Selective Laser Melting of a Ti-6Al-4V Lattice-Structure Gear: Design, Topology Optimization, and Experimental Validation

Abstract

1. Introduction

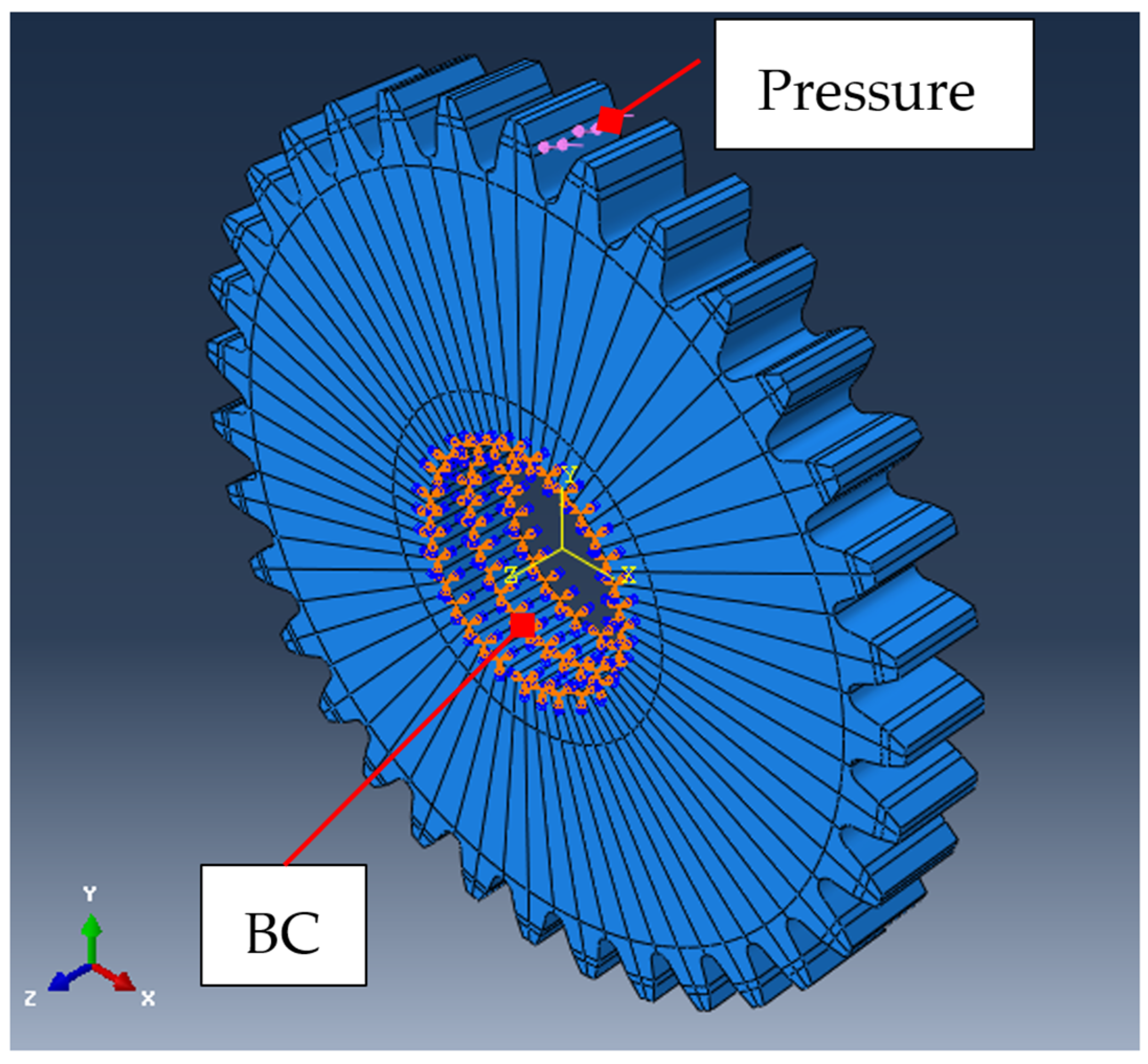

2. Design and Optimization

2.1. Numerical Model

