2.1. EM Density Gauge Theory

To measure the density of asphalt mixture in the field was used PQI 380 electromagnetic (EM) density gauge, the operation of nuclear or non-nuclear density meters (non-destructive methods) is generally similar, this process includes calibration, the input value of asphalt mixture density through specimens in laboratory (cores or test pieces), and data collection [

33,

34].

The EM density was used, a device that uses electroscopic impedance to measure the electrical response of the asphalt from which you want to calculate its density. The electric field is transmitted through the material by the sensor on the equipment plate [

30].

The EM density gauge is a device that uses impedance spectroscopy to make readings of the electrical response of the asphalt, from which the density of the asphalt mixture is calculated directly. The electric transmission field is transmitted from the sensor located in the plate of the EM density gauge through the material (asphalt mixture), to subsequently measure the electrical impedance (

Figure 2) and use it within the calculation of the density of the specific rock aggregate [

34].

It has been found that the dielectric constant of a matrix consisting of several materials is proportional to the volume fractions and the dielectric constants of these materials, as shown in Equation (1) [

35].

where

εrn are the dielectric constants of the materials constituting the matrix and v

n are the fractions of the volume of the materials involved, α is a constant that explains the effects of interfacial dielectric polarization for engineering materials, α = 0.5.

Table 2 below shows the usual data for each of the materials making up an asphalt mixture [

35].

The value of the dielectric constant for stone aggregates depends on their petrographic and chemical composition; in the case of this research, we used basalt (εr = 3.2), but granite (εr = 4.5) can also be used.

According to the results expected from the equation of the asphalt dielectric constant, it is shown that the temperature coefficient in a mixture having a content of 2% water of −1% per 10 °C, for a temperature of 150 °C corresponding to 0.025 g/cm3.

If required, a correction of the densities should be made according to the temperature range (at every 10 °C) in which they are carried out, as shown in Equation (2) [

35]:

