Abstract

The integration of renewable energy sources, battery energy storage, and electric vehicles into industrial systems unlocks new opportunities for reducing emissions and improving sustainability. However, the coordination and management of these new technologies also pose new challenges due to complex interactions. This paper proposes a methodology for designing a holistic energy management system, based on advanced digital twins and optimization techniques, to minimize the cost of supplying industry loads and electric vehicles using local renewable energy sources, second-life battery energy storage systems, and grid power. The digital twins represent and forecast the principal energy assets, providing variables necessary for optimizers, such as photovoltaic generation, the state of charge and state of health of electric vehicles and stationary batteries, and industry power demand. Furthermore, a two-layer optimization framework based on mixed-integer linear programming is proposed. The optimization aims to minimize the cost of purchased energy from the grid, local second-life battery operation, and electric vehicle fleet charging. The paper details the mathematical fundamentals behind digital twins and optimizers. Finally, a real-world case study is used to demonstrate the operation of the proposed approach within the context of the waste collection and management industry. The study confirms the effectiveness of digital twins for forecasting and performance analysis in complex energy systems. Furthermore, the optimization strategies reduce the operational costs by 1.3%, compared to the actual industry procedure, resulting in daily savings of EUR 24.2 through the efficient scheduling of electric vehicle fleet charging.

1. Introduction

The industrial sector is shifting toward electrification and energy self-generation, with a particular focus on renewable energy sources (RES). This transition is mainly driven by electric vehicles (EVs), battery energy storage systems (BESS), and photovoltaic (PV) panels [1]. These technologies enable companies to reduce their carbon footprint and operational costs while also decreasing their dependence on the power grid, mitigating the impact of electricity market volatility. Nonetheless, the complexity of managing and operating these different technologies often prevents the operator from extracting their full potential [2,3].

The advancement of the Internet of Things (IoT) and the emergence of innovative communication technologies have propelled the world into a new digital era, where data analysis plays a pivotal role. Most systems are now digitized and monitored, enabling data visualization through user interfaces. This evolution has led to the appearance of new ways of improving management and understanding the behavior of complex systems.

Digital twins (DTs) and cloud computing are examples of these new tools and are currently employed in a wide variety of fields such as healthcare, sports, economy, industrial engineering, or the energy sector [4]. DT use in situ measured variables, forecasts, and advanced cloud-based models to create a virtual replica of a real system, process, or service. This unlocks deeper analysis of system status, future behavior estimation, and decision-making support [5]. The application of DT and cloud-based solutions in complex energy systems has gained a lot of attention. Most studies agree on their ability to improve operations by providing better insights into current states and more accurate estimations of future behavior.

The EV and energy storage sectors are a clear example of this evolution and have also embraced the DT capabilities, to enhance battery operation with energy management systems (EMSs). Authors in [6] developed a DT to improve control, energy management, and battery degradation for a hybrid EV. The DT was constantly updated using real-time data. Moreover, the DT was used to simulate several control scenarios, which allowed us to improve the EMS performance under uncertainties. Also, authors in [7,8] reviewed several works on DT applications for EV. However, the applications for EV charging optimization were not included. Moreover, authors in [9] leveraged DT to simulate the performance of EV charging infrastructure, integrated with RES and BESS, estimating its self-sufficiency and self-consumption ratios under different sizing, demand, and generation scenarios. Nevertheless, the work does not provide an optimization framework for the EV charging infrastructure. Authors in [10] proposed an EV battery DT to estimate the state of charge (SOC) and internal resistance with an equivalent circuit model (ECM). The DT was used to estimate and optimize the EV charging in a RES-based infrastructure. However, the behavior of the remaining assets involved was not considered in the optimization. Weihan et al. [11] proposed a DT to enhance the accuracy of SOC and state of health (SOH) estimations of a BESS, using an ECM coupled with Kalman filtering strategies. Reniers et al. [12] explored the potential benefits of using DT to assess the influence of thermal management in the degradation of MWh-scale batteries by using Physics-Based Models (PBMs), demonstrating an efficiency improvement and increase in the total usable energy of the BESS considered.

Furthermore, many authors have highlighted the potential of DT to optimize industrial processes. For instance, Wei et al. [13] investigated their application with a focus on minimizing the environmental impact. Authors in [14,15] proposed DT to support the optimization of manufacturing operation decision-making systems by assessing optimization scenarios in a virtual environment to predict the impact of optimized decisions on the final product and production line efficiency. However, these works are mostly conceptual and lack detailed mathematical models and algorithmic descriptions, and limited validation results are presented only in [15]. Authors in [16] or [17] used similar approaches.

Other works highlighted the relevance of DT in enhancing microgrid operations [18]. Authors in [19,20] developed a DT for a grid-connected microgrid powered by RES and BESS and proposed an optimization framework based on reinforcement learning. However, BESS degradation was not considered in either the DT model or the optimization proposed. Yalçin et al. [21] investigated how data-driven models (DDMs), implemented in digital twins, can improve the operation of RES. Various DDMs were employed to forecast system performance and predict component failure, enabling more effective maintenance strategies.

There are multiple examples of DT use in energy systems, as shown above. However, most existing investigations are focused either on individual technologies [4] or overlook the potential synergies between DT and operations optimization for more sustainable industries. Furthermore, few works that explored the use of DT for energy systems optimization often neglect the impact of battery degradation on the optimization decisions. This leaves a research gap for a comprehensive methodology to integrate DT in enhanced decision-support systems based on deterministic optimization approaches. This study, conducted within the framework of a Spanish R&D project called GENIUS, addresses this research gap by proposing a methodology to build an EMS that leverages DT and deterministic optimization to minimize the carbon footprint and operational costs of energy-intensive industries using RES, BESS, and EV fleets. The article overviews the formulations behind four DTs and introduces a novel two-layer optimization strategy. A real case study from a waste management and collection company is used to validate the proposed solution.

The article is structured as follows: Section 2 provides a detailed overview of the methodology followed to develop the DT-based EMS. The mathematical foundations of the DT and optimization algorithms are presented in Section 3. Section 4 details the case study specifications. Section 5 presents the results obtained from applying the EMS to optimize system operation, compared with the actual plant operation. Finally, Section 6 summarizes the key findings of the study.

2. Methodology

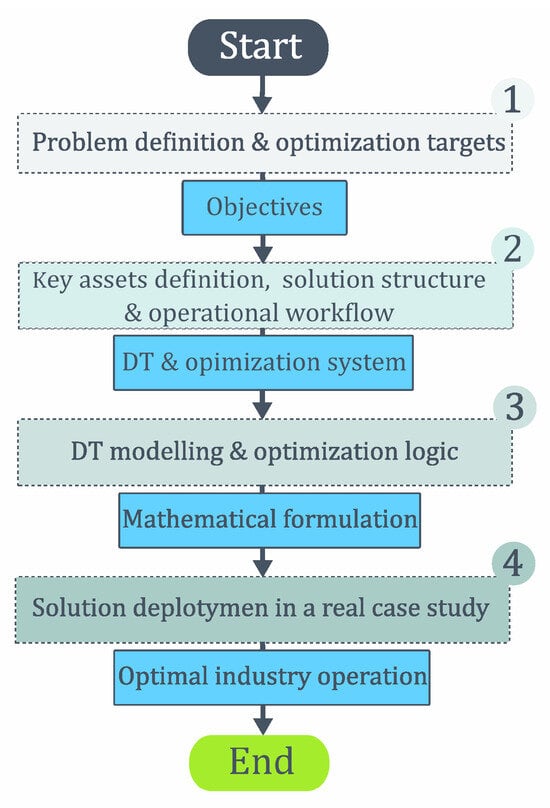

The methodology followed to develop the DT-based EMS is outlined in Figure 1. The first step involves the definition of the primary objectives of the solution, along with the intrinsic characteristics of the problem. In the second phase, the key energy assets are identified, each of which needs to be individually represented by a DT. Based on the specific features of the system, the appropriate optimization layers are then defined, including the hierarchy and data flow between DT and optimization modules. In the third stage, the mathematical formulation of the DT and optimization models is determined. The final stage involves implementing the designed EMS in a real-world application, allowing the optimization of a complex energy system.

Figure 1.

Methodology for developing a DT-based energy management system, from objectives to implementation. The numbers show step sequence, dashed boxes describe each stage, and blue boxes indicate key outcomes.

The proposed procedure can be adapted to a wide range of complex energy systems or industrial applications requiring optimization. In the subsequent sections, this methodology is applied to a specific case to demonstrate its effectiveness in a real-world scenario.

2.1. Problem Definition and Objectives

This study aims to effectively manage, control, and forecast the power consumption of CLD, a waste collection and management plant based in Barcelona, Spain. Its facilities present operational challenges due to the diverse energy assets involved, including EV fleet, EV charging stations, PV installation, a second-life battery energy storage system (SESS), and industrial load consumption.

