Multi-Parameter Structural Optimization of Shale-Hydrocarbon-Dissolvable Ball Seat Slips Based on Safety and Performance Assessment Methods

Abstract

1. Introduction

2. Materials and Methods

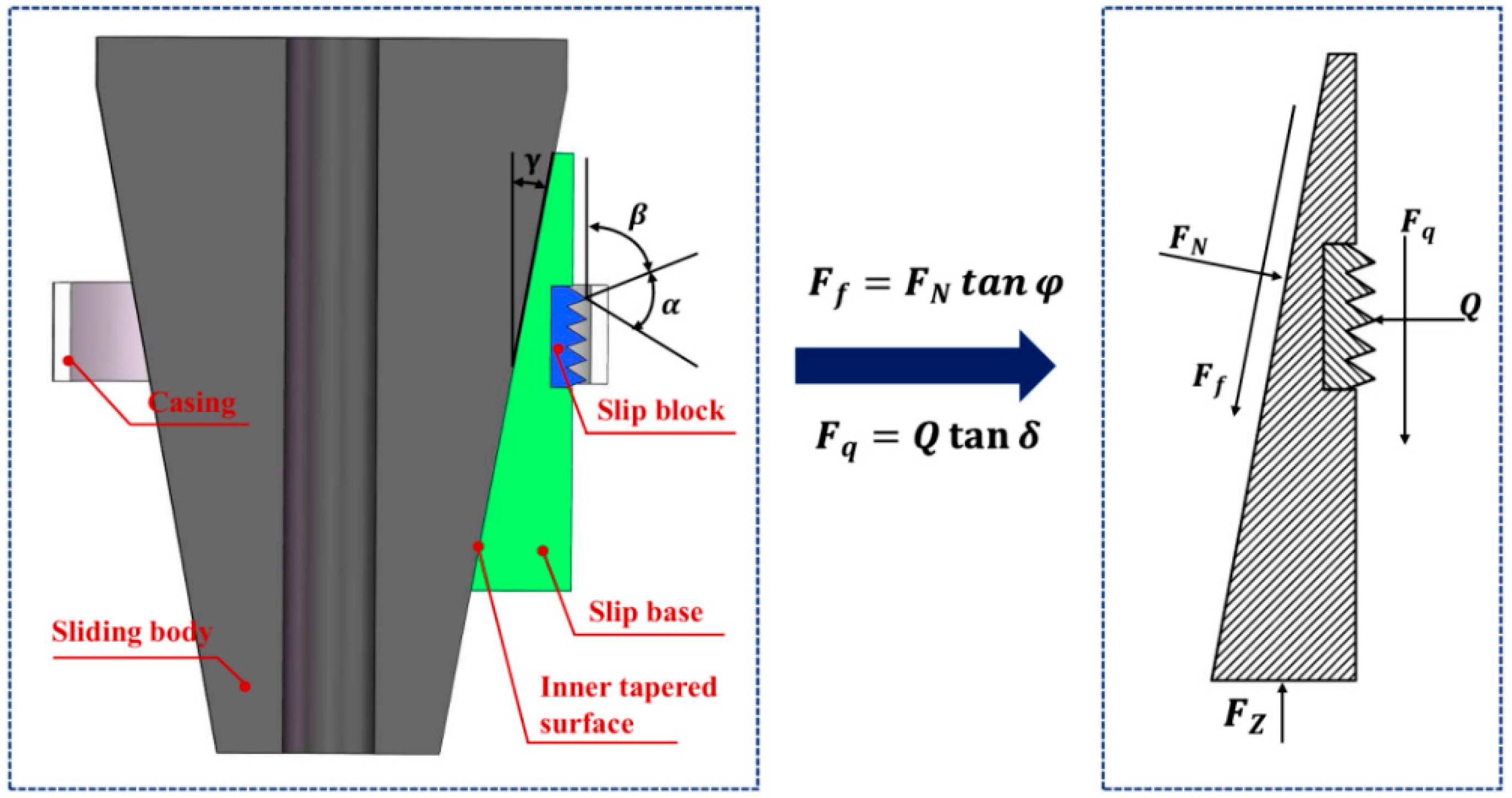

2.1. Setting Process and Mechanical Analysis of DBS Slip

2.1.1. Analysis of the Fracturing Setting Process of DBS Slip

2.1.2. Mechanical Analysis of the Slip During Setting Process

2.2. The Index Establishment of DBS Slip Anchoring Performance Assessment Method

2.2.1. Structural Safety Evaluation Index: Strength Criteria