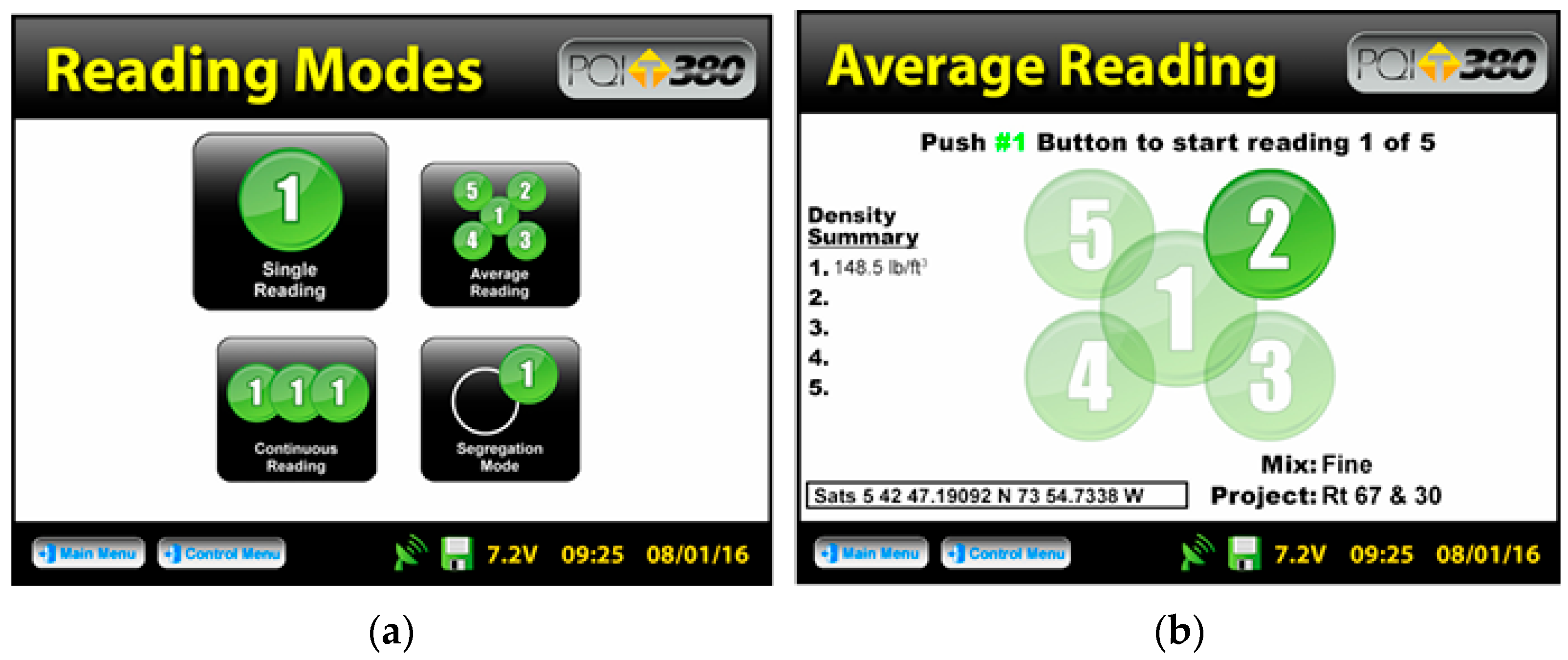

There are two common measurement methodologies in the EM density gauge (PQI 380) to obtain the results of the density of asphalt mixtures, which are simple measurements, or with the average measurement of 5 points, the density measurement range of the PQI is 18–2.5 g/cm

3. For optimal results, the calibration of the PQI 380 with the core method is the most accurate and consistent readings; to ensure the methodology is reproducible, the calibration cycle must be monthly or in every change in the aggregate type and size, as well as the changes in the binders, produce a wide variety of electrical properties [

36].

The EM densimeter can take density readings of several modalities (

Figure 3a), with the simple reading and regional average method of 5 points. In the regional average, method density readings are taken at 5 points, which start in the center and move the equipment to 2″ from the upper and lower ends on both sides of the starting point (

Figure 3b).

Due to the practicality of the procedure and the analysis that is performed on more than 586 points, it was decided to perform the simple reading method (one reading per point) with the equipment.

