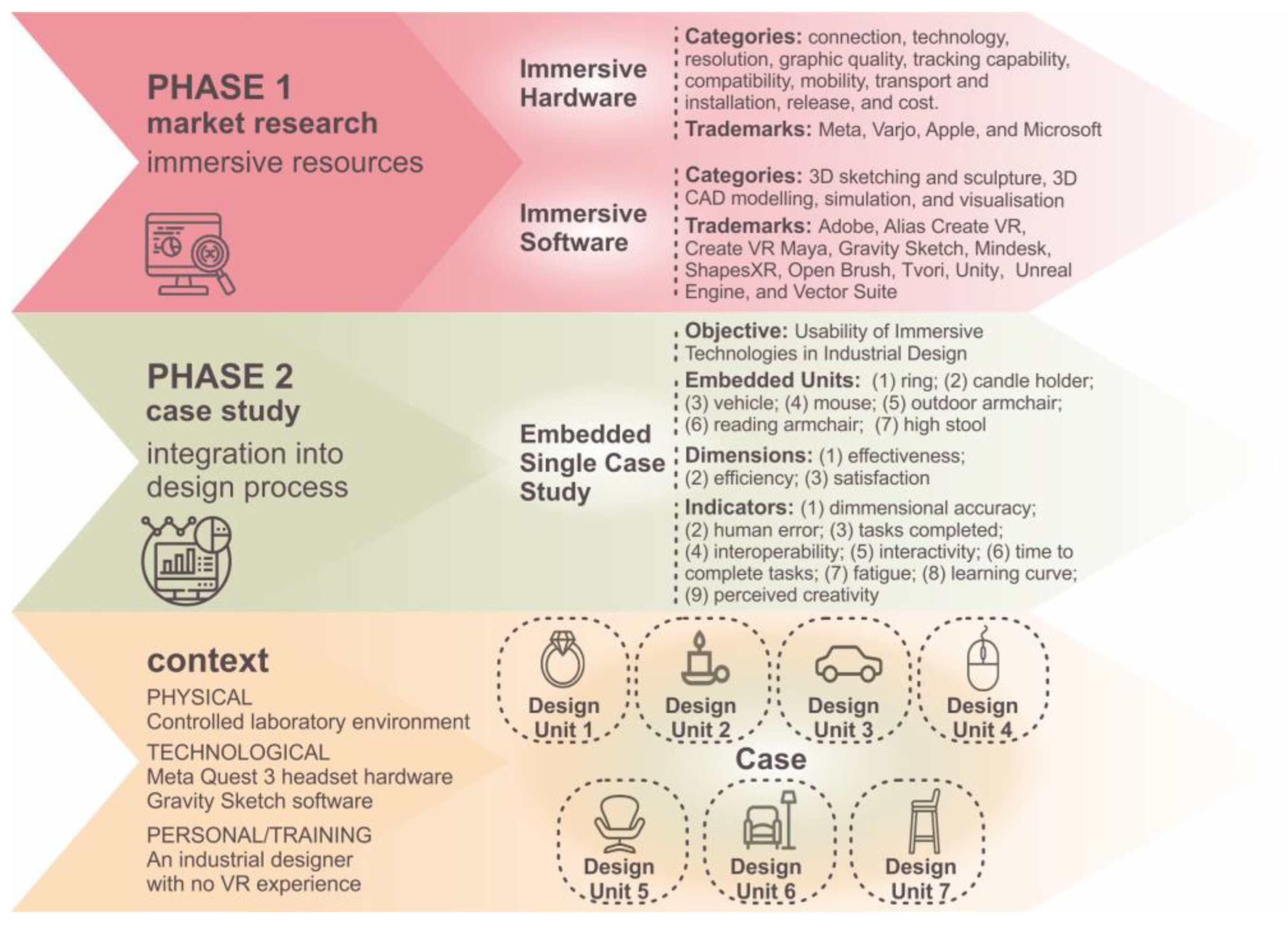

The Role of Virtual and Augmented Reality in Industrial Design: A Case Study of Usability Assessment

Abstract

1. Introduction

2. Methods

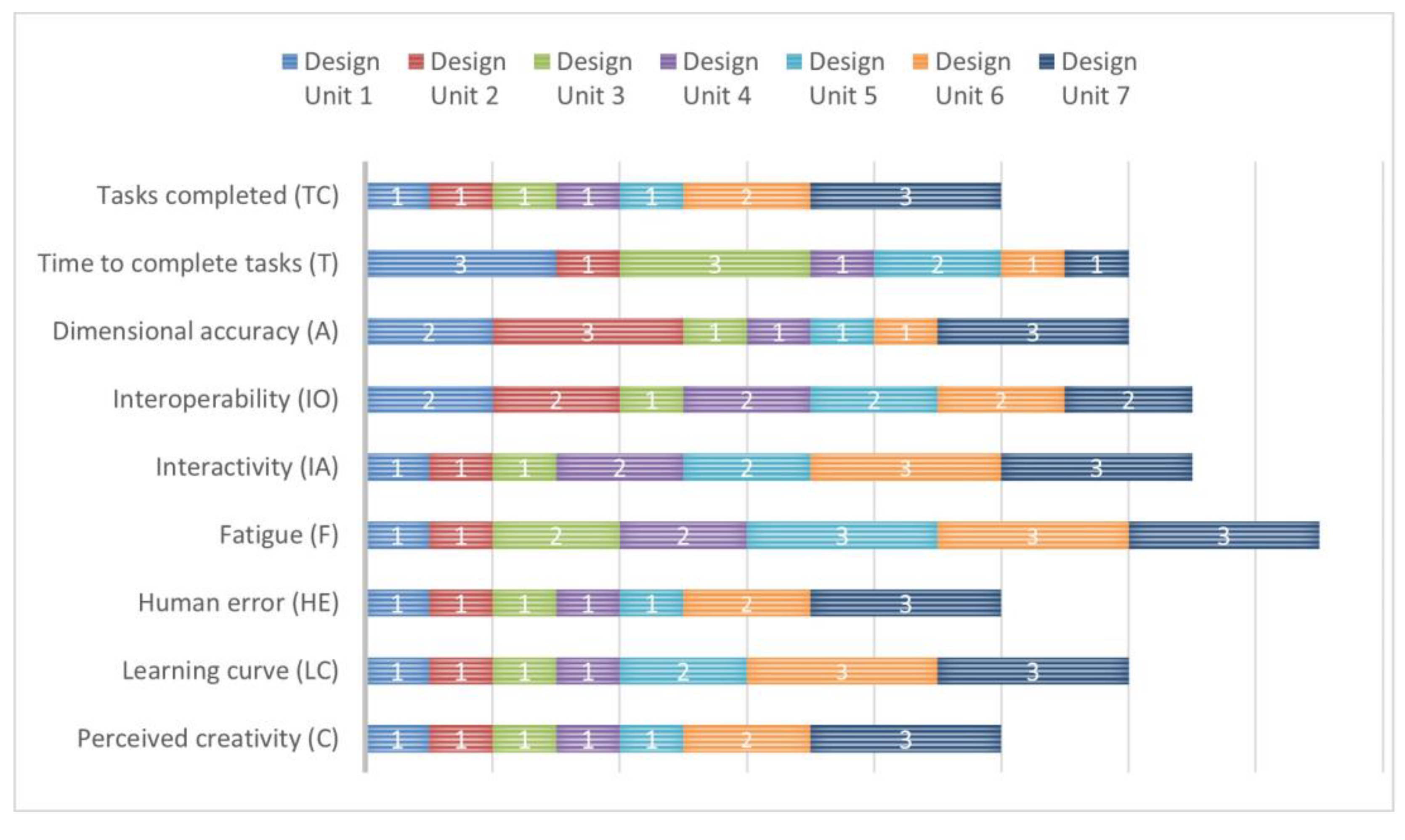

- Tasks completed (TC): The proportion of design tasks successfully completed according to established objectives.

- Time to complete tasks (T): The total time required to complete a design task in an immersive environment.

- Dimensional accuracy (A): The degree to which the designed model conforms to the intended dimensions or characteristics of the actual product.

- Interoperability (IO): How easily the generated models can be transferred and used between different platforms or design software.

- Interactivity (IA): The ability of the user to perform actions in the virtual environment and receive immediate responses.

- Fatigue (F): The level of physical and/or mental effort accumulated by the user while performing the tasks.

- Human error (HE): The ability of the user to perform tasks without making errors that require restarting or relevant correction.

- Learning curve (LC): The speed with which the user improves their performance by repeating tasks in the virtual environment.