2.2.2. First Index of Slip Anchoring Performance Evaluation: Peak Contact Pressure Criteria

2.2.3. Second Index of Slip Anchoring Performance Evaluation: Contact Uniformity Criteria

3. Analysis and Results

3.1. Numerical Analysis of the Anchoring Performance of DBS Slips

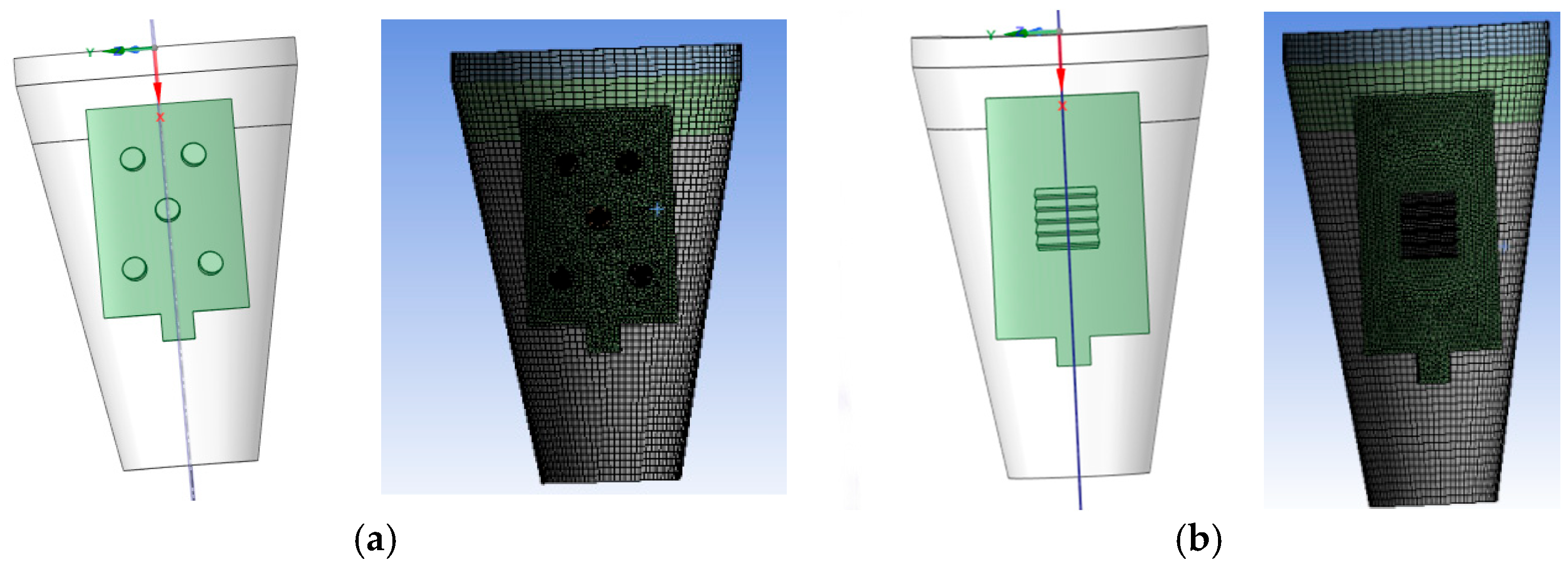

3.1.1. Finite Element Model of DBS Slips

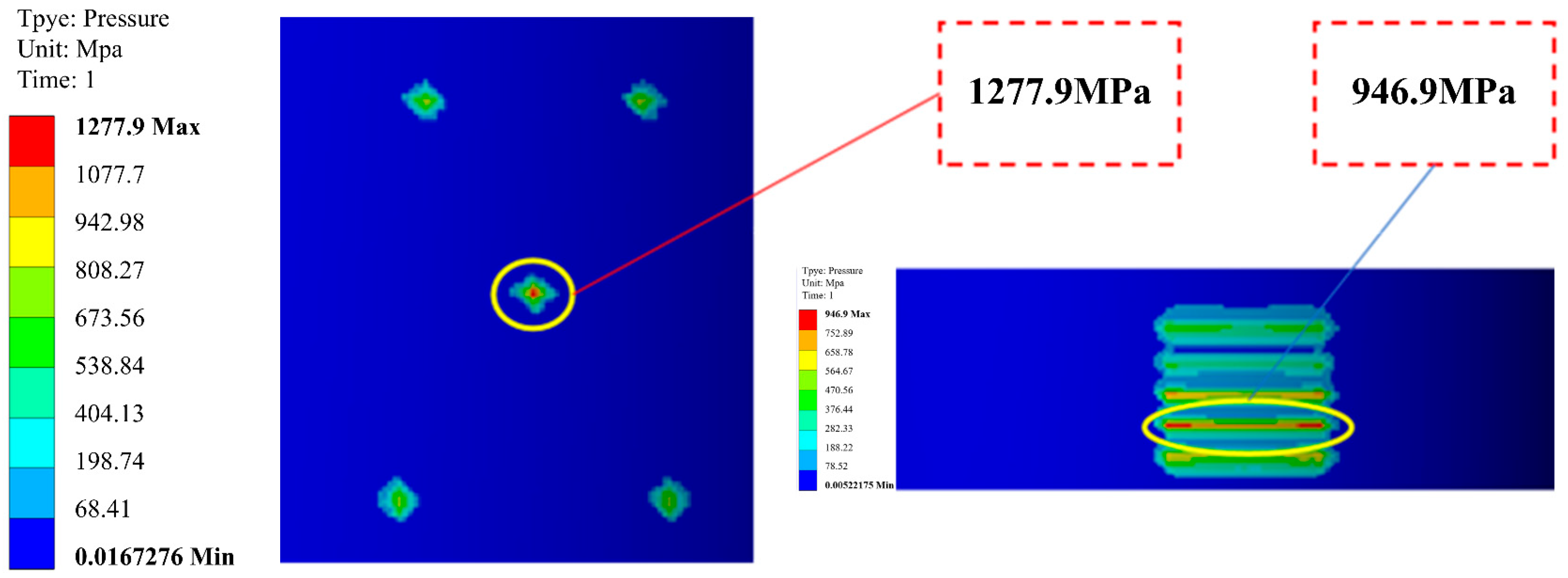

3.1.2. Analysis of Calculation Results Between the Slip Snail and Slip Block

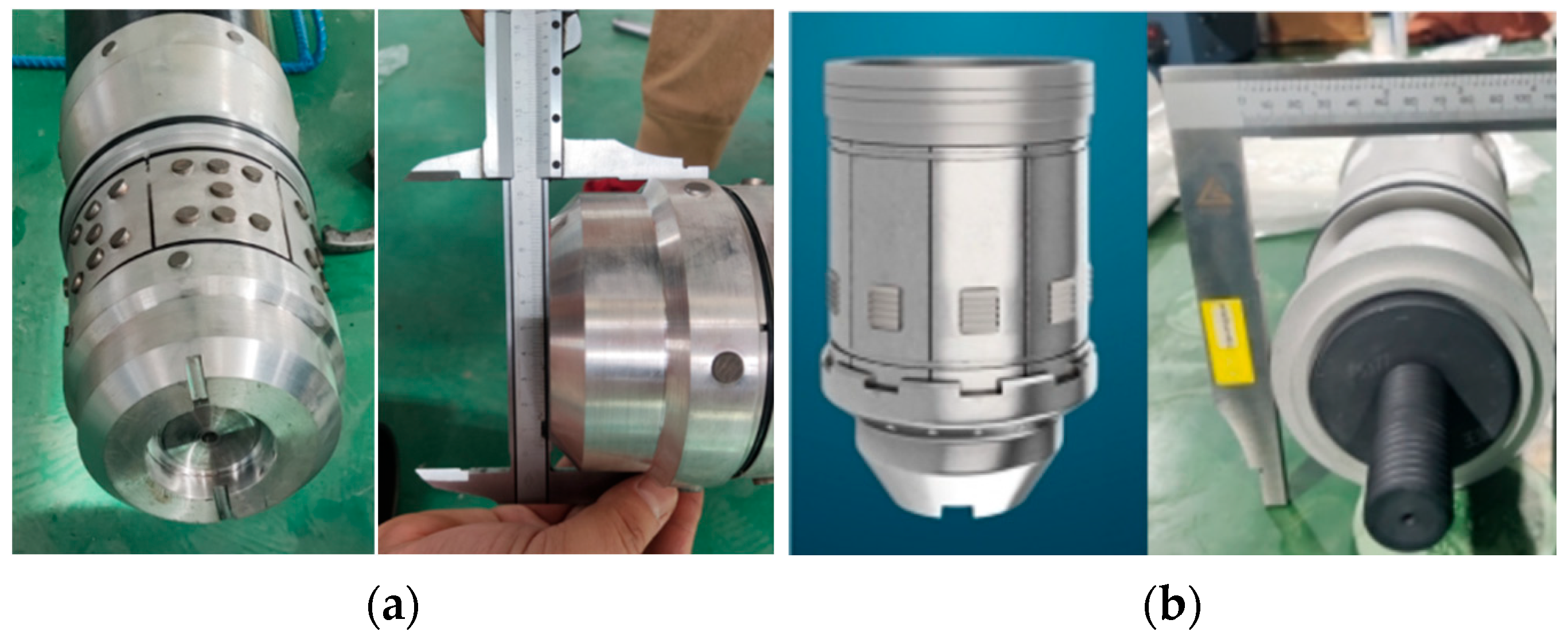

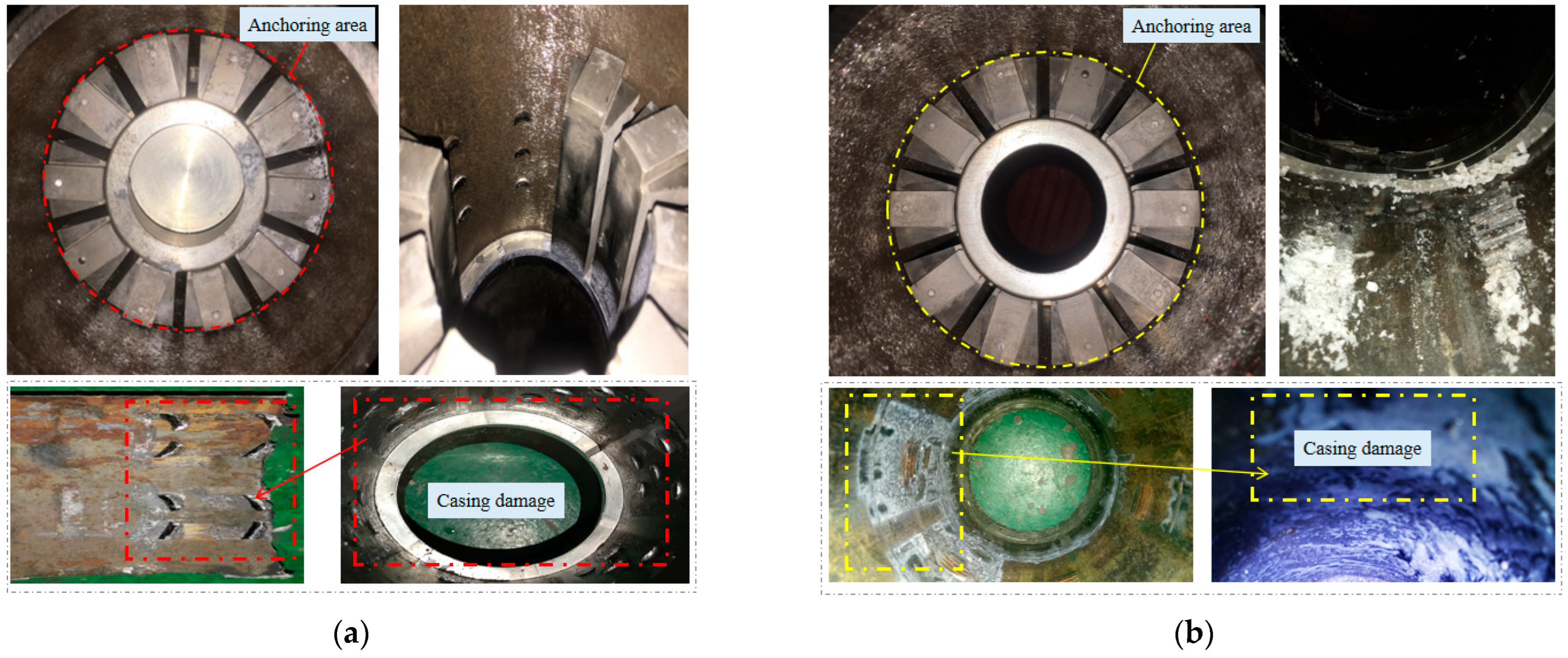

