Technical Chains in Civil and Urban Engineering: Review of Selected Solutions, Shaping, Geometry, and Dimensioning

Abstract

1. Introduction

1.1. Research Gap and Study Objective

- Which combinations of polymer matrices, reinforcements, and functional additives achieve the minimum working load limit demanded by civil engineering chain classes?

- How do link-scale geometric parameters modify stress localization across different material categories?

- Which knowledge gaps currently prevent codification of design rules for non-metallic chains?

1.2. Life Cycle Assessment (LCA)

1.3. Market Identification

1.4. Scope and Limitations

1.5. Review Strategy

- Explicit testing of chain or link specimens;

- Numerical/analytical dimensioning studies;

- Material innovations relevant to load-bearing chains.

2. Keyword Analysis

3. Research Area and General Purpose of Study

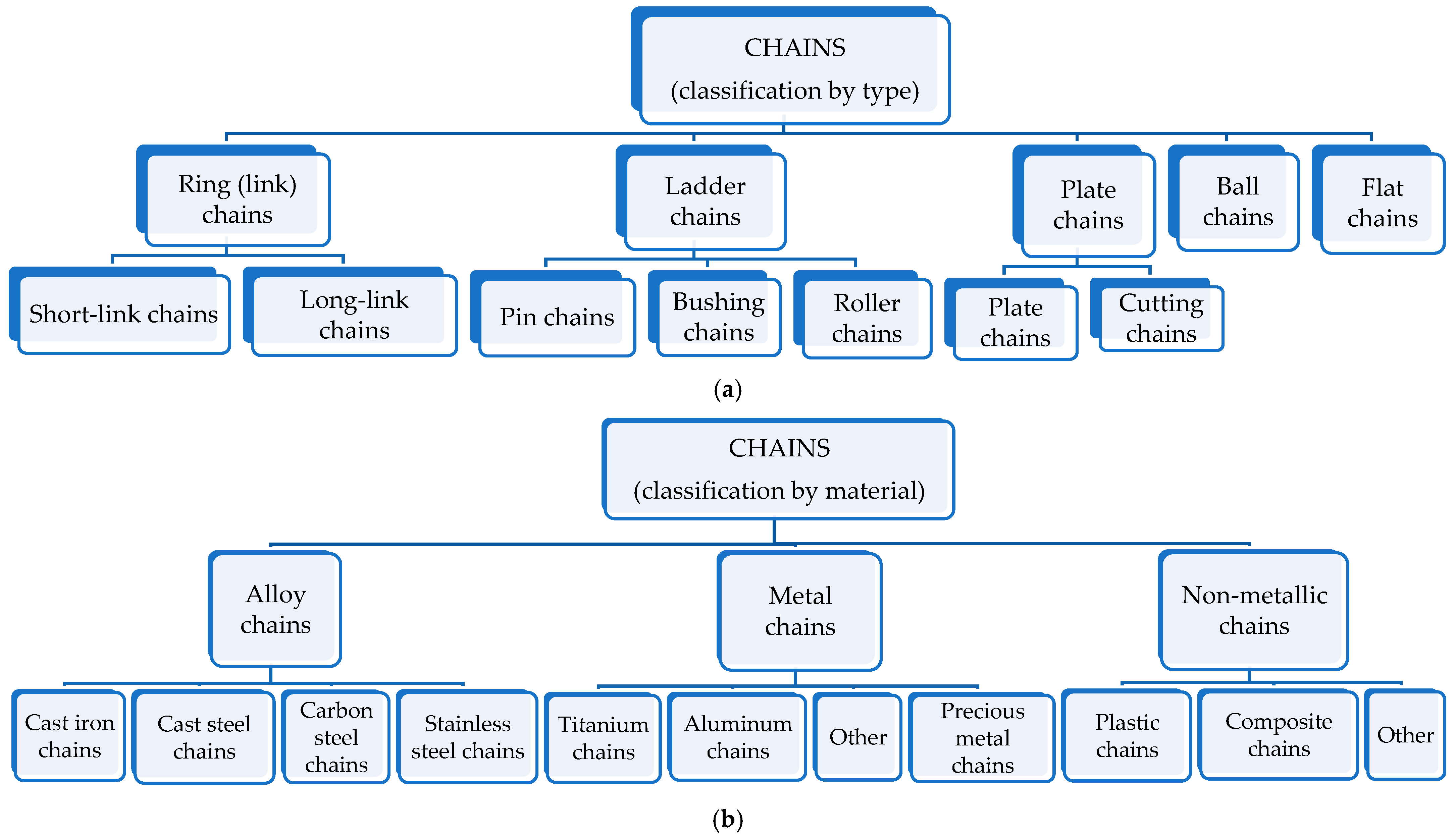

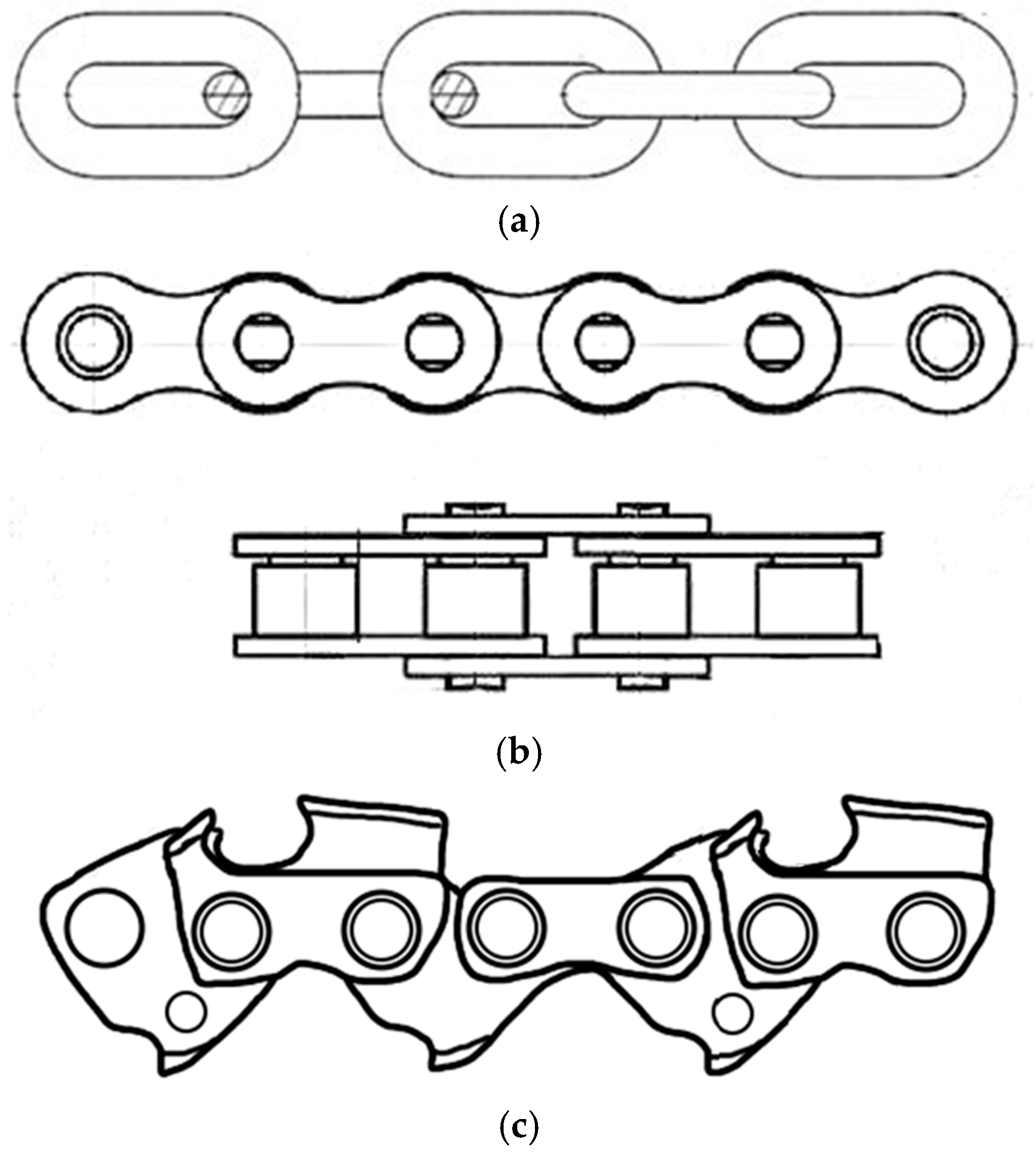

- Types, materials, and applications: A classification of chains is provided based on type, material, and intended function, with an emphasis on their wide use across various industrial sectors. The importance of proper material selection is discussed in relation to durability, strength, and corrosion resistance. The role of modern plastics and composites is also highlighted, especially in terms of improving energy efficiency and supporting sustainable industrial development.