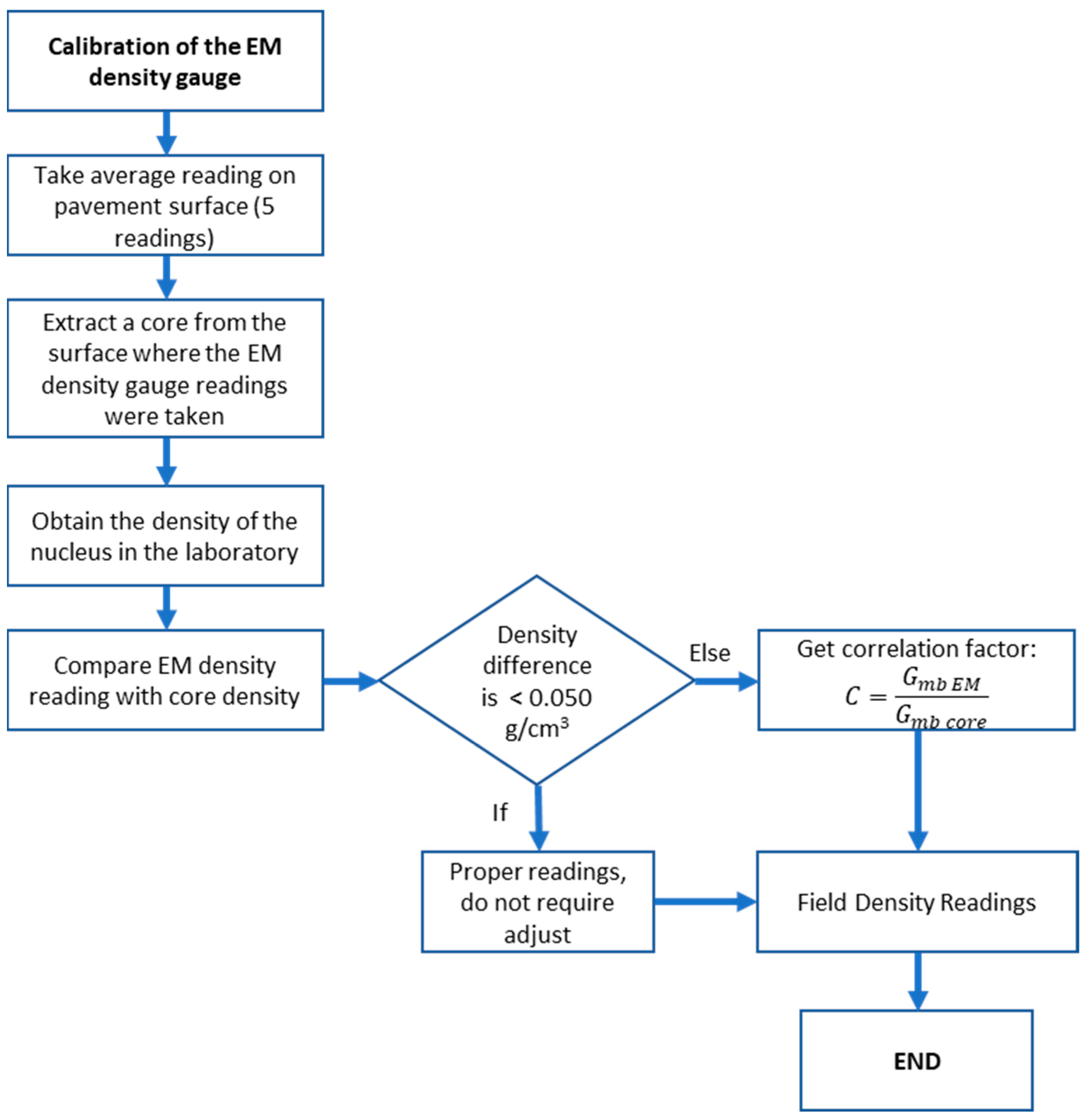

Performing the electromagnetic densimeter calibration process depends on the specifications provided by the manufacturer, who usually agree that the equipment should be calibrated for each new asphalt mixing working formula (JMF) in order to obtain approximate and consistent readings. This is mainly due to the fact that field work in construction uses different types of asphalt mixtures, which have small variations, which are mainly the change in the type and size of the stone aggregate or a change in the asphalt; these slight changes cause the electrical properties of the mixtures to be altered.

The standard calibration procedure should be performed using the average reading mode (5 readings of the area under analysis) of the electromagnetic field densimeter; subsequently, a core will be extracted from this surface in order to determine the density in the laboratory and make a comparison between both readings, having to adjust the densimeter reading to the result obtained with the core in the laboratory. This procedure is shown in the following flow diagram in

Figure 4.

For the case of this investigation, the method of simple readings was used; that is to say, the result is recorded at a point (area of the plate) on the surface of the asphalt mixture, as shown in

Figure 5. This test method with simple readings was chosen because of its ease and speed to obtain better field measurement performance, since the approximation and certainty of existing theoretical models for density prediction with EM equipment depends mainly on an extensive set of specimens for calibration [

32]. Density readings from the HMA were taken every 50 m away on the axis.

To improve the accuracy of the electromagnetic density gauge, the laboratory core density is used as a reference. At least the density of the HMA shall be estimated with the electric field response and displayed on the display [

33].

2.2. Characteristics of the Analysis Section

As the length of the built HMA surface is a high specification road of the Network of Toll Roads, which has 2 bodies, each body with 2 traffic lanes of 3.50 m each, and 1.80 m, the section under analysis has a length of approximately 71.2 km, with traffic conditions as shown in

Table 3.

Where the classification indicates Annual Daily Average Traffic (ADAT) of 4506 and 4618 mixed vehicles, of which there are motorcycles (M), light vehicles (A), and heavy vehicles (B, C2, C3, T3S2, T3S3, and T3S2R4), where there are buses (B), freight trucks (C), and tractor units (T) with semi-trailers (S) or complete trailers (R), and the number accompanying them is the number of axles composing them. According to the vehicle composition of the section (

Table 3), it is estimated that there is a 39.6% and 39.9% traffic of heavy vehicles in A and B, respectively.

The stretch is located in the state of Michoacán, where the prevailing climatic conditions (

Table 4) consider it an area of “temperate climate”.