3.1.3. Anchoring Performance Tests of Dissolvable Ball Seat Slips

3.2. Effects of Structural Parameters on Slip Anchoring Performance

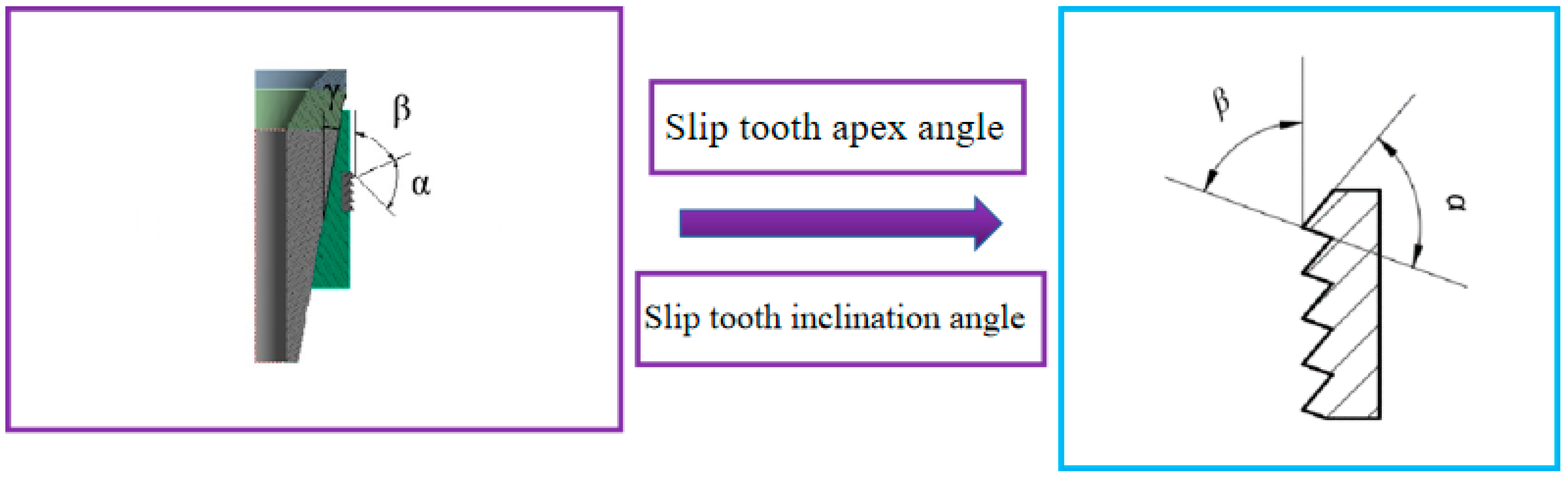

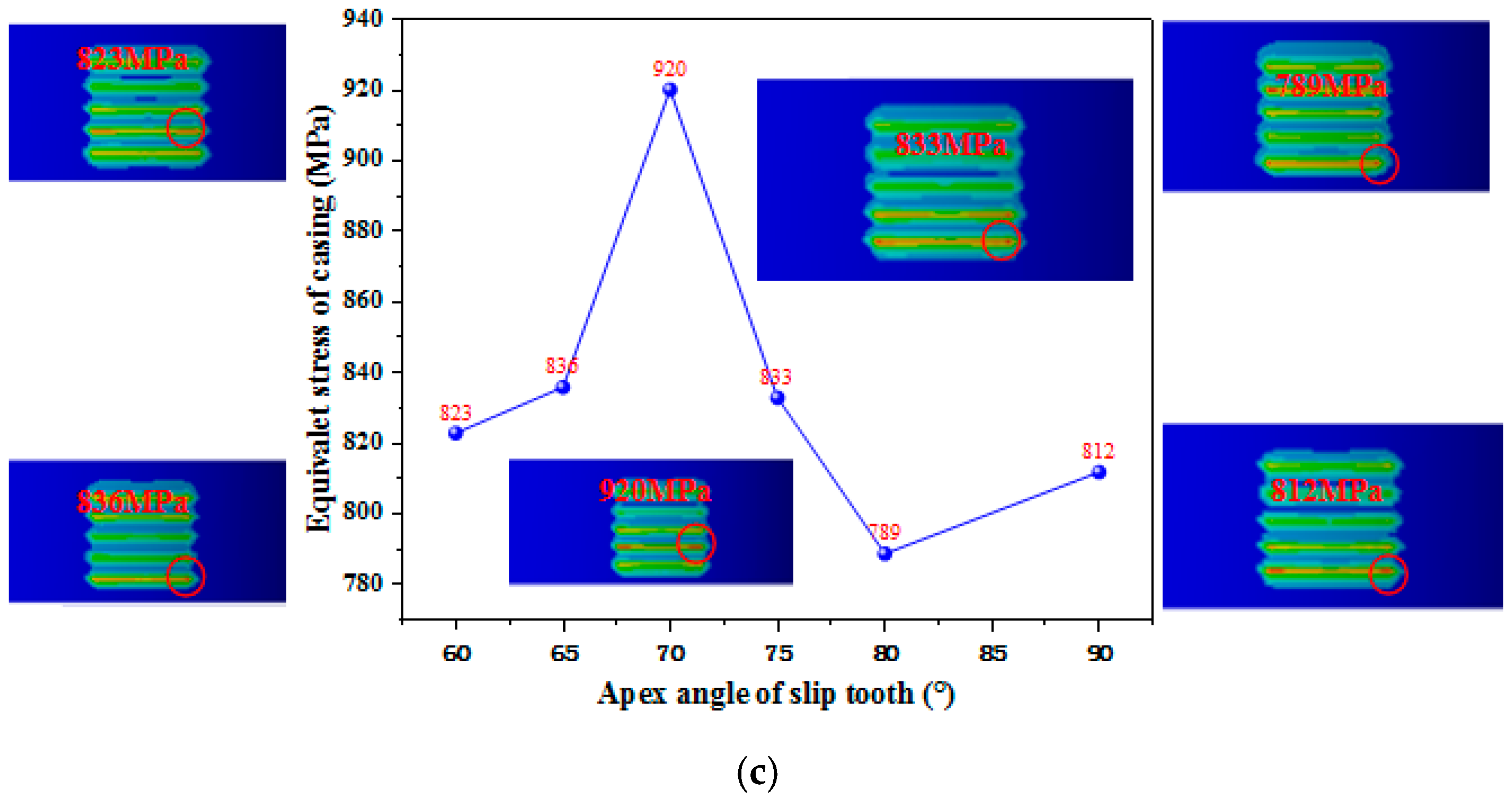

3.2.1. The Effect Law Analysis of Slip Tooth Apex Angle on Anchoring Performance

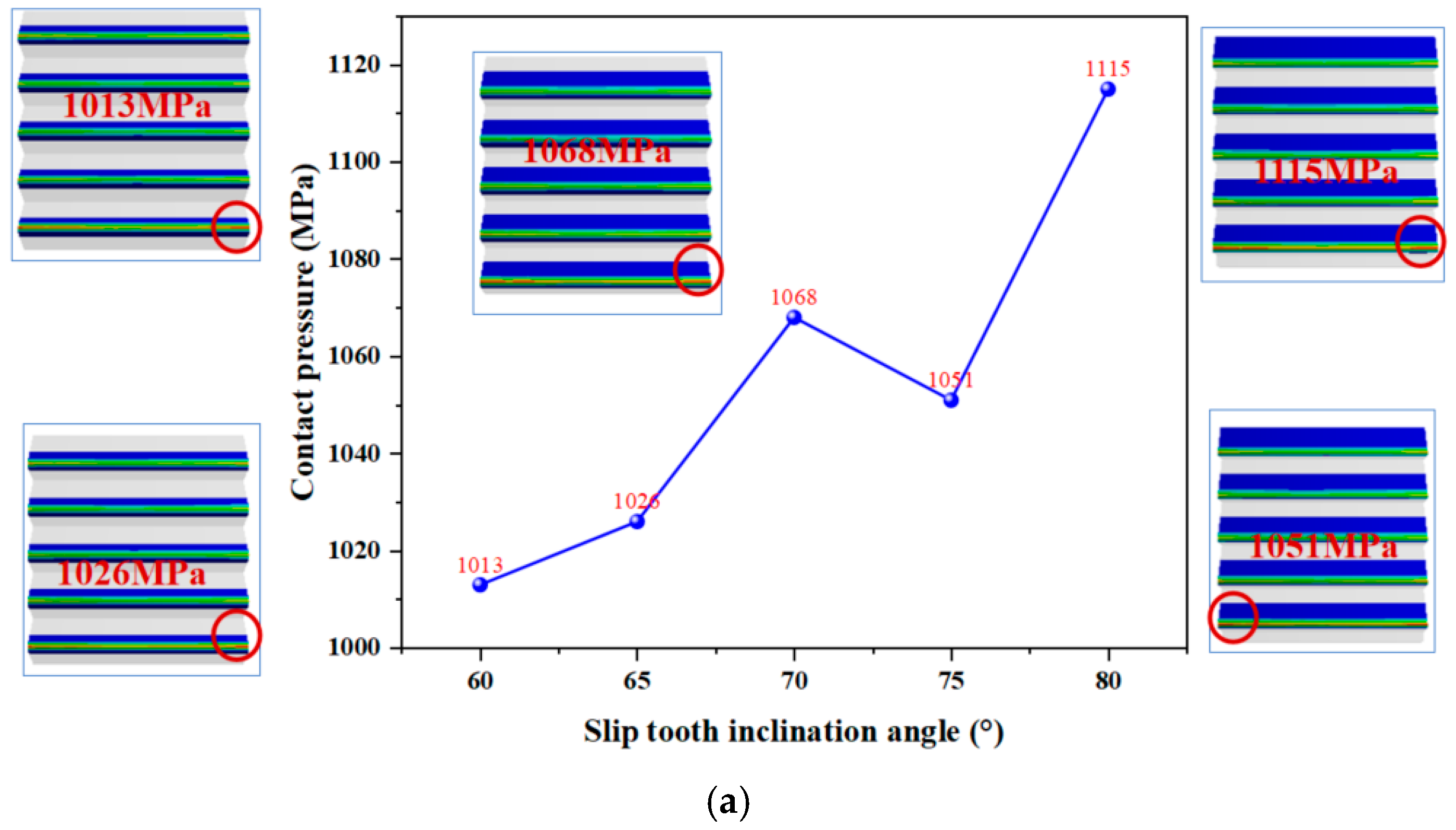

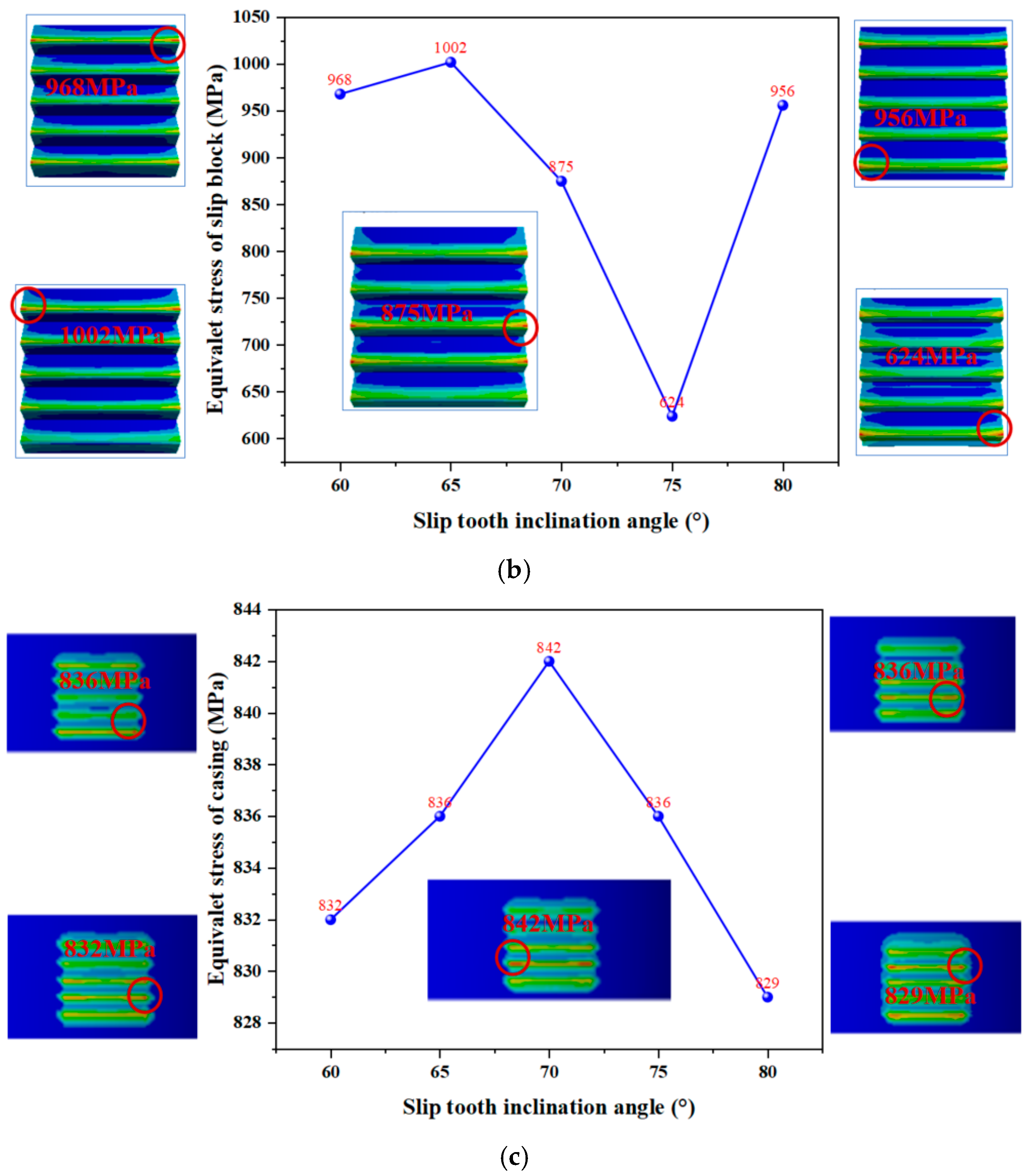

3.2.2. The Effect Law Analysis of Slip Tooth Inclination Angle on Anchoring Performance

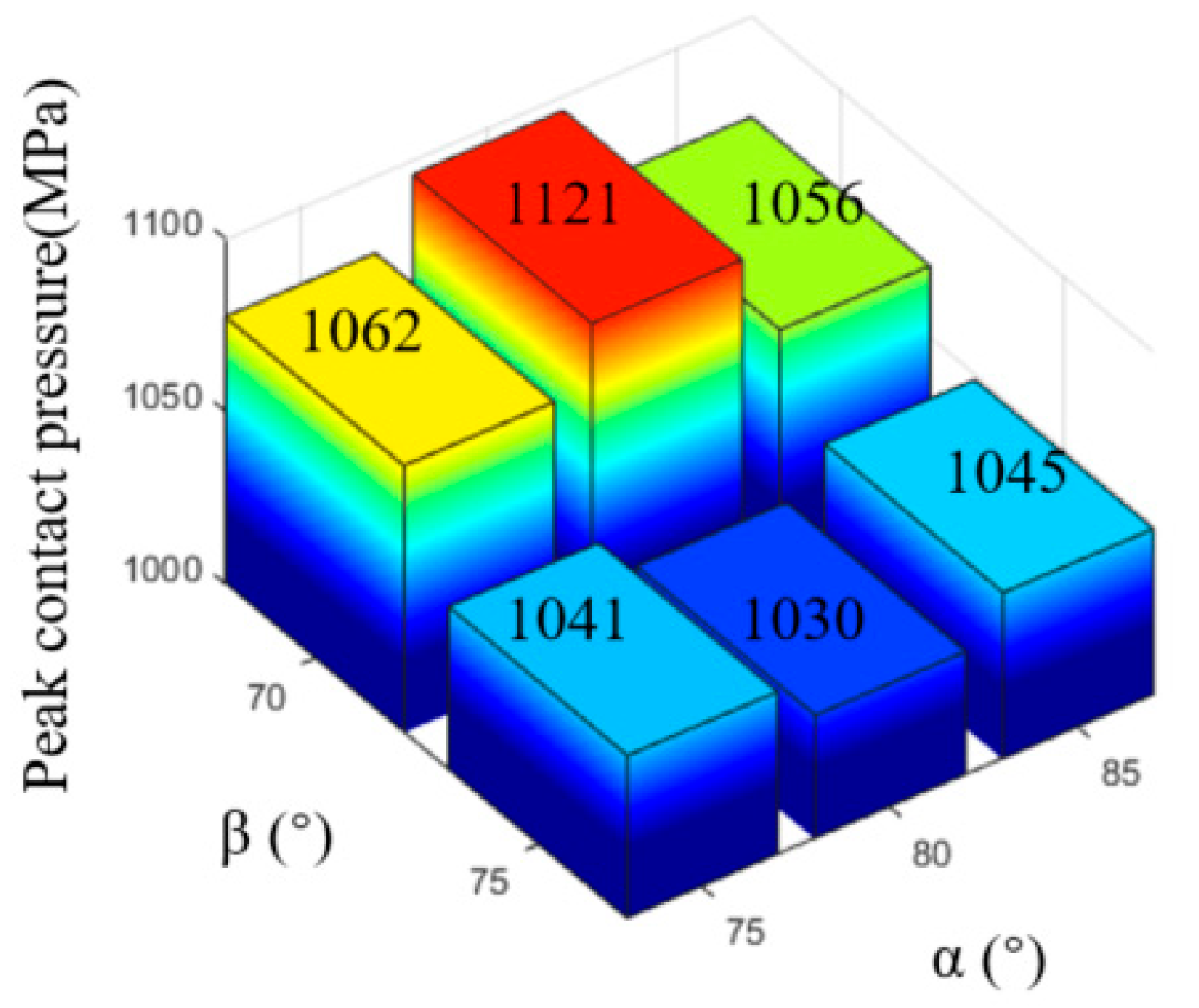

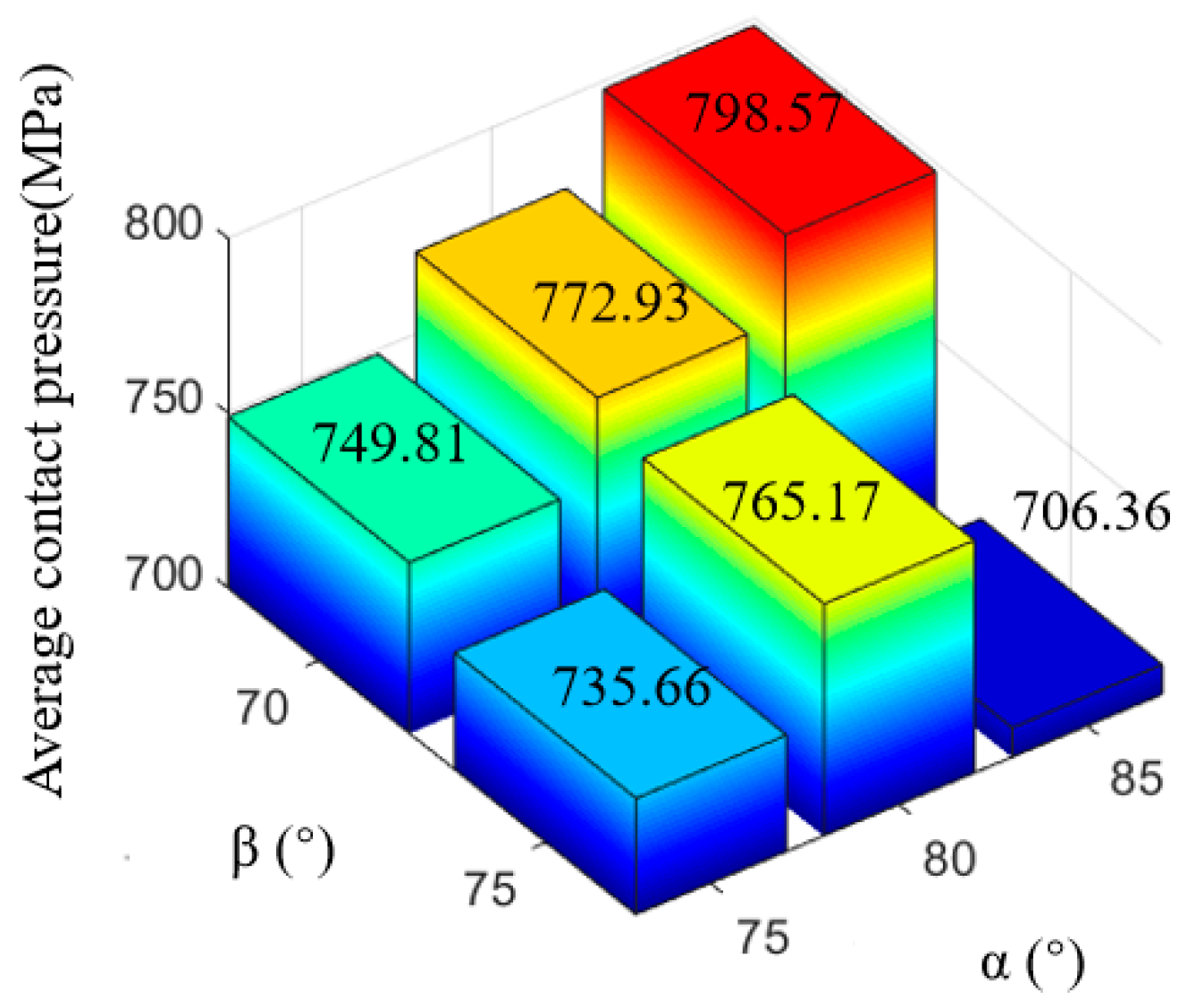