2.2. Topology Optimization

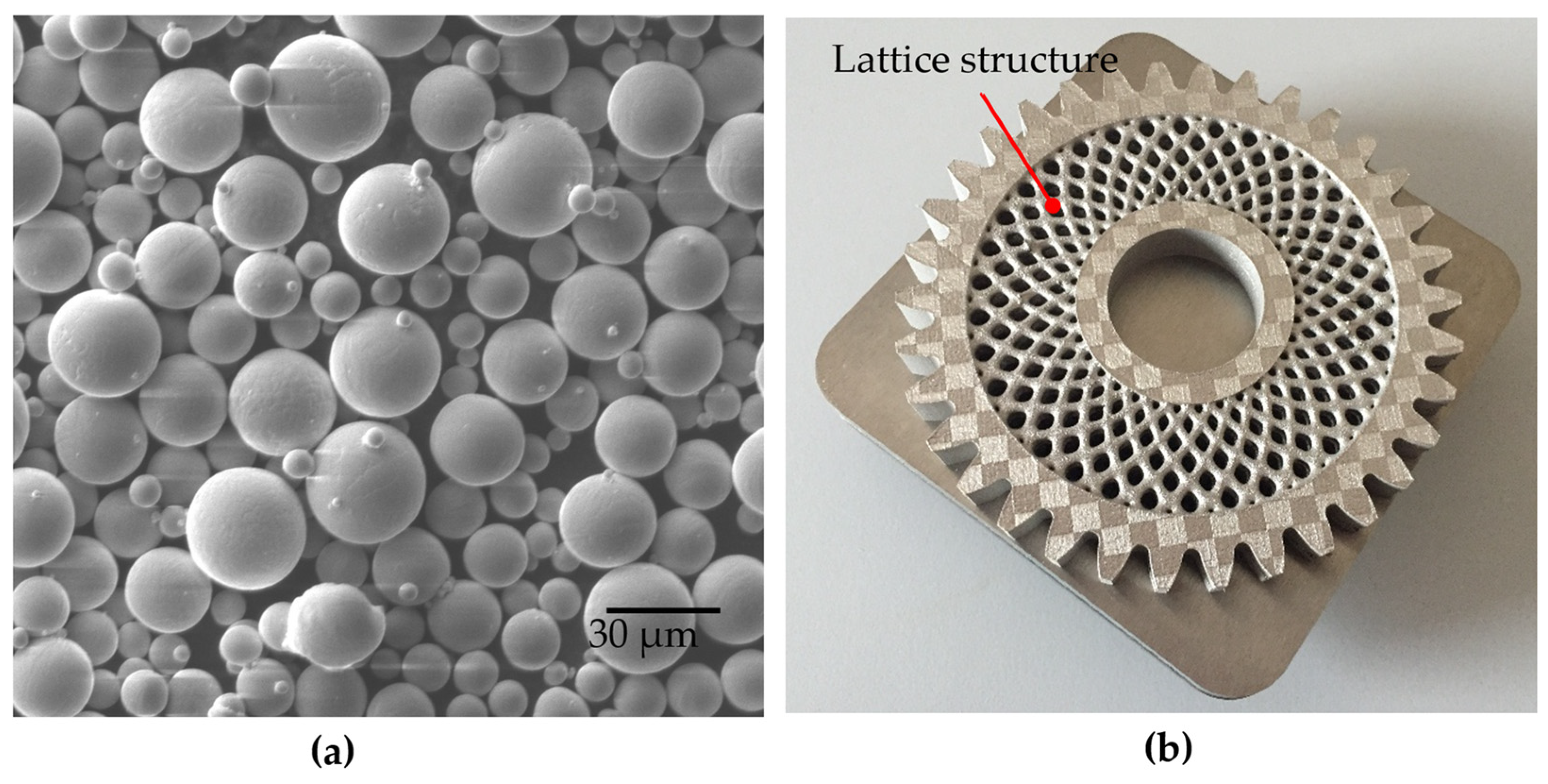

3. Gear Manufacturing

3.1. Material Selection

3.2. Effects of Manufacturing Parameters

3.3. Manufacturing Build-Up Direction

3.4. Gear Fabrication Problems

3.5. Post Processing