Without leaving aside the company’s operational obligations, the proposed solution aims to optimize the usage of the aforementioned systems, with two principal objectives: reducing the carbon footprint and lowering operational costs. To achieve these goals, the system is managed according to the following priorities:

- Maximizing the use of on-site renewable energy generation.

- Optimizing EV charging to ensure the highest possible consumption of renewable energy. When this is not feasible, charging is scheduled during periods of low electricity prices and managed to avoid high peak power demands.

- Minimizing EV degradation by analyzing usage patterns, the operation, and charging procedures.

- Efficiently using the SESS to store surplus PV energy and charge from the grid during low-price periods, while also considering system life-cycle impacts.

2.2. DT and Optimization System

With a clear understanding of the problem characteristics and the primary objectives of the solution, the DT, optimization algorithms, and overall operational workflow can be defined.

2.2.1. Digital Twins

To enable a comprehensive analysis and management of the industrial systems, the most critical energy assets are individually examined. Based on the characteristics of the waste management facility, the availability of data, and the impact on overall energy consumption, four DTs are developed and analyzed in this study:

- DT-PV: A virtual replica of the photovoltaic system, designed to predict its power generation using weather forecast and other relevant variables.

- DT-IAS: Responsible for evaluating and forecasting grid energy prices and power consumption of the Industrial Asset System (IAS), including offices, mechanical workshops, and non-DT-related activities.

- DT-EV: Each EV within the facility is modeled with a dedicated DT, capable of estimating current SOC and SOH, and predicting future performance under varying usage patterns.

- DT-SESS: This DT monitors the SESS and provides its SOC under operation.

The outputs generated by each DT are then consumed by the optimization system, reducing in this way its computational complexity.

2.2.2. Optimization System

For the optimal operation of the system, two main subsystems are identified. The first includes the PV generator, SESS, grid connection, and industrial loads, resembling the microgrid concept [22]. The second comprises the EV fleet and the associated charging infrastructure, with one charger per vehicle. Both subsystems are fairly complex and nonlinear, making simultaneous optimization computationally burdensome, which could limit the scalability and robustness of the solution. Mixed integer linear programming (MILP) is a common approach to overcoming this issue in energy systems optimization. By using simpler models (piecewise linear models, etc.), MILP can reduce the complexity of nonlinear problems and still achieve good accuracy and higher computational efficiency compared to nonlinear models [23].

Optimizing EV fleet charging is typically a binary-heavy problem due to the On/Off charging decisions and piecewise linearization used to account for the nonlinear charging behavior. Even if MILP is more efficient than nonlinear approaches, binary-based linearization could limit the solution scalability, especially when microgrid models are added to the same optimization problem [24]. To mitigate this issue, this work proposes a two-layer optimization framework to increase the robustness and scalability of the solution.

The first layer corresponds to the electric vehicle optimizer (EVO), which optimally schedules EV charging by selecting timing and power delivered to each vehicle. The second layer, represented by the industry asset optimizer (IAO), receives the charging schedule generated by the EVO and other inputs to coordinate the power dispatch from the microgrid energy assets, focusing on the optimal usage of the SESS.

The decomposition of the problem enables each optimization layer to include detailed models of its main subsystem and simpler models for the rest of the system. This allows for prioritizing modeling detail to achieve more accurate EV charging while acknowledging the impact of EV charging demand on the microgrid. Hence, this approach is scalable for larger EV fleets and microgrid assets, avoiding premature problem relaxations and suboptimal solutions needed with a single optimization approach [24,25]. Additionally, in the case of IAO failure, the EVO outputs can serve as a suboptimal EMS for the microgrid assets, providing redundancy and robustness to the solution.

2.2.3. Operational Workflow

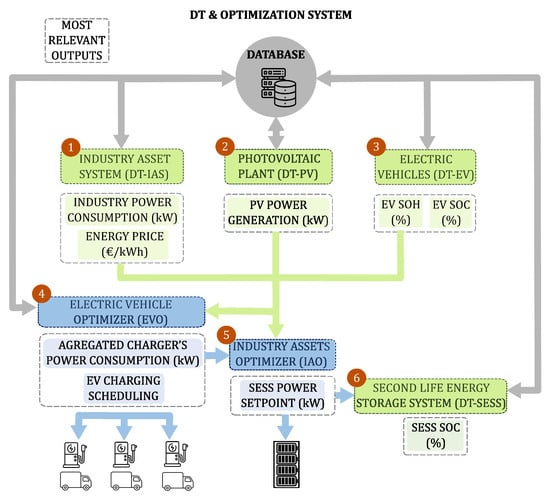

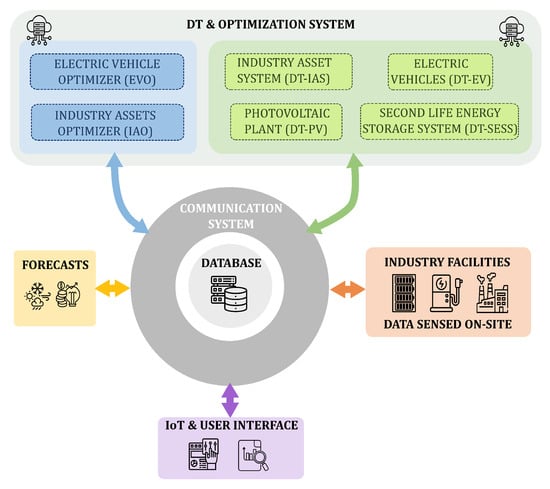

Figure 2 summarizes the execution sequence, highlighting the order and principal interactions. The DT-IAS, DT-PV, and DT-EV are executed initially, relying on the data available in the database. Once they are executed, the EVO is triggered, utilizing outputs from the previous DT. Among other key outputs, such as the EV charging scheduling, this optimizer provides the aggregate power demand of the chargers, which is necessary for the IAO. This last optimizer determines the power setpoint for the SESS, which is then consumed by the DT-SESS to assess the SOC of the battery.

Figure 2.

Simplified diagram of the DT-based EMS solution showing sequence, interactions, and main outputs. Numbers indicate execution order, green boxes denote DTs, and blue boxes represent the optimization algorithms.

Regarding the sequencing, the DT-PV, DT-IAS, DT-SESS, EVO, and IAO are executed every 15 min, producing forecasts for the subsequent 24 h period. This temporal resolution ensures continuous and accurate monitoring of plant operations and reduces the risk of significant deviations. The DT-EV module consists of two separate algorithms: one for estimating the SOC, executed at 10 s intervals, and another for assessing the SOH, executed weekly. The SOC requires frequent updates due to its rapid fluctuations and its critical role in representing the fleet’s current operational status. In comparison, SOH varies more slowly over time, making weekly evaluations adequate for capturing long-term degradation trends.

The primary objective of this article is to present this methodology and assess its potential advantages compared to the actual operational practices of the industrial facility under study, which is not optimized. A future publication will further compare the benefits of this approach with those offered by other existing optimization solutions.

3. Mathematical Formulation

This section provides details on the fundamental principles of the DTs and optimization layers.

3.1. Digital Twins

The four DTs aim to accurately represent the behavior of each subsystem with complex models implemented in the cloud. The DTs mainly use on-site sensor measurements and forecasts, such as weather forecasts, that are available in a cloud database. This approach offers a multitude of advantages, one of the most significant being its ability to get precise analysis and forecasts of their particular behavior [5].

The models used in each case depend on the required inputs, outputs, and the intrinsic characteristics of each system. The following sections provide a detailed explanation of each DT, including its underlying principles and the variables necessary for analyzing and predicting the state of each system.

3.1.1. DT-EV

CLD owns a diverse EV fleet, including garbage trucks, cleaning vehicles, vans, and trucks. Each EV has a battery management system (BMS) integrated with the battery pack, ensuring safe operation. Due to the low computational capacity onboard, the models used in the BMS are relatively simple, resulting in reduced precision and greater deviations [26]. Over the battery lifespan, this affects critical parameters such as SOC or SOH calculation, which are key for the proper operation of the system.

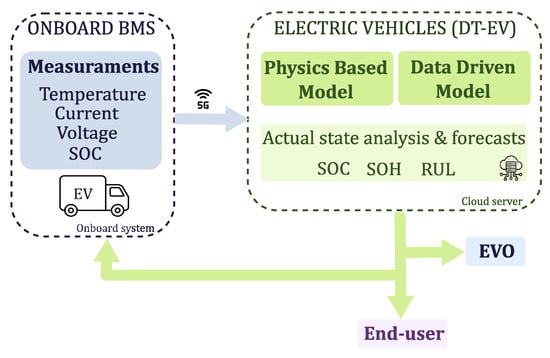

The DT-EV uses raw data (temperature, current, voltage, SOC) from the onboard BMS as input, transmitted to the cloud via integrated dataloggers that enables the data transference between the EV and the cloud database. Advanced models then process this data to generate outputs such as SOC, SOH, Remaining Useful Life (RUL), and Full Equivalent Cycles (FECs), which are provided to both the end user and the EVO [27]. This enables more precise analysis and accurate forecasting, leading to improved EV fleet operation. Figure 3 reflects the data exchange procedure and the main assets of the DT-EV system.

