Advanced Planning Systems in Production Planning Control: An Ethical and Sustainable Perspective in Fashion Sector

Abstract

Featured Application

Abstract

1. Introduction

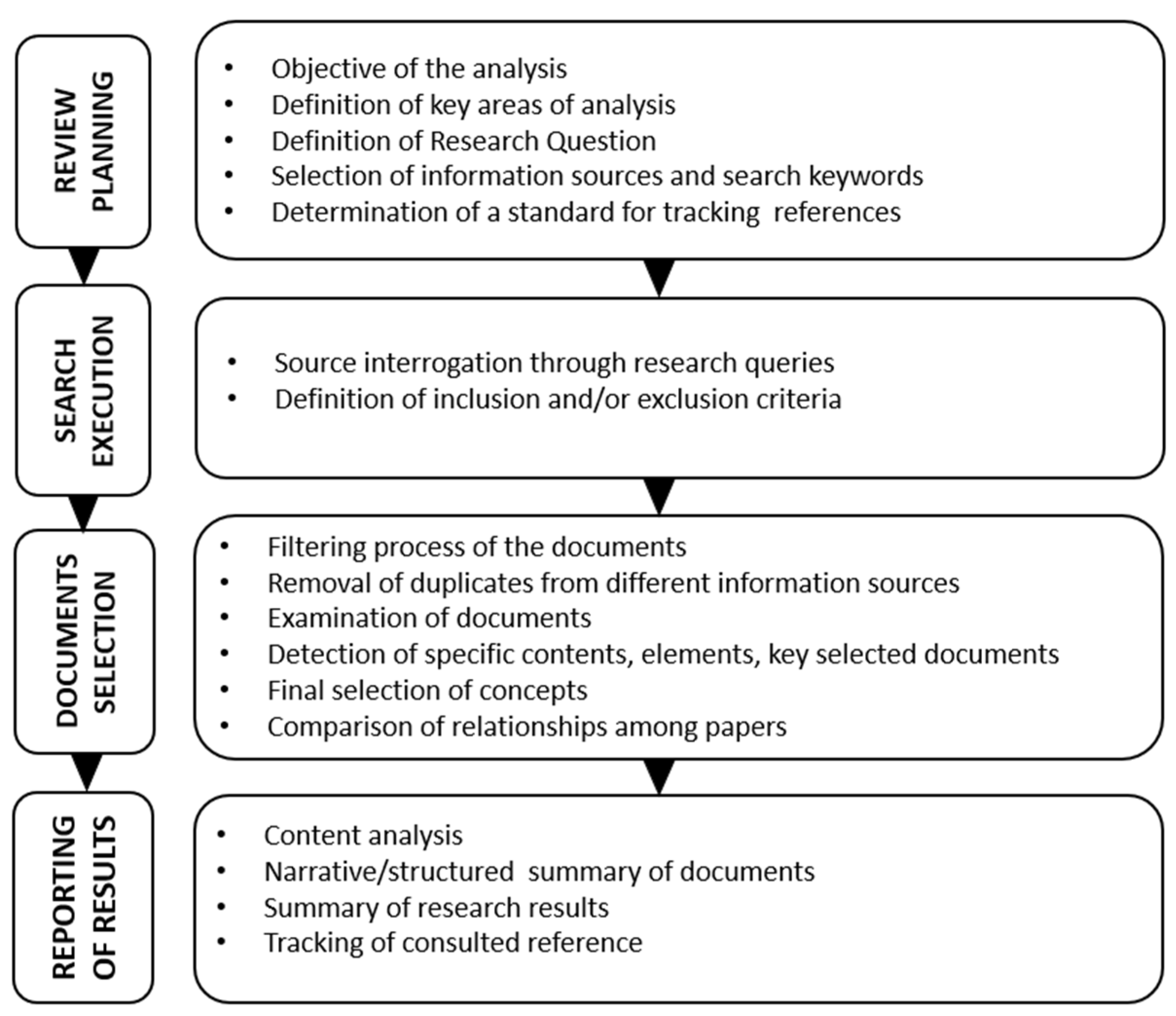

2. Research Methodology

2.1. Review Plannnig

2.2. Search Execution

2.3. Document Selection

2.4. Reporting of Results

3. Analysis of Literature Resources

3.1. Production Planning, Control, and Scheduling

- Complexity: Scheduling must handle multiple factors such as the timing of each production operation (including arrival, start-up, loading, unloading, processing, waiting between machines, and transport times) as well as external factors like the availability of material and human resources, such as skilled operators. With the increasing complexity of the scheduling problems, the computational effort as well as the time required to find an optimal solution—or a sub-optimal one—rises [25].

- Randomness: Dynamic environments and conditions (e.g., machine breakdowns, order changes, etc.) affect stability [25].

- Multiple constraints: Sequence-dependent setup times, varying process types (e.g., single jobs vs. batch processing), and fluctuating process times complicate scheduling and operations [25,27]. Indeed, relevant uncertainties such as production delays, plant shutdowns, rush orders, price fluctuations, and shifts in demand can distort previously optimal or sub-optimal schedules [28]. Single-machine scheduling often overlooks maintenance, assuming constant system availability, an approach that raises the risk of breakdowns and disrupts optimal production performance [29].

- Multi-objective requirements: Balancing productivity, cost-efficiency, and customer satisfaction under competing Key Performance Indicators (KPIs) [25,30,31,32]. This involves minimizing losses and inventory costs while maximizing output and efficiency. However, achieving these goals is challenging due to their interconnected nature and operational constraints [25]. A core challenge in production scheduling lies in reconciling conflicting priorities; e.g., customers demand lower costs, higher efficiency, and better service, while manufacturers aim to simplify production and maximize profit [3].

