5.0 principles; additionally, incorporating AI-driven optimization tools like neural networks and genetic algorithms [

90,

91,

92], and early-stage cost-reduction strategies [

93], could further enhance process efficiency, decision-making [

94,

95], and sustainability across additive manufacturing workflows.

Author Contributions

Conceptualization, B.F.S., V.N., S.S. and S.F.; methodology, B.F.S., V.N., S.S. and S.F.; software, B.F.S., V.N., S.S. and S.F.; validation, B.F.S., V.N., S.S. and S.F.; formal analysis, B.F.S., V.N., S.S. and S.F.; investigation, B.F.S., V.N., S.S. and S.F.; resources, B.F.S., V.N., S.S. and S.F.; data curation, B.F.S., V.N., S.S. and S.F.; writing—original draft preparation, B.F.S., V.N., S.S. and S.F.; writing—review and editing, B.F.S., V.N., S.S. and S.F.; visualization, B.F.S., V.N., S.S. and S.F.; supervision, B.F.S., V.N., S.S. and S.F.; project administration, B.F.S., V.N., S.S. and S.F.; funding acquisition, B.F.S., V.N., S.S. and S.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are contained within the paper.

Acknowledgments

This research was supported by the SIU Foundation’s project ‘Sustainable railways—Investigation of the energy efficiency of electric rail vehicles and their infrastructure’. This paper was prepared by the research team “SZE-RAIL”.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| CAD | Computer-Aided Design |

| DIC | Digital Image Correlation |

| DfM | Design for Manufacturability |

| FEA | Finite Element Analysis |

| FDM | Fused Deposition Modeling |

| HD | High Definition |

| HDT | Heat Deflection Temperature |

| ISO | International Organization for Standardization |

| LCD | Liquid Crystal Display |

| MSLA | Masked Stereolithography |

| PET-G | Polyethylene Terephthalate Glycol |

| PLA | Polylactic Acid |

| SLA | Stereolithography |

| UV | Ultraviolet |

References

- Junk, S.; Bär, F. Design Guidelines for Additive Manufacturing Using Masked Stereolithography MSLA. Procedia CIRP 2023, 119, 1122–1127. [Google Scholar] [CrossRef]

- Prabhakar, M.M.; Saravanan, A.K.; Lenin, A.H.; Leno, I.J.; Mayandi, K.; Ramalingam, P.S. A Short Review on 3D Printing Methods, Process Parameters and Materials. Mater. Today Proc. 2020, 45, 6108–6114. [Google Scholar] [CrossRef]

- Orzeł, B.; Stecuła, K. Comparison of 3D Printout Quality from FDM and MSLA Technology in Unit Production. Symmetry 2022, 14, 910. [Google Scholar] [CrossRef]

- Suryatal, B.K.; Sarawade, S.S.; Deshmukh, S.P. Fabrication of Medium Scale 3D Components Using a Stereolithography System for Rapid Prototyping. J. King Saud Univ. Eng. Sci. 2023, 35, 40–52. [Google Scholar] [CrossRef]

- Gaikwad, S.R.; Pawar, N.H.; Sapkal, S.U. Comparative Evaluation of 3D Printed Components for Deviations in Dimensional and Geometrical Features. Mater. Today Proc. 2022, 59, 297–304. [Google Scholar] [CrossRef]

- Štaffová, M.; Ondreáš, F.; Svatík, J.; Zbončák, M.; Jančář, J.; Lepcio, P. 3D Printing and Post-Curing Optimization of Photopolymerized Structures: Basic Concepts and Effective Tools for Improved Thermomechanical Properties. Polym. Test. 2022, 108, 107499. [Google Scholar] [CrossRef]

- Ożóg, P.; Elsayed, H.; Grigolato, L.; Savio, G.; Kraxner, J.; Galusek, D.; Bernardo, E. Engineering of Silicone-Based Blends for the Masked Stereolithography of Biosilicate/Carbon Composite Scaffolds. J. Eur. Ceram. Soc. 2022, 42, 6192–6198. [Google Scholar] [CrossRef]