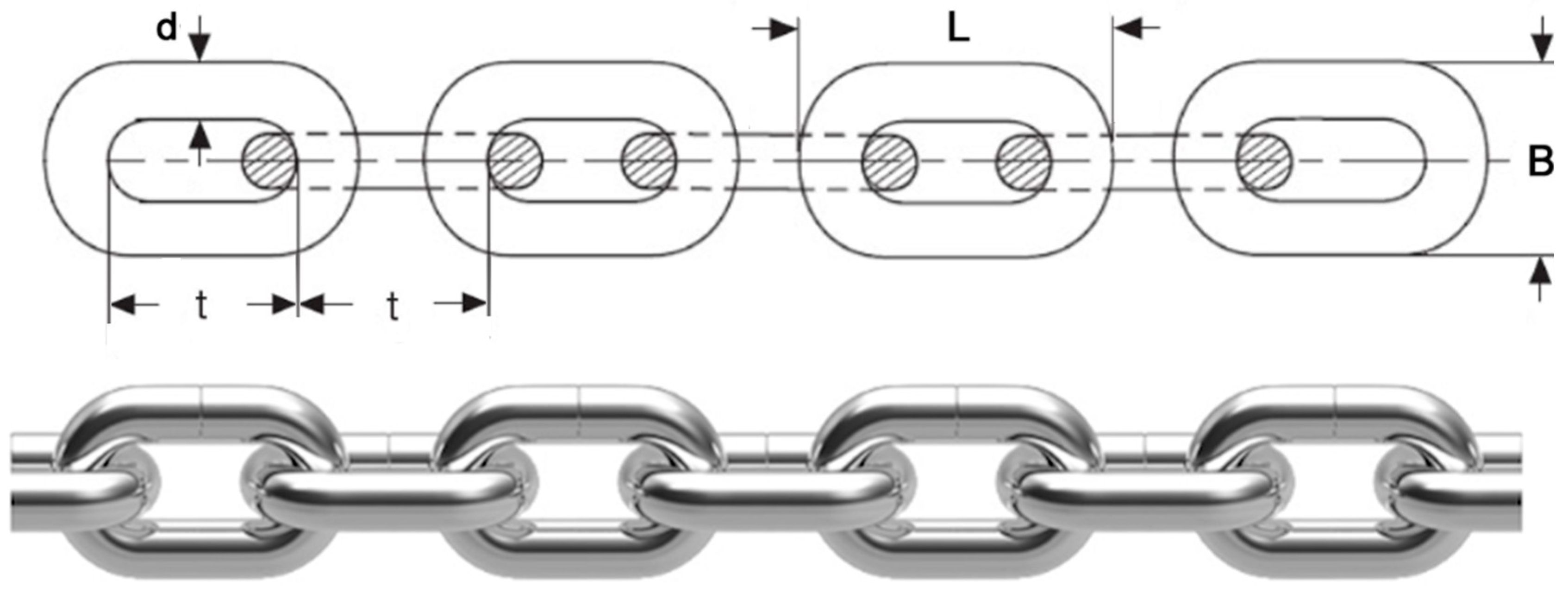

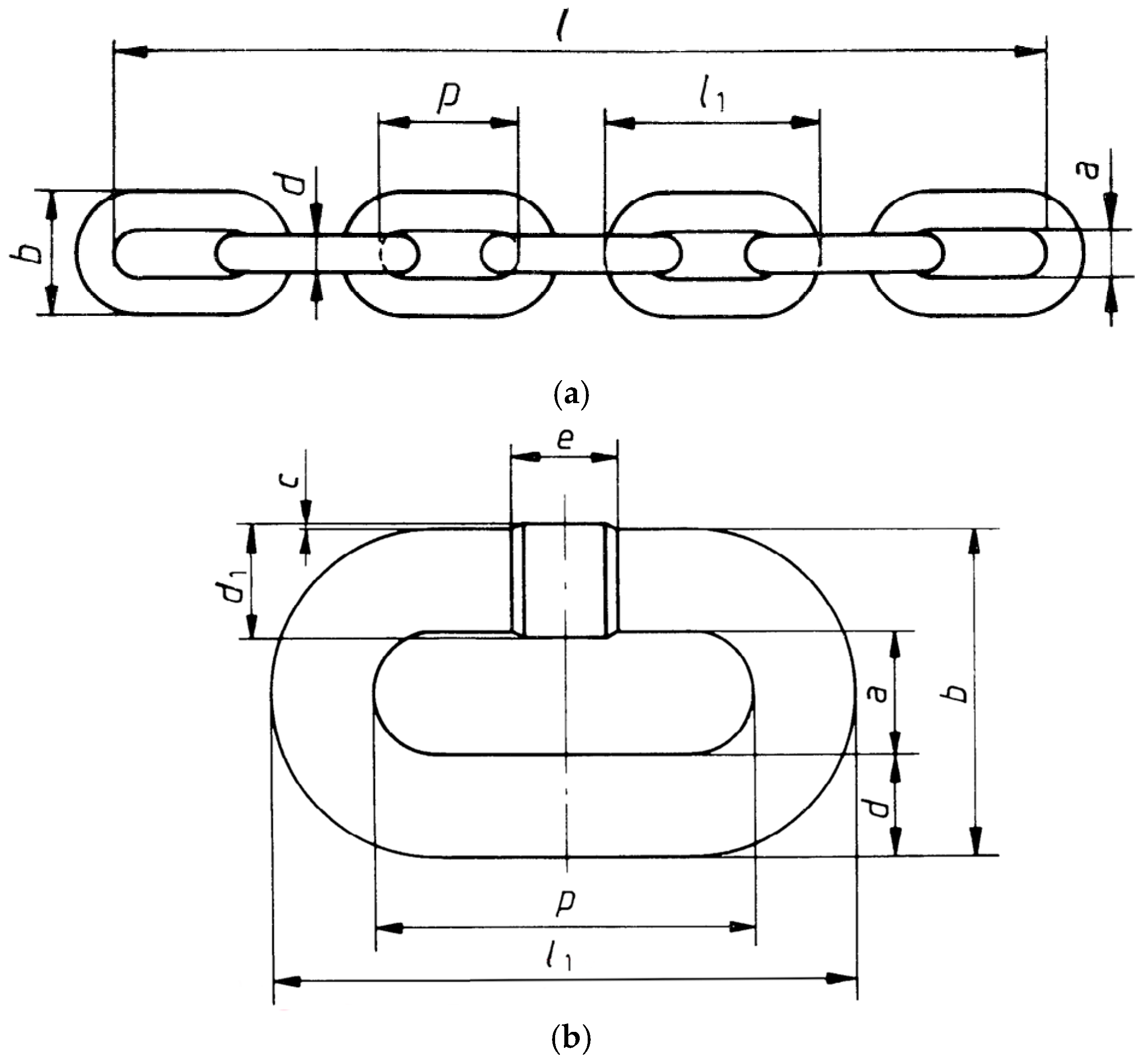

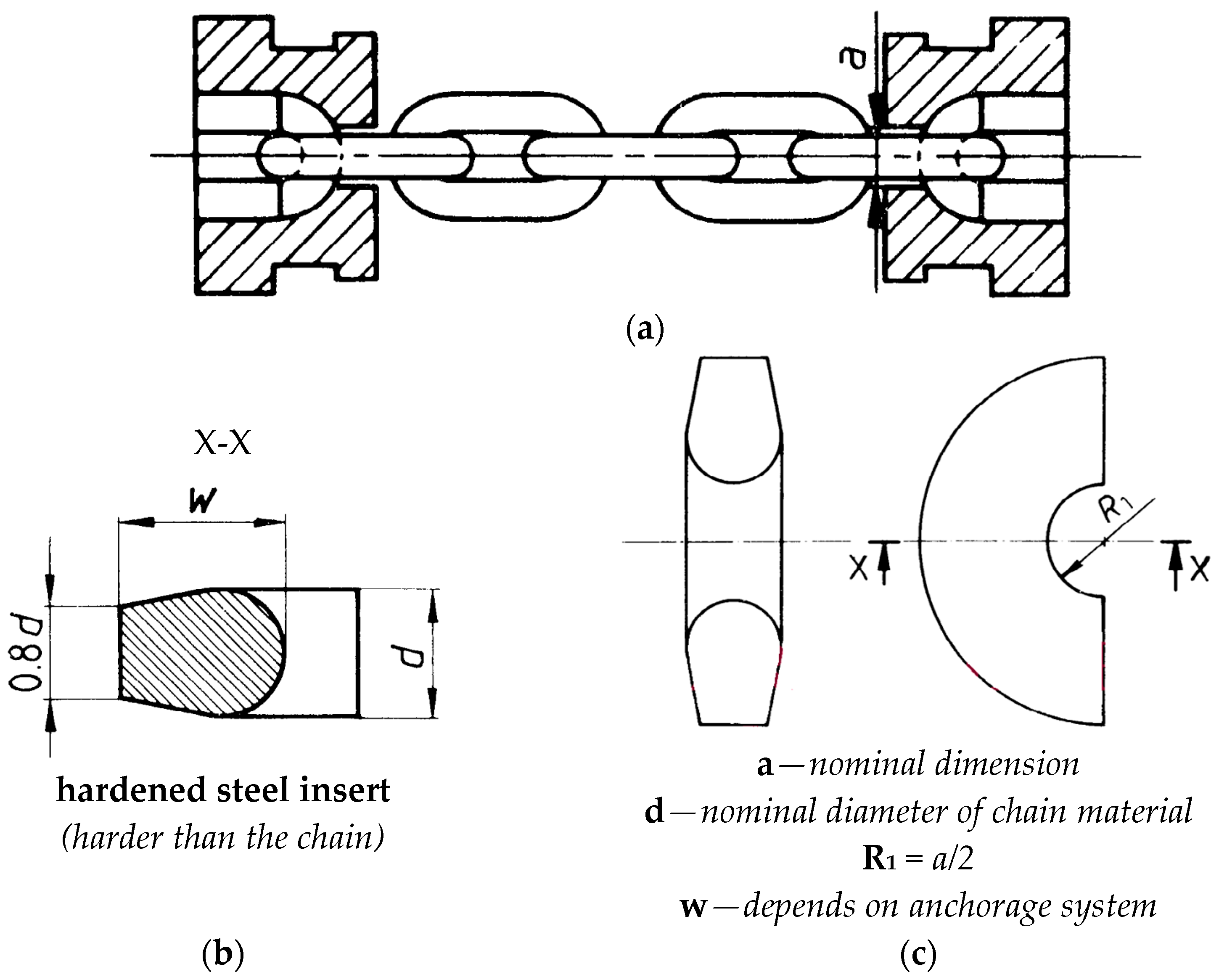

- Basic requirements and dimensioning: A compilation of selected standards related to the manufacturing and design of steel chains is presented. However, such standards are lacking for chains made of other materials, particularly polymers. A sample description of the design and fabrication of a link chain is included.