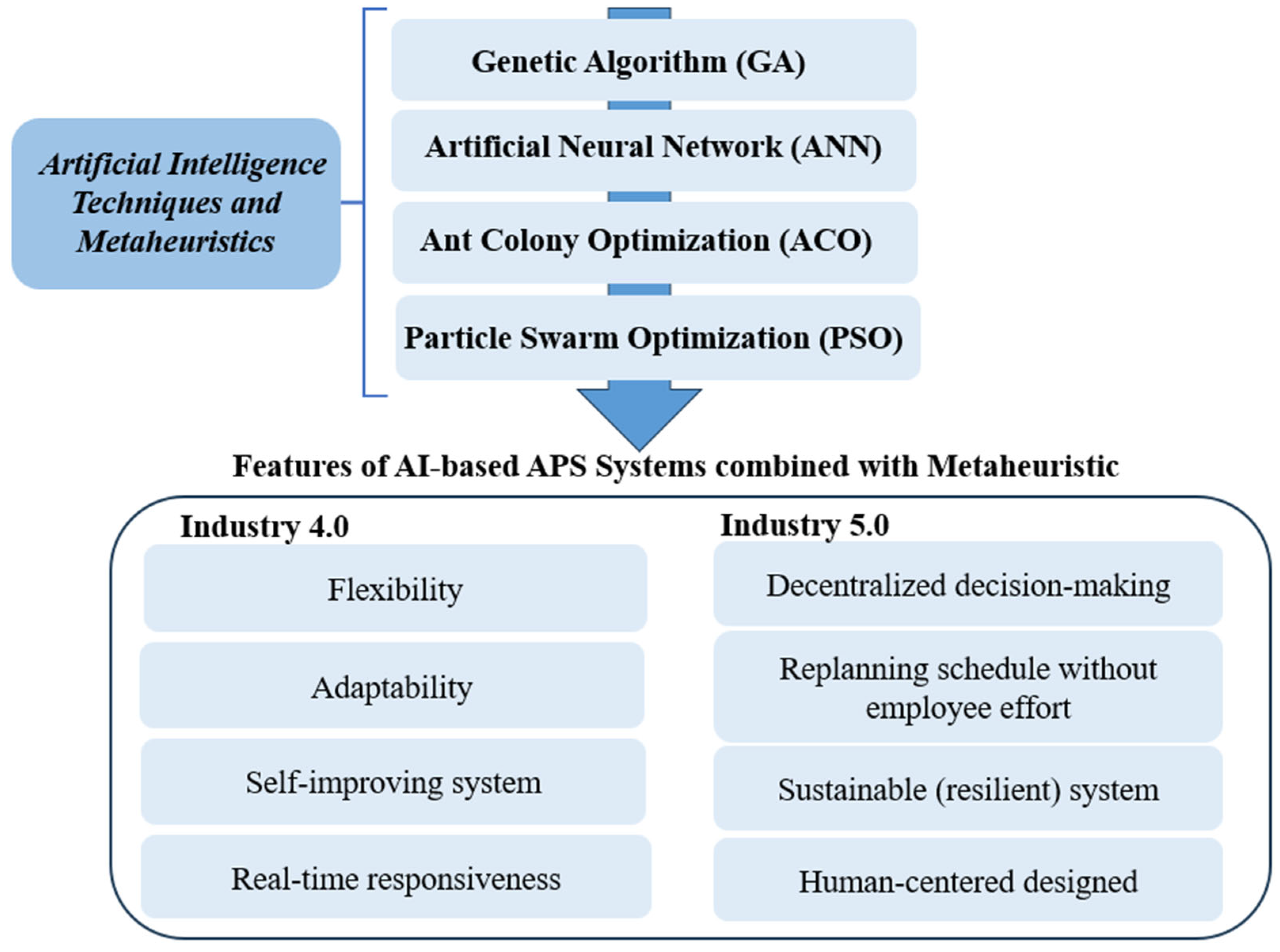

3.2. AI Techniques to Support APS Systems

3.2.1. Supervised ML Techniques

3.2.2. Reinforcement Learning and Deep Learning Techniques

3.3. Metaheurisitc Techniques

3.3.1. Single-State Metaheuristics

3.3.2. Population-Based Metaheuristics

3.4. Hybrid Metaheuristics

3.5. Ethical and Sustainability Perspectives in Manufacturing and Fashion Sector

4. A Summary Structured Framework

5. Discussion and Conclusions

- Bridging the gap between technological innovation and real-world decision-making, ensuring that AI tools are designed as effective decision-support systems that empower human planners rather than replace them;

- Embedding human-centric values into production scheduling, consistent with I5.0’s emphasis on collaboration, fairness, and employee well-being, ensuring ethical and inclusive automation;

- Advancing the ethical, sustainable, and inclusive vision of I5.0 by promoting transparency, accountability, and environmental responsibility in AI-driven production systems;

- Providing sector-specific solutions for complex, multi-actor ecosystems such as fashion, addressing the unique challenges of fast-changing markets, short product lifecycles, and diverse supply chain participants.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACO | Ant Colony Optimization |

| ACTS | Ant Colony Tabu Search |

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| APS | Advanced Planning and Scheduling |

| BDA | Big Data Analytics |

| CNN | Convolutional Neural Network |

| CPPS | Cyber–Physical Production System |

| CPS | Cyber–Physical System |

| DL | Deep Learning |

| DNN | Deep Neural Network |

| DQN | Deep Q-Network |

| DT | Digital Twins |

| EA | Evolutionary Algorithm |

| ERP | Enterprise Resource Planning |

| FJSSP | Flexible Job Shop Scheduling Problem |

| FSA | Fish Swarm Algorithm |

| GA | Genetic Algorithm |

| GA-ACO | Genetic Algorithm–Ant Colony Optimization |

| I4.0 | Industry 4.0 |

| I5.0 | Industry 5.0 |

| ICTs | Information and Communication Technologies |

| IIoT | Industrial Internet of Things |

| IoT | Internet of Things |

| JSSP | Job Shop Scheduling Problem |

| KPIs | Key Performance Indicators |

| LSTM | Long Short-Term Memory |

| MARL | Multi-Agent Reinforcement Learning |

| ML | Machine Learning |

| MPS | Master Production Scheduling |

| MRP | Material Requirements Planning |

| NSGA-II | Non-Dominated Sorting Genetic Algorithm II |

| NGSA | Non-Dominance Genetic Simulating Annealing |

| NNs | Neural Networks |

| NP | Non-Deterministic Polynomial-Time |

| PPC | Production Planning and Control |

| PSO | Particle Swarm Optimization |

| Q | Query |

| RCPSP | Resource-Constrained Project Scheduling Problem |

| RL | Reinforcement Learning |

| RNN | Recurrent Neural Network |

| RQ | Research Question |

| RTS | Reactive Tabu Search |

| SA | Simulated Annealing |

| SC | Supply Chain |

| SI | Swarm Intelligence |

| SLR | Systematic Literature Review |

| S&OP | Sales And Operations Planning |

| SMEs | Small and Medium Enterprises |

| TITLE-ABS-KEY | Title–Abstract–Keywords |

| TS | Tabu Search |

| WoS | Web of Science |

| XAI | eXplainable Artificial Intelligence |

References

- Kaven, L.; Huke, P.; Göppert, A.; Schmitt, R.H. Multi agent reinforcement learning for online layout planning and scheduling in flexible assembly systems. J. Intell. Manuf. 2024, 35, 3917–3936. [Google Scholar] [CrossRef]