- Perceived creativity (C): The ability of the environment to facilitate the generation of diverse ideas during the design process.

- S (successfully completed tasks): Number of tasks completed correctly without errors or interruptions.

- F (failures or incomplete tasks): Number of errors or tasks that were not completed.

- R (restarts): Number of restarts required due to loss of control or serious errors during the task.

- I (interruptions): Number of interruptions caused by interface interaction difficulties.

- L (loss of control): Number of times work control was lost, forcing task to be abandoned or redone.

- Te (error correction time): Total time spent correcting errors, including repetitions or adjustments needed to proceed.

- Tt (total task time): Total time required to complete task, including errors, interruptions, and repetitions.

3. Market Research: Current State of Immersive Technologies in Industrial Design

3.1. Application of Immersive Technologies in Industrial Design

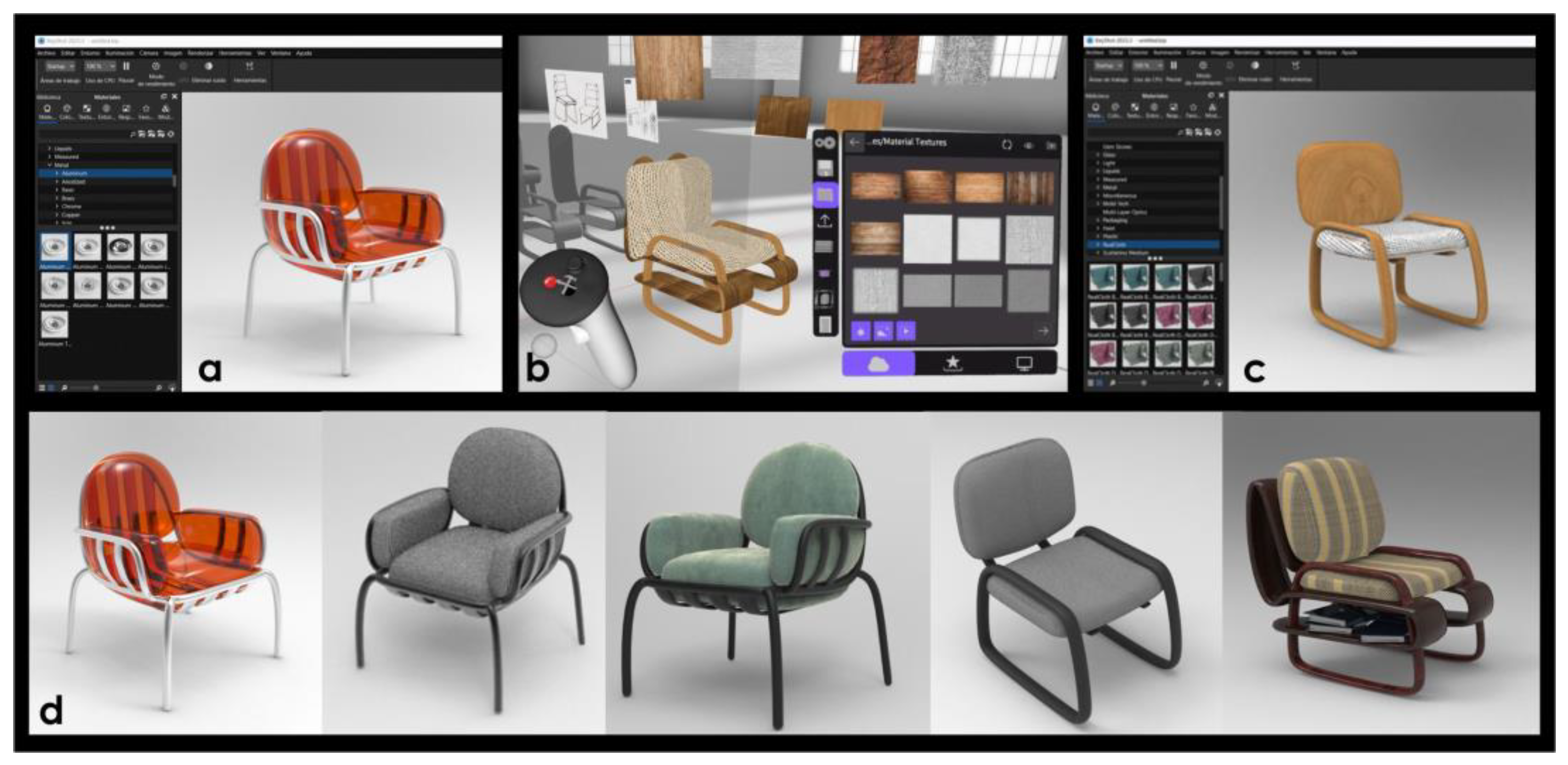

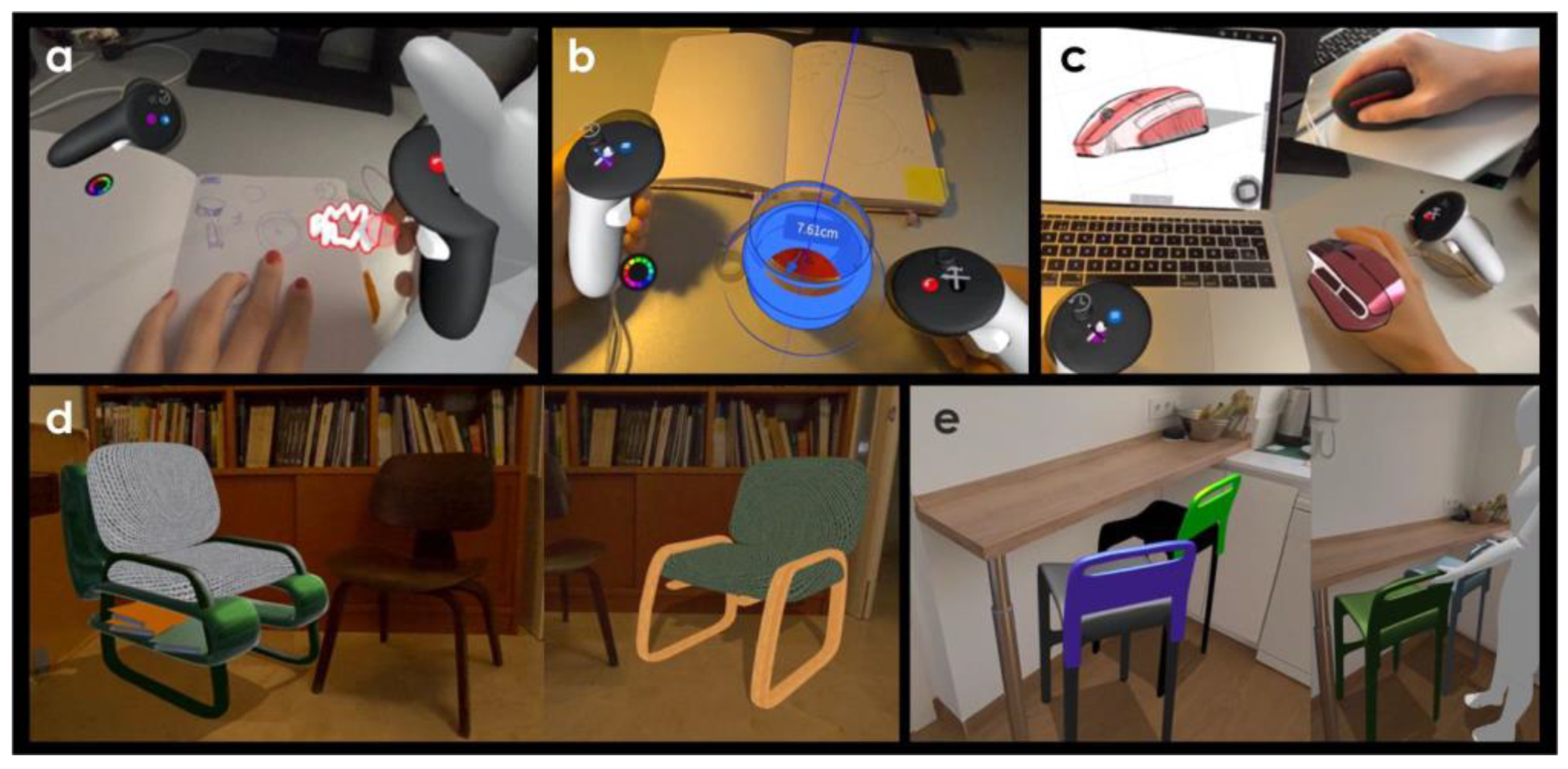

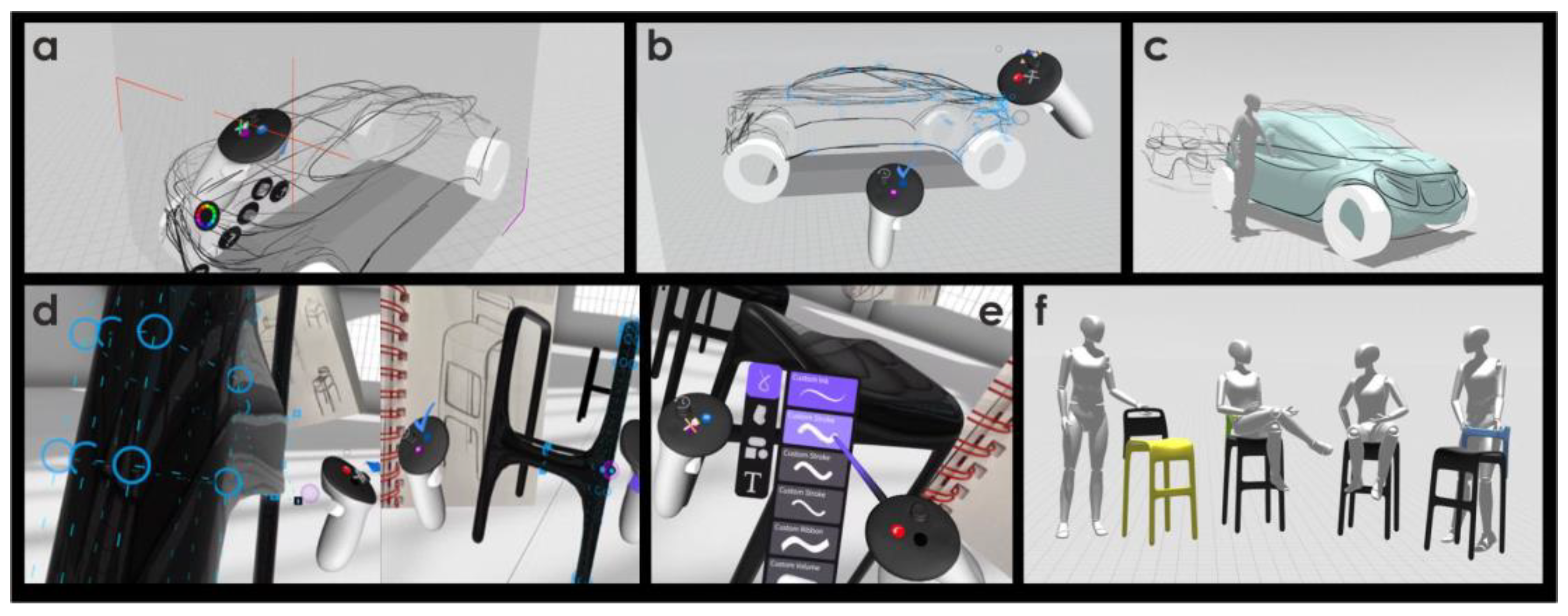

3.2. Available Resources of Immersive Tools for Industrial Design

3.2.1. Hardware Analysis for Immersive Design

3.2.2. Analysis of Software for Immersive Design

4. Results: Analysis of the Integration of VR, AR, and MR in the Design Process

4.1. Results of Usability Indicator Analysis

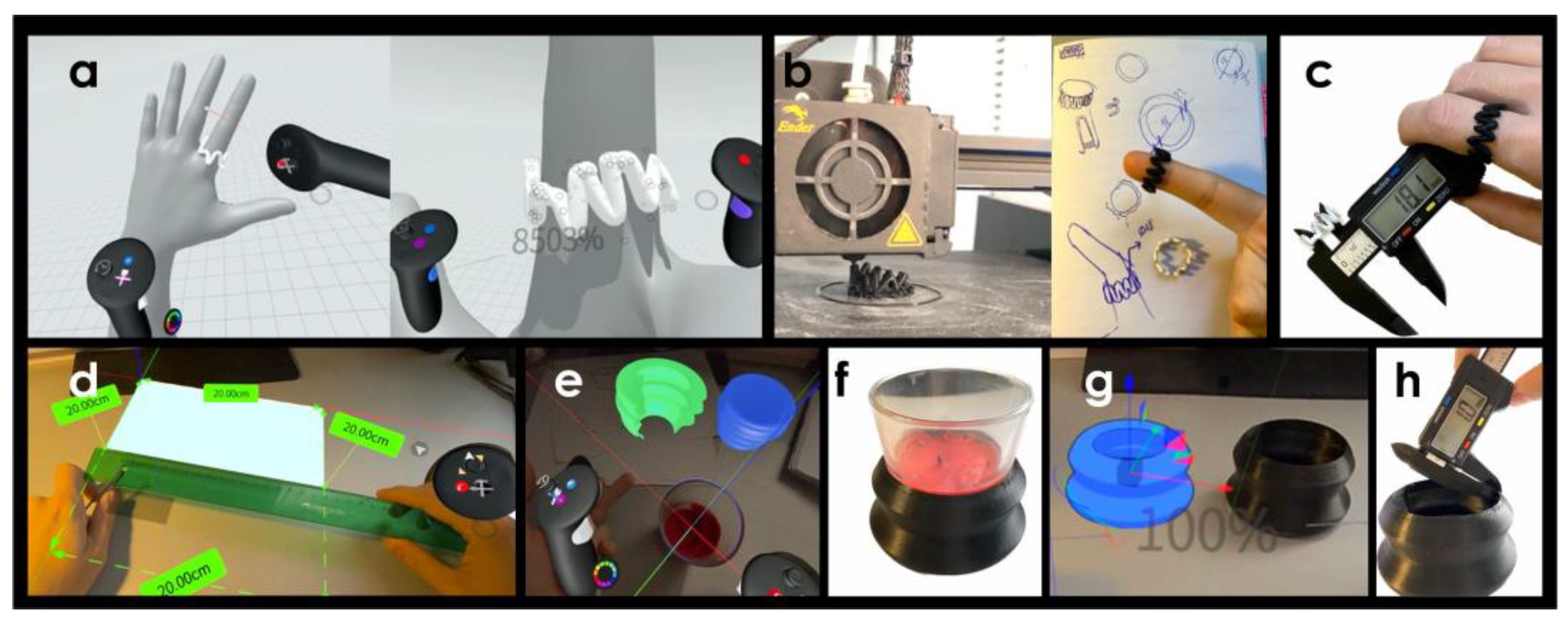

4.1.1. Dimensional Accuracy

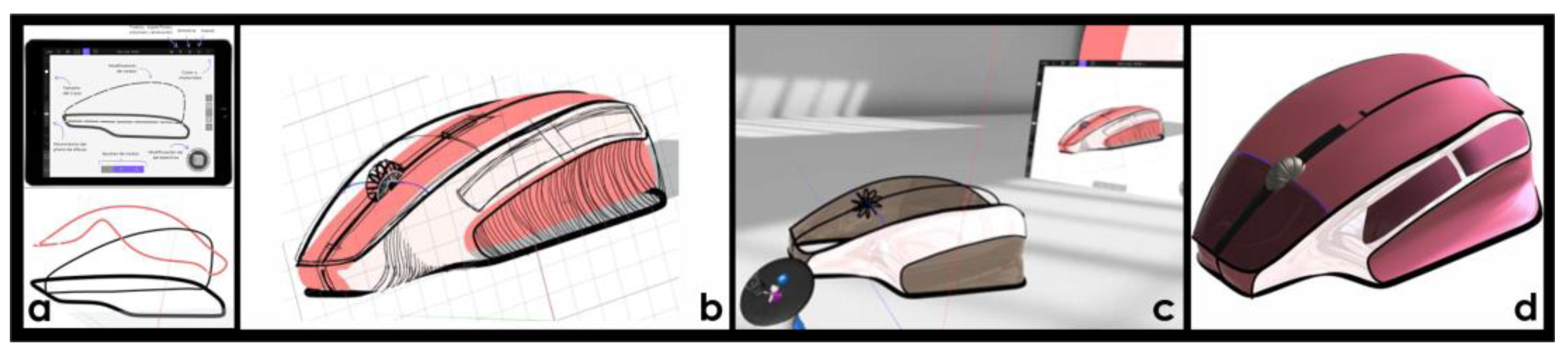

4.1.2. User Performance

4.1.3. Interoperability