3.6. The Final Gear Product

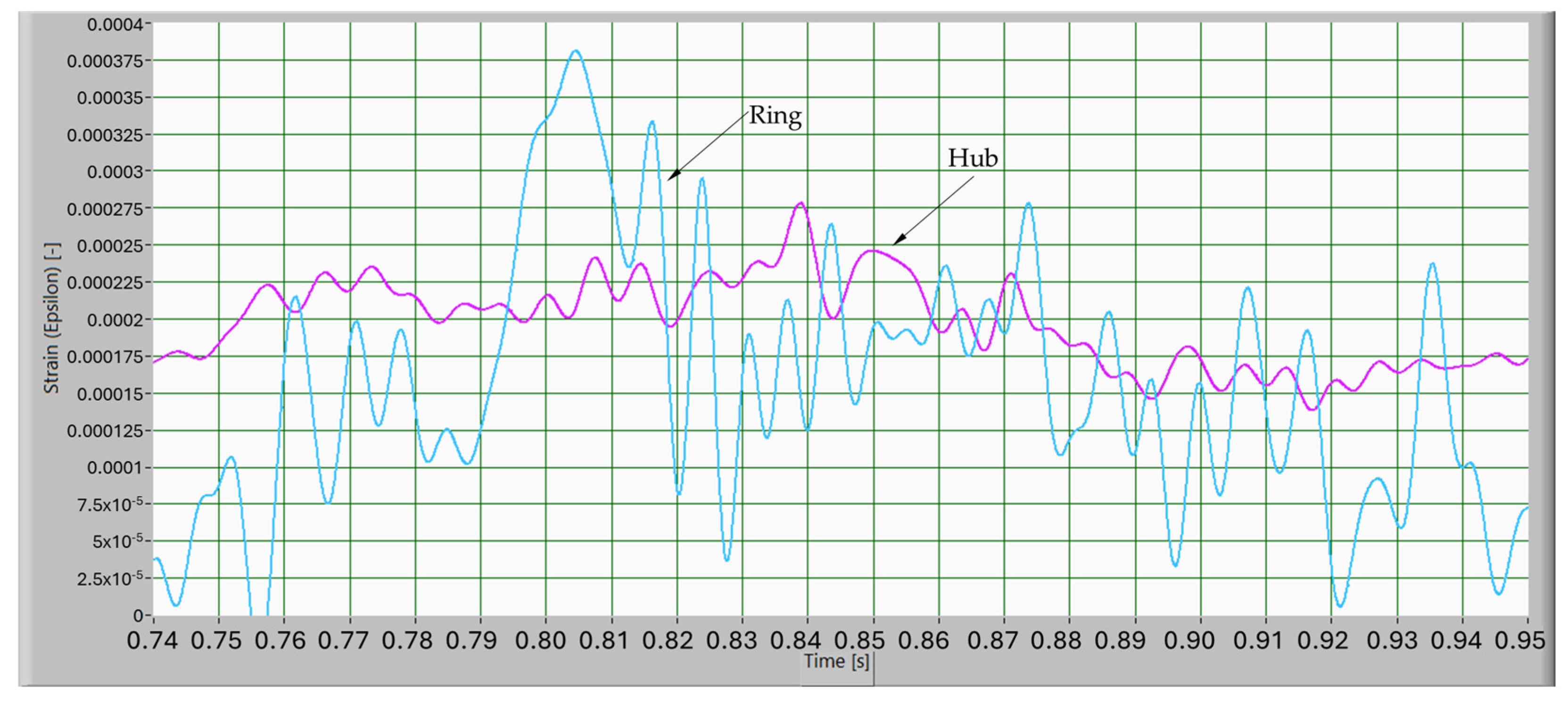

4. Strain Measurement System Development and Results

4.1. Test Rig Development

4.2. Experimental Setup for Strain Measurement

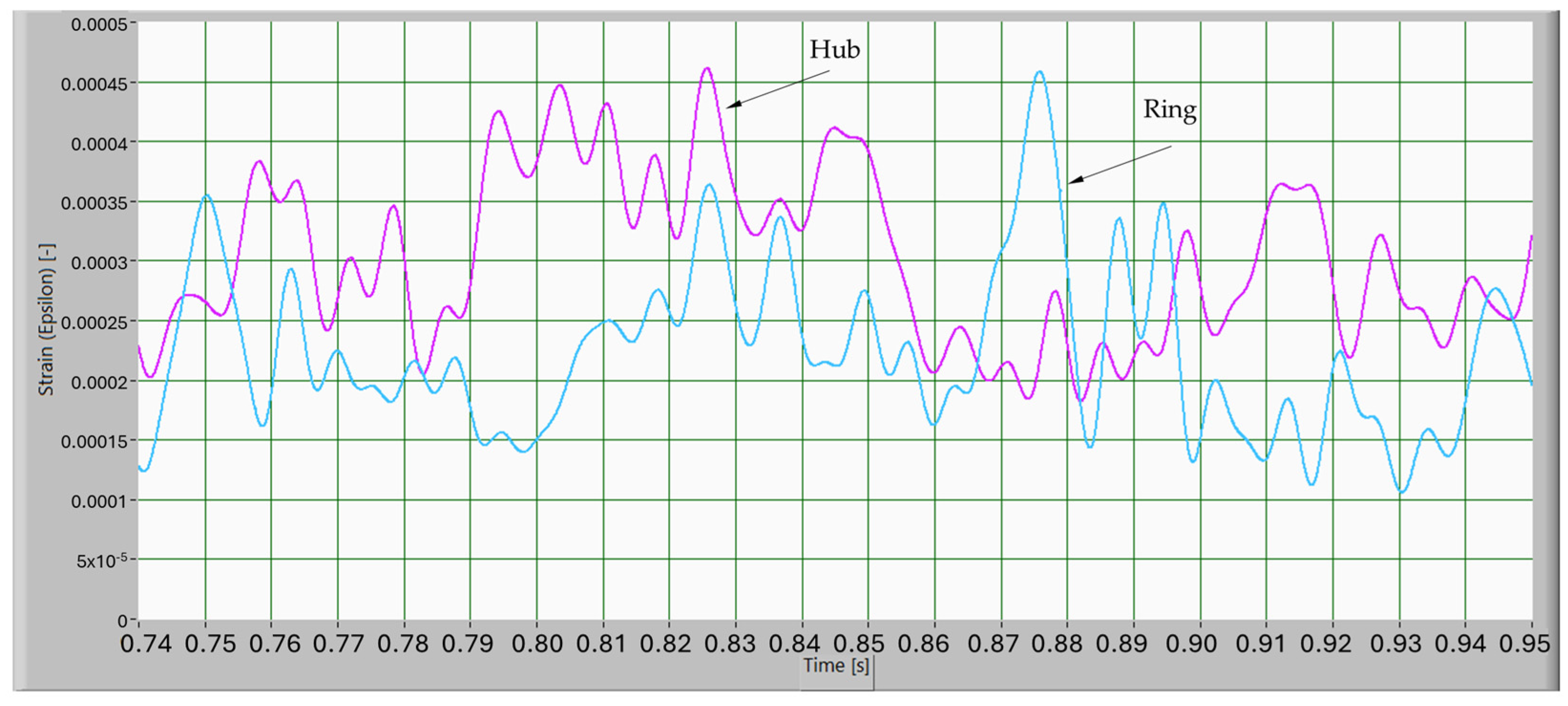