Figure 3.

DT-EV schema, interactions, data-flows, and cloud algorithms.

Lithium-ion battery (LIB) models are generally classified into three types: ECM, PBM, and DDM [28]. ECM, based on Thevenin circuits with resistors and capacitors, is widely used in the automotive sector due to its simplicity, low computational requirements, and fast response. However, the model accuracy decreases over the battery lifespan and generally does not account for degradation. PBM, on the other hand, provides a detailed representation of the electrochemical processes happening inside the battery, offering higher accuracy and better predictions of parameters like RUL and SOH [29]. Nevertheless, they rely on nonlinear equations, which increases their computational requirements, limiting their application in real-time BMS implementations. DDM is based on machine learning (ML) techniques and has gained attention for its ability to handle nonlinearities with relatively low computational cost. While it offers better long-term accuracy than ECM, this highly depends on the datasets used for training. Moreover, its integration into BMS remains challenging due to computational constraints and instability in certain scenarios [26,30].

For DT-EV, two models have been implemented: a PBM and a DDM model. This approach allows us to benefit from both methodologies: the reliability of PBM and the precision and adaptability of DDM. The PBM is based on the Pseudo 2-Dimensional (P2D) model [29], which represents how ions move alongside the battery in two dimensions: the particle radius (r) and the overall location on the battery dimension (x). It is based on the resolution of 5 partial differential equations and has a requirement of 35 parameters that depend on the intrinsic characteristics of the cells, such as the type of electrodes, electrolyte, or separator [29]. Manufacturers tend not to share the necessary information to execute these types of algorithms, for confidentiality reasons, which makes the calibration process challenging. In this case, the necessary values have been extracted from a well-known study such as [31], where a commercial NMC811 cell is parametrized and has been validated in a wide range of scenarios.

This model has been integrated with additional equations that introduce temperature dependencies and degradation. The thermal behavior was characterized by a lumped model, which treats the cell as a uniform system with a unique temperature [32]. This simplification reduces the computational cost and eases its implementation, but provides higher error at high currents [33]. The degradation model considers four principal phenomena: solid electrolyte interface (SEI) growth, lithium plating, particle cracking, and loss of active material, as described in [34]. By integrating these algorithms, the PBM provides insights into the current state of the LIB and forecasts its behavior, considering operating conditions (such as temperature, usage pattern, c-rate, etc.) and their impact on coupled degradation mechanisms. The SOH is then calculated as a function of the lithium lost estimated by the PBM. The arbitrary evolution of degradation phenomena [33], the simplifications of the thermal model, and the assumptions made by [34] may lead to possible deviations from the real EV degradation state.

To mitigate the risk of inaccurate state estimations, a DDM has also been implemented to forecast both SOC and SOH more reliably. In this case, a model based on the Random Forest (RF) technique is used, a supervised learning technique that employs ensemble learning for classification and regression, suitable for working with battery data and predicting state variables [35]. It is build on the “wisdom of crowds”, where multiple independent models collectively outperform the response of each one working individually. It is an effective method for complex nonlinear problems and time series data, and requires the definition of the number of trees.

In an RF regression, the final prediction for an input x is the average of predictions from all trees. Each tree i applies its decision function , and the overall prediction is given by

The data used for validating both models and training the DDM has been generated at the laboratory under different temperatures (20–40 °C) and with different vehicle usage patterns.

Using different types of algorithms to analyze changes in variables such as the SOC or SOH enhances the accuracy of the provided assessments. On the one hand, the PBM is a robust algorithm and provides consistent results with a physical interpretation. However, it is a bit rigid, has low adaptability, and the assumptions considered can lead to deviations in future LIB performance. In contrast, the developed DDM can learn from the processed data and adapt to the battery’s state. Nevertheless, if the input values fall outside the training range, the model could produce incorrect results falling outside operational limits. Both algorithms have been implemented in Python using PyBamm library [36] for the PBM and Scikit-Learn for the DDM [37].

3.1.2. DT-PV

The DT-PV serves as a virtual model of the photovoltaic installation, enabling precise monitoring and optimization of energy production. As detailed in [38], the DT-PV integrates mathematical representations of the PV modules, the power electronics, and the maximum power point tracking (MPPT) controller, facilitating predictive analytics and improved decision-making in industrial energy management sectors.

The PV system comprises an array of photovoltaic modules connected to a PV inverter, which regulates the DC output voltage to optimize energy conversion. The electrical behavior and generation of the PV modules are represented by a single-diode equivalent circuit model, where the current–voltage (I-V) relationship is as in (2):

where represents the light-generated current or photocurrent; is the cell saturation of dark current, in A; q is the electron charge, 1.602176634 · 10−19 C; K is the Boltzmann’s constant, 1.38 · 10−23 J/K; T is the cell’s working temperature in K; a is an ideal factor, which represents the deviation of the actual cell behavior from the ideal behavior of a theoretical PV cell ( means ideal behavior); is the shunt resistance of the cell, in Ohm; and is the series resistance of the cell, .

The real-time implementation of this model within the digital twin allows dynamic adaptation to environmental conditions by continuously updating irradiance, temperature, and voltage measurements.

The PV inverter includes an embedded MPPT algorithm to maximize the power extracted from the PV array. The perturb and observe (P&O) method is implemented in the DT-PV, adjusting the operating voltage based on instantaneous power variations. The DT-PV ensures that power extraction remains near the optimal point despite fluctuations in solar radiation.

3.1.3. DT-SESS

This model accurately simulates the internal states of the SESS, as well as the operational constraints. As detailed in [38], this device has a lot of potential for optimizing energy management strategies, enhancing adaptability to system dynamics.

The physical layer of the SESS consists of a pack composed of repurposed battery cells, coupled with an AC/DC converter. The battery model employs an ECM, where the open-circuit voltage, represented as , is in function of the SOC, denoted as . The electrical impedance of the pack is modeled through a combination of resistive–capacitive (RC) branches in series with a pure ohmic resistance. These parameters capture both the instantaneous voltage drop and the slower transient dynamics. The SOC evolution over time is governed by (3)

where , in A, is the current at time step k, , in p.u., represents the Coulombic efficiency, and Q denotes the rated capacity of the battery in As. The current through the resistive part of the RC branches follows

and characterize the specific impedance of each branch, and j is the branch index. Thus, the battery terminal voltage is obtained through

The AC/DC converter model ensures power flow alignment with optimization setpoints while maintaining system stability. The DT interacts with real-time measurement systems to continuously update internal states, preventing unsafe operating conditions. Suppose the battery voltage, grid frequency, or current exceeds safe operational thresholds. In that case, an automatic disconnection mechanism is triggered, and an error flag is sent to the DT to halt further updates, thus preventing erroneous optimization decisions.

3.1.4. DT-IAS

The DT-IAS is a forecasting algorithm that aims to predict and analyze the industry energy demand and is based on an autoregressive integrated moving average (ARIMA) model [39]. The ARIMA model integrates autoregressive and moving average elements, as well as differencing, to address non-stationarity in time series data. It is selected due to its high accuracy in modeling temporal dynamics, outperforming alternative approaches such as moving averages, multiple regression techniques, exponential smoothing, and neural networks [39].

For that, the DT-IAS reads the historical data for the past days to then predict the next 24 h using the ARIMA model. Thus, the outputs of the DT-IAS are the industry consumption in real time, the consumption history, and the consumption forecast for the next 24 h. The output of the consumption prediction for the next 24 h will be needed as the input to the optimization algorithm of Section 3.2.1 and Section 3.2.2.

DT-IAS collects the measurements from sensors at consumption points using an API to extract the necessary information from the database. This data can be retrieved for periods of up to 1 week and longer, but for the case study, the past 7 days are considered. Total industry consumption aggregates multiple loads, including office electricity use, EV charging stations, and gas-powered compressors. While office consumption remains stable, charging stations and compressors create peak loads, introducing fluctuations that require management through energy storage and optimization strategies.

3.2. Optimization System

Both EVO and IAO leverage the DT systems described in Section 3.1 to provide operational decisions over a 24 h horizon. A rolling horizon strategy is used to implement this solution, considering a 15 min time step. Therefore, only the control action (EV charging power) corresponding to the first time step is executed, while the subsequent steps represent a forecast of future charging events, which are used in the IAO as a load forecast. The main fundamentals of both layers are outlined in the following sections.