4.1.4. Interactivity

4.1.5. Design Process Performance

4.1.6. Perceived Creativity

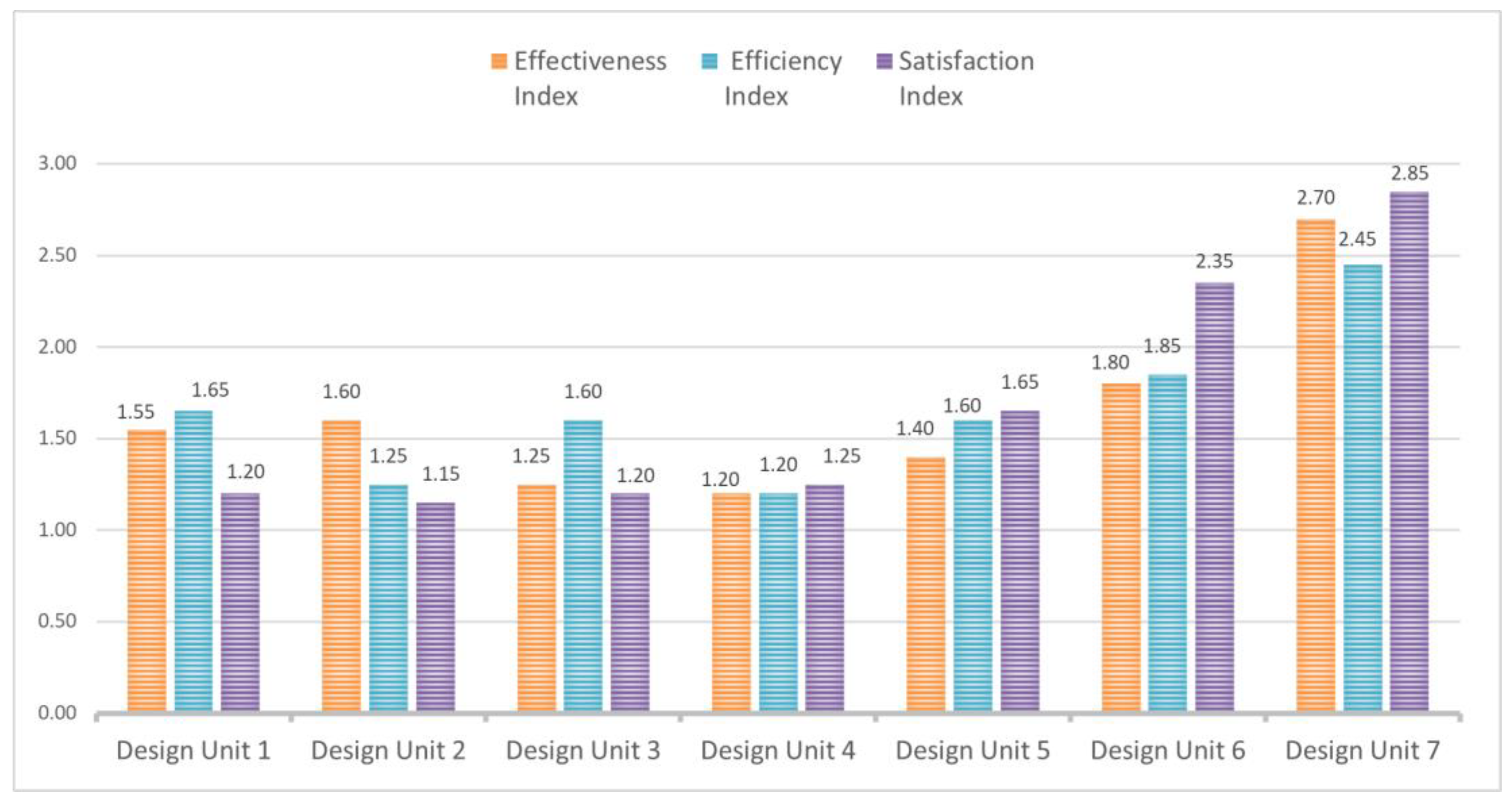

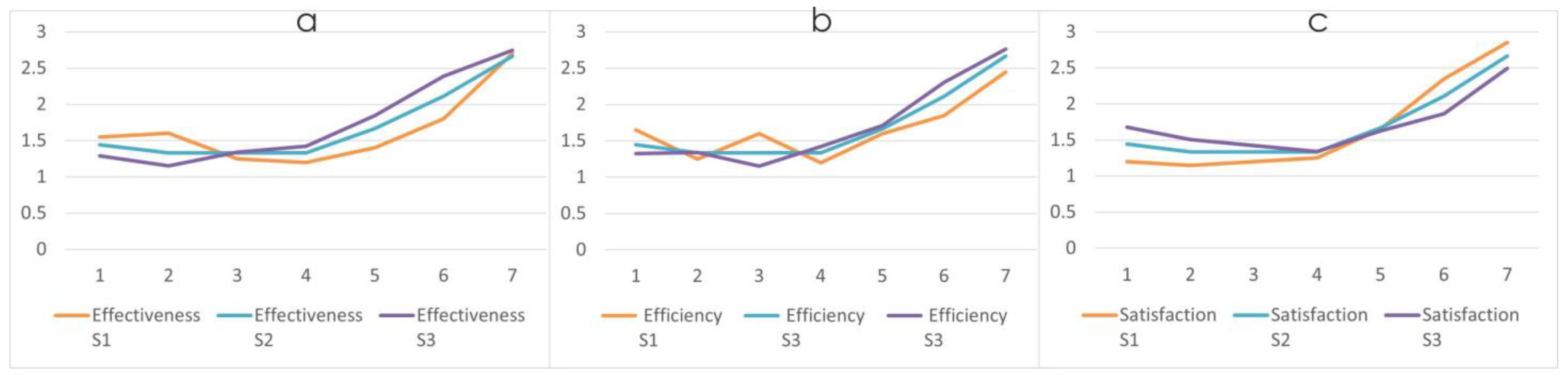

4.2. Aggregated Results by Usability Dimension: Effectiveness, Efficiency, and Satisfaction

4.3. Sensitivity Analysis

5. Discussion

Limitations and Future Work

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| VR | Virtual Reality |

| AR | Augmented Reality |

| MR | Mixed Reality |

| HMD | Head-Mounted Display |

| CAD | Computer-Aided Design |

| 2D | Two-Dimensional |

| 3D | Three-Dimensional |

| PC | Personal Computer |

| OBJ | Object Replacement Character Files |

| FBX | Filmbox Files |

| MCA | Multi-Criteria Analysis |

References

- Liu, R.; Peng, C.; Zhang, Y.; Husarek, H.; Yu, Q. A Survey of Immersive Technologies and Applications for Industrial Product Development. Comput. Graph. 2021, 100, 137–151. [Google Scholar] [CrossRef]

- Stadler, S. Potential Usages of Virtual Reality in Design Research and Practice–A Review. In Proceedings of the En 4th International Conference Business Meets Technology 2022, Universitat Politecnica de Valencia, Valencia, Spain, 10 January 2023. [Google Scholar]

- Yu, W.; Zhao, Y.; Zhao, J.; Yu, W.; Wen, L.; Zhao, L.-A.; Min, S. Application Research of VR Technology in Product Design. J. Phys. Conf. Ser. 2021, 1966, 012028. [Google Scholar] [CrossRef]

- Andreoletti, D.; Paoliello, M.; Luceri, L.; Leidi, T.; Peternier, A.; Giordano, S. A Framework for Emotion-Driven Product Design Through Virtual Reality. Lect. Notes Bus. Inf. Process. 2022, 442, 42–61. [Google Scholar] [CrossRef]