4.3. Strain on the Solid-Body Gear

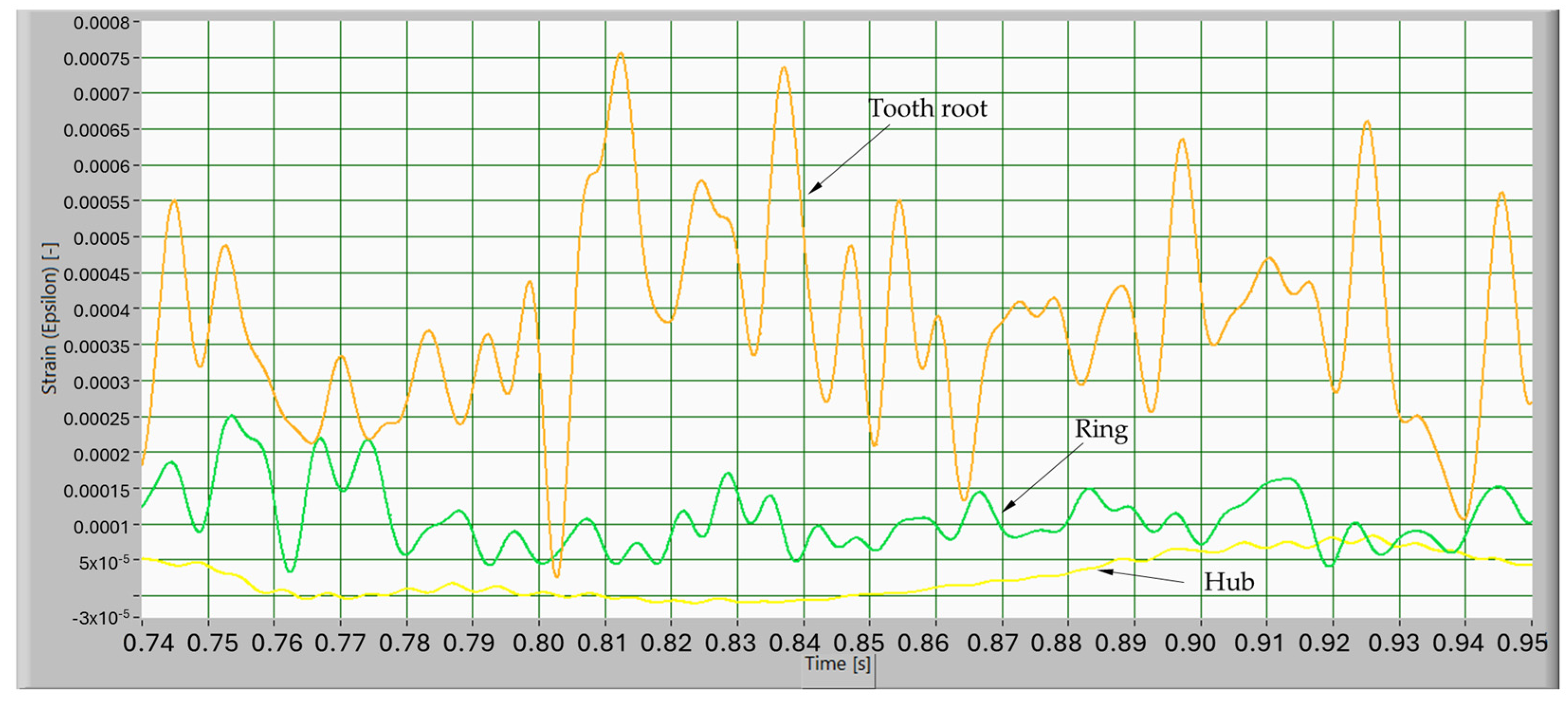

4.4. Strain on the Lattice-Structure Gear

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Czerwinski, F. Current trends in automotive lightweighting strategies and materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Hopkins, N.; Jiang, L.; Brooks, H. Energy consumption of common desktop additive manufacturing technologies. Clean. Eng. Technol. 2021, 2, 100068. [Google Scholar] [CrossRef]