3.2.1. EVO

The EVO solves an optimization problem that aims to define the charging schedule for each EV. It uses the current state of each EV (SOC and SOH) and the forecasts of local PV generation, the SESS condition, and the local industry power demand. Hence, this optimizer relies on the results of DT-EV, DT-PV, and DT-IAO. The main inputs for the EVO are the following:

- Scheduled trips data (departure and arrival time, distance (km) or energy intensity (kWh)).

- Forecast of the PV energy production, industry demand, and grid energy price, coming from DT-PV, DT-IAS, and day-ahead prices, respectively.

- SOC, SOH, and FEC since EV fleet commissioning, coming from DT-EV.

- SOC of the SESS, coming from DT-SESS.

With this information, the optimizer minimizes the cost of charging the EV fleet, while the technical constraints of the microgrid remain unaffected. Therefore, the algorithm should consider the microgrid even if it is not in charge of managing it. Hence, the main EVO outputs are as follows:

- A charging profile for each EV.

- Forecast of the aggregated charging power demand for the next 24 h.

The MILP model that defines the EVO aims to minimize the cost associated with the charge of EVs, considering the grid energy cost and other factors such as the SESS and vehicle battery degradation. The objective function is depicted in (6)–(9).

where , , and represent the cost of grid-supplied energy and the degradation costs associated with the SESS and EV systems, respectively. Furthermore, k is the time step and h is the time horizon considered to solve the optimization, with . Moreover, is the energy price per kWh, is the purchased power from the grid, is hours per time step, and and are the degradation cost per kWh drawn from the SESS and the power demand of the SESS, respectively. Furthermore, and are the cycling and calendar degradation cost of the EV batteries, and and are the charging power and energy available at each EV, respectively, with .

The cycling and calendar degradation costs are estimated using (10) and (11), while (12) describes a linear approximation of calendar aging in terms of the energy available during storage.

where is the price per kWh, is the size of the battery, is the end of life state of health, is the time since the battery’s initial commissioning, is the charging and idle time per time slot, and and b are coefficients of the linear approximation of the nonlinear calendar degradation function described in [40,41].

The minimization problem should consider operational and technical constraints that ensure safe and economic EV charging events. Equations (13)–(29) mathematically represent these constraints. Equation (13) defines the microgrid power balance constraint, (14)–(17) represent the power limits for the grid, PV installation, and charging and discharging of the second-life battery, (18) and (19) guarantees that the second-life battery do not charge and discharge at the same time, (20) is the energy balance of the second-life battery, (21)–(25) define a piecewise linear approximation for the nonlinear charging profile of each EV for a generic s-pieces function, (26) and (27) define the operating range for the charging power and energy available of each EV, respectively, (28) defines the energy balance of each EV, and (29) defines the aggregated charging power requested by the EV fleet.

where is the power requested for the PV installation, and are the power demanded by the building and EV charging infrastructure, respectively, , , , and are the maximum power of the grid, the PV, and the second-life SESS charging and discharging limits, respectively, and are Boolean variables that indicate whether SESS is charging or discharging, and are the SESS charging and discharging power, respectively, is the energy available in the SESS, is the maximum charging power for each , and and are the energy available in each EV battery and the estimated consumed energy of each EV per time slot.

3.2.2. IAO

The IAO is responsible for the energy management of the industrial microgrid, ensuring the optimal operation of all its assets, including the second-life battery, photovoltaic generation, building demand, EV charging, and grid integration. The IAO is designed to minimize operational and environmental costs while maximizing self-consumption of renewable energy and extending battery lifetime.

The optimization strategy used by the IAO is based on the model described in [38], where a DT and energy management-based approach is proposed to assess the impact of the SESS and PV systems in industrial environments. This strategy integrates forecasting models for energy prices, PV generation, and industrial consumption, enabling an adaptive energy management strategy.

The IAO operates as a higher-level optimizer, incorporating inputs from the EVO to generate a global optimal dispatch for all industrial assets. The primary inputs for the IAO include the following:

- PV generation forecast.

- Industrial consumption forecast (aggregate consumption of the expected fixed consumption of the industry and the expected EV charging consumption).

- Grid electricity price forecast.

- Emission generation data from the grid, SESS, and PV system.

- SESS battery data, such as initial SOC, operation, and degradation parameters.

The IAO follows a multi-objective optimization approach, balancing economic and environmental criteria. The objective function is formulated as

are the economic operational costs, considering the energy exchanged with the grid, the power contracted, and the aging of the batteries. This yields a cost in monetary units through the following equation:

where is the energy purchased from the grid at time t, is the cost of electricity at time step k, in EUR/kWh, is the energy sold to the grid at time t, in kWh, is the electricity selling price to the grid at time t, in EUR/kWh, is the cost of the contracted power, in EUR/kW-day, is the contracted power from the grid, in kW, is the energy charged by the battery at time t, in kWh, is the energy discharged by the battery at time t, is the SESS capacity, in kWh, and is a penalization cost, in EUR/cycle, associated with the battery number of cycles, which depends on the aging, the cyclability, and the total energy storage capacity of the batteries, expressed in

where is the battery nominal price, in EUR/kWh, is the battery price reduction factor for second-life applications, in p.u., and is the battery remaining cycles of the second-life application, in units.

corresponds to the environmental operational costs for the industry, formulated to minimize CO2-equivalent emissions. The calculation is based on emission factors aligned with the IPCC 100-year Global Warming Potential (GWP) methodology, which represent cradle-to-grave emissions in kgCO2/kWh for grid energy (), battery usage (), and PV generation (), being

where is the photovoltaic energy generated at time t, in kWh.

The weighting factor defines the trade-off between economic () and environmental () criteria. The terms and denote the reference economic and environmental costs under pure cost minimization () and pure environmental minimization (), respectively.

The optimization constraints ensure the proper operation of the microgrid, including the following:

- Energy balance: the sum of PV generation, SESS discharge, and grid import must match industrial consumption and EV charging demand.

- SESS operational limits: SOC constraints, charge/discharge power limits, and degradation minimization strategies.

- Grid power constraints: avoiding exceeding contracted power to reduce fixed costs.

Simulation results from [38] demonstrate that integrating an IAO can effectively reduce operational costs and CO2 emissions, depending on the industrial consumption profile and optimization parameters. Integrating the SESS with PV generation, supported by intelligent forecasting and optimization, presents a viable path toward industrial decarbonization.

4. Case Study

Once the fundamental principles of each algorithm have been outlined, the objective of this section is to validate the effectiveness of the proposed solution in optimizing energy management. This includes reducing peak power demand, enhancing the self-consumption of renewable energy, and ensuring the optimal utilization of both the SESS and the EV.

The analysis is conducted under two distinct operational scenarios:

- Baseline: The charging of the EV fleet is not optimized, resulting in nighttime consumption. This reflects actual operational practices of the industry, in which vehicles are connected to charging stations immediately after finishing their routes. Also, SOC is usually kept at high levels.

- EV charging optimization: The EVO is used to optimize the charging of the EV fleet, resulting in charging at the times of higher solar irradiation and lower SOC levels.

These case studies will help test the effectiveness of the EVO, IAO, and DT under different conditions, resulting in various energy management strategies that aim for a global optimum, following a deterministic optimization approach. The principal parameters considered for the case study are listed in Table 1, and a detailed description of the industrial system is provided in the following section.

Table 1.

Use case infrastructure and main considerations.

4.1. System Description

CLD primary activities include waste collection and management, as well as cleaning and maintenance of public spaces. To efficiently perform these operations, the company utilizes a diverse fleet of electric, gas, and diesel-powered vehicles. The EV charging infrastructure is configured with one charger per vehicle. Additionally, the site includes a PV installation for on-site renewable energy generation and an SESS, which enhances energy flexibility and supports the evaluation of second-life battery applications in industrial settings.

The primary assets considered by this methodology are outlined in Figure 4 and described in more detail in the following subsections.

Figure 4.

Main energy assets at CLD facilities considered in this study.

4.2. EV Fleet

The industry has a diverse range of EVs, with varying capabilities and battery capacities, which enables them to effectively accomplish their tasks. The actual fleet consists of a total of 137 vehicles, and its full electrification is expected to be completed in the upcoming years. For simplicity, the case study considers a fleet of 10 D WIDE ZE heavy-duty waste collection trucks, which are typically operated at night to minimize traffic disruptions.

Fleet scheduling is generally fixed, using the same vehicle for the same route daily. Upon completing a route, vehicles are immediately recharged to 100% SOC for the next operation. Usage patterns and battery consumption depend on route characteristics, waste volume, and environmental conditions, factors that influence battery degradation over time.