- Yuan, Q.; Huai, Y. Immersive Sketch-Based Tree Modeling in Virtual Reality. Comput. Graph. 2021, 94, 132–143. [Google Scholar] [CrossRef]

- Dargan, S.; Bansal, S.; Kumar, M.; Mittal, A.; Kumar, K. Augmented Reality: A Comprehensive Review. Arch. Comput. Methods Eng. 2023, 30, 1057–1080. [Google Scholar] [CrossRef]

- Muñoz-Saavedra, L.; Miró-Amarante, L.; Domínguez-Morales, M. Augmented and Virtual Reality Evolution and Future Tendency. Appl. Sci. 2020, 10, 322. [Google Scholar] [CrossRef]

- Anthes, C.; García-Hernández, R.J.; Wiedemann, M.; Kranzlmüller, D. State of the Art of Virtual Reality Technology. In Proceedings of the 2016 IEEE Aerospace Conference, Big Sky, MT, USA, 5–12 March 2016. [Google Scholar] [CrossRef]

- Maher, S.; Cohen, J. Virtual Reality at NASA/Goddard Space Flight Center. Comput. Graph. ACM 1996, 30, 49–50. [Google Scholar] [CrossRef]

- Mcgreevy, M.W. The Virtual Environment Display System. In National Aeronautics and Space Administration, Technology 2000; National Aeronautics and Space Administration, NASA Ames Research Center: Moffett Field, CA, USA, 1991; Volume 1. [Google Scholar]

- Robertson, G.G.; Card, S.K.; Mackinlay, J.D. Three Views of Virtual Reality: Virtual Environments in the US Military. Computer 1993, 26, 81–82. [Google Scholar] [CrossRef]

- Rosenberg, L.B. The Use of Virtual Fixtures as Perceptual Overlays to Enhance Operator Performance in Remote Environments. Available online: https://apps.dtic.mil/sti/citations/ADA292450 (accessed on 6 May 2025).