- Guo, Z.X.; Wong, W.K. Fundamentals of artificial intelligence techniques for apparel management applications. In Optimizing Decision Making in the Apparel Supply Chain Using Artificial Intelligence (AI); Elsevier: Amsterdam, The Netherlands, 2013; pp. 13–40. [Google Scholar] [CrossRef]

- Chen, S.; Wang, J.; Li, H.; Wang, Z.; Liu, F.; Li, S. Top-Down Human-Cyber-Physical Data Fusion Based on Reinforcement Learning. IEEE Access 2020, 8, 134233–134245. [Google Scholar] [CrossRef]

- Paul, J.; Criado, A.R. The art of writing literature review: What do we know and what do we need to know? Int. Bus. Rev. 2020, 29, 101717. [Google Scholar] [CrossRef]

- Cronin, P.; Ryan, F.; Coughlan, M. Undertaking a literature review: A step-by-step approach. Br. J. Nurs. 2008, 17, 38–43. [Google Scholar] [CrossRef]

- Corallo, A.; Crespino, A.M.; Vecchio, V.D.; Lazoi, M.; Marra, M. Understanding and Defining Dark Data for the Manufacturing Industry. IEEE Trans. Eng. Manage. 2023, 70, 700–712. [Google Scholar] [CrossRef]

- Corallo, A.; Lazoi, M.; Striani, F. Process mining and industrial applications: A systematic literature review. Knowl. Process Manag. 2020, 27, 225–233. [Google Scholar] [CrossRef]

- Ely, C.; Scott, I. Essential Study Skills; Mosby: Edinburgh, UK; Elsevier: New York, NY, USA, 2007. [Google Scholar]

- Pranckutė, R. Web of Science (WoS) and Scopus: The Titans of Bibliographic Information in Today’s Academic World. Publications 2021, 9, 12. [Google Scholar] [CrossRef]

- Cumpston, M.S.; McKenzie, J.E.; Welch, V.A.; Brennan, S.E. Strengthening systematic reviews in public health: Guidance in the Cochrane Handbook for Systematic Reviews of Interventions, 2nd edition. J. Public Health 2022, 44, e588–e592. [Google Scholar] [CrossRef]

- Petticrew, M.; Roberts, H. Systematic Reviews in the Social Sciences: A Practical Guide; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Paré, G.; Trudel, M.-C.; Jaana, M.; Kitsiou, S. Synthesizing information systems knowledge: A typology of literature reviews. Inf. Manag. 2015, 52, 183–199. [Google Scholar] [CrossRef]

- Webster, J.; Watson, R.T. Analyzing the past to prepare for the future: Writing a literature review. MIS Q. 2002, 26, xiii–xxiii. [Google Scholar]

- Boell, S.K.; Cecez-Kecmanovic, D. On being ‘systematic’ in literature reviews in IS. J. Inf. Technol. 2015, 30, 161–173. [Google Scholar] [CrossRef]

- Chagas, R.R.F.F.; Modesti, P.H.; Borsato, M. Bibliometric and Systemic Analysis of Production Planning Optimization. In Advances in Transdisciplinary Engineering; Pokojski, J., Gil, M., Newnes, L., Stjepandić, J., Wognum, N., Eds.; IOS Press: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Chiurco, A.; Elbasheer, M.; Longo, F.; Nicoletti, L.; Solina, V. Data Modeling and ML Practice for Enabling Intelligent Digital Twins in Adaptive Production Planning and Control. Procedia Comput. Sci. 2022, 217, 1908–1917. [Google Scholar] [CrossRef]

- Zhang, C.; Juraschek, M.; Herrmann, C. Deep reinforcement learning-based dynamic scheduling for resilient and sustainable manufacturing: A systematic review. J. Manuf. Syst. 2024, 77, 962–989. [Google Scholar] [CrossRef]

- Serrano-Ruiz, J.C.; Mula, J.; Poler, R. Smart master production schedule for the supply chain: A conceptual framework. Computers 2021, 10, 156. [Google Scholar] [CrossRef]

- Bertolini, M.; Mezzogori, D.; Neroni, M.; Zammori, F. Machine Learning for industrial applications: A comprehensive literature review. Expert. Syst. Appl. 2021, 175, 114820. [Google Scholar] [CrossRef]

- Singh, J.; Singh, A.; Singh, H.; Doyon-Poulin, P. Implementation and evaluation of a smart machine monitoring system under industry 4.0 concept. J. Ind. Inf. Integr. 2025, 43, 100746. [Google Scholar] [CrossRef]

- Shen, W. Production Scheduling Optimization of Clothing Intelligent Manufacturing System Based on Association Rule Algorithm and Big Data Platform. In Proceedings of the 2024 International Conference on Electrical Drives, Power Electronics & Engineering (EDPEE), Athens, Greece, 27–29 February 2024; pp. 776–780. [Google Scholar]

- Usuga Cadavid, J.P.; Lamouri, S.; Grabot, B.; Pellerin, R.; Fortin, A. Machine learning applied in production planning and control: A state-of-the-art in the era of industry 4.0. J. Intell. Manuf. 2020, 31, 1531–1558. [Google Scholar] [CrossRef]

- Harjunkoski, I.; Ikonen, T.; Mostafaei, H.; Deneke, T.; Heljanko, K. Synergistic and Intelligent Process Optimization: First Results and Open Challenges. Ind. Eng. Chem. Res. 2020, 59, 16684–16694. [Google Scholar] [CrossRef]

- Guo, K.; Yang, M.; Zhu, H. Application research of improved genetic algorithm based on machine learning in production scheduling. Neural Comput. Appl. 2020, 32, 1857–1868. [Google Scholar] [CrossRef]

- Grumbach, F.; Badr, N.E.A.; Reusch, P.; Trojahn, S. A Memetic Algorithm with Reinforcement Learning for Sociotechnical Production Scheduling. IEEE Access 2023, 11, 68760–68775. [Google Scholar] [CrossRef]

- Schneckenreither, M.; Haeussler, S.; Peiró, J. Average reward adjusted deep reinforcement learning for order release planning in manufacturing. Knowl.-Based Syst. 2022, 247, 108765. [Google Scholar] [CrossRef]

- Hubbs, C.D.; Li, C.; Sahinidis, N.V.; Grossmann, I.E.; Wassick, J.M. A deep reinforcement learning approach for chemical production scheduling. Comput. Chem. Eng. 2020, 141, 106982. [Google Scholar] [CrossRef]

