Multi-Region OpenFOAM Solver Development for Compact Toroid Transport in Drift Tube

Abstract

1. Introduction

2. Models

2.1. Physical Model

2.2. Implementation of the mhdF Solver Algorithm

- Momentum prediction: In this step, the pressure gradient and Lorentz force term are treated explicitly to obtain an estimated velocity for the current time step.

- Energy equation solution: Based on the estimated velocity and other explicitly treated variables, the energy equation is solved. Subsequently, the estimated temperature is derived from the relationship between temperature and internal energy. This allows for the estimation of the compressibility coefficient and the density .

- n inner loops for solving the pressure equation: The pressure equation is derived from the combination of the momentum and continuity equations using the previously estimated velocity , density , and the compressibility coefficient . After n inner iterations, the corrected pressure value is obtained, the velocity flux and velocity are updated, and the density is recalculated using the equation of state.

- n inner loops for solving the magnetic induction equation: The algorithm for solving the magnetic induction equation is analogous to the PISO algorithm and fundamentally follows Brackbill’s projection method, aiming to enforce the divergence-free constraint . First, the magnetic induction equation is solved to obtain an estimated magnetic flux density . Subsequently, based on Brackbill’s projection method and the relationship between the magnetic flux density and its vector/scalar potentials , a Poisson equation for the scalar potential is formulated and solved. The scalar potential is then used to correct the magnetic flux density, yielding . After n iterations, the magnetic flux density approximately satisfies the divergence-free constraint.