- Zimmerman, T.G.; Lanier, J.; Blanchard, C.; Bryson, S.; Harvill, Y. A Hand Gesture Interface Device. ACM SIGCHI Bull. 1986, 18, 189–192. [Google Scholar] [CrossRef]

- Souza, D.F.L.; MacHado, L.S.; Moraes, R.M. Integration of Tracking Systems for the Development of Virtual Reality Applications. IEEE Lat. Am. Trans. 2010, 8, 714–721. [Google Scholar] [CrossRef]

- Fisher, S.S.; Wenzel, E.M.; Coler, C.; McGreevy, M.W. Virtual Interface Environment Workstations. In Proceedings of the Human Factors Society Annual Meeting, Anaheim, CA, USA, 24–28 October 1988; SAGE PublicationsSage CA: Los Angeles, CA, USA, 1988; Volume 32, pp. 91–95. [Google Scholar]

- Billinghurst, M.; Kato, H. Collaborative Mixed Reality. In Proceedings of the Mixed Reality; Springer: Berlin/Heidelberg, Germany, 1999; pp. 261–284. [Google Scholar]

- Cruz-Neira, C.; Sandin, D.J.; DeFanti, T.A. Surround-Screen Projection-Based Virtual Reality: The Design and Implementation of the CAVE. In Proceedings of the 20th Annual Conference on Computer Graphics and Interactive Techniques, SIGGRAPH 1993, Anaheim, CA, USA, 2–6 August 1993; Association for Computing Machinery: New York, NY, USA, 1993; pp. 135–142. [Google Scholar]

- Coburn, J.Q.; Freeman, I.; Salmon, J.L. A Review of the Capabilities of Current Low-Cost Virtual Reality Technology and Its Potential to Enhance the Design Process. J. Comput. Inf. Sci. Eng. 2017, 17, 031013. [Google Scholar] [CrossRef]

- Wolfartsberger, J.; Zenisek, J.; Sievi, C.; Silmbroth, M. A Virtual Reality Supported 3D Environment for Engineering Design Review. In Proceedings of the 2017 23rd International Conference on Virtual Systems and Multimedia, VSMM 2017, Dublin, Ireland, 31 October–4 November 2017. [Google Scholar] [CrossRef]

- Berni, A.; Borgianni, Y. Applications of Virtual Reality in Engineering and Product Design: Why, What, How, When and Where. Electronics 2020, 9, 1064. [Google Scholar] [CrossRef]

- Salim, A.; Indra, I.; Nugraha, U.; Abdulghani, T.; Anwar, S. Augmented Reality and Virtual Reality Applications: Enhancing User Experience Across Industries. Glob. Int. J. Innov. Res. 2024, 2, 840–849. [Google Scholar] [CrossRef]

- Sharma, A.; Mehtab, R.; Mohan, S.; Mohd Shah, M.K. Augmented Reality–an Important Aspect of Industry 4.0. Ind. Robot. 2022, 49, 428–441. [Google Scholar] [CrossRef]

- Shen, Y.; Ong, S.K.; Nee, A.Y.C. Augmented Reality for Collaborative Product Design and Development. Des. Stud. 2010, 31, 118–145. [Google Scholar] [CrossRef]

- Wiedenmaier, S.; Oehme, O.; Schmidt, L.; Luczak, H. Augmented Reality (AR) for Assembly Processes Design and Experimental Evaluation. Int. J. Hum. Comput. Interact. 2003, 16, 497–514. [Google Scholar] [CrossRef]

- Ottosson, S. Virtual Reality in the Product Development Process. J. Eng. Des. 2002, 13, 159–172. [Google Scholar] [CrossRef]

- Topal, B.; Sener, B. Appraisal of Augmented Reality Technologies for Supporting Industrial Design Practices. In International Conference on Virtual, Augmented and Mixed Reality, Proceedings of the Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics), Los Angeles, CA, USA, 2–7 August 2015; Springer: Berlin/Heidelberg, Germany, 2015; Volume 9179, pp. 513–523. [Google Scholar]

- Bernardo, N.; Duarte, E. Industrial Design Education and Immersive Virtual Reality: Perceptions on Utility and Integration. In Proceedings of the Design, User Experience, and Usability—12th International Conference DUXU 2023, Copenhagen, Denmark, 23–28 July 2023; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2023; Volume 14031, pp. 371–387. [Google Scholar]

- Oti, A.; Crilly, N. Immersive 3D Sketching Tools: Implications for Visual Thinking and Communication. Comput. Graph. 2021, 94, 111–123. [Google Scholar] [CrossRef]

- Giunchi, D.; James, S.; Steed, A. 3D Sketching for Interactive Model Retrieval in Virtual Reality. In Proceedings of the Proceedings-Expressive 2018: Computational Aesthetics Sketch-Based Interfaces and Modeling Non-Photorealistic Animation and Rendering, Victoria, BC, Canada, 17–19 August 2018; Association for Computing Machinery, Inc: New York, NY, USA, 2018; pp. 1–12. [Google Scholar]

- Lorusso, M.; Rossoni, M.; Colombo, G. Conceptual Modeling in Product Design within Virtual Reality Environments. Comput. Aided. Des. Appl. 2020, 18, 383–398. [Google Scholar] [CrossRef]

- Vo, H. Design Creativity in Industry 4.0: Gravity Sketch and 3D Printing in a Luminaire Design Project. J. Eng. Des. Technol. 2022, 22, 1413–1432. [Google Scholar] [CrossRef]

- Chang, Y.S. Influence of Virtual Reality on Engineering Design Creativity. Educ. Stud. 2022, 48, 341–357. [Google Scholar] [CrossRef]

- Hinricher, N.; König, S.; Schröer, C.; Backhaus, C. Influence of Virtual Reality on User Evaluation of Prototypes in the Development Process—A Comparative Study with Control Rooms for Onshore Drilling Rigs. Appl. Sci. 2023, 13, 8319. [Google Scholar] [CrossRef]

- Berg, L.P.; Vance, J.M. An Industry Case Study: Investigating Early Design Decision Making in Virtual Reality. J. Comput. Inf. Sci. Eng. 2017, 17, 011001. [Google Scholar] [CrossRef]

- Korkut, E.H.; Surer, E. Visualization in Virtual Reality: A Systematic Review. Virtual Real. 2023, 27, 1447–1480. [Google Scholar] [CrossRef]

- Huang, Y.C.; Huang, P.H. A Study on the Application of Visualization Technology in Virtual Product Design. In Proceedings of the 2023 9th International Conference on Computer and Communications, ICCC 2023, Chengdu, China, 8–11 December 2023; pp. 2483–2487. [Google Scholar] [CrossRef]

- Using Gravity Sketch & 3D Printing to Make Outdoor Furniture. Available online: https://gravitysketch.com/blog-post/articles/meet-the-designers-using-gravity-sketch-and-3d-printing-to-make-rough-and-ready-outdoor-furniture/ (accessed on 9 May 2025).