4.3. Charging Stations

For charging the EV fleet, there is a charger per EV, with different power capabilities. The vast majority of them are slow chargers of Type 2, which work at 22 kW AC power and are equipped with two outputs. Additionally, the parking load is also equipped with four fast chargers, with two outputs each, that work on CC mode and with power capabilities in the range of 50–100 kW.

It is also worth mentioning that they are mostly fed from the external grid through an MV/LV transformer rated at 1 MVA. The maximum active power consumption from the grid is 380 kW, and this value has been calculated considering that not all equipment can be operated at the same time (chargers, lighting, etc.). For this reason, the company supervises the chargers’ operation through a SCADA and commands the majority of them with a control system that adjusts the power consumed to avoid exceeding the grid operator’s limits.

4.4. PV Installation

The facilities are equipped with a PV installation, located on a pergola covering one of the parking spaces. The PV installation has a maximum peak power output of 333.72 kWp and is conformed by three inverters of 100 kW each, resulting in a total nominal power of 300 kW. The estimated annual energy generation ranges between 310 and 400 MWh/year. The PV inverters, according to the information provided by the manufacturer, Huawei, would consume around 84 Wh/day and 30,660 Wh/year. According to the expected energy generated per year (407,490 kWh/year), the energy consumed by the PV inverters would represent just 0.0075% of total generation.

The generation varies depending on the season. In general, the highest energy production occurs during May, June, and July, whereas the lowest production is observed in January and December. During peak irradiation hours in high-production periods, the system generates more energy than the industry necessitates. The facility can feed energy into the grid; therefore, when surplus energy is generated, it is either stored in the SESS or sold.

4.5. SESS

During the GENIUS project, an SESS was installed at CLD facilities. This system utilizes repurposed cells previously employed in electrical transportation applications, with their SOH ranging between 55% and 80%. The battery module was assembled by one of the partners involved in the project, who conducted individual cell testing to select those in optimal condition for module construction. The implementation of the SESS provides significant benefits to the industry, offering additional flexibility in energy management. It also helps to mitigate the impact of intermittent renewable generation and reduces grid dependency, allowing CLD to store surplus energy generated by the photovoltaic (PV) system or drain energy from the grid when prices are low.

The final capacity of the battery is 166 kWh, with a maximum admissible power of 191 kW and a peak current of 270 A. It is estimated that the system has approximately 1000 remaining cycles before reaching its end of life (EOL).

4.6. Industry Facilities

After describing the primary energy assets, it is also relevant to take into account the energy consumption purchased from the grid, due to the fact that renewable generation is not enough to feed all the demand. This energy usage is predominantly attributed to electric vehicle charging. However, the industrial facilities also consume energy from other sources. These include the electricity consumption of office spaces, mechanical workshops dedicated to vehicle maintenance and repair, and a gas compression plant to charge a few trucks of the fleet still propelled with this fuel. These electrical loads are non-manageable by the industry operator, because they are not equipped with dedicated monitoring and/or control assets. This way, such loads are intended as base loads, leaving EVs and associated chargers as the only electrical consumption to actively manage.

All in all, the company exhibits significant energy consumption, reaching an approximate annual consumption of 2570 MWh, with slight fluctuations depending on the season. The maximum power consumption from the grid is 625 kW, and the energy price changes depending on the period and time of the year.

4.7. Communication, Database, Servers, and Ancillary Equipment

To execute the DT and optimizers in the cloud and in an autonomous way, additional systems are needed. Figure 5 exhibits a simplified schema of the architecture created for this case study, capable of enabling the flow of information between the cloud and the industry operators. The principal assets are as follows:

Figure 5.

Simplified schema of the architecture designed to enable the communication between DTs, optimizers, the database, the industry, forecasts, and end user.

- Communication system: Responsible for ensuring the efficient transmission of data between the different systems participating. It collects the information from industrial Supervisory Control and Data Acquisition (SCADA) systems, as well as from sensors associated with PV generation, the SESS, EVs, chargers, and any other relevant facility’s energy consumption. Its primary function is to establish a secure and coherent data flow between physical systems and the cloud while ensuring database integrity. For variables that were not previously digitized, such as electric vehicle monitoring, data loggers have been used.

- Database: It can be considered as the central component of the system, where all the relevant information is stored and acts as an intermediary between cloud-based applications, physical systems, and the user interface. It stores all measured variables from the plant, along with additional relevant data such as weather forecasts and energy prices. Also, the digital twins and optimization algorithms extract the necessary information for the algorithms and store the generated outputs. Subsequently, other applications, including the IoT platform and the user visualization interface, extract from this system the key insights to provide end users useful information about industry status and operation.

- Server and Cloud System: To enable the execution of the different digital twins and optimizers in the cloud, a computational infrastructure is required. In this case, a server, Application Programming Interfaces (API’s), and other tools for orchestrating the different workflows were considered. The server is responsible for hosting and executing the algorithms, while the API functions as a communication interface, facilitating various operations such as triggering DT and optimizers, interacting with the database, and processing data. Since each algorithm deployed in the cloud has distinct execution times, and some rely on the outputs of others, workflow orchestration tools like Apache Airflow (Version 2.5.0) [43] are employed to manage dependencies and ensure efficient task execution.

- IoT platform and user interface: The IoT platform enables the integration of different software tools, leveraging the key outcomes provided by DT and decision support systems. The user interface is responsible for the data visualization and user interaction with the monitored systems, providing access to outputs generated by the cloud-based applications.

5. Results

This section presents the results of the case study, structured in three parts. First, the industrial operation is analyzed, highlighting the contributions of the DT-PV, DT-SESS, DT-IAS, and the IAO. Second, the outcomes of the EVO are discussed, with a focus on EV charging scheduling. Finally, the third part presents key insights from the DT-EV, emphasizing its role in evaluating EV battery degradation.

5.1. Industry Devices Optimization, SESS, PV, and IAS Forecasts

The optimization of the industrial energy assets that are not directly related to the EV’s operation are executed using the IAO, DT-IAS, DT-PV, and DT-SESS. These tools enable real-time monitoring, predictive forecasting and operational decision-making, improving cost-effectiveness and minimizing environmental impact.

These three DTs are updated every 10 s, extracting real-time data from the database to run the models and refresh their key outputs. Also, following a Rolling Horizon scheme, the IAO optimizer is executed periodically to generate control instructions for the SESS. The sequence of the results to validate the integration of the systems is shown below.

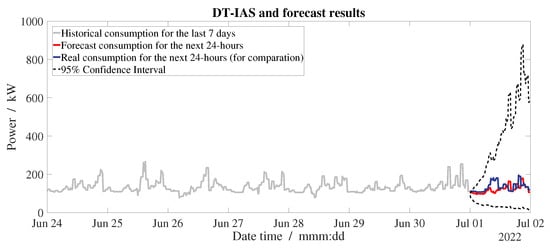

To execute the IAO, forecasts for the next 24 h of industrial energy consumption, PV generation, and electricity prices are required. These forecasts are provided by the DT-IAS and DT-PV models. Further details regarding the energy price forecasting methodology can be found in [38]. Additionally, it is important to note that the IAO also requires the aggregated power demand from EV chargers. Therefore, if the fleet charging scheduling is optimized, its execution is carried out after the EVO. The results produced by the DT-IAS and the associated forecasting algorithm are presented in Figure 6.

Figure 6.

Results of DT-IAS and forecast of the consumption profile. Comparison between forecasted and real consumption patterns.

The DT-IAS captures and analyzes historical consumption data from the industrial facility. Figure 6 illustrates the results of an execution of this algorithm. The data for the last seven days is successfully extracted using the API, and the forecast algorithm is then executed. The consumption data for the next 24 h, predicted by the ARIMA model, follow a similar trend to the actual consumption data obtained, with the forecast data being within a 95% confidence interval. The industrial consumption forecast will be subsequently aggregated with the power demand from electric vehicle chargers, which are not included in the initial prediction.

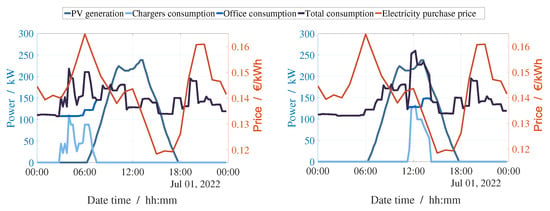

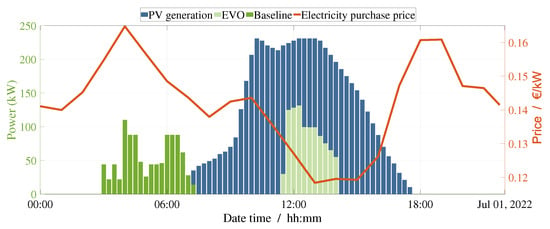

Once the data for the next 24 h has been obtained and the power demand due to EV charging is known, the necessary conditions for executing the IAO are met. Figure 7 shows the input data for the two study cases, the left image being the baseline consumption scenario and the right image the EV charging optimization scenario. The PV generation forecast is effectively generated by the DT-PV and the forecast tools. In the baseline consumption scenario, where the EV charging scheduling is not optimized, the generation power exceeds the consumption during the hours of maximum irradiance. In contrast, in the EV charging optimization scenario where the EVO is used, the industry consumption covers a higher power demand during the hours of solar generation.