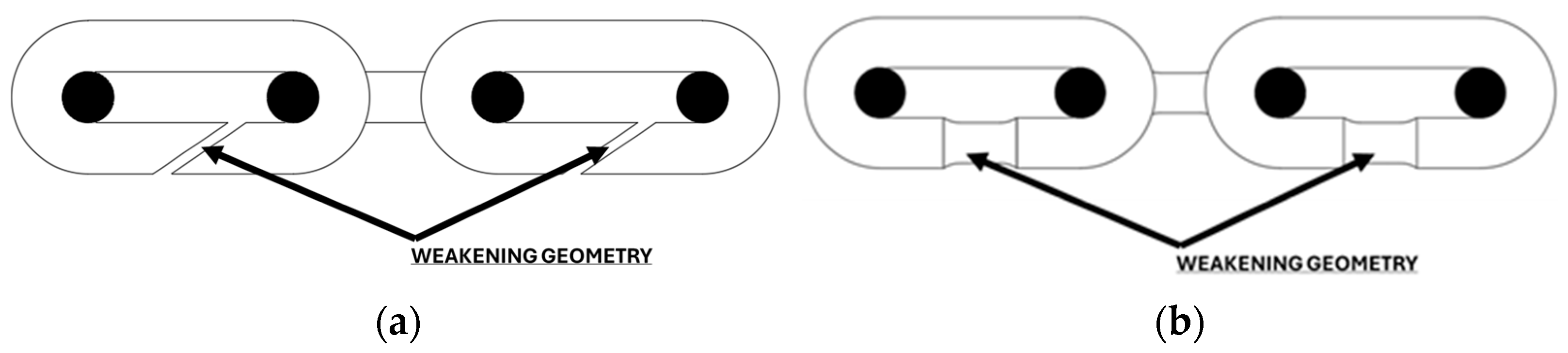

- Shaping and geometry: The geometry of chain links plays a critical role in their strength and functionality. Properly designed link geometry reduces stress concentrations and deformation, thereby enhancing the chain’s longevity. Numerical simulations enable precise optimization of link shapes, reducing the risk of mechanical failure.

4. Constructional and Functional Aspects of Chains

4.1. Types, Materials, and Applications

4.2. Requirements and Dimensioning

- Chain size, defined as the nominal diameter of the wire or steel rod used to produce the chain.

- Breaking force—the maximum tensile force a finished chain sample can withstand before failure.

- Proof force—a specified force that a finished chain sample must withstand without exceeding the defined elongation limit.

- Acceptance force—a specified force that must be applied to the entire chain after processing, without causing permanent deformation or damage; this force may be reapplied at the discretion of the purchaser or inspector.

- Percentage elongation—the measured elongation expressed as a percentage of the gauge length.

- Processing—any post-welding operation such as heat treatment, calibration, or surface finishing.

- Calibration—the application of force to the entire chain during production to control link dimensions.

- Elastic limit—the maximum force that can be applied to the chain without causing permanent deformation.

- Setting force—the force used to hold the specimen under tension while the gauge length is marked or a strain gauge is installed.

4.3. Link Shaping and Geometry

5. Future, Perspectives, and Research Gaps

6. Conclusions

- A classification of chains by type, material, and application was developed. Steel remains the predominant material used in chain manufacturing, although polymer composites are gaining relevance.

- While numerous standards exist for the design and manufacturing of technical steel link chains, similar guidelines are lacking for chains made from other materials, especially modified polymers.

- The geometry of chain links is critical for strength and operational performance, particularly under harsh conditions. Proper link design reduces stress concentrations and deformation, improving chain durability. Three-dimensional modeling and numerical simulations help optimize link dimensions and minimize failure risk.

Author Contributions

Funding

Conflicts of Interest

References

- Makoto, K. The Complete Guide to Chain, 1st ed.; Otoshi, K., Kanehira, M., Eds.; U.S. Tsubaki Inc. (original publisher: Sachio Shimura): Wheling, IL, USA, 1997; ISBN 0-9658932-0-0. [Google Scholar]

- Kandzia, R.; Szot, M. Technological aspects of mining chain production development. Min. Inform. Autom. Electr. Eng. 2023, 1, 35–44. [Google Scholar] [CrossRef]

- Shigley, J.E.; Budynas, R.G.; Mischke, C.R. Mechanical Engineering Design, 7th ed.; McGraw-Hill Science: London, UK, 2003; ISBN 978-0-07-123270-8. [Google Scholar]

- Vitruvius Pollio, M. De Architectura—Ten Books on Architecture; Dover Publications: Garden City, NY, USA, 1960. [Google Scholar]

- Bohdan Szafrański Łańcuchy Napędowe–Główny Mechanik. Available online: https://glowny-mechanik.pl/2019/07/02/lancuchy-napedowe-2/ (accessed on 18 December 2024).

- History of Chain. Available online: https://www.conkordengineering.com/history-of-chain.php (accessed on 31 December 2024).

- 不详. 周礼 (Zhou Li)—Zhou’ Rituals; Not applicable (original manuscript): Ancient China, 250BC. [Google Scholar]

- 孙子 (Sun Tzu). 孙子兵法 (Sunzi Bingfa)—The Art of War; Not applicable (original manuscript): Ancient China, 500BC. [Google Scholar]

- Lawrence, A.W. Greek Architecture.; Cambridge University Press (CUP): Cambridge, England, 1958; Volume 38. [Google Scholar]

- Georgius, A. De Re Metallica; Dover Publications: Bazylea, Switzerland, 1556. [Google Scholar]

- Landels, J.G. Engineering in the Ancient World; University of California Press: St. Oakland, CA, USA, 1978; ISBN 0-520-03429-5. [Google Scholar]

- Braudel, F. The Structure of Everyday Life—The Limits of Possible; University of California Press: St. Oakland, CA, USA, 1979. [Google Scholar]

- A Brief History of Chain|Leaf Chain Hub. Available online: https://www.leafchain.com/knowledge-hub/a-brief-history-of-chain (accessed on 31 December 2024).

- Eiffel, G. La Tour de 300 Mètres; Taschen GmbH: Paris, France, 1889. [Google Scholar]

- Materiały Konstrukcyjne Wykorzystywane w Produkcji Łańcuchów Przemysłowych—Schipolska. Available online: https://schipolska.pl/blog/materialy-konstrukcyjne-wykorzystywane-w-produkcji-lancuchow-przemyslowych/ (accessed on 30 December 2024).

- Nowoczesne Materiały w Produkcji Łańcuchów Transportowych: Lekkość, Wytrzymałość, Trwałość—Schipolska. Available online: https://schipolska.pl/blog/nowoczesne-materialy-w-produkcji-lancuchow-transportowych-lekkosc-wytrzymalosc-trwalosc/ (accessed on 30 December 2024).