- Benkert, T.; Hiller, M.; Volk, W. Multi-component lightweight gearwheels with deep-drawn wheel body for automotive applications. J. Phys. Conf. Ser. 2017, 896, 012083. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, A.; Shi, L.; Qin, D.; Lim, T.C. Modeling and dynamic characteristics of planetary gear transmission in non-inertial system of aerospace environment. J. Mech. Des. Trans. ASME 2020, 142, 031103. [Google Scholar] [CrossRef]

- Andary, F.; Berroth, J.; Jacobs, G. An Energy-Based Load Distribution Approach for the Application of Gear Mesh Stiffness on Elastic Bodies. J. Mech. Des. Trans. ASME 2019, 141, 095001. [Google Scholar] [CrossRef]

- Gu, X.; Velex, P.; Sainsot, P.; Bruyère, J. Analytical investigations on the mesh stiffness function of solid spur and helical gears. J. Mech. Des. Trans. ASME 2015, 137, 063301. [Google Scholar] [CrossRef]

- Hu, Z.; Tang, J.; Chen, S.; Lei, D. Effect of mesh stiffness on the dynamic response of face gear transmission system. J. Mech. Des. Trans. ASME 2013, 135, 071005. [Google Scholar] [CrossRef]

- Faggioni, M.; Samani, F.S.; Bertacchi, G.; Pellicano, F. Dynamic optimization of spur gears. Mech. Mach. Theory 2011, 46, 544–557. [Google Scholar] [CrossRef]

- Ghosh, S.S.; Chakraborty, G. On optimal tooth profile modification for reduction of vibration and noise in spur gear pairs. Mech. Mach. Theory 2016, 105, 145–163. [Google Scholar] [CrossRef]

- Ma, H.; Pang, X.; Feng, R.; Wen, B. Evaluation of optimum profile modification curves of profile shifted spur gears based on vibration responses. Mech. Syst. Signal Process. 2016, 70, 1131–1149. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Lee, C.H. Multi-parameter optimization-based design of lightweight vibration-reduction gear bodies. J. Mech. Sci. Technol. 2022, 36, 1879–1887. [Google Scholar] [CrossRef]

- Shweiki, S.; Palermo, A.; Mundo, D. A Study on the Dynamic Behaviour of Lightweight Gears. Shock Vib. 2017, 2017, 7982170. [Google Scholar] [CrossRef]

- Xiao, W.; Huang, Y.; Jiang, H.; Jin, L. Effect of powder material on vibration reduction of gear system in centrifugal field. Powder Technol. 2016, 294, 146–158. [Google Scholar] [CrossRef]

- Xiao, W.; Li, J.; Wang, S.; Fang, X. Study on vibration suppression based on particle damping in centrifugal field of gear transmission. J. Sound Vib. 2016, 366, 62–80. [Google Scholar] [CrossRef]

- Li, S. Experimental investigation and FEM analysis of resonance frequency behavior of three-dimensional, thin-walled spur gears with a power-circulating test rig. Mech. Mach. Theory 2008, 43, 934–963. [Google Scholar] [CrossRef]

- Iandiorio, C.; Mattei, G.; Marotta, E.; Costanza, G.; Tata, M.E.; Salvini, P. The Beneficial Effect of a TPMS-Based Fillet Shape on the Mechanical Strength of Metal Cubic Lattice Structures. Materials 2024, 17, 1553. [Google Scholar] [CrossRef]

- Iandiorio, C.; Milani, D.; Salvini, P. Optimal Uniform Strength Design of Frame and Lattice Structures. Comput. Struct. 2024, 301, 107430. [Google Scholar] [CrossRef]

- Dong, G.; Tang, Y.; Li, D.; Zhao, Y.F. Design and optimization of solid lattice hybrid structures fabricated by additive manufacturing. Addit. Manuf. 2020, 33, 101116. [Google Scholar] [CrossRef]

- CAESS ProTOp. Available online: www.caess.eu (accessed on 12 March 2025).