3.3. Structural Parameter Optimization Analysis of the Dissolvable Ball Seat

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DBS | Dissolvable ball seats |

| FEA | Finite element analysis |

References

- Huang, C.; Zhang, P.; Wang, W.; Huang, Z.; Lv, J.; Liu, J.; Yue, G.; Ni, W. The upgrading of coal-fired power generation industry supports China’s national strategy of energy conservation, emission reduction and carbon neutrality. Therm. Power Gener. 2021, 50, 1–6. [Google Scholar]

- Ma, X.; Wang, X.; Sun, X.; Shi, Q.; Chen, J.; Dang, L. Research on Influencing Factors of Carbon Emission Intensity of Coal-fired Generating Units. Therm. Power Gener. 2022, 51, 190–195. [Google Scholar]

- Qiu, S.; Lei, T.; Wu, J.; Bi, S. Energy demand and supply planning of China through 2060. Energy 2021, 234, 121193. [Google Scholar] [CrossRef]

- Semieniuk, G.; Taylor, L.; Rezai, A.; Duncan, K.F. Plausible energy demand patterns in a growing global economy with climate policy. Nat. Clim. Change 2021, 11, 313–318. [Google Scholar] [CrossRef]

- Justine, K.T.; Edcel, I.M.; Kaye, A.S.; Jonathan, J.I. A bibliometric analysis of sustainable oil and gas production research using VOSviewer. Clean. Eng. Technol. 2022, 7, 100437. [Google Scholar]

- Ailin, J.; Chen, G.; Chen, W.; Li, Y. Forecast of natural gas supply and demand in China under the background of “Dual Carbon Targets”. Pet. Explor. Dev. 2023, 50, 492–504. [Google Scholar]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Qin, Y.; Moore, T.A.; Shen, J.; Yang, Z.; Shen, Z.; Geoff, W. Resources and geology of coalbed methane in China: A review. In Coal Geology of China; Taylor and Francis Group: Abingdon, UK, 2019; pp. 247–282. [Google Scholar]