- Qamhan, A.A.; Ahmed, A.; Al-Harkan, I.M.; Badwelan, A.; Al-Samhan, A.M.; Hidri, L. An Exact Method and Ant Colony Optimization for Single Machine Scheduling Problem With Time Window Periodic Maintenance. IEEE Access 2020, 8, 44836–44845. [Google Scholar] [CrossRef]

- Bindi, B.; Bandinelli, R.; Fani, V.; Pero, M.E.P. Supply chain strategy in the luxury fashion industry: Impacts on performance indicators. Int. J. Prod. Perform. Manag. 2023, 72, 1338–1367. [Google Scholar] [CrossRef]

- Fani, V.; Antomarioni, S.; Bandinelli, R.; Bevilacqua, M. Data-driven decision support tool for production planning: A framework combining association rules and simulation. Comput. Ind. 2023, 144, 103800. [Google Scholar] [CrossRef]

- Kuhnle, A.; Jakubik, J.; Lanza, G. Reinforcement learning for opportunistic maintenance optimization. Prod. Eng. Res. Dev. 2019, 13, 33–41. [Google Scholar] [CrossRef]

- Waschneck, B.; Reichstaller, A.; Belzner, L.; Altenmüller, T.; Bauernhansl, T.; Knapp, A.; Kyek, A. Optimization of global production scheduling with deep reinforcement learning. Procedia CIRP 2018, 72, 1264–1269. [Google Scholar] [CrossRef]

- Del Gallo, M.; Mazzuto, G.; Ciarapica, F.E.; Bevilacqua, M. Artificial Intelligence to Solve Production Scheduling Problems in Real Industrial Settings: Systematic Literature Review. Electronics 2023, 12, 4732. [Google Scholar] [CrossRef]

- Kawaguchi, S.; Kokubo, T.; Fukuyama, Y. Parallel reactive tabu search for job-shop scheduling problems considering energy management. In Proceedings of the 2017 IEEE Symposium Series on Computational Intelligence (SSCI), Honolulu, HI, USA, 27 November–1 December 2017; pp. 1–8. [Google Scholar]

- Ying, K.-C.; Lin, S.-W. Minimizing makespan in two-stage assembly additive manufacturing: A reinforcement learning iterated greedy algorithm. Appl. Soft Comput. 2023, 138, 110190. [Google Scholar] [CrossRef]

- Priyanga, P.; Sridevi, S.; Ashwini, K.; Deepa, S.R. The Smart Factory of Tomorrow: Artificial Intelligence and Machine Learning Reshaping Manufacturing Processes. In Proceedings of the 2023 Second International Conference on Smart Technologies for Smart Nation (SmartTechCon), Singapore, 18–19 August 2023; pp. 1477–1481. [Google Scholar]

- Zhang, R.; Song, S.; Wu, C. Robust Scheduling of Hot Rolling Production by Local Search Enhanced Ant Colony Optimization Algorithm. IEEE Trans. Ind. Inform. 2020, 16, 2809–2819. [Google Scholar] [CrossRef]

- Oluyisola, O.E.; Bhalla, S.; Sgarbossa, F.; Strandhagen, J.O. Designing and developing smart production planning and control systems in the industry 4.0 era: A methodology and case study. J. Intell. Manuf. 2022, 33, 311–332. [Google Scholar] [CrossRef]

- Fani, V.; Antomarioni, S.; Bandinelli, R.; Ciarapica, F.E. Data Mining and Augmented Reality: An Application to the Fashion Industry. Appl. Sci. 2023, 13, 2317. [Google Scholar] [CrossRef]

- Göppert, A.; Mohring, L.; Schmitt, R.H. Predicting performance indicators with ANNs for AI-based online scheduling in dynamically interconnected assembly systems. Prod. Eng. Res. Devel. 2021, 15, 619–633. [Google Scholar] [CrossRef]

- Sobottka, T.; Kamhuber, F.; Faezirad, M.; Sihn, W. Potential for Machine Learning in Optimized Production Planning with Hybrid Simulation. Procedia Manuf. 2019, 39, 1844–1853. [Google Scholar] [CrossRef]

- Gomes, M.; Silva, F.; Ferraz, F.; Silva, A.; Analide, C.; Novais, P. Developing an ambient intelligent-based decision support system for production and control planning. In Intelligent Systems Design and Applications: Proceedings of the 16th International Conference on Intelligent Systems Design and Applications (ISDA 2016), Porto, Portugal, 16–18 December 2016; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2017; Volume 557, pp. 984–994. [Google Scholar] [CrossRef]

- Onaran, E.; Yanık, S. Predicting Cycle Times in Textile Manufacturing Using Artificial Neural Network. In Intelligent and Fuzzy Techniques in Big Data Analytics and Decision Making; Kahraman, C., Cebi, S., Cevik Onar, S., Oztaysi, B., Tolga, A.C., Sari, I.U., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2020; Volume 1029, pp. 305–312. [Google Scholar] [CrossRef]

- Pereira, M.S.; Aquino, P.T.; Mattos, C.A.D.; Lima, F. Energy Estimation and Production Scheduling in Job Shop Using Machine Learning. IEEE Access 2024, 12, 104177–104189. [Google Scholar] [CrossRef]

- Sajko, N.; Kovacic, S.; Ficko, M.; Palcic, I.; Klancnik, S. Manufacturing lead time prediction for extrusion tools with the use of neural networks. Manag. Prod. Eng. Rev. 2020, 11, 48–55. [Google Scholar] [CrossRef]

- Grumbach, F.; Müller, A.; Reusch, P.; Trojahn, S. Robust-stable scheduling in dynamic flow shops based on deep reinforcement learning. J. Intell. Manuf. 2024, 35, 667–686. [Google Scholar] [CrossRef]

- Jung, H.-S.; Park, S. A Study on the Deep Learning based Prediction of Production Demand by using LSTM under the State of Data Sparsity. IOP Conf. Ser. Mater. Sci. Eng. 2020, 926, 012031. [Google Scholar] [CrossRef]

- Huang, J.; Chang, Q.; Arinez, J. Product Completion Time Prediction Using a Hybrid Approach Combining Deep Learning and System Model. J. Manuf. Syst. 2020, 57, 311–322. [Google Scholar] [CrossRef]

- Zareian Beinabadi, H.; Baradaran, V.; Rashidi Komijan, A. Sustainable supply chain decision-making in the automotive industry: A data-driven approach. Socio-Econ. Plan. Sci. 2024, 95, 101908. [Google Scholar] [CrossRef]

- Riemer-Sorensen, S.; Rosenlund, G.H. Deep Reinforcement Learning for Long Term Hydropower Production Scheduling. In Proceedings of the 2020 International Conference on Smart Energy Systems and Technologies (SEST), Istanbul, Turkey, 7–9 September 2020; pp. 1–6. [Google Scholar]