2.3. Multi-Region Coupling Framework and Interface Coupling Boundary Conditions

3. Program Verification

3.1. The mhdF Solver Verification

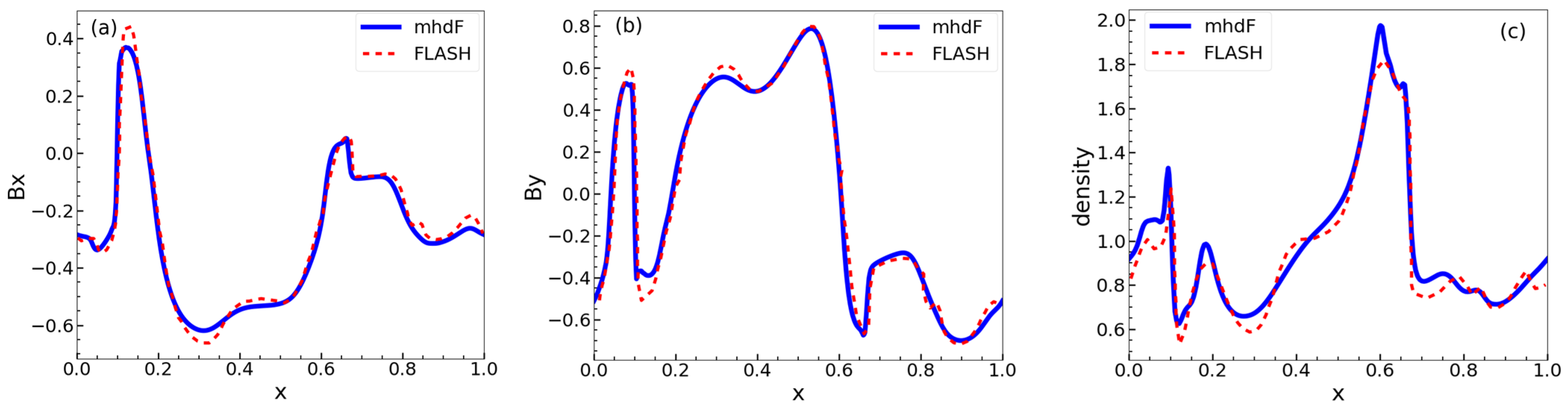

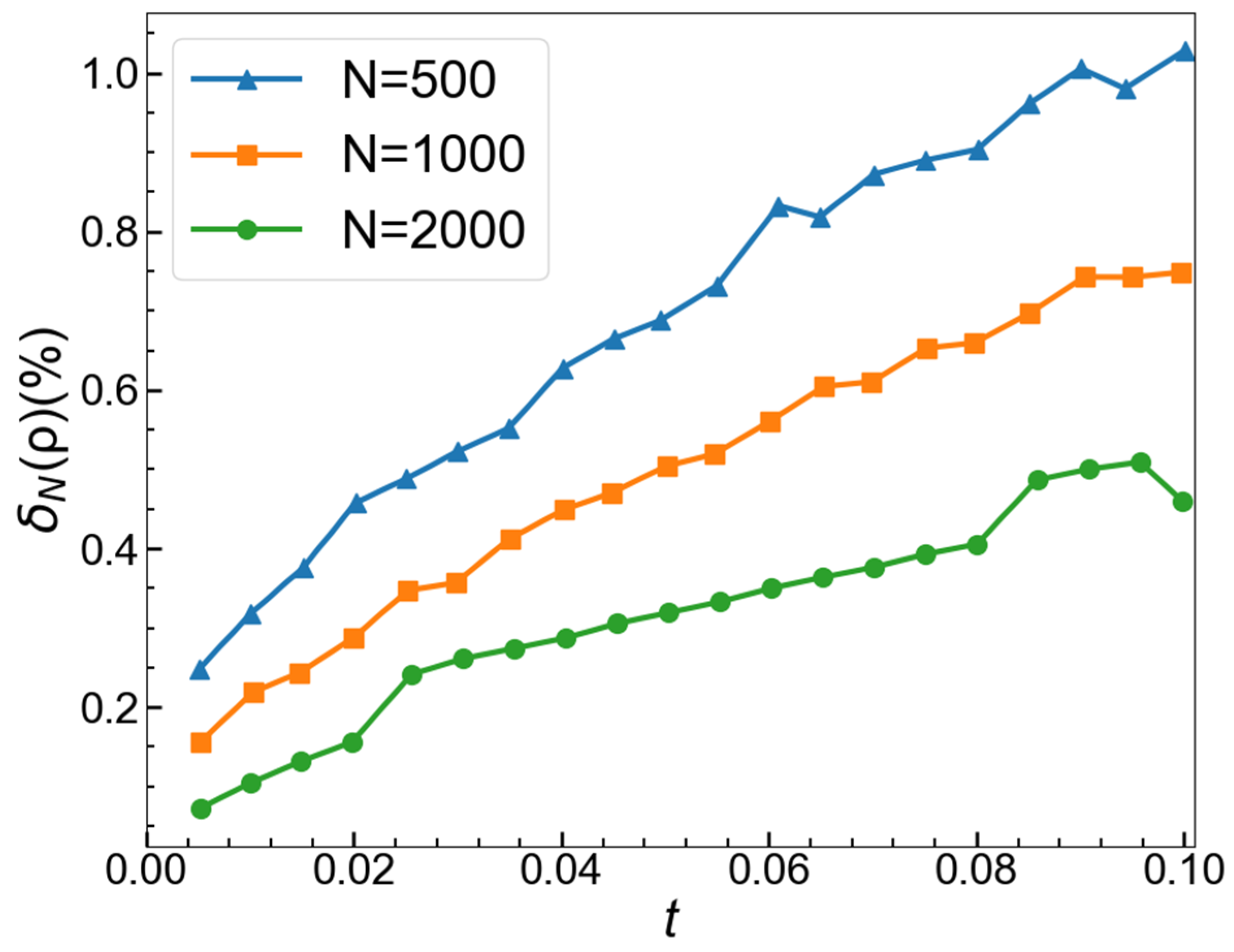

3.1.1. Orszag–Tang MHD Vortex Problem

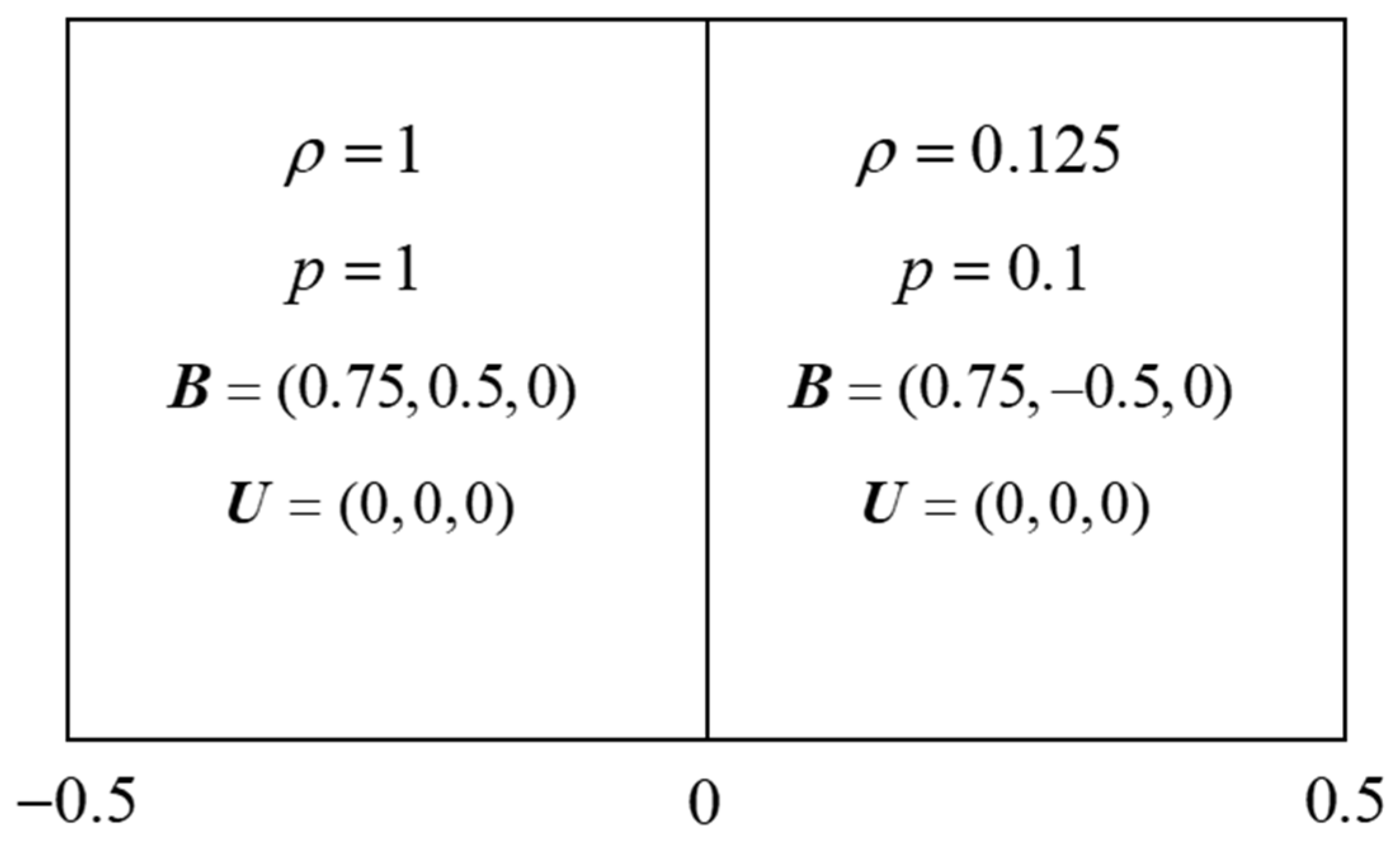

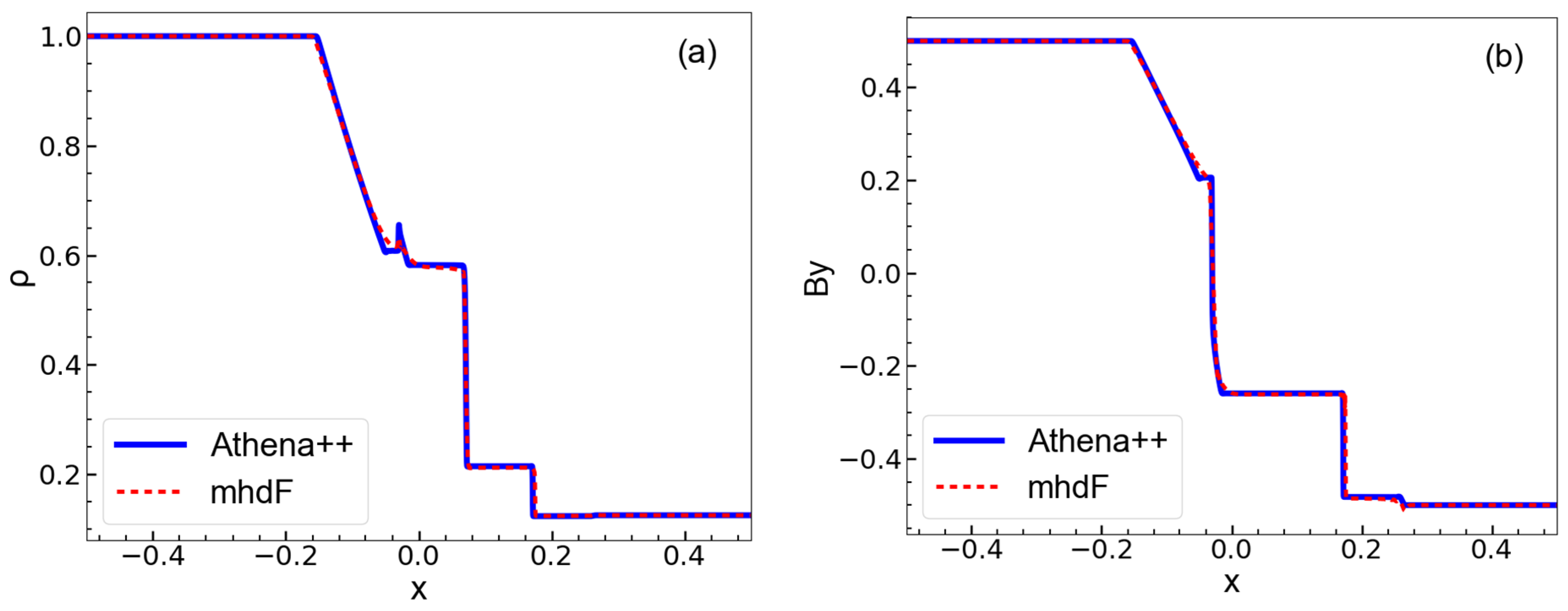