- Burton, Z.F.M.; Kroeger, K.F. Tectonic Uplift Destabilizes Subsea Gas Hydrate: A Model Example from Hikurangi Margin, New Zealand. Geophys. Res. Lett. 2020, 47, e2020GL087150. [Google Scholar] [CrossRef]

- Tarek, M.; Mohamed, M. Coalbed methane characterization and modeling: Review and outlook. In Energy Sources, Part A: Recovery, Utilization, and Environmental Effects; Taylor and Francis Group: Abingdon, UK, 2025; Volume 47, pp. 2874–2896. [Google Scholar]

- Christophe, M.; Jamie, S.; Steve, S. Unconventional gas—A review of regional and global resource estimates. Energy 2013, 55, 571–584. [Google Scholar]

- Barry, K.; Ling, G.; Jessica, L.; Yushi, R.Z. Geology still matters—Unconventional petroleum system disappointments and failures. Unconv. Resour. 2021, 1, 18–38. [Google Scholar]

- Burton, Z.F.M.; Dafov, L.N. Testing the Sediment Organic Contents Required for Biogenic Gas Hydrate Formation: Insights from Synthetic 3-D Basin and Hydrocarbon System Modelling. Fuels 2022, 3, 555–562. [Google Scholar] [CrossRef]

- Temoor, M.; Qureshi, H.A.; Syed, F.I.; Aziz, H.; Siyal, A.; Kalantari-Dahaghi, A.; Negahban, S. Unconventional hydrocarbon resources: Geological statistics, petrophysical characterization, and field development strategies. J. Pet. Explor. Prod. Technol. 2022, 12, 1463–1488. [Google Scholar]

- Burton, Z.F.M.; Dafov, L.N. Salt Diapir-Driven Recycling of Gas Hydrate. Geochem. Geophys. Geosystems 2023, 24, e2022GC010704. [Google Scholar] [CrossRef]

- Dafov, L.N.; Burton, Z.F.M.; Haines, S.S.; Scheirer, A.H.; Masurek, N.; Boswell, R.; Frye, M.; Seol, Y.; Graham, S.A. Terrebonne Basin, Gulf of Mexico gas hydrate resource evaluation and 3-D modeling of basin-scale sedimentation, salt tectonics, and hydrate system evolution since the early Miocene. Mar. Pet. Geol. 2025, 176, 107330. [Google Scholar] [CrossRef]

- Passey, Q.R.; Bohacs, K.M.; Esch, W.L.; Sinha, S. From Oil-Prone Source Rock to Gas-Producing Shale Reservoir—Geologic and Petrophysical Characterization of Unconventional Shale Gas Reservoirs. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010. [Google Scholar]

- Glorioso, J.C.; Rattia, A.J. Unconventional Reservoirs: Basic Petrophysical Concepts for Shale Gas. In Proceedings of the SPE/EAGE European Unconventional Resources Conference and Exhibition, Vienna, Austria, 20–22 March 2012. [Google Scholar]

- Zoback, M.D.; Kohli, A.H. Unconventional Reservoir Geomechanics, Unconventional Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Burton, Z.F.M.; McHargue, T.; Kremer, C.H.; Bloch, R.B.; Gooley, J.T.; Jaikla, C.; Harrington, J.; Graham, S.A. Peak Cenozoic warmth enabled deep-sea sand deposition. Sci. Rep. 2023, 13, 1276. [Google Scholar] [CrossRef]

- Burton, Z.F.M.; McHargue, T.R.; Graham, S.A. Global Eocene-Oligocene unconformity in clastic sedimentary basins. Earth-Sci. Rev. 2024, 258, 104912. [Google Scholar]

- Ramiro-Ramirez, S.; Bhandari, A.R.; Reed, R.M.; Flemings, P.B. Permeability of upper Wolfcamp lithofacies in the Delaware Basin: The role of stratigraphic heterogeneity in the production of unconventional reservoirs. AAPG Bull. 2024, 108, 293–326. [Google Scholar] [CrossRef]

- Cipolla, C.L.; Warpinski, N.R.; Mayerhofer, M.J. Hydraulic Fracture Complexity: Diagnosis, Remediation, and Exploitation. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 20–22 October 2008. [Google Scholar]

- Secchi, S.; Schrefler, B.A. Hydraulic fracturing and its peculiarities. Asia Pac. J. Comput. Eng. 2014, 1, 8. [Google Scholar] [CrossRef]

- Bunger, A.P.; Lecampion, B. Four critical issues for successful hydraulic fracturing applications. Rock Mech. Eng. 2017, 5, 551–593. [Google Scholar]

- Wu, Z.; Cui, C.; Jia, P.; Wang, Z.; Sui, Y. Advances and challenges in the development of hydraulic fracturing of tight reservoirs: A critical review. Energy Geosci. 2022, 3, 427–435. [Google Scholar] [CrossRef]

- Shi, C. Research on Volume Fracturing Technology of Tight Oil Reservoirs. Chem. Ind. Manag. 2023, 13, 70–72. [Google Scholar]

- Zhao, Z.; An, Q.; Li, D. Feasibility Study and Understanding of Volume Fracturing Technology for Tight Gas Wells. Pet. Ind. Tech. Superv. 2022, 38, 55–59. [Google Scholar]

- Lin, Z. Research and Application of Spherical Seat Soluble Bridge Plug Based on Volume Fracturing. Oil Prod. Eng. 2020, 4, 77. [Google Scholar]

- Sun, J.; Lin, Z.; Li, Q.; Zhao, L.; Yao, F. Research Status and Development Trend of soluble bridge Plug Tools. Oil Prod. Eng. 2019, 3, 79. [Google Scholar]

- Dong, L.; Zhong, L.; Zhou, Z.; Qiu, S.; Wang, G. Structural Design and Performance Analysis of All-Metal Soluble Ball Seat Sealing Rin. Drill. Prod. Technol. 2023, 46, 106–112. [Google Scholar]

- Liang, Y.; Ji, Z.; Li, L.; Chen, X.; Zhang, Q. Structure optimization of completion packer slips for offshore thermal recovery wells. Oil Drill. Prod. Technol. 2023, 45, 568–574. [Google Scholar]

- Tang, Y.; Zhang, W.; Zhang, Y.; Wang, Y. Simulation and Experimental Research on the Bearing Resistance Performance of the Retaining Wall and the Damage Characteristics of the Pipe Wall of the Pipeline Blocking Robot. China Mech. Eng. 2023, 34, 2758–2771. [Google Scholar]

- Tan, Y.; Feng, D.; Yang, Z. Optimization of the structure of the toothed soluble bridge plug slip. Pet. Mach. 2022, 6, 58–63. [Google Scholar]

- Wang, F.; Zhang, Y.; Chen, X.; Li, X.; Wang, X. Optimum Design and Experimental Analysis of Split Slip Structure. China Pet. Mach. 2021, 49, 71–77. [Google Scholar]