Figure 7.

Main forecasted inputs required for the IAO execution. Blue lines (left axis) represent power-related variables, while the orange line (right axis) reflects the estimated electricity price. (Left plot): Inputs for the baseline consumption scenario. (Right plot): Inputs for the EV charging optimization scenario.

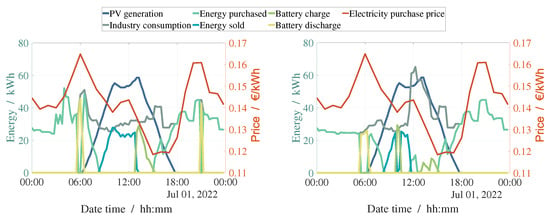

With all this data, the IAO is then executed to optimize the power demand of the SESS, using as prioritization variables an economic prioritization = 0.75 and an environmental impact prioritization = 0.25, simulating a company that is balancing financial constraints with social responsibility objectives [38]. The performance of the IAO is illustrated in Figure 8, where the two distinct industrial energy consumption scenarios are plotted. The left plot corresponds to a case where the industrial load profile is predominantly nocturnal, while the right plot depicts a scenario with a more diurnal demand pattern, influenced by the use of EVO.

Figure 8.

Main results and forecasts from IAO. Green lines (left axis) represent energy-related variables, while orange line (right axis) reflects the estimated electricity price. (Left plot): Outputs for the baseline scenario. (Right plot): Outputs for the EV charging optimization scenario.

In the baseline case, the industry optimizer effectively schedules the charging of the second-life battery during periods of low electricity prices and high PV generation, particularly in the midday hours. This stored energy is then discharged during the evening and night to meet the industry’s demand, reducing reliance on grid purchases when electricity prices are elevated. The energy sold to the grid is high in this case due to the surpluses generated during the day, as energy consumption is shifted to nighttime periods.

In the EV charging optimization scenario, the IAO optimizer adjusts its strategy accordingly. The SESS is charged in the early morning and, to a lesser extent, during peak PV generation periods. In this case, energy surpluses are lower due to the use of EVO, which allows the electric trucks to be charged during periods of higher solar generation. This strategy improves energy utilization efficiency, leading to an operational cost reduction greater than 6% and a decrease in environmental impact of over 10%.

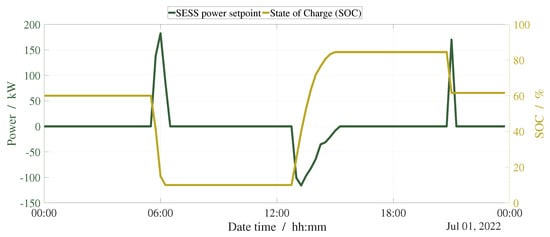

After obtaining the SESS power profile, it is provided to the internal controller in the industry. The measured battery data is then used to run the DT-SESS periodically to extract the battery status. Since the results of the algorithms are exposed in a simulation environment, the IAO output power is used as the measured battery power. Figure 9 shows the results of the DT-SESS, monitoring the power and state of charge of the battery during the simulation period. It is observed that the battery is maintained within safety margins between a maximum and minimum SOC. In addition, by incorporating the battery degradation costs, the battery usage is optimized by minimizing the number of cycles to reduce degradation [38].

Figure 9.

(Left axis): SESS power setpoint provided by the IAO. (Right axis): State of charge calculation of the DT−SESS.

To complete the analysis, the economic and environmental performance of the IAO optimizer is evaluated across different scenarios. The results are compared under two configurations: one considering the presence of the SESS and another without it. Obtaining the resulting value of the monetary cost function () and the environmental cost function () after the subsequent IAO execution allows direct quantification of the monetary costs and CO2 equivalent emissions linked to the energy exchange strategy.

In general, using an efficient management of the industry’s consumption increases the savings by 6.66% using the SESS with the IAO optimization program, and savings of 6.99% in the case of not using a battery. Similarly, using an efficient management of industry consumption reduces the environmental impact by 10.95% using the SESS with the IAO optimization program and by 10.33% in the case of not using a battery.

In the baseline consumption scenario, the use of the IAO with the second-life battery resulted in a total energy cost of EUR 269.70/day, compared to EUR 273.24/day without the battery, representing a daily cost reduction of EUR 3.54, equivalent to 1.30% savings. From an environmental perspective, however, CO2 emissions slightly increased from 468.03 kgCO2/day (without battery) to 476.72 kgCO2/day (with battery), corresponding to a 1.85% increase.

In the EV charging optimization scenario, the total daily cost was reduced from EUR 254.13/day (without battery) to EUR 251.72/day (with battery), a EUR 2.41 reduction (0.95% savings). Similarly, emissions increased slightly with battery usage, from 419.65 kgCO2/day to 424.51 kgCO2/day, a 1.16% rise.

5.2. Electric Vehicle Charging Schedule

As previously mentioned, in the baseline scenario, EV charging is not optimized. It is assumed that vehicles are connected to chargers immediately upon arrival at the depot and charged to 100% or the maximum SOC while EVs are waiting for the next trip. Consequently, this section will primarily focus on the EV charging optimization scenario, where the EVO is employed to optimize the charging schedules of the electric trucks.

The case study focuses exclusively on night-shift operations, which last for 8 h and begin at 22:00. However, it is important to note that some vehicles return to the depot intermittently during the night, resting short periods and covering more than one trip. This can be observed in Table 2, where the EV schedule considered is presented.

Table 2.

Trip schedule and EV assignment considered for the case study.

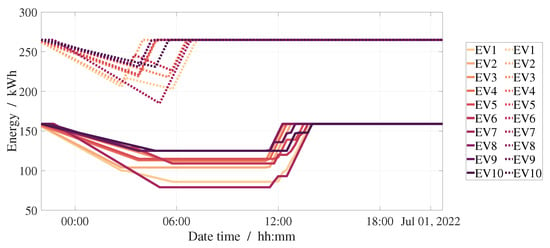

The simulation results obtained from the EV charging scheduler are presented in Figure 10 and Figure 11. Where the baseline scenario and EV charging optimization scenario (referred to as EVO) are compared.

Figure 10.

Aggregated power demand from the EV fleet. Comparison of baseline scenario and EV charging optimization (EVO). Green and blue lines correspond to power-related variables (left axis), and the electricity price is shown on the (right axis), in orange.

Figure 11.

Energy track of all EVs analyzed in this study, comparing the baseline scenario (dashed lines) with the optimized EVO solution (solid lines).

Figure 10 presents the power demanded by the charging infrastructure during the day. The results show that the EVO solution charges the vehicles when there is more PV production, different from the baseline case, in which the vehicles are charged as they arrive at the depot. This results in cost savings and a higher rate of use of the renewable resource.

Furthermore, Figure 11 shows the available energy for each vehicle. The discharging profile is approximated considering the average energy requested per trip. The charging profiles show how EVO delays the charging events, ensuring that not only is the photovoltaic production shared with the rest of the industrial loads, but also the idle time of the EVs is at a lower SOC, reducing the calendar degradation cost.

Additionally, a cost analysis is conducted for three different forecasting horizons: one, three, and five days. The results are summarized in Table 3. It is observed that the highest savings, 18.3% compared to the baseline, are achieved with a 1-day horizon. As the forecasting horizon increases, the savings decrease, with the lowest savings observed at the 5-day horizon. This reduction in savings is attributed to the increased uncertainty associated with longer forecasting horizons, which may lead to greater deviations in the optimal charging times.

Table 3.

EV charging cost comparison depending on the time horizon considered.

Finally, the EVO scalability is assessed by increasing the EV fleet. Table 4 presents the execution time of EVO for different fleet sizes. This shows that the approach proposed can reach execution times that are practically feasible for large EV fleets of up to 100 vehicles. However, it is essential to note the exponential increase in execution time, which may necessitate a longer execution time (>15 min). However, for EV fleets with hundreds of vehicles, the step size could be increased. Further investigation in this regard is out of the scope of this study.

Table 4.

EVO scalability assessment: analysis of the number of EVs considered and the impact on the final execution time.