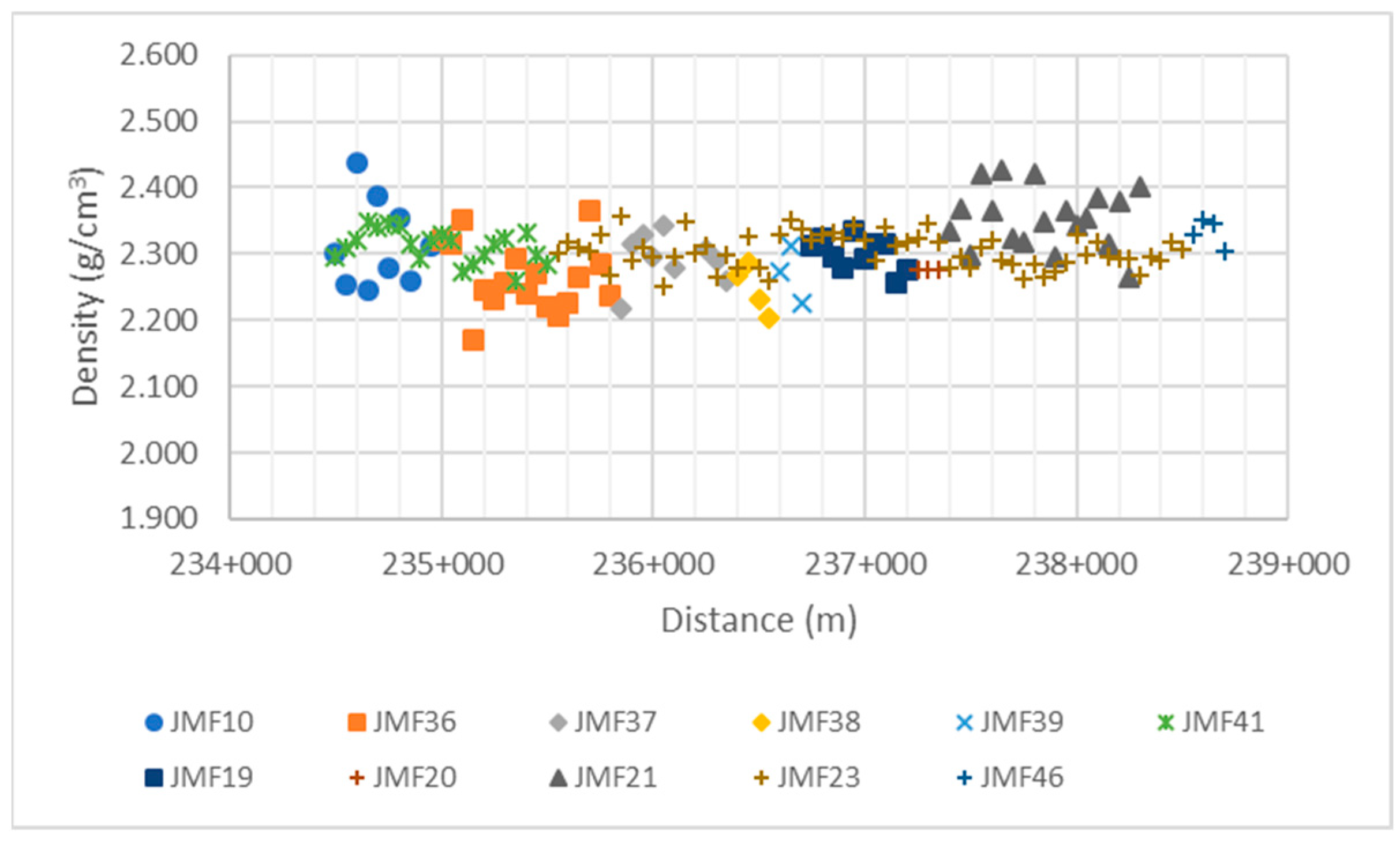

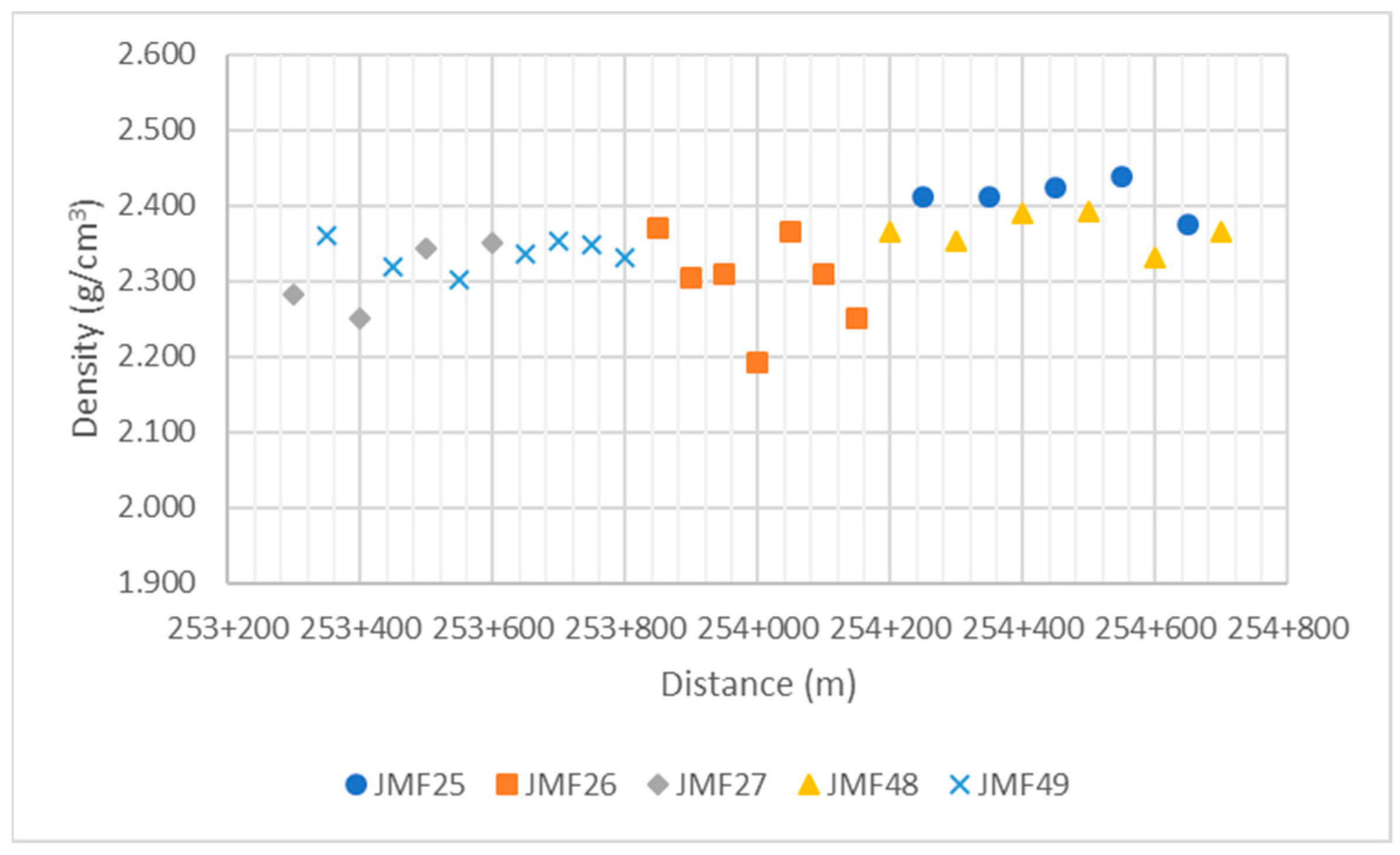

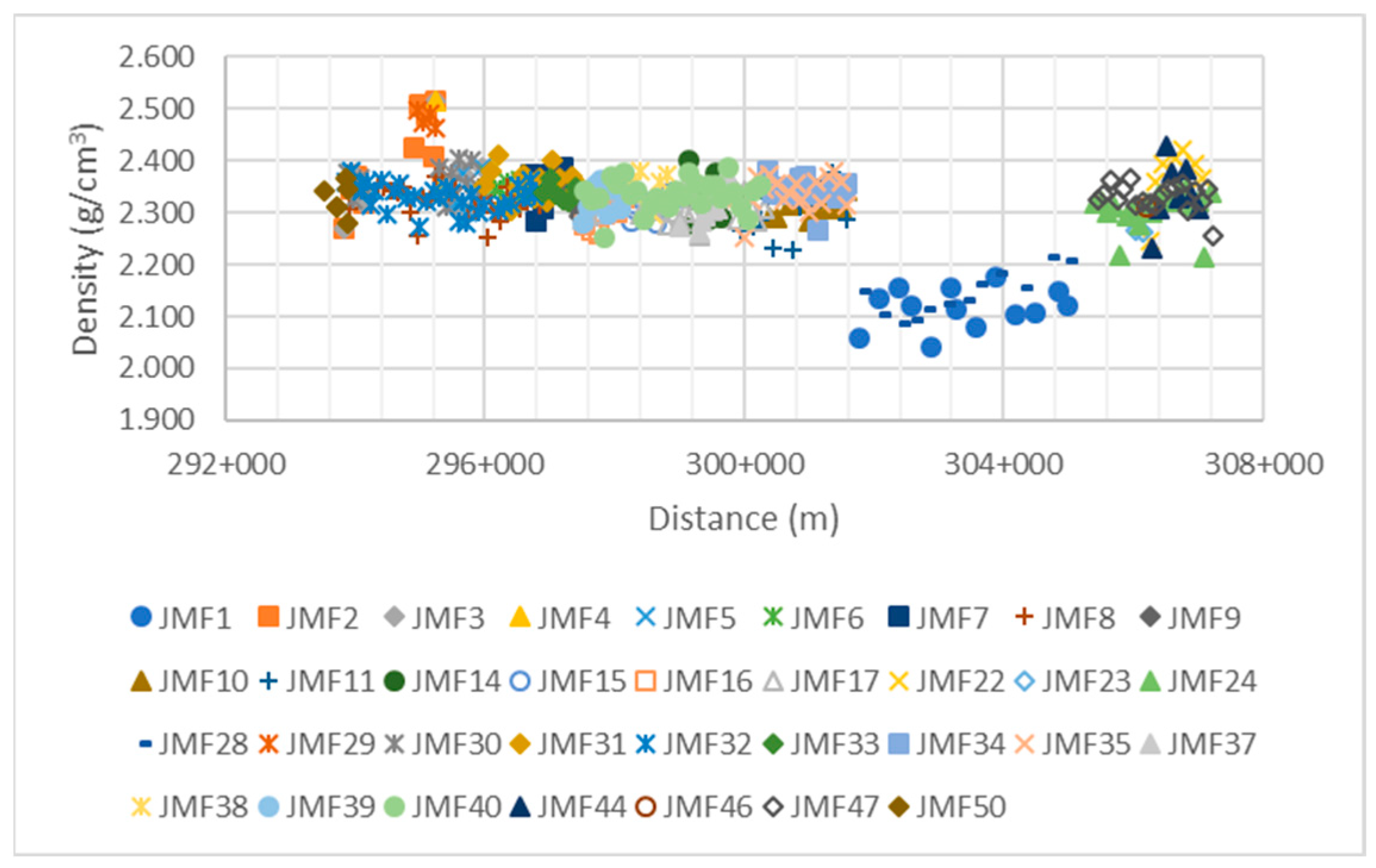

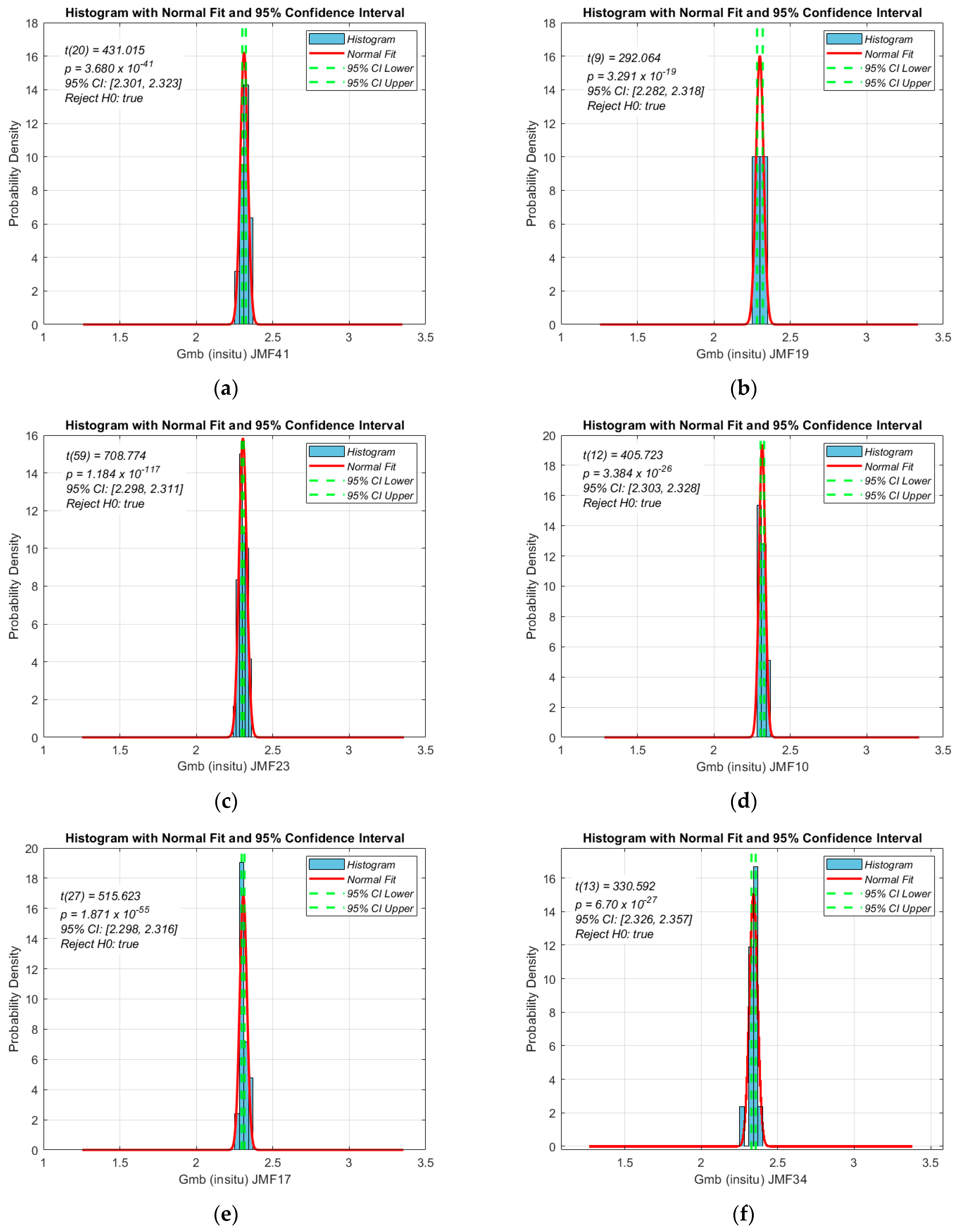

In addition, because the study was carried out in segments of construction work by segments, it was decided to carry out the analysis of the data on the densities of the asphalt mixture by segments, due to the discontinuity of the sections covered, all the works in Body A of the road. It should be mentioned that quality control analyses of the design of the asphalt mixture were carried out every day of production of the plant; in this way, we have 50 job mix formulae (JMFs), i.e., 50 asphalt mix designs, and each one has raw density data of the mixture (Gmb) and maximum theoretical density of the asphalt mixture (Gmm, total mass of the mixture excluding the volume of water-permeable pores). It should be mentioned that more than 50 JMFs were obtained for the preparation of asphalt mixtures, because the conditions of the stone aggregates (granulometry, mainly) and the asphalt to be used changed; although the material bank or asphalt supplier was not changed, production conditions in the plant can change from one day to another, so these characteristics were obtained within the internal quality control process.