- Aimon, A.H.; Singh, S.; Pedersen, D.B.; Tosello, G.; Calaon, M. Integration of Soft Tooling by Additive Manufacturing in Polymer Profile Extrusion Process Chain. Mater. Des. 2024, 243, 113065. [Google Scholar] [CrossRef]

- Trajković, I.; Rakin, M.; Milošević, M.; Mitrović, N.; Travica, M.; Sedmak, A.; Medjo, B. Selective Laser Sintered Pipe Ring Notched Tension Specimens for Examination of Fracture Properties of Pipeline Materials. Eng. Fract. Mech. 2023, 292, 109573. [Google Scholar] [CrossRef]

- Gljušćić, M.; Franulović, M.; Lanc, D. Božić Digital Image Correlation of Additively Manufactured CFRTP Composite Systems in Static Tensile Testing. Procedia Struct. Integr. 2021, 31, 116–121. [Google Scholar] [CrossRef]

- Sabik, A.; Rucka, M.; Andrzejewska, A.; Wojtczak, E. Tensile Failure Study of 3D Printed PLA Using DIC Technique and FEM Analysis. Mech. Mater. 2022, 175, 104506. [Google Scholar] [CrossRef]

- Ivanicic, D.; Marohnic, T.; Basan, R. Application of Digital Image Correlation Method for Verification of Topology Optimization of 3D Printed Load-Bearing Element. Procedia Struct. Integr. 2023, 51, 199–205. [Google Scholar] [CrossRef]

- Mohan, D.; Sajab, M.; Bakarudin, S.; Roslan, R.; Kaco, H. 3D Printed Polyurethane Reinforced Graphene Nanoplatelets. Mater. Sci. Forum 2021, 1025, 47–52. [Google Scholar] [CrossRef]

- Alshaikh, A.A.; Khattar, A.; Almindil, I.A.; Alsaif, M.H.; Akhtar, S.; Khan, S.Q.; Gad, M.M. 3D-Printed Nanocomposite Denture-Base Resins: Effect of ZrO2 Nanoparticles on the Mechanical and Surface Properties In Vitro. Nanomaterials 2022, 12, 2451. [Google Scholar] [CrossRef]

- Cazin, I.; Ocepek, M.; Kecelj, J.; Stražar, A.; Schlögl, S. Synthesis of Bio-Based Polyester Resins for Vat Photopolymerization 3D Printing. Materials 2024, 17, 1890. [Google Scholar] [CrossRef]

- Li, S.; Sun, D.; Li, A.; Cui, Y. Study on Curing Shrinkage and Mechanism of DHOM-Modified Epoxy-Acrylate-Based UV-Curing 3D Printing Materials. J. Appl. Polym. Sci. 2020, 138, 49859. [Google Scholar] [CrossRef]

- Alshamrani, A.; Alhotan, A.; Kelly, E.; Ellakwa, A. Mechanical and Biocompatibility Properties of 3D-Printed Dental Resin Reinforced with Glass Silica and Zirconia Nanoparticles: In Vitro Study. Polymers 2023, 15, 2523. [Google Scholar] [CrossRef]

- Warr, C.; Valdoz, J.; Bickham, B.; Knight, C.; Franks, N.; Chartrand, N.; Van Ry, P.M.; Christensen, K.A.; Nordin, G.P.; Cook, A.D. Biocompatible PEGDA Resin for 3D Printing. ACS Appl. Bio Mater. 2020, 3, 2239–2244. [Google Scholar] [CrossRef]

- Bürgers, R.; Schubert, A.; Müller, J.; Krohn, S.; Rödiger, M.; Leha, A.; Wassmann, T. Cytotoxicity of 3D-Printed, Milled, and Conventional Oral Splint Resins to L929 Cells and Human Gingival Fibroblasts. Clin. Exp. Dent. Res. 2022, 8, 650–657. [Google Scholar] [CrossRef]