5.3. EV Degradation Analysis and Forecast

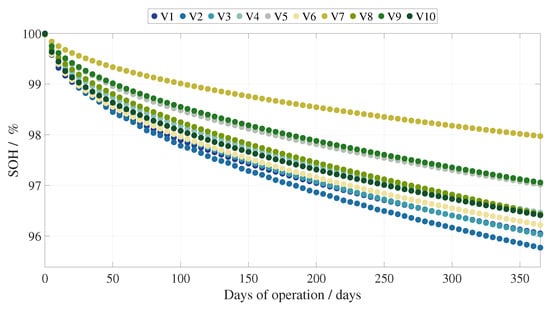

This section serves as an example of the valuable insights that can be derived from the DT-EV outputs, which offer essential information regarding the state of degradation of the EV. To enable this analysis, the DT-EV requires measurements of battery status parameters, such as current, voltage, temperature or SOC. These variables have been recorded over the course of one week, while the EVs listed in Table 2 were in operation under the baseline scenario.

Assuming that the vehicles follow the same usage pattern and operating conditions over the course of a year, the DT-EV is able to estimate how the vehicles will degrade. Figure 12 presents the SOH evolution of the EV considered over the course of one year, assuming an initial SOH of 100%. The vehicle V7 exhibits the lowest level of degradation, maintaining a SOH of 98%, followed by V9 and V5, both of which remain close to 97%. These three vehicles typically perform shorter trips with lower energy demands, which results in reduced battery stress.

Figure 12.

SOH evolution over one year of EV fleet operation, based on the DT-EV forecasts under the baseline scenario usage profiles.

In contrast, vehicle V2 shows the highest rate of degradation, losing over 4% of its initial capacity after one year. This is due to its intensive usage, as it travels the longest daily distance and completes two trips per day. The remaining vehicles degrade at a similar rate, with final SOH values between 96% and 97%.

The same analysis was conducted under the EV charging optimization scenario. The resulting degradation pattern is very similar to that observed in the baseline case, indicating that the usage while the EVs are on route has a greater impact on battery degradation than charging or resting periods.

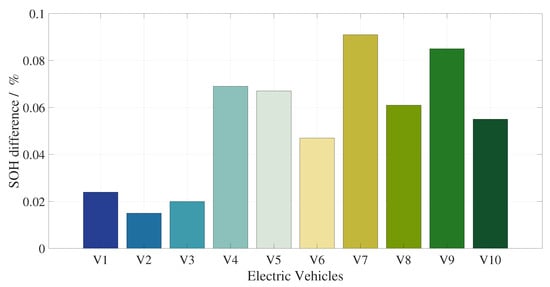

Nevertheless, a slight reduction in degradation is observed across all vehicles if the EVO schedules the charging. Figure 13 shows the difference in SOH between the DT-EV estimations for the baseline and the EV charging optimization scenarios, after 365 days. Vehicles V7 and V9 benefit the most from the optimization, with reductions in degradation of 0.091% and 0.085%, respectively. These vehicles follow shorter routes and therefore spend more time parked. This reduction may be attributed to the fact that, under the EV charging optimization strategy, vehicles spend less time at high SOC levels while resting in the parking lot, which helps mitigating degradation mechanisms such as calendar aging [44,45].

Figure 13.

Estimated SOH difference after one year between the baseline and EV charger optimization scenarios. Positive values indicate reduced battery degradation under EVO charging strategy.

Vehicles V1, V2, and V3 are the least affected by the optimized charging schedule, as they spend less time parked and their degradation is primarily driven by route usage.

These outputs enable end users to gain a comprehensive understanding of the effects associated with specific vehicle operation patterns. In addition, the DT-EV can predict future battery degradation based on current operational patterns and assess the SOH under alternative usage scenarios.

6. Conclusions

This paper presented a comprehensive framework for an EMS focused on more sustainable energy-intensive industries that integrates RES, BESS, and EV. The proposed solution leverages the capabilities of DT to enhance the EMS, which is based on a two-layer optimization approach. The formulations of four DTs (PV, IAS, SESS, and EV) were presented. Also, the mathematical foundation for the optimization framework was described in detail. To validate the proposed approach, a case study based on a waste collection and management company was presented. Key aspects of the industry facilities and operations were considered in the optimization.

The study demonstrated the validity of the methodology proposed. The DT facilitated the optimization operation by forecasting the necessary inputs. Results from the two-level optimization framework indicate reductions in operational costs and environmental impact by 6.66% and 10.95%, respectively, compared to current industry practices. The DT-EV demonstrated the effectiveness of EVO in reducing EV fleet battery degradation by 0.015–0.091% relative to the baseline scenario. Additionally, scalability analysis confirmed that the framework can be extended to different time horizons and EV fleet sizes, without compromising computational efficiency.

Future work will compare other optimization and DT approaches to further investigate the impact on the optimization objectives and the practical scalability and robustness of the solution. Moreover, further studies on how to integrate detailed battery degradation models in optimization algorithms are still necessary. Finally, concepts such as EV route scheduling and vehicle-to-grid (V2G) integration will be incorporated into the optimization framework.

Author Contributions

Introduction, A.C.H.-M. and A.B.-S.; Methodology, A.B.-S. and F.D.-G.; Mathematical Formulation, A.C.H.-M., G.B.-O. and A.B.-S.; Case Study, F.D.-G. and A.B.-S.; Results, A.C.H.-M., G.B.-O. and A.B.-S.; Conclusions, A.C.H.-M. and A.B.-S.; Review of the manuscript, D.H.-P., F.D.-G. and L.T.; Funding acquisition, L.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research is part of Project PLEC2021-008152, funded by MCIN/AEI/10.13039/501100011033 and by the European Union “NextGenerationEU”/PRTR.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data used in this research is confidential, but may be made available upon reasonable request. Interested parties may contact the corresponding author to inquire about access.

Acknowledgments

This research was supported by the Joan Oró predoctoral grant program from the Department of Research and Universities of the Generalitat de Catalunya, co-funded by the European Social Fund Plus (2024 FI-1 00324) and also by the project DIGIBAT funded by the Generalitat de Catalunya in the ACCIO program.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- IEA. Renewables 2024. International Energy Agency, Paris, 2024. Available online: https://www.iea.org/reports/renewables-2024 (accessed on 26 February 2025).

- Thebault, M.; Gaillard, L. Optimization of the integration of photovoltaic systems on buildings for self-consumption–Case study in France. City Environ. Interact. 2021, 10, 100057. [Google Scholar] [CrossRef]

- Tian, J.; Jia, H.; Wang, G.; Huang, Q.; Wu, R.; Gao, H.; Liu, C. Integrated optimization of charging infrastructure, fleet size and vehicle operation in shared autonomous electric vehicle system considering vehicle-to-grid. Renew. Energy 2024, 229, 120760. [Google Scholar] [CrossRef]

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, use cases, challenges, and opportunities. Decis. Anal. J. 2023, 6, 100165. [Google Scholar] [CrossRef]

- Naseri, F.; Gil, S.; Barbu, C.; Cetkin, E.; Yarimca, G.; Jensen, A.; Larsen, P.; Gomes, C. Digital twin of electric vehicle battery systems: Comprehensive review of the use cases, requirements, and platforms. Renew. Sustain. Energy Rev. 2023, 179, 113280. [Google Scholar] [CrossRef]

- Jia, C.; Liu, W.; He, H.; Chau, K. Deep reinforcement learning-based energy management strategy for fuel cell buses integrating future road information and cabin comfort control. Energy Convers. Manag. 2024, 321, 119032. [Google Scholar] [CrossRef]

- Bhatti, G.; Mohan, H.; Raja Singh, R. Towards the future of smart electric vehicles: Digital twin technology. Renew. Sustain. Energy Rev. 2021, 141, 110801. [Google Scholar] [CrossRef]

- Ibrahim, M.; Rjabtšikov, V.; Gilbert, R. Overview of Digital Twin Platforms for EV Applications. Sensors 2023, 23, 1414. [Google Scholar] [CrossRef]

- Francisco, A.M.B.; Monteiro, J.; Cardoso, P.J.S. A Digital Twin of Charging Stations for Fleets of Electric Vehicles. IEEE Access 2023, 11, 125664–125683. [Google Scholar] [CrossRef]

- Iyer, N.G.; Ponnurangan, S.; Abdul Gafoor, N.A.; Rajendran, A.; Lashab, A.; Saha, D.; Guerrero, J.M. A Novel Heuristic Algorithm Integrating Battery Digital-Twin-Based State-of-Charge Estimation for Optimized Electric Vehicle Charging. Electronics 2024, 13, 4412. [Google Scholar] [CrossRef]

- Li, W.; Rentemeister, M.; Badeda, J.; Jöst, D.; Schulte, D.; Sauer, D.U. Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation. J. Energy Storage 2020, 30, 101557. [Google Scholar] [CrossRef]

- Reniers, J.M.; Howey, D.A. Digital twin of a MWh-scale grid battery system for efficiency and degradation analysis. Appl. Energy 2023, 336, 120774. [Google Scholar] [CrossRef]