- Bourgeois-Bougrine, S.; Bonnardel, N.; Burkhardt, J.M.; Thornhill-Miller, B.; Pahlavan, F.; Buisine, S.; Guegan, J.; Pichot, N.; Lubart, T. Immersive Virtual Environments’ Impact on Individual and Collective Creativity. Immersive Virtual Environ. Impact Individ. Collect. Creat. 2022, 27, 237–253. [Google Scholar] [CrossRef]

- Conesa, J.; Mula, F.J.; Bartlett, K.A.; Naya, F.; Contero, M. The Influence of Immersive and Collaborative Virtual Environments in Improving Spatial Skills. Appl. Sci. 2023, 13, 8426. [Google Scholar] [CrossRef]

- Herodek, A.; Vilmar, A. Collaborative Creativity in Ad Hoc Virtual Teams: Testing and Evaluating the Acceptance and Usability of Selected Creativity Techniques in a Virtual Workspace. Braz. Creat. Ind. J. 2021, 1, 23–48. [Google Scholar] [CrossRef]

- Bellalouna, F. Industrial Case Studies for Digital Transformation of Engineering Processes Using the Virtual Reality Technology. Procedia CIRP 2020, 90, 636–641. [Google Scholar] [CrossRef]

- Fedko, D. Virtual Reality (VR) in the Automotive-Guide with Examples. Available online: https://wear-studio.com/vr-in-automotive-industry/ (accessed on 9 May 2025).

- A Showcase Becomes a Reality: Audi Brings VR Experience Platform to CES 2023|Audi MediaCenter. Available online: https://www.audi-mediacenter.com/en/press-releases/a-showcase-becomes-a-reality-audi-brings-vr-experience-platform-to-ces-2023-15106 (accessed on 9 May 2025).

- Khamis Studio x Gravity Sketch Footwear Workflow. Available online: https://get.gravitysketch.com/khamis-studio-gravity-sketch/ (accessed on 9 May 2025).

- Halarnkar, P.; Shah, S.; Shah, H.; Shah, H.; Shah, A. A Review on Virtual Reality. Int. J. Comput. Sci. Issues IJCSI 2012, 9, 325–330. [Google Scholar]

- Azuma, R.T. A Survey of Augmented Reality. Presence Teleoperators Virtual Environ. 1997, 6, 355–385. [Google Scholar] [CrossRef]

- Jahangir Moshayedi, A.; Reza, K.M.S.; Sohail Khan, A.; Nawaz, A. Integrating Virtual Reality and Robotic Operation System (ROS) for AGV Navigation. EAI Endorsed Trans. AI Robot. 2023, 2, e3. [Google Scholar] [CrossRef]

- Ajayakumar Sujatha, A.; Kolahdooz, A.; Jafari, M.; Hajfathalian, A. Simulation and Control of the KUKA KR6 900EX Robot in Unity 3D: Advancing Industrial Automation through Virtual Environments. EAI Endorsed Trans. AI Robot. 2025, 4. [Google Scholar] [CrossRef]

- Giunta, L.; O’Hare, J.; Gopsill, J.; Dekoninck, E. A Review of Augmented Reality Research for Design Practice: Looking to the Future. In Proceedings of the DS 91: Proceedings of NordDesign 2018, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Hamurcu, A.; Timur, Ş.; Rızvanoğlu, K. An Overview of Virtual Reality within Industrial Design Education. J. Eng. Des. Technol. 2020, 18, 1889–1905. [Google Scholar] [CrossRef]

- Ma, J.H.; Erdogmus, E.; Kangisser, S.; Yang, E. A Comparative Analysis of the Effectiveness of Immersive Virtual Reality on End-User Design Review. Build Environ. 2025, 267, 112237. [Google Scholar] [CrossRef]

- Alsswey, A.; Malak, M.Z.; El-Qirem, F.A. Effect of Virtual Reality on Perceptions of Usability, Suitability, Satisfaction, and Self-Efficacy among Architecture and Design University Students. Arch. Sci. Rev. 2025, 68, 56–64. [Google Scholar] [CrossRef]

- Xiao, L. A Review of Interactive Design and User Experience Research on Virtual Simulation Technology in Commercial Product Presentation. In Proceedings of the ICADI ‘24: Proceedings of the 2024 International Conference on Artificial Intelligence, Digital Media Technology and Interaction Design, Tianjin, China, 29 November–1 December 2024; pp. 170–178. [Google Scholar] [CrossRef]

- Xin, C. Exploring the Effectiveness of VR-Based Product Demonstrations Featuring Items of Furniture. Libr. Hi Tech 2024, 42, 471–495. [Google Scholar] [CrossRef]

- Prabhakaran, A.; Mahamadu, A.M.; Mahdjoubi, L.; Manu, P.; Che Ibrahim, C.K.I.; Aigbavboa, C.O. The Effectiveness of Interactive Virtual Reality for Furniture, Fixture and Equipment Design Communication: An Empirical Study. Eng. Constr. Archit. Manag. 2020, 28, 1440–1467. [Google Scholar] [CrossRef]

- Hinricher, N.; Schröer, C.; Backhaus, C. Design of Control Elements in Virtual Reality: Investigation of Factors Influencing Operating Efficiency, User Experience, Presence, and Workload. Appl. Sci. 2023, 13, 8668. [Google Scholar] [CrossRef]

- Kim, Y.M.; Rhiu, I. Development of a Virtual Reality System Usability Questionnaire (VRSUQ). Appl. Erg. 2024, 119, 104319. [Google Scholar] [CrossRef]

- Falcão, C.S.; Soares, M.M. Ergonomics, Usability and Virtual Reality: A Review Applied to Consumer Product. In Advances in Usability Evaluation Part II; CRC Press: Boca Raton, FL, USA, 2012; pp. 297–306. ISBN 9781466560550. [Google Scholar]

- Ahn, J.; Choi, S.; Lee, M.; Kim, K. Investigating Key User Experience Factors for Virtual Reality Interactions. J. Ergon. Soc. Korea 2017, 36, 267–280. [Google Scholar] [CrossRef]

- Vinicius De Freitas, F.; Vinicius Mendes Gomes, M.; Winkler, I. Benefits and Challenges of Virtual-Reality-Based Industrial Usability Testing and Design Reviews: A Patents Landscape and Literature Review. Appl. Sci. 2022, 12, 1755. [Google Scholar] [CrossRef]

- Arnfred, B.; Svendsen, J.K.; Adjourlu, A.; Horthøj, C. Scoping Review of the Hardware and Software Features of Virtual Reality Exposure Therapy for Social Anxiety Disorder, Agoraphobia, and Specific Phobia. Front. Virtual Real. 2023, 4, 952741. [Google Scholar] [CrossRef]

- Kugler, L. The State of Virtual Reality Hardware. Commun. ACM 2021, 64, 15–16. [Google Scholar] [CrossRef]

- Kourtesis, P.; MacPherson, S.E. How Immersive Virtual Reality Methods May Meet the Criteria of the National Academy of Neuropsychology and American Academy of Clinical Neuropsychology: A Software Review of the Virtual Reality Everyday Assessment Lab (VR-EAL). Comput. Hum. Behav. Rep. 2021, 4, 100151. [Google Scholar] [CrossRef]

- Smutny, P. Learning with Virtual Reality: A Market Analysis of Educational and Training Applications. Interact. Learn. Environ. 2023, 31, 6133–6146. [Google Scholar] [CrossRef]

- ISO 9241-11:2018; Ergonomics of Human-System Interaction—Part 11: Usability: Definitions and Concepts. ISO: Geneva, Switzerland, 2018.

- Yin, R.K. Case Study Research and Applications Design and Methods, 6th ed.; SAGE Publications, Inc: Thousand Oaks, CA, USA, 2017; Volume 43, ISBN 9781506336169. [Google Scholar]

- Meta Quest MR, VR Headsets and Accessories-Meta Store. Available online: https://www.meta.com/gb/quest/ (accessed on 18 June 2025).

- Gravity Sketch. Available online: https://gravitysketch.com/ (accessed on 9 May 2025).

- 3D Modeling Software for 3D Sculpting-Adobe Substance 3D. Available online: https://www.adobe.com/products/substance3d/apps/modeler.html (accessed on 16 May 2025).

- Autodesk Alias Create VR. Available online: https://help.autodesk.com/view/ALIAS/2024/ENU/?guid=Alias_CreateVR_aboutcreatevr_html (accessed on 16 May 2025).

- Autodesk Create VR for Autodesk Maya. Available online: https://apps.autodesk.com/MAYA/en/Detail/Index?id=3751509454670639690 (accessed on 19 June 2025).

- Mindesk-Your Real-Time BIM and CAD Platform. Available online: https://mindeskvr.com/ (accessed on 16 May 2025).

- ShapesXR-Bring Ideas to Life in 3D and XR. Available online: https://www.shapesxr.com/ (accessed on 16 May 2025).

- Vector Suite. Available online: https://vectorsuite.co.uk/ (accessed on 9 May 2025).