3.1.2. Brio–Wu Shock Tube Problem

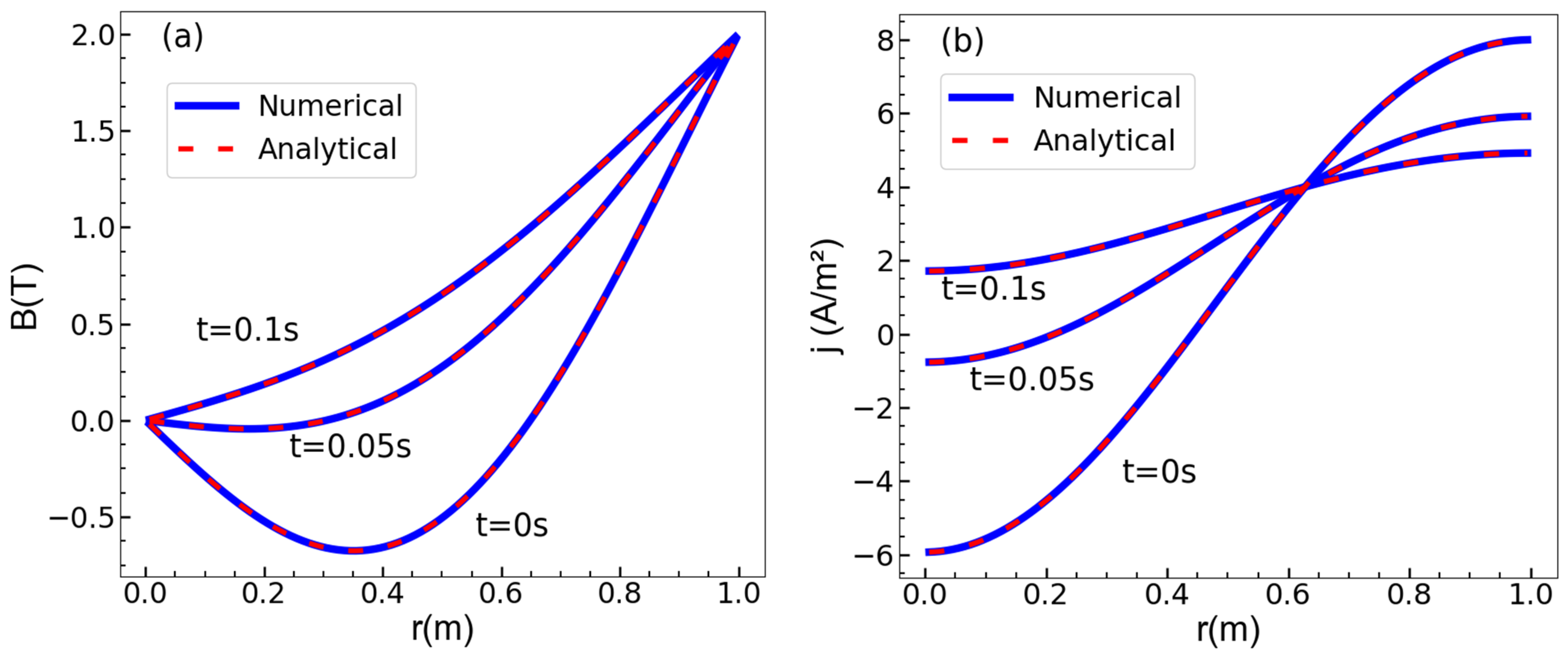

3.2. Magnetic Diffusion Solver Verification

3.3. The mhdMRF Solver Verification

4. Numerical Simulation of CT Magnetohydrodynamics

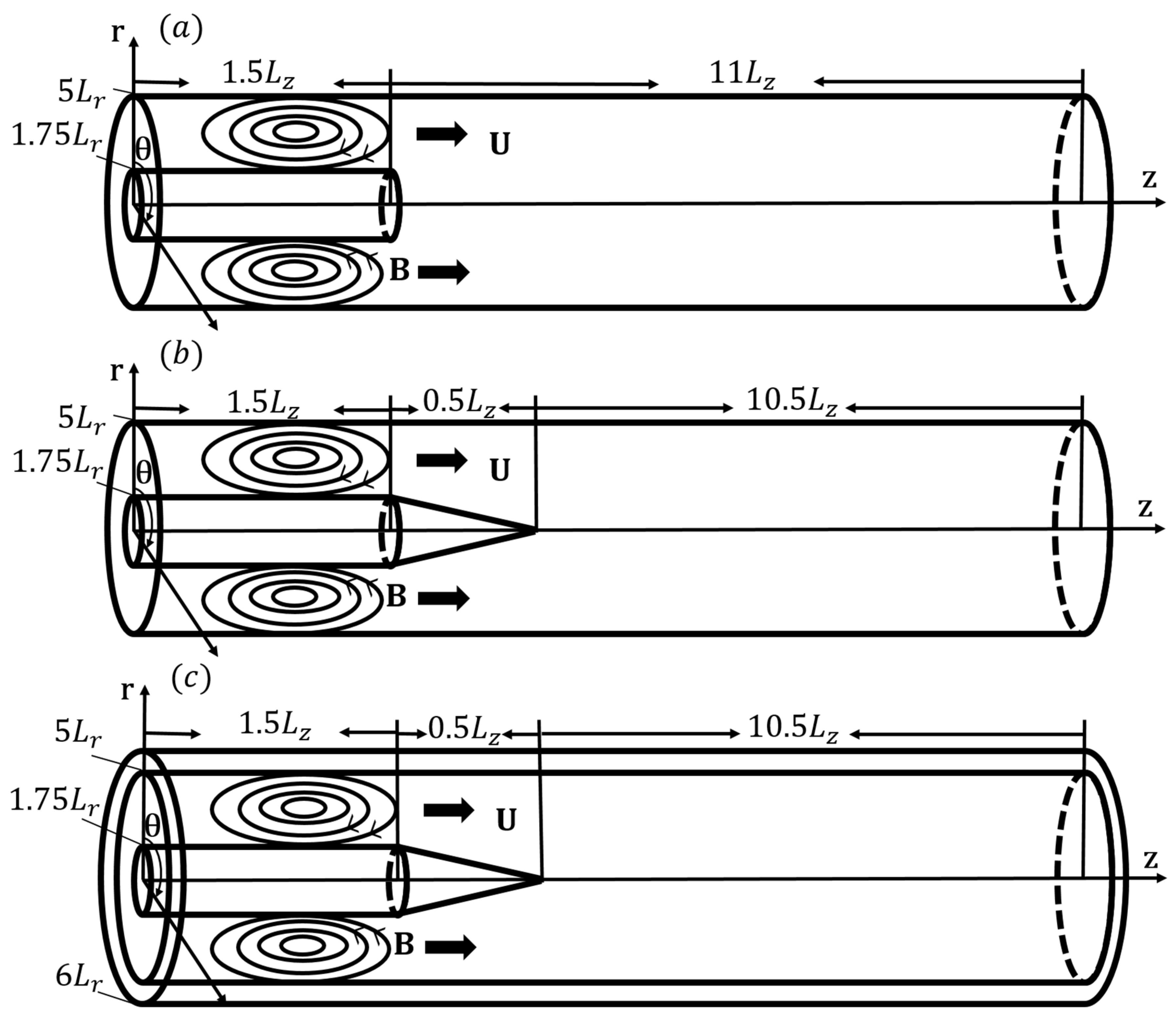

4.1. Geometric Structure and Simulation Parameter Settings

- Case 1: the internal metal electrode is a pure cylinder (hereinafter referred to as the cylindrical inner electrode);

- Case 2: a conical transition section is added to the end of the cylinder (hereinafter referred to as the conical inner electrode);

- Cases 3 and 4: based on the geometry of Case 2, an outer finite resistivity wall region is added, with different wall resistivity values in each case.