- Zalety i Wady Różnych Materiałów Używanych w Produkcji Łańcuchów Przemysłowych—Schipolska. Available online: https://schipolska.pl/blog/zalety-i-wady-roznych-materialow-uzywanych-w-produkcji-lancuchow-przemyslowych/ (accessed on 30 December 2024).

- Zhang, S.; Gan, J.; Lv, J.; Shen, C.; Xu, C.; Li, F. Environmental impacts of carbon fiber production and decarbonization performance in wind turbine blades. J. Environ. Manag. 2024, 351, 119893. [Google Scholar] [CrossRef]

- Khorgade, P.; Rettinger, M.; Burghartz, A.; Schlaich, M. A comparative cradle-to-gate life cycle assessment of carbon fiber-reinforced polymer and steel-reinforced bridges. Struct. Concr. 2023, 24, 1737–1750. [Google Scholar] [CrossRef]

- Kawajiri, K.; Sakamoto, K. Environmental impact of carbon fibers fabricated by an innovative manufacturing process on life cycle greenhouse gas emissions. Sustain. Mater. Technol. 2022, 31, e00365. [Google Scholar] [CrossRef]

- Khayyam, H.; Naebe, M.; Milani, A.S.; Fakhrhoseini, S.M.; Date, A.; Shabani, B.; Atkiss, S.; Ramakrishna, S.; Fox, B.; Jazar, R.N. Improving energy efficiency of carbon fiber manufacturing through waste heat recovery: A circular economy approach with machine learning. Energy 2021, 225, 120113. [Google Scholar] [CrossRef]

- Directive (Eu) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the reduction of the impact of certain plastic products on the environment. Off. J. Eur. Union 2019, 155, 1–19.

- Kildahl, H.; Wang, L.; Tong, L.; Ding, Y. Cost effective decarbonisation of blast furnace—Basic oxygen furnace steel production through thermochemical sector coupling. J. Clean. Prod. 2023, 389, 135963. [Google Scholar] [CrossRef]

- Understand Your Steel Emissions. Available online: https://www.carbonchain.com/blog/understand-your-steel-emissions (accessed on 27 June 2025).

- Meng, F.; McKechnie, J.; Turner, T.; Wong, K.H.; Pickering, S.J. Environmental Aspects of Use of Recycled Carbon Fiber Composites in Automotive Applications. Environ. Sci. Technol. 2017, 51, 12727–12736. [Google Scholar] [CrossRef]

- Na, H.; Sun, J.; Yuan, Y.; Qiu, Z.; Zhang, L.; Du, T. Theoretical Energy Consumption Analysis for Sustainable Practices in Iron and Steel Industry. Metals 2024, 14, 563. [Google Scholar] [CrossRef]

- A European Strategy for Plastics in a Circular Economy. 2018. Available online: https://commission.europa.eu/system/files/2018-01/plastics-factsheet-challenges-opportunities_en.pdf?utm_source (accessed on 27 June 2025).

- EN 10025-2:2019; Hot Rolled Products of Structural Steels. British Standards Institution (BSI): London, UK, 2019.

- Mehl, R.F.; Bever, M.B. Mechanical Metallurgy; McGraw-Hill Inc.: New York, NY, USA, 1961. [Google Scholar]

- Dieter, G.E. Mechanical Metallurgy; McGraw-Hill Inc.: New York, NY, USA, 2011. [Google Scholar] [CrossRef]

- Limbago, J.S.; Bacabac, M.M.A.; Fajardo, D.R.M.; Mueda, C.R.T.; Bitara, A.U.; Ceguerra, K.L.P.; Lopez, M.R.C.; Posa, G.A.V.; Nacorda, H.M.E. Occurrence and Polymer Types of Microplastics from Surface Sediments of Molawin Watershed of the Makiling Forest Reserve, Los Baños, Laguna, Philippines. Environ. Nat. Resour. J. 2021, 19, 57–67. [Google Scholar] [CrossRef]

- IEC 60093:1980; Methods of Test for Volume Resistivity of Insulating Materials. International Electrotechnical Commission (IEC): Geneva, Switzerland, 1980.

- Łańcuchy Nierdzewne DIN 766—Metfix Sp z o.o. Available online: https://www.metfix.com.pl/oferta/liny-lancuchy-nierdzewne/lancuchy-nierdzewne/din-766/ (accessed on 31 December 2024).

- DIN763 Link Chain|Qingdao Lige Machinery Co., Ltd. Available online: https://www.ligemachinery.com/din763-link-chain.html (accessed on 28 June 2025).

- Łańcuch Podnoszący Klasy 80|Qingdao Lige Machinery Co., Ltd. Available online: https://www.ligemachinery.com/grade-80-lifting-chain.html (accessed on 31 December 2024).

- Roller Chains Triplex DIN ISO 606, Curved Link Plate|Norelem. Available online: https://www.norelem.com/xs_db/DOKUMENT_DB/www/NORELEM/DataSheet/en/22/22202_Datasheet_21793_Roller_chains_triplex_DIN_ISO_606_curved_link_plate--en.pdf (accessed on 28 June 2025).

- Łańcuch Plastikowy 6 mm × 5 m 10 kg Czarny—Leroy Merlin. Available online: https://www.leroymerlin.pl/produkty/lancuch-plastikowy-6-mm-x-5-m-10-kg-czarny-89112898.html (accessed on 31 December 2024).

- Łańcuch Plastikowy o Skoku 8 mm Serii 3309 (50 Ogniw/400 mm, Czarny)—Sklep V-Slot OpenBuilds Polska. Available online: https://www.v-slot.pl/pl/p/Lancuch-plastikowy-o-skoku-8-mm-serii-3309-50-ogniw-400-mm%2C-czarny/2492 (accessed on 31 December 2024).

- Direct Industry. Security Chain AL-31/05. Available online: https://www.directindustry.com/prod/catu/product-12569-1988500.html (accessed on 28 June 2025).

- Tsubaki. ANSI Single Pitch P Chain. Available online: https://tsubaki.eu/products/chain/plastic-conveyor-chain/ansi-single-pitch-p/ (accessed on 28 June 2025).

- Flexlink. XK Plastic Chain Conveyors. Available online: https://flex-lineautomation.com/wp-content/uploads/2022/09/15234453635694695910_08XK.pdf (accessed on 28 June 2025).