- Al-Ameri, A.; Alothman, O.; Alsadon, O.; Durgesh, B. An In-Vitro Evaluation of Strength, Hardness, and Color Stability of Heat-Polymerized and 3D-Printed Denture Base Polymers after Aging. Polymers 2025, 17, 288. [Google Scholar] [CrossRef]

- Gad, M.M.; Albazroun, Z.; Aldajani, F.; Elakel, A.M.; El Zayat, M.; Akhtar, S.; Khan, S.Q.; Ali, S.; Rahoma, A.M. Repair Bond Strength of Conventionally and Digitally Fabricated Denture Base Resins to Auto-Polymerized Acrylic Resin: Surface Treatment Effects In Vitro. Materials 2022, 15, 9062. [Google Scholar] [CrossRef]

- Kim, S.; Shin, Y.; Kim, I.; Song, J. In Vitro Study on the Bond Strength Between 3D-Printed Resin and Resin Cement for Pediatric Crown Restoration. J. Korean Acad. Pediatr. Dent. 2023, 50, 104–112. [Google Scholar] [CrossRef]

- Weng, Z.; Huang, X.; Peng, S.; Zheng, L.; Wu, L. 3D Printing of Ultra-High Viscosity Resin by a Linear Scan-Based Vat Photopolymerization System. Nat. Commun. 2023, 14, 39913. [Google Scholar] [CrossRef]

- Shinde, V.; Celestine, A.; Beckingham, L.; Beckingham, B. Stereolithography 3D Printing of Microcapsule Catalyst-Based Self-Healing Composites. ACS Appl. Polym. Mater. 2020, 2, 5048–5057. [Google Scholar] [CrossRef]

- Shahzadi, L.; Maya, F.; Breadmore, M.; Thickett, S. Functional Materials for DLP-SLA 3D Printing Using Thiol–Acrylate Chemistry: Resin Design and Postprint Applications. ACS Appl. Polym. Mater. 2022, 4, 3896–3907. [Google Scholar] [CrossRef]

- Jang, S.; Cho, S. The Effects of Polyaniline Nanofibers and Graphene Flakes on the Electrical and Mechanical Properties of ABS-like Resin Composites Obtained by DLP 3D Printing. Polymers 2023, 15, 3079. [Google Scholar] [CrossRef]

- Kaiahara, F.H.; Pizi, E.C.G.; Straioto, F.G.; Galvani, L.D.; Kuga, M.C.; Arrué, T.A.; Junior, A.R.; Só, M.V.R.; Pereira, J.R.; Vidotti, H. Influence of Printing Orientation on the Mechanical Properties of Provisional Polymeric Materials Produced by 3D Printing. Polymers 2025, 17, 265. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, Z.; Li, C.; Du, H.; Fang, N.; Wu, L.; Song, Y. Continuous 3D Printing from One Single Droplet. Nat. Commun. 2020, 11, 18518. [Google Scholar] [CrossRef]

- Zhao, L.; Jiang, Z.; Zhang, C.; Wen-Ping, L. Influence of 3D Printing Stress Wave on Residual Stress. Europhys. Lett. 2021, 135, 64002. [Google Scholar] [CrossRef]

- Ling, L.; Lai, T.; Chung, P.; Sabet, S.; Tran, V.; Malyala, R. A Novel 3D-Printing Model Resin with Low Volumetric Shrinkage and High Accuracy. Polymers 2025, 17, 610. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, R.; Sun, Z.; Liu, Q.; He, X.; Li, H.; Ye, H.; Yang, X.; Wei, X.; Li, Z.; et al. Centrifugal Multimaterial 3D Printing of Multifunctional Heterogeneous Objects. Nat. Commun. 2022, 13, 35622. [Google Scholar] [CrossRef]