- Kuhnle, A.; May, M.C.; Schäfer, L.; Lanza, G. Explainable reinforcement learning in production control of job shop manufacturing system. Int. J. Prod. Res. 2022, 60, 5812–5834. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Y.; Tan, Y.; Zhang, J.; Yu, H. Dynamic Jobshop Scheduling Algorithm Based on Deep Q Network. IEEE Access 2021, 9, 122995–123011. [Google Scholar] [CrossRef]

- Zhu, Z.; Xu, H.; He, Y.; Pan, Z.; Zhang, M.; Jian, C. A DRL-based online real-time task scheduling method with ISSA strategy. Clust. Comput. 2024, 27, 8207–8223. [Google Scholar] [CrossRef]

- Wang, S.; Li, J.; Jiao, Q.; Ma, F. Design patterns of deep reinforcement learning models for job shop scheduling problems. J. Intell. Manuf. 2024. [Google Scholar] [CrossRef]

- Du, Y.; Li, J. A deep reinforcement learning based algorithm for a distributed precast concrete production scheduling. Int. J. Prod. Econ. 2024, 268, 109102. [Google Scholar] [CrossRef]

- Wan, L.; Fu, L.; Li, C.; Li, K. Flexible job shop scheduling via deep reinforcement learning with meta-path-based heterogeneous graph neural network. Knowl.-Based Syst. 2024, 296, 111940. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, C.; Yan, Y.; Hu, Y. Distributed Real-Time Scheduling in Cloud Manufacturing by Deep Reinforcement Learning. IEEE Trans. Ind. Inform. 2022, 18, 8999–9007. [Google Scholar] [CrossRef]

- Waschneck, B.; Reichstaller, A.; Belzner, L.; Altenmuller, T.; Bauernhansl, T.; Knapp, A.; Kyek, A. Deep reinforcement learning for semiconductor production scheduling. In Proceedings of the 2018 29th Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC), Saratoga Springs, NY, USA, 30 April–3 May 2018; pp. 301–306. [Google Scholar]

- Zhou, Y.; Yang, J.-J.; Zheng, L.-Y. Multi-Agent Based Hyper-Heuristics for Multi-Objective Flexible Job Shop Scheduling: A Case Study in an Aero-Engine Blade Manufacturing Plant. IEEE Access 2019, 7, 21147–21176. [Google Scholar] [CrossRef]

- Tremblet, D.; Thevenin, S.; Dolgui, A. Makespan estimation in a flexible job-shop scheduling environment using machine learning. Int. J. Prod. Res. 2024, 62, 3654–3670. [Google Scholar] [CrossRef]

- Górnicka, D.; Markowski, M.; Burduk, A. Optimization of Production Organization in a Packaging Company by Ant Colony Algorithm. In Intelligent Systems in Production Engineering and Maintenance—ISPEM 2017; Burduk, A., Mazurkiewicz, D., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2018; Volume 637, pp. 336–346. [Google Scholar] [CrossRef]

- Peiris, A.; Hui, F.K.P.; Duffield, C.; Ngo, T. Production scheduling in modular construction: Metaheuristics and future directions. Autom. Constr. 2023, 150, 104851. [Google Scholar] [CrossRef]

- Rubaiee, S.; Yildirim, M.B. An energy-aware multiobjective ant colony algorithm to minimize total completion time and energy cost on a single-machine preemptive scheduling. Comput. Ind. Eng. 2019, 127, 240–252. [Google Scholar] [CrossRef]

- Ghasemi, A.; Kabak, K.E.; Heavey, C. Demonstration of the Feasibility of Real Time Application of Machine Learning to Production Scheduling. In Proceedings of the 2022 Winter Simulation Conference (WSC), Singapore, 11–14 December 2022; pp. 3406–3417. [Google Scholar]

- Liu, Q.; Li, J. The Progress of Business Analytics and Knowledge Management for Enterprise Performance Using Artificial Intelligence and Man-Machine Coordination. J. Glob. Inf. Manag. 2022, 30, 1–21. [Google Scholar] [CrossRef]

- Qiu, Y.; Ji, W.; Zhang, C. A Hybrid Machine Learning and Population Knowledge Mining Method to Minimize Makespan and Total Tardiness of Multi-Variety Products. Appl. Sci. 2019, 9, 5286. [Google Scholar] [CrossRef]

- Delgoshaei, A.; Ali, A. An applicable method for scheduling temporary and skilled-workers in dynamic cellular manufacturing systems using hybrid ant colony optimization and tabu search algorithms. J. Ind. Prod. Eng. 2017, 34, 425–449. [Google Scholar] [CrossRef]

- Ren, P.; Wang, J.; Zhang, Y.; Zhang, T. Design and Implementation of Dongfeng Plate-Making Business Management System. J. Phys. Conf. Ser. 2018, 1069, 012058. [Google Scholar] [CrossRef]

- Tarigan, M.; Gaol, F.L.; Mauritsius, T.; Budiharto, W. Scheduling Production in the Flexible Packaging Industry Using Mathematical Models and Genetic Algorithms. In Proceedings of the 2023 International Conference on Informatics Engineering, Science & Technology (INCITEST), Bandung, Indonesia, 25 October 2023; pp. 1–5. [Google Scholar]

- El Khoukhi, F.; Boukachour, J.; El Hilali Alaoui, A. The “Dual-Ants Colony”: A novel hybrid approach for the flexible job shop scheduling problem with preventive maintenance. Comput. Ind. Eng. 2017, 106, 236–255. [Google Scholar] [CrossRef]

- Aungkulanon, P.; Ruekkasaem, L.; Luangpaiboon, P. Manufacturing and Production Planning via Fish Swarm Optimization Method and Its Hybridizations. In Proceedings of the 2020 2nd World Symposium on Artificial Intelligence (WSAI), Guangzhou, China, 27–29 June 2020; pp. 73–78. [Google Scholar]

- Kato, E.R.R.; Aranha, G.D.D.A.; Tsunaki, R.H. A new approach to solve the flexible job shop problem based on a hybrid particle swarm optimization and Random-Restart Hill Climbing. Comput. Ind. Eng. 2018, 125, 178–189. [Google Scholar] [CrossRef]

- Sidahmed Alamin, K.S.; Chen, Y.; Gaiardelli, S.; Spellini, S.; Calimera, A.; Beghi, A.; Susto, A.; Fummi, F.; Macii, E.; Vinco, S. SMART-IC: Smart Monitoring and Production Optimization for Zero-waste Semiconductor Manufacturing. In Proceedings of the 2022 IEEE 23rd Latin American Test Symposium (LATS), Montevideo, Uruguay, 5–8 September 2022; pp. 1–6. [Google Scholar]