- Biron, M. Plastics Solutions for Practical Problems, 3rd ed.; Biron, M., Ed.; Thermoplastics and Thermoplastic Composites; William Andrew Publishing: Norwich, NY, USA, 2018; ISBN 9780081025017. [Google Scholar]

- William, D.; Callister, D.G.R., Jr. Materials Science and Engineering: An Introduction, 10th ed.; Wiley: Hoboken, NJ, USA, 2018; ISBN 978-1-119-40549-8. [Google Scholar]

- Giraldi, A.L.F.D.M.; Bartoli, J.R.; Velasco, J.I.; Mei, L.H.I. Glass fibre recycled poly(ethylene terephthalate) composites: Mechanical and thermal properties. Polym. Test. 2005, 24, 507–512. [Google Scholar] [CrossRef]

- Scelsi, L.; Hodzic, A.; Soutis, C.; Hayes, S.A.; Rajendran, S.; AlMa’adeed, M.A.; Kahraman, R. A review on composite materials based on recycled thermoplastics and glass fibres. Plast. Rubber Compos. 2011, 40, 1–10. [Google Scholar] [CrossRef]

- Kráčalík, M.; Pospíšil, L.; Šlouf, M.; Mikešová, J.; Sikora, A.; Šimoník, J.; Fortelný, I. Recycled poly(ethylene terephthalate) reinforced with basalt fibres: Rheology, structure, and utility properties. Polym. Compos. 2008, 29, 437–442. [Google Scholar] [CrossRef]

- Singleton, A.C.N.; Baillie, C.A.; Beaumont, P.W.R.; Peijs, T. On the mechanical properties, deformation and fracture of a natural fibre/recycled polymer composite. Compos. Part B Eng. 2003, 34, 519–526. [Google Scholar] [CrossRef]

- Mondadori, N.M.L.; Nunes, R.C.R.; Canto, L.B.; Zattera, A.J. Composites of Recycled PET Reinforced with Short Glass Fiber. J. Thermoplast. Compos. Mater. 2012, 25, 747–764. [Google Scholar] [CrossRef]

- Perron, B.E.; Victor, B.G.; Hodge, D.R.; Salas-Wright, C.P.; Vaughn, M.G.; Taylor, R.J. Laying the Foundations for Scientometric Research: A Data Science Approach. Res. Soc. Work Pract. 2017, 27, 802–812. [Google Scholar] [CrossRef]

- Zitt, M.; Bassecoulard, E. Challenges for scientometric indicators: Data demining, knowledge-flow measurements and diversity issues. Ethics Sci. Environ. Polit. 2008, 8, 49–60. [Google Scholar] [CrossRef]

- Singh, V.K.; Banshal, S.K.; Singhal, K.; Uddin, A. Scientometric mapping of research on ‘Big Data’. Scientometrics 2015, 105, 727–741. [Google Scholar] [CrossRef]

- Gile, D. Analyzing Translation studies with scientometric data: From CIRIN to citation analysis. Perspectives 2015, 23, 240–248. [Google Scholar] [CrossRef]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, Web of Science, and Google Scholar: Strengths and weaknesses. FASEB J. 2007, 22, 338–342. [Google Scholar] [CrossRef]

- Scopus|Abstract and Citation Database|Elsevier. Available online: https://www.elsevier.com/products/scopus (accessed on 18 November 2023).

- Łańcuch Rolkowy: Podział i Norma Europejska—JANUS Sp. z o.o. Available online: https://www.janus.com.pl/lancuch-rolkowy-podzial-i-norma-europejska/ (accessed on 17 December 2024).

- Kilka Słów o Stalowym Łańcuchu Ogniwowym—Blog Jumbo Shop. Available online: https://www.jumbo-shop.pl/blog/pare-slow-o-lancuchu/ (accessed on 17 December 2024).

- Ogniwo Łańcucha Rolkowego—co to, Jaki Materiał, Jak Liczyć? Available online: https://www.ebmia.pl/wiedza/porady/mechanika-porady/ogniwo-lancucha-rolkowego-co-to-jaki-material-jak-liczyc/ (accessed on 17 December 2024).

- Maszyny Rolnicze—Naprawy Napędów Łańcuchowych z Łańcuchem Rolkowym—Ocena Stanu Technicznego, Wymagania i Badania; Politechnika Białostocka. Zakład Maszyn i Urządzeń Rolniczych, Wydawnictwo Normalizacyjne: Białystok, Poland, 1981; pp. 1–4.

- Łańcuchy SKF. Available online: https://prema.com.pl/wp-content/uploads/2022/06/SKF_-_ancuchy_6772_PL.pdf (accessed on 17 December 2024).

- Łańcuchy Ogniwowe Górnicze BN-76/1709-01; Centralny Ośrodek Projektowo Konstrukcyiny Maszyn Górniczych, Wydawnictwo Normalizacyjne: Gliwice, Poland, 1977; pp. 1–8. Available online: https://dlibra.pbs.edu.pl/Content/1691/PDF/BN_76_1709_01.pdf (accessed on 28 June 2025).

- Łańcuchy Napędowe—Rodzaje, Budowa i Zastosowanie—Wiedza EBMiA.pl. Available online: https://www.ebmia.pl/wiedza/porady/mechanika-porady/lancuchy/ (accessed on 17 December 2024).

- Łańcuchy Napędowe—Rodzaje i Zastosowanie—Akcesoria CNC. Available online: https://www.akcesoria.cnc.info.pl/porady/232-lancuchy-napedowe-rodzaje-i-zastosowanie (accessed on 17 December 2024).

- Łańcuchy—Do Czego Służą Poszczególne Rodzaje?|Metmet.pl. Available online: https://metmet.pl/blog/lancuchy-do-czego-sluza-poszczegolne-rodzaje/ (accessed on 17 December 2024).

- Łańcuch Stalowy: Atrybuty i Rodzaje—AO BIZNES. Available online: https://aobiznes.pl/aktualnosci/porady/lancuch-stalowy-atrybuty-i-rodzaje (accessed on 17 December 2024).

- European Patent Office European Patent Application 98200860.9 1998. Available online: https://patents.google.com/patent/EP1795201A1/es (accessed on 28 June 2025).

- Data Sheet—Nilcra® Zirconia MS Grade 2013; 286773. Available online: https://www.morgantechnicalceramics.com/media/qd4d2kv2/nilcra-zirconia-ms-grade.pdf/ (accessed on 28 June 2025).

- Taylor, S.V.; Moustafa, A.R.; Cordero, Z.C. Interpenetrating Lattices with Tailorable Energy Absorption in Tension. Acta Mater. 2021, 216, 117115. [Google Scholar] [CrossRef]

- Kim, C.U.; Song, J.I. Development of lightweight fiber-reinforced composite pins for heavy load long pitch roller chains. Compos. Struct. 2020, 236, 111839. [Google Scholar] [CrossRef]

- Rădulescu, B.; Mihalache, A.M.; Păduraru, E.; Hriţuc, A.; Rădulescu, M.C.; Slătineanu, L.; Ermolai, V. Tensile Behavior of Chain Links Made of Polymeric Materials Manufactured by 3D Printing. Polymers 2023, 15, 3178. [Google Scholar] [CrossRef] [PubMed]

- Mooney, B.; Kourousis, K.I. A Review of Factors Affecting the Mechanical Properties of Maraging Steel 300 Fabricated via Laser Powder Bed Fusion. Metals 2020, 10, 1273. [Google Scholar] [CrossRef]

- ISO 3076; Round Steel Short Link Chains for General Lifting Purposes. International Organization for Standardization: Geneva, Switzerland, 2012.