- Dong, G.; Tang, Y.; Zhao, Y.F. A survey of modeling of lattice structures fabricated by additive manufacturing. J. Mech. Des. Trans. ASME 2017, 139, 100906. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, Y.; Xiao, R.; Bai, Y.; Song, C.; Wang, D. Evaluation of topology-optimized lattice structures manufactured via selective laser melting. Mater. Des. 2018, 143, 27–37. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Condruz, M.R.; Badea, T.A.; Paraschiv, A. Compressive Behavior of Inconel 625 and Ti-6Al-4V Strut Lattices Fabricated by LPBF. Appl. Sci. 2024, 14, 11909. [Google Scholar] [CrossRef]

- Sambo, A.M.; Younas, M.; Njuguna, J. Insights into Machining Techniques for Additively Manufactured Ti6Al4V Alloy: A Comprehensive Review. Appl. Sci. 2024, 14, 10340. [Google Scholar] [CrossRef]

- Cuesta, I.I.; Díaz, A.; Rojo, M.A.; Peral, L.B.; Martínez, J.; Alegre, J.M. Parameter Optimisation in Selective Laser Melting on C300 Steel. Appl. Sci. 2022, 12, 9786. [Google Scholar] [CrossRef]

- Arun, A.P.; Giriraj, B.; Rahaman, A.F. Gear test rig—A review. Int. J. Mech. Mechatron. Eng. 2014, 14, 16–26. [Google Scholar]

- Uctu, O.; Sevim, I. Investigation of parallel axis gear test rigs and selection criterias to design. In Proceedings of the 2017 8th International Conference on Mechanical and Aerospace Engineering, ICMAE 2017, Prague, Czech Republic, 22–25 July 2017. [Google Scholar] [CrossRef]

- Abruzzo, M.; Beghini, M.; Santus, C.; Manconi, S. Dynamic behavior of a power re-circulating gear test rig including periodic variation of mesh stiffness and static transmission error. Mech. Mach. Theory 2021, 159, 104247. [Google Scholar] [CrossRef]

- Patil, C.M.; Pingale, A.D. Measurement of Gear Stiffness of Healthy and Cracked Spur Gear by Strain Gauge Technique. Int. J. Mech. Eng. 2018, 5, 9–15. [Google Scholar] [CrossRef]

- Raghuwanshi, N.K.; Parey, A. Experimental measurement of gear mesh stiffness of cracked spur gear by strain gauge technique. Measurement 2016, 86, 266–275. [Google Scholar] [CrossRef]

- Dai, H.; Chen, F.; Xun, C.; Long, X. Numerical calculation and experimental measurement for gear mesh force of planetary gear transmissions. Mech. Syst. Signal Process. 2022, 162, 108085. [Google Scholar] [CrossRef]

- KiSSsift Hirnware. Available online: https://www.kisssoft.com/en (accessed on 2 March 2025).

- Abaqus/CAE 6.14 User’s Guide. Available online: http://62.108.178.35:2080/v6.14/books/usi/default.htm (accessed on 13 February 2025).

- Harl, B.; Predan, J.; Gubeljak, N.; Kegl, M. On configuration-based optimal design of load-carrying lightweight parts. Int. J. Simul. Model. 2017, 16, 219–228. [Google Scholar] [CrossRef]

- Ramadani, R.; Belsak, A.; Kegl, M.; Predan, J.; Pehan, S. Topology Optimization Based Design of Lightweight and Low Vibration Gear Bodies. Int. J. Simul. Model. 2018, 17, 92–104. [Google Scholar] [CrossRef]