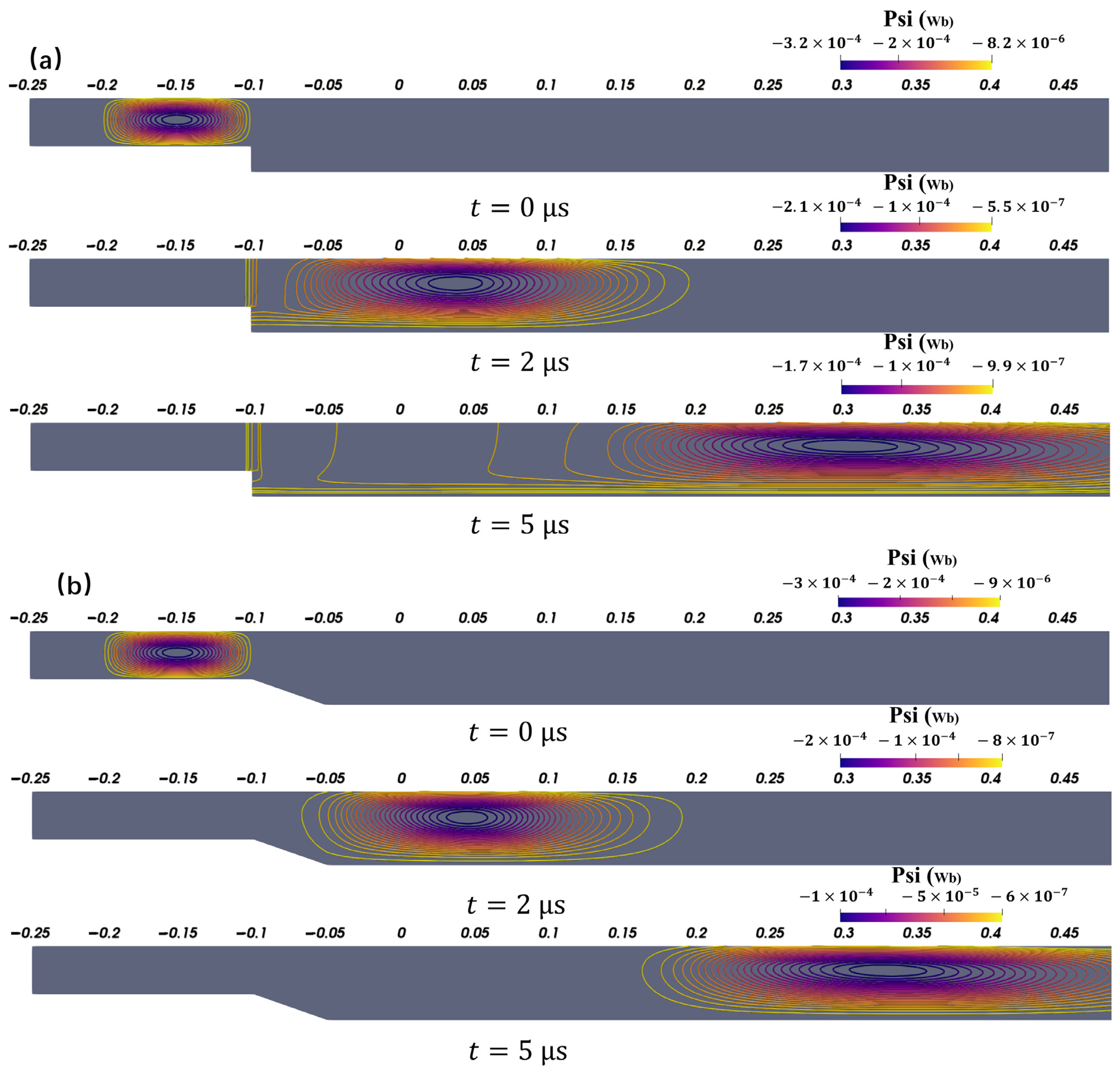

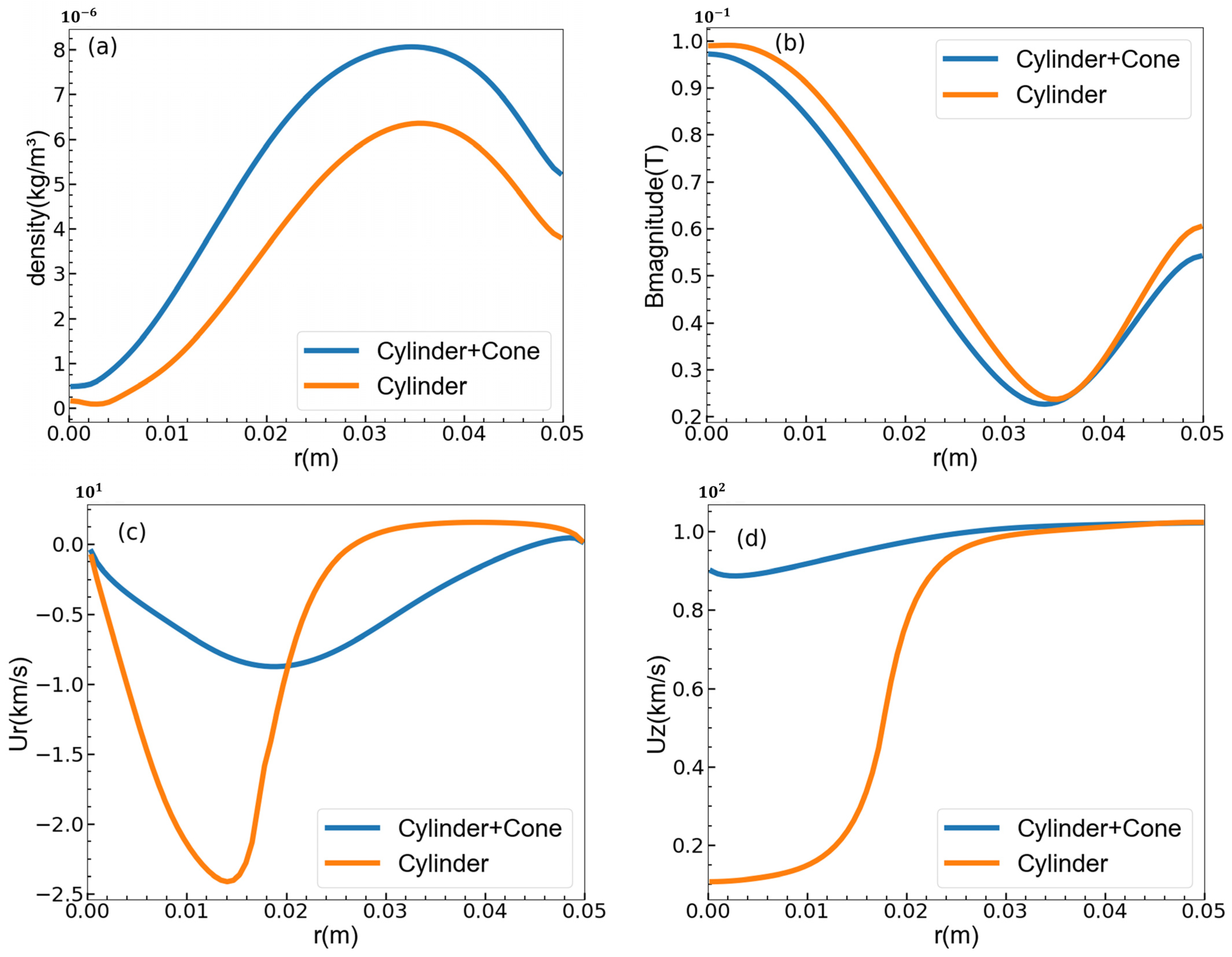

4.2. Influence of Inner Electrode End Geometry on CTs

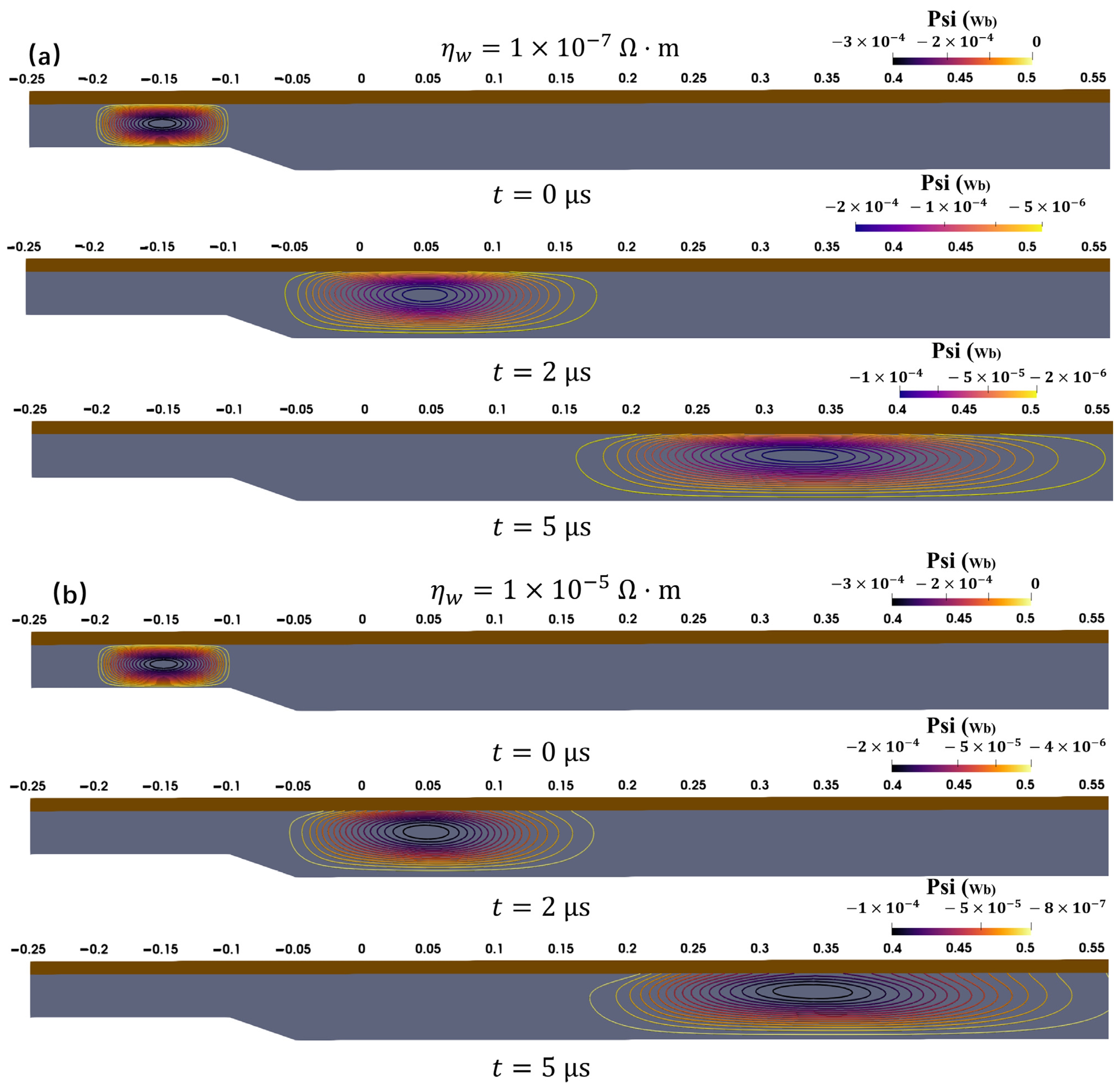

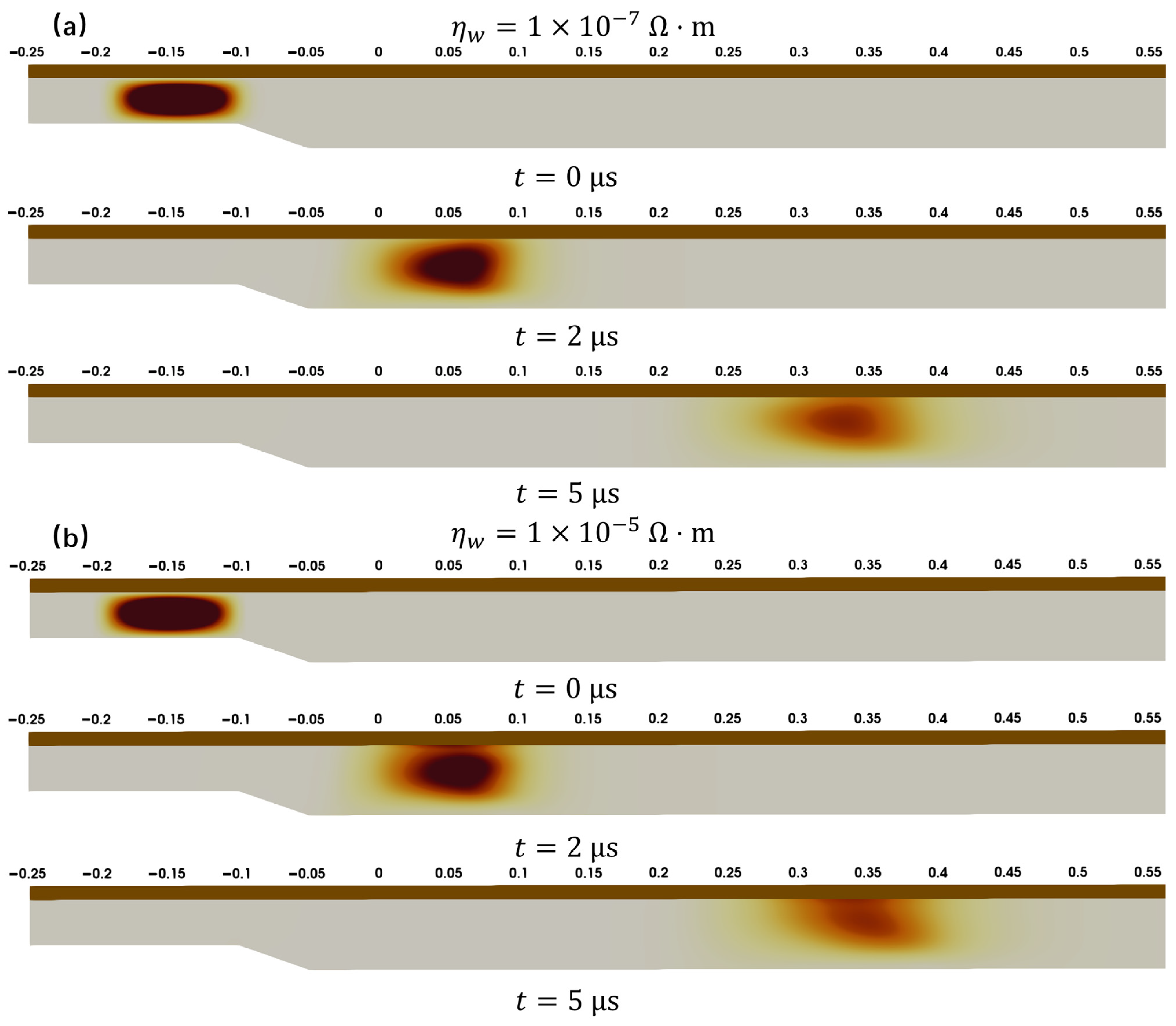

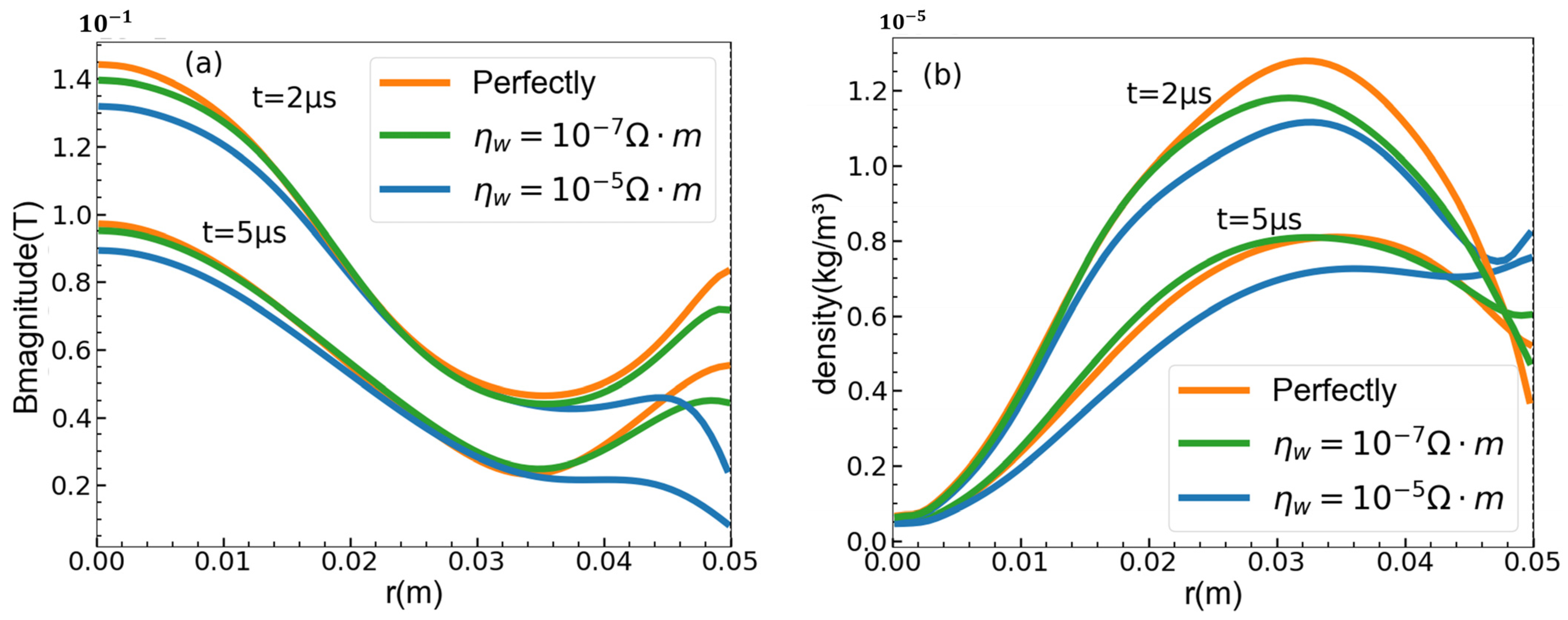

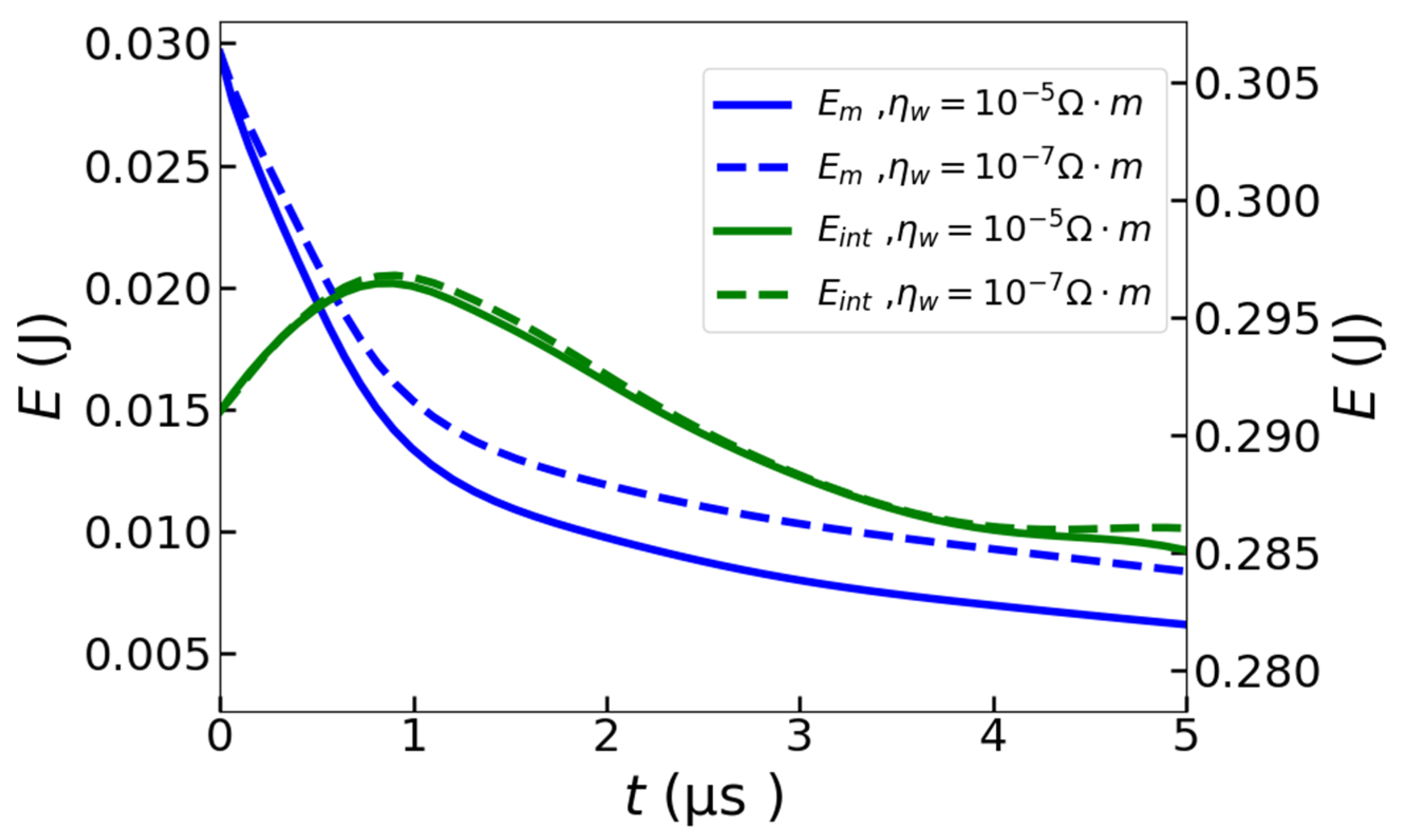

4.3. Influence of Finite-Resistivity Walls on CTs

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, C.; Rohollahi, A.; Onchi, T.; Dreval, M.; Elgriw, S.; Hirose, A. Momentum injection and repetitive CT operation experiments. Radiat. Eff. Defects Solids 2017, 172, 713–717. [Google Scholar] [CrossRef]

- Rohollahi, A.; Elgriw, S.; Basu, D.; Wolfe, S.; Hirose, A.; Xiao, C. Modification of toroidal flow velocity through momentum Injection by compact torus injection into the STOR-M tokamak. Nucl. Fusion 2017, 57, 056023. [Google Scholar] [CrossRef]

- Jackson, G.L.; Chan, V.S.; Stambaugh, R.D. An Analytic Expression for the Tritium Burnup Fraction in Burning-Plasma Devices. Fusion Sci. Technol. 2013, 64, 8. [Google Scholar] [CrossRef]