- Obróbka Cieplna Metali—FREZMET 2. Available online: https://frezmet.pl/obrobka-cieplna-metali/ (accessed on 31 January 2025).

- Bogdan Pawłowski Obróbka cieplna i cieplno-chemiczna stali—[Heat and thermo-chemical treatment of steel]. In Metaloznawstwo: Wybrane Zagadnienia; Pacyna, J., Ed.; Akademia Górniczo-Hutnicza im. Stanisława Staszica w Krakowie: Cracow, Poland, 2005; pp. 175–202. [Google Scholar]

- EN 818; Short Link Chain for Lifting Purposes. European Committee for Standardization: Brussels, Belgium, 2008.

- ISO 1834; Short-Link Chain for Lifting Purposes—General Conditions of Acceptance. International Organization for Standardization: Geneva, Switzerland, 1999.

- ASTM A391/A391M; Standard Specification for Grade 80 Alloy Steel Chain. ASTM International: West Conshohocken, PA, USA, 2021.

- DIN 5685; Chain Links—Short Link Chain (Type A) and Long Link Chain (Type C). Beuth Verlag GmbH: Berlin, Germany, 1985.

- DIN—German Institute for Standardization. Available online: https://www.din.de/en (accessed on 1 January 2025).

- European and International Standards Catalog. Available online: https://www.en-standard.eu/ (accessed on 1 January 2025).

- ANSI Webstore—Catalog. Available online: https://webstore.ansi.org/ (accessed on 2 January 2025).

- ASTM International—Standards Worldwide. Available online: https://www.astm.org/ (accessed on 2 January 2025).

- Catalog of Standards ISO. Available online: https://www.iso.org/standards-catalogue/browse-by-ics.html (accessed on 1 January 2025).

- ISO 610:1990; High-Tensile Steel Chains (Round Link) for Chain Conveyors and Coal Plows. International Organization for Standardization: Geneva, Switzerland, 1990.

- ISO 1834:1999; Short Link Chain for Lifting Purposes—General Conditions of Acceptance. International Organization for Standardization: Geneva, Switzerland, 1999.

- ISO 1835:2018; Round Steel Short Link Chains for Lifting Purposes—Medium Tolerance Sling Chains—Grade 4, Stainless Steel. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 3076:2012; Round Steel Short Link Chains for General Lifting Purposes—Medium Tolerance Sling Chains for Chain Slings—Grade 8. International Organization for Standardization: Geneva, Switzerland, 2012.

- DIN 762-2; Quenched and Tempered Grade 5, Round Steel Link Chains. Deutsches Institut für Normung: Berlin, Germany, 1992.

- DIN 763; Tested, Non-Calibrated, Long-Link Round Steel Chains. Deutsches Institut für Normung: Berlin, Germany, 1990.

- DIN 764; Calibrated and Tested Round Steel Link Chains for Continuous Conveyors. Deutsches Institut für Normung: Berlin, Germany, 1992.

- DIN 766; Calibrated and Tested Grade 3 Round Steel Link Chains. Deutsches Institut für Normung: Berlin, Germany, 1986.

- DIN 5692; Round Steel Link Chains—Forged Steel Components—Chain Shortener, Grade 8. Deutsches Institut für Normung: Berlin, Germany, 2011.

- DIN 8197; Steel Link Chains—Reference Profiles of Hobs for Sprockets for Roller Chains. Deutsches Institut für Normung: Berlin, Germany, 1980.

- DIN 5684; Calibrated and Tested Round Steel Link Chains for Lifting Purposes. Deutsches Institut für Normung: Berlin, Germany, 1984.

- DIN 5687-1; Round Steel Link Chains—Part 1: Grade 5, Medium Tolerance, Tested. Deutsches Institut für Normung: Berlin, Germany, 1996.

- DIN 17115; Steels for Welded Round Link Chains and Chain Components—Technical Delivery Conditions. Deutsches Institut für Normung: Berlin, Germany, 2012.

- DIN 22252; Round Link Chains for Use in Continuous Conveyors and Winning in Mining. Deutsches Institut für Normung: Berlin, Germany, 1973.

- DIN 22255; Flat Link Chains for Use in Continuous Conveyors in Mining. Deutsches Institut für Normung: Berlin, Germany, 2012.

- DIN 32891; Tested Non-Calibrated Round Steel Link Chains—Grade 2. Deutsches Institut für Normung: Berlin, Germany, 1996.

- DIN EN 818; Short Link Chain for Lifting Purposes. Deutsches Institut für Normung: Berlin, Germany, 2008.

- ASME B29.22-2001 (R2021); Drop Forged Rivetless Chains, Sprocket Teeth Drive Chain/Drive Dogs. American Society of Mechanical Engineers: New York, NY, USA, 2021.

- ASTM Volume 01.05; Steel–Bars, Forgings, Bearing, Chain, Tool. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM A466-2007 (R2020); Standard Specification for Weldless Chain. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM A413-2021; Standard Specification for Carbon Steel Chain. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM A391-2021; Standard Specification for Grade 80 Alloy Steel Chain. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM A973-2021; Standard Specification for Grade 100 Alloy Steel Chain. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 610:2015; High-Tensile Steel Chains (Round Link) for Chain Conveyors and Coal Ploughs. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 643:1983; Steels—Micrographic Determination of the Ferritic or Austenitic Grain Size. International Organization for Standardization: Geneva, Switzerland, 1983.

- ISO 7500-1:1986; Metallic Materials—Verification of Static Uniaxial Testing Machines—Part 1: Tensile Testing Machines. International Organization for Standardization: Geneva, Switzerland, 1986.

- AD 388 Partial Factors for Material Properties for Design in the UK 2015. 2015. Available online: https://www.steelconstruction.info/images/c/c0/AD-388.pdf/ (accessed on 28 June 2025).

- Av, A. Data Sheet—Arnite AV2 390 2025. Available online: https://plasticsfinder.envalior.com/en/datasheet/Arnite%C2%AE%20AV2%20390/x8Ed3?b=0/ (accessed on 28 June 2025).