- Han, C.; Peng, X.; Li, L. Anchoring mechanical behavior of packer slips and its HTHP experimental analysis. Nat. Gas Ind. 2020, 40, 76–82. [Google Scholar]

- Karpenko, M.; Stosiak, M.; Šukevičius, Š.; Skačkauskas, P.; Urbanowicz, K.; Deptuła, A. Hydrodynamic Processes in Angular Fitting Connections of a Transport Machine’s Hydraulic Drive. Machines 2023, 11, 355. [Google Scholar] [CrossRef]

- Liu, B.; Cai, M.; Li, J.; Yang, Z.; Lu, S. Application and Analysis of Fracture Simulation of the Slip of the Permanent Packer. In Proceedings of the 2019 International Conference on Modeling, Simulation, Optimization and Numerical Techniques (SMONT 2019), Shenzhen, China, 27–28 February 2019; Atlantis Press: Dordrecht, The Netherlands, 2019; pp. 270–274. [Google Scholar]

- Zheng, C.; Liu, Z.; Wu, X.; Abulimiti, A.; Qin, J.; Zheng, X.; Liu, Y. Effect of structural parameters on the setting performance of plug slips during hydraulic fracturing. Pet. Sci. 2022, 19, 731–742. [Google Scholar] [CrossRef]

- Chen, J.; Dou, Y.; Cao, Y.; Qin, Y. Application of finite element analysis in mechanics analysis of completion packer. In Proceedings of the Mechanics and Mechatronics (ICMM2015) Proceedings of the 2015 International Conference on Mechanics and Mechatronics (ICMM2015), Changsha, China, 13–15 March 2015; World Scientific Publishing: Singapore, 2016; pp. 189–194. [Google Scholar]

- Tang, Y.; Sun, P.; Wang, G.; Wang, L. Analysis of pressure-bearing performance and optimization of structural parameters of the slip in a compression packer. Sci. Prog. 2020, 103, 0036850419881106. [Google Scholar] [CrossRef]

- Li, D.; Zhao, H.; Liu, X.; Zheng, S.; Geng, D.; Zhang, S. Design of Y422 Retrievable Fracture Bridge Plug and Analysis of Slip Characteristics. Adv. Mater. Res. 2010, 139, 1064–1067. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, H.; Yu, C.; Meng, F. Design and performance experiment of staged fracturing degradable bridge plug for horizontal well. J. Phys. Conf. Series. 2021, 2044, 012033. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Q.; Zheng, F. Contact analysis between packer slips and casing based on abaqus. Adv. Mater. Res. 2014, 850, 262–265. [Google Scholar] [CrossRef]

- Hao, D.; He, X.; Wang, G. Simulation and Experimental Study on Integral Kava Fracture. J. Appl. Mech. 2020, 37, 1641–1648. [Google Scholar]

- Hao, D.; He, X.; Wang, G.; Fang, X.; Liao, D.; Fang, H. Optimization design of soluble bridge plug integral slip structure. Pet. Drill. Tech. 2019, 47, 69–75. [Google Scholar]

- Xiong, T. Study on Anchoring Performance of Dissolvable Ball Seat Slips and Metal Ring Sealing in Horizontal Well Staged Fracturing with Structural Optimization; Southwest Petroleum University: Chengdu, China, 2022. [Google Scholar]

| Parts | Modulus of Elasticity/MPa | Poisson’s Ratio | Yield Strength |

|---|---|---|---|

| Slip Body | 70,000 | 0.35 | 350 |

| Slip blocks/Slip nails | 230,000 | 0.26 | 981 |

| Casing | 210,000 | 0.26 | 738 |

| Slip Tooth Apex Angle α (°) | Peak Contact Pressure (MPa) | Average Contact Pressure (MPa) | Standard Deviation of Contact Pressure |

|---|---|---|---|

| 60 | 921 | 655.6 | 101.28 |

| 65 | 956 | 669.51 | 101.63 |

| 70 | 1018 | 705.33 | 146.22 |

| 75 | 1062 | 752.71 | 126.19 |

| 80 | 1121 | 775.19 | 125.77 |

| 90 | 1031 | 656.28 | 112.93 |

| Slip Tooth Inclination Angle β (°) | Peak Contact Pressure (MPa) | Average Contact Pressure (MPa) | Standard Deviation of Contact Pressure |

|---|---|---|---|

| 60 | 1013 | 704.38 | 117.06 |

| 65 | 1026 | 717.68 | 105.18 |

| 70 | 1068 | 705.11 | 145.23 |

| 75 | 1051 | 716.52 | 114.72 |

| 80 | 1115 | 735.85 | 119.35 |

| Scheme | Tooth Apex Angle α | Tooth Inclination Angle β |

|---|---|---|

| 1 | 75° | 70° |

| 2 | 80° | 70° |

| 3 | 85° | 70° |

| 4 | 75° | 75° |

| 5 | 80° | 75° |

| 6 | 85° | 75° |

| Scheme | Peak Contact Pressure (MPa) | Average Contact Pressure (MPa) | Standard Deviation of Contact Pressure |

|---|---|---|---|

| 1 | 1062 | 749.81 | 126.78 |

| 2 | 1121 | 772.93 | 101.55 |

| 3 | 1056 | 798.57 | 106.53 |

| 4 | 1041 | 735.66 | 123.82 |

| 5 | 1030 | 765.17 | 109.33 |

| 6 | 1045 | 706.36 | 116.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, S.; Mu, A.; Chen, Z.; Ying, X.; Chen, N.; Ran, Q. Multi-Parameter Structural Optimization of Shale-Hydrocarbon-Dissolvable Ball Seat Slips Based on Safety and Performance Assessment Methods. Appl. Sci. 2025, 15, 7554. https://doi.org/10.3390/app15137554

Jing S, Mu A, Chen Z, Ying X, Chen N, Ran Q. Multi-Parameter Structural Optimization of Shale-Hydrocarbon-Dissolvable Ball Seat Slips Based on Safety and Performance Assessment Methods. Applied Sciences. 2025; 15(13):7554. https://doi.org/10.3390/app15137554

Chicago/Turabian StyleJing, Shuang, Anle Mu, Zhen Chen, Xiaoyang Ying, Nengpeng Chen, and Qingjie Ran. 2025. "Multi-Parameter Structural Optimization of Shale-Hydrocarbon-Dissolvable Ball Seat Slips Based on Safety and Performance Assessment Methods" Applied Sciences 15, no. 13: 7554. https://doi.org/10.3390/app15137554

APA StyleJing, S., Mu, A., Chen, Z., Ying, X., Chen, N., & Ran, Q. (2025). Multi-Parameter Structural Optimization of Shale-Hydrocarbon-Dissolvable Ball Seat Slips Based on Safety and Performance Assessment Methods. Applied Sciences, 15(13), 7554. https://doi.org/10.3390/app15137554