- Adjogble, F.K.; Warschat, J.; Hemmje, M. Advanced Intelligent Manufacturing in Process Industry Using Industrial Artificial Intelligence. In Proceedings of the 2023 Portland International Conference on Management of Engineering and Technology (PICMET), Monterrey, Mexico, 23–27 July 2023; pp. 1–16. [Google Scholar]

- Zhang, Y.; Zhu, H.; Tang, D.; Zhou, T.; Gui, Y. Dynamic job shop scheduling based on deep reinforcement learning for multi-agent manufacturing systems. Robot. Comput. Integr. Manuf. 2022, 78, 102412. [Google Scholar] [CrossRef]

- Zhou, T.; Tang, D.; Zhu, H.; Wang, L. Reinforcement Learning with Composite Rewards for Production Scheduling in a Smart Factory. IEEE Access 2021, 9, 752–766. [Google Scholar] [CrossRef]

- Antons, O.; Arlinghaus, J.C. Data-driven and autonomous manufacturing control in cyber-physical production systems. Comput. Ind. 2022, 141, 103711. [Google Scholar] [CrossRef]

- Para, J.; Del Ser, J.; Nebro, A.J. Energy-Aware Multi-Objective Job Shop Scheduling Optimization with Metaheuristics in Manufacturing Industries: A Critical Survey, Results, and Perspectives. Appl. Sci. 2022, 12, 1491. [Google Scholar] [CrossRef]

- Wang, L.; Pan, Z.; Wang, J. A Review of Reinforcement Learning Based Intelligent Optimization for Manufacturing Scheduling. Complex Syst. Model. Simul. 2021, 1, 257–270. [Google Scholar] [CrossRef]

- Skycode. SkyPlanner APS—AI Production Planning and Scheduling. 2019. Available online: https://skycode.fi/en/skyplanner-aps-ai-production-planning-and-scheduling/ (accessed on 10 January 2021).

| Filter Type | Description | Database |

|---|---|---|

| Language | English | Scopus, WoS |

| Document type | Journal, conference proceedings | Scopus |

| Article, review article, proceeding papers | WoS | |

| Subject area | Engineering, Computer Science, Mathematics, Decision Science, Business, Management and Accounting | Scopus |

| Engineering, Computer Science, Mathematics, Operations Research, Management Science | WoS | |

| Total | 2017−2024 | Scopus, WoS |

| ID | Reference | Aim of Paper | Research Gap | Industrial Sector |

|---|---|---|---|---|

| R1 | Kaven et al. [1] | Propose Multi-Agent Reinforcement Learning (MARL) approach for online layout planning and scheduling in flexible assembly systems | Limited exploration of MARL in real-time applications for layout planning and scheduling in flexible assembly systems | Manufacturing (flexible assembly systems) |

| R2 | Chen et al. [3] | Present human–cyber–physical data fusion method based on Reinforcement Learning (RL) | Lack of comprehensive frameworks for human–cyber–physical data fusion using RL across various applications | Steel manufacturing |

| R3 | Chagas et al. [16] | Conduct bibliometric and systemic analysis of production planning optimization | Limited integration of Digital Twins (DTs) with ML in adaptive production planning and control systems | Manufacturing (production planning) |

| R4 | Chiurco et al. [17] | Discuss data modeling and ML practices to enable intelligent DTs in adaptive production planning and control | Gaps in understanding scalability of DRL approaches for dynamic scheduling in sustainable manufacturing | Manufacturing (DTs) |

| R5 | Zhang et al. [18] | Provide systematic review of DLR-based dynamic scheduling for resilient and sustainable manufacturing | Insufficient theoretical and practical exploration of smart master production scheduling frameworks in diverse supply chains | Sustainable manufacturing |

| R6 | Serrano-Ruiz et al. [19] | Develop conceptual framework for smart master production schedule in supply chain | Lack of tailored ML techniques specific to various industrial applications and challenges | Supply chain management |

| R7 | Bertolini et al. [20] | Offer comprehensive literature review of ML applications in industrial contexts | Limited empirical studies on effectiveness of smart machine monitoring systems in different I4.0 contexts | Manufacturing |

| R8 | Singh et al. [21] | Evaluate smart machine monitoring system under I4.0 concept | Need for further investigation into application of big data analytics in production scheduling optimization | Manufacturing (I4.0) |

| R9 | Shen [22] | Optimize production scheduling of intelligent manufacturing systems for clothing using association rule algorithm | Insufficient examination of tailored ML techniques for production planning and control in I4.0 contexts | Clothing manufacturing |

| R10 | Usuga Cadavid et al. [23] | Explore ML applications in production planning and control in I4.0 era | Gaps in empirical research on challenges of synergistic and intelligent process optimization in complex manufacturing environments | Manufacturing (production planning) |

| R11 | Harjunkoski et al. [24] | Present initial results and open challenges in synergistic and intelligent process optimization | Limited exploration of improved GAs based on ML in practical production scheduling scenarios | Chemical production |

| R12 | Guo et al. [25] | Research application of improved GA based on ML in production scheduling | Need for further studies on integration of memetic algorithms and RL in sociotechnical production scheduling | Manufacturing (production scheduling) |

| R13 | Grumbach et al. [26] | Propose memetic algorithm with RL for sociotechnical production scheduling | Gaps in understanding of average reward adjustments in DRL for order release planning | Discrete manufacturing (assembly) |

| R14 | Schneckenreither et al. [27] | Develop average-reward-adjusted DRL approach for order release planning | Need for more empirical studies on application of DRL in chemical production scheduling | Chemical production |

| R15 | Hubbs et al. [28] | Present DRL approach for scheduling | Limited exploration of exact methods and ACO in single-machine scheduling problems with periodic maintenance | Chemical production |

| R16 | Qamhan et al. [29] | Propose exact method and ACO for single-machine scheduling problem with time window periodic maintenance | Few models handled periodic maintenance simultaneously, with scheduling often treated separately | Manufacturing |

| R17 | Bindi et al. [30] | Analyze impact of supply chain strategy in luxury fashion industry on performance indicators | Need for more empirical studies evaluating impact of supply chain strategies in luxury fashion industry on performance indicators | Fashion industry/supply chain |

| R18 | Fani et al. [31] | Develop data-driven decision-support tool for production planning, combining association rules and simulation | Limited frameworks integrating association rules and simulation in production planning decision-support systems | Fashion industry/supply chain |