- Wang, E.Y. An Introduction to the Supersonic Molecular Beam Injection. Plasma Sci. Technol. 2001, 3, 673. [Google Scholar]

- Rêgo, I.d.S.; Sato, K.N.; Aoki, T.; Goto, K.; Miyoshi, Y.; Thang, D.H.; Sakamoto, M.; Kawasaki, S. Cryogenic pellets with controlled length for pellet ablation studies. Fusion Eng. Des. 2006, 81, 2649. [Google Scholar] [CrossRef]

- Bhatt, S.B.; Kumar, A.; Subramanian, K.P.; Atrey, P.K.; Team, A. Gas puffing by molecular beam injection in Aditya tokamak. Fusion Eng. Des. 2005, 75–79, 655–661. [Google Scholar] [CrossRef]

- Hammer, J.H.; Hartman, C.W.; Eddleman, J.L.; McLean, H.S. Experimental Demonstration of Acceleration and Focusing of Magnetically Confined Plasma Rings. Phys. Rev. Lett. 1988, 61, 2843. [Google Scholar] [CrossRef]

- Taylor, J.B. Relaxation and magnetic reconnection in plasmas. Rev. Mod. Phys. 1986, 58, 741. [Google Scholar] [CrossRef]

- Perkins, L.J.; Ho, S.K.; Hammer, J.H. Deep penetration fuelling of reactor-grade tokamak plasmas with accelerated compact toroids. Nucl. Fusion 1988, 28, 1365. [Google Scholar] [CrossRef]

- Parks, P.B. Refueling Tokamaks by Injection of Compact Toroids. Phys. Rev. Lett. 1988, 61, 1364. [Google Scholar] [CrossRef]

- Brown, M.R.; Bellan, P.M. Efficiency and scaling of current drive and refuelling by spheromak injection into a tokamak. Nucl. Fusion 1992, 32, 1125. [Google Scholar] [CrossRef]

- Sen, S.; Xiao, C.; Hirose, A.; Cairns, R.A. Role of Parallel Flow in the Improved Mode on the STOR-M Tokamak. Phys. Rev. Lett. 2002, 88, 185001. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, T.; Fukumoto, N.; Nagata, M.; Ogawa, H.; Maeno, M.; Hasegawa, K.; Shibata, T.; Uyama, T.; Miyazawa, J.; Kasai, S. Compact toroid injection experiment in JFT-2M. Nucl. Fusion 1999, 39, 1911. [Google Scholar] [CrossRef]

- Chen, C.; Lan, T.; Xiao, C. Development of a compact torus injection system for the Keda Torus eXperiment. Plasma Sci. Technol. 2022, 24, 045102. [Google Scholar] [CrossRef]