- Ishizaka, A.; Nemery, P. Multi-Criteria Decision Analysis: Methods and Software; Wiley: Hoboken, NJ, USA, 2013; pp. 1–296. [Google Scholar] [CrossRef]

- Salvendy, G. Handbook of Human Factors and Ergonomics, 4th ed.; John Wiley and Sons: Hoboken, NJ, USA, 2012; ISBN 9780470528389. [Google Scholar]

- Bowman, D.A.; Rhoton, C.J.; Pinho, M.S. Text Input Techniques for Immersive Virtual Environments: An Empirical Comparison. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2002, 46, 2154–2158. [Google Scholar] [CrossRef]

- Berg, L.P.; Vance, J.M. Industry Use of Virtual Reality in Product Design and Manufacturing: A Survey. In Virtual Reality; Springer: London, UK, 2017; Volume 21, pp. 1–17. [Google Scholar]

- Hoang, D.; Naderi, E.; Cheng, R.; Aryana, B. Adopting Immersive Technologies for Design Practice: The Internal and External Barriers. Proc. Des. Soc. Int. Conf. Eng. Des. 2019, 1, 1903–1912. [Google Scholar] [CrossRef]

- Ford Collaboration with Gravity Sketch Introduces Co-Creation Feature, Allowing Designers Across Globe to Work in Same Virtual Reality Space. Available online: https://media.ford.com/content/fordmedia/fna/us/en/news/2019/05/06/ford-collaboration-gravity-sketch-co-creation.html (accessed on 9 May 2025).

- New Apple Vision Pro App for the Porsche 911 Spirit-Porsche Newsroom. Available online: https://newsroom.porsche.com/en/2025/products/porsche-apple-vision-pro-app-911-spirit-70-39299.html (accessed on 9 May 2025).

- BMW i Augmented Reality Visualiser Launches on Google Play. Available online: https://www.press.bmwgroup.com/global/article/detail/T0268031EN/bmw-i-augmented-reality-visualiser-launches-on-google-play?language=en (accessed on 9 May 2025).

- Renault and Dacia Make New Car Buying Easier than Ever. Available online: https://www.press.renault.co.uk/releases/2726 (accessed on 9 May 2025).

- How Mercedes-Benz Uses Virtual And Augmented Reality To Sell Cars, Train Staff, And Create New Customer Experiences. Available online: https://www.forbes.com/sites/bernardmarr/2023/05/12/how-mercedes-benz-uses-virtual-and-augmented-reality-to-sell-cars-train-staff-and-create-new-customer-experiences/ (accessed on 9 May 2025).

- Zellerfeld Designs Using Gravity Sketch-Gravity Sketch. Available online: https://gravitysketch.com/resources/type/community/zellerfeld-designs-using-gravity-sketch/ (accessed on 9 May 2025).

- Live Project with Adidas and Gravity Sketch Sets Footwear Design Students up for Success. Available online: https://www.dmu.ac.uk/about-dmu/news/2024/may/live-project-with-adidas-and-gravity-sketch-sets-footwear-design-students-up-for-success.aspx (accessed on 9 May 2025).

- Apparel & Footwear-Gravity Sketch. Available online: https://gravitysketch.com/apparel-footwear/ (accessed on 9 May 2025).

- Super Chair. Available online: https://www.baker.studio/work/super (accessed on 9 May 2025).

- Batmaz, A.U.; Mutasim, A.K.; Stuerzlinger, W. Precision vs. Power Grip: A Comparison of Pen Grip Styles for Selection in Virtual Reality. In Proceedings of the Proceedings-2020 IEEE Conference on Virtual Reality and 3D User Interfaces, VRW 2020, Atlanta, GA, USA, 22–26 March 2020; Institute of Electrical and Electronics Engineers Inc: Piscataway, NJ, USA, 2020; pp. 23–28. [Google Scholar]

- Creative Tools for Artists and Designers-Unity Tools. Available online: https://unity.com/solutions/artist-designers (accessed on 16 May 2025).

- Unreal Engine for Extended Reality (XR): AR, VR & MR. Available online: https://www.unrealengine.com/en-US/xr (accessed on 16 May 2025).

- Qin, L.; Si, Z. Visual Information Transfer Design of Packaging Product Instructions Based on Unity Platform. In Advances in Graphic Communication, Printing and Packaging Technology and Materials; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2021; Volume 754 LNEE, pp. 257–262. [Google Scholar]

- Avdonina, N.; Russo, M. VR Feedback System for Product Design Service. In Advances in Representation. Digital Innovations in Architecture, Engineering and Construction; Springer: Cham, Switzerland, 2024; pp. 923–935. ISBN 978-3-031-62963-1. [Google Scholar]

- NX Immersive Designer-Siemens Software. Available online: https://plm.sw.siemens.com/en-US/nx/products/nx-immersive-designer/ (accessed on 16 May 2025).

- Review 2D & 3D Designs with EDrawings-EDrawings Viewer. Available online: https://www.edrawingsviewer.com/ (accessed on 16 May 2025).

- Immersive Design Review Workspace-Autodesk Workshop XR. Available online: https://workshopxr.autodesk.com/ (accessed on 16 May 2025).

- Create Augmented Reality with AR Software-Adobe Aero. Available online: https://www.adobe.com/products/aero.html (accessed on 16 May 2025).

- KeyShot Studio VR KeyShot. Available online: https://www.keyshot.com/es/keyshot-studio-vr/?srsltid=AfmBOorc6oW2n-DW3ry_jOczDe59Qhgil1c-aRQ_4BDT6JaoCgxlmJ-h (accessed on 16 May 2025).

- Cognitive3D|Analytics for VR, AR, MR. Available online: https://cognitive3d.com/ (accessed on 16 May 2025).

- Nelis, H. Product Design, as It Should Be: Our Investment in Gravity Sketch. Available online: https://www.accel.com/noteworthies/product-design-as-it-should-be-our-investment-in-gravity-sketch (accessed on 16 May 2025).

- Zou, Q.; Bai, H.; Gao, L.; Lee, G.A.; Fowler, A.; Billinghurst, M. Stylus and Gesture Asymmetric Interaction for Fast and Precise Sketching in Virtual Reality. Int. J. Hum. Comput. Interact. 2023, 40, 8124–8141. [Google Scholar] [CrossRef]

- Joundi, J.; Christiaens, Y.; Saldien, J.; Conradie, P.; De Marez, L. An Explorative Study towards UsingVR Sketching as a Tool for Ideation and Prototyping in Product Design. Proc. Des. Soc. Des. Conf. 2020, 1, 225–234. [Google Scholar] [CrossRef]

- Rieuf, V.; Bouchard, C.; Omhover, J.-F. Emotional Activity in Early Immersive Design: Sketches and Moodboards in Virtual Reality. Des. Stud. 2017, 48, 43–75. [Google Scholar] [CrossRef]

- Roberts, S.; Page, R.; Richardson, M. Designing in Virtual Environments: The Integration of Virtual Reality Tools into Industrial Design Research and Education. In DRS Biennial Conference Series; Design Research Society: London, UK, 2020; Volume 4, pp. 11–14. [Google Scholar]

- Liao, T.; She, J. How Does Virtual Reality (VR) Facilitate Design? A Review of VR Usage in Early-Stage Engineeging Design. Proc. Des. Soc. 2023, 3, 2115–2124. [Google Scholar] [CrossRef]

| Indicator | w | Shapes XR | Gravity Sketch |

|---|---|---|---|

| (a) Includes advanced tools | 10 | 70 | 100 |

| (b) Intuitive learning | 5.72 | 45.76 | 51.48 |

| (c) Visual quality of materials | 1.42 | 8.52 | 11.36 |

| (d) Exchangeable formats | 5.72 | 34.32 | 40.04 |

| (e) Collaborative tool | 8.57 | 68.56 | 68.56 |

| (f) File accessibility | 5.72 | 34.32 | 45.76 |

| (g) Creation of environments | 2.85 | 25.65 | 19.95 |

| Total | 40 | 287.13 | 337.15 |

| Indicator | Evaluation Criteria | Low Level (1) | Medium Level (2) | High Level (3) |

|---|---|---|---|---|

| Tasks completed (TC) | Success rate or successful tasks | TC < 5 | 5 < TC < 10 | TC > 10 |

| Time to complete tasks (T) | Total time to complete a design | T > 6 h | 2 h < T < 6 h | T < 2 h |

| Dimensional accuracy (DA) | Difference between model dimensions and reality | p > 5 mm | 0 mm < p < 5 mm | p = 0 mm |

| Interoperability (IO) | Number of applications used | IO = 0 | 1 < IO < 3 | IO > 3 |

| Interactivity (IA) | Ease of interacting with the system (Likert scale) | IA < 3 | 3 < IA < 5 | IA = 5 |