- Silva, M.; Nunes, T.; Viotto, H.; Coelho, S.; Souza, R.; Pero, A. Microbial Adhesion and Biofilm Formation by Candida albicans on 3D-Printed Denture Base Resins. PLoS ONE 2023, 18, e0292430. [Google Scholar] [CrossRef]

- Chi, H.; Lin, Z.; Chen, Y.; Zheng, R.; Qiu, H.; Hu, X.; Bai, H. Three-Dimensional Printing and Recycling of Multifunctional Composite Material Based on Commercial Epoxy Resin and Graphene Nanoplatelet. ACS Appl. Mater. Interfaces 2022, 14, 13758–13767. [Google Scholar] [CrossRef]

- Gad, M.; Fouda, S. Factors Affecting Flexural Strength of 3D-Printed Resins: A Systematic Review. J. Prosthodont. 2023, 32, 96–110. [Google Scholar] [CrossRef]

- Risdiyono. Study on Resin-Based 3D Printed Product for Spin Casting Mold Making. J. Phys. Conf. Ser. 2024, 2739, 012032. [Google Scholar] [CrossRef]

- Soto-Montero, J.; Romano, B.; Noronha, M.; André, C.; Giannini, M. Microtensile Bond Strength of Resin Cements to 3D-Printed and Milled Temporary Restorative Resins. Odovtos Int. J. Dent. Sci. 2023, 25, 114–130. [Google Scholar] [CrossRef]

- Gad, M.; Fouda, S.; Abualsaud, R.; Alshahrani, F.; Al-Thobity, A.; Khan, S.; Akhtar, S.; Ateeq, I.S.; Helal, M.A.; Al-Harbi, F.A. Strength and Surface Properties of a 3D-Printed Denture Base Polymer. J. Prosthodont. 2021, 31, 412–418. [Google Scholar] [CrossRef]

- Shin, J.-W.; Kim, J.-E.; Choi, Y.-J.; Shin, S.-H.; Nam, N.-E.; Shim, J.-S.; Lee, K.-W. Evaluation of the Color Stability of 3D-Printed Crown and Bridge Materials against Various Sources of Discoloration: An In Vitro Study. Materials 2020, 13, 5359. [Google Scholar] [CrossRef]

- Myagmar, G.; Lee, J.; Ahn, J.; Yeo, I.; Yoon, H.; Han, J. Wear of 3D Printed and CAD/CAM Milled Interim Resin Materials after Chewing Simulation. J. Adv. Prosthodont. 2021, 13, 144. [Google Scholar] [CrossRef]

- Pruksawan, S.; Chong, Y.; Zhao, Y.; Sivaraja, V.; Ngo, A.; Jin, P.; Wang, F. Minimizing Polymer Curl Distortion and Heat Impact to Improve Digital Light Processing Printing Accuracy via Subdivision Method. Adv. Eng. Mater. 2024, 26, 2401674. [Google Scholar] [CrossRef]

- Kim, S. Comparison of Microhardness According to the Layered Thickness of 3D Printing Resin. Int. J. Clin. Prev. Dent. 2023, 19, 34–37. [Google Scholar] [CrossRef]

- Arora, O.; Ahmed, N.; Siurkel, Y.; Ronsivalle, V.; Cicciù, M.; Minervini, G. A Comparative Evaluation of Physical Properties of CAD/CAM Complete Denture Resins—An In Vitro Study. BMC Oral Health 2024, 24, 37. [Google Scholar] [CrossRef]

- Tulcan, A.; Vasilescu, M.; Tulcan, L. Comparative Study of the Influence of Bio-Resin Color on the Dimension, Flatness and Straightness of the Part in the 3D Printing Process. Polymers 2021, 13, 1412. [Google Scholar] [CrossRef]

- Raffaini, J.; Soares, E.; Oliveira, R.; Vivanco, R.; Amorim, A.; Caetano, A.; Pires-de-Souza, F.C.P. Effect of Artificial Aging on Mechanical and Physical Properties of CAD-CAM PMMA Resins for Occlusal Splints. J. Adv. Prosthodont. 2023, 15, 227. [Google Scholar] [CrossRef]