| R19 | Kuhnle et al. [32] | Explore RL for opportunistic maintenance optimization | Lack of exploration into application of DRL in different industrial contexts for production scheduling | Manufacturing (maintenance optimization) |

| R20 | Waschneck et al. [33] | Optimize global production scheduling using DRL | Need for systematic review that addresses both theoretical and practical applications of AI in production scheduling | Semiconductor manufacturing |

| R21 | Del Gallo et al. [34] | Conduct SLR on application of AI to solve production scheduling problems in real industrial settings | Insufficient research on energy management considerations in Job Shop Scheduling Problems | Manufacturing (production scheduling) |

| R22 | Kawaguchi et al. [35] | Address Job Shop Scheduling Problems, considering energy management using parallel Reactive TS | Gaps in understanding how RL can be effectively applied to minimize makespan in assembly processes | Manufacturing (job shop scheduling) |

| R23 | Ying and Lin [36] | Minimize makespan in two-stage assembly additive manufacturing using RL-iterated greedy algorithm | Need for empirical validation of AI and ML applications in reshaping manufacturing processes | Manufacturing (additive manufacturing) |

| R24 | Priyanga et al. [37] | Discuss how AI and ML reshape manufacturing processes in smart factories | Limited research on robust scheduling techniques in hot rolling production environments | Smart manufacturing |

| R25 | Zhang et al. [38] | Develop robust scheduling method for hot rolling production using local-search-enhanced ACO algorithm | Need for more comprehensive methodologies that integrate smart production planning and control systems in I4.0 | Steel manufacturing |

| R26 | Oluyisola et al. [39] | Design and develop smart production planning and control systems in I4.0 era through methodology and case study | Lack of detailed guidance on how to translate system-level requirements—such as scalability, flexibility, and real-time responsiveness—into low-level architecture components (like algorithms) | Semiconductor manufacturing |

| R27 | Fani et al. [40] | Apply data mining and augmented reality to enhance decision-making in production | Limited application of data mining and augmented reality techniques in fashion industry for decision-making processes | Fashion industry |

| R28 | Göppert et al. [41] | Predict performance indicators with ANNs for AI-based online scheduling in dynamically interconnected assembly systems | Gaps in understanding of potential of ML in optimized production planning using hybrid simulation | Automotive/industrial assembly |

| R29 | Sobottka et al. [42] | Investigate potential of ML in optimized production planning with hybrid simulation | Need for empirical validation of ambient intelligent-based decision-support systems in production planning and control | Discrete manufacturing |

| R30 | Gomes et al. [43] | Develop intelligent-based decision-support system for production and control planning | Limited understanding of cycle time prediction in textile manufacturing using Neural Networks (NNs) | Textile manufacturing |

| R31 | Onaran and Yanık [44] | Predict cycle times in textile manufacturing using ANNs | Gaps in energy estimation techniques and production scheduling methodologies for job shops using ML | Textile manufacturing |

| R32 | Pereira et al. [45] | Estimate energy consumption and production scheduling in job shop environments using ML | Limited research on application of NNs for predicting manufacturing lead times, particularly extrusion tools | Job shop energy estimation |

| R33 | Sajko et al. [46] | Predict manufacturing lead times for extrusion tools using NNs | Need for further exploration of innovative hybrid approaches for FJSS that incorporate preventive maintenance | Plastic/metal tool-making |

| R34 | Grumbach et al. [47] | Propose robust–stable scheduling in dynamic flow shops based on Deep Reinforcement Learning (DRL) | Lack of comprehensive studies on integration of ML and augmented reality in production planning | Assembly manufacturing |

| R35 | Jung and Park [48] | Study DL-based prediction of production demand using Long Short-Term Memory (LSTM) under data sparsity conditions | Limited empirical evidence on effectiveness of data-driven decision-making tools in fashion industry | Manufacturing/supply chain management |

| R36 | Huang et al. [49] | Predict product completion times using hybrid approach combining DL and system modeling | Insufficient research on scalability of RL techniques for large-scale production scheduling | Discrete manufacturing |

| R37 | Zareian Beinabadi et al. [50] | Address sustainable supply chain decision-making in automotive industry using data-driven approach | Need for more diverse case studies to validate application of AI in production control across different manufacturing sectors | Automotive |

| R38 | Riemer-Sorensen and Rosenlund [51] | Apply DRL for long-term hydropower production scheduling. | Gaps in understanding challenges of implementing intelligent scheduling systems in real-world manufacturing environments. | Energy (hydropower) |

| R39 | Kuhnle et al. [52] | Explore explainable RL in production control for job shop manufacturing systems. | Limited exploration of impact of data quality on effectiveness of ML algorithms in production scheduling. | Manufacturing (maintenance optimization) |

| R40 | Zhao et al. [53] | Develop dynamic job shop scheduling algorithm based on DQN | Insufficient theoretical frameworks for integrating various AI techniques in supply chain management | Flexible job shop/supply chain management |

| R41 | Zhu et al. [54] | Propose DRL-based online real-time task scheduling method with ISSA strategy | Need for more research on interaction between human operators and AI systems in production environments | Flexible job shop |

| R42 | Wang et al. [55] | Discuss design patterns for DRL models addressing Job Shop Scheduling Problems | Gaps in the understanding of the role of big data analytics in enhancing production efficiency and decision-making | Flexible job shop |

| R43 | Du and Li [56] | Present DRL-based algorithm for distributed precast concrete production scheduling | Limited exploration of real-time data integration techniques for improved scheduling in manufacturing | Construction |

| R44 | Wan et al. [57] | Explore FJSS using DRL with meta-path-based heterogeneous graph NNs | Need for empirical studies focusing on application of AI in optimizing energy consumption in manufacturing processes | Manufacturing |

| R45 | Zhang et al. [58] | Investigate distributed real-time scheduling in cloud manufacturing using DRL | Insufficient examination of impact of Machine Learning (ML) on reducing lead times in production systems | Cloud manufacturing |

| R46 | Waschneck et al. [59] | Apply DRL for semiconductor production scheduling | Gaps in research on how to effectively combine traditional scheduling methods with modern AI techniques | Semiconductor manufacturing |

| R47 | Zhou et al. [60] | Use multi-agent-based hyperheuristics for multi-objective FJSS in aero-engine blade manufacturing plant | Limited understanding of benefits and challenges of using cloud-based solutions for production scheduling | Aero-engine Manufacturing |

| R48 | Tremblet et al. [61] | Estimate makespan in flexible job shop scheduling environments using ML | Need for further exploration of ethical implications of AI in manufacturing and production planning | Manufacturing (flexible job shop scheduling) |