- Chain Size in millimeters Chain Chain Grade 30 proof coil Grade 43 high test Grade 70 transport Grade 80 alloy Grade 100 alloy Manila Size Polypropylene Size Double Braided Nylon Working Load Limits for Synthetic Webbing Working Load Limits for Steel Stra 2–3. Available online: https://www.carriersedge.com/courses/endicott_course_files/cargo/Working-Load-Limits.pdf (accessed on 28 June 2025).

- Monti, M.; Scrivani, M.T.; Kociolek, I.; Larsen, Å.G.; Olafsen, K.; Lambertini, V. Enhanced Impact Strength of Recycled PET/Glass Fiber Composites. Polymers 2021, 13, 1471. [Google Scholar] [CrossRef]

- Naresh, K.S.; Rakshith, K. A Studies on Static Analysis of Link Chain—A Case Study. Int. J. Sci. Res. Sci. 2021, 9, 120–124. [Google Scholar]

- The Low-Down on Twisting Safety Chains—From the Mechanic Elements. Available online: https://mechanicalelements.com/twisting-safety-chains/ (accessed on 4 January 2025).

- Ostrowski, K.A.; Spyrowski, M.M.; Romańska, P.; Furtak, K. Evaluation of mechanical properties of recycled polyethylene terephthalate (rPET) reinforced with glass fibers. In Proceedings of the 4th International Conference on Sustainable Development in Civil, Urban and Transportation Engineering 2024, Wroclaw, Poland, 14–17 October 2024; pp. 1–7. [Google Scholar]

| Chain Type | Material | Diameter [mm] | Breaking Force [kN] |

|---|---|---|---|

| Link chain DIN 766 [33] | Stainless steel | 2–16 | 1.2–127.5 |

| Link chain DIN 763 [34] | Carbon steel | 2–32 | 1.25–400 |

| Lifting chain, grade 80 [35] | Alloy steel, quenched and tempered | 6–42 | 45.2–2200 |

| Roller drive chain “B” ISO [36] | High-grade steel | 3.28–8.28 | 24.9–160 |

| Plastic link chain [37] | Polyethylene | 6 | 0.4 |

| Plastic roller chain [38] | Polyethylene | 3 | 0.44 |

| Link chain AL-31 [39] | PVC | 6.5 | - |

| Single Pitch P Chain [40] | Polyacetal chain/steel pins | 4–6 | - |

| XK Plastic Chain Conveyors [41] | PVC chain/steel pins | 5 | 2.5 |

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) | Density (g/cm3) |

|---|---|---|---|---|---|

| Steel (general) | 370–700 | 250–600 | 200 | 10–25 | 7.85 |

| Stainless Steel (304) | 505 | 215 | 193 | 40–60 | 8.00 |

| Carbon Steel (AISI 1045) | 570–700 | 310–530 | 200 | 16–18 | 7.87 |

| Polyethylene (HDPE) | 20–37 | 19–30 | 0.8 | 500–1000 | 0.95 |

| Nylon (PA6) | 75–100 | 45–80 | 2.5–3.0 | 50–300 | 1.14 |

| Acetal (POM) | 60–70 | 50–60 | 2.8–3.0 | 20–60 | 1.41 |

| Polypropylene (PP) | 30–40 | 20–30 | 1.5–2.0 | 200–700 | 0.90 |

| Polyamide (PA66) | 80–100 | 50–90 | 2.8–3.5 | 20–100 | 1.14 |

| Standard | Number | Title |

|---|---|---|

| ISO | 610:1990 | High-tensile steel chains (round link) for chain conveyors and coal plows [83] |

| ISO | 1834:1999 | Short link chain for lifting purposes—General conditions of acceptance [84] |

| ISO | 1835:2018 | Round steel short link chains for lifting purposes—Medium tolerance sling chains—Grade 4, stainless steel [85] |

| ISO | 3076:2012 | Round steel short link chains for general lifting purposes—Medium tolerance sling chains for chain slings—Grade 8 [86] |

| DIN | 762-2 | Quenched and tempered grade 5, round steel link chains [87] |

| DIN | 763 | Tested, non-calibrated, long-link round steel chains [88] |

| DIN | 764 | Calibrated and tested round steel link chains for continuous conveyors [89] |

| DIN | 766 | Calibrated and tested grade 3 round steel link chains [90] |

| DIN | 5692 | Round steel link chains—Forged steel components—Chain shortener, grade 8 [91] |

| DIN | 8197 | Steel link chains—Reference profiles of hobs for sprockets for roller chains [92] |

| DIN | 5684 | Calibrated and tested round steel link chains for lifting purposes [93] |

| DIN | 5687-1 | Round steel link chains—Part 1: Grade 5, medium tolerance, tested [94] |

| DIN | 17115 | Steels for welded round link chains and chain components—Technical delivery conditions [95] |

| DIN | 22252 | Round link chains for use in continuous conveyors and winning in mining [96] |

| DIN | 22255 | Flat link chains for use in continuous conveyors in mining [97] |

| DIN | 32891 | Tested non-calibrated round steel link chains—Grade 2 [98] |

| DIN EN | 818 | Short link chain for lifting purposes [99] |

| ASME | B29.22-2001 (R2021) | Drop Forged Rivetless Chains, Sprocket Teeth Drive Chain/Drive Dogs [100] |

| ASTM | Volume 01.05 | Steel–Bars, Forgings, Bearing, Chain, Tool [101] |

| ASTM | A0466-2007 (R2020) | Standard Specification for Weldless Chain [102] |

| ASTM | A0413-2021 | Standard Specification for Carbon Steel Chain [103] |

| ASTM | A0391-2021 | Standard Specification for Grade 80 Alloy Steel Chain [104] |

| ASTM | A0973-2021 | Standard Specification for Grade 100 Alloy Steel Chain [105] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostrowski, K.A.; Spyrowski, M. Technical Chains in Civil and Urban Engineering: Review of Selected Solutions, Shaping, Geometry, and Dimensioning. Appl. Sci. 2025, 15, 7600. https://doi.org/10.3390/app15137600

Ostrowski KA, Spyrowski M. Technical Chains in Civil and Urban Engineering: Review of Selected Solutions, Shaping, Geometry, and Dimensioning. Applied Sciences. 2025; 15(13):7600. https://doi.org/10.3390/app15137600

Chicago/Turabian StyleOstrowski, Krzysztof Adam, and Mariusz Spyrowski. 2025. "Technical Chains in Civil and Urban Engineering: Review of Selected Solutions, Shaping, Geometry, and Dimensioning" Applied Sciences 15, no. 13: 7600. https://doi.org/10.3390/app15137600

APA StyleOstrowski, K. A., & Spyrowski, M. (2025). Technical Chains in Civil and Urban Engineering: Review of Selected Solutions, Shaping, Geometry, and Dimensioning. Applied Sciences, 15(13), 7600. https://doi.org/10.3390/app15137600