- Reeponmaha, T.; Angwaravong, O.; Angwarawong, T. Comparison of Fracture Strength after Thermo-Mechanical Aging between Provisional Crowns Made with CAD/CAM and Conventional Method. J. Adv. Prosthodont. 2020, 12, 218. [Google Scholar] [CrossRef]

- Pereira, A.; Souza, B.; Miranda, L.; Curinga, M.; Sousa, L.; Queiroz, E.; Barão, V.A.R.; Carreiro, A.F.P. Evaluation of the Bond Strength, Surface Roughness and Wettability between 3D-Printed Denture Base Resin to Denture Lining Material to Different Surface Treatments. J. Clin. Exp. Dent. 2025, 17, e249–e258. [Google Scholar] [CrossRef]

- Jurinovs, M.; Barkāne, A.; Platnieks, O.; Beļuns, S.; Grase, L.; Dieden, R.; Staropoli, M.; Schmidt, D.F.; Gaidukovs, S. Vat Photopolymerization of Nanocellulose-Reinforced Vegetable Oil-Based Resins: Synergy in Morphology and Functionalization. ACS Appl. Polym. Mater. 2023, 5, 3104–3118. [Google Scholar] [CrossRef]

- Ataei, K.; Ghaffari, T.; Moslehifard, E.; Dizaj, S. Physico-Chemical and Mechanical Assessments of a New 3D Printed PMMA-Based Acrylic Denture Base Material. Open Dent. J. 2024, 18, 1635. [Google Scholar] [CrossRef]

- Jain, S.; Sayed, M.E.; Shetty, M.; Alqahtani, S.M.; Al Wadei, M.H.D.; Gupta, S.G.; Othman, A.A.A.; Alshehri, A.H.; Alqarni, H.; Mobarki, A.H.; et al. Physical and Mechanical Properties of 3D-Printed Provisional Crowns and Fixed Dental Prosthesis Resins Compared to CAD/CAM Milled and Conventional Provisional Resins: A Systematic Review and Meta-Analysis. Polymers 2022, 14, 2691. [Google Scholar] [CrossRef]

- Bora, P.; Ahmed, A.; Alford, A.; Pitttman, K.; Thomas, V.; Lawson, N. Characterization of Materials Used for 3D Printing Dental Crowns and Hybrid Prostheses. J. Esthet. Restor. Dent. 2023, 36, 220–230. [Google Scholar] [CrossRef]

- Böcherer, D.; Li, Y.; Rein, C.; Corredor, S.; Hou, P.; Helmer, D. High-Resolution 3D Printing of Dual-Curing Thiol-Ene/Epoxy System for Fabrication of Microfluidic Devices for Bioassays. Adv. Funct. Mater. 2024, 34, 2401516. [Google Scholar] [CrossRef]

- Schittecatte, L.; Geertsen, V.; Bonamy, D.; Nguyen, T.; Guénoun, P. From Resin Formulation and Process Parameters to the Final Mechanical Properties of 3D Printed Acrylate Materials. MRS Commun. 2023, 13, 357–377. [Google Scholar] [CrossRef]

- Poker, B.; Oliveira, V.; Macedo, A.; Gonçalves, M.; Ramos, A.; Silva-Lovato, C. Evaluation of Surface Roughness, Wettability and Adhesion of Multispecies Biofilm on 3D-Printed Resins for the Base and Teeth of Complete Dentures. J. Appl. Oral Sci. 2024, 32, 326. [Google Scholar] [CrossRef]

- Cheng, J.; Shou-Yi, Y.; Wang, R.; Ge, Q. Digital Light Processing Based Multimaterial 3D Printing: Challenges, Solutions and Perspectives. Int. J. Extrem. Manuf. 2024, 6, 042006. [Google Scholar] [CrossRef]