- Textor, M.; Sittig, C.; Frauchiger, V.; Tosatti, S.; Brunette, D.M. 7 Properties and Biological Significance of Natural Oxide Films on Titanium and Its Alloys; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Boivineau, M.; Cagran, C.; Doytier, D.; Eyraud, V.; Nadal, M.-H.; Wilthan, B.; Pottlacher, G. Thermophysical properties of solid and liquid Ti-6Al-4V (TA6V) alloy. Int. J. Thermophys 2006, 27, 507–529. [Google Scholar] [CrossRef]

- Pegues, J.; Roach, M.; Williamson, R.S.; Shamsaei, N. Surface roughness effects on the fatigue strength of additively manufactured Ti-6Al-4V. Int. J. Fatigue 2018, 116, 543–552. [Google Scholar] [CrossRef]

- Moosa, A.U.; Hernández-Nava, E.; Mejbel, M.K.; Todd, I. The joining of CP-vanadium and Ti–6Al–4V using the Electron Beam Melting Additive Manufacturing method. Adv. Ind. Manuf. Eng. 2022, 5, 100102. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Tagliaferri, F.; Venettacci, S.; Horn, M.; Giannini, O.; Guarino, S. Re-Engineering of an Impeller for Submersible Electric Pump to Be Produced by Selective Laser Melting. Appl. Sci. 2021, 11, 7375. [Google Scholar] [CrossRef]

- Ramadani, R.; Pal, S.; Kegl, M.; Predan, J.; Drstvenšek, I.; Pehan, S.; Belšak, A. Topology optimization and additive manufacturing in producing lightweight and low vibration gear body. Int. J. Adv. Manuf. Technol. 2021, 113, 3389–3399. [Google Scholar] [CrossRef]

- Gu, Q.; Li, H.; Yang, Z.; Zhang, Y.; Liu, X.; Li, G. Microstructure and Phase Transformation Temperature of NiTiNb Shape Memory Alloy Prepared by Laser Solid Forming Using Mixed Powder. Appl. Sci. 2022, 12, 2371. [Google Scholar] [CrossRef]

- Mayoral, N.; Medina, L.; Rodríguez-Aparicio, R.; Díaz, A.; Alegre, J.M.; Cuesta, I.I. Process Parameter Optimisation in Laser Powder Bed Fusion of Duplex Stainless Steel 2205. Appl. Sci. 2024, 14, 6655. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Fiocchi, J.; Biffi, C.A.; Chiandussi, G.; Rossetto, M.; Tuissi, A. VHCF Response up to 109 Cycles of SLM AlSi10Mg Specimens Built in a Vertical Direction. Appl. Sci. 2019, 9, 2954. [Google Scholar] [CrossRef]

| Element | Wt.% |

|---|---|

| Ti | Balanced |

| Al | 6 |

| V | 4 |

| N | <0.1 |

| C | <0.1 |

| H | <0.1 |

| Fe | <0.1 |

| O | <0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramadani, R.; Pal, S.; Belšak, A.; Predan, J. Selective Laser Melting of a Ti-6Al-4V Lattice-Structure Gear: Design, Topology Optimization, and Experimental Validation. Appl. Sci. 2025, 15, 7949. https://doi.org/10.3390/app15147949

Ramadani R, Pal S, Belšak A, Predan J. Selective Laser Melting of a Ti-6Al-4V Lattice-Structure Gear: Design, Topology Optimization, and Experimental Validation. Applied Sciences. 2025; 15(14):7949. https://doi.org/10.3390/app15147949

Chicago/Turabian StyleRamadani, Riad, Snehashis Pal, Aleš Belšak, and Jožef Predan. 2025. "Selective Laser Melting of a Ti-6Al-4V Lattice-Structure Gear: Design, Topology Optimization, and Experimental Validation" Applied Sciences 15, no. 14: 7949. https://doi.org/10.3390/app15147949

APA StyleRamadani, R., Pal, S., Belšak, A., & Predan, J. (2025). Selective Laser Melting of a Ti-6Al-4V Lattice-Structure Gear: Design, Topology Optimization, and Experimental Validation. Applied Sciences, 15(14), 7949. https://doi.org/10.3390/app15147949