- Kong, D.; Zhuang, G.; Lan, T. Design and platform testing of the compact torus central fueling device for the EAST tokamak. Plasma Sci. Technol. 2023, 25, 065601. [Google Scholar] [CrossRef]

- Mozgovoy, A.G.; Romadanov, I.V.; Ryzhkov, S.V. Formation of a compact toroid for enhanced efficiency. Phys. Plasmas 2014, 21, 022501. [Google Scholar] [CrossRef]

- Dunlea, C.; Xiao, C.; Hirose, A. A model for plasma–neutral fluid interaction and its application to a study of CT formation in a magnetized Marshall gun. Phys. Plasmas 2020, 27, 062103. [Google Scholar] [CrossRef]

- Fukumoto, N.; Inoo, I.; Nomura, M.; Nagata, M.; Uyama, T.; Ogawa, H.; Kimura, H.; Uehara, U.; Shibata, T.; Kashiwa, Y.; et al. An experimental investigation of the propagation of a compact toroid along curved drift tubes. Nucl. Fusion 2004, 44, 982. [Google Scholar] [CrossRef]

- Matsumoto, T.; Roche, T.; Allfrey, I.; Sekiguchi, J.; Asai, T.; Gota, H.; Cordero, M.; Garate, E.; Kinley, J.; Valentine, T.; et al. Characterization of compact-toroid injection during formation, translation, and field penetration. Rev. Sci. Instrum. 2016, 87, 11D406. [Google Scholar] [CrossRef]

- Suzuki, Y.; Watanabe, T.-H.; Sato, T.; Hayashi, T. Three dimensional simulation study of spheromak injection into magnetized plasmas. Nucl. Fusion 2000, 40, 277. [Google Scholar] [CrossRef]

- Suzuki, Y.; Hayashi, T.; Kishimoto, Y. Dynamics of spheromak-like compact toroids in a drift tube. Nucl. Fusion 2001, 41, 769. [Google Scholar] [CrossRef]

- Liu, W.; Hsu, S.; Hui, L. Ideal magnetohydrodynamic simulations of low beta compact toroid injection into a hot strongly magnetized plasma. Nucl. Fusion 2009, 49, 095008. [Google Scholar] [CrossRef]

- Weller, H.G.; Tabor, G.; Jasak, H.; Fureby, C. A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput. Phys. 1998, 12, 620–631. [Google Scholar] [CrossRef]

- Xisto, C.M.; Páscoa, J.C.; Oliveira, P.J.; Nicolini, D.A. Implementation of a 3D Compressible MHD Solver able to Model Transonic Flows. In Proceedings of the European Conference on Computational Fluid Dynamics, Lisbon, Portugal, 14–17 June 2010. [Google Scholar]

- Chelem Mayigué, C.; Groll, R. A density-based method with semi-discrete central-upwind schemes for ideal magnetohydrodynamics. Arch. Appl. Mech. 2017, 87, 667–683. [Google Scholar] [CrossRef]

- Hattab, F.; Siriano, S.; Giannetti, F. An OpenFOAM multi-region solver for tritium transport modeling in fusion systems. Fusion Eng. Des. 2024, 202, 114362. [Google Scholar] [CrossRef]

- Siriano, S.; Melchiorri, L.; Pignatiello, S.; Tassone, A. A multi-region and a multiphase MHDOpenFOAM solver for fusion reactor analysis. Fusion Eng. Des. 2024, 200, 114216. [Google Scholar] [CrossRef]

- Alkafri, H.; Habes, C.; Fadeli, M.E.; Hess, S.; Beale, S.B.; Zhang, S.; Jasak, H.; Marschall, H. multiRegionFoam: A Unified Multiphysics Framework for Multi-Region Coupled Continuum-Physical Problems. Eng. Comput. 2024, 41, 1051–1084. [Google Scholar] [CrossRef]

- Uekermann, B.; Gatzhammer, B.; Mehl, M. Coupling Algorithms for Partitioned Multi-Physics Simulations. Lecture Notes in Informatics (LNI), Proceedings—Series of the Gesellschaft fur Informatik (GI). 2014. Available online: https://www.researchgate.net/publication/277077418 (accessed on 15 October 2024).

- FLASH User’s Guide Version 4.5. Available online: http://flash.uchicago.edu/site/publications/flash_pubs.shtml (accessed on 15 October 2024).

- Brio, M.; Wu, C.C. An upwind differencing scheme for the equations of ideal magnetohydrodynamics. J. Comput. Phys. 1988, 75, 400. [Google Scholar] [CrossRef]

- Miller, D.S. Exact Magnetic Diffusion Solutions for Magnetohydrodynamic Code Verification. In Proceedings of the Nuclear Explosives Code Developers Conference, Los Alamos, NM, USA, 18–22 October 2010. [Google Scholar]

- Degnan, J.H.; Peterkin, R.E.; Baca, G.P.; Beason, J.D.; Bell, D.E.; Dearborn, M.E.; Dietz, D.; Douglas, M.R.; Englert, S.E.; Englert, T.J.; et al. Compact toroid formation, compression, and acceleration. Phys. Fluids B Plasma Phys. 1993, 5, 2938. [Google Scholar] [CrossRef]

| 50 | 0.19712 | 0.20513 | 0.23659 | 0.19642 | 0.20881 | — |

| 100 | 0.11271 | 0.11359 | 0.13713 | 0.10884 | 0.11807 | 0.82 |

| 200 | 0.05668 | 0.05661 | 0.06963 | 0.05531 | 0.05956 | 0.90 |

| 300 | 0.03443 | 0.03243 | 0.04792 | 0.03846 | 0.03831 | 0.95 |

| 400 | 0.01792 | 0.01764 | 0.02222 | 0.01736 | 0.01878 | 1.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, K.; Wang, F.; Qu, C.; Kong, D.; Song, J. Multi-Region OpenFOAM Solver Development for Compact Toroid Transport in Drift Tube. Appl. Sci. 2025, 15, 7569. https://doi.org/10.3390/app15137569

Bao K, Wang F, Qu C, Kong D, Song J. Multi-Region OpenFOAM Solver Development for Compact Toroid Transport in Drift Tube. Applied Sciences. 2025; 15(13):7569. https://doi.org/10.3390/app15137569

Chicago/Turabian StyleBao, Kun, Feng Wang, Chengming Qu, Defeng Kong, and Jian Song. 2025. "Multi-Region OpenFOAM Solver Development for Compact Toroid Transport in Drift Tube" Applied Sciences 15, no. 13: 7569. https://doi.org/10.3390/app15137569

APA StyleBao, K., Wang, F., Qu, C., Kong, D., & Song, J. (2025). Multi-Region OpenFOAM Solver Development for Compact Toroid Transport in Drift Tube. Applied Sciences, 15(13), 7569. https://doi.org/10.3390/app15137569