| R49 | Górnicka et al. [62] | Optimize production organization in packaging company using ACO | Insufficient research on effectiveness of hybrid algorithms in solving complex scheduling problem | Packaging |

| R50 | Peiris et al. [63] | Discuss production scheduling in modular construction using metaheuristics and future directions | Gaps in empirical evaluation of smart factory concepts in enhancing operational efficiency | Transportation |

| R51 | Rubaiee and Yildirim [64] | Present energy-aware multi-objective ant colony algorithm to minimize total completion time and energy costs in single-machine preemptive scheduling | Limited studies addressing integration of maintenance strategies with production scheduling | Discrete manufacturing |

| R52 | Ghasemi et al. [65] | Demonstrate feasibility of real-time application of Machine Learning in production scheduling | Need for more comprehensive frameworks that consider entire supply chains in production scheduling | Semiconductor manufacturing |

| R53 | Liu and Li [66] | Examine progress of business analytics and knowledge management for enterprise performance using Artificial Intelligence and human–machine coordination | Insufficient research on role of IoT in enhancing production planning and control systems | Business management |

| R54 | Qiu et al. [67] | Propose hybrid ML and population knowledge mining method to minimize makespan and total tardiness for multi-variety products | Gaps in understanding of impact of variability in production processes on scheduling effectiveness | Manufacturing |

| R55 | Delgoshaei and Ali [68] | Present method for scheduling temporary and skilled workers in dynamic cellular manufacturing systems using hybrid ACO and TS algorithms | Limited exploration of potential of RL in adaptive manufacturing systems | Manufacturing |

| R56 | Ren et al. [69] | Design and implement business management system for Dongfeng plate-making | Need for empirical validation of simulation models used in production scheduling decisions | Packaging industries |

| R57 | Tarigan et al. [70] | Schedule production in flexible packaging industry using mathematical models and Genetic Algorithms | Insufficient examination of how organizational culture influences adoption of AI in manufacturing | Packaging manufacturing |

| R58 | El Khoukhi et al. [71] | Introduce “Dual-Ants Colony,” novel hybrid approach for FJSS with preventive maintenance. | Gaps in research on integration of sustainability considerations into production scheduling methodologies | Manufacturing (job shop scheduling) |

| R59 | Aungkulanon et al. [72] | Explore manufacturing and production planning via fish swarm optimization method and its hybridizations | Limited studies on application of AI in SMEs for production management | Manufacturing (optimization) |

| R60 | Kato et al. [73] | Propose new approach to solve FJSSP based on hybrid particle swarm optimization and random-restart hill climbing | Need for more case studies to illustrate practical challenges of implementing AI in production systems | Manufacturing (job shop problems) |

| R61 | Alamin et al. [74] | Present SMART-IC for smart monitoring and production optimization for zero-waste semiconductor manufacturing | Insufficient research on relationship between supply chain resilience and advanced scheduling techniques | Semiconductor manufacturing |

| R62 | Adjogble et al. [75] | Discuss advanced intelligent manufacturing in process industry using AI | Gaps in understanding of role of ML in predictive maintenance for manufacturing equipment | Process industry |

| R63 | Zhang et al. [76] | Develop dynamic job shop scheduling method based on DRL for multi-agent manufacturing systems | Limited exploration of use of multi-agent systems in collaborative production scheduling | Manufacturing (job shop scheduling) |

| R64 | Zhou et al. [77] | Use RL with composite rewards for production scheduling in smart factory | Need for empirical studies on effectiveness of ML models in dynamic production environments | Smart manufacturing |

| R65 | Antons and Arlinghaus [78] | Explore data-driven and autonomous manufacturing control in CPPSs | Insufficient research on impact of training and skill development on successful AI implementation | Autonomous manufacturing |

| R66 | Para et al. [79] | Survey and critically assess energy-aware, multi-objective job shop scheduling optimization in manufacturing, highlighting state-of-the-art metaheuristics and their results | Gaps in existing literature regarding energy considerations in scheduling; lack of comparative profiles and future directions for energy-aware multi-objective approaches | Manufacturing |

| R67 | Wang et al. [80] | Provide comprehensive review of RL approaches applied to intelligent scheduling in manufacturing systems. | Prior reviews lacked depth in RL applications in scheduling; this paper compiles RL methods, challenges, and insights. | Manufacturing |

| Algorithm Category | Algorithm Name | Features (References) |

|---|---|---|

| Supervised ML | Artificial Neural Network (ANN) | |

| Recurrent Neural Network (RNN) | ||

| Convolutional Neural Network (CNN) |

| |

| Reinforcement Learning (RL) | Deep Learning (DL) |

|

| Deep RL (DRL) |

| |

| Deep Q-Network (DQN) | ||

| Single-State Metaheuristics | Simulated Annealing (SA) |

|

| Tabu Search (TS) |

| |

| Population Method Metaheuristics | Genetic Algorithm (GA) |

|

| Non-Dominated Sorting Genetic Algorithm II (NSGA-II) |

| |

| Ant Colony Optimization (ACO) | ||

| Particle Swarm Optimization (PSO) | ||

| Fish Swarm Algorithm (FSA) | ||

| Hybrid Metaheuristics | Ant Colony Tabu Search (ACO+TS) |

|

| Genetic Ant Colony (GA+ACO) | ||

| Non-Dominance Sequencing Genetic Algorithm + Simulated Annealing (NGSA) |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Giovanni, M.; Lazoi, M.; Bandinelli, R.; Fani, V. Advanced Planning Systems in Production Planning Control: An Ethical and Sustainable Perspective in Fashion Sector. Appl. Sci. 2025, 15, 7589. https://doi.org/10.3390/app15137589

De Giovanni M, Lazoi M, Bandinelli R, Fani V. Advanced Planning Systems in Production Planning Control: An Ethical and Sustainable Perspective in Fashion Sector. Applied Sciences. 2025; 15(13):7589. https://doi.org/10.3390/app15137589

Chicago/Turabian StyleDe Giovanni, Martina, Mariangela Lazoi, Romeo Bandinelli, and Virginia Fani. 2025. "Advanced Planning Systems in Production Planning Control: An Ethical and Sustainable Perspective in Fashion Sector" Applied Sciences 15, no. 13: 7589. https://doi.org/10.3390/app15137589

APA StyleDe Giovanni, M., Lazoi, M., Bandinelli, R., & Fani, V. (2025). Advanced Planning Systems in Production Planning Control: An Ethical and Sustainable Perspective in Fashion Sector. Applied Sciences, 15(13), 7589. https://doi.org/10.3390/app15137589