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy digital twin technology for industrial energy management: Classification, challenges and future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Bécue, A.; Maia, E.; Feeken, L.; Borchers, P.; Praça, I. A New Concept of Digital Twin Supporting Optimization and Resilience of Factories of the Future. Appl. Sci. 2020, 10, 4482. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Q.; Chen, X.; Zhang, D.; Leng, J. A Digital Twin-Based Approach for Designing and Multi-Objective Optimization of Hollow Glass Production Line. IEEE Access 2017, 5, 26901–26911. [Google Scholar] [CrossRef]

- Florescu, A. Digital Twin for Flexible Manufacturing Systems and Optimization Through Simulation: A Case Study. Machines 2024, 12, 785. [Google Scholar] [CrossRef]

- Lee, D.; Kim, C.K.; Yang, J.; Cho, K.Y.; Choi, J.; Noh, S.D.; Nam, S. Digital Twin-Based Analysis and Optimization for Design and Planning of Production Lines. Machines 2022, 10, 1147. [Google Scholar] [CrossRef]

- Wu, Y.; Guerrero, J.M.; Wu, Y.; Bazmohammadi, N.; Vasquez, J.C.; Cabrera, A.J.; Lu, N. Digital Twins for Microgrids: Opening a New Dimension in the Power System. IEEE Power Energy Mag. 2024, 22, 35–42. [Google Scholar] [CrossRef]

- Özkan, E.; Kök, I.; Özdemır, S. DeepTwin: A Deep Reinforcement Learning Supported Digital Twin Model for Micro-Grids. IEEE Access 2024, 12, 196432–196441. [Google Scholar] [CrossRef]

- Miao, L.; Zhao, J.; Ma, J.; Wei, X.; Hu, Y. Study on Optimization and Scheduling Strategies of Distributed Energy Storage Based on Digital Twin. In Proceedings of the 2024 4th International Conference on Smart Grid and Energy Internet (SGEI), Shenyang, China, 13–15 December 2024; pp. 32–36. [Google Scholar] [CrossRef]

- Yalçin, T.; Paradell Solà, P.; Stefanidou-Voziki, P.; Domínguez-García, J.L.; Demirdelen, T. Exploiting Digitalization of Solar PV Plants Using Machine Learning: Digital Twin Concept for Operation. Energies 2023, 16, 5044. [Google Scholar] [CrossRef]

- Lasseter, R.; Akhil, A.; Marnay, C.; Stephens, J.; Dagle, J.; Guttromsom, R.; Meliopoulos, A.; Yinger, R.; Eto, J. Integration of distributed energy resources. In The CERTS Microgrid Concept; California Energy Commission: Berkeley, CA, USA, 2002. [Google Scholar] [CrossRef]

- Epelle, E.I.; Gerogiorgis, D.I. A computational performance comparison of MILP vs. MINLP formulations for oil production optimisation. Comput. Chem. Eng. 2020, 140, 106903. [Google Scholar] [CrossRef]

- Alemany, J.; Kasprzyk, L.; Magnago, F. Effects of binary variables in mixed integer linear programming based unit commitment in large-scale electricity markets. Electr. Power Syst. Res. 2018, 160, 429–438. [Google Scholar] [CrossRef]

- Ham, A.; Park, M.J.; Kim, K. Energy-Aware Flexible Job Shop Scheduling Using Mixed Integer Programming and Constraint Programming. Math. Probl. Eng. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Bernabeu, A.; Clemente, A.; Díaz, F.; Trilla, L. Experimental data granularity studies for the development of NMC Li-ion battery models. In Proceedings of the IECON 2024-50th Annual Conference of the IEEE Industrial Electronics Society, Chicago, IL, USA, 3–6 November 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Montes, T.; Etxandi-Santolaya, M.; Eichman, J.; Ferreira, V.J.; Trilla, L.; Corchero, C. Procedure for Assessing the Suitability of Battery Second Life Applications after EV First Life. Batteries 2022, 8, 122. [Google Scholar] [CrossRef]

- Ji, C.; Dai, J.; Zhai, C.; Wang, J.; Tian, Y.; Sun, W. A Review on Lithium-Ion Battery Modeling from Mechanism-Based and Data-Driven Perspectives. Processes 2024, 12, 1871. [Google Scholar] [CrossRef]

- Chaturvedi, N.A.; Klein, R.; Christensen, J.; Ahmed, J.; Kojic, A. Algorithms for Advanced Battery-Management Systems. IEEE Control Syst. Mag. 2010, 30, 49–68. [Google Scholar] [CrossRef]

- Heinrich, F.; Klapper, P.; Pruckner, M. A comprehensive study on battery electric modeling approaches based on machine learning. Energy Inform. 2021, 4, 17. [Google Scholar] [CrossRef]

- Chen, C.H.; Brosa Planella, F.; O’Regan, K.; Gastol, D.; Widanage, W.D.; Kendrick, E. Development of Experimental Techniques for Parameterization of Multi-scale Lithium-ion Battery Models. J. Electrochem. Soc. 2020, 167, 080534. [Google Scholar] [CrossRef]

- Timms, R.; Marquis, S.G.; Sulzer, V.; Please, C.P.; Chapman, S.J. Asymptotic Reduction of a Lithium-Ion Pouch Cell Model. SIAM J. Appl. Math. 2021, 81, 765–788. [Google Scholar] [CrossRef]

- Marquis, S.G. Long-Term Degradation of Lithium-Ion Batteries. Ph.D. Thesis, University of Oxford, Oxford, UK, 2020. [Google Scholar]

- O’Kane, S.E.J.; Ai, W.; Madabattula, G.; Alonso-Alvarez, D.; Timms, R.; Sulzer, V.; Edge, J.S.; Wu, B.; Offer, G.J.; Marinescu, M. Lithium-ion battery degradation: How to model it. Phys. Chem. Chem. Phys. 2022, 24, 7909–7922. [Google Scholar] [CrossRef]

- Jafari, S.; Byun, Y.C. Optimizing Battery RUL Prediction of Lithium-Ion Batteries Based on Harris Hawk Optimization Approach Using Random Forest and LightGBM. IEEE Access 2023, 11, 87034–87046. [Google Scholar] [CrossRef]

- Sulzer, V.; Marquis, S.G.; Timms, R.; Robinson, M.; Chapman, S.J. Python Battery Mathematical Modelling (PyBaMM). J. Electrochem. Soc. 2021, 9, 14. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Borrego-Orpinell, G.; Forero, J.F.; Caprara, A.; Díaz-González, F. Impact Assessment of Second-Life Batteries and Local Photovoltaics for Decarbonizing Enterprises Through System Digitalization and Energy Management. Energies 2025, 18, 1198. [Google Scholar] [CrossRef]

- Sen, P.; Roy, M.; Pal, P. Application of ARIMA for forecasting energy consumption and GHG emission: A case study of an Indian pig iron manufacturing organization. Energy 2016, 116, 1031–1038. [Google Scholar] [CrossRef]

- Stroe, D.I.; Swierczynski, M.; Stroe, A.I.; Teodorescu, R.; Laerke, R.; Kjaer, P.C. Degradation behaviour of Lithium-ion batteries based on field measured frequency regulation mission profile. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 14–21. [Google Scholar] [CrossRef]

- Montes, T.; Pinsach Batet, F.; Igualada, L.; Eichman, J. Degradation-conscious charge management: Comparison of different techniques to include battery degradation in Electric Vehicle Charging Optimization. J. Energy Storage 2024, 88, 111560. [Google Scholar] [CrossRef]

- Trucks, R. D26 ZE LEC Spec Sheet 2022, 2022. Available online: https://www.renault-trucks.co.uk/sites/default/files/2022-05/D26%20ZE%20LEC%20Spec%20Sheet%202022.pdf (accessed on 23 March 2025).

- Apache Airflow, Version 2.5.0. Apache Software Foundation, 2015. Available online: https://airflow.apache.org (accessed on 15 January 2025).

- Li, Y.; Guo, W.; Stroe, D.I.; Zhao, H.; Kjær Kristensen, P.; Rosgaard Jensen, L.; Pedersen, K.; Gurevich, L. Evolution of aging mechanisms and performance degradation of lithium-ion battery from moderate to severe capacity loss scenarios. Chem. Eng. J. 2024, 498, 155588. [Google Scholar] [CrossRef]

- Wei, Y.; Yao, Y.; Pang, K.; Xu, C.; Han, X.; Lu, L.; Li, Y.; Qin, Y.; Zheng, Y.; Wang, H.; et al. A Comprehensive Study of Degradation Characteristics and Mechanisms of Commercial Li(NiMnCo)O2 EV Batteries under Vehicle-To-Grid (V2G) Services. Batteries 2022, 8, 188. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).