It is very important to mention that core extractions were carried out (at least 3 extractions per day for statistical averages) for each day of construction work. The extracted cores were taken to the laboratory to obtain the density parameters of the HMA in order to calibrate and more adequately correlate the results of the EM density gauge.

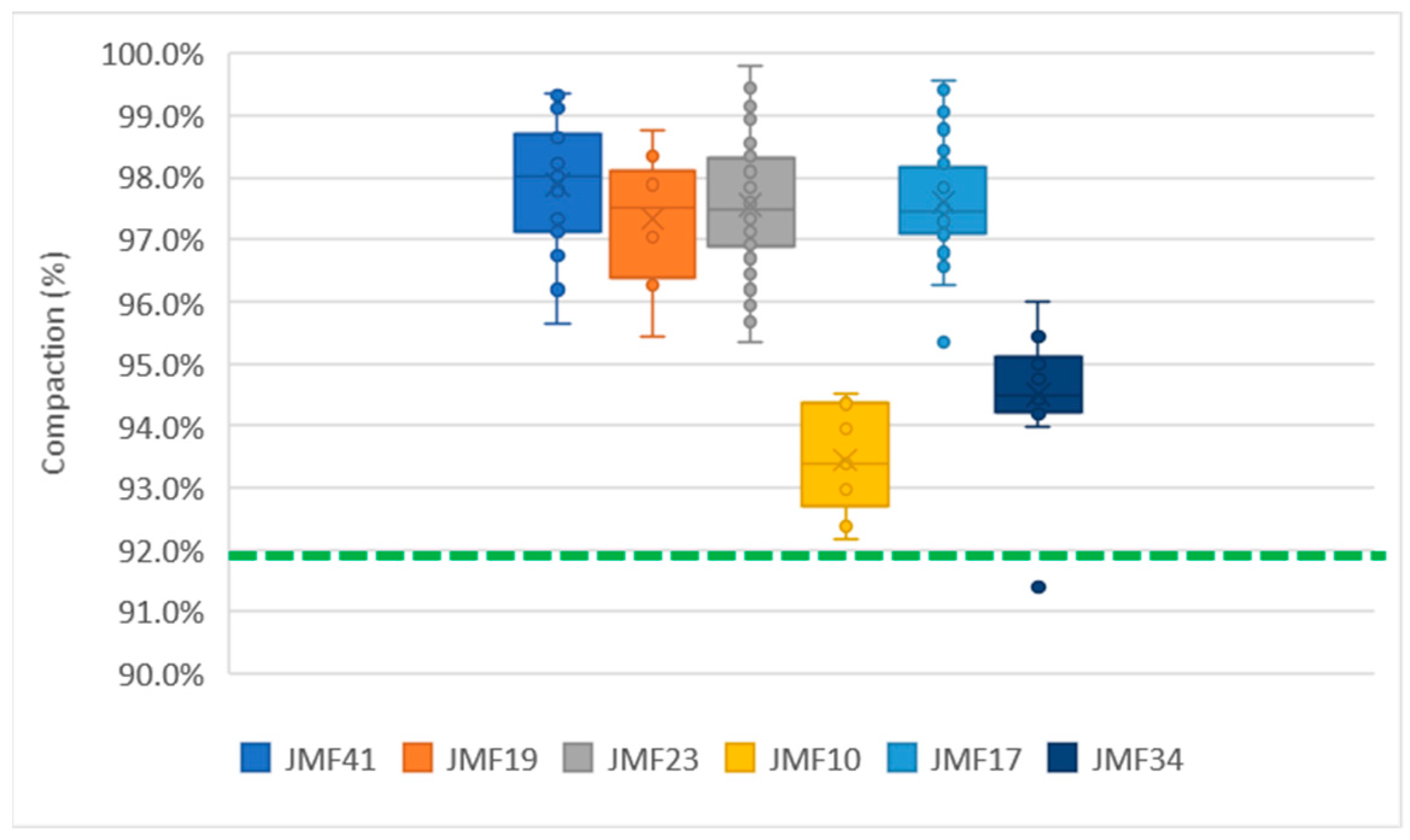

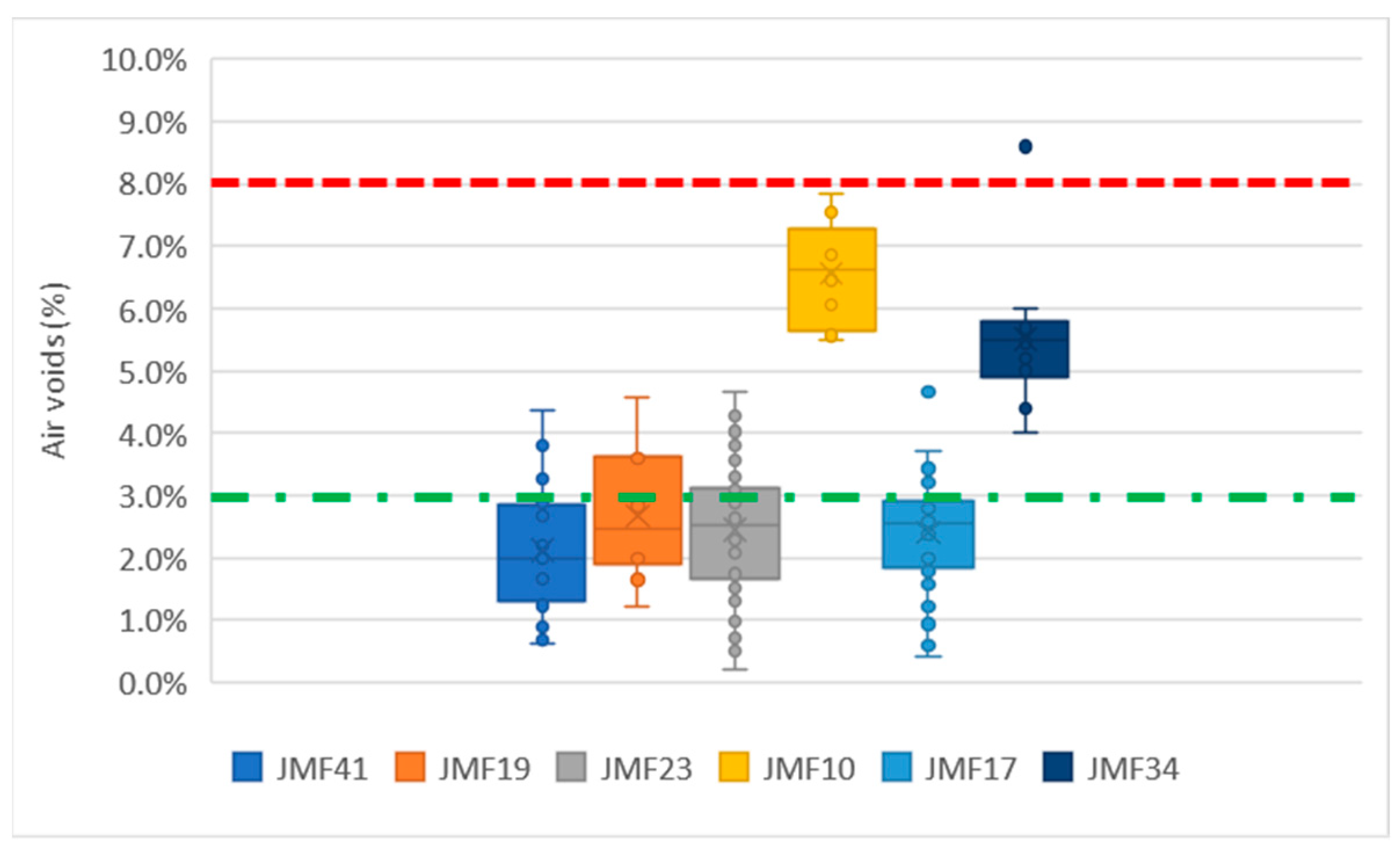

Once obtained the density readings of the asphalt mixture in field to perform the compaction calculation of it, which is indirectly associated with the maximum theoretical gravity of the mixture (Gmm), because this parameter is taken as design data in the laboratory of the mixture, and, by making a direct relationship of the field specific gravity divided with Gmm, it is possible to find the percentage of compaction, and the difference from 100% is the air void content is shown in Equations (3) and (4):

As shown in Equations (3) and (4), the calculation of the percentage of compaction of the asphalt mixture is relevant, since this data allows us to know the content of air voids within the asphalt mixture. The content of air voids is associated with the durability of the asphalt mixture and the correct performance of it, and most references consider that this value of air voids should be 3–8% [

1,

2,

3,

4,

5].