- Khattar, A.; Alghafli, J.A.; Muheef, M.A.; Alsalem, A.M.; Al-Dubays, M.A.; AlHussain, H.M.; AlShoalah, H.M.; Khan, S.Q.; AlEraky, D.M.; Gad, M.M. Antibiofilm Activity of 3D-Printed Nanocomposite Resin: Impact of ZrO2 Nanoparticles. Nanomaterials 2023, 13, 591. [Google Scholar] [CrossRef]

- Rueda, S.; Sepsick, H.; Hammamy, M.; Nejat, A.; Kee, E.; Lawson, N. The Effect of Different Surface Treatments on the Roughness, Translucency, and Staining of 3D-Printed Occlusal Device Materials. J. Esthet. Restor. Dent. 2025, 37, 1940–1948. [Google Scholar] [CrossRef]

- Pongwisuthiruchte, A.; Dubas, S.; Aumnate, C.; Potiyaraj, P. Mechanically Tunable Resins Based on Acrylate-Based Resin for Digital Light Processing (DLP) 3D Printing. Sci. Rep. 2022, 12, 24667. [Google Scholar] [CrossRef]

- Islam, M.; Rahman, M.; Gibbon, L.; Hall, E.; Ulven, C.; Scala, J. Mechanical Characterization and Production of Various Shapes Using Continuous Carbon Fiber-Reinforced Thermoset Resin-Based 3D Printing. Polymers 2024, 16, 1828. [Google Scholar] [CrossRef]

- Dong, W.; Bao, C.; Liu, R.; Li, S. Interfacial Performance of Phenolic-Sized Continuous Carbon Fiber-Reinforced Phenolic Resin Composites with Different Impregnation Nozzle Diameters via 3D Printing. Polym. Compos. 2023, 44, 9063–9073. [Google Scholar] [CrossRef]

- Tessanan, W.; Daniel, P.; Phinyocheep, P. Development of Photosensitive Natural Rubber as a Mechanical Modifier for Ultraviolet-Curable Resin Applied in Digital Light Processing-Based Three-Dimensional Printing Technology. ACS Omega 2021, 6, 14838–14847. [Google Scholar] [CrossRef]

- Robinson, L.; Self, J.; Fusi, A.; Bates, M.; Alaniz, J.; Hawker, C.; Bates, C.M.; Sample, C.S. Chemical and Mechanical Tunability of 3D-Printed Dynamic Covalent Networks Based on Boronate Esters. ACS Macro Lett. 2021, 10, 857–863. [Google Scholar] [CrossRef]

- Bae, J.-H.; Won, J.C.; Lim, W.B.; Lee, J.H.; Min, J.G.; Kim, S.W.; Kim, J.-H.; Huh, P. Highly Flexible and Photo-Activating Acryl-Polyurethane for 3D Steric Architectures. Polymers 2021, 13, 844. [Google Scholar] [CrossRef]

- Arun, N.; Yang, H.; Yao, L.; Feinberg, A. Nonplanar 3D Printing of Epoxy Using Freeform Reversible Embedding. Adv. Mater. Technol. 2023, 8, 221542. [Google Scholar] [CrossRef]

- Yu, L.; Zhu, Y.; Wang, L.; Zhang, J.; Zhou, J.; Fu, Y. Influence of 3D Printing Process Parameters on the Tribological Properties of Acrylic Resin. J. Appl. Polym. Sci. 2022, 140, 53448. [Google Scholar] [CrossRef]

- Gad, M.; Al-Harbi, F.; Akhtar, S.; Fouda, S. 3D-Printable Denture Base Resin Containing SiO2 Nanoparticles: An In Vitro Analysis of Mechanical and Surface Properties. J. Prosthodont. 2022, 31, 784–790. [Google Scholar] [CrossRef]

- Casucci, A.; Verniani, G.; Barbieri, A.; Ricci, N.; Cagidiaco, E.; Ferrari, M. Flexural Strength Analysis of Different Complete Denture Resin-Based Materials Obtained by Conventional and Digital Manufacturing. Materials 2023, 16, 6559. [Google Scholar] [CrossRef]