| Fatigue (F) | Continuous time without discomfort | E < 15 min | 15 min < E < 30 min | E > 30 min |

| Human error (HE) | Error rate per task or ratio of success to errors | HE < 0.06 | 0.06 < HE < 0.12 | HE > 0.12 |

| Learning curve (LC) | Decrease in task completion time between successive trials | LC < 1 min | 1 min < LC < 5 min | LC > 5 min |

| Perceived creativity (C) | Number of different variants produced | C < 4 | 4 < C < 10 | C > 10 |

| Indicator | w_Effectiveness | w_Efficiency | w_Satisfaction |

|---|---|---|---|

| Tasks completed (TC) | 0.25 | 0.1 | 0.1 |

| Time to complete tasks (T) | 0.1 | 0.25 | 0.05 |

| Dimensional accuracy (A) | 0.25 | 0.1 | 0.05 |

| Interoperability (IO) | 0.1 | 0.05 | 0.05 |

| Interactivity (IA) | 0.05 | 0.05 | 0.1 |

| Fatigue (F) | 0.05 | 0.1 | 0.1 |

| Human error (HE) | 0.1 | 0.25 | 0.05 |

| Learning curve (LC) | 0.05 | 0.05 | 0.25 |

| Perceived creativity (C) | 0.05 | 0.05 | 0.25 |

| Device | VR | AR | MR | Connection | Resolution | FOV | Release Date | Price (USD) | Software Compatibility |

|---|---|---|---|---|---|---|---|---|---|

| Apple Vision Pro | ✓ | ✓ | ✓ | Wireless | 3660 × 3200 | ≈100° | 2024 | 3499 | In development (Apple apps, Unity, Gravity Sketch) |

| HP Reverb G2 | ✓ | X | X | Wired | 2160 × 2160 | 114° | 2020 | 599 | High (Windows MR, SteamVR, Unity, Mindesk) |

| HTC Vive | ✓ | X | X | Wireless | 1080 × 1200 | 110° | 2016 | 599 | High (SteamVR, Unity, Unreal, Gravity Sketch) |

| HTC Vive Pro 2 | ✓ | X | X | Wired | 2448 × 2448 | 120° | 2021 | 799 | High (SteamVR, Mindesk, Unity, Gravity Sketch) |

| Magic Leap 2 | X | ✓ | ✓ | Wireless | 1440 × 1760 | 70° | 2022 | 3200 | Medium (Unity, Unreal, contextual AR) |

| Meta Quest 2 | ✓ | ✓ | ✓ | Wireless | 1832 × 1920 | 90° | 2020 | 299 | High (native apps and Air Link for design software) |

| Meta Quest 3 | ✓ | ✓ | ✓ | Wireless | 2064 × 2208 | 110° | 2023 | 499 | Very high (Gravity Sketch, ShapesXR, Unity, Unreal, etc.) |

| Microsoft HoloLens 2 | X | ✓ | ✓ | Wireless | 2048 × 1080 | 52° | 2019 | 3500 | Medium (Unity AR, Vuforia, industrial apps) |

| Oculus Rift | ✓ | X | X | Wired | 1080 × 1200 | 110° | 2016 | 399 | High (SteamVR, Unity, Unreal, Gravity Sketch PC) |

| Pico 4 | ✓ | ✓ | ✓ | Wireless | 2160 × 2160 | 105° | 2022 | 429 | Medium (limited support for creative apps) |

| Pico Neo 3 | ✓ | ✓ | ✓ | Wireless | 1832 × 1920 | 98° | 2021 | 699 | Medium (enterprise, Unity, limited AR) |

| Valve Index | ✓ | X | X | Wired | 1440 × 1600 | 130° | 2019 | 999 | High (SteamVR, Unity, Unreal, Gravity Sketch PC) |

| Varjo XR-3 | ✓ | ✓ | ✓ | Wired | 1920 × 1920 | 115° | 2021 | 6495 | Very high (Mindesk, Unity, Unreal, professional design) |

| Varjo XR-4 | ✓ | ✓ | ✓ | Wired | 1920 × 1920 (estimate) | 120° | 2024 | 5990 | Very high (CAD, Mindesk, Unity, Unreal, etc.) |

| Vive Focus 3 | ✓ | ✓ | ✓ | Wireless | 2448 × 2448 | 120° | 2021 | 1300 | High (XR Suite, Unity, Unreal, Gravity Sketch) |

| Vive XR Elite | ✓ | ✓ | ✓ | Wireless | 1920 × 1920 | 110° | 2023 | 1099 | High (Unity, Unreal, increasing compatibility) |

| Software | Primary Category 1 | Requires PC | Recommended Hardware | CAD Compatibility 2 | Collaboration | Learning Curve 3 |

|---|---|---|---|---|---|---|

| Adobe Substance Modeler | (1) | ✓ | Meta Quest, Reverb G2 | Medium | Low | Medium |

| Autodesk Alias Create VR | (2) | ✓ | HTC Vive Pro 2, Valve Index | High | Medium | High |

| Autodesk Create VR (Maya) | (1) | ✓ | Vive Pro, Index, Reverb | High | Medium | Medium |

| Gravity Sketch | (1) (3) (5) | X | Meta Quest 2/3, Vive XR Elite | Partial | Medium | Low |

| Mindesk | (2) (5) | ✓ | Varjo XR-3, Reverb G2, Vive Pro | Very high | High | High |

| ShapesXR | (3) (5) | X | Meta Quest 2/3, Pico 4 | Partial | High | Low |

| Tilt Brush/OpenBrush | (1) | X | Meta Quest 2/3, Pico Neo 3 | None | Low | Low |

| Tvori | (4) | ✓ | PC VR | Low– medium | Medium | Medium |

| Unity | (4) (5) | ✓ | Varjo XR, Quest Pro, Vive XR Elite | High | High | Very high |

| Unreal Engine | (4) (5) | ✓ | Varjo XR, Reverb, Vive XR Elite | High | High | Very high |

| Vector Suite | (1) (5) | ✓ | Vive Pro, Reverb G2, Index | Partial | High | Medium |

| Design Units | S | F | R | I | L | Te | Tt | Human Error (HE) |

|---|---|---|---|---|---|---|---|---|

| 1. Ring | 1 | 4 | 3 | 20 | 10 | 1 | 2 | 0.03 |

| 2. Candle Holder | 1 | 8 | 10 | 5 | 5 | 5 | 7 | 0.03 |

| 3. Vehicle | 1 | 5 | 4 | 10 | 5 | 1 | 1 | 0.04 |

| 4. Mouse | 1 | 6 | 5 | 9 | 4 | 1 | 8 | 0.04 |

| 5. Outdoor Armchair | 1 | 5 | 8 | 4 | 5 | 2 | 6 | 0.04 |

| 6. Reading Armchair | 2 | 14 | 3 | 2 | 3 | 1 | 8 | 0.08 |

| 7. High Stool | 4 | 15 | 4 | 3 | 3 | 2 | 8 | 0.14 |

| Effectiveness | Efficiency | Satisfaction | |

|---|---|---|---|

| %RSD S1/S2 | 12.61 | 12.32 | 10.86 |

| %RSD S1/S3 | 22.4 | 19.95 | 21.45 |

| RMSE S1/S2 | 0.2 | 0.19 | 0.17 |

| RMSE S1/S3 | 0.35 | 0.31 | 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Mariscal, A.; Torres-Leal, C.; Aguilar-Planet, T.; Peralta, E. The Role of Virtual and Augmented Reality in Industrial Design: A Case Study of Usability Assessment. Appl. Sci. 2025, 15, 8725. https://doi.org/10.3390/app15158725

Martín-Mariscal A, Torres-Leal C, Aguilar-Planet T, Peralta E. The Role of Virtual and Augmented Reality in Industrial Design: A Case Study of Usability Assessment. Applied Sciences. 2025; 15(15):8725. https://doi.org/10.3390/app15158725

Chicago/Turabian StyleMartín-Mariscal, Amanda, Carmen Torres-Leal, Teresa Aguilar-Planet, and Estela Peralta. 2025. "The Role of Virtual and Augmented Reality in Industrial Design: A Case Study of Usability Assessment" Applied Sciences 15, no. 15: 8725. https://doi.org/10.3390/app15158725

APA StyleMartín-Mariscal, A., Torres-Leal, C., Aguilar-Planet, T., & Peralta, E. (2025). The Role of Virtual and Augmented Reality in Industrial Design: A Case Study of Usability Assessment. Applied Sciences, 15(15), 8725. https://doi.org/10.3390/app15158725