- Palavicini, J.; Quin, S.L.; Zakkour, W.; Zakkour, K.; Manafi Varkiani, S.; Xu, X.; Lawson, N.C.; Nejat, A.H. Bond Strength of Reline Materials to 3D-Printed Provisional Crown Resins. Polymers 2023, 15, 3745. [Google Scholar] [CrossRef]

- Dong, W.; Bao, C.; Liu, R.; Li, S. Parameter Design of Continuous Carbon Fiber-Reinforced Phenolic Resin Composites via In Situ-Curing 3D Printing Technology. J. Reinf. Plast. Compos. 2024, 44, 650–660. [Google Scholar] [CrossRef]

- Mohammed, E.; Elddamony, E.; Mohamed, S. Evaluation of Metal Base Adaptation and Clinical Retention of Upper Complete Dentures with a Co-Cr Metal Palate Constructed by Two Different Approaches. Egypt. Dent. J. 2022, 68, 3771–3782. [Google Scholar] [CrossRef]

- Dizon, J.; Delda, R.; Villablanca, M.; Monserate, J.; Cancino, L.; Cascolan, H. Material Development for Additive Manufacturing: Compressive Loading Behavior of SLA 3D-Printed Thermosets with Nanosilica Powders. Mater. Sci. Forum 2023, 1087, 137–142. [Google Scholar] [CrossRef]

- Hata, K.; Ikeda, H.; Nagamatsu, Y.; Masaki, C.; Hosokawa, R.; Shimizu, H. Development of Dental Poly (Methyl Methacrylate)-Based Resin for Stereolithography Additive Manufacturing. Polymers 2021, 13, 4435. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, K. Preparation and Characterization of Color Photocurable Resins for Full-Color Material Jetting Additive Manufacturing. Polymers 2020, 12, 650. [Google Scholar] [CrossRef]

- Traugutt, N.; Mistry, D.; Luo, C.; Yu, K.; Ge, Q.; Yakacki, C. Liquid-Crystal-Elastomer-Based Dissipative Structures by Digital Light Processing 3D Printing. Adv. Mater. 2020, 32, 2000797. [Google Scholar] [CrossRef]

- ISO 20482:2013; Metallic Materials—Sheet and Strip—Erichsen Cupping Test. International Organization for Standardization: Geneva, Switzerland, 2013.

- Ficzere, P. The Role of Artificial Intelligence in the Development of Rail Transport. Cogn. Sustain. 2023, 2, 81. [Google Scholar] [CrossRef]

- Zamfirache, I.A.; Precup, R.E.; Petriu, E.M. Q-Learning, Policy Iteration and Actor-Critic Reinforcement Learning Com-bined with Metaheuristic Algorithms in Servo System Control. Facta Univ. Ser. Mech. Eng. 2023, 21, 615–630. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Aglikov, A.S. Triboinformatics: Machine Learning Methods for Frictional Instabilities. Facta Univ. Ser. Mech. Eng. 2024, 22, 423–433. [Google Scholar] [CrossRef]

- Biswas, S.; Božanić, D.; Pamučar, D.; Marinković, D. A spherical fuzzy based decision making framework with Einstein aggregation for comparing preparedness of SMES in quality 4.0. Facta Univ. Ser. Mech. Eng. 2023, 21, 453–478. [Google Scholar] [CrossRef]

- Köken, E. Soft computing implementations for evaluating Los Angeles abrasion value of rock aggregates from Kütahya, Turkey. Acta Tech. Jaurinensis 2024, 17, 36–44. [Google Scholar] [CrossRef]

- Ézsiás, L.; Tompa, R.; Fischer, S. Investigation of the Possible Correlations between Specific Characteristics of Crushed Stone Aggregates. Spectr. Mech. Eng. Oper. Res. 2024, 1, 10–26. [Google Scholar] [CrossRef]

- Fischer, S. Investigation of the Settlement Behavior of Ballasted Railway Tracks Due to Dynamic Loading. Spectr. Mech. Eng. Oper. Res. 2025, 2, 24–46. [Google Scholar] [CrossRef]

- Fischer, S.; Hermán, B.; Kocsis Szürke, S. Possibilities for determining the energy consumption of electric locomotives during acceleration and constant-speed traction. Cogn. Sustain. 2025, 4, 154. [Google Scholar] [CrossRef]

- Fischer, S.; Harangozó, D.; Németh, D.; Kocsis, B.; Sysyn, M.; Kurhan, D.; Brautigam, A. Investigation of Heat-Affected Zones of Thermite Rail Welding. Facta Univ. Ser. Mech. Eng. 2024, 22, 689–710. [Google Scholar] [CrossRef]

- Semenov, S.; Mikhailov, E.; Kliuiev, S.; Dižo, J.; Blatnický, M.; Ishchuk, V. Improving the energy efficiency of a tram’s running gear. Acta Polytech. 2023, 63, 216–226. [Google Scholar] [CrossRef]

- Volkov, V.; Taran, I.; Volkova, T.; Pavlenko, O.; Berezhnaja, N. Determining the Efficient Management System for a Spe-cialized Transport Enterprise. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2020, 2020, 185–191. [Google Scholar] [CrossRef]

- Saukenova, I.; Oliskevych, M.; Taran, I.; Toktamyssova, A.; Aliakbarkyzy, D.; Pelo, R. Optimization of Schedules for Early Garbage Collection and Disposal in the Megapolis. East.-Eur. J. Enterp. Technol. 2022, 1, 13–23. [Google Scholar] [CrossRef]

- Gola, A. Design and Management of Manufacturing Systems. Appl. Sci. 2021, 11, 2216. [Google Scholar] [CrossRef]

- Bocewicz, G.; Nielsen, I.; Gola, A.; Banaszak, Z. Reference Model of Milk-Run Traffic Systems Prototyping. Int. J. Prod. Res. 2021, 59, 4495–4512. [Google Scholar] [CrossRef]

- Pizoń, J.; Gola, A. The Meaning and Directions of Development of Personalized Production in the Era of Industry 4.0 and Industry 5.0. In Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2023; pp. 1–12. [Google Scholar] [CrossRef]

- Świć, A.; Wołos, D.; Gola, A.; Kłosowski, G. The Use of Neural Networks and Genetic Algorithms to Control Low Rigidity Shafts Machining. Sensors 2020, 20, 4683. [Google Scholar] [CrossRef]

- Udvardy, K.; Görbe, P.; Bódis, T.; Botzheim, J. Conceptual Framework for Adaptive Bacterial Memetic Algorithm Parameterization in Storage Location Assignment Problem. Mathematics 2024, 12, 3688. [Google Scholar] [CrossRef]

- Görbe, P.; Bódis, T. Generalized Objective Function to Ensure Robust Evaluation for Evolutionary Storage Location Assignment Algorithms. In Computational Collective Intelligence; Springer: Cham, Switzerland, 2023; pp. 546–559. [Google Scholar] [CrossRef]

- Relich, M.; Nielsen, I.; Gola, A. Reducing the Total Cost at the Product Design Stage. Appl. Sci. 2022, 12, 1921. [Google Scholar] [CrossRef]

- Tadić, D.; Lukić, J.; Komatina, N.; Marinković, D.; Pamučar, D. A Fuzzy Decision-Making Approach to Electric Vehicle Evaluation and Ranking. Teh. Vjesn. 2025, 32, 1066–1075. [Google Scholar] [CrossRef]

- Petrović, N.; Jovanović, V.; Marković, S.; Marinković, D.; Nikolić, B. Multi-criteria Decision-Making Approach for choising e-Bus for Urban Public Transport in the City of Niš. Acta Tech. Jaurinensis 2025, 18